Patents

Literature

1019results about How to "Reduce extraction costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

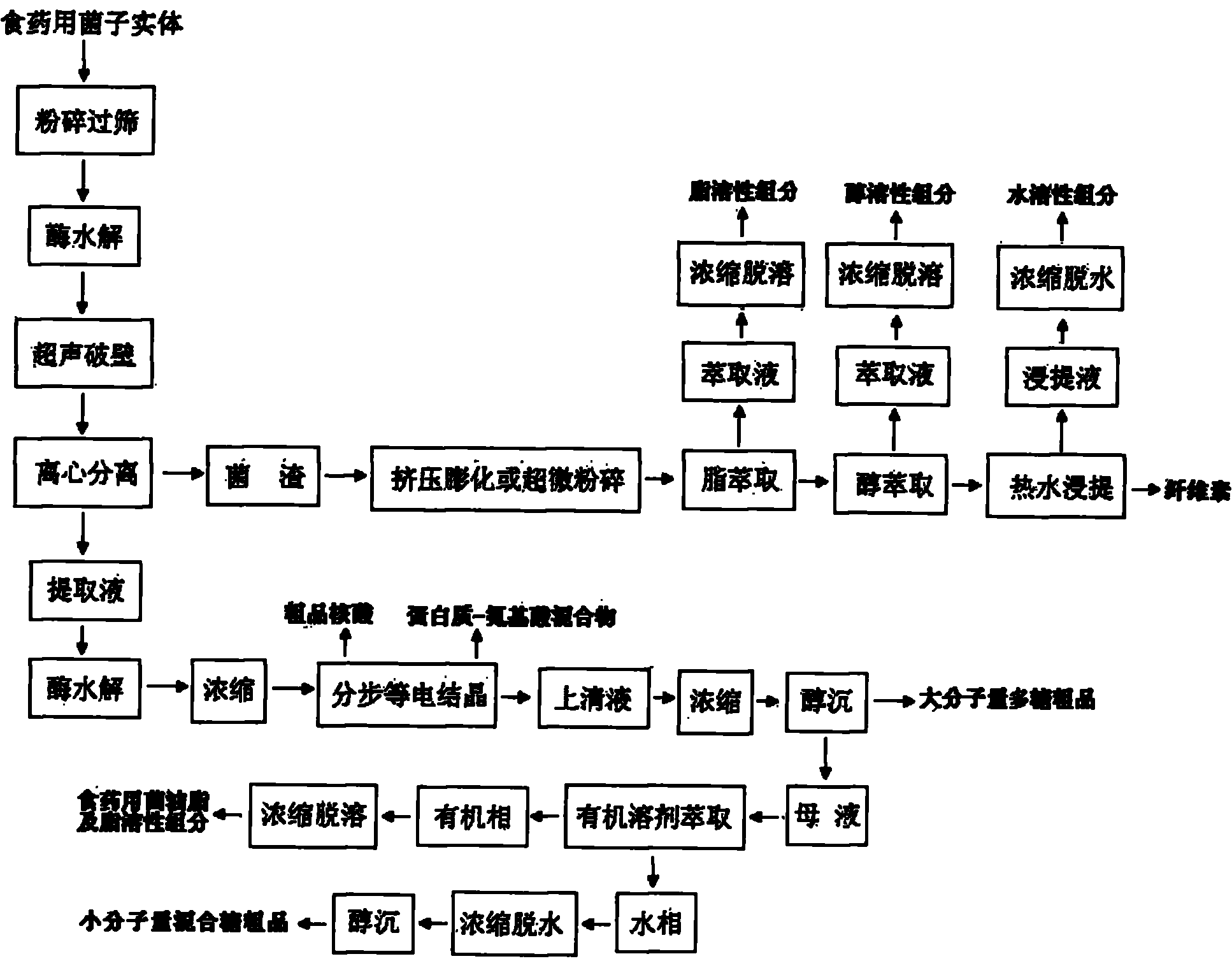

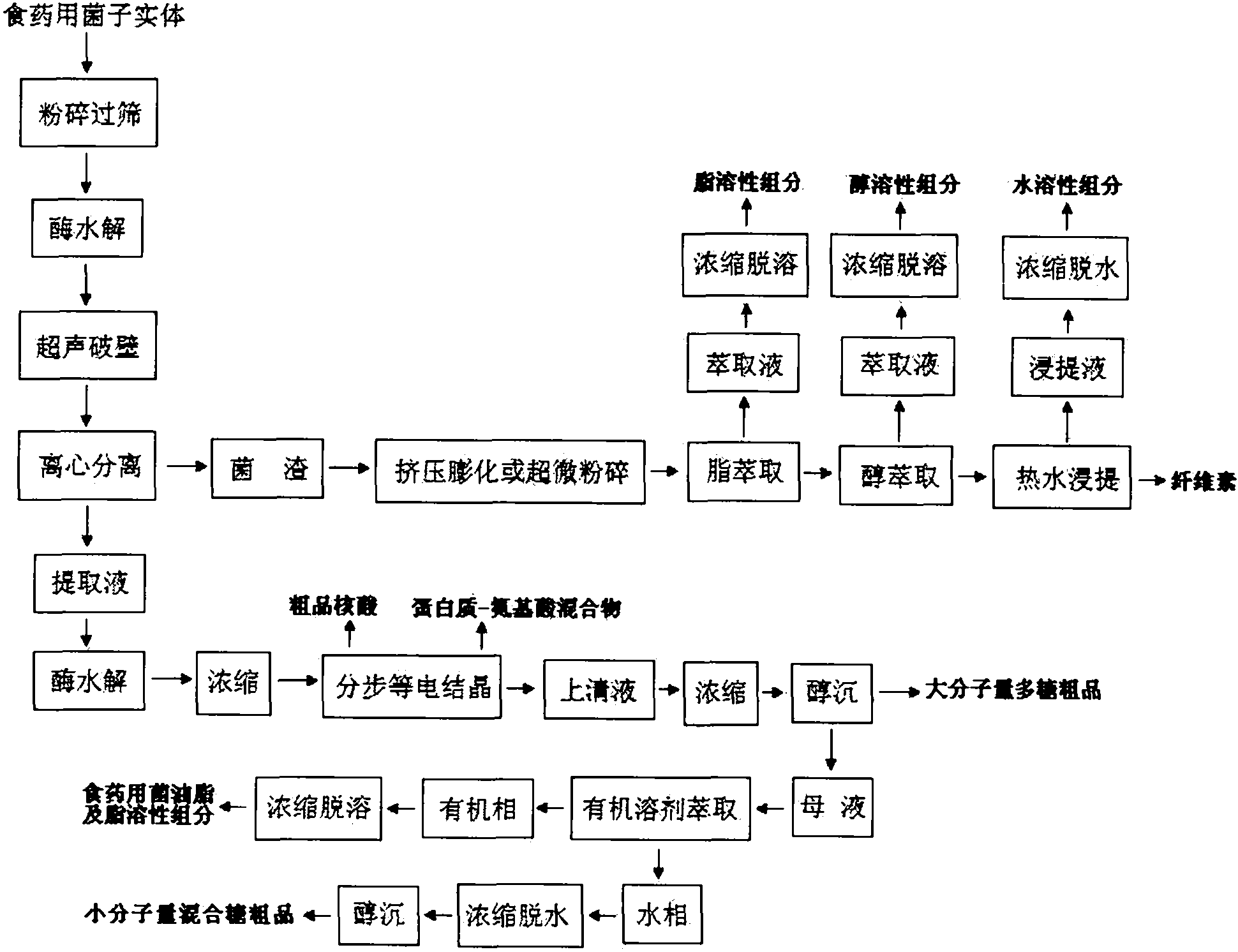

Edible and medical fungus cell component comprehensive extraction method and use of extract

ActiveCN101933610AHigh extraction yieldRealize comprehensive utilizationFood preparationCelluloseSlag

The invention discloses an edible and medical fungus cell component comprehensive extraction method and use of extract, which belong to the technical field of natural product extraction and application. The method comprises: breaking walls of the cells of the edible and medical fungi by combining an enzymic process and ultrasonic waves; extracting the extract and fungus slag by processes of water extraction, alcohol extraction and fat extraction in different sequences to obtain various nutritive components and bioactive components, such as cellulose, protein, nucleic acid, polysaccharide and fatty acid. In the invention, due to the adoption of a wall breaking-first and extraction-second scheme, the extraction rate of the cell components of the edible and medical fungi is improved considerably; the extract is extracted by water extraction, alcohol extract and fat extraction in turn and the fungus slag is extracted by fat extraction, alcohol extraction and water extraction in turn, so the flavor of the edible fungi is retained effectively; the various cell components of the edible and medical fungi serving as raw materials are extracted comprehensively and further developed; and the extracted components are natural materials, have both nutritive and health-care and pharmacological effects and can be made into various products according to the characteristics of the extracted components.

Owner:JIANGSU ANHUI BIO TECH +1

Method for extracting industrial hemp oil rich in cannabidiol

InactiveCN105505565ASimple processReduce energy consumptionFatty-oils/fats productionSolventChemistry

The invention discloses a method for extracting industrial hemp oil rich in cannabidiol. The method includes the steps that supercritical carbon dioxide fluid is adopted for extracting industrial hemp oil from industrial hemp, during extraction, cooled industrial hemp powder is placed in a material barrel of an extraction kettle, CO2 gas is injected into the extraction kettle, the temperature and pressure in the extraction kettle are kept, the CO2 gas makes contact with raw materials in a supercritical state, the industrial hemp oil and other ingredients in the industrial hemp powder are dissolved in the supercritical fluid, the fluid containing cannabidiol and other ingredients throttles and expands in the extraction kettle and enters a separation kettle to be analyzed, and the industrial hemp oil is obtained and collected. The CO2 fluid in the supercritical state is used as an extraction solvent, reuse is achieved in the same system, the process is simple, energy consumption is low, the extraction period is short, is only 1-2 h and is 1 / 4 of the production period in the prior art, and the extracted industrial hemp oil has the advantages of being good in quality, high in purity, free of abnormal smells, solvent residues and environmental pollution and the like.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP +1

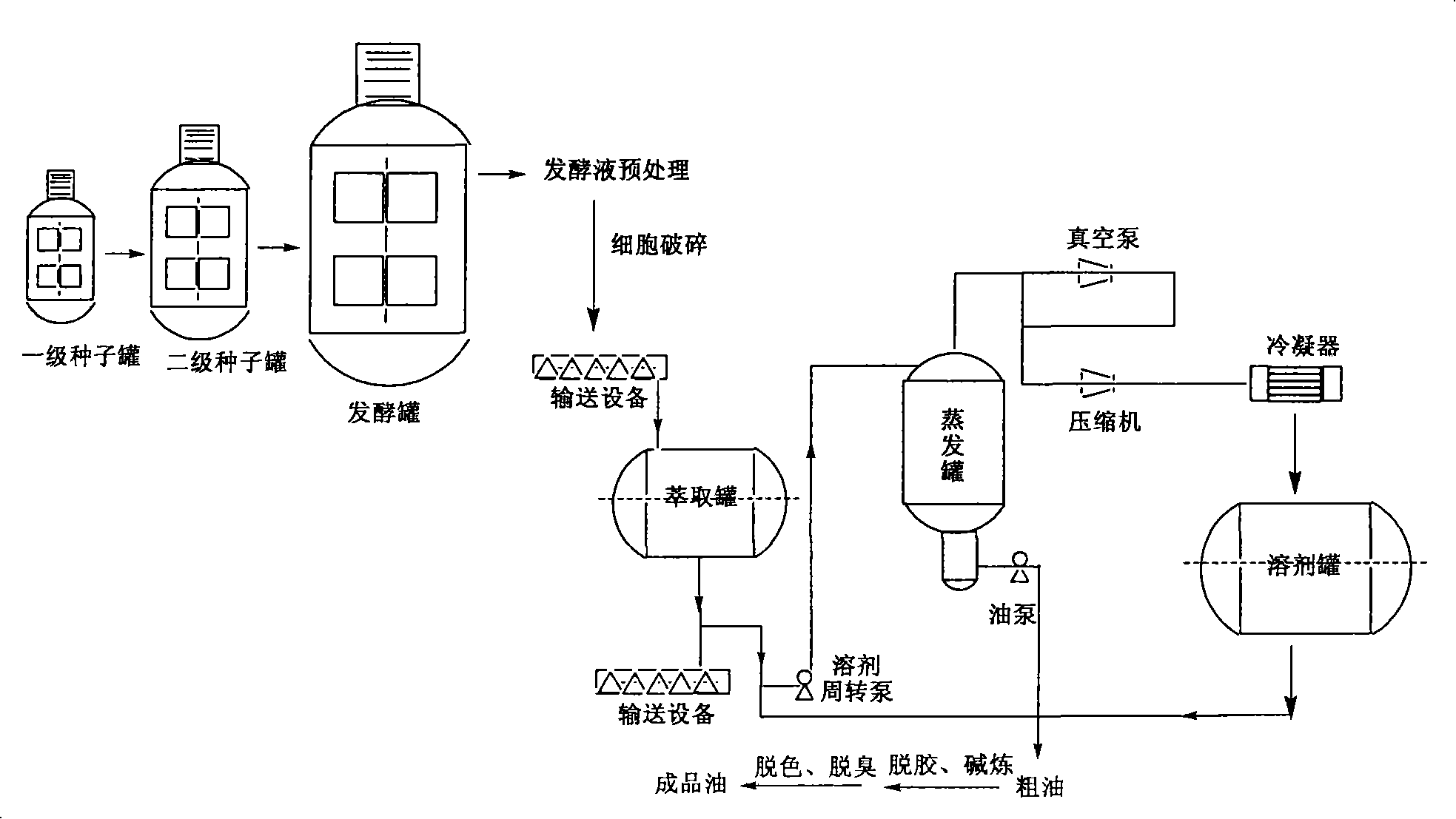

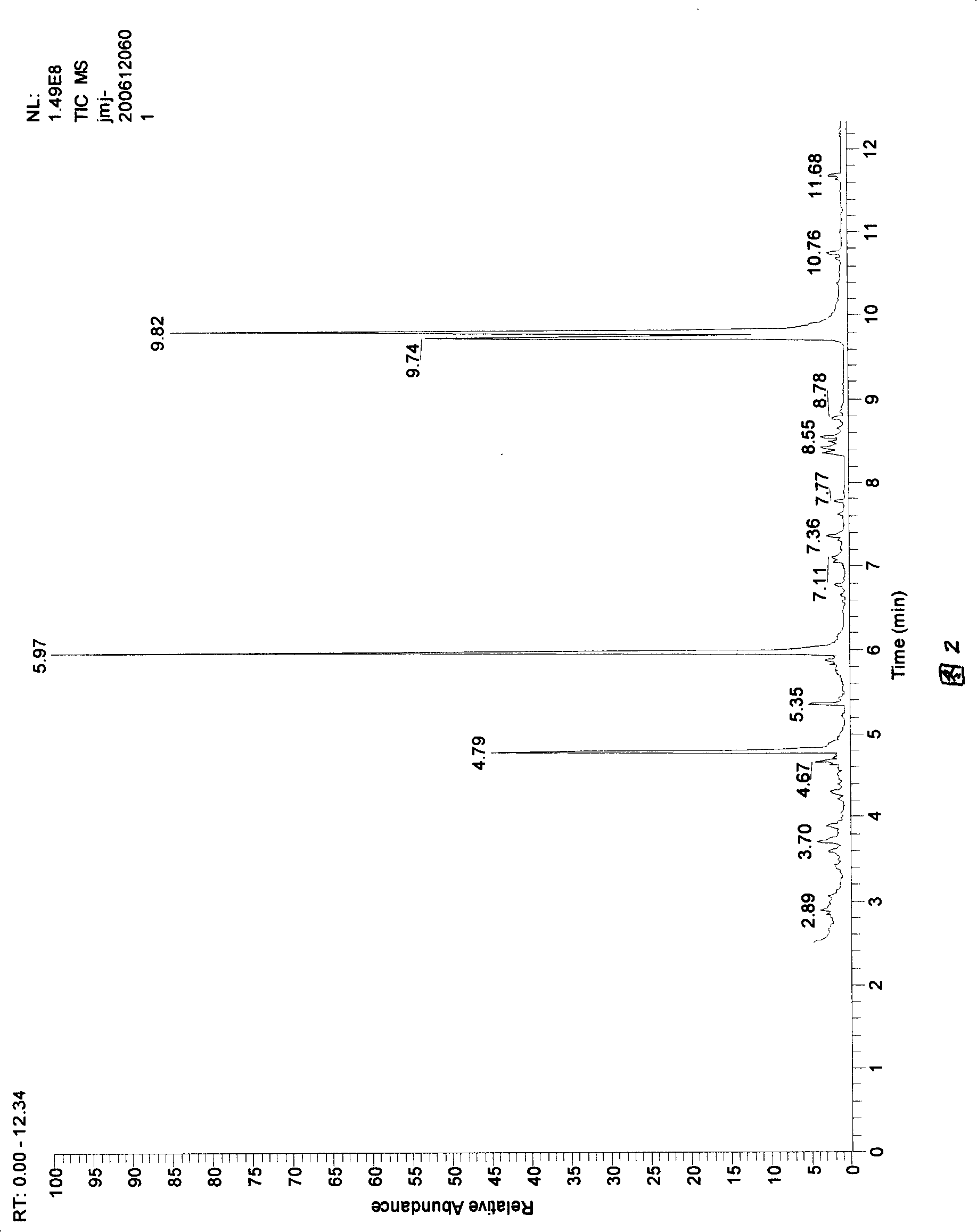

Technique for extracting and refining DHA enriched fatty acid from Crypthecodinium cohnii

ActiveCN101168501AEasy to operateReduce extraction costsCarboxylic compound separation/purificationChemistryOrganic solvent

The invention discloses a process for extracting and refining fatty acid rich in DHA from Cryptidinosa. The process first flocculates the fermentation broth of Crypthecodinium cohnii and then separates the solid from the liquid. After breaking the wall with alkali, the cells are mechanically broken, and then the broken bacteria are extracted with an organic solvent to obtain DHA crude oil; the DHA crude oil is passed through DHA essential oil is obtained after degumming, alkali refining, decolorization and deodorization. The method is simple to operate and can reduce the cost of extracting DHA oil. Only organic solvents are used in the operation process, and there is no residue in the end. After refining, the quality of DHA oil is improved. The DHA content in the extract is about 40-50%, which is suitable for DHA Large-scale production.

