Technique for extracting and refining DHA enriched fatty acid from Crypthecodinium cohnii

A technology for cryptodinia and fatty acid, applied in the biological field, can solve the problems of simple content, no description of the fatty acid extraction method in microalgae, etc., and achieves the effects of simple operation, reduced extraction cost, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

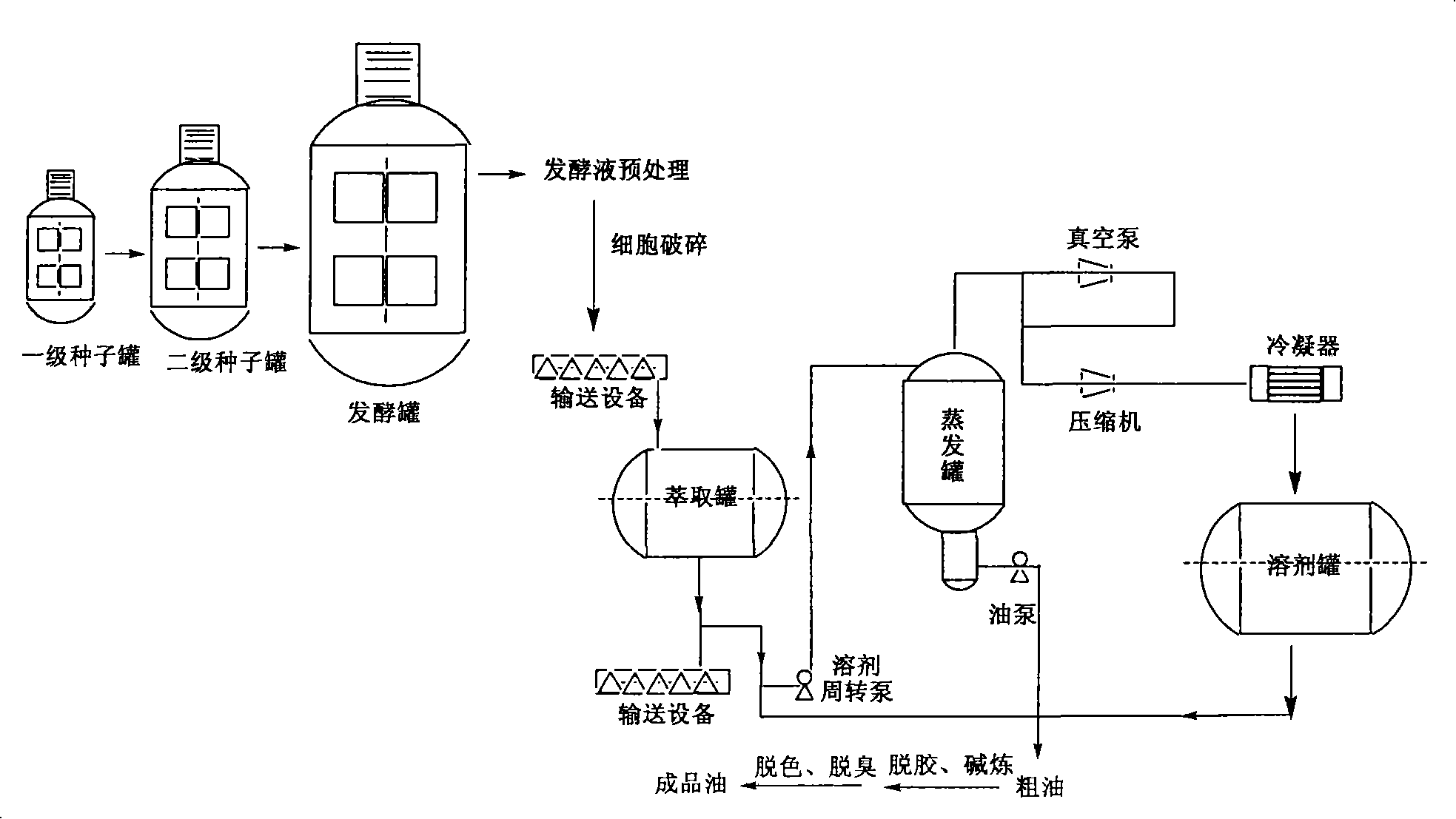

Method used

Image

Examples

Embodiment 1

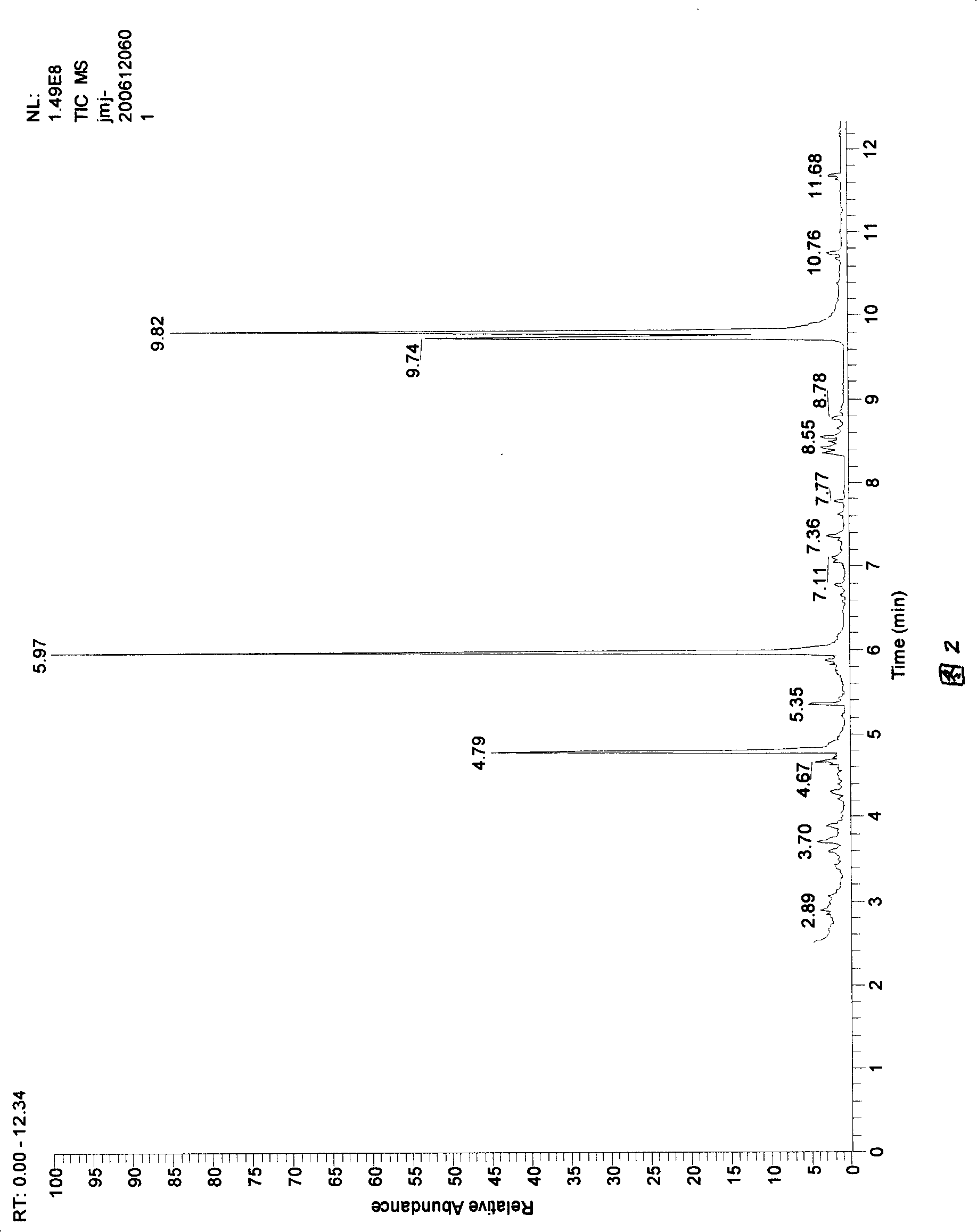

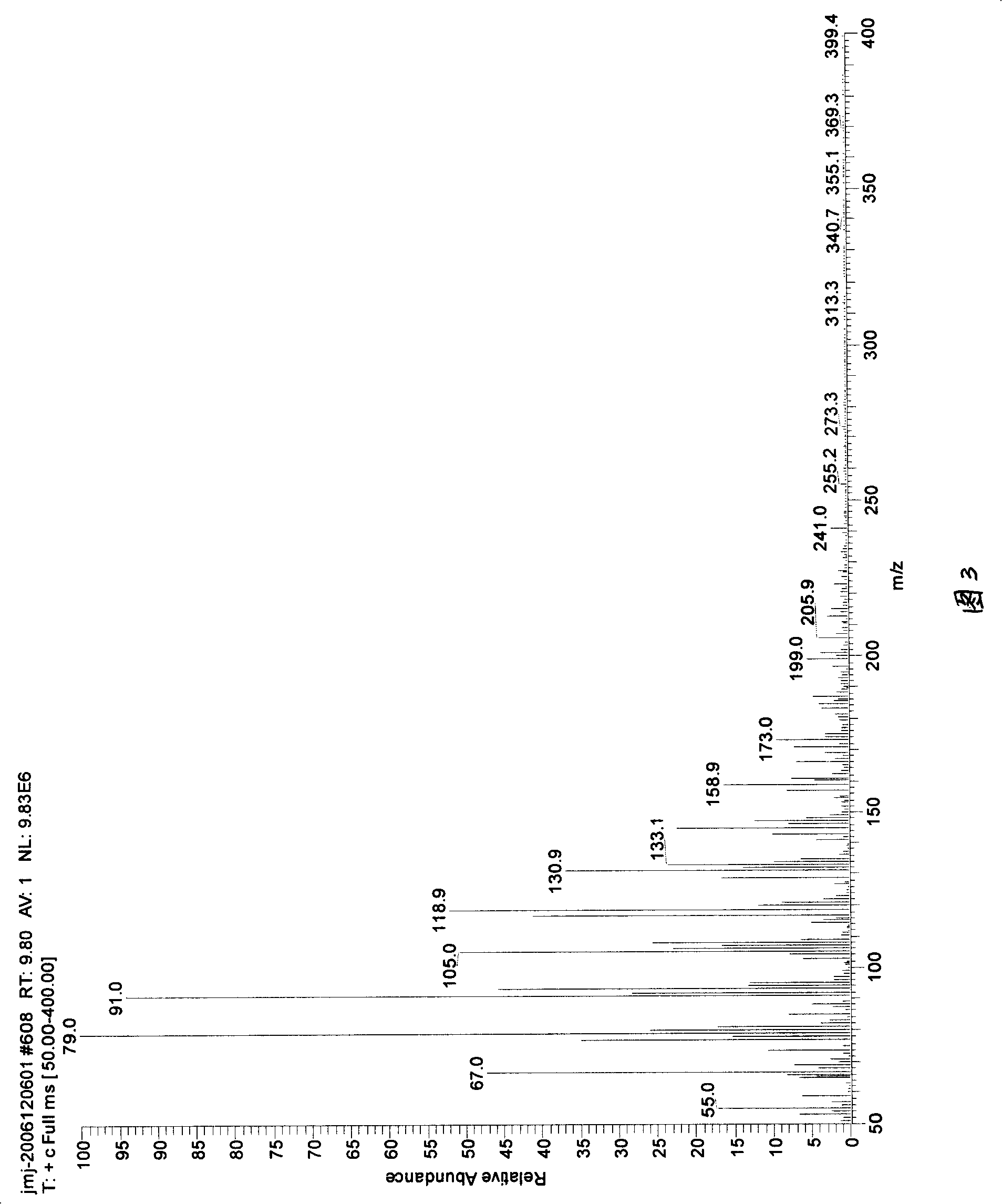

[0052] Example 1 Fatty acid extraction and refining of algae harvested by fermentation in a 5L fermenter

[0053] Carry out 5 L tank fermentation according to above-mentioned cultivation method, harvest algae body. Pour the fermented liquid into the solvent tank, add 45g ferric chloride to make the cells flocculate and precipitate, after standing still, release the upper layer solution, add 800ml alcohol to the tank to make more bacteria settle, and release the upper layer liquid, The bacterial cells obtained above are centrifuged with a centrifuge to realize further solid-liquid separation. Use NaOH to prepare an aqueous