Patents

Literature

142results about How to "Improve processing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

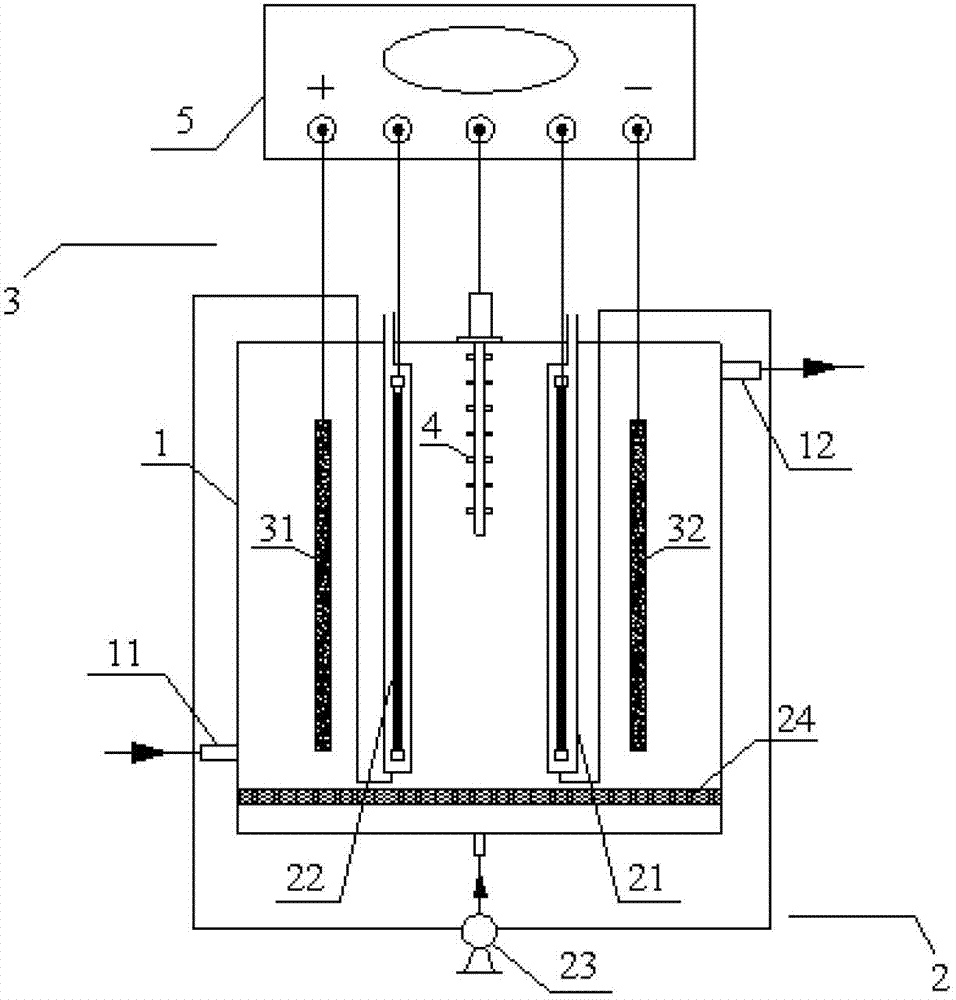

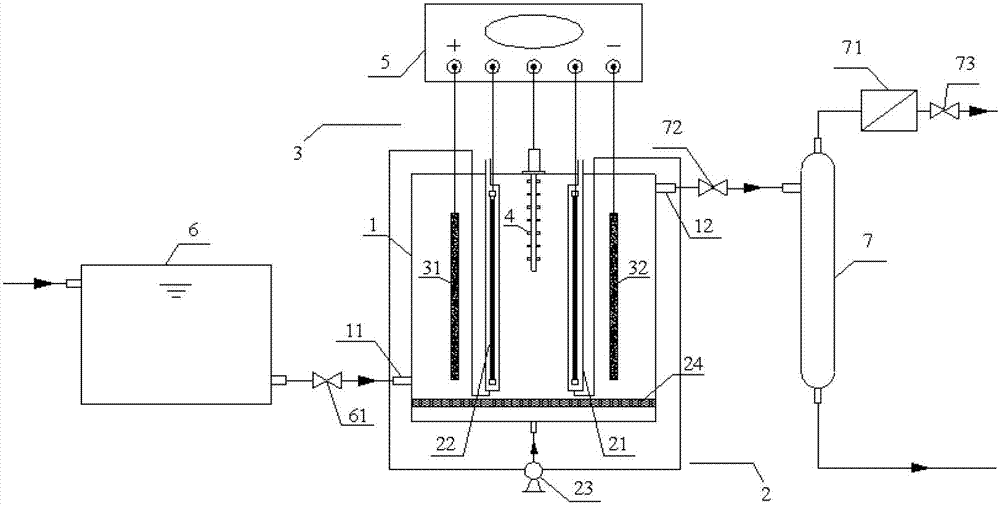

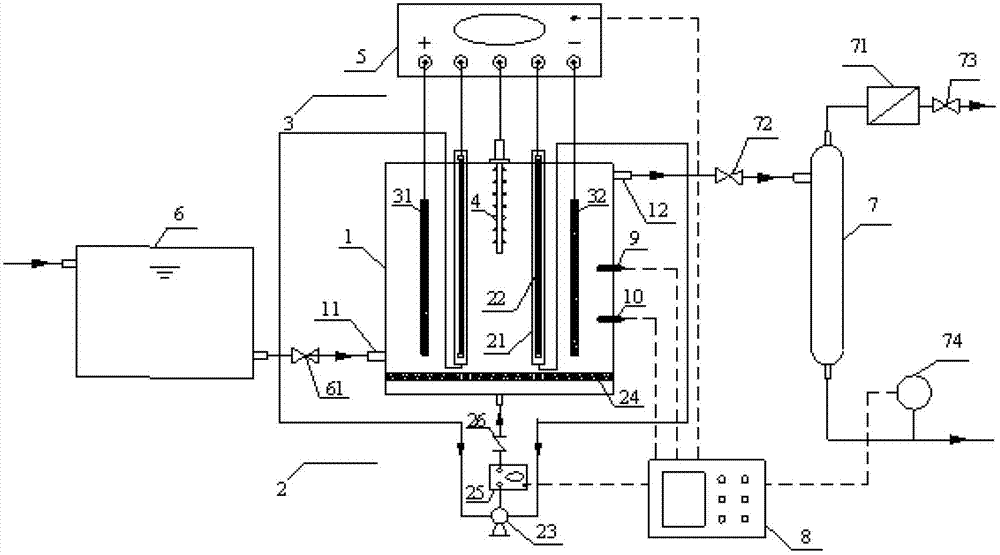

Device and method for integrally treating refractory organic wastewater

ActiveCN102863110AEasy to handleReduce processing costsMultistage water/sewage treatmentWastewaterWater quality

The invention provides a device for integrally treating refractory organic wastewater. The device comprises a reaction unit, an ultraviolet / ozone generating diffusion unit, an electrochemistry catalysis unit, an ultrasound unit and a power supply. A water inlet is arranged on the lower portion of the reaction unit, and a water outlet is arranged on the upper portion of the reaction unit; the ultraviolet / ozone generating diffusion unit comprises a quartz casing pipe with an ultraviolet lamp tube arranged inside, a gas pump and a gas diffuser which are connected successively, and the gas diffuser is arranged at the bottom of the reaction unit; the quartz casing pipe is arranged in the reaction unit, one end of the quartz casing pipe is provided with a gas inlet tube, and the other end is provided with a gas outlet tube and connected with the gas pump; the electrochemistry catalysis unit and the ultrasound unit are arranged in the reaction unit; and the ultraviolet lamp tube, the electrochemistry catalysis unit and the ultrasound unit are connected with the power supply respectively. The device is simple and compact in structure, small in occupied area, convenient to use, low in cost, convenient to operate and manage, good in water quality purifying effect and high in treatment efficiency.

Owner:无锡博泛特工程设备有限公司

Process for producing methane by dry-type fermentation of stalks

InactiveCN101338325ALess investmentReduce operating costsBio-organic fraction processingClimate change adaptationSlagSlurry

The invention provides a technique for producing biogas by utilizing stalk dry fermentation which includes the steps: I, cracking the stalks into 2 to 8mm by a cracking machine; II, transmitting the cracked stalks into a pre-treatment pool, adding hot water of 40 to 53 DEG C and a stalk fermentation agent in the pre-treatment pool to carry out pre-treatment; the cracked stalks and the biogas slurry refluxed by the anaerobic digester of the pre-treatment pool are mixed according to a proportion of 2 to 1; after stirring, the solid content rate of the stalk liquid is 20 to 35 percent; III, using a mud pump to equally transmit the stalk liquid to the top part of the anaerobic digester with a fermentation temperature of 40 to 53 DEG C; IV, the biogas generated by fermentation is purified to be clean fuel by gas-liquid separation. The technique can lead the stalks of 1.5kg to generate the biogas of 1m<3> (the content of methane is larger or equal to 55 percent); the degrading rate is more than 90 percent. The technique of the invention can continuously feed and discharge; the biogas slurry can be repeatedly used; only biogas slag is discharged; the biogas slag is manufactured into organic fertilizer by processing and can not cause any pollution to the environment.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

Comprehensive utilization method of red mud coal-base rotary kiln method

The invention discloses a comprehensive utilization method of a red mud coal-base rotary kiln method, belonging to the field of comprehensive utilization of solid wastes. The method comprises the following steps: fully mixing the red mud, calcium-containing compound which occupies 8-14% of the red mud, and a carbon material which occupies 20-50% of the red mud; carrying out carbon smelting reduction in a coal-base rotary kiln at the temperature of 1000-1550 DEG C; and reacting for 2-6 hours to obtain sponge iron or hot molten iron and a byproduct building material. In the method, the red mud discarded in smelting aluminum oxide is effectively comprehensively utilized, thus the solid zero emission is realized. The method provided by the invention has high utilization; and the metal reduction rate reaches 95-98%, and the metal recovery rate reaches 96-98%.