Owner:NANJING UNIV OF TECH

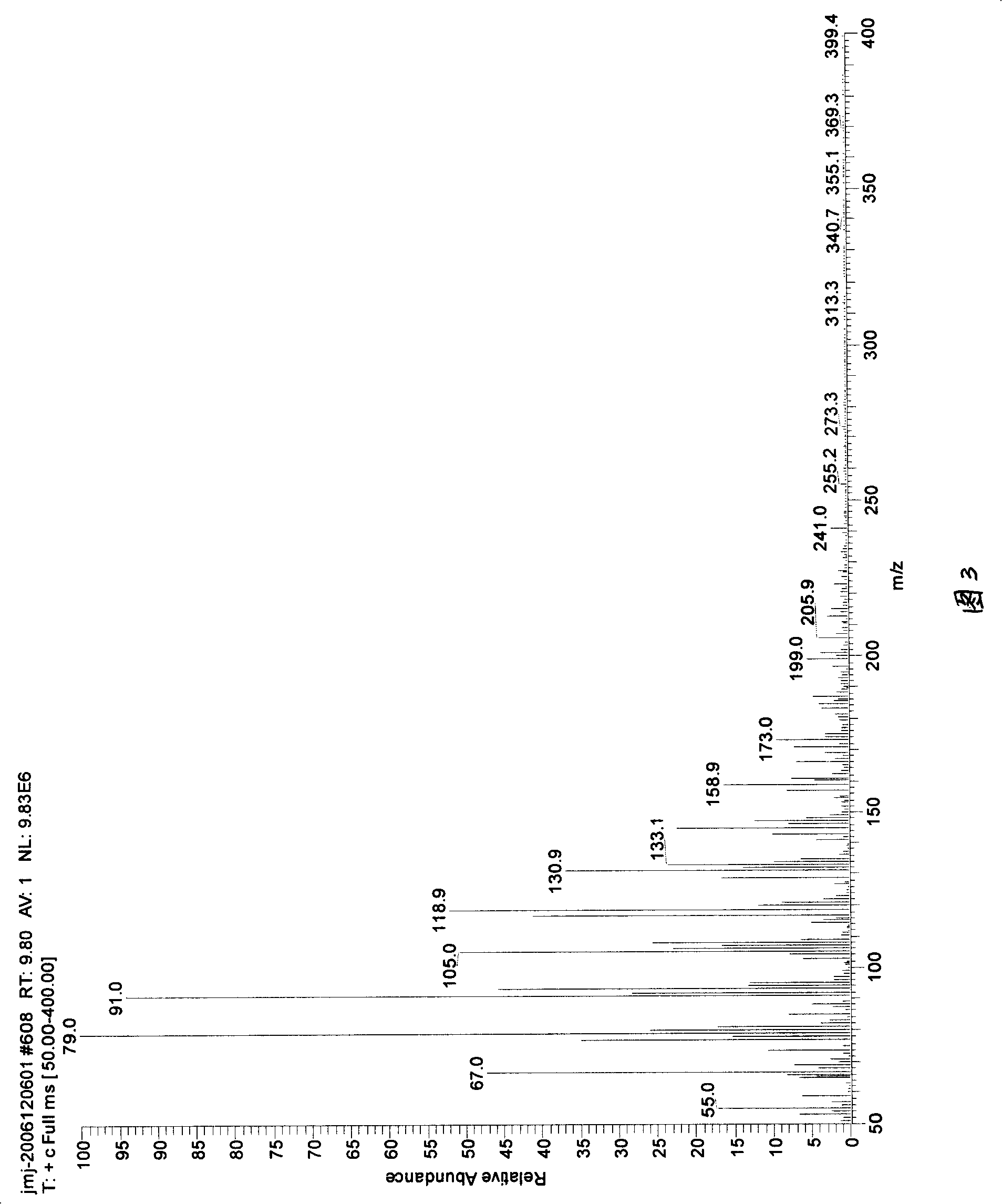

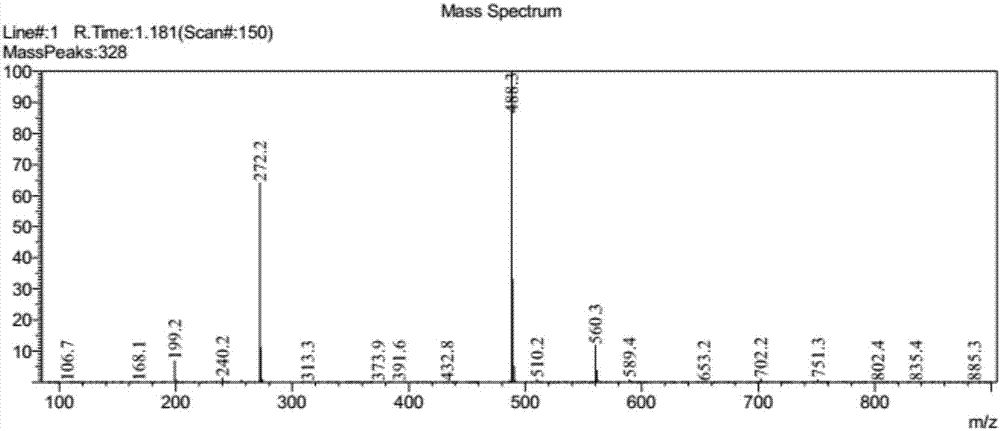

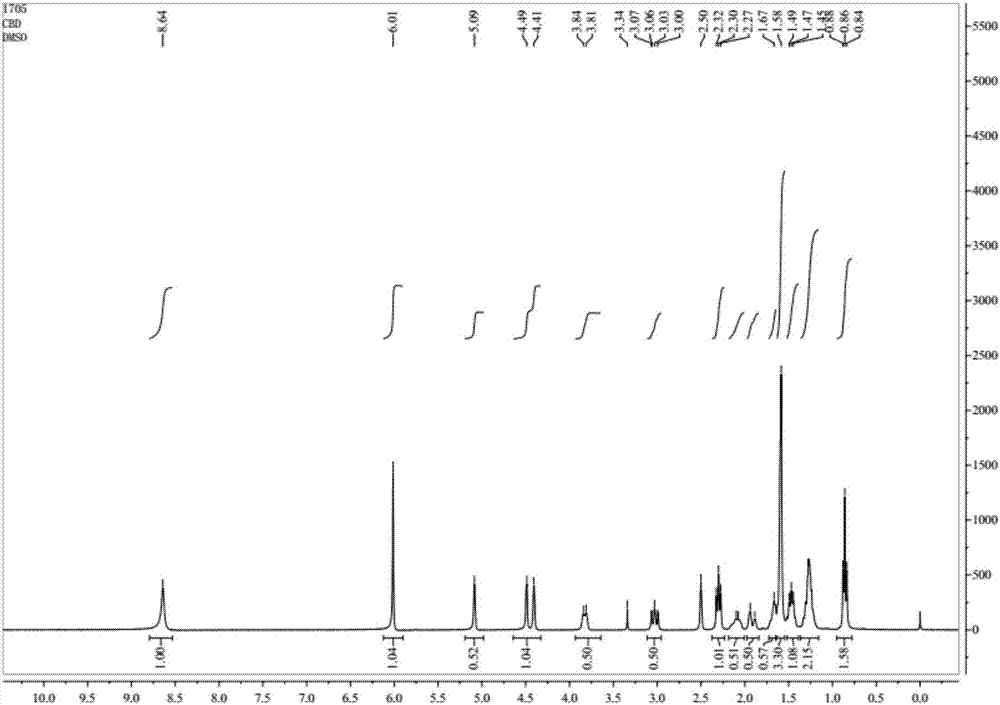

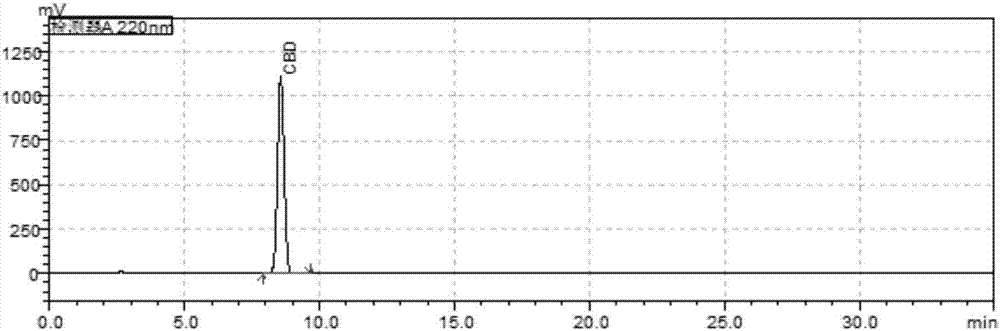

Method for extracting and purifying cannabidiol from China-hemp

ActiveCN107337586AImprove solubilityHigh extraction rateOrganic chemistryOrganic compound preparationOrganic solventElution

The invention belongs to the technical field of extraction and purification of plant ingredients and particularly relates to a method for extracting and purifying cannabidiol from China-hemp. In the method, an ingredient of cannabidiol is extracted from floral leaves in a mature period of the China-hemp according to a supercritical CO2 extraction technique, a cannabidiol extract is further purified by macroporous adsorbent resin and a rapid purification system, a cannabidiol content of an obtained product is 98% or higher, and the cannabidiol product does not contain a psychotoxic ingredient tetrahydrocannabinol. According to the method, a chemical organic solvent is not used in an extraction process, so that the method is environment-friendly and is low in toxicity and high in efficiency; the loss of cannabidiol in an adsorption elution process is reduced in a purification process, so that the impurity ingredients such as tetrahydrocannabinol and the like are effectively removed, and the use of an organic regent is decreased, so that the purification cost is lowered, and the environmental pollution is reduced. The product is high in yield and purity, and the requirement for development of a value-added product of the China-hemp, in particular to the market requirement of the active ingredient of the cannabidiol product in the China-hemp, can be met, and especially, the cannabidiol product has the great application advantage in the pharmaceutical field.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

