Preparation method of polyetheretherketone resin

A technology of polyetheretherketone resin and polyetheretherketone, which is applied in the field of preparation of polyetheretherketone resin, can solve the problems of low level, discontinuous process flow, and unclean polymer product purity, etc., and achieves high purity, Ensure purity and performance, overcome the effect of low purity of polymer products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of polyether ether ketone resin, including polymerization reaction and precipitation and purification treatment of reaction products, wherein:

[0021] The raw materials and their molar ratios in polyether ether ketone polymerization are: 4,4′-difluorobenzophenone: hydroquinone: catalyst: diphenyl sulfone: dehydrating agent = 1: 1: 1.2: 4.1~4.5 ︰1.4~1.6;

[0022] The precipitation treatment of the reaction product is as follows: after the polymerization reaction is completed, the reaction temperature is lowered to 210-230 °C, and the stirring is accelerated to make the polyether ether ketone resin system uniformly precipitated. When the temperature in the reactor is stable, trimethylbenzene is added and stirred until the reaction system After uniformity, the reaction temperature is lowered to 90-110°C (preferably 100°C), so that all the polyether ether ketone resins are uniformly crystallized and precipitated, and the reaction...

Embodiment 1

[0044] The preparation of embodiment 1 polyetheretherketone resin

[0045] Taking a 200L polymerization kettle as an example, prepare raw materials according to the following quality: 4,4'-difluorobenzophenone (10.9Kg), hydroquinone (5.5Kg), potassium carbonate (4.96Kg), sodium carbonate (2.54 Kg), diphenylsulfone 46.8Kg), trimethylbenzene (9.3Kg).

[0046] Accurately weigh the above formula components respectively, add diphenyl sulfone and trimethylbenzene into a 200L polymerization kettle equipped with a water separator, agitator (frame-type paddle-type two-way stirring) and a heating device, and pass in an inert gas nitrogen protection , start stirring (frame stirring 30r / min, paddle stirring 60r / min), the jacket of the reactor is heated to 140°C, after 40 minutes all diphenyl sulfone is dissolved, and 4,4'-difluorobenzophenone is added in sequence and hydroquinone, continue to stir for 10 minutes to dissolve the monomer, add catalyst potassium carbonate and sodium carbona...

Embodiment 2

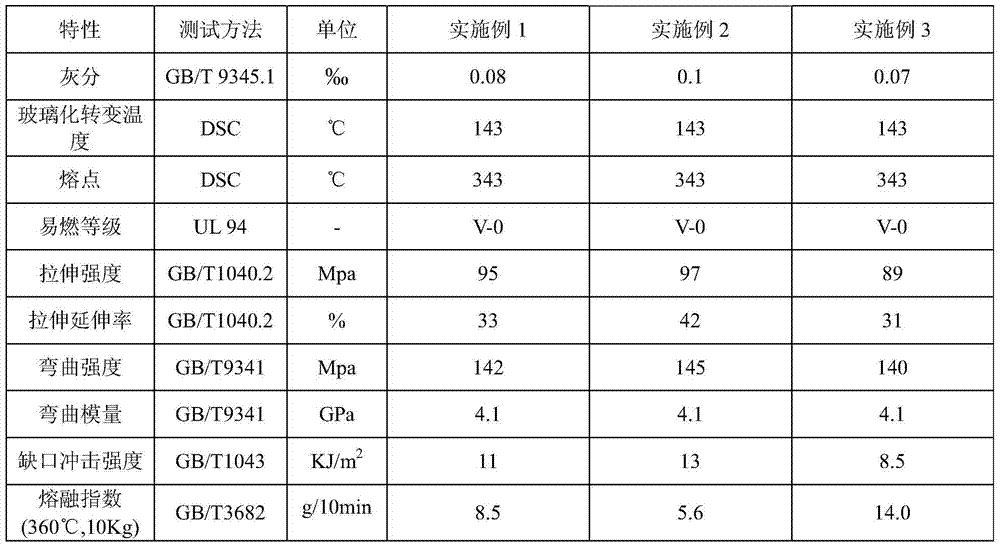

[0054] Refer to Example 1 for the specific method. The only difference from the example is that the reflux reaction time is extended by 30 minutes, and the polymerization reaction is extended by 30 minutes; the properties of the obtained polyether ether ketone resin are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com