Crystalline polymer synthesis solvent recovery method and polyphenylene sulfide production method

A polyphenylene sulfide and production method technology, applied in the field of polymer materials, can solve the problems of limiting the application range of resin, low product purity, difficult to separate mixing, etc., to ensure purity and performance, overcome low purity, and reduce energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

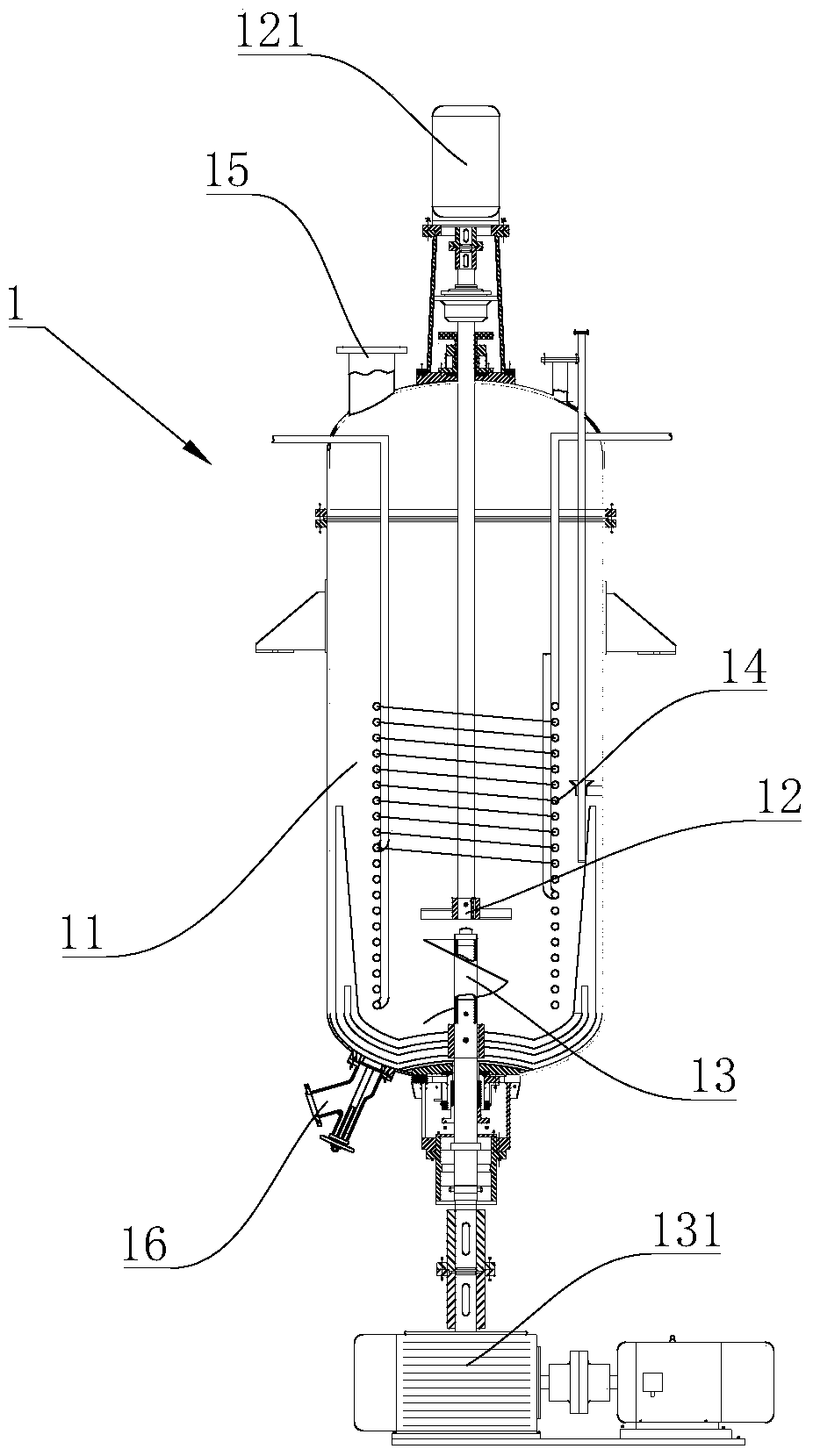

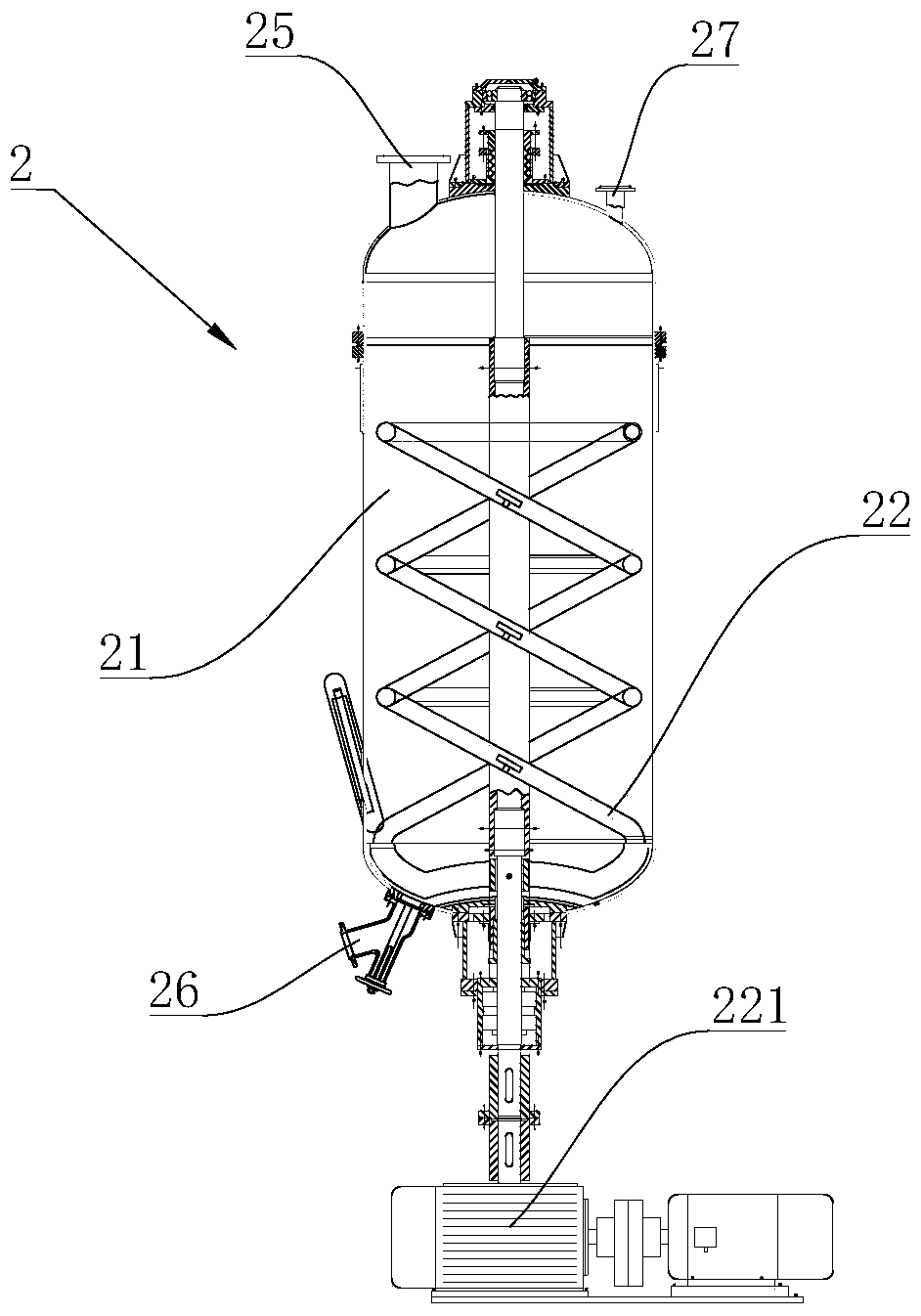

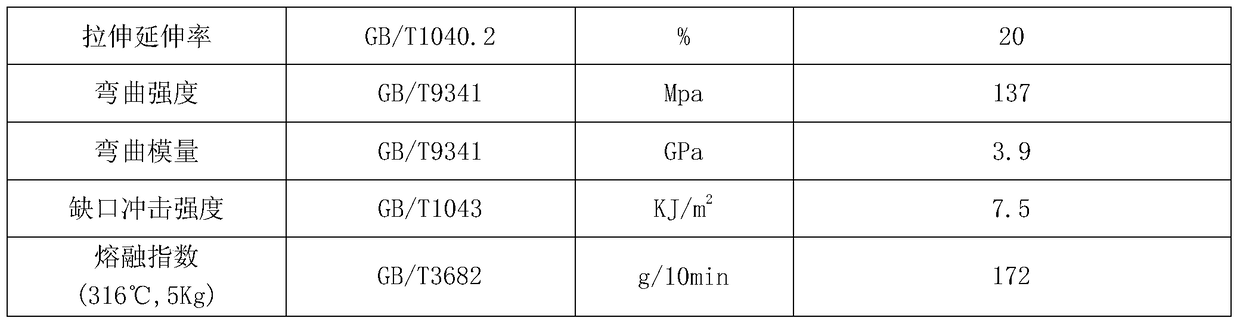

Embodiment 1

[0060] Prepare raw materials according to the molar ratio of raw materials: p-dichlorobenzene: sodium polyhydrate: lithium chloride: N-methylpyrrolidone = 1: 1: 0.3: 7. The production solvent N-methylpyrrolidone of polyphenylene sulfide resin, the raw material sodium polyhydrate, and the catalyst lithium chloride were successively put into the polymerization kettle, and the temperature was raised to 200°C under nitrogen protection to dissolve and dehydrate sodium polyhydrate for 2 hours. Then cool down to 165°C and add the raw material p-dichlorobenzene, heat up to the polymerization temperature of 260°C, keep the pressure in the kettle at about 1.1MPa, avoid violent temperature fluctuations through the cooling coil, and open the connection between the polymerization kettle and the flash tank after 3 hours of polymerization reaction After the pressure is balanced, put all the materials into the flash tank, turn on the stirring and vacuum system, keep the temperature of the flas...

Embodiment 2

[0066] Prepare raw materials according to the molar ratio of raw materials: p-dichlorobenzene: sodium polyhydrate: lithium chloride: N-methylpyrrolidone = 1: 1: 0.3: 8. The production solvent N-methylpyrrolidone of polyphenylene sulfide resin, the raw material sodium polyhydrate, and the catalyst lithium chloride were successively put into the polymerization kettle, and the temperature was raised to 200°C under nitrogen protection to dissolve and dehydrate sodium polyhydrate for 2.5 hours. Then cool down to 165°C and add the raw material p-dichlorobenzene, heat up to the polymerization temperature of 270°C, keep the pressure in the kettle at about 1.1MPa, avoid violent temperature fluctuations through the cooling coil, and open the connection between the polymerization kettle and the flash tank after 4 hours of polymerization reaction After the pressure is balanced, put all the materials into the flash tank, turn on the stirring and vacuum system, keep the temperature of the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com