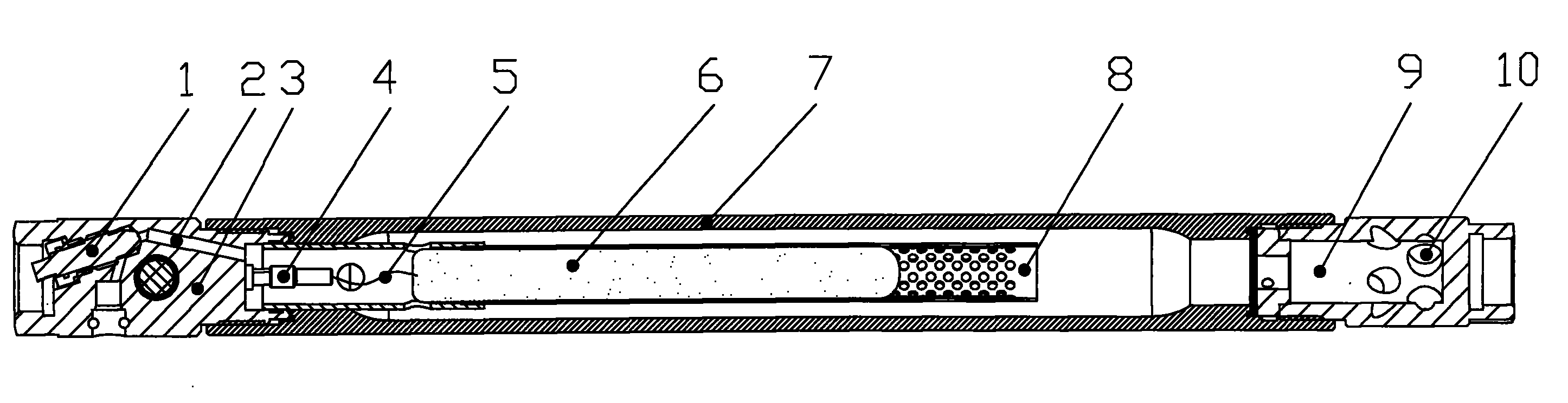

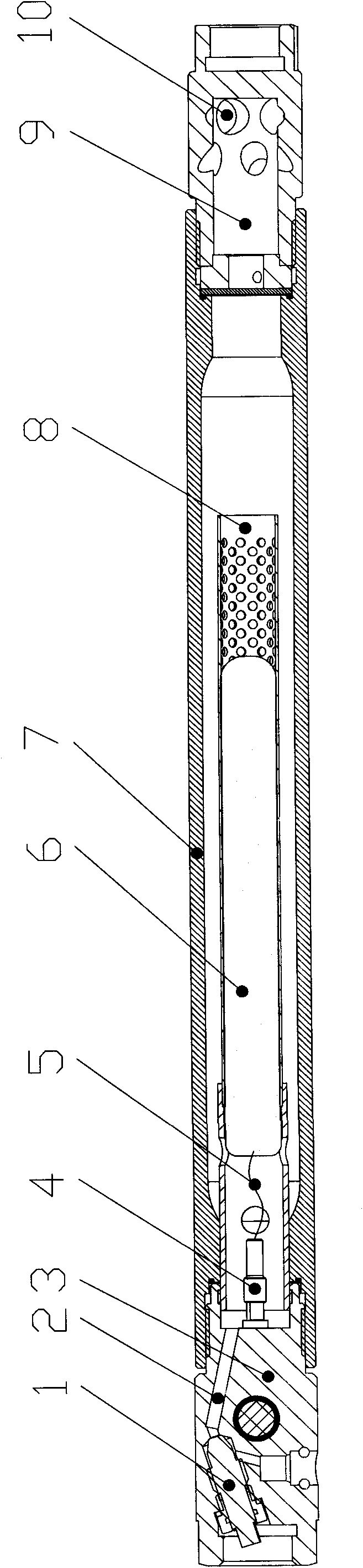

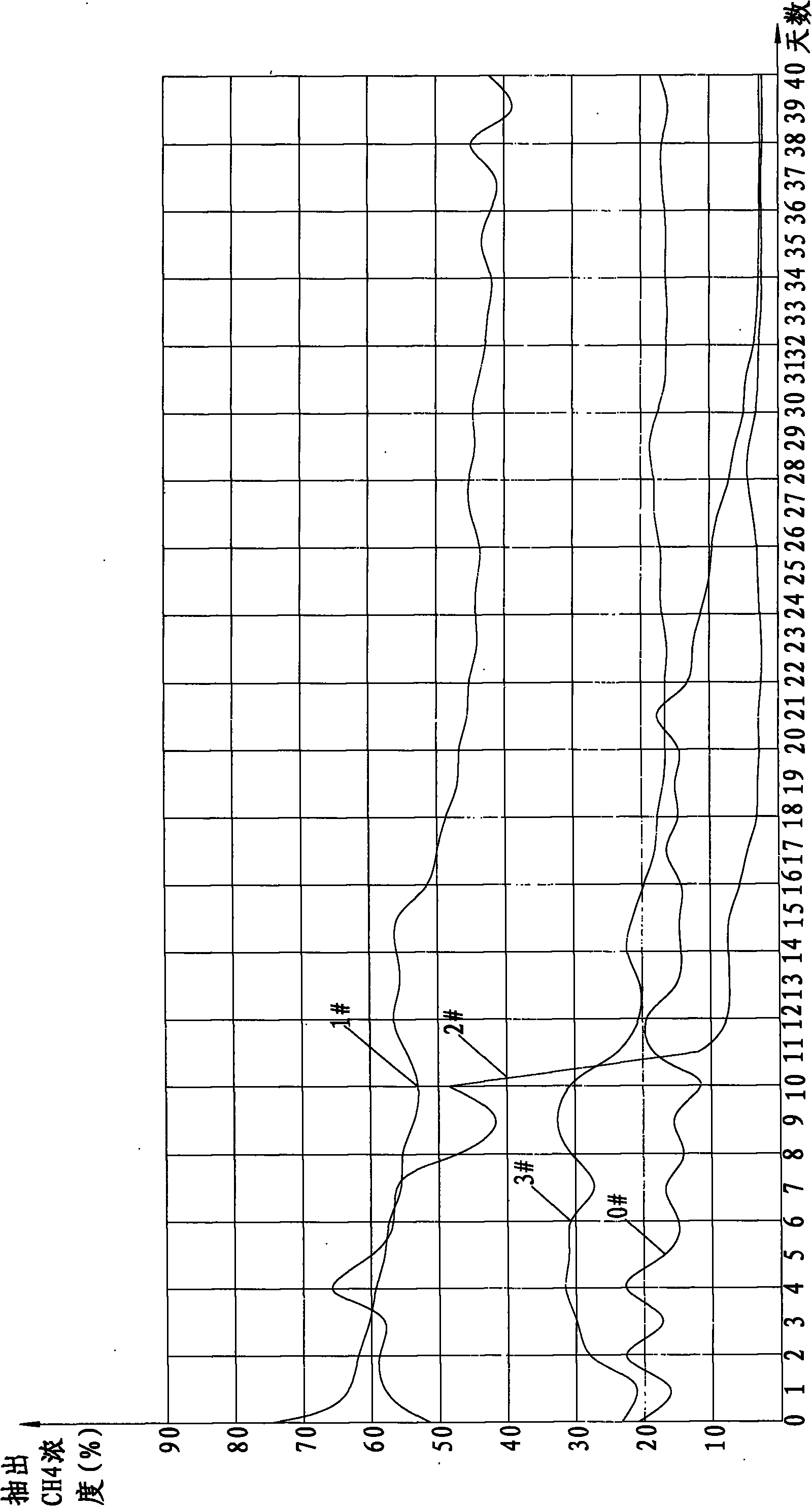

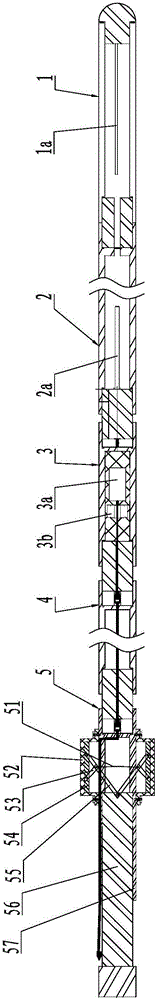

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

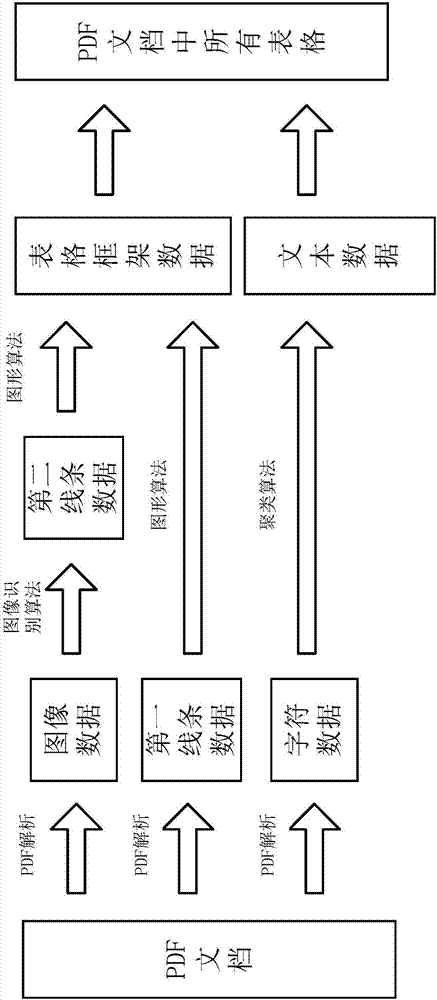

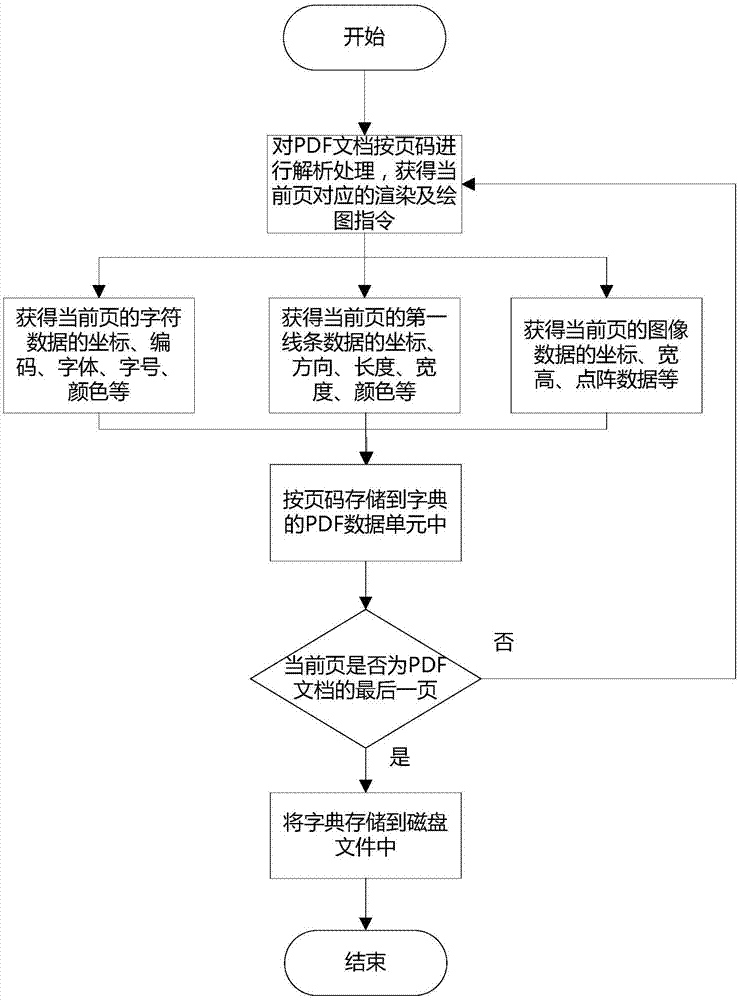

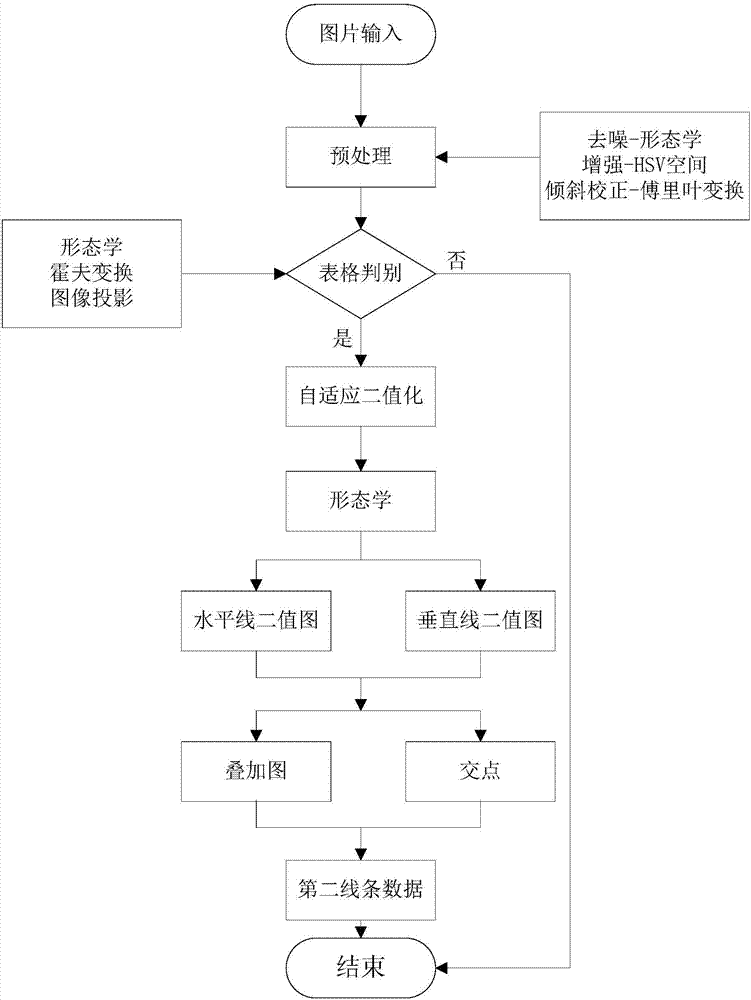

PDF form extraction method

ActiveCN106897690AEffective mergerEfficient separationCharacter recognitionGraphicsCluster algorithm

The invention discloses a PDF form extraction method. According to the technical scheme, the method comprises the steps of analyzing a PDF document by a page number to obtain all image data, first line data and character data, processing the image data in sequence according to the page number by adopting an image identification algorithm, and obtaining second line data corresponding to form data from the image data with the form data; processing the first line data and the second line data in sequence according to the page number by adopting a graphic algorithm, thereby obtaining form frame data with form row data and column data; performing clustering processing on the character data by adopting a clustering algorithm to obtain text data with a character string set; and obtaining all the form data in the PDF document through final all form frames and all text data. According to the method for extracting forms in the PDF document, the accuracy and efficiency of extracting the forms in the PDF document are improved, and more accurate form data can be obtained; and the method is suitable for the field with higher requirements on the accuracy and efficiency of extracting the form data.

Owner:南京述酷信息技术有限公司

Process for preparing glass fiber composite type silicon dioxide aerogel insulation quilt

The invention discloses a process for preparing a glass fiber composite type silicon dioxide aerogel insulation quilt. The process mainly comprises the following steps: absorbing a silicon dioxide aerogel liquid till being saturated by using a glass fiber quilt, gelling under specific conditions, and drying supercutical fluid CO2 to form a reinforced aerogel material. The glass fiber composite type silicon dioxide aerogel insulation quilt prepared by using the process is excellent in heat preservation property, mechanical property and fireproof and waterproof property, and is convenient to construct. By adopting the process, a solvent replacement step is avoided, the operation is simple and easy, the operation process is controllable, and continuous production can be achieved.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

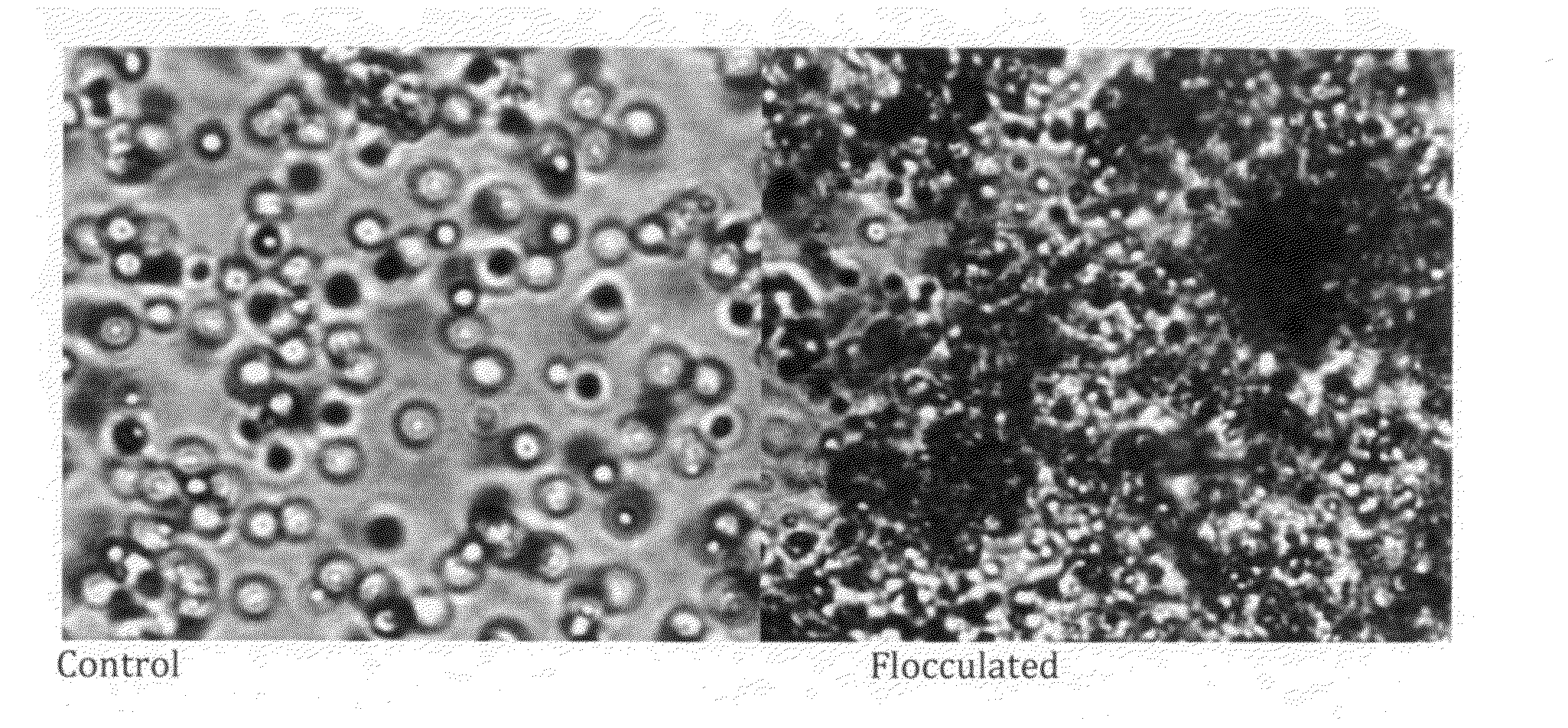

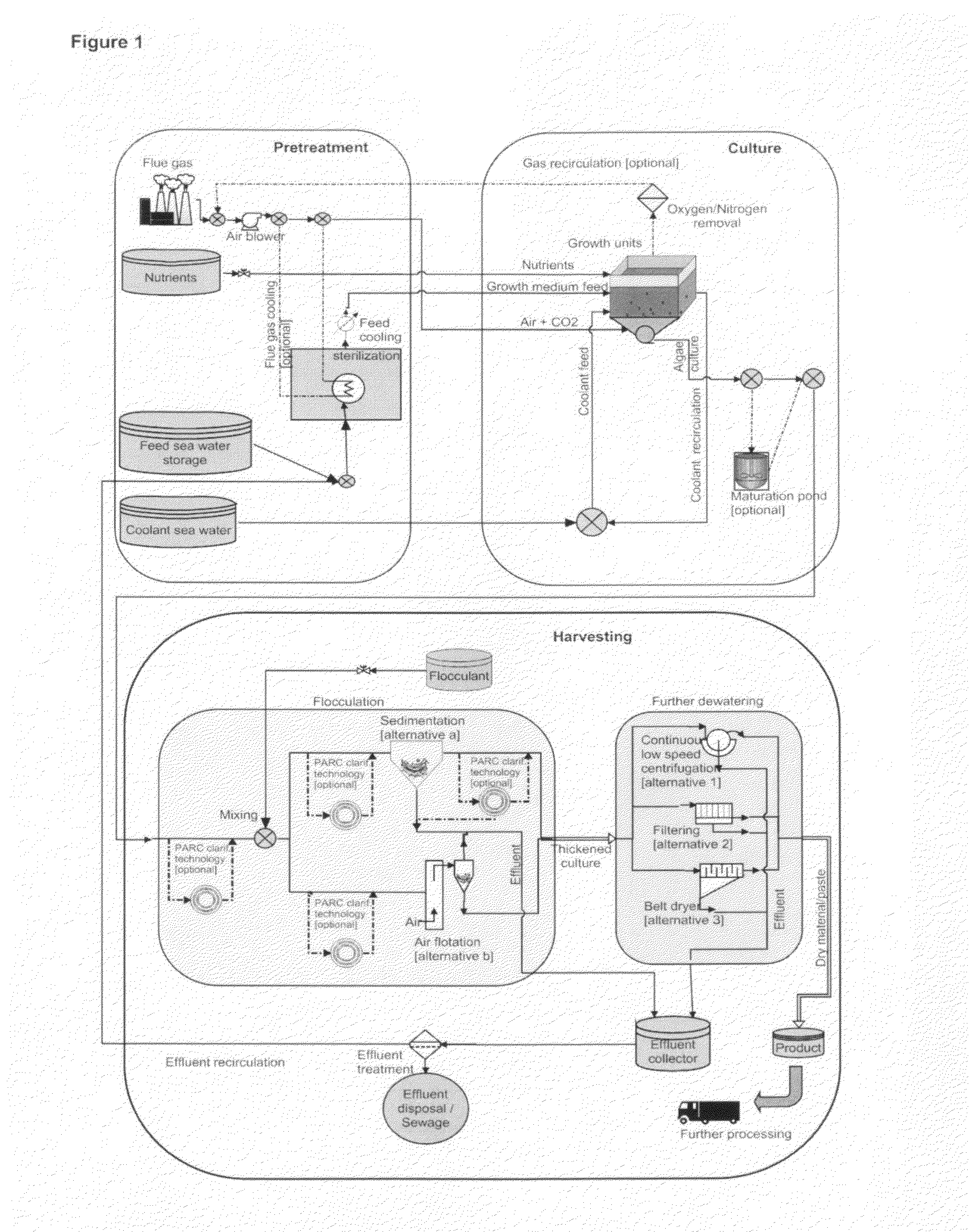

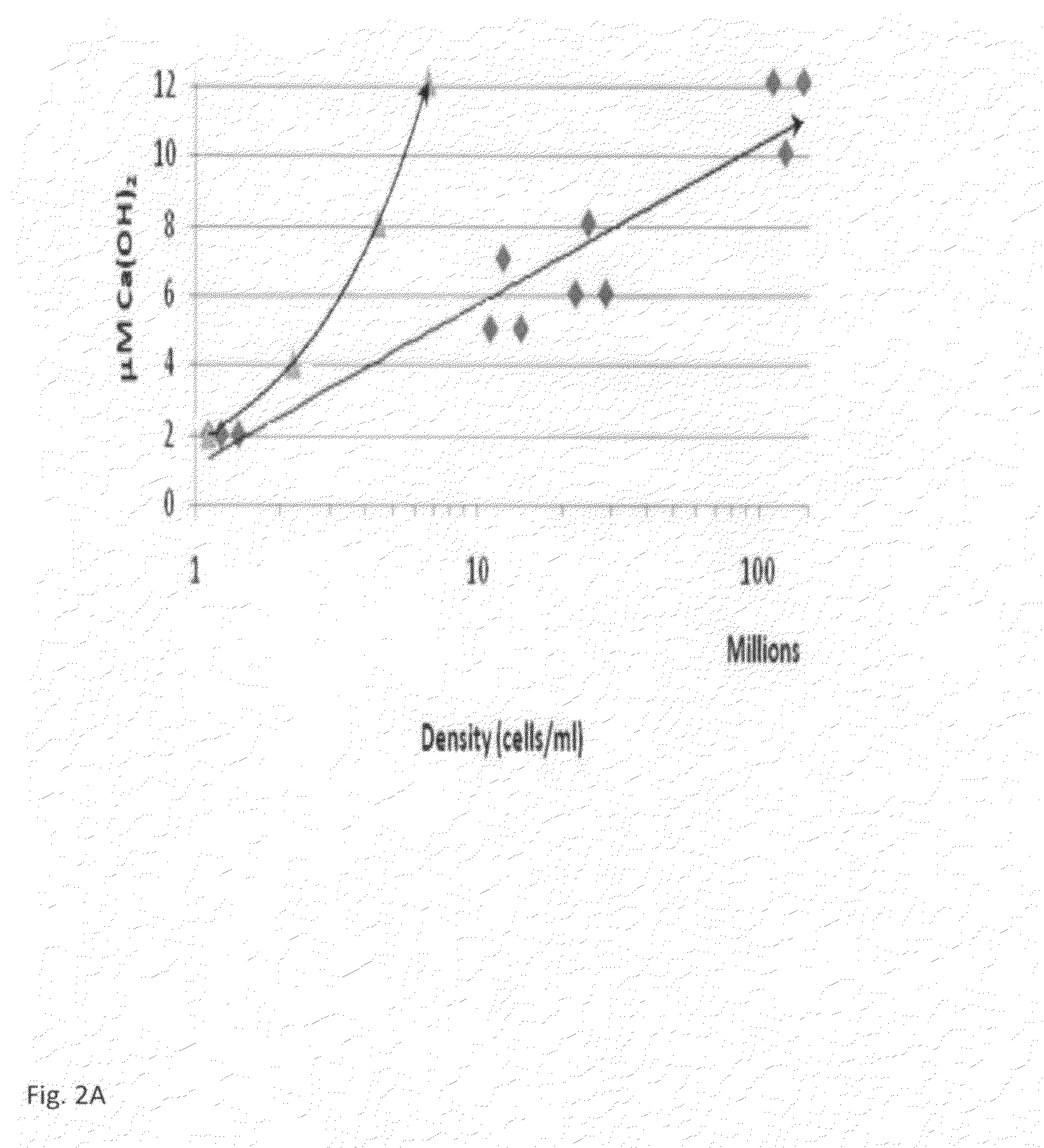

Method and system for efficient harvesting of microalgae and cyanobacteria

The high-speed centrifugation heretofore required for harvesting micro algae and cyanobacteria cultured for biofuels and other co-products is a major cost constraint. Mixing algae / cyanobacteria at high-density culture with far less alkali than previously assumed is sufficient to flocculate the cells. The amount of flocculant required is a function of the logarithm of cell density, and is not a linear function of cell density as had been thought. The least expensive alkali treatments are with slaked limestone or dolomite (calcium hydroxide and magnesium hydroxides). Further water can be removed from the floc by sedimentation, low speed centrifugation, dissolved air flotation or filtration, prior to further processing to separate oil from valuable co-products.