solution with a pH of 14, pour the bacteria obtained in the previous step into the alkali wall, then send the cells into a colloid mill, grind the material into small particles, and send it to a homogenizer for high-pressure crushing to obtain Broken bacteria. Centrifuge again (speed 8000rpm) to remove water, pour the crushed thalline into the extraction ta...

Embodiment 2

[0056] Example 2 Fatty acid extraction and refining of algae harvested by fermentation in a 5L fermenter

[0057] Carry out 5 L tank fermentation according to above-mentioned cultivation method, harvest algae body. Pour the fermentation broth into a solvent tank, add 45g of aluminum sulfate to make the cells flocculate and precipitate, and after standing still, release the upper layer solution; add 800ml alcohol to the tank to make more bacteria settle, and release the upper layer liquid; Centrifuge the bacteria obtained above to realize further solid-liquid separation. Use NaOH to prepare an aqueous solution with a pH of 13, pour the bacteria obtained in the previous step into the alkali wall, then send the cells into a colloid mill, grind the material into small particles, and send it to a homogenizer for high-pressure crushing to obtain Broken bacteria. Centrifuge again (speed 8000rpm) to remove water, pour the broken bacteria into the extraction tank, pour it into the ex...

Embodiment 3

[0060] Example 3 Fatty acid extraction and refining of algae harvested by fermentation in a 5-ton fermenter

[0061] Carry out 5 ton tank fermentation according to above-mentioned culture method, harvest algae body. Pour the fermentation broth into a solvent tank, add 50kg of polyaluminum chloride to flocculate and precipitate the cells, and release the upper layer solution after standing still; add 15L alcohol to the tank to make more bacteria settle, and release the upper layer liquid as well; The bacterial cells obtained above are centrifuged with a centrifuge to realize further solid-liquid separation. Use NaOH to prepare an aqueous solution with a pH of 12, pour the bacteria obtained in the previous step into the alkali wall, then send the cells into a colloid mill, grind the material into small particles, and send it to a homogenizer for high-pressure crushing to obtain Broken bacteria. Centrifuge again (speed 8000rpm) to remove water, pour the broken bacteria into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com