Method for extracting europium oxide and yttrium oxide from waste fluorescent powder

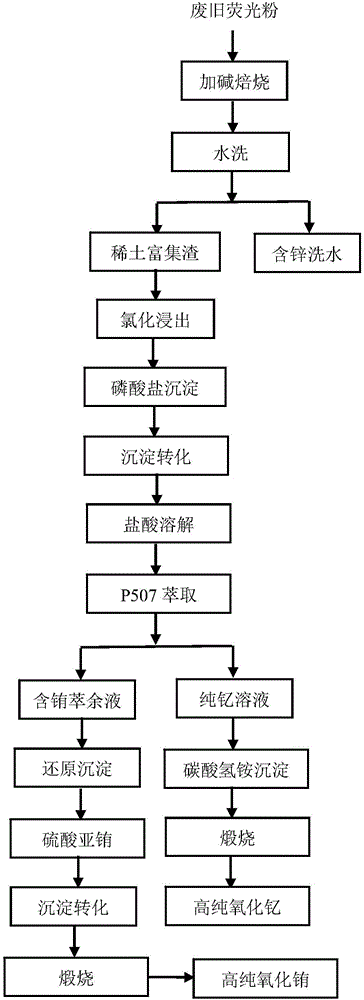

A technology of fluorescent powder and europium oxide, which is applied in the field of extraction of rare earth elements, can solve the problems of high recycling cost and long process flow, and achieve the effect of low extraction cost, short process flow, and simple and easy-to-control process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The method for extracting europium oxide and yttrium oxide from waste fluorescent powder comprises following 7 steps:

[0056] 1) Alkali-adding and roasting step: according to the weight ratio between solid and liquid of 0.75:1, liquid sodium hydroxide is added to the waste fluorescent powder, and after granulation, it is roasted in a furnace;

[0057] 2) Chlorination leaching step: wash the roasted material with water; place the washed slag in a hydrochloric acid solution with a pH value of 3 at 85°C with chlorine gas for chlorination leaching, wash again and mix the leachate with the slag separation;

[0058] The chlorine gas is added in a ratio of 0.1:1 according to the mass ratio of chlorine element to waste fluorescent powder;

[0059] 3) Phosphate precipitation step: According to the molar ratio of phosphate and rare earth elements of 1.1-2:1, sodium phosphate is added to the above leaching solution, the reaction temperature is controlled at 90°C, the pH value is...

Embodiment 2

[0070] The method for extracting europium oxide and yttrium oxide from waste fluorescent powder comprises following 7 steps:

[0071] 1) Alkali-adding and roasting step: according to the weight ratio between solid and liquid of 0.75:1, liquid potassium hydroxide is added to the waste fluorescent powder, and it is roasted in a furnace after granulation;

[0072] 2) Chlorination leaching step: washing the roasted material with water;

[0073] The washed slag is chlorinated and leached with sodium chlorate in a sulfuric acid solution with a pH value of 3 at 75°C, washed again and the leaching solution is separated from the slag;

[0074] The sodium chlorate is added in a ratio of 0.2.5:1 by the mass ratio of chlorine element to waste fluorescent powder;

[0075] 3) Phosphate precipitation step: According to the molar ratio of phosphate and rare earth elements of 1.5:1, ammonium phosphate is added to the above leachate, the reaction temperature is controlled at 75 ° C, the pH val...

Embodiment 3

[0086] The method for extracting europium oxide and yttrium oxide from waste fluorescent powder comprises following 7 steps:

[0087] 1) Alkali-adding and roasting step: according to the weight ratio between solid and liquid of 0.85:1, add liquid barium hydroxide to the waste fluorescent powder, granulate and roast in the furnace;

[0088] 2) Chlorination leaching step: washing the roasted material with water;

[0089] The washed slag is chlorinated and leached with sodium hypochlorite in an acetic acid solution with a pH value of 3 at 80°C, washed again and the leaching solution is separated from the slag;

[0090] The sodium hypochlorite is added in a ratio of 0.35:1 by the mass ratio of chlorine element to waste fluorescent powder;

[0091] 3) Phosphate precipitation step: According to the molar ratio of phosphate and rare earth elements of 1.6:1, potassium phosphate is added to the above leaching solution, the reaction temperature is controlled at 80°C, the pH value is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com