Owner:TRANSALGAE ISRAEL

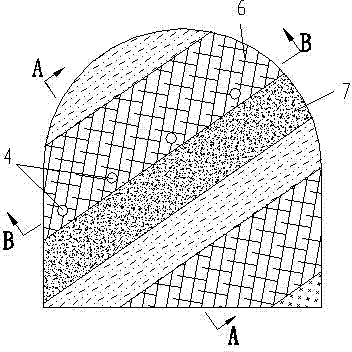

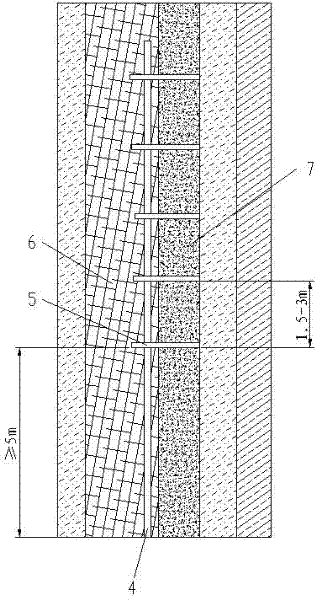

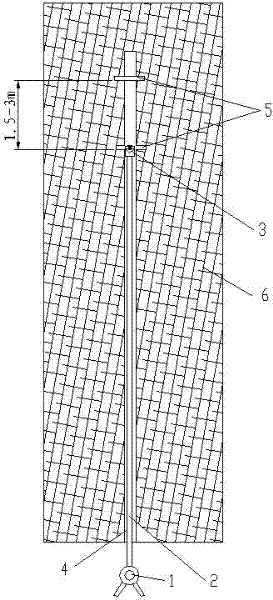

Depressurized extraction method for cutting through roof or floor of coal seam by abrasive water jet

InactiveCN102493833AGood sealing effectReduce gas extraction costsFluid removalGas removalAbrasive water jetCoal

The invention discloses a depressurized extraction method for cutting through a roof or a floor of a coal seam by an abrasive water jet, which comprises the following steps: a. drilling a bedding drill hole to set depth on the roof or the floor of a coal-rock mass or a hard layer by using a drilling machine through a drill stem and a slotting drill bit; b. delivering a high-pressure abrasive water jet of which the pressure is 25-30MPa to the slotting drill bit through the drill stem, wherein the drill stem rotates in situ; forming a radial slit on the hole wall of the bedding drill hole, wherein the slit penetrates the roof or the floor of the coal-rock mass or the hard layer and a soft layer; c. enabling the drill stem to rapidly retreat for 1.5-3m so as to form a new slit; d. repeating the step c until a plurality of radial slits are formed on the bedding drill hole, and moreover, reserving a safety rock pillar of at least 5m at the slit located at the position of the orifice of the bedding drill hole at a certain distance from the orifice; e. retreating the drill stem and the slotting drill bit and sealing the hole; and f. extracting gas by a gas extraction system. The depressurized extraction method for cutting through the roof or the floor of the coal seam by the abrasive water jet has the beneficial effects that the drill hole does not have potential safety hazards and is easy to form; a hole sealing effect is good; the time of reaching the standards of extraction is short; the production efficiency is high; and the extraction is safe.

Owner:重庆市能源投资集团科技有限责任公司

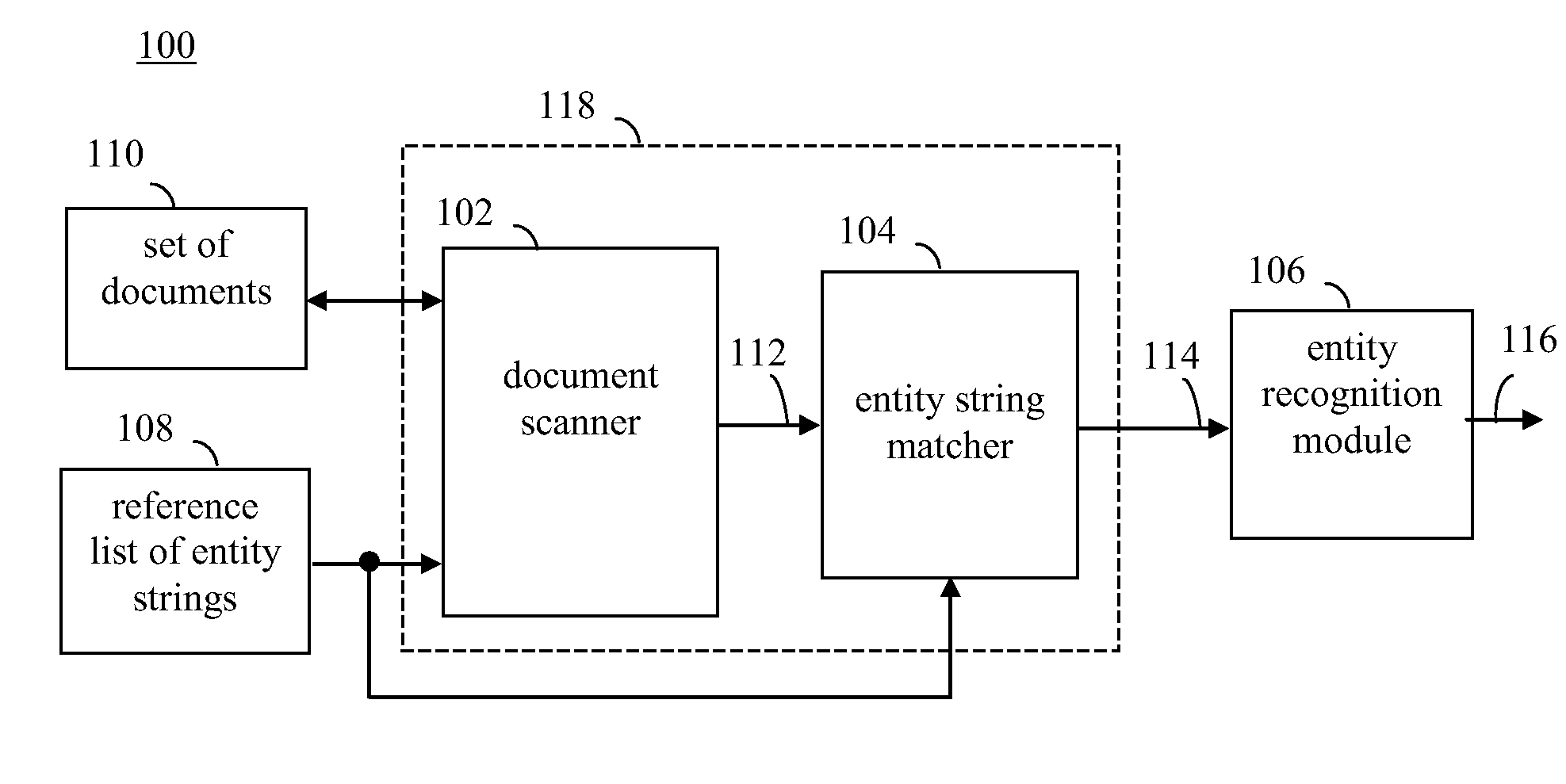

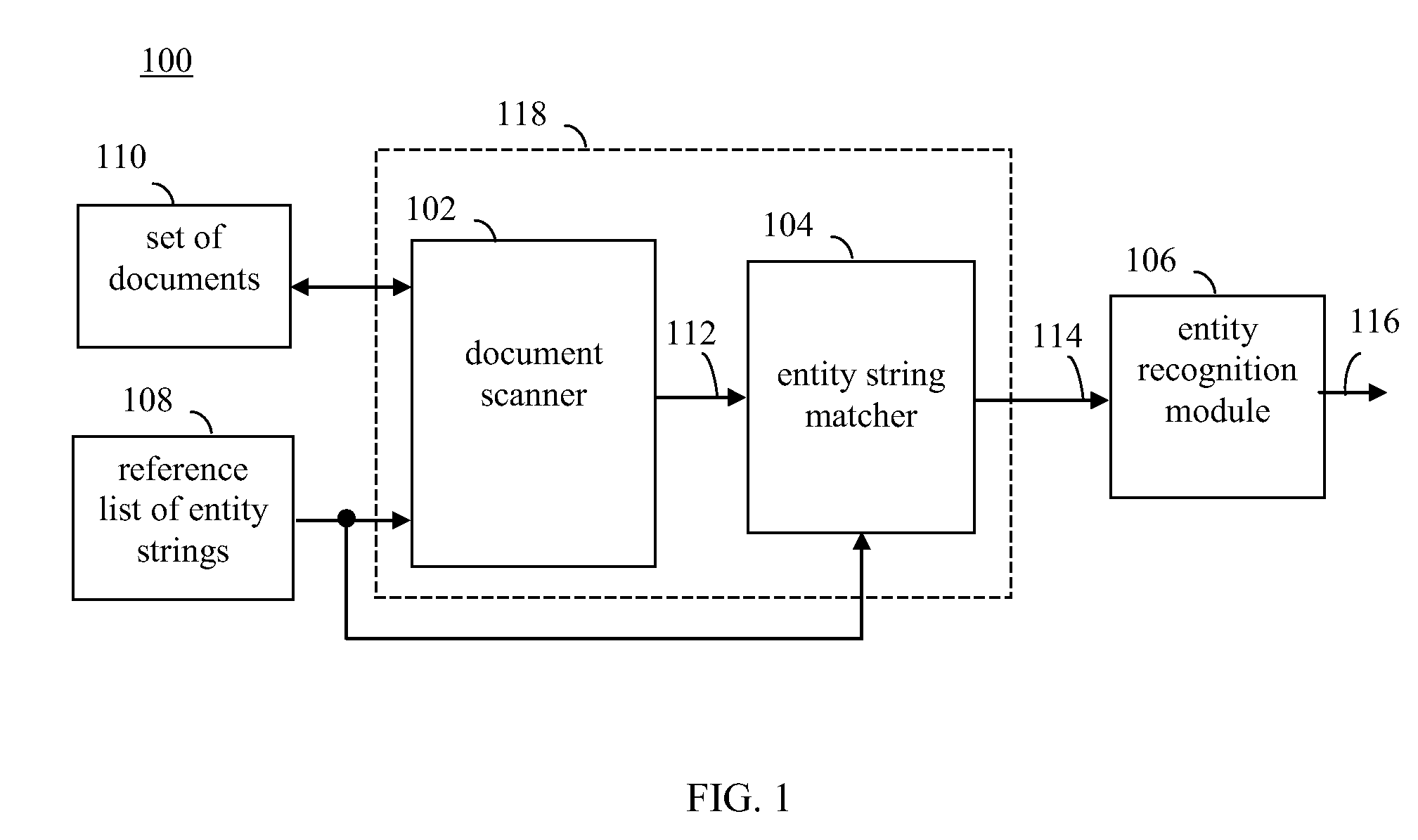

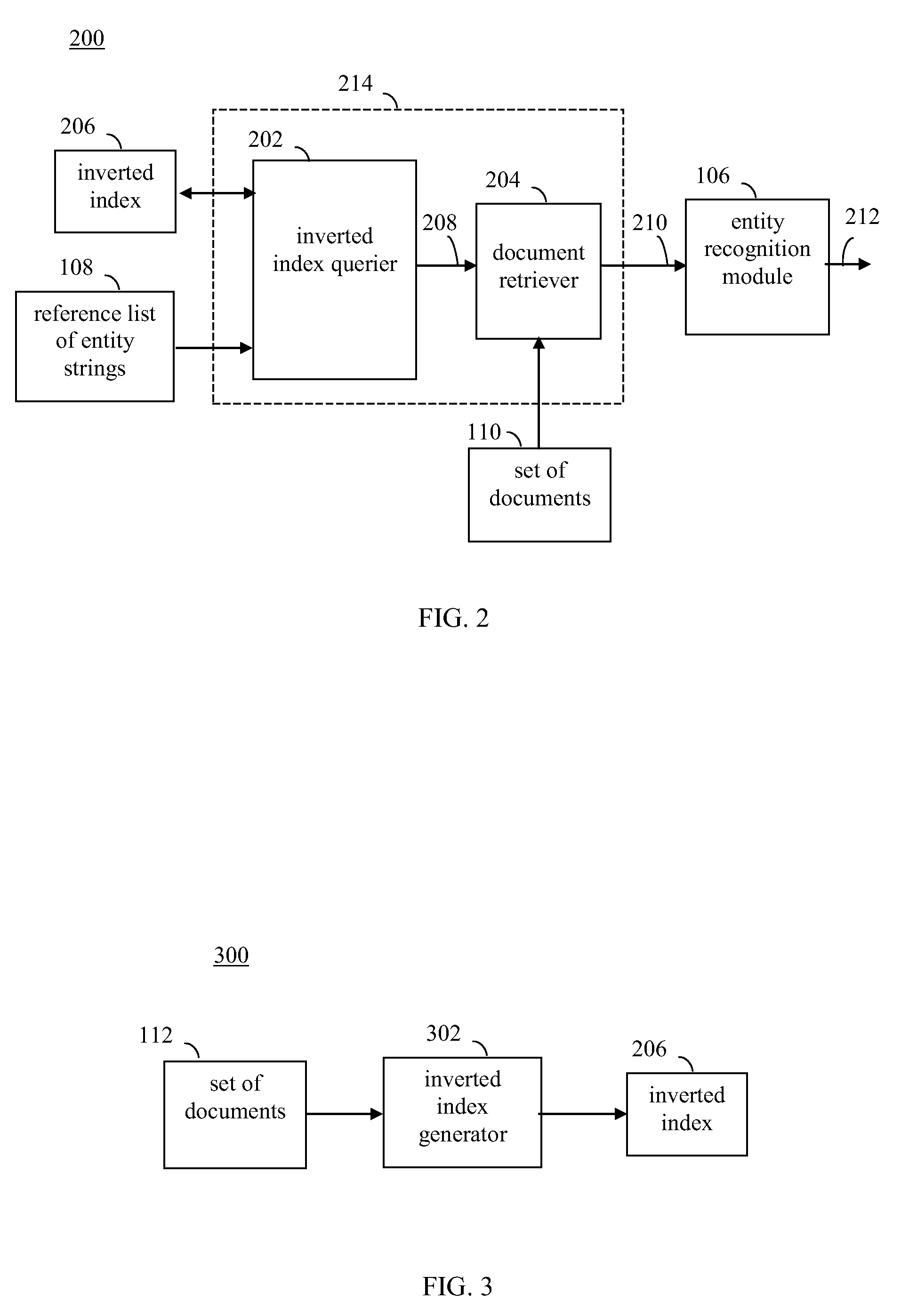

Scalable lookup-driven entity extraction from indexed document collections

ActiveUS20090319500A1Reduce extraction costsDigital data processing detailsNatural language data processingDocument preparationInverted index

A set of documents is filtered for entity extraction. A list of entity strings is received. A set of token sets that covers the entity strings in the list is determined. An inverted index generated on a first set of documents is queried using the set of token sets to determine a set of document identifiers for a subset of the documents in the first set. A second set of documents identified by the set of document identifiers is retrieved from the first set of documents. The second set of documents is filtered to include one or more documents of the second set that each includes a match with at least one entity string of the list of entity strings. Entity recognition may be performed on the filtered second set of documents.

