Recovering method for molybdenum and copper in tungsten smelting molybdenum removing slag

A recovery method and molybdenum slag removal technology, applied in the field of tungsten smelting, can solve the problems of complex molybdenum removal slag composition, complicated occurrence conditions, harsh leaching conditions, etc., and achieve the effects of reducing extraction cost, efficient recovery and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

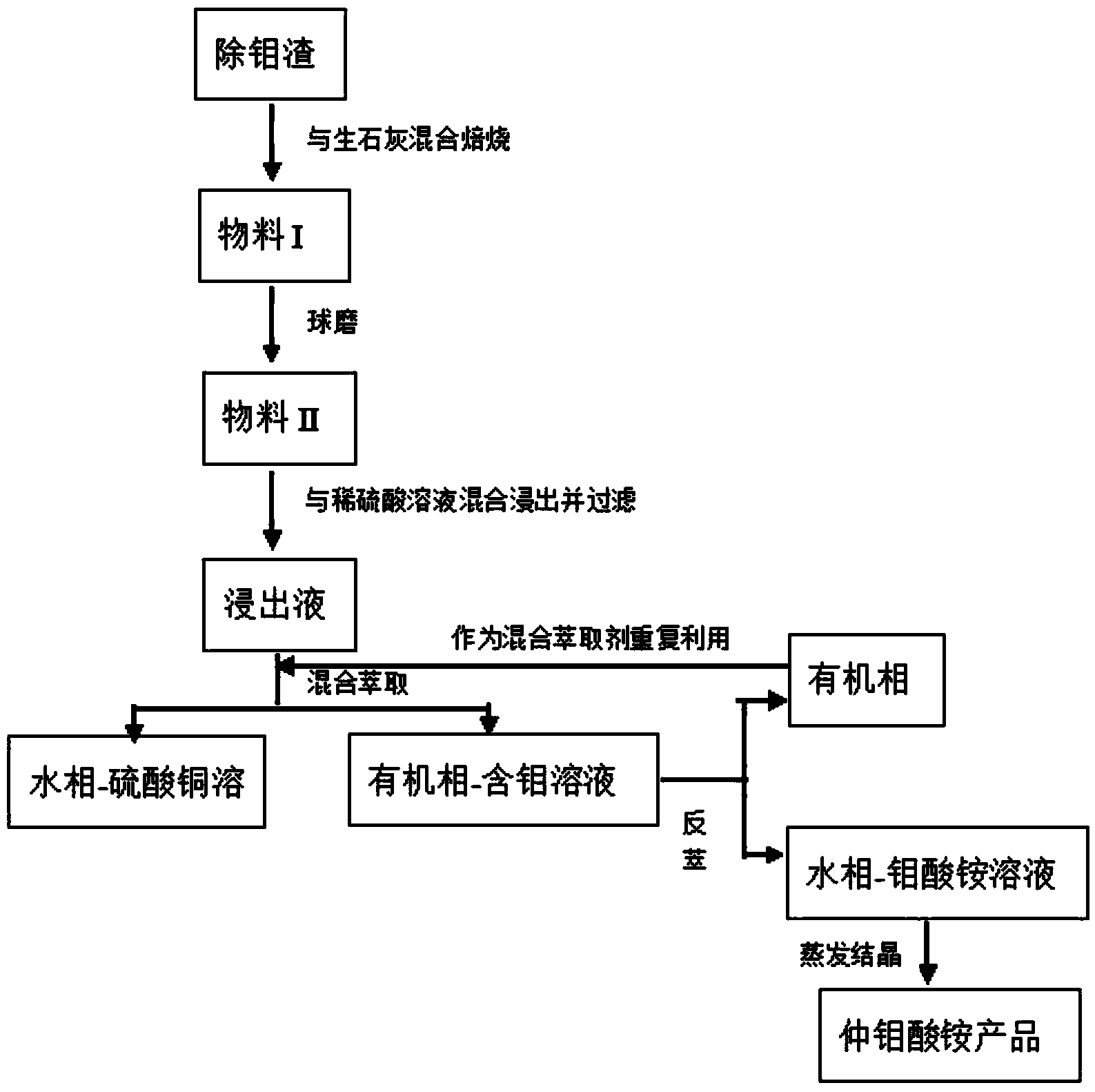

[0037] Weigh 100g of molybdenum removal slag, and it has been determined that the main components and contents of molybdenum removal slag are: Mo 16.82%, Cu 28.17%, S 27.43%, WO 3 4.35%; mix the weighed molybdenum removal slag and 3g of quicklime evenly, and then send it into a box-type resistance furnace for roasting. The roasting temperature is 600 ° C. After reaching the roasting temperature, it is kept for 30 minutes; after roasting, it is ball milled to about 400 mesh. The material II was obtained, and the material II was leached with four times the volume of 8% dilute sulfuric acid to obtain a leaching solution, wherein the leaching temperature was 60° C., the leaching time was 1 h, and the stirring speed was 180 r / min.

[0038] The leaching solution was filtered for solid-liquid separation. The contents of molybdenum and copper in the obtained filtrate were 0.07g / mL and 0.12g / mL respectively, and the leaching rates of molybdenum and copper in the molybdenum removal resid...

Embodiment 2

[0040] Weigh 100g of molybdenum removal slag, and it has been determined that the main components and contents of molybdenum removal slag are: Mo 17.65%, Cu29.34%, S 32.84%, WO 3 5.46%; mix the weighed molybdenum removal slag and 3g of quicklime evenly and send it into a box-type resistance furnace for roasting at a roasting temperature of 600°C. After reaching the roasting temperature, keep it warm for 30 minutes; after roasting, carry out ball milling to about 400 mesh. The material II was obtained, and the material II was leached with four times the volume of 8% dilute sulfuric acid to obtain a leaching solution, wherein the leaching temperature was 60° C., the leaching time was 1 h, and the stirring speed was 180 r / min.

[0041] The leaching solution was filtered for solid-liquid separation. The contents of molybdenum and copper in the obtained filtrate were 0.072g / mL and 0.121g / mL respectively, and the leaching rates of molybdenum and copper in the molybdenum removal resid...

Embodiment 3

[0043] Weigh 100g of molybdenum removal slag, and it has been determined that the main components and contents of molybdenum removal slag are: Mo 18.22%, Cu 26.77%, S 27.30%, WO 3 8.14%; mix the weighed molybdenum removal slag and 3g of quicklime evenly and send it to a box-type resistance furnace for roasting at a roasting temperature of 600°C. After reaching the roasting temperature, keep it warm for 30 minutes; The material II was obtained, and the material II was leached with four times the volume of 8% dilute sulfuric acid to obtain a leaching solution, wherein the leaching temperature was 60° C., the leaching time was 1 h, and the stirring speed was 180 r / min.

[0044] The leaching solution was filtered for solid-liquid separation. The contents of molybdenum and copper in the obtained filtrate were 0.074g / mL and 0.11g / mL respectively, and the leaching rates of molybdenum and copper in the molybdenum removal residue reached 98.02% and 97.55%, respectively. The leaching so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com