Owner:胡长春

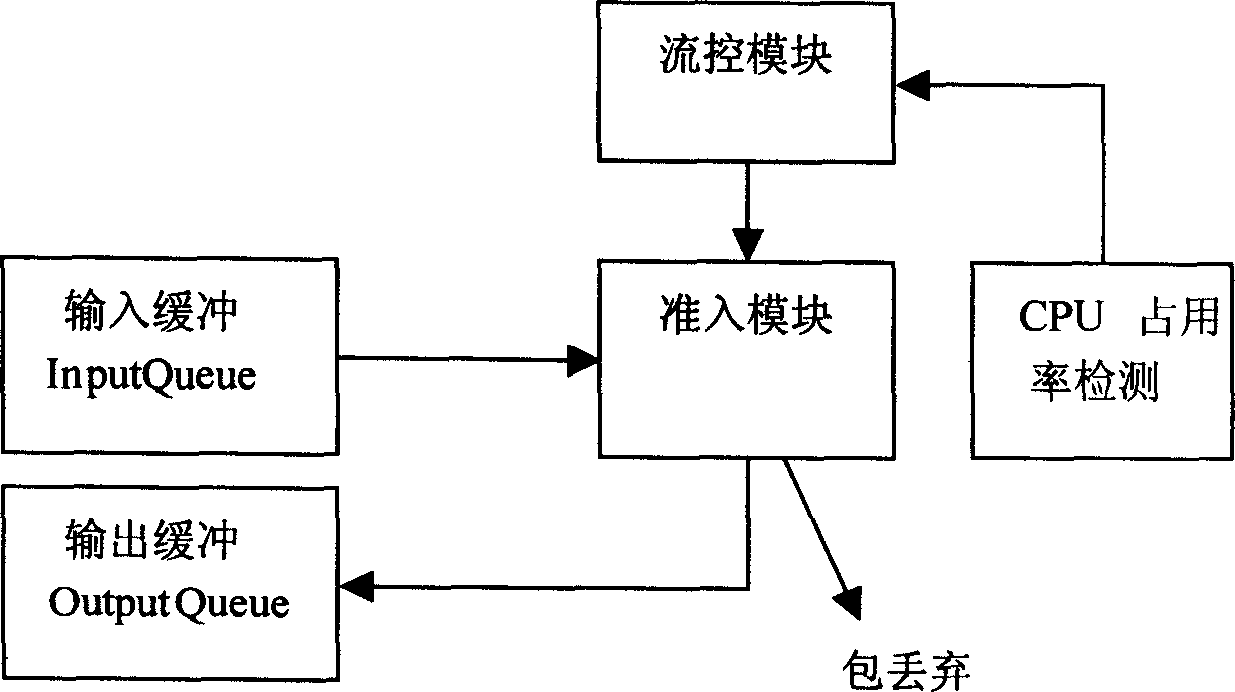

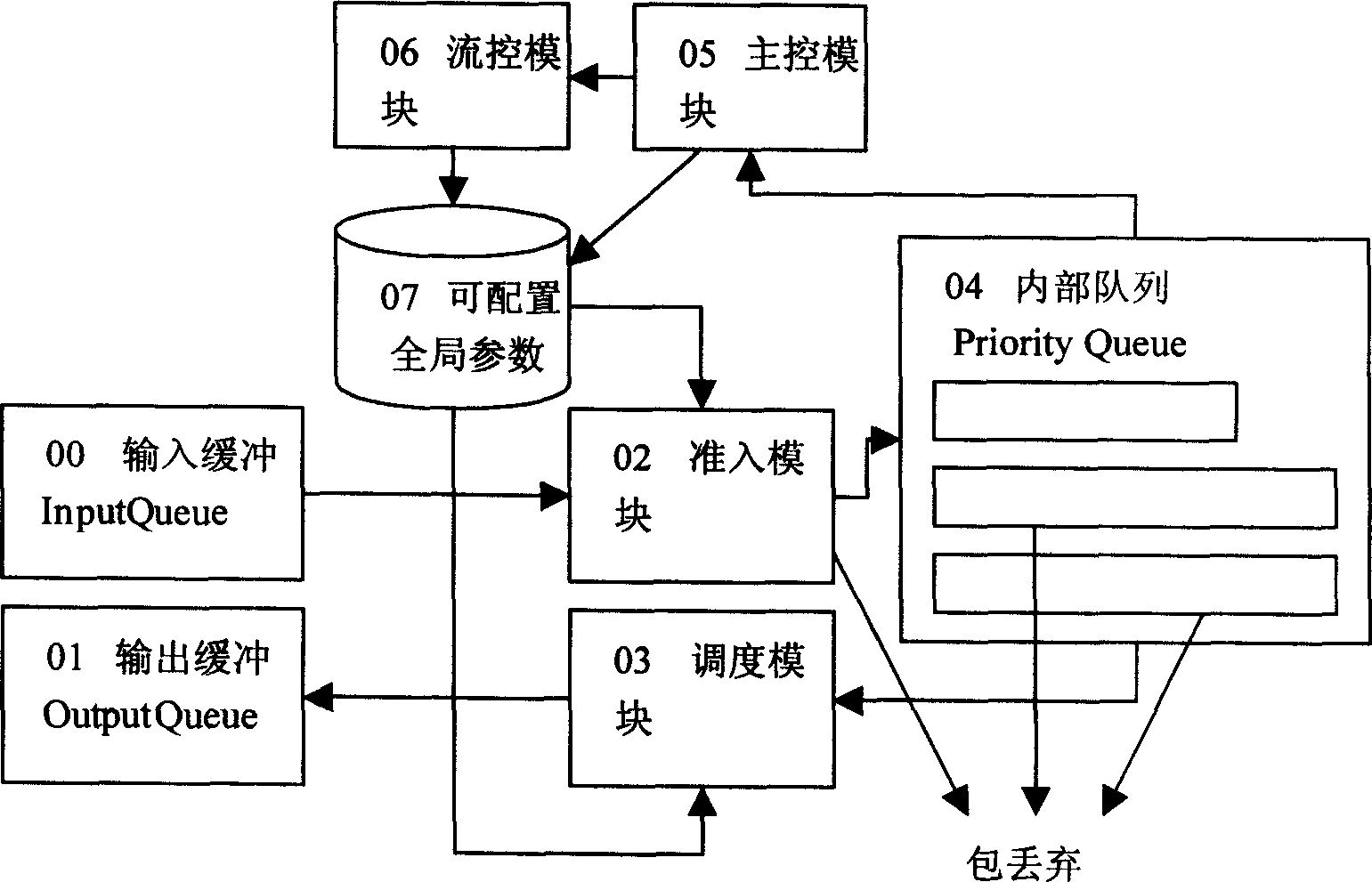

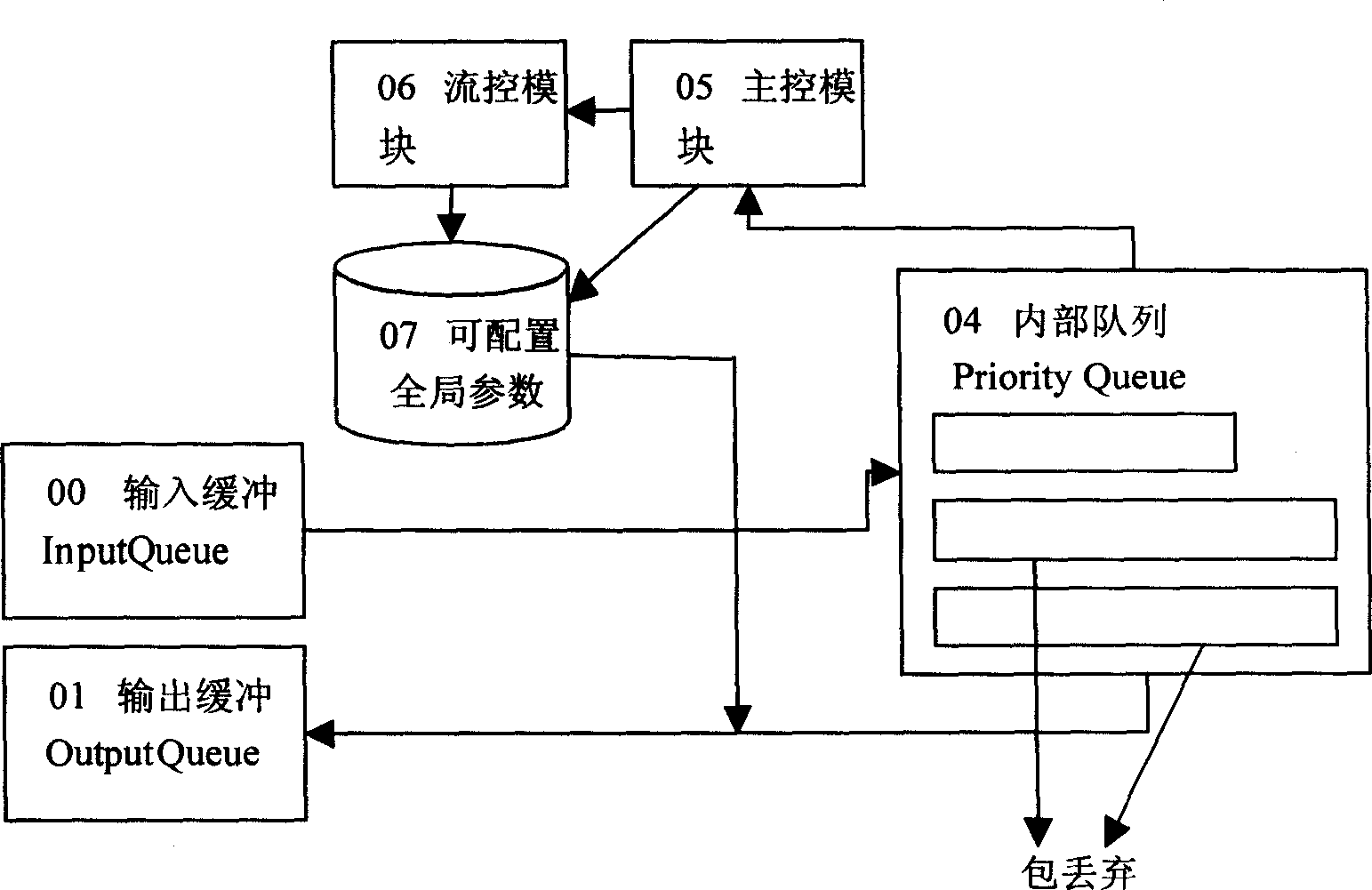

Method and system for carrying out flow-control

InactiveCN1878131ASolve the problem of effective processing rate declineAccurate grasp of overload conditionsData switching networksControl flowRetention time

The invention discloses a control method and system of flow capacity, which comprises the following steps: obtaining synthetic parameter or of even retention time in the inner array for inner array length and message or detecting result of CPU occupying rate; controlling flow capacity through setting global sharing parameter when the obtained parameter or detecting result exceeds the setting threshold value. The invention guarantees the precision of system overload condition, which improves effective disposal rate of system and information.

Owner:SHENZHEN TINNO WIRELESS TECH

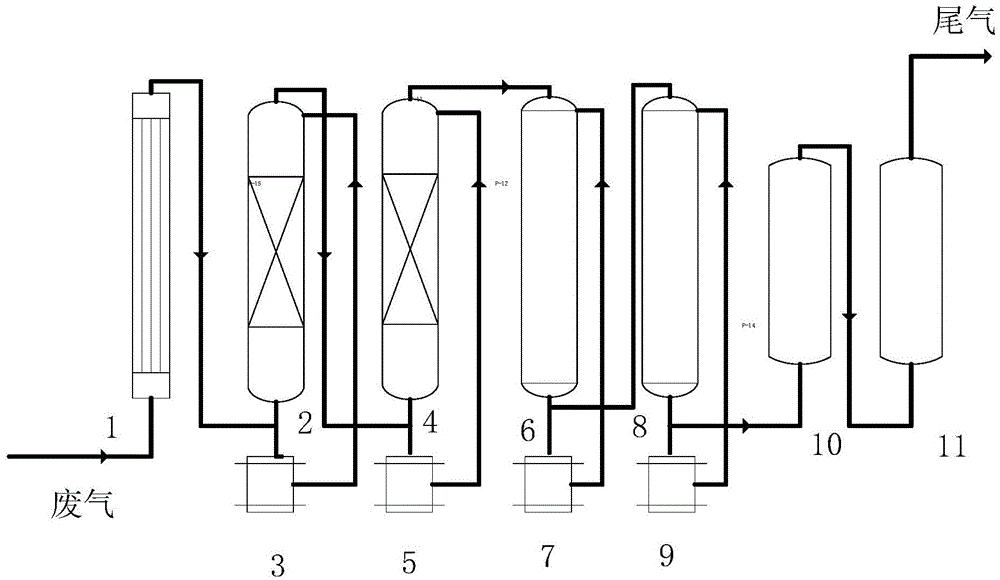

Treatment method for mixed organic waste gas containing chlorine, hydrogen chloride and oxynitride

ActiveCN105597535AImprove removal effectIncrease concentrationGas treatmentDispersed particle separationNitric oxideOxidation reduction

The invention discloses a treatment method for mixed organic waste gas containing chlorine, hydrogen chloride and oxynitride. The method is capable of not only achieving a favorable removal effect on oxynitride, but also achieving a favorable removal effect on chlorine. A condensation unit, an absorbing unit and an adsorption unit are adopted in the treatment method, wherein the condensation unit adopts one-grade condensation; the absorbing unit adopts four-grade absorption; the absorption unit adopts two-grade absorption; waste gas firstly passes through a cooler and a demister of the condensation unit, so that VOCs with relatively high boiling points in the waste gas are cooled as much as possible and then recycled; then the waste gas enters into an aqueous urea solution absorption tower of the absorbing unit, and nitric oxides and chlorine in the waste gas are completely oxidized, reduced, decomposed and absorbed by virtue of a catalytic absorption reaction, so that nitrogen and chlorine are removed; the waste gas with nitrogen and chlorine removal enters into an aqueous falling film solution absorption tower of the absorbing unit, so that by-product hydrochloric acid is obtained; finally, the residual waste gas passes through an absorption tower of the absorption unit, so that the residual VOCs are adsorbed, and thus up-to-standard release is achieved.

Owner:NANJING TECH UNIV

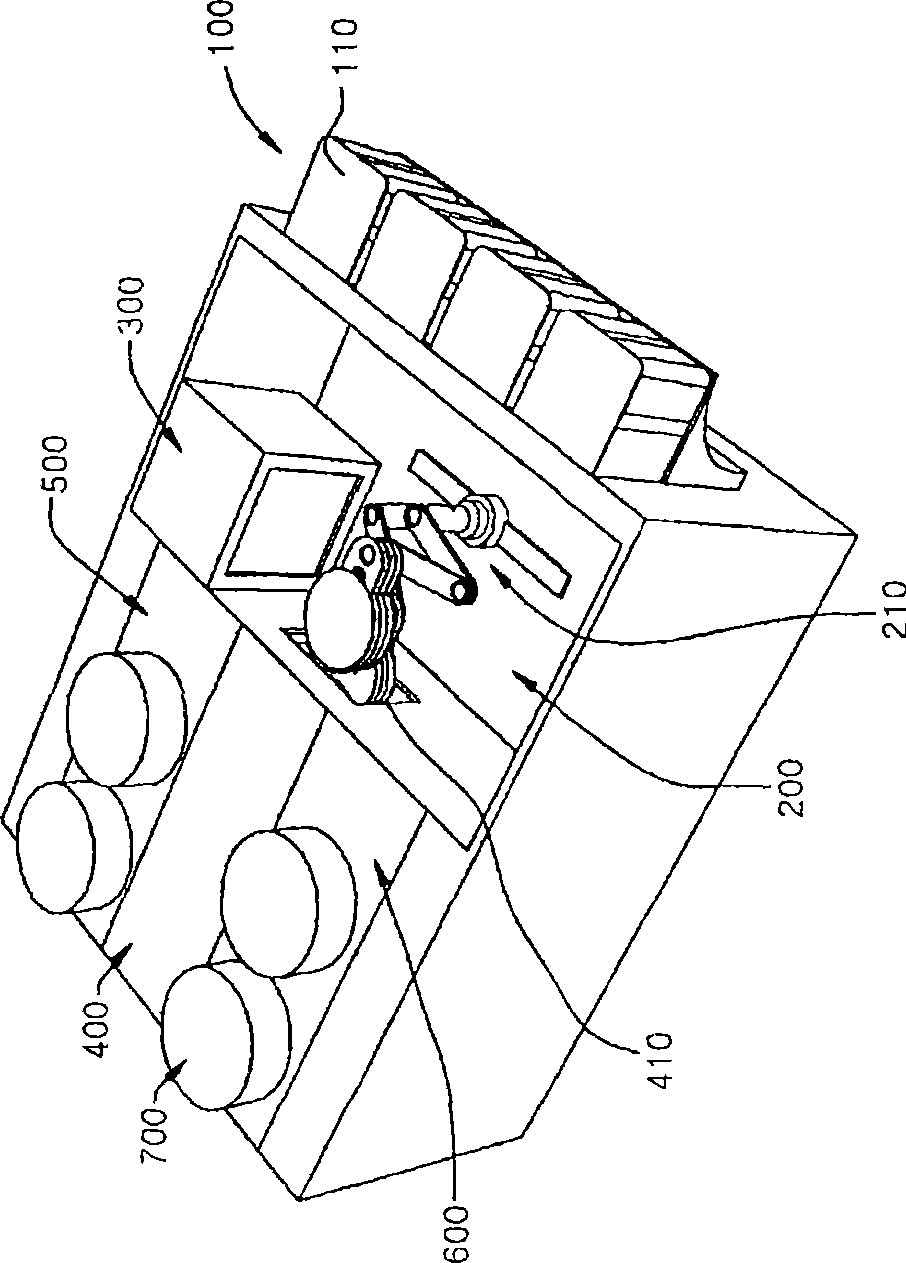

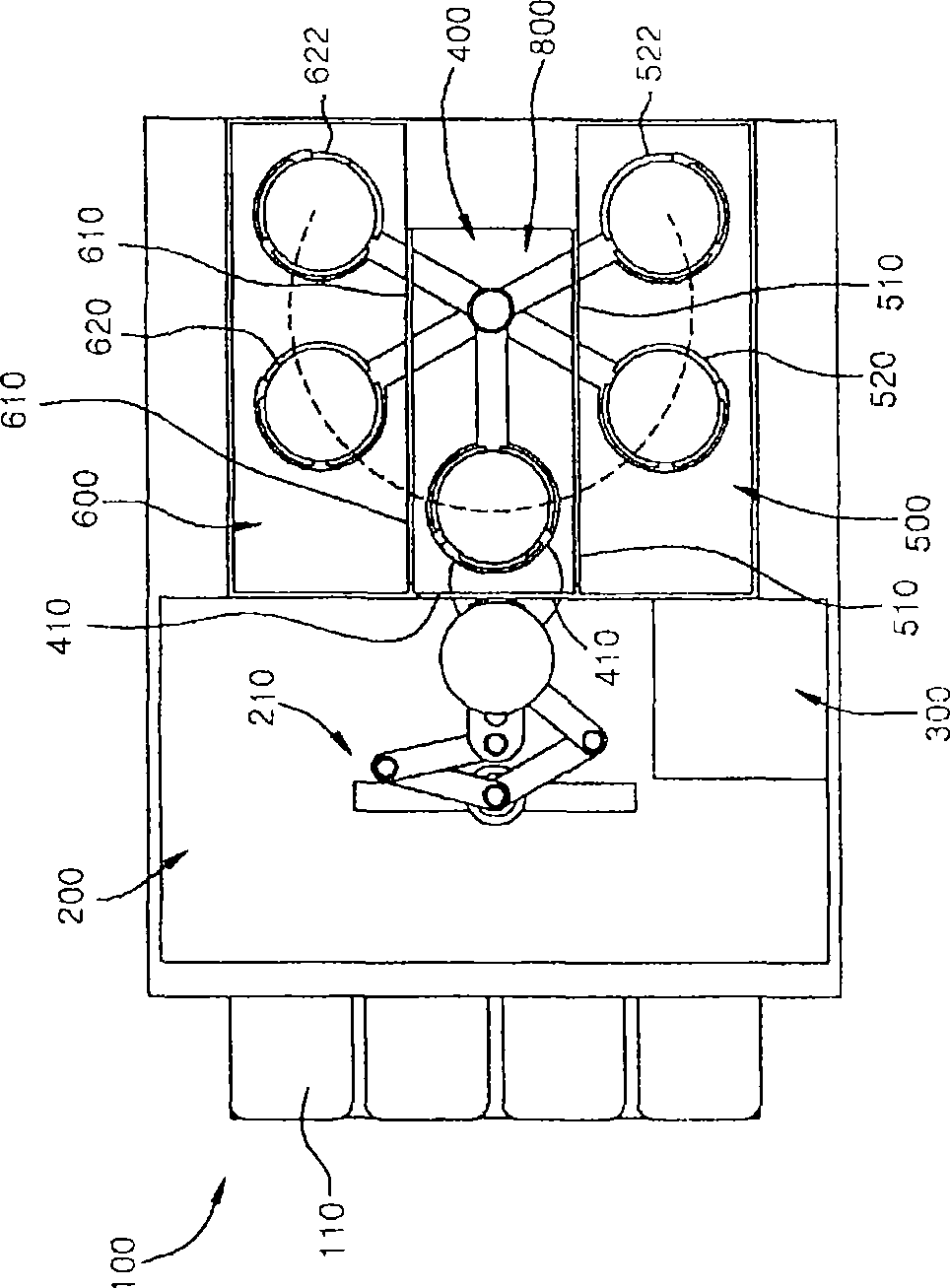

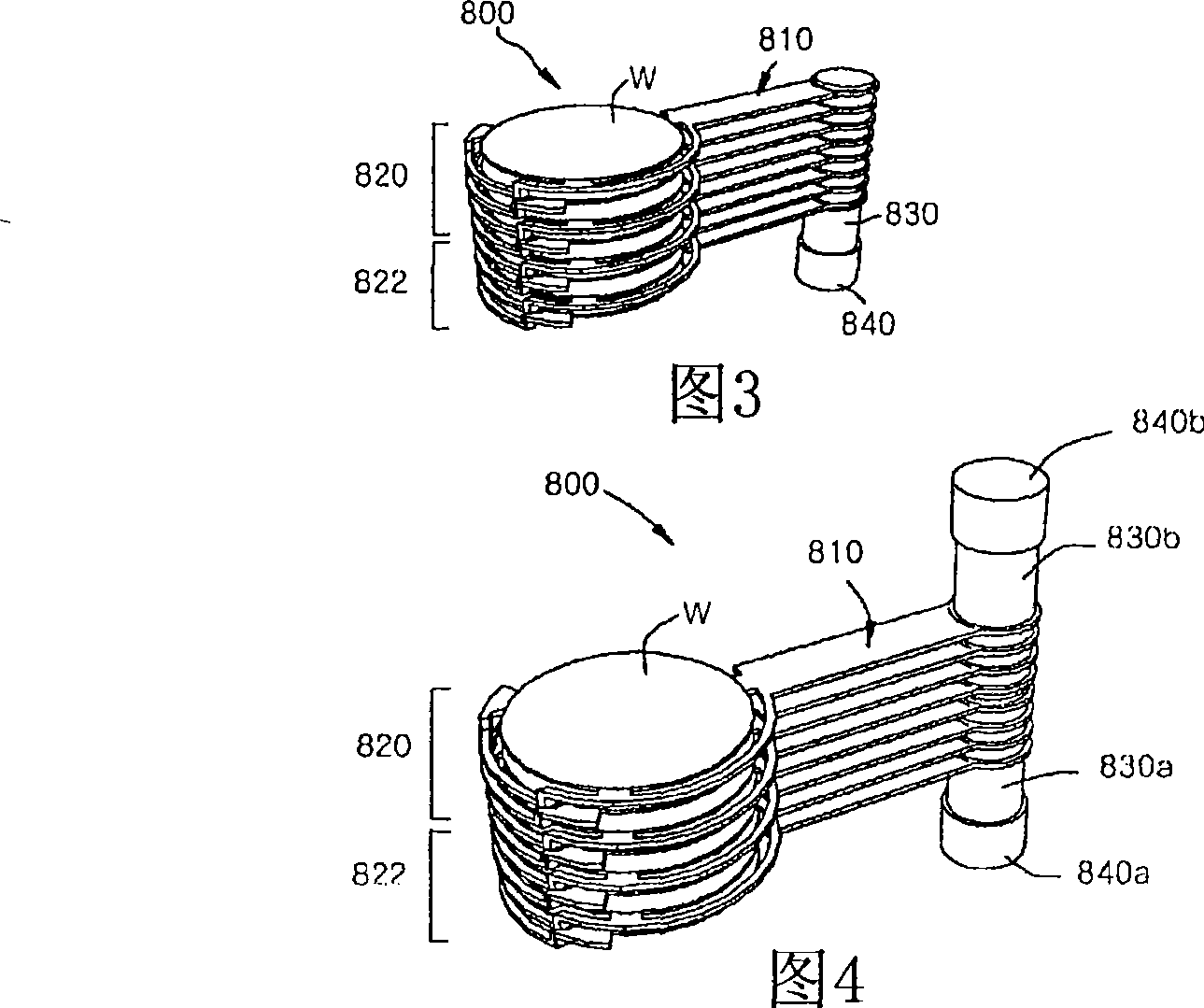

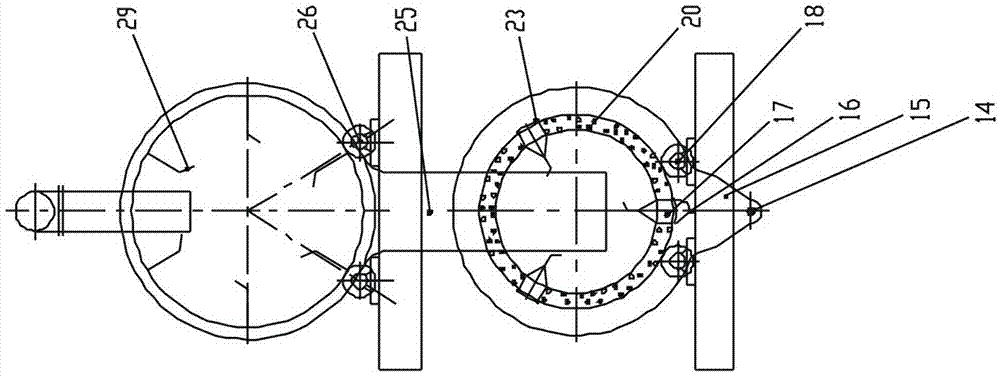

Substrate transfer equipment and substrate processing system using the same

InactiveCN101461051AImprove productivityExtension of timeProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