Owner:MICROSOFT TECH LICENSING LLC

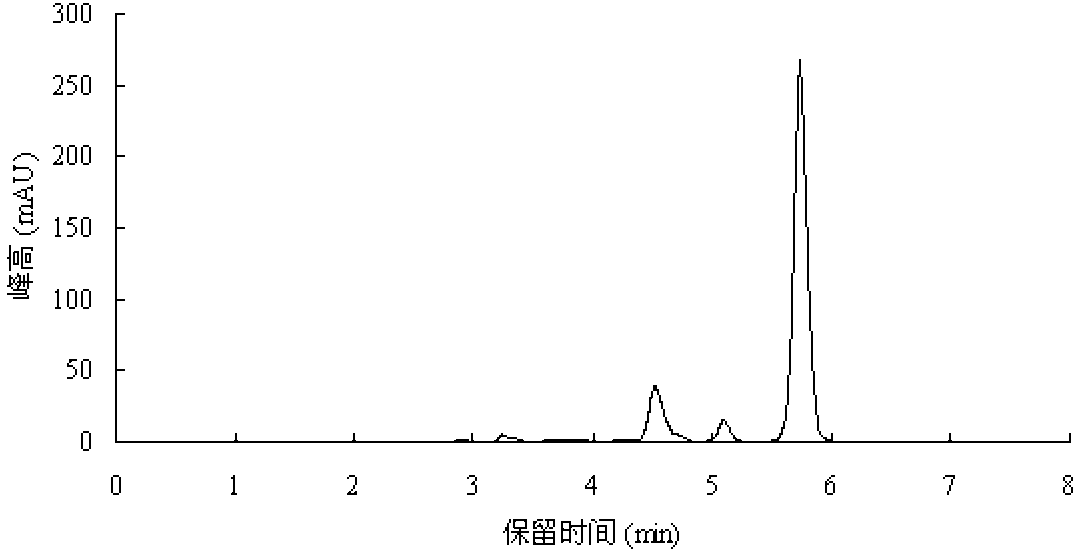

Novel extraction process of coenzyme Q10

ActiveCN104694613AIncrease productionReduce extraction costsQuinone separation/purificationMicroorganism based processesOrganic solventAlcohol

The invention belongs to the technical field of biology and discloses a novel extraction process of coenzyme Q10. The novel extraction process of the coenzyme Q10 takes coenzyme Q10 fermentation liquid as a raw material and comprises the following steps: extracting through an organic solvent, carrying out base-alcohol saponification, carrying out chromatography through a silica gel column, crystallizing through absolute ethyl alcohol, and carrying out suction filtration and vacuum drying to prepare the coenzyme Q10 product. The process is simple to operate, low in pollution, low in requirements on instruments and equipment and low in cost.

Owner:XINJIANG FUFENG BIOTECH

Technological process for preparing stevioside from stevia rebaudiana bertoni

InactiveCN102060891ANo pollution in the processReduce extraction costsSugar derivativesSugar derivatives preparationCyclic processSolvent

The invention discloses a technological process for preparing stevioside from stevia rebaudiana bertoni. The technological process comprises the following steps: carrying out countercurrent extraction on the dried stevia rebaudiana bertoni raw material with water, sequentially adsorbing the obtained extracting solution with macroporous absorption resin columns which are connected in series, allowing the residual liquid after absorption to enter a countercurrent extraction device for cyclic extraction, reabsorbing the obtained extracting solution with the resin columns which are connected in series once again, and completing the extraction separation closed cycle process; after the whole countercurrent extraction and absorption process is completed, eluting the resin columns with water for removing impurities, desorbing with stripping liquid, collecting the stripping liquid, concentrating and drying to obtain the crude extract of the stevioside; and refining the crude extract by a solvent method and decolorizing resin respectively to finally obtain the stevioside product. In the obtained product, the content of the stevioside compound is 70-100%, wherein, two components such as the stevioside and rebaudioside account for 70-90% of the whole stevioside compound, thus meeting the standards for a medicine, a healthcare product or food.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

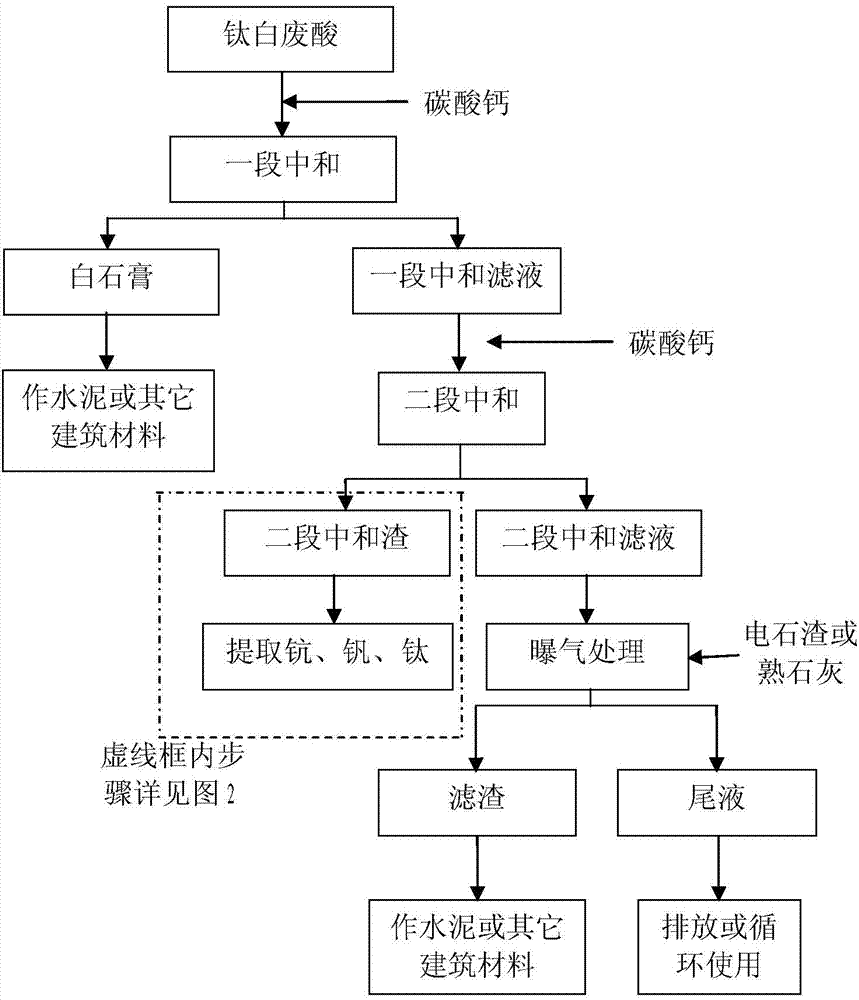

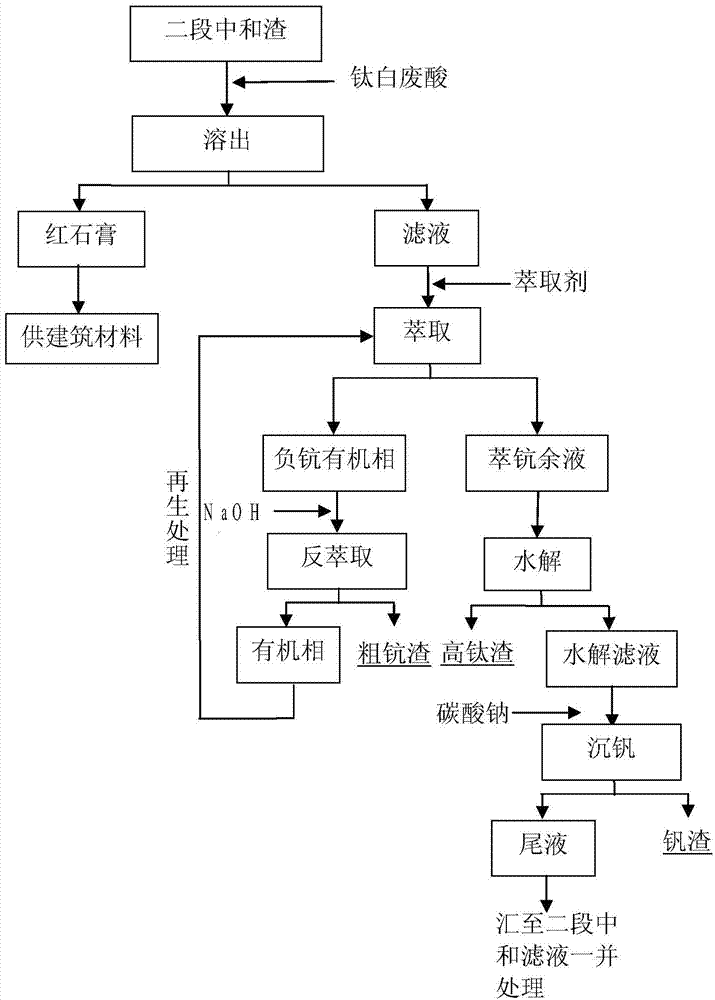

Method for enriching scandium, titanium and vanadium from sulfuric acid method titanium dioxide waste acid, and for treating waste acid

InactiveCN103540752ARealize environmental protectionReduce extraction costsNature of treatment waterWater/sewage treatment by neutralisationDissolutionHydrolysis

The invention relates to a method for enriching scandium, titanium and vanadium from sulfuric acid method titanium dioxide waste acid, and for treating waste acid. The method comprises the steps that: titanium dioxide waste acid is subjected to two-stage neutralization by using calcium carbonate, such that white gypsum is obtained, and two-stage neutralization slag with enriched scandium, titanium and vanadium are obtained; the two-stage neutralization slag is dissolved by using titanium dioxide waste acid; the dissolution liquid is subjected to scandium extraction and stripping, such that crude scandium slag is obtained; scandium extraction residue liquid is subjected to titanium hydrolysis, such that high-titanium slag is obtained; the hydrolysis filtrate is subjected to neutralization vanadium precipitation by using sodium carbonate, such that vanadium slag is obtained; the liquid after vanadium precipitation is subjected to aeration and further neutralization with the two-stage neutralization filtrate, and can reach a discharge standard and can be discharged. With the method provided by the invention, scandium, titanium and vanadium can be effectively enriched from titanium dioxide waste acid, and the treated waste acid tail liquid can reach a discharge standard and can be discharged.

Owner:广西冶金研究院有限公司

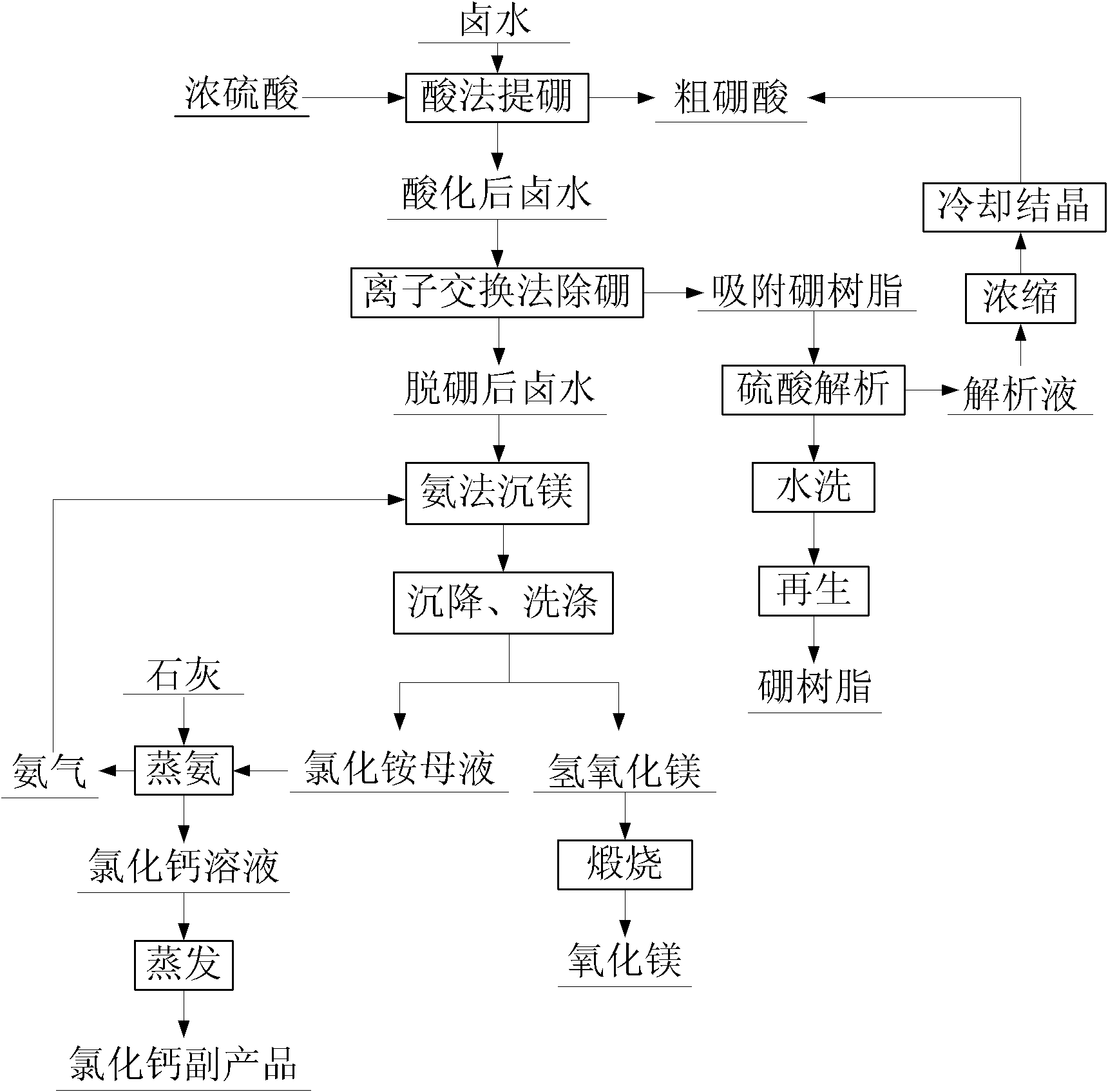

Method for preparing high-purity magnesium oxide with high boron salt lake brine

InactiveCN102491379ALarge particlesReduce extraction costsBoron-oxygen compoundsMagnesiaReaction temperatureIon-exchange resin

Provided is a method for preparing high-purity magnesium oxide with high boron salt lake brine. Salt lake brine is evaporated through a salt pan, concentrated to crystallize potassium sulfate, sodium chloride and potassium chloride and is drawn with lithium in adsorption mode so as to obtain master sauce brine containing magnesium and boron. Concentrated sulfuric acid is added into master sauce brine for reacting, and coarse boracic acid and acidized brine are obtained after cooling and filtering. Potential of hydrogen (pH) value of acidized brine is adjusted to be 5.5-6.5, and acidized brine passes through ion exchange resin adsorbing boron. When boron concentration in effluent liquid is higher than 5 mg / L, brine is not injected, boron-removed brine is obtained, then boron-removed brine and ammonium chloride solution are filled with ammonia for stirring and to produce magnesium sedimentation reaction, reaction temperature ranges from 60 DEG C to 80 DEG C, pH ranges from 7.5 to 8.0, the reaction is stopped when concentration of free ammonia reaches 1.8-2.2 mol / L, and magnesium hydroxide and magnesium sedimentation mother solution are obtained. Magnesium oxide is obtained by calcining magnesium hydroxide, content of magnesium oxide is larger than 99.8%, and magnesium extraction ratio is larger than 90%. Sedimentation mother solution adopts lime to steam ammonia, and generated ammonia circulates to magnesium sedimentation reaction. Mother solution after ammonia steaming is evaporated, concentrated and crystallized to obtain calcium chloride. Ion exchange resin adsorbing boron is washed, analyzed and regeneratively cycled for use. Boron-containing analysis solution is concentrated and cooled to pick up coarse boracic acid, and coarse boracic acid is recrystallized to obtain refined boracic acid with purity larger than 99%. High-purity magnesium oxide prepared by the method is high in purity, good in economic benefit, free of environment pollution, strong in operability and favorable for industrial production.

Owner:CENT SOUTH UNIV

Comprehensive utilization method of red mud coal-base rotary kiln method

The invention discloses a comprehensive utilization method of a red mud coal-base rotary kiln method, belonging to the field of comprehensive utilization of solid wastes. The method comprises the following steps: fully mixing the red mud, calcium-containing compound which occupies 8-14% of the red mud, and a carbon material which occupies 20-50% of the red mud; carrying out carbon smelting reduction in a coal-base rotary kiln at the temperature of 1000-1550 DEG C; and reacting for 2-6 hours to obtain sponge iron or hot molten iron and a byproduct building material. In the method, the red mud discarded in smelting aluminum oxide is effectively comprehensively utilized, thus the solid zero emission is realized. The method provided by the invention has high utilization; and the metal reduction rate reaches 95-98%, and the metal recovery rate reaches 96-98%.

Owner:胡长春

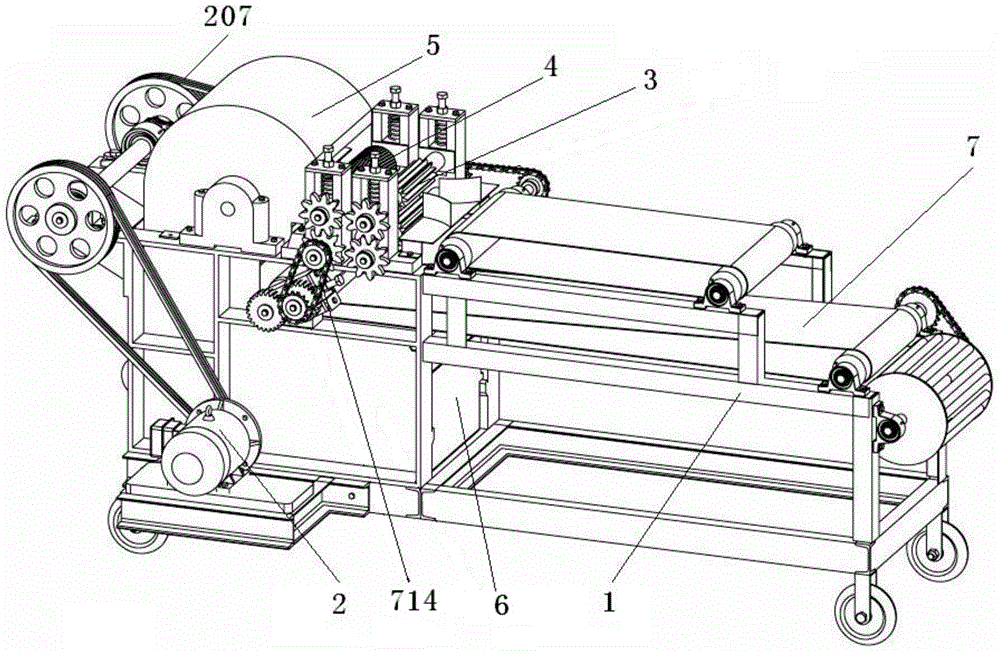

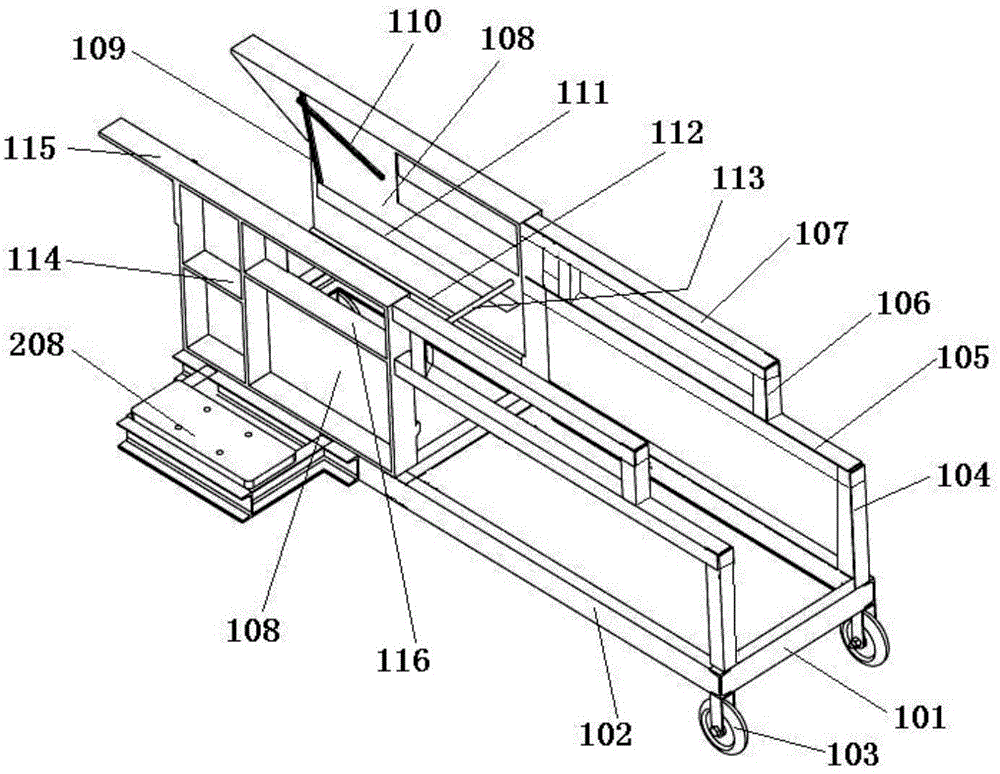

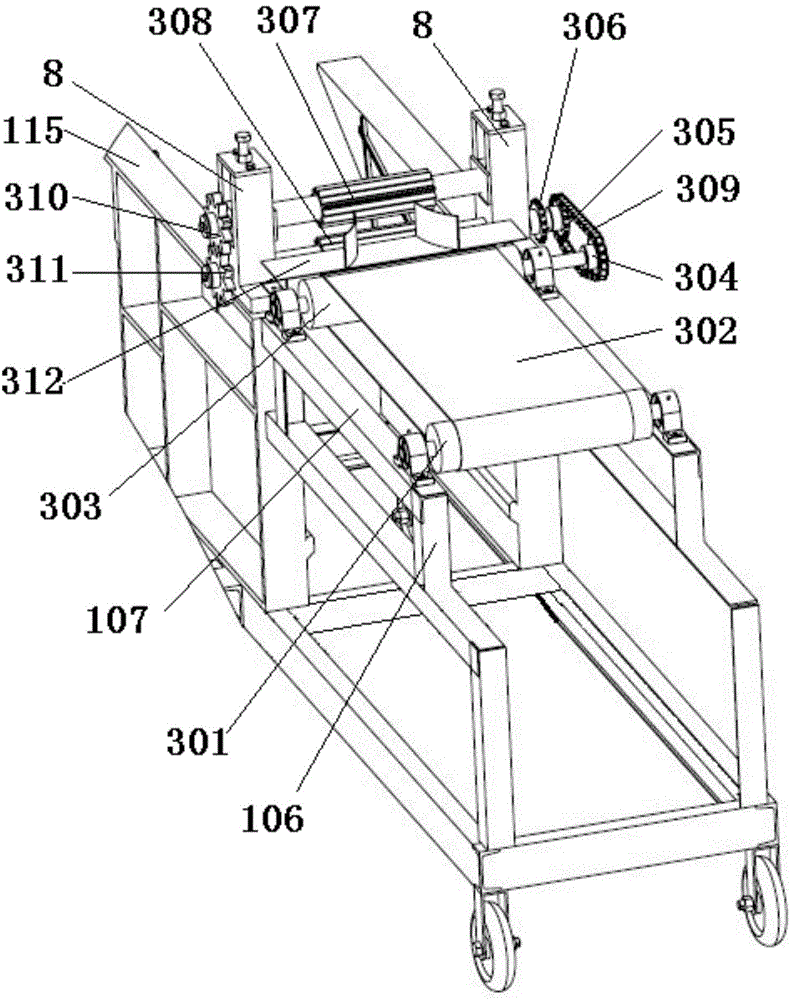

Movable wholly-feeding banana stem comprehensive utilizing machine

InactiveCN104695028AAvoid stickingRealize comprehensive utilizationMechanical fibre separationFiberPulp and paper industry

The invention belongs to the technical field of agricultural machinery and relates to a movable wholly-feeding banana stem comprehensive utilizing machine. A feeding device, a water squeezing device and a fiber scraping device are sequentially disposed on the upper layer of a rack from front to rear, a recycling device is disposed on the rear portion of the rack, and a discharging device is disposed on the middle layer of the rack. Driven by a power device, banana stems sequentially pass the feeding device, the water squeezing device and the fiber scraping device for water squeezing, fiber scraping and separating of scraping residues, the recycling device recycles the scraping residues and a small amount of thrown-out fibers, and the discharging device conveys extracted fibers out. The banana stems are treated by adopting five processes including whole feeding, rolling water squeezing, fiber scraping, recycling and discharging as well as conveying, so that comprehensive utilizing of the banana stems is realized. The machine is high in fiber extraction efficiency, capable of recycling the scraping residues and suitable for comprehensively utilizing the banana stems in main banana producing areas and promoting income increasing of banana growers.

Owner:HAINAN UNIVERSITY

Technology for producing high-purity humate by using coal

The invention provides a technology for producing high-purity humate by using coal. The technology comprises the following steps: selecting weathered coal or lignitic coal or peat with humate content of not less than 40%, removing impurities, crushing into coal powder with 80-120 meshes, and adding 100-120kg of the coal powder and 120-200kg of nitric acid solution with concentration of 1.0-2.0% to a reaction kettle at the same time; heating at the temperature of 70-80 DEG C, reacting for 1 hour while stirring, controlling the PH value at 1.5-4, and keeping standing for cooling; performing high-speed centrifugal separation at centrifugal speed of 3000RPM, adding 10-12kg of precipitate to another reaction kettle, adding water which is as 2-5 times as weight of the precipitate and 0.3-0.6kg of sodium carbonate, stirring, and reacting at the temperature of 80-95 DEG C for 90 minutes; keeping the temperature unchanged, adding 0.5-0.9kg of sodium hydroxide or potassium hydroxide, and continuously reacting for 1 hour; and taking reaction solution after cooling and precipitation, centrifuging to remove precipitate, and drying the obtained solution to obtain the finished product, wherein, the PH value of the solution is 9-11. The technology has the advantages of simple and practical process, no environmental pollution, low extraction cost, fast extraction speed and high extraction rate.

Owner:方宁

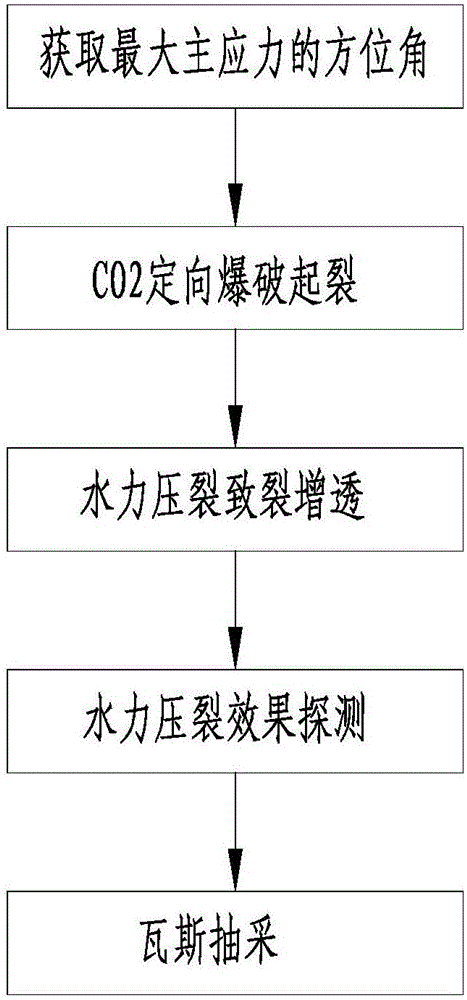

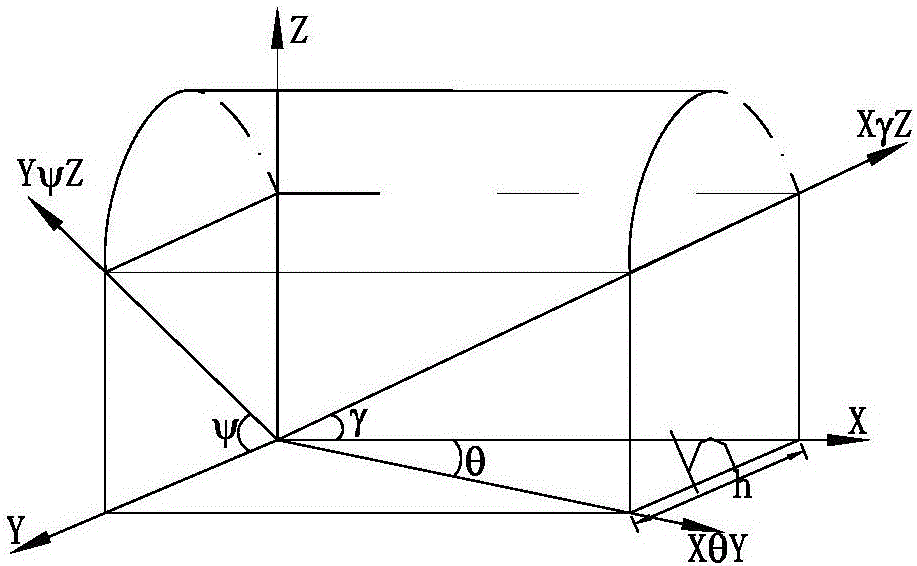

Gas extraction method through CO2 directional blasting crack initiation and hydrofracture coupling permeability increase

ActiveCN106285768AImprove extraction efficiencyReduce extraction costsFluid removalGas removalSplit shapeCoupling

The invention discloses a gas extraction method through CO2 directional blasting crack initiation and hydrofracture coupling permeability increase. The maximum main stress direction of a preset fracturing point is calculated first; then in the maximum main stress direction, CO2 blasting fracturing is conducted on the fracturing point to form a fracturing hole; afterwards, hydrofracture fracturing permeability increase is conducted on the fracturing hole, the effect of hydrofracture is detected to obtain the hydrofracture influence range; and finally, coal bed gas extraction is conducted within the hydrofracture influence range. Therefore, CO2 is released in the maximum main stress direction, and the influence range of a CO2 phase change blasting fracturing crack is widened significantly. Compared with a single CO2 directional blasting fracturing permeability increase method, the permeability increase influence range is widened significantly. Compared with a single hydrofracture permeability increase method, the permeability increase cracks are more uniform. In addition, after the hydrofracture influence range is detected, drill holes are arranged reasonably for gas extraction, work amount of gas extraction drilling and fracturing holes is reduced effectively, and the cost of gas extraction is reduced.

Owner:CHONGQING UNIV

Method for producing humate from base waste liquid

ActiveCN102336915ANo pollutionNo wasteClimate change adaptationSewage/sludge fertilisersLiquid wasteElectrolysis

The invention provides a method for producing fertilizer from base waste liquid. The method comprises the following processes: collecting soluble-base-containing wastewater generated in a base factory or saline solution electrolysis process, airing and concentrating to obtain base waste liquid with a base concentration of 18-22%; processing weathered coal or lignite or peat into coal powder by using a pulverizer, mixing the coal powder and the base waste liquid according to a weight ratio of 1:(8-10) and adding the mixture to a reaction kettle, uniformly stirring, heating, standing and precipitating, and thus obtaining the reaction precipitate and reaction supernatant after the reaction materials in the reaction kettle are still and precipitate; adding hydrochloric acid solution to the reaction supernatant, and drying the supernatant precipitate to obtain humic acid; and placing the reaction precipitate to a precipitating pond, uniformly mixing the reaction precipitate and humic acid according to a weight ratio of reaction precipitate to humic acid being 1:(0.5-0.8), standing for 2-3 hours, and spraying and granulating the mixed material to obtain a finished product used as fertilizer. The method has the advantages that wastewater can be recycled, environmental pollution is avoided, the process is simple and practical, the extraction cost is low, therefore, the method can be popularized and used.

Owner:祁长喜

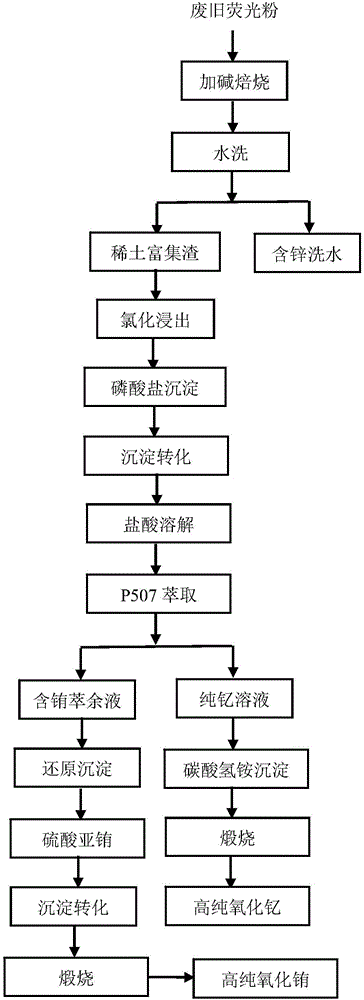

Method for extracting europium oxide and yttrium oxide from waste fluorescent powder

InactiveCN104532006AGreat tasteReduce cleaning difficultyProcess efficiency improvementRare-earth elementPhosphate

The invention discloses a method for extracting europium oxide and yttrium oxide from waste fluorescent powder, which mainly comprises the following seven steps: sodium carbonate roasting, chlorination leaching, phosphate precipitation, precipitation conversion, yttrium extraction separation, high-purity yttrium oxide extraction and high-purity europium oxide extraction, wherein the yttrium extraction separation is performed through a P507 extraction separation method to realize simplified efficient continuous separation of rare earth yttrium and europium, and the method is high in separation efficiency and low in cost. Compared with the prior art, the method has the advantages of short process flow, high rare earth element extraction rate, high rare earth product purity, low extraction cost and the like.