There are provided a substrate transferring apparatus for continuously loading / unloading a plurality of substrates in and from a process chamber to reduce time spent on transferring the substrates and to improve productivity and a substrate processing system using the same. The substrate transfer apparatus is installed in the transfer chamber and transfers substrates between first and second process chambers which is positioned lateral sides of the transfer chamber and a load rock chamber. The substrate transfer apparatus includes a driving unit to supply a rotational force, a spindle connected to the driving unit, first swivel plate arms to load / unload substrate to / from first process chamber, and second swivel plate arms to load / unload substrate to / from second process chamber. Since substrates before and after being processed are rapidly exchanged during the simultaneous or continuous process of plural substrates, processing rate increases and overall productivity can be increased.

Owner:AFO株式会社

Rotating dual-roller incinerator

InactiveCN104728846AContinuous and stable spontaneous combustionExtension of timeIncinerator apparatusCombustionFlue gas

The invention relates to a garbage incinerator, in particular to a rotating dual-roller incinerator. The flue gas residual heat is used as a heating source of garbage drying. The natural air is used as the combustion improver for garbage burning. The consumption plan that the flying ash is used for absorbing dioxin and heavy metal and substituting the auxiliary fuel for combustion supporting and the absorbent is input to purify the glue gas is adopted. The methods of active prevention and the decomposition and elimination of the organic pollutant substitute the passive preventive measures after the generation of the pollutants. The rotating dual-roller incinerator enables the garbage burning and treatment to save resources and overcome the secondary pollution, realizes the coexistence of environment protection and economy, and achieves the dual purposes of energy saving and environment protection.

Owner:福建沃丰达纺织有限公司

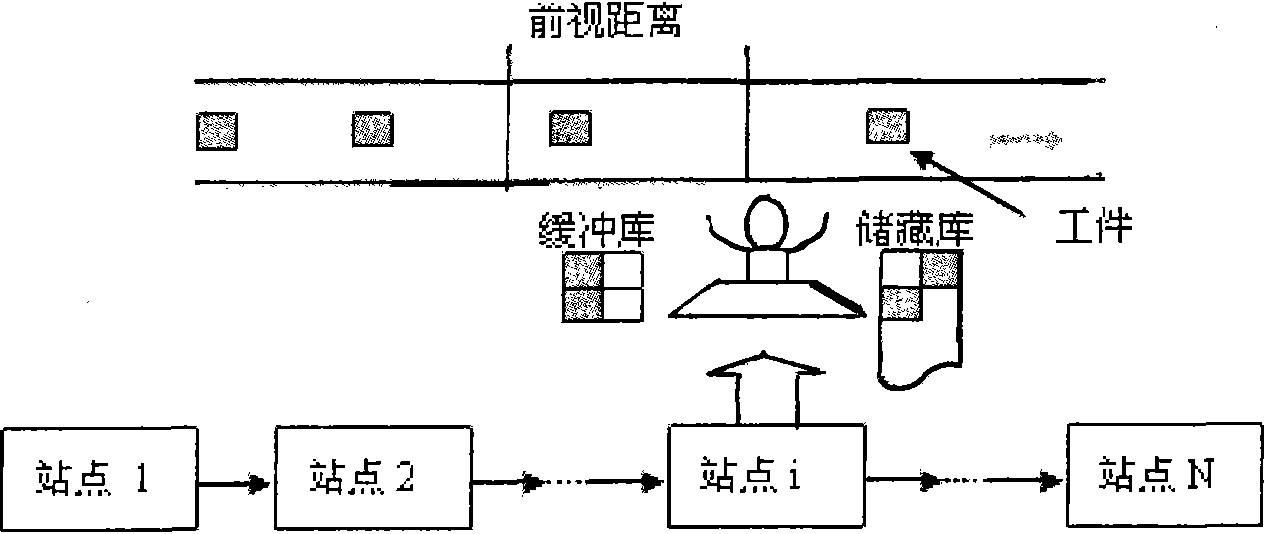

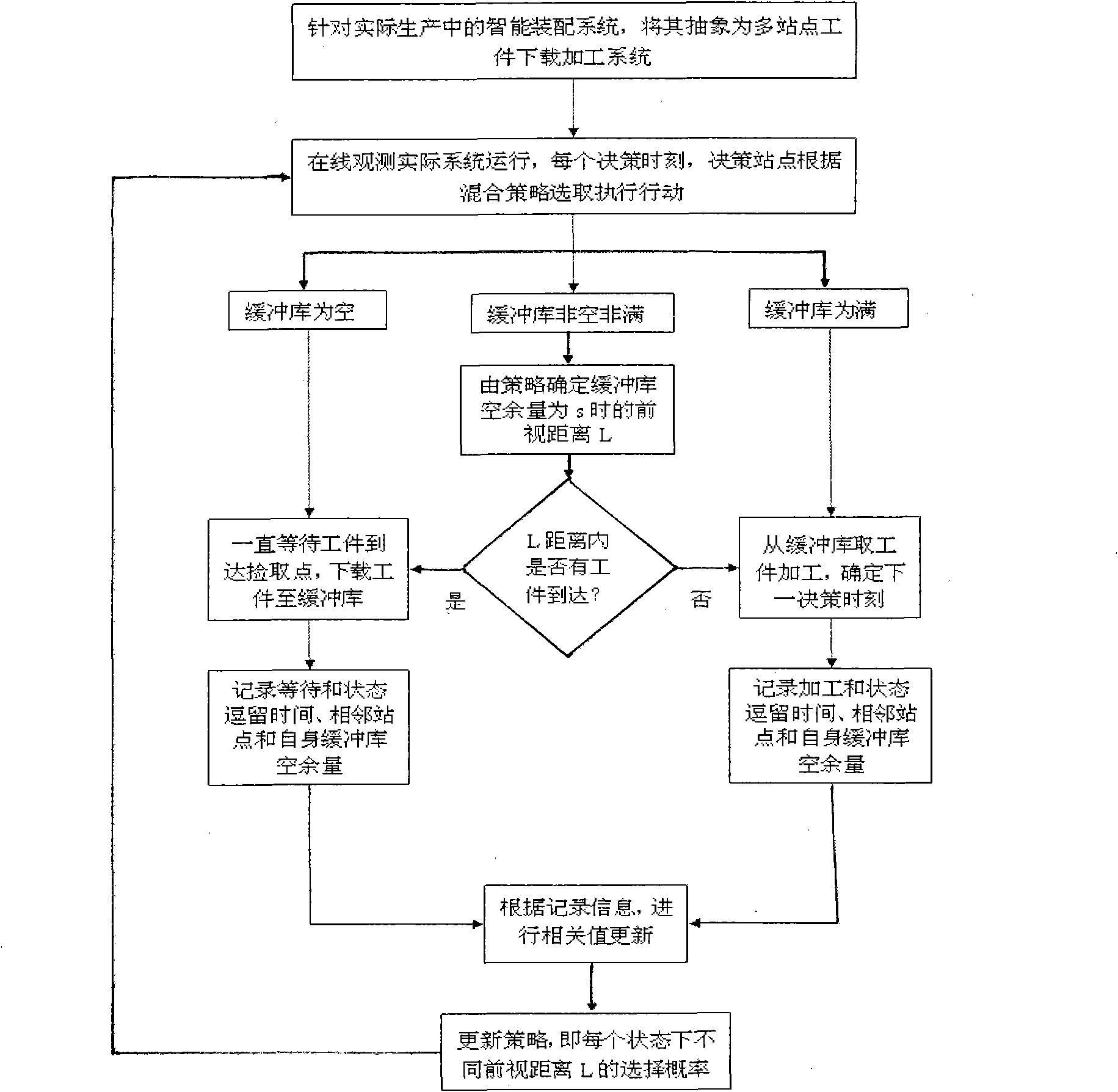

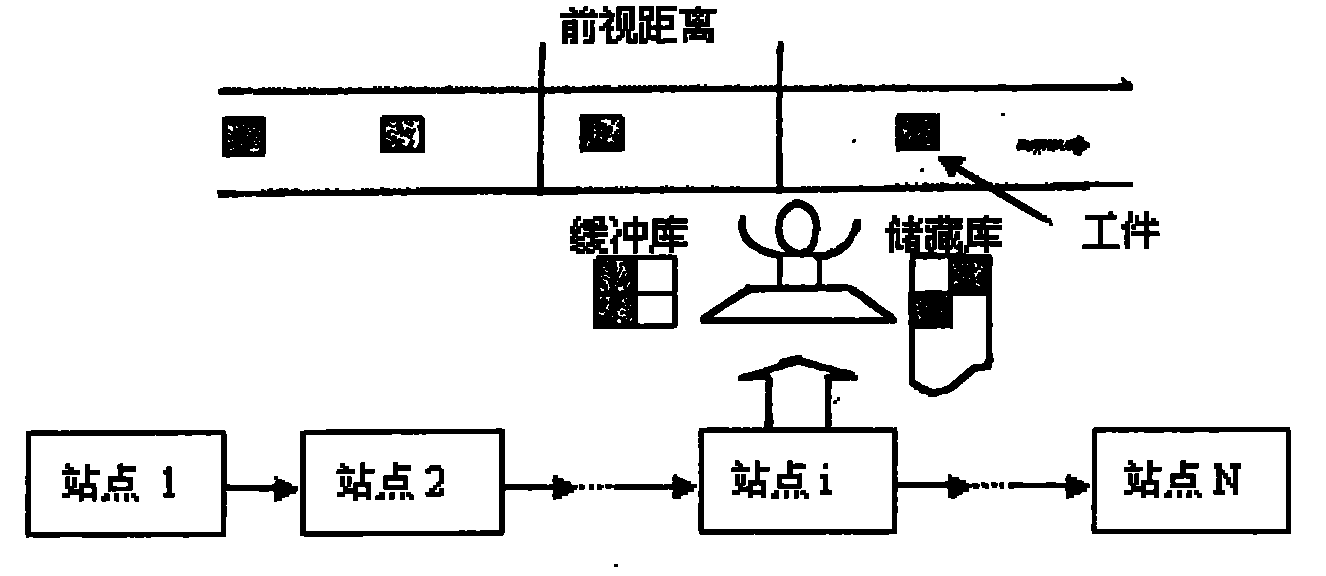

Optimization control method of multi-site conveyor belt feeding production processing site system

InactiveCN101788787AImprove load balancingImprove processing rateAdaptive controlMulti sitePerformance function

The invention discloses an optimization control method of a multi-site conveyor belt feeding production processing site system. A reaction item and a diffusion item of a performance function are respectively constructed according to the site self information and the interactive information of adjacent sites, wherein the reaction item is regarded as the feedback of the site self information, and the diffusion item is regarded as the feedback of downstream sites to upstream sites. Compared with a method only relying on the site self information, by introducing a reaction diffusion ideal and designing a new performance function, the invention favorably improves the load balance of the sites, obviously improves the working piece processing rate of the whole system and can effectively solve the problems of dimension disaster and modeling difficulty of a large-scale multi-agent system. Meanwhile, aiming to the problems of two performance criterions of discount and average, through the function constructed in the invention, a uniform continuous-time multi-agent study formula and an optimization algorithm can be established.

Owner:HEFEI UNIV OF TECH

Unfired magnesia-calcium brick and preparation method thereof

The invention discloses an unfired magnesia-calcium brick which is prepared from the following raw materials in percentage by weight: 9-16 percent of 5-7mm magnesia-calcium sand, 9-16 percent of 3-5mm magnesia-calcium sand, 9-16 percent of 1-3mm magnesia-calcium sand, 9-16 percent of 0.5-1mm magnesia-calcium sand, 4-16 percent of 0.5-1 mm magnesia sand, 5-25 percent of not larger than 0.5mm magnesia sand, 1-10 percent of graphite, 2-5 percent of anhydrous resin bonding agent and 1-3 percent of additive formed by mixing magnesia powder and zircon sand. The processing method comprises the following steps of: crushing, grinding, compounding, pressing and forming, heating, baking and carrying out waterproof treatment. In the invention, the unfired magnesia-calcium brick with great volume density and high compression strength can be prepared due to reasonable compounding and a scientific treatment process, and particularly, the additive formed by mixing the magnesia powder and the zircon sand is used, therefore, the product has good medium-temperature strength, waterproofness and crack resistance.