Owner:SHANDONG UNIV OF SCI & TECH

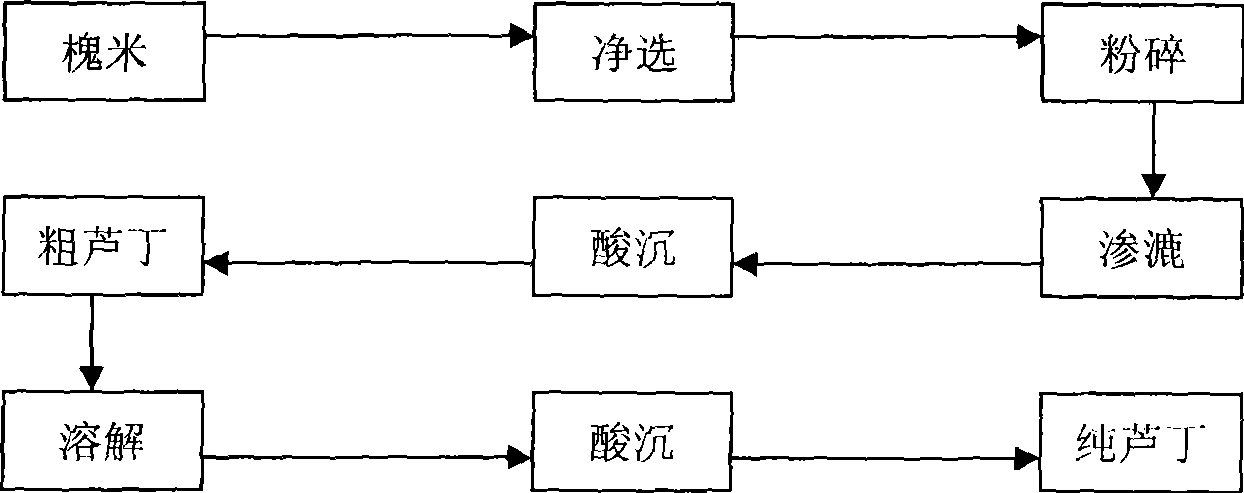

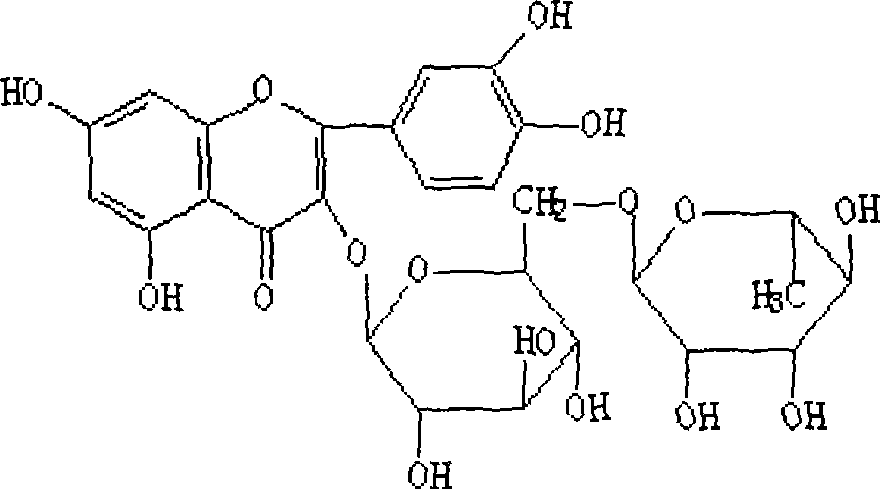

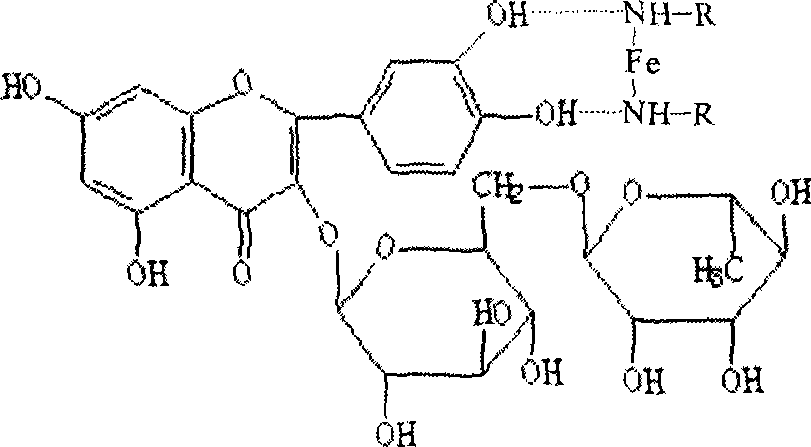

Production process for extracting high-purity birutan from flos sophora

ActiveCN101423538AImprove solubilityThe chance of mutual aggregation is reducedSugar derivativesSugar derivatives preparationSolubilityFlos

The invention discloses a production process for extracting high-purity rutin from bud of Chinese scholartree. The process mainly comprises the following steps: selecting clean bud of Chinese scholartree, crushing the bud of Chinese scholartree, percolating the bud of Chinese scholartree through a dissolvent, carrying out the acid precipitation of the filtrate, and drying the filtrate, so as to obtain crude rutin; dissolving the crude rutin in saturated ferric ammonium citrate solution, putting the solution in water bath at a temperature between 40 and 50 DEG C; and stirring the solution for 30 minutes, filtrating, cooling down the solution through standing, then carrying out acid precipitation and suction filtration, cleaning the filter residue through purified water to reach neutrality, and drying the filter residue, so as to obtain the refined rutin. The production process has the advantages that ferric ammonium citrate is taken as the flux of rutin, thereby polymerizing the ferric ammonium citrate molecule and the ortho-phenolic hydroxyl in the rutin molecule, ensuring that the planar structure of the rutin molecule is polymerized into a heterocycle-shaped complex steric structure, reducing the mutual polymerization of the rutin molecules, and greatly improving the solubility of the rutin in water; the production process not only has high yield and purity, but also has simple technology and low manufacturing cost.

Owner:GUANGXI CHANFANG PHARMACEUTICAL CO LTD

Process for extracting anthocyanin of purple sweet potato by utilizing citric acid solution

Firstly, cleaning purple sweet potato and pulverizing it, using 4-5% citric acid aqueous solution (weight percentage) to extract it according to the ratio of 1:3-1:4, extracting for 3-4 hr. at 50-60 deg.C, filtering, making secondary extraction of the filter residue with 4-5 % citric and aqueous solution, removing filter residue, combining two filtrates, removing precipitate impurity insoluble incold water, vacuum reduced pressure concentrating to obtain liquid product, also can adopt macroporous adsorption resin to make separation and purification, refining and washing out impurity, using 40%-60% ethyl alcohol to strip and elute the colouring matter liquor, vacuum reduced pressure concentrating and spray-drying said colouring matter liquor at 65-75 deg.C so as to obtain the invented product.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

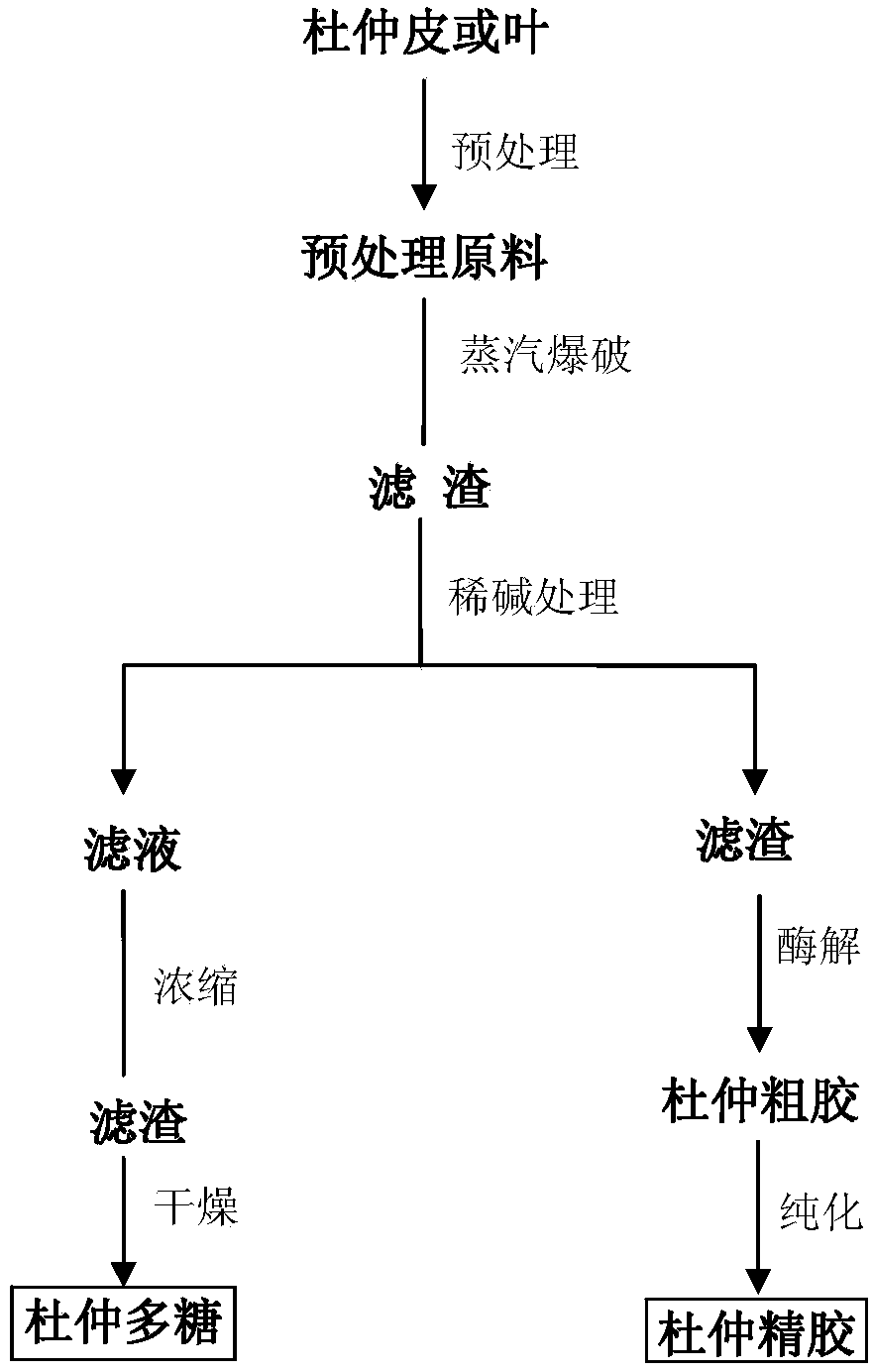

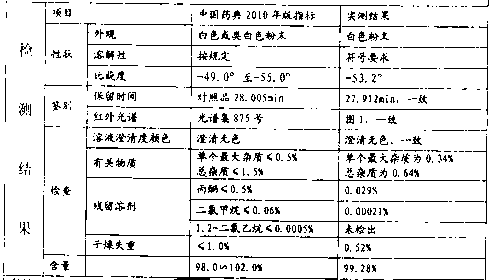

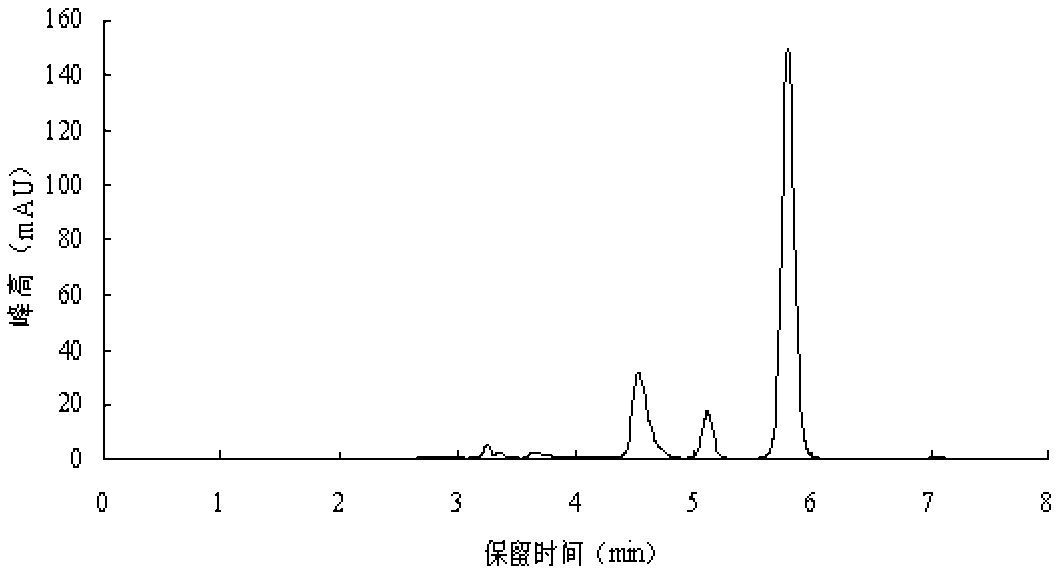

Method for extracting and separating eucommia ulmoides rubber

ActiveCN104231281APrevent oxidationMaintain biological characteristicsSeparation technologyPolysaccharide

The invention discloses a method for extracting and separating eucommia ulmoides rubber. The method comprises the following steps: performing pretreatment, performing alkali treatment, performing enzymolysis, and performing extraction and purification. The innovative points are that the step of steam explosion pretreatment is carried out after the step of pretreatment and comprises the following sub-steps: soaking a pretreated material in water with the temperature of 20-30 DEG C for 0-24 hours, and performing steam explosion on the soaked material in a steam explosion device. According to the method, the eucommia ulmoides rubber is extracted and separated by the steam explosion process, the eucommia ulmoides raw material does not need to be excessively ground, the extraction and separation time is short, the oxidation of part of the eucommia ulmoides rubber caused by long-time fermentation is effectively avoided, the natural filament eucommia ulmoides rubber can be obtained, the biological characteristics, physical performance and physical state of a rubber body are kept, and the original molecular structure and polymerization degree are kept; in addition, while the eucommia ulmoides rubber is extracted and separated by the steam explosion pretreatment, eucommia ulmoides polysaccharides are obtained by a membrane concentration and separation technology and the added value of a product is increased.

Owner:NORTHWEST A & F UNIV

Method for extracting paclitaxel from taxus chinensis branch and leaf

ActiveCN103172598AImprove performanceReduce extraction costsOrganic chemistryFiltrationGradient elution

The invention relates to a method for extracting paclitaxel from taxus chinensis branches and leaves, and the method comprises the following steps of: (1) soaking 1000 kg of pulverized taxus chinensis branches and leaves by using 5 m<3> of methanol, and filtering; (2) decoloring filter liquor; (3) decompressing and concentrating a decolored solution, and extracting; (4) degreasing and dewaxing extract liquor, crystallizing, depositing, filtering, and drying to obtain a primary product; (5) removing impurities contained in the primary product in a silicagel column, carrying out gradient elution, collecting paclitaxel-containing elution flows, and decompressing and concentrating to obtain a crude product; (6) stirring the crude product into silica gel, packing, carrying out gradient elution, collecting the paclitaxel-containing elution flows, and decompressing and concentrating to obtain a semi-finished product; (7) dissolving the semi-finished product, adding petroleum ether, standing, filtering, and drying to obtain a semi-finished product with the content more than or equal to 30%; (8) removing the impurities contained in the semi-finished product obtained from the step (7) in a silicagel column, carrying out gradient elution, collecting the paclitaxel-containing elution flows, and decompressing and concentrating to obtain a semi-finished product with the content more than or equal to 95%; and (9) dissolving the semi-finished product obtained from the step (8), filtering, adding normal hexane, standing, carrying out suction filtration; and drying to obtain a finished product with the content more than or equal to 99%.

Owner:SICHUAN XIANGGUANG AGRI TECH DEV

Simple method for extracting natural taurine

ActiveCN103342669ALow costHigh extraction rateOrganic chemistryOrganic compound preparationAnhydrous ethanolHomotaurine

The invention provides a simple method for extracting natural taurine. The invention is characterized by comprising the following steps: raw material pretreatment: after cleaning seashells, boiling at high temperature, collecting the soup, and concentrating; impurity removal with ethanol: adding ethanol into the concentrated soup to obtain a precipitate and a supernatant; concentrating the supernatant to obtain a concentrated solution; crystallization: adding 3-4 times by volume of anhydrous ethanol into the concentrated solution, immediately carrying out vacuum filtration for impurity removal, standing the filtrate at 4 DEG C to crystallize for more than 24 hours, carrying out vacuum filtration, and drying the solid to obtain the taurine coarse crystal; and for enhancing the purity of the taurine, carrying out recrystallization one or more times as required. The method provided by the invention can effectively utilize seashell processing byproducts and enhance the utilization ratio of ocean resources. The invention has the advantages of simple technique, low extraction cost, high extraction rate, energy saving and environmental protection. The ethanol used in the method can be recycled, thereby being beneficial to industrialized production.

Owner:JIMEI UNIV

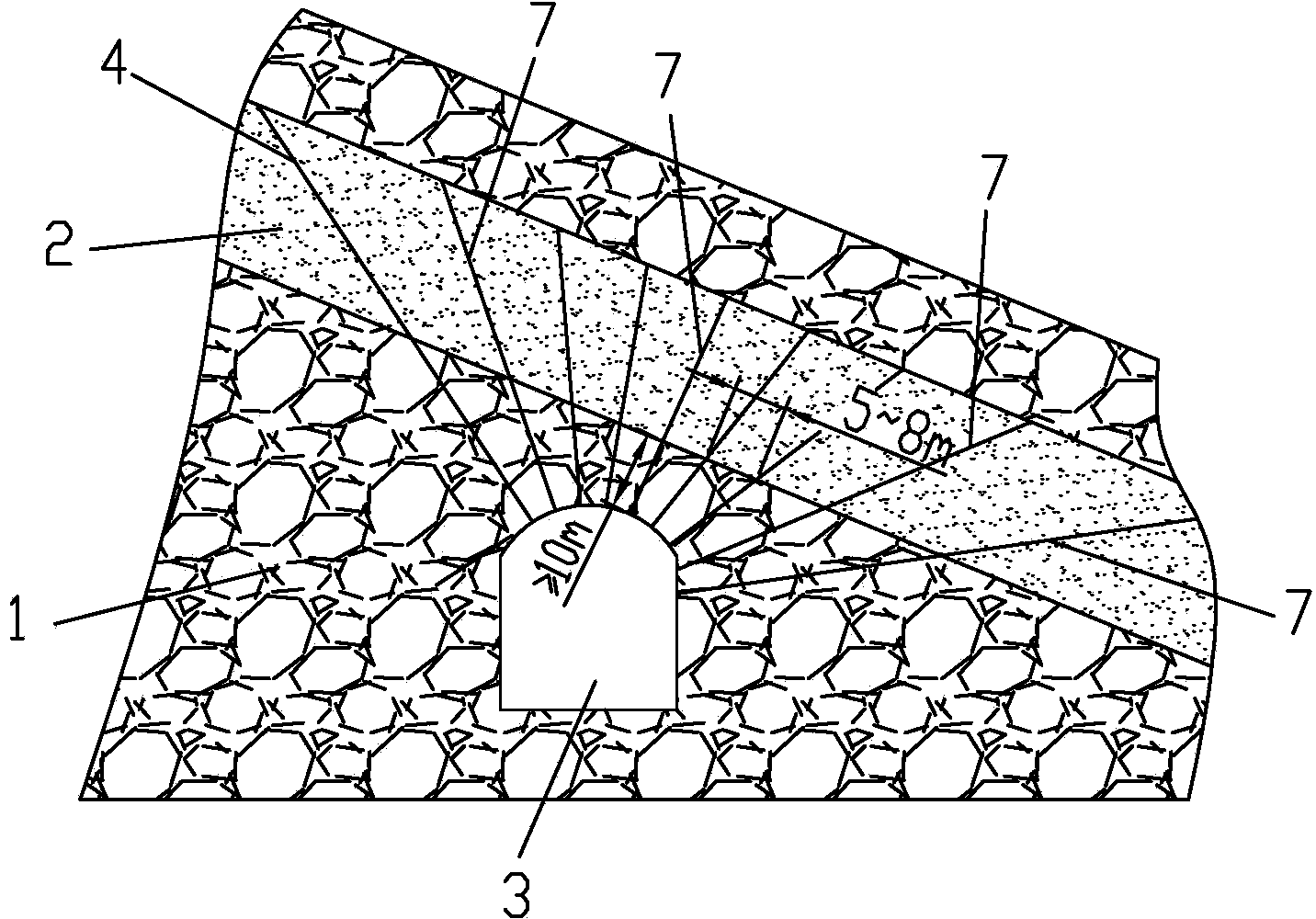

Method for fast extracting gas on coalface

The invention discloses a method for fast extracting gas on a coalface. The method includes that a bottom extraction roadway with the distance to a coal seam no smaller than 5 m is tunneled on a coal seam floor; a plurality of fracture drill holes extending into the coal seam are formed in the bottom extraction roadway, the center distance between every two adjacent fracture drill holes in the position entering the coal seam is between 30 m and 50 m, and the depth of the fracture drill holes in the rock stratum is not smaller than 10 m; the fracture drill holes are sealed according to fracture sealing requirements, and the coal seam is hydraulically fractured; the fracture drill holes are connected with an underground gas extraction system of a coal mine, and then coal seam gas can be extracted; a plurality of extraction holes extending into the coal seam are formed in the bottom extraction roadway, and the center distance from any extraction hole to the adjacent extraction holes or the position for the corresponding fracture drill hole to enter the coal seam is between 5 m and 8 m; the extraction holes are sealed according to extraction sealing requirements; coal seam gas is extracted through the extraction holes till the coal seam gas content reaches the standard. The method for fast extracting gas on the coalface has the advantages of having fewer drill holes and being high in extraction efficiency and coal mining efficiency, and roadway tunneling and coal mining work can be performed safely.

Owner:重庆市能源投资集团科技有限责任公司

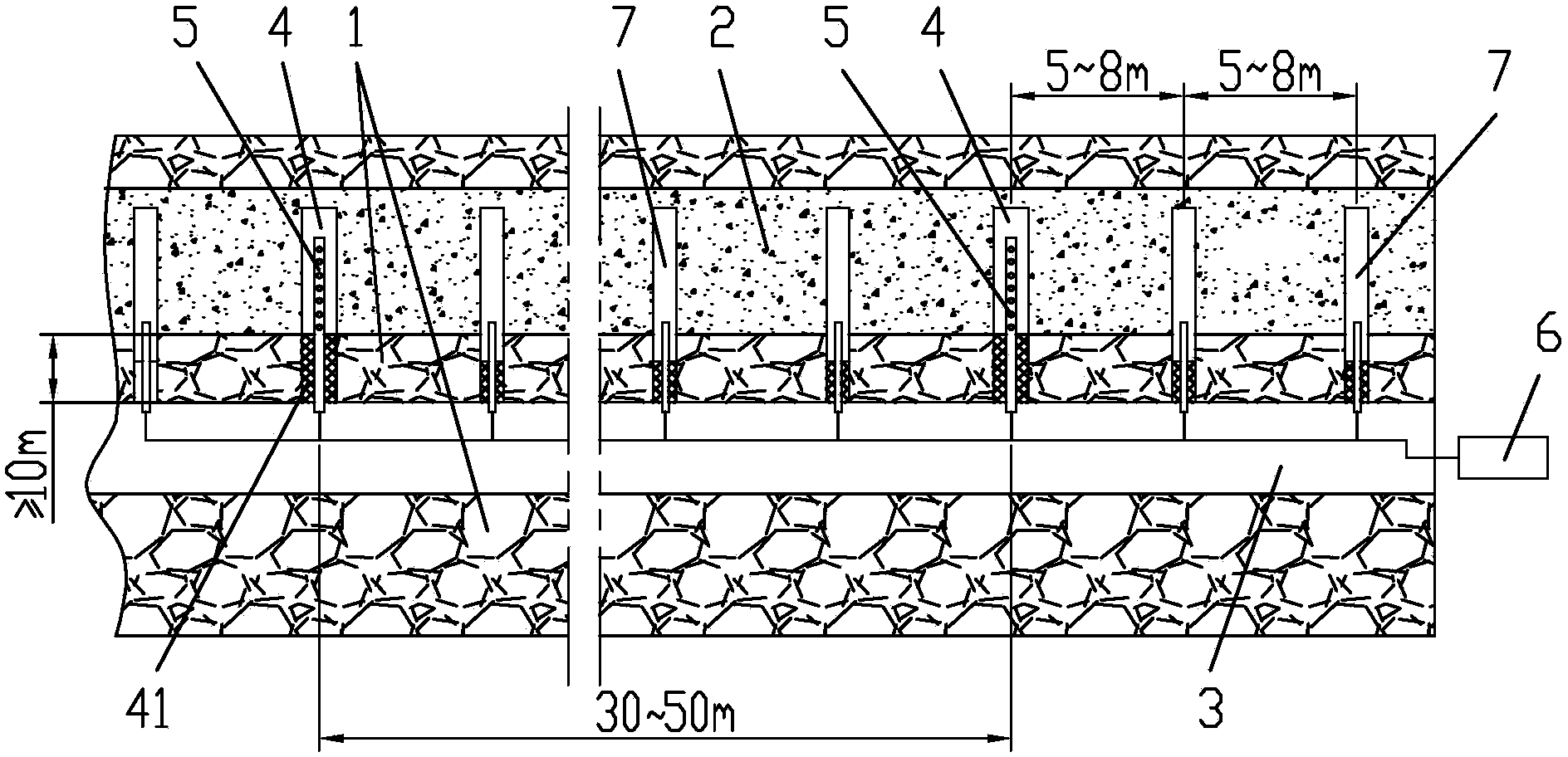

Method for extracting curcumin from turmeric

ActiveCN105669410AHigh selectivityHigh purityCarbonyl compound separation/purificationEthyl acetateEthyl fumarate

The invention provides a method for extracting curcumin from turmeric. The method comprises the following steps: weighing a certain amount of turmeric powder, adding 70-85% acetone according to the liquid-solid ratio of 1: 8-10, extracting for three times, decompressing and recovering acetone to obtain a dark brown oily extract, carrying out liquid-liquid extraction by the use of petroleum ether, water and ethyl acetate, carrying out crude separation, crystallizing and recrystallizing by the use of ethanol-water to obtain needle curcumin crystal, and measuring mass fraction by HPLC. Through calculation, purity detected by HPLC after crystallization can reach 88% and above, and purity detected by HPLC after recrystallization can reach 95% and above.

Owner:BEIJING UNION UNIVERSITY

Method simultaneously extracting lipid and protein from corn plantule

InactiveCN101402670AHigh extraction rateHigh purityFatty-oils/fats refiningPeptide preparation methodsUltrasonic assistedCentrifugation

The invention discloses a method for extracting grease and protein simultaneously from cereal germs, and pertains to the technical field of comprehensive utilization of agricultural byproducts. The method comprises the comprehensive utilization of technologies of reversed micellar extraction, ultrasonic-associated extraction, protein refining, grease refining, drying and so on. Cereal germs are sieved after crushing, added into reversed micellar solution, stirred or ultrasonic forward extracted and centrifugated to obtain forward extraction solution, and the forward extraction solution is processed by ultrasonic backward extraction and centrifugation, the upper layer is extracted by ethanol to remove a residual surfactant, a solvent is removed to obtain grease and after water, salt and the surfactant are removed from the lower layer, cereal germ protein product is obtained; or the solvent in the forward extraction solution is directly removed, protein in a residual solid substance is precipitated by a mixed solvent, and then washing and drying are carried out to obtain the cereal germ protein product. The method has simple technology and low cost, solves the problem that the traditional grease production causes damage to protein, improves reutilization value of cereal germ protein, and is an environmental friendly production method. The product has the advantages of high yield rate, high purity, low chemical modification and the like.

Owner:JIANGNAN UNIV

Method for preparing stevioside and chlorogenic acid from stevia step by step

ActiveCN102924544AAvoid damageHigh yieldSugar derivativesCarboxylic acid esters separation/purificationWater savingFlocculation

The invention discloses a method for preparing stevioside and chlorogenic acid from stevia step by step. The method comprises the following steps of: (1) soaking the stevia with cold water and extracting to obtain extract; (2) adding a bivalent iron salt into the extract to regulate pH value, flocculating, and filtering the flocculation solution to obtain filtrate and a filter cake; (3) adsorbing the filtrate by using macroporous adsorption resin, desorbing and refining to obtain the stevioside; (4) dissolving the filter cakes with water, regulating the pH value to be 0.5-5.5 by using acid, and filtering to obtain the chlorogenic acid filtrate; and (5) adsorbing the chlorogenic acid filtrate by using macroporous adsorption resin, desorbing, concentrating, drying, and re-crystallizing, thus obtaining chlorogenic acid. According to the method, the stevioside and the chlorogenic acid are extracted at the same time, so that a product is added, and the extraction cost of the stevioside is reduced; and the method is easy to operate, low in cost, high in chlorogenic acid yield, water-saving, environment-friendly, simple in equipment, high in utilization rate of raw materials and equipment and suitable for industrialized production.

Owner:CHENGUANG BIOTECH GRP CO LTD

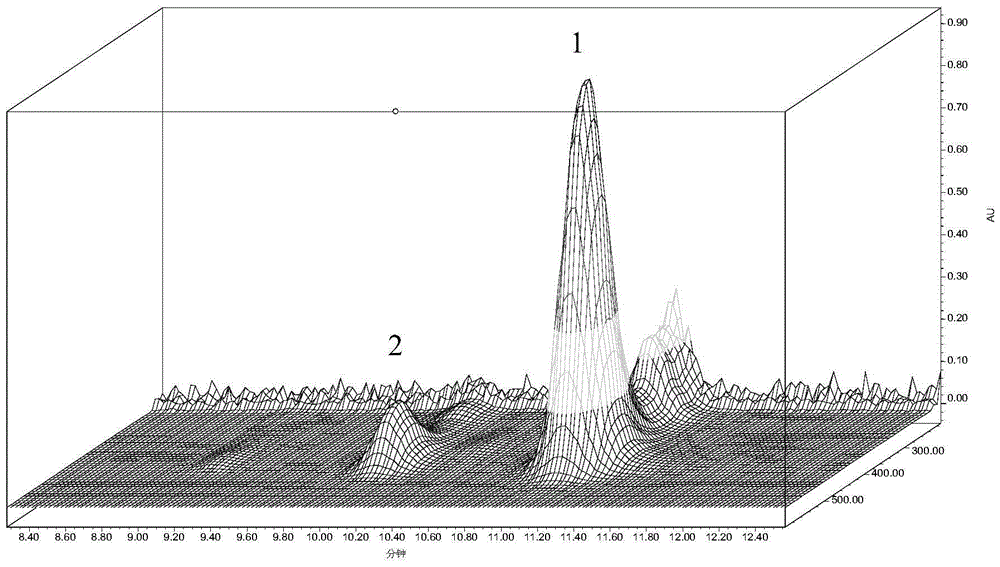

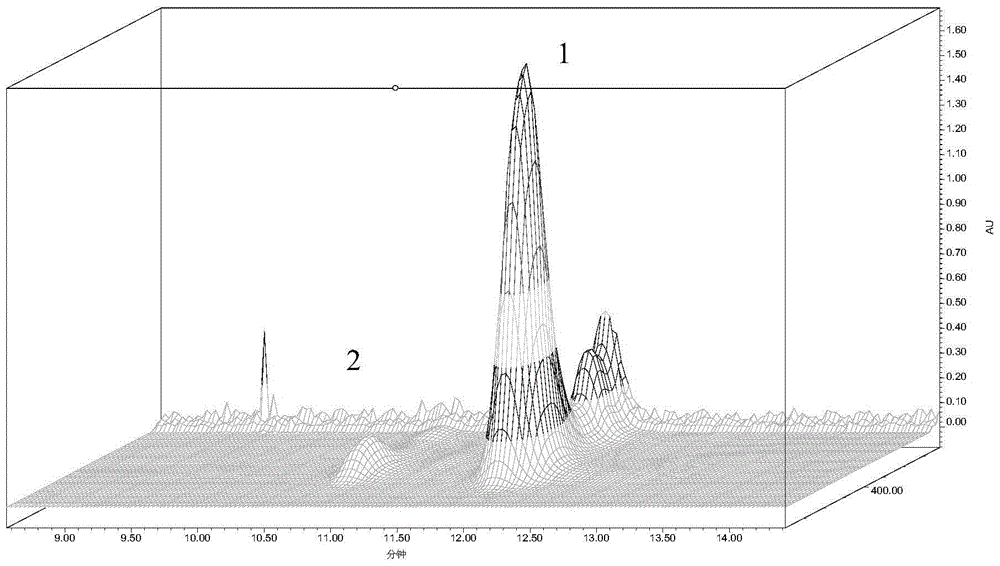

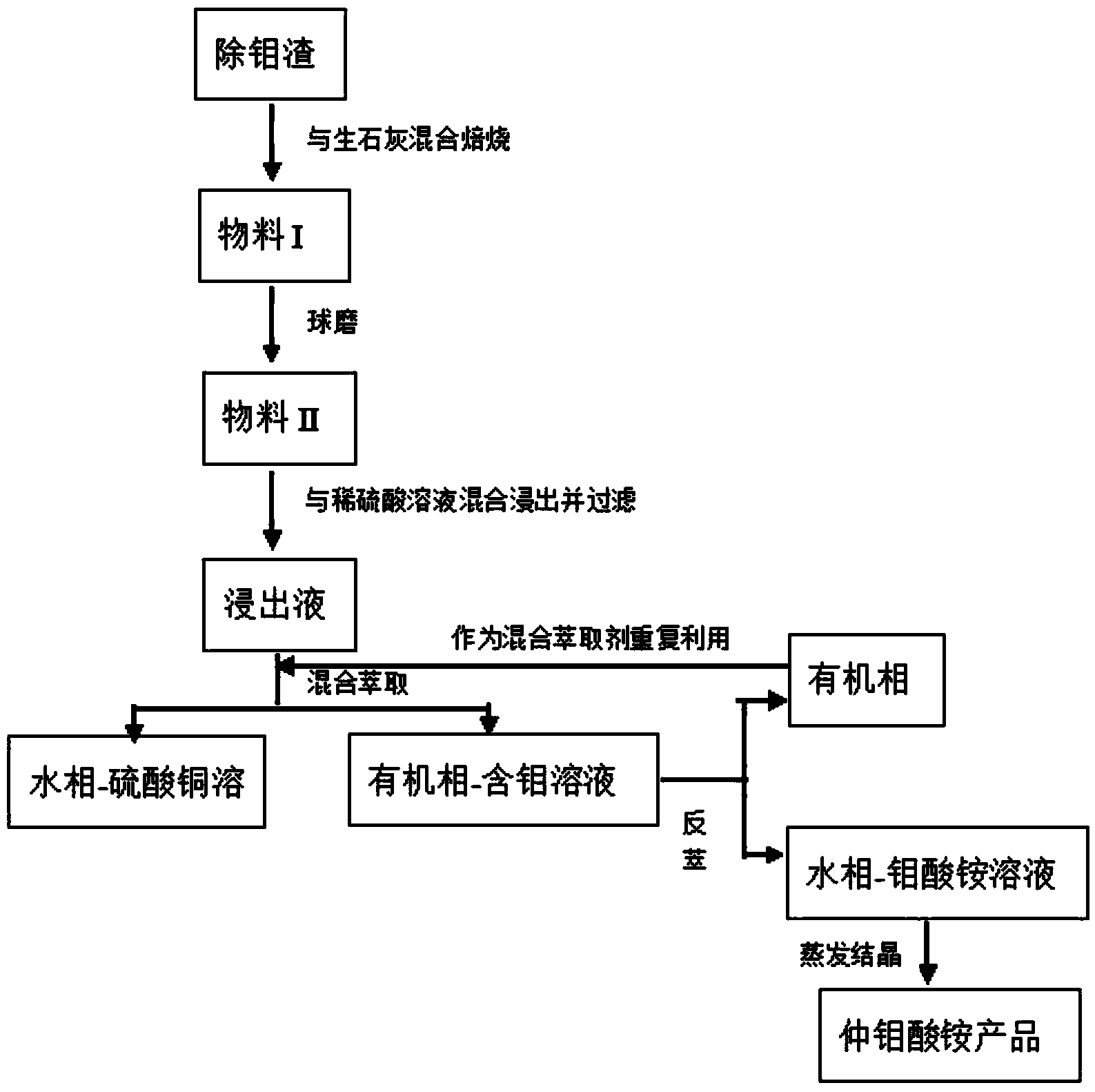

Recovering method for molybdenum and copper in tungsten smelting molybdenum removing slag

ActiveCN104263955AMake up for the lack of poor separation effectEfficient recyclingProcess efficiency improvementSlagEvaporation

The invention discloses a recovering method for molybdenum and copper in tungsten smelting molybdenum removing slag. The recovering method comprises the following steps: after mixing the molybdenum removing slag and quicklime, feeding the mixture into a resistance furnace for carrying out calcination, ball-milling calcined clinker until a certain granularity is reached, then leaching with dilute sulfuric acid, filtering to obtain filter residues which mainly comprise calcium sulfate and obtain a leaching solution which is an acid solution containing molybdenum and copper, carrying out mixed extraction with a mixed extractant containing N235 and TBP to obtain a water phase which mainly comprises a copper sulfate solution and can be used for a molybdenum removing procedure, reversely extracting an obtained organic phase with ammonia water after washing with dilute sulfuric acid to obtain a water phase which mainly comprises an ammonium molybdate solution, carrying out evaporation crystallization to obtain an ammonium paramolybdate product, wherein the obtained organic phase can be returned to the extraction procedure to be cyclically used. The recovering method has the advantages that the impurity removing effect is great, the product purity is high, the molybdenum and copper yields reach 98% above, obtained side products can also be cyclically utilized, no pollution is generated, the recovering cost is greatly reduced, and the comprehensive economical benefit is improved.

Owner:CNMC GUANGXI PGMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com