Owner:浙江金磊耐火材料有限公司

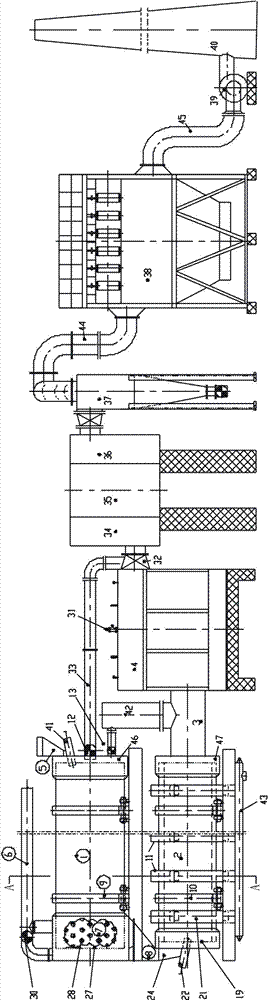

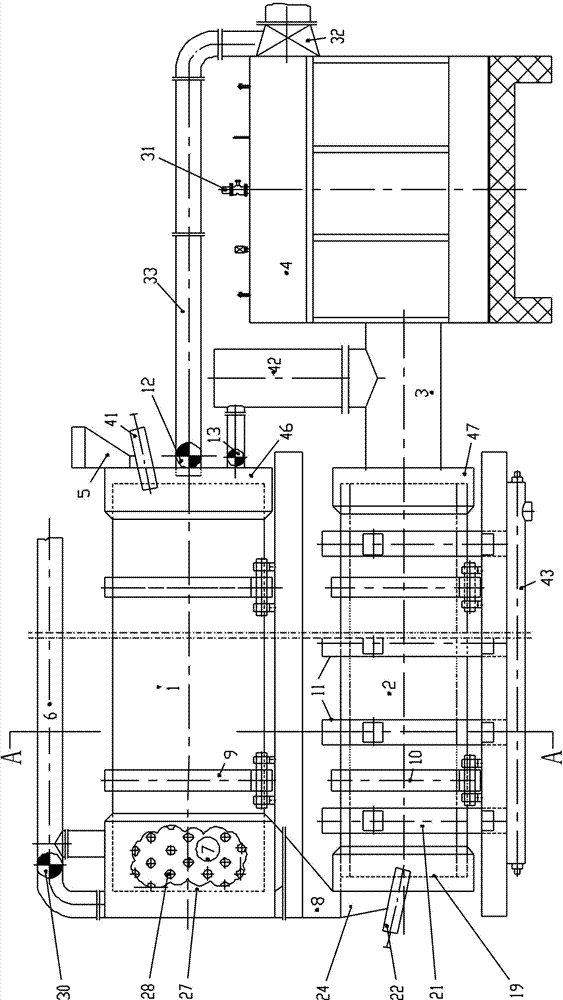

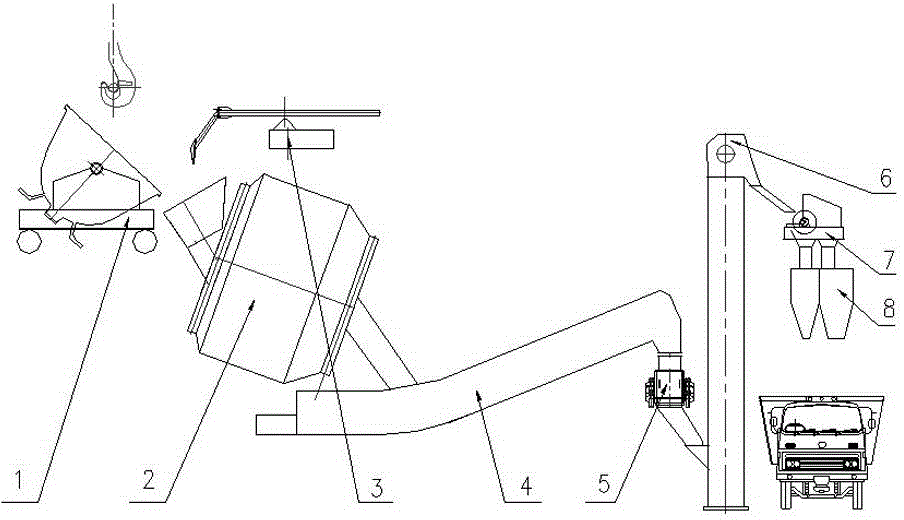

Rotating-drum method based full flow processing system and rotating-drum method based full flow processing technique

InactiveCN104894309AImprove processing rateImprove securityRecycling and recovery technologiesElectrical controlSlag

The invention discloses a rotating-drum method based full flow processing system and a rotating-drum method based full flow processing technique. The system mainly comprises a tipping device, a slagging-off device, a rotating drum device, a finished-product conveying device, a vibratory separation device, a bucket-type lifting device, an online magnetic separation device, a storage device, a dust removal device, a water system device and an electrical control device. The tipping device and the slagging-off device are used for assisted feeding. The rotating drum device is used for core processing of steel slags. The rotating-drum method based full flow processing system and the rotating-drum method based full flow processing technique have the advantages that rotating-drum processing rate of the steel slags can be increased remarkably, slag feeding safety and reliability of a rotating drum can be improved, and travelling crane occupancy rate can be reduced; the steel slags processed by the rotating drum can be subjected to online separation and initial magnetic separation; materials can be stored in a overhead bunker, and environmental pollution and surplus input both caused by secondary and multiple loading and unloading of finished slags are avoided.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

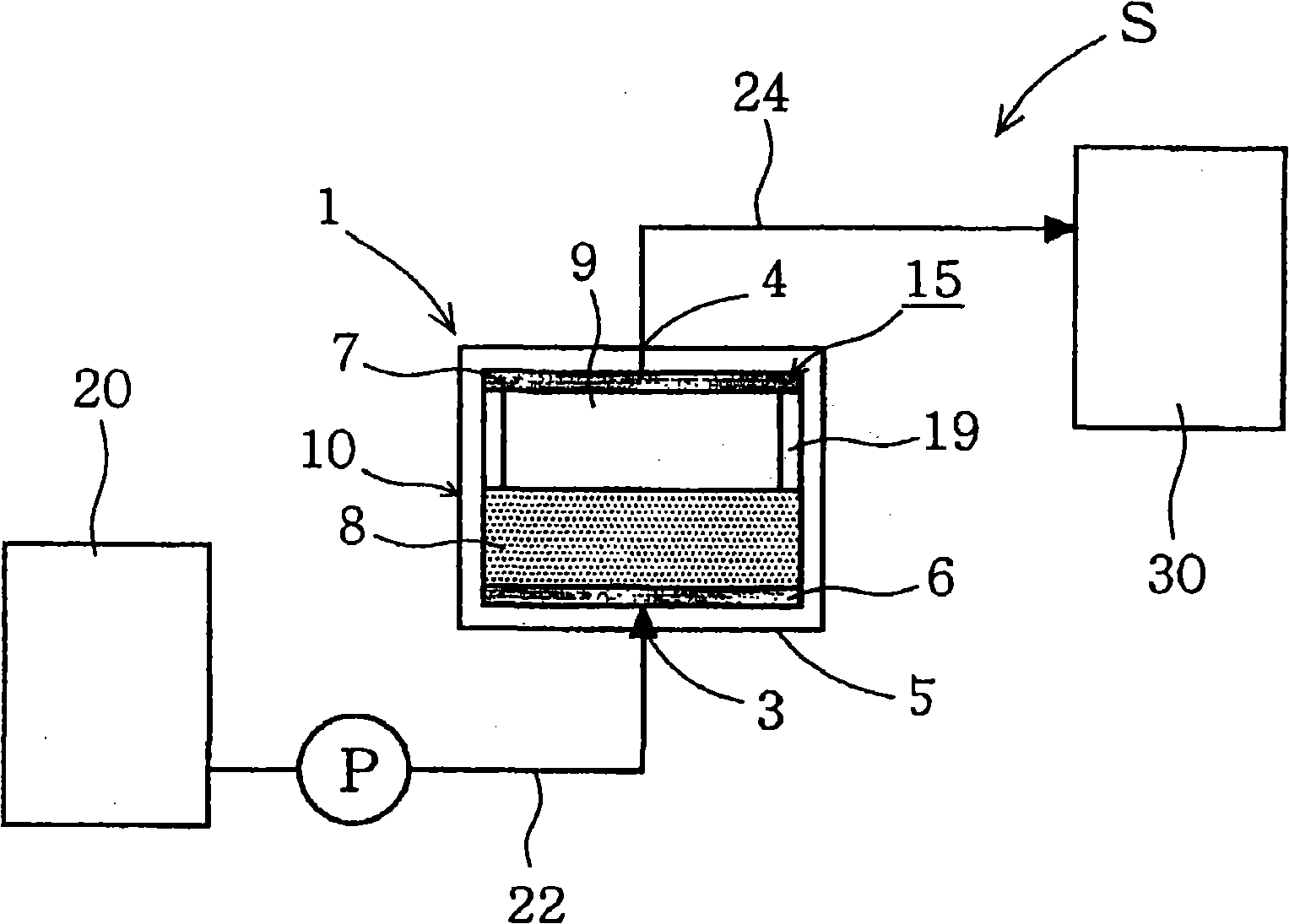

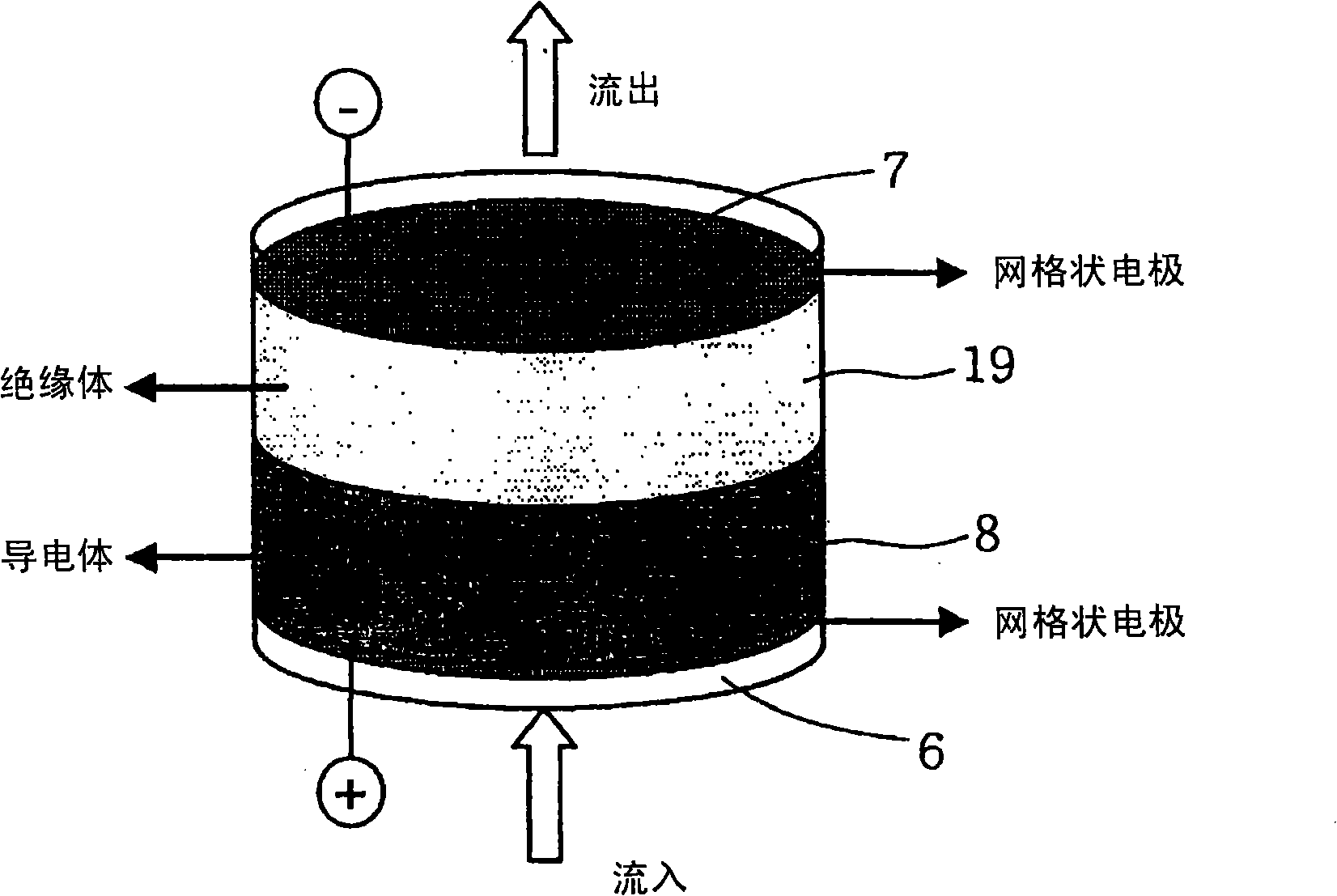

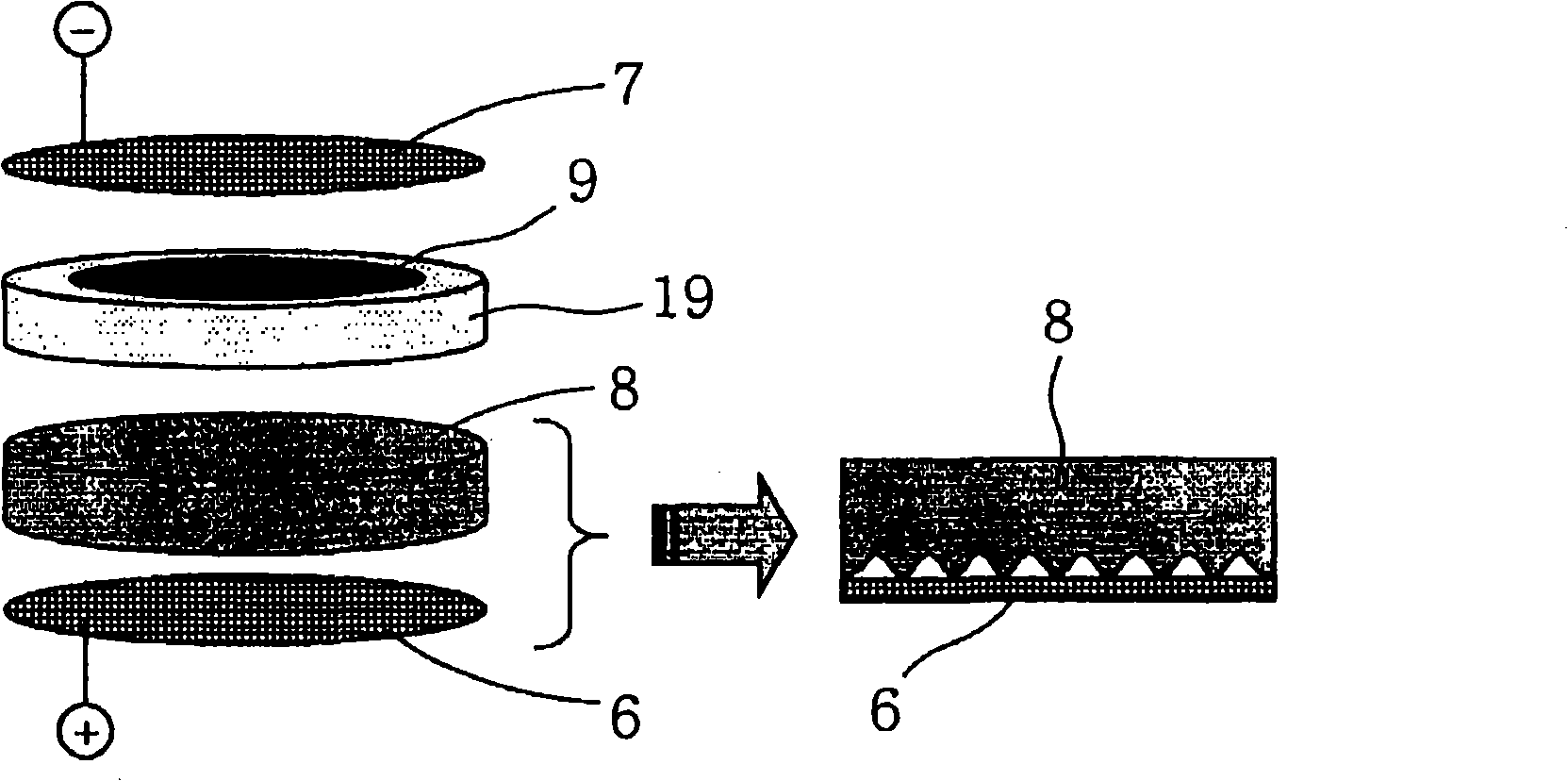

Water treatment device

InactiveCN101306854AReduce contact resistanceIncrease contact areaSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsFiberEngineering

The invention provides a water treatment device capable of improving the treatment efficiency of the treated water and passing the treated water once to sufficiently treat the water without repeated circulation, and the water treatment device (1) includes a water passing first electrode (6) arranged in the channel of the treated water, a conductive fiber (8) positioned on the downstream side of this first electrode (6) and energized by the first electrode (6), a water passing electrode (7) positioned on the downstream side of this conductive fiber (8) and forming a pair with the first electrode (6), an insulating porous spacer (9) interposed between this electrode (7) and the conductive fiber (8), and a supply section which supplies voltages to both of the electrodes (6, 7).

Owner:SANYO ELECTRIC CO LTD

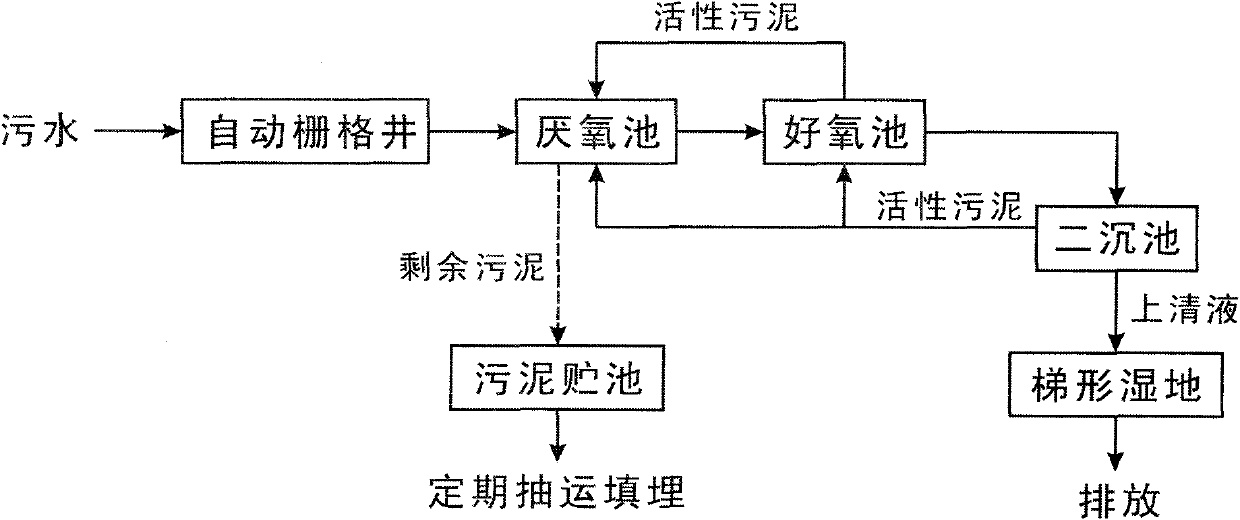

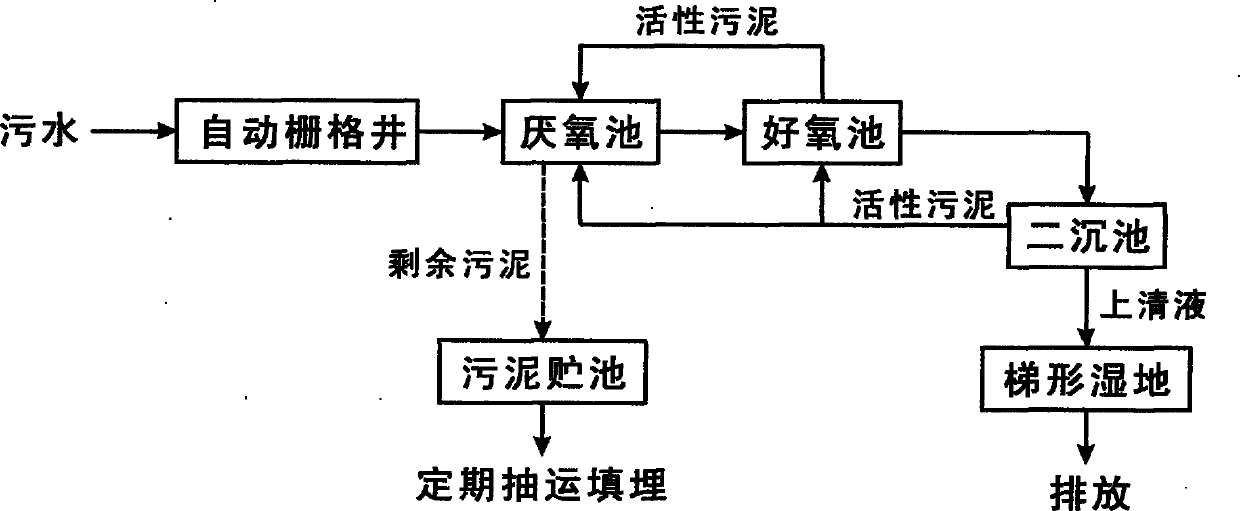

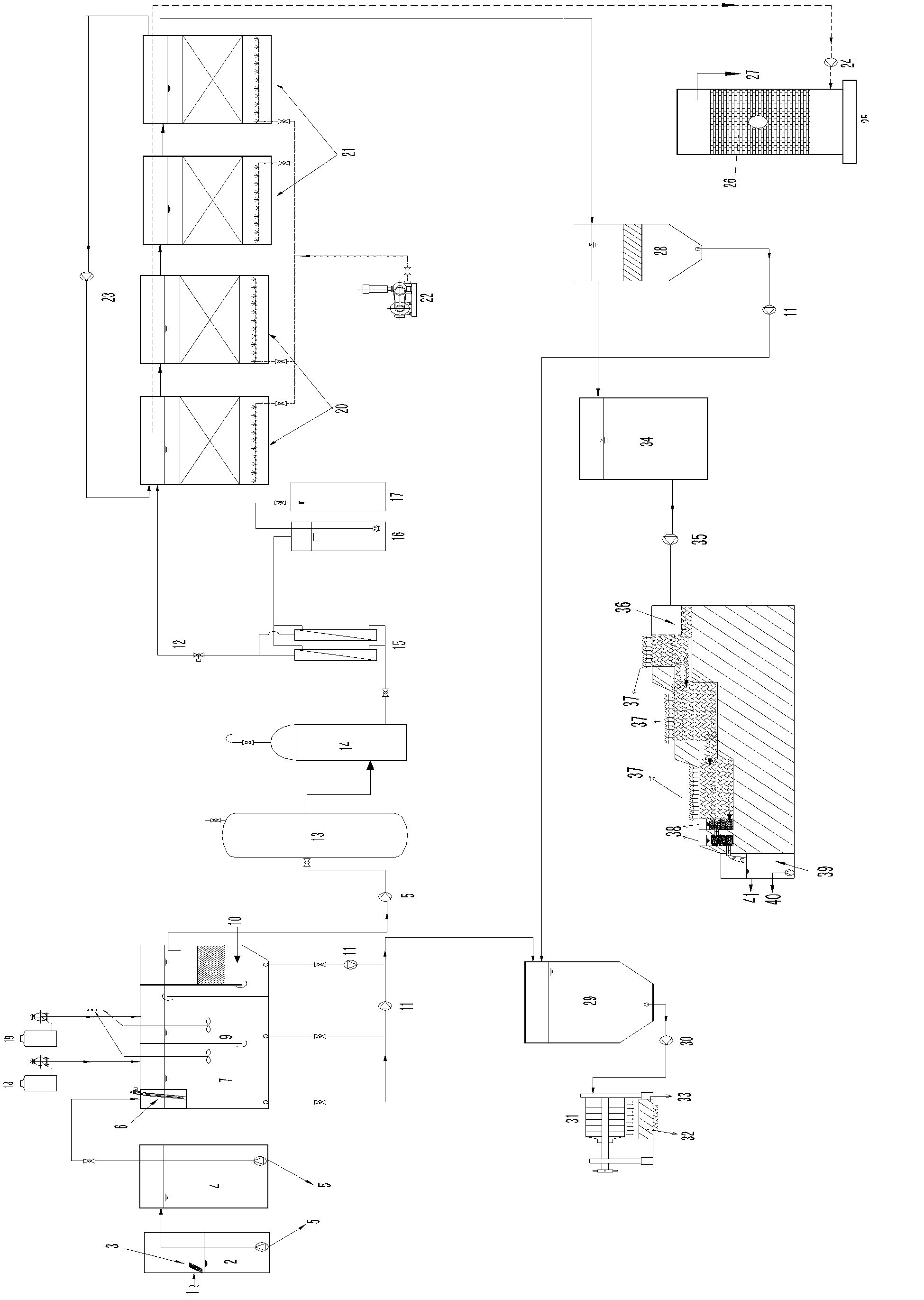

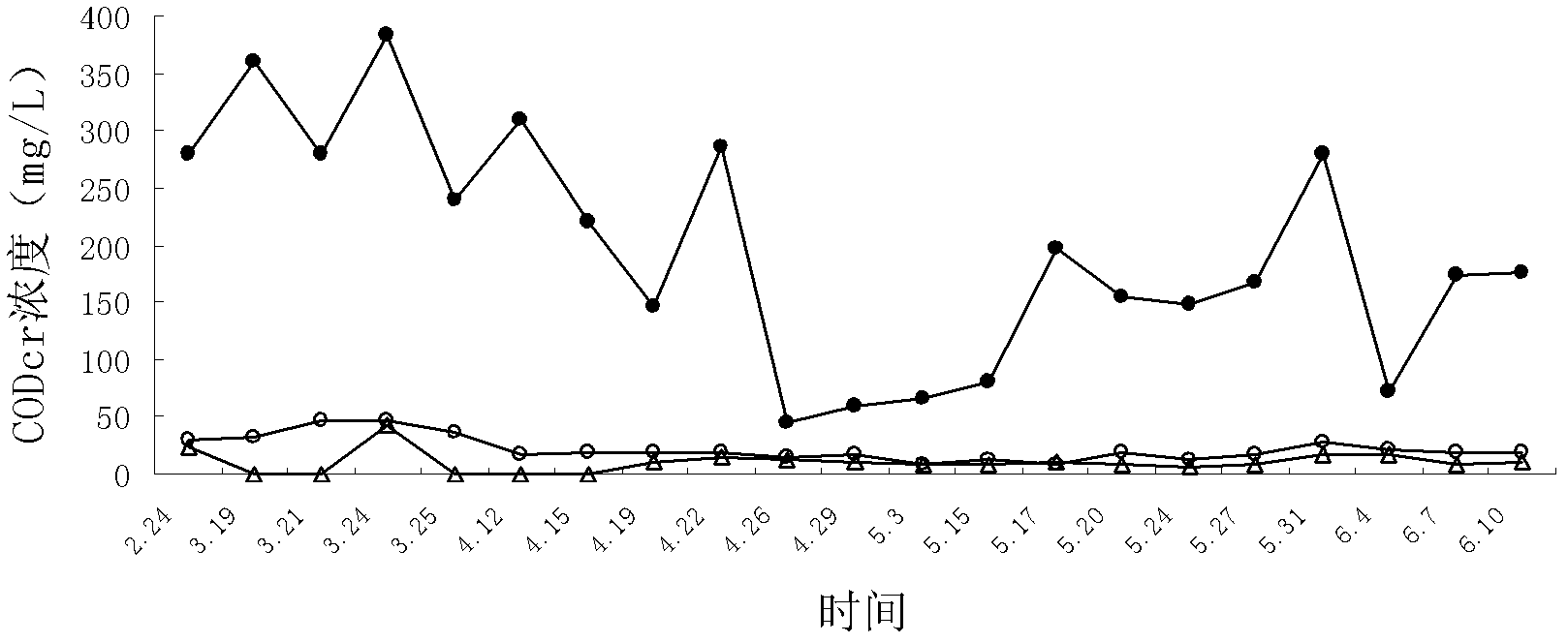

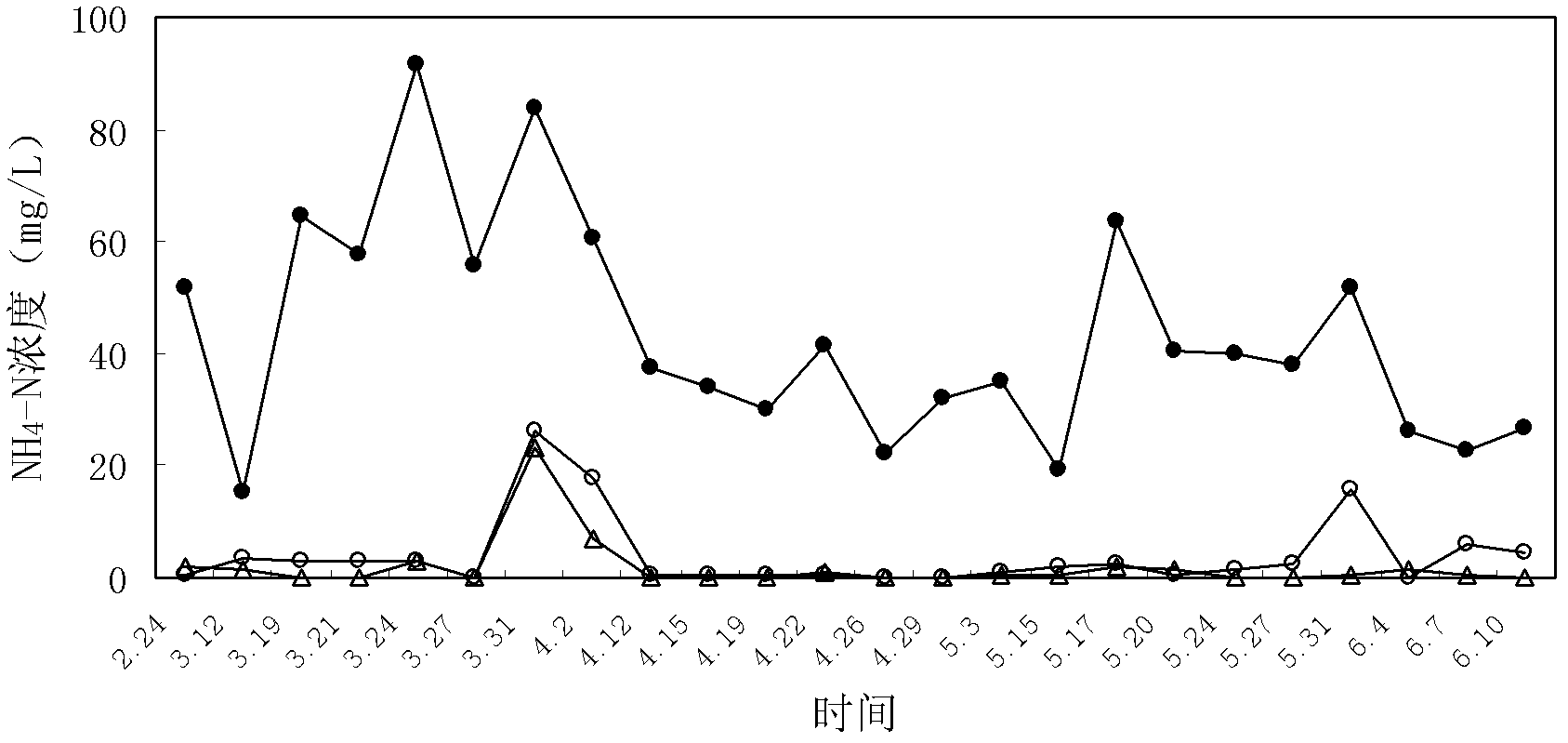

System for disposing artificial wetland sewage and disposal method thereof

InactiveCN101792234AReduce maintenanceLower requirementTreatment with anaerobic digestion processesMultistage water/sewage treatmentActivated sludgeConstructed wetland

The invention relates to a system for disposing artificial wetland sewage. The system comprises a pre-treatment system, a biochemical treatment system, and a sludge storage tank according to a disposal sequence and is characterized by further comprising a tail water advanced treatment system after the biochemical treatment system, wherein the pre-treatment system comprises an automatic grating well; the biochemical treatment system comprises an anaerobic tank, an aerobic tank and a secondary sedimentation tank; the tail water advanced treatment system comprises an artificial wetland; and the artificial wetland comprises four waterproof walls, a packed bed body, and an aquatic plant layer arranged above the packed bed body. The method for disposing the artificial wetland sewage by utilizing the system comprises the following main steps that: impurities in the sewage are separated by automatic gratings; organic matters are acidulated and degraded by anaerobic water; after the sewage is settled and separated, supernate is discharged outside; activated sludge in the secondary sedimentation tank is refluxed to the anaerobic tank and the aerobic tank; water discharged from the secondary sedimentation tank enters the artificial wetland; plants on the surface of the packed bed body are used for purifying the sewage; and the remaining sludge enters the sludge storage tank and is pumped and disposed by an environmental health department.

Owner:ZHEJIANG LIUYUAN ENVIRONMENTAL TECH

Epichlorohydrin production wastewater treating method

InactiveCN105271597AReduce COD valueImprove processing rateMultistage water/sewage treatmentChemistrySettling

The invention discloses an epichlorohydrin production wastewater treating method. Multiple technologies such as micro-electrolysis, deep oxidation, flocculent settling, adsorption retardance, membrane separation and the like are specifically combined, epichlorohydrin wastewater is treated online in a targeted manner, the COD value can be significantly reduced, and the method is high in treatment rate and removal rate, has the obvious effect and can treat both current problems and root causes. Repeated experiments and detection analysis indicate that the wastewater contains 10,000-20,000 ppm of COD and about 15,000 ppm of soluble salts originally, the COD value is decreased below 100 ppm and the treatment rate is up to 98% after the technological treatment, approximately 7,000 ppm of the soluble salts are left, and the removal rate is up to 95%.

Owner:广西钦州环科水处理有限公司

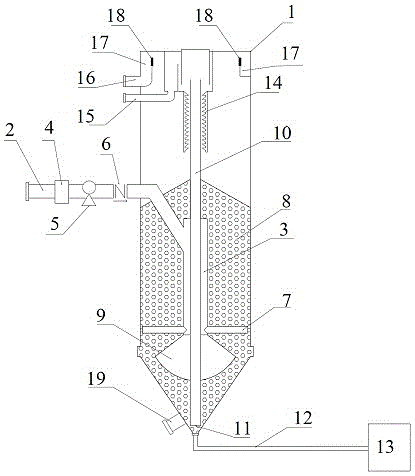

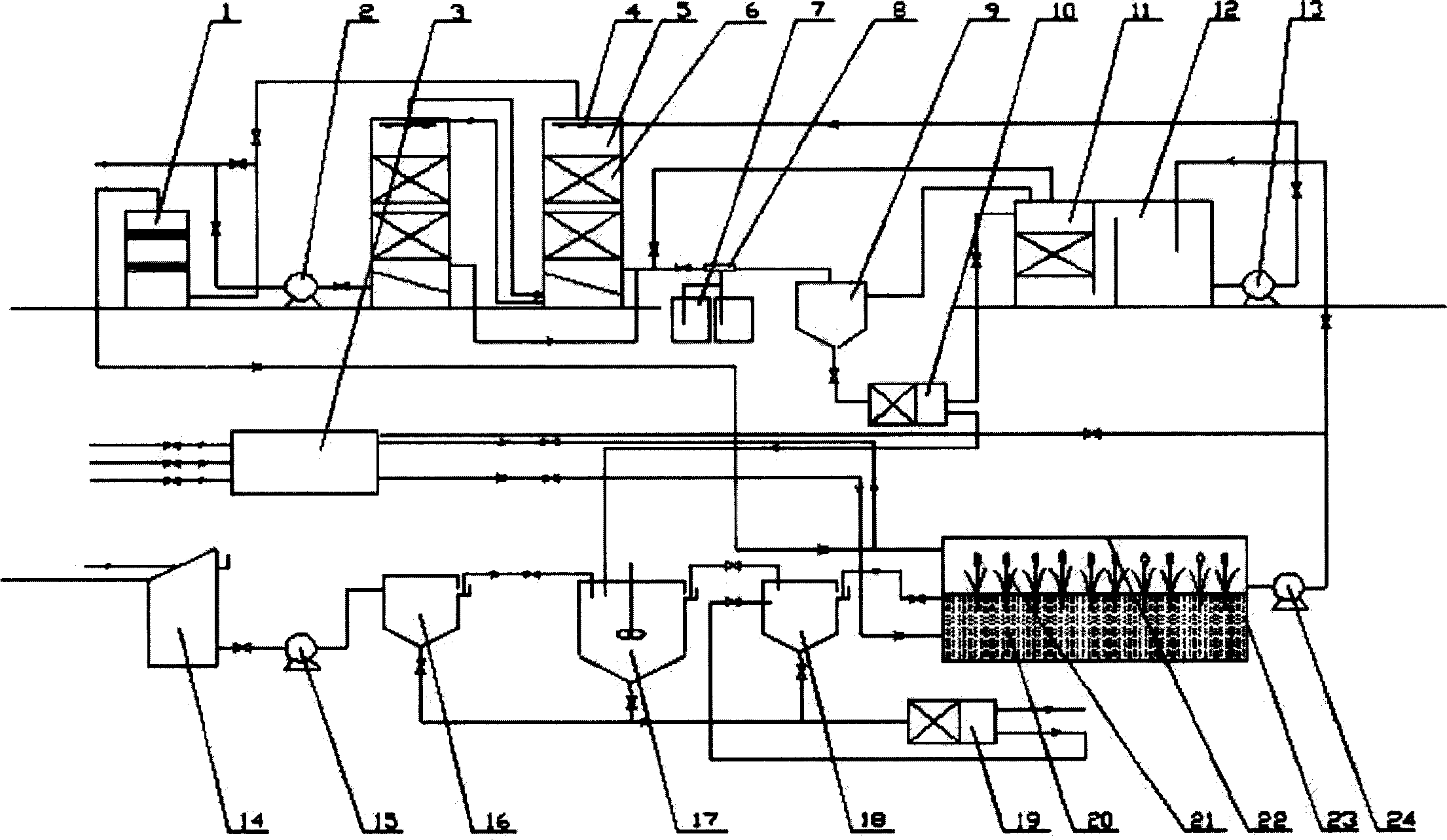

Multifunctional stereo comprehensive treatment and recycling system for urban sewage

InactiveCN102491594AImprove processing rateSmall footprintMultistage water/sewage treatmentUltrafiltrationAir blower

A multifunctional stereo comprehensive treatment and recycling system for urban sewage relates to urban sewage treatment equipment, integrates tertiary sewage treatment and landscape greening, and has the advantages of few occupied areas, low energy consumption, high treatment efficiency, recyclable discharged water and the like. The multifunctional stereo comprehensive treatment and recycling system for urban sewage comprises secondary treatment equipment and tertiary treatment equipment. The secondary treatment equipment comprises a sewage hoisting shaft, a water collecting tank, an adjusting tank, an acid-base feeding device, a coagulation reaction tank, a coagulant feeding device, a primary sedimentation tank, an anaerobic filtering tank, an aerobic filtering tank, an air blower, a secondary sedimentation tank, a sludge thickener, a sludge pressure filter, a filter-press water collecting tank, a clear water tank, a lift pump, a deodorization filtering tank, a quartz sand filter, acartridge filter, an ultrafiltration column, a thick water temporary storage tank and a heavy metal recovery device. The tertiary treatment equipment comprises a clear water lift pump, a perforated water distributor, a wetland planting area, a filtering tank and a reservoir. The sewage hoisting shaft is externally connected with a civil sewage outlet.

Owner:XIAMEN UNIV +1

Method for treating sludge of urban sewage treatment plants in controllable composting mode

ActiveCN101838090AIncrease throughputReduce processing costsBio-organic fraction processingOrganic fertiliser preparationOrganic manureEngineering

The invention relates to a method for treating sludge of urban sewage treatment plants, in particular to the method for treating the sludge of the urban sewage treatment plants in a controllable composting mode. The method is characterized by comprising the following steps of: a, preparing organic fertilizer auxiliary materials; b, placing the sludge into a conventional stirring machine at the normal temperature, mixing the sludge and the organic fertilizer auxiliary materials to obtain a mixture, and fully stirring the mixture to form high-temperature compost; c, placing the high-temperature compost in ventilated and rain sheltering environment for high-temperature composting, regulating and controlling the internal temperature of the high-temperature compost by using an air blower during the process of the high-temperature composting, controlling the internal temperature to quickly rise and keeping the temperature about 75 DEG C to perform rapid fermentation on organic matters, and keeping for 15 to 20 days to form organic fertilizer primary products; and d, screening the decomposed and dehydrated organic fertilizer primary products, stabilizing the organic fertilizer at the normal temperature for 10 to 15 days to form organic fertilizer finished products, and finally bagging the organic fertilizer finished products to obtain the fertilizer products.

Owner:张丽 +2

High-density ultrahigh-purity magnesia-calcium brick and preparation method thereof

The invention discloses a high-density ultrahigh-purity magnesia-calcium brick and a preparation method thereof. The high-density ultrahigh-purity magnesia-calcium brick is prepared from 9 to 16% of magnesia-calcium sand having particle sizes of 5-7mm, 9 to 16% of magnesia-calcium sand having particle sizes of 3-5mm, 9 to 16% of magnesia-calcium sand having particle sizes of 1-3mm, 13 to 32% of magnesia-calcium sand having particle sizes of 0.5-1mm, 5 to 25% of magnesia-calcium sand having particle sizes less than or equal to 0.5mm, 5 to 10% of high-purity magnesia sand fine powder having particle sizes less than or equal to 0.044mm, 2 to 5% of tar resin or paraffin, and 2 to 5% of fused zirconia. The preparation method comprises the following steps of raw material proportioning, raw material blending, mixing, molding, sintering, waxing and vacuum aluminium foil package. The high-density ultrahigh-purity magnesia-calcium brick has a high product compact degree and excellent hydration resistance. The high-density ultrahigh-purity magnesia-calcium brick has high purity and thus high slag corrosion resistance and high flushing resistance are obtained. Compared with other like products, the high-density ultrahigh-purity magnesia-calcium brick has better thermal shock resistance. The high-density ultrahigh-purity magnesia-calcium brick contains a large amount of dissociative CaO and thus the high-density ultrahigh-purity magnesia-calcium brick has excellent molten steel cleaning performances and is especially suitable for production of high cleanliness steel such as stainless steel.

Owner:PERFECT WORLD CO LTD

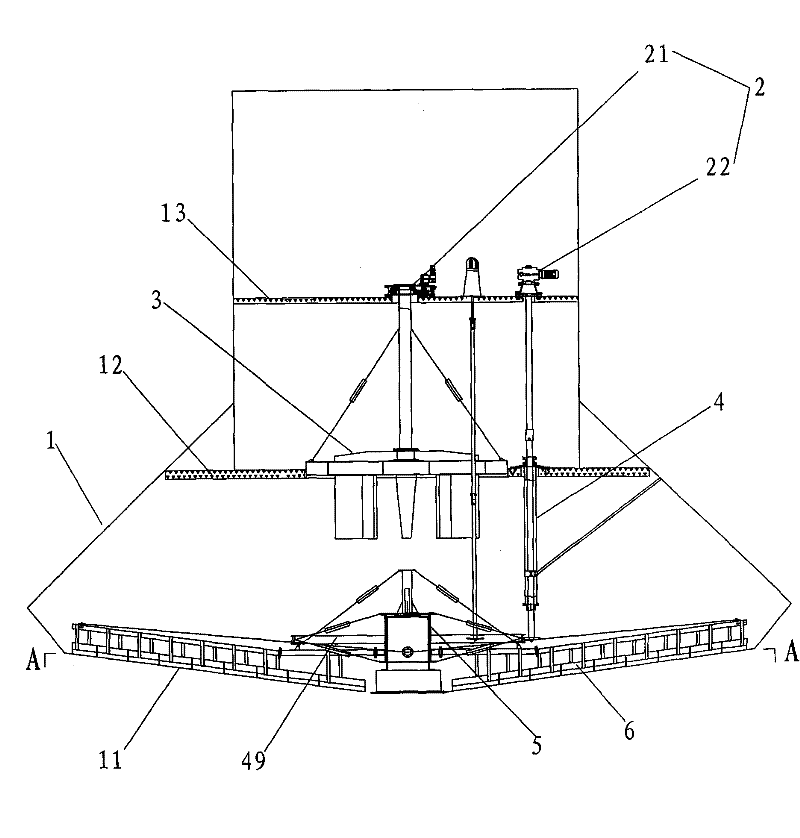

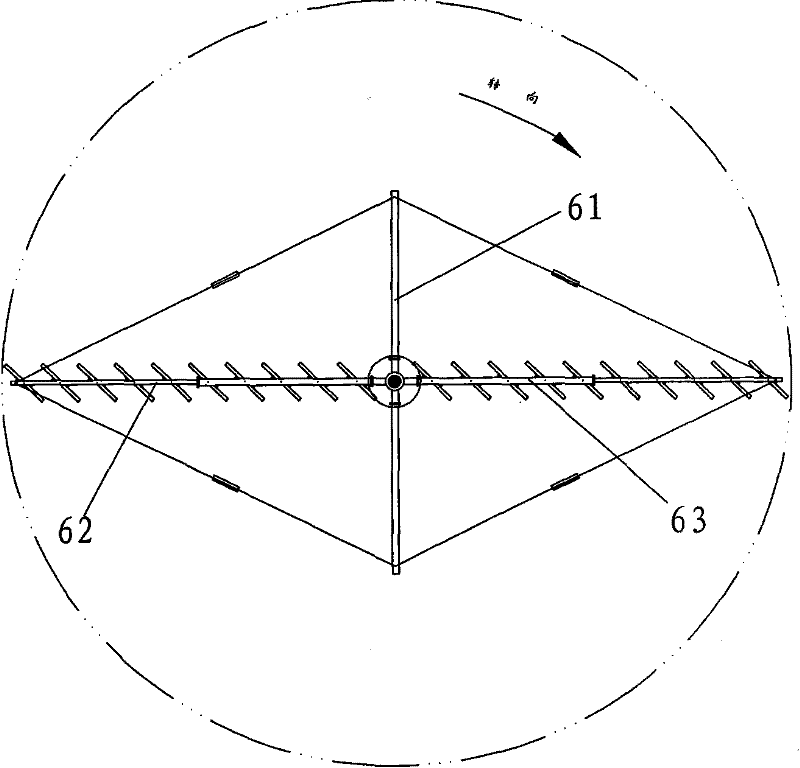

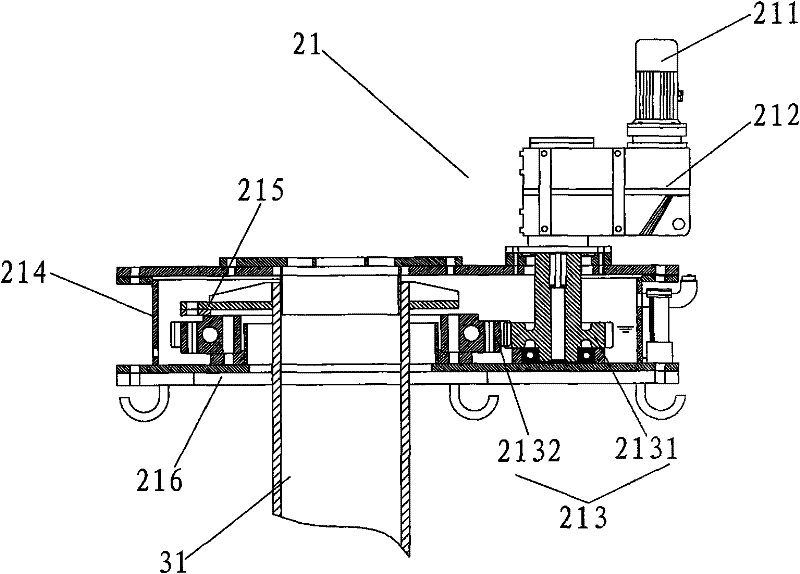

Machine capable of independently stirring and scraping mud

ActiveCN102172440AImprove processing rateEasy to handleSettling tanks feed/dischargeSedimentation settling tanksWork periodWater processing

The invention relates to a machine capable of independently stirring and scraping mud, which is arranged in a settling pond and comprises a drive mechanism, a stirring mechanism, a mud scraping mechanism and a mud scraping transmission mechanism, wherein, the drive mechanism comprises a stirring drive mechanism and a mud scraping drive mechanism; the stirring drive mechanism is connected with a stirring mechanism; and the mud scraping drive mechanism is connected with the mud scraping transmission mechanism which is connected with the mud scraping mechanism; when in use, the stirring mechanism and the mud scraping mechanism are respectively driven by the stirring drive mechanism and the mud scraping drive mechanism, the stirring and mud scraping are enabled to be not interfered and be mutually matched in operation, thus the mud and sand processing efficiency is high, and the water processing effect is good; and the machine has simple structure, is convenient in maintenance, and has low manufacturing cost compared with habitually used machine.

Owner:深圳市中邦(集团)建设总承包有限公司

Method for preparing fermention medium, and producing biological pesticide by using wastewater from fermentation

ActiveCN1916155AImprove processing rateReduce processing costsMicroorganismsWater/sewage treatmentMonosodium glutamateFermentation

This invention relates to a method for preparing fermentation culture medium and producing biological pesticide from fermentation wastewater. The method comprises: (1) utilizing fermentation liquid, ethanol wastewater and monosodium glutamate wastewater as the raw materials, and Streptomyces griseus as the strain; (2) fermenting at 28 deg.C and 100-150 rpm for 7-10 days; (3) filtering, concentrating and purifying to obtain biological pesticide. The method utilizes fermentation wastewater to prepare fermentation culture medium and produce biological pesticide, thus can effectively combine the treatment of fermentation wastewater and utilization of useful resources in fermentation wastewater. The treatment rate is high and the cost is low. Besides, the method for produing biological pesticide has such advantages as simple process, low cost, high productivity, and low probability of culture medium pollution and good antibacterial effect of the biological pesticide.

Owner:CHINA NAT RICE RES INST

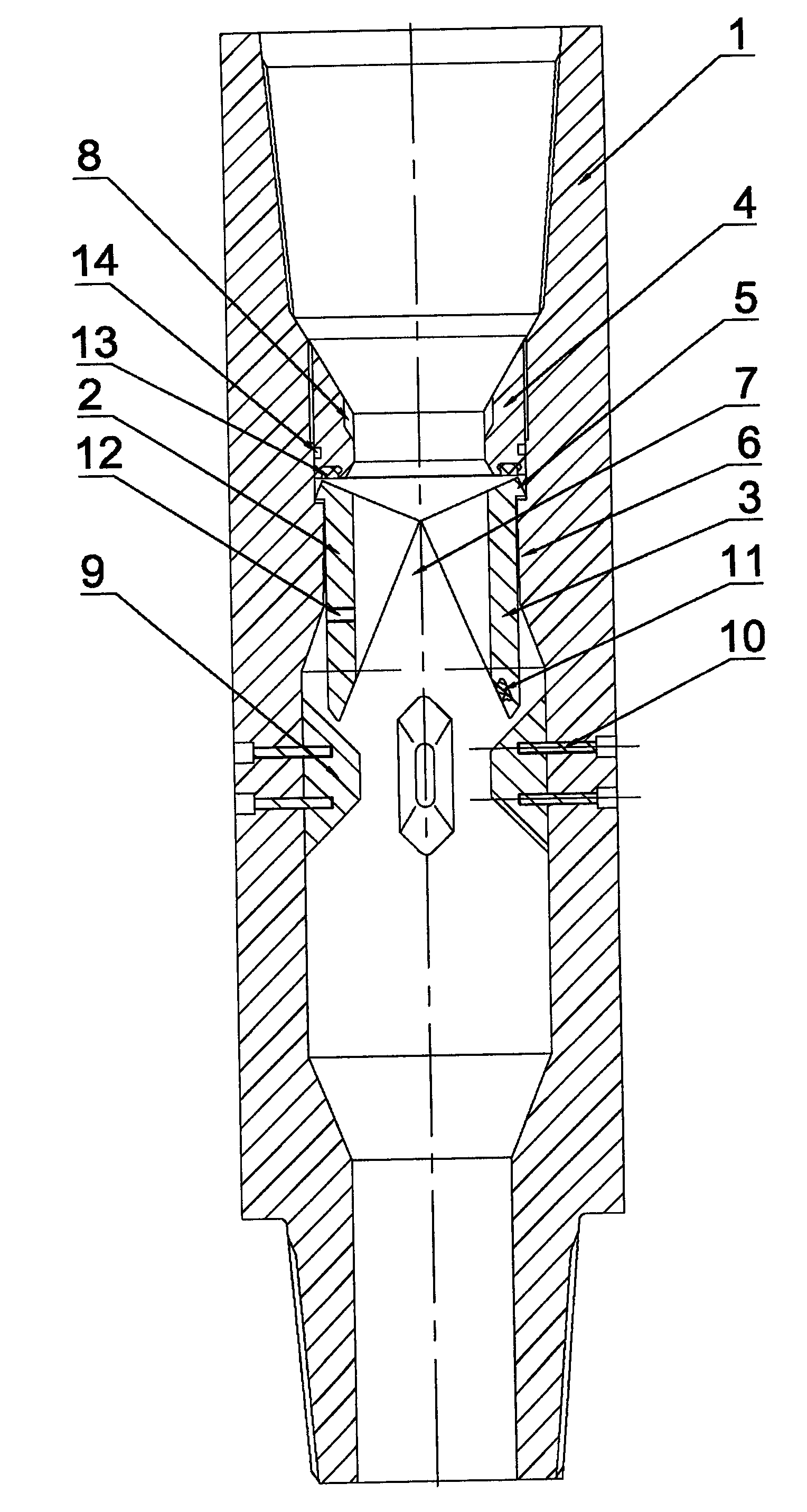

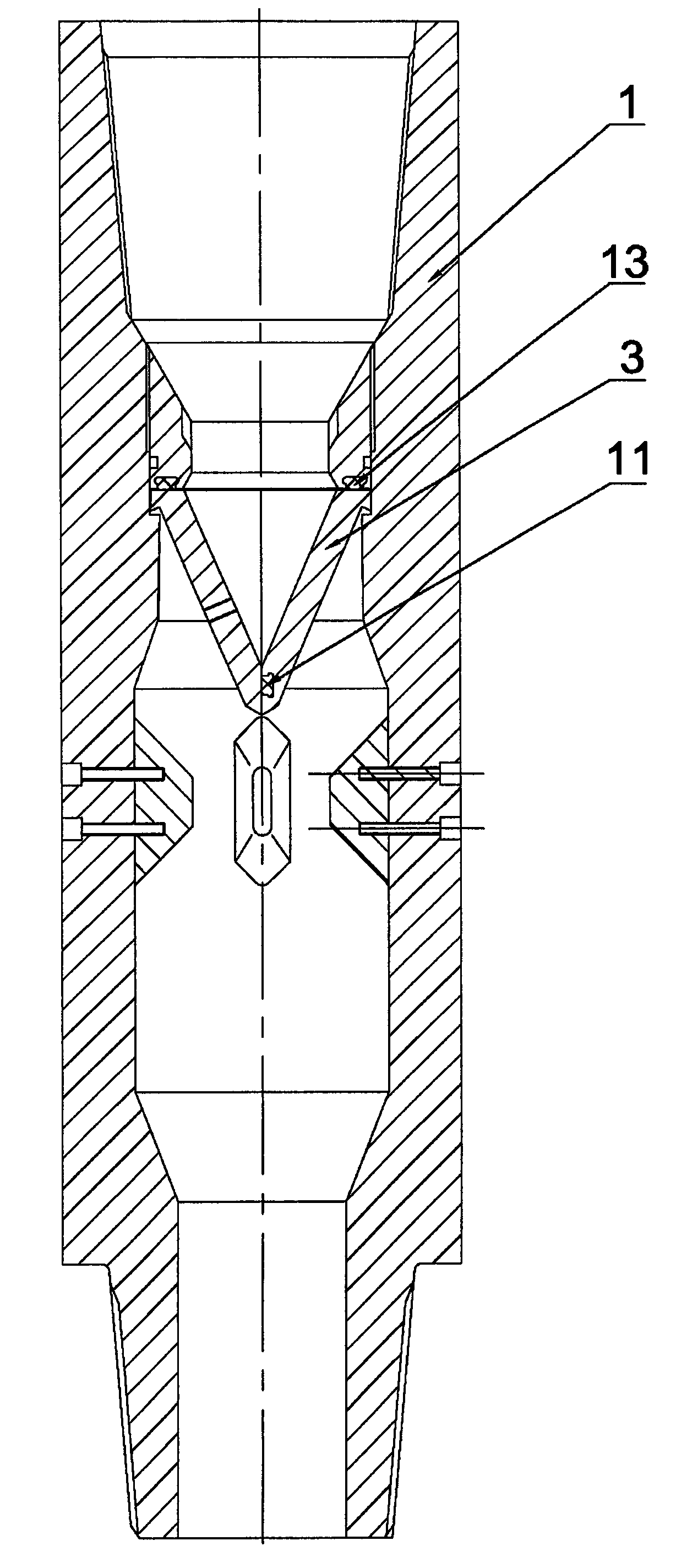

Inner blowout preventer of full-port drilling tool

ActiveCN101629480AImprove erosion resistanceNo erosionWell/borehole valve arrangementsSealing/packingSEMI-CIRCLEWell drilling

The invention relates to an inner blowout preventer of a full-port drilling tool. A valve body is internally provided with a passage and a lug boss; a left valve plate and a right valve plate are semi-circle conical; and the upper ends of the left valve plate and the right valve plate are respectively provided with outer flanges which are hung on the upper end surface of the lug boss and are in an open state so that the passage is in a through state. The invention has reasonable and compact structure and convenient use; and the conical valve plates can be fully opened in a positive cycle or static state to smoothen the passage of the drilling tool so as to reduce circulating pressure loss, basically have no erode to a valve core and carry out corresponding drilling operation by various instruments and tools with outside diameters smaller than a certain size. The inner blowout preventer of the full-port drilling tool can be automatically closed under the push of liquid dynamic power soas to take the blowout-preventing effect in case of blowouts in the drilling tool during the drilling operation, thereby not only extremely improving the processing rate during downhole accidents, but also improving the anti-erosion capability of the valve and further measuring the pressure of a vertical pipe.

Owner:中国石油集团西部钻探工程有限公司准东钻井公司

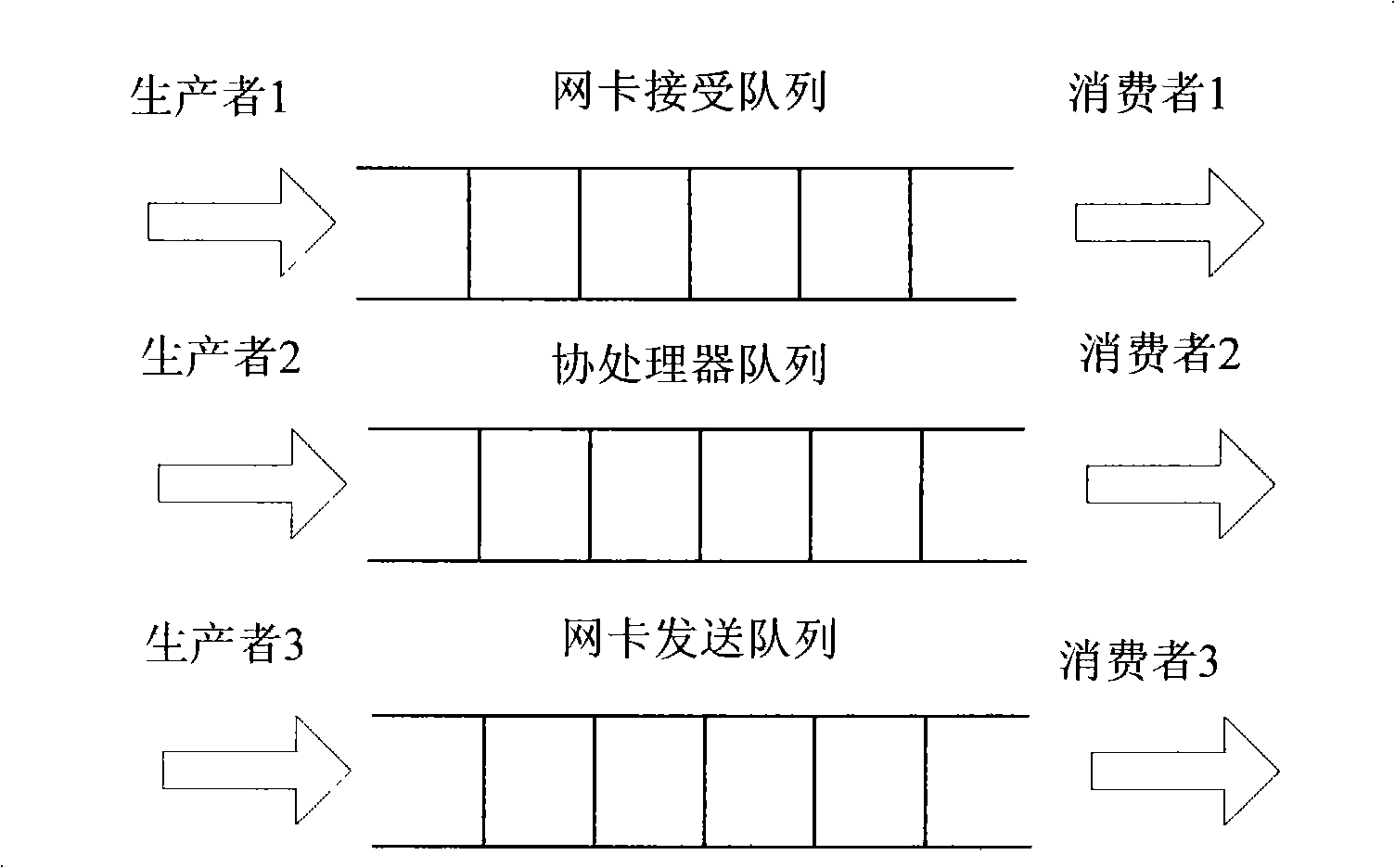

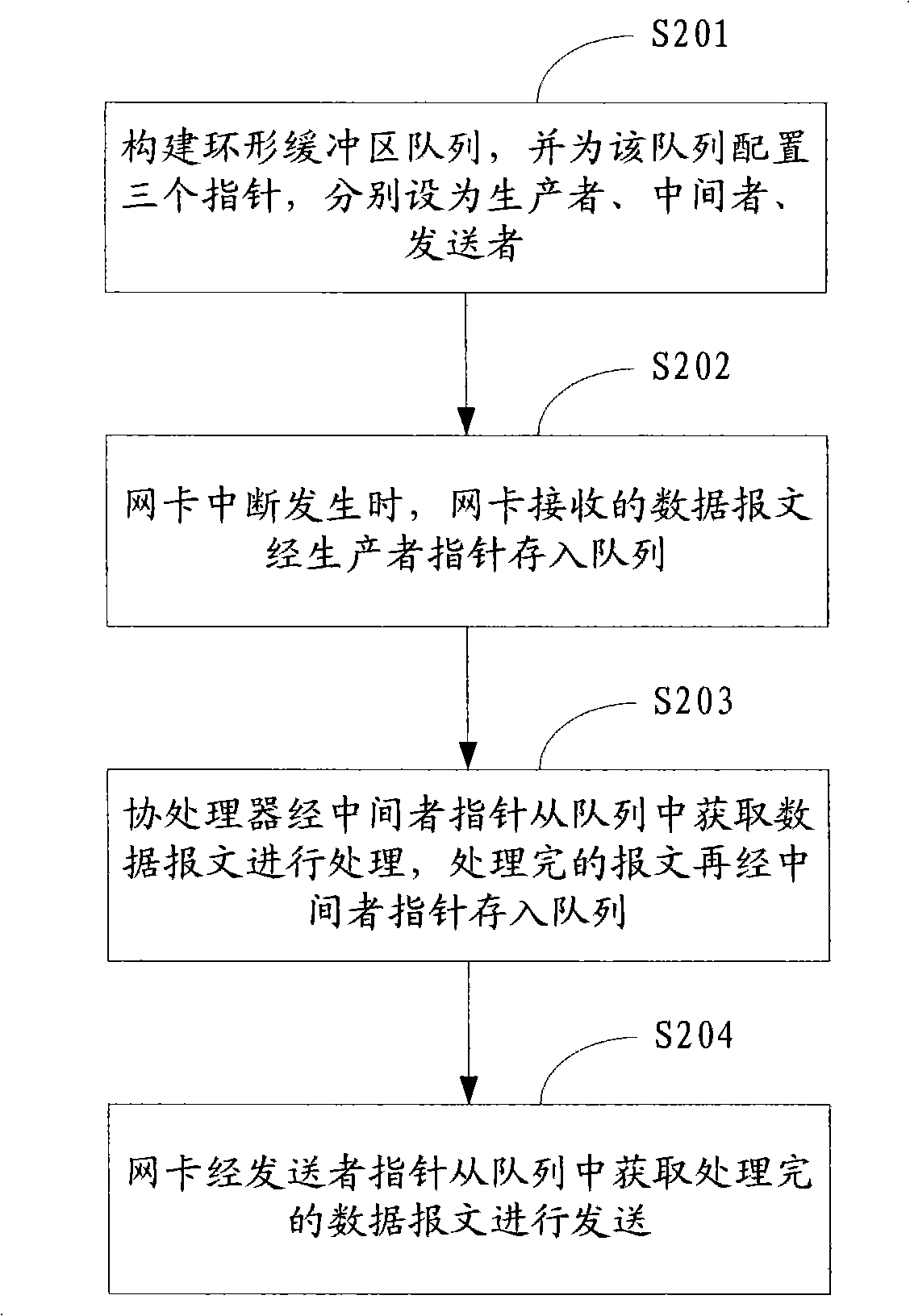

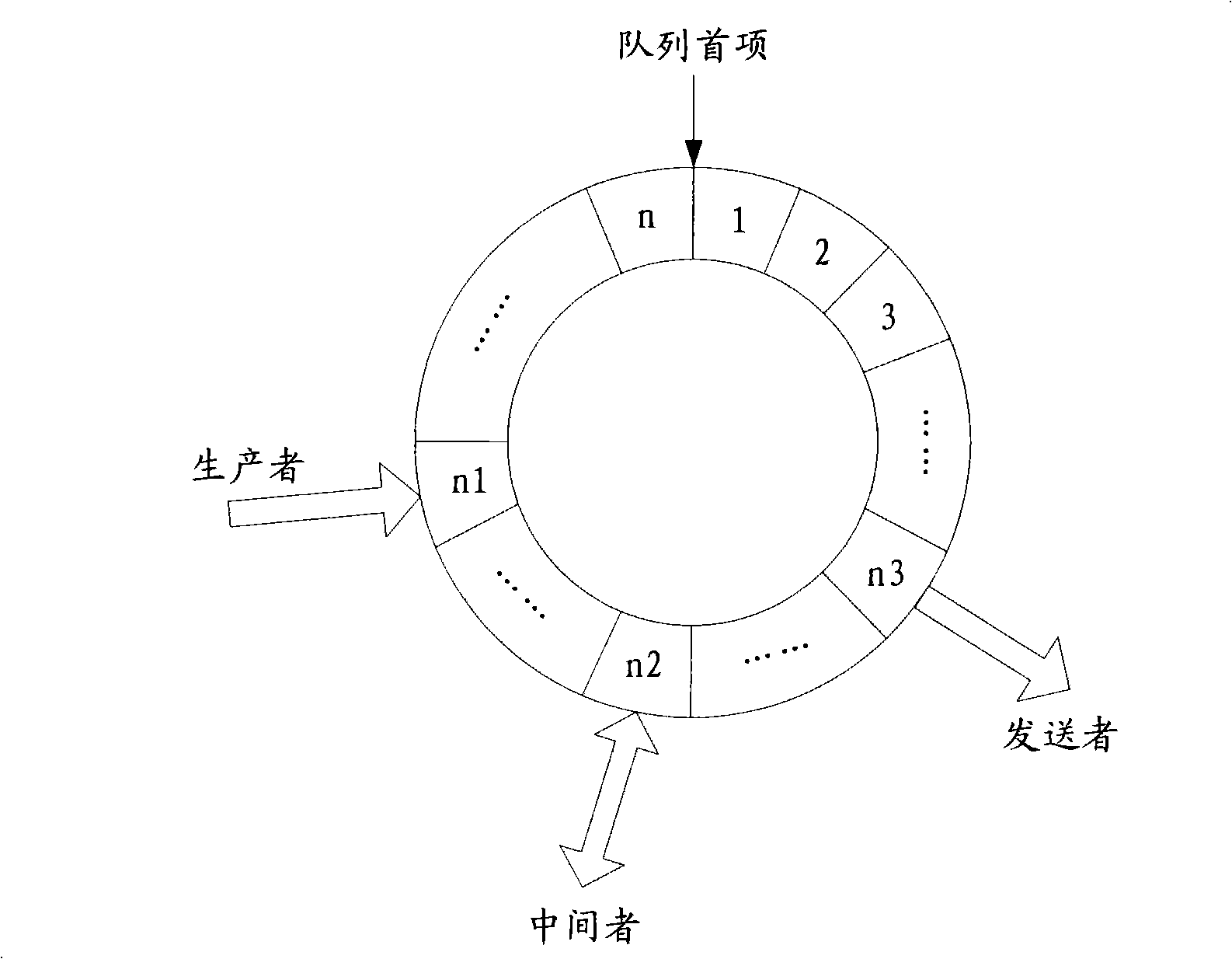

Network datagram processing method, system and device

InactiveCN101309261AImprove processing rateImprove utilization efficiencyData switching networksData transmissionSynchronism

The invention is applicable to the data communication field and provides a network data message processing method, a system and a device; the processing method includes that a ring buffer queue is constructed; the queue is configured with three pointers, including a generator pointer, an intermediate pointer and a sender pointer; the data message received by a network processor and unprocessed by a coprocessor is stored in the ring buffer queue through the generator pointer; the coprocessor acquires the data message from the ring buffer queue through the intermediate pointer for processing the data message; the processed data message is stored in the ring buffer queue through the intermediate pointer; the network processor acquires the data message processed by the coprocessor from the ring buffer queue and sends the processed data message through the sender pointer. Compared with the prior art, the network data message processing method can greatly reduce the cost brought by the data transmission and synchronism sustaining and improve the processing rate of the data message and the utilization rate of the coprocessor greatly.

Owner:成都卫士通信息产业股份有限公司

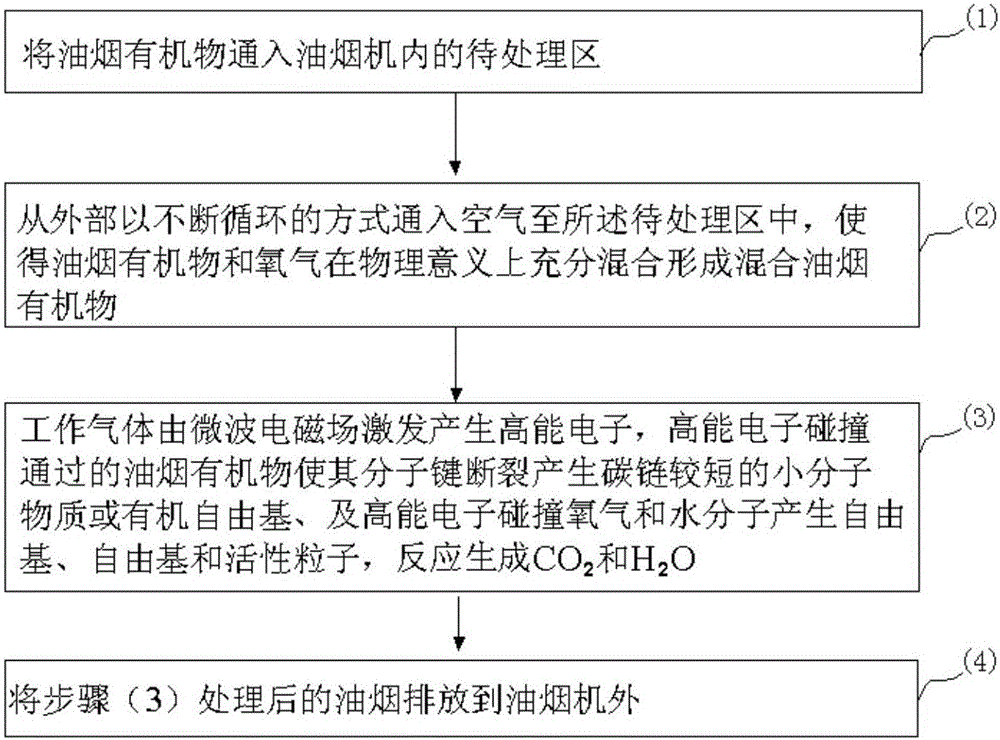

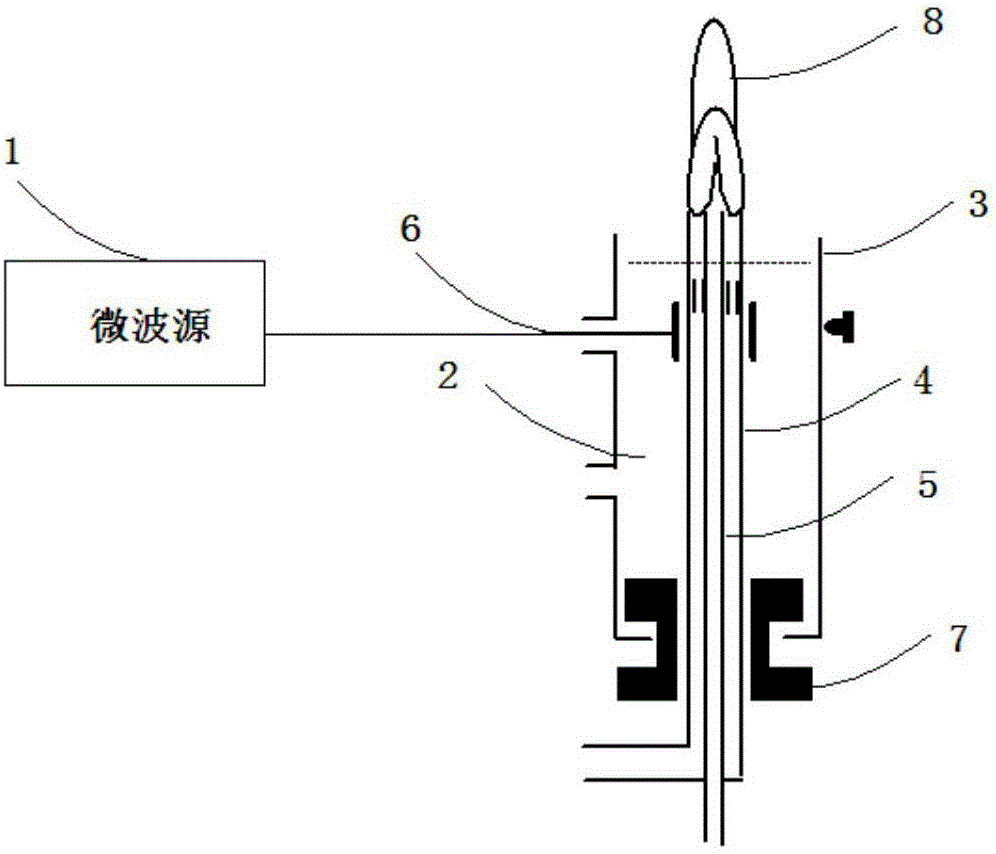

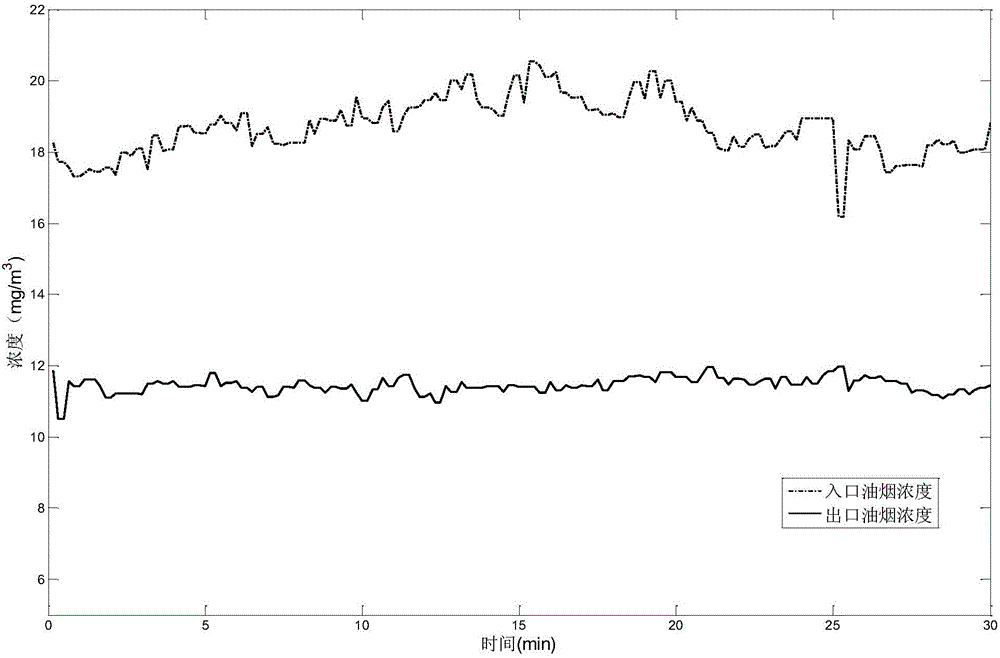

Method for purifying cooking fume organic matter

ActiveCN105148693AAvoid pollution problemsImprove processing rateDispersed particle separationPlasma torchAmount of substance

The invention provides a method for purifying cooking fume organic matter. The method includes: air is fed into a to-be-processed area in a constant circulation manner to allow the cooking fume organic matter and oxygen to be physically sufficiently mixed to form mixed cooking fume organic matter; working gas at the starting end of the torch tube of a microwave plasma torch device is stimulated by a microwave electromagnetic field to generate high-energy electrons, the mixed cooking fume organic matter in the to-be-processed area is allowed to pass the plasma flame of the microwave plasma torch device, the high-energy electrons collide with the passing cooking fume organic matter to allow the molecular bonds of the cooking fume organic matter to sequentially break according to bond energy magnitude so as to generate small molecular substances and / or organic free radicals, the high-energy electrons collide with oxygen and water molecules to generate O free radicals, OH free radicals and active particles, and the small molecular substances and / or organic free radicals react with the O free radicals, OH free radicals or active particles to generate CO2 and H2O; the processed cooking fume is discharged out of a range hood. The method is suitable for being popularized in domestic range hoods, good in cooking fume removing effect and stable.

Owner:ZHEJIANG SUPCON RES

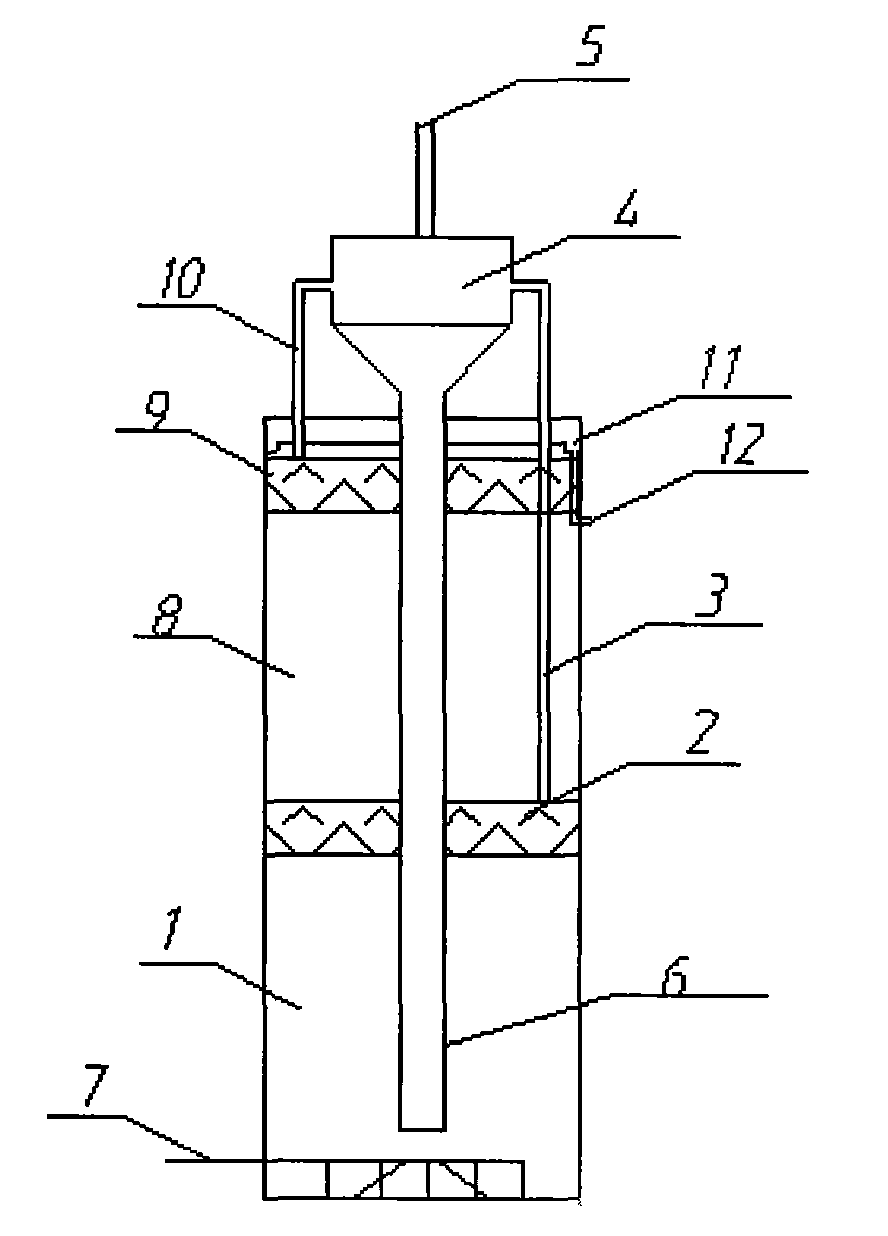

Biogas-lift reinforced anaerobic reactor and application thereof

InactiveCN101597561AImprove stabilityEasy loadingGas production bioreactorsWaste based fuelHigh concentrationReaction rate

A biogas-lift reinforced anaerobic reactor and application thereof belong to the waste recycling processing technical field. In the invention, the anaerobic reactor consists of two anaerobic reaction chambers one above to the other in series. The biogas generated by a first anaerobic chamber at the lower part is taken as power to realize internal recycle of mixed liquid at the lower part, so that reinforced pretreatment can be carried out on waste water; post treatment is continuously carried out on the waste water in a second anaerobic reaction chamber at the upper part, so that water discharge can meet the predetermined treating requirement. The invention has the advantages of high stability and loading and can deal with waste water with high-concentration poisonous substance to generate biogas. In the invention, the composite recycle method containing internal recycle, external recycle and biogas recycle is used to improve mass transferring condition between microorganism and matrix, quicken reaction rate and increase waste water processing efficiency.

Owner:JIANGNAN UNIV

Sewage deep treatment method by using oxygenation filter system

InactiveCN105060488APrevent refillImprove adsorption capacityTreatment with aerobic and anaerobic processesChemical oxygen demandTotal nitrogen

The invention discloses a sewage deep treatment method by using an oxygenation filter system. The method is implemented by establishing an oxygenation filter system, wherein the oxygenation filter system comprises a sewage deep treatment tank in which a filter layer is arranged. Domestic sewage is sufficiently oxygenated through an oxygenation device, and sent into the sewage deep treatment tank through a water inlet pump; the sewage flowing out of a water distributor passes through the filter layer from bottom to top; a porous sintered ceramic granule filter material with developed pore structure can provide an attachment space for microbial films; the growth of the microbial films can enhance the removal effect on COD (chemical oxygen demand) and ammonia nitrogen in the sewage; as the water flow ascends, the dissolved oxygen content in the sewage gradually decreases, and an anoxic layer is formed on the upper part of the filter layer, thereby implementing the denitrification action and lowering the total nitrogen content in water; and since the filter layer has favorable adsorption and entrapment actions, the (suspended sediment) SS content in the sewage is lowered. The oxygenation filter system is small in occupied area and simple to operate, does not need to clean the filter layer after shutdown, and provides favorable conditions for removing COD, ammonia nitrogen and TN (total nitrogen).

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

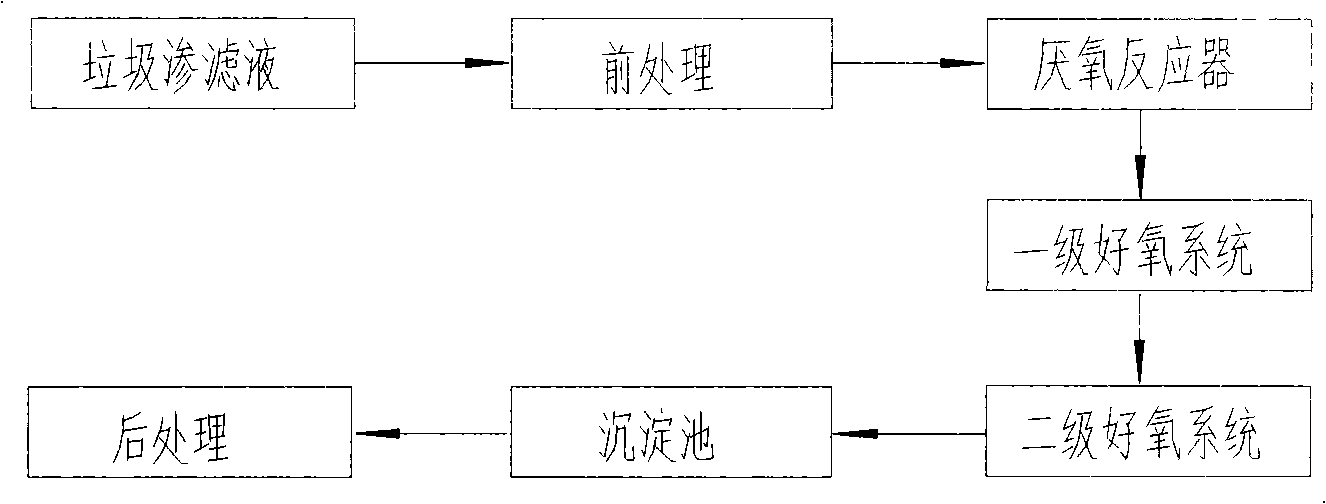

Garbage percolate treatment method

InactiveCN101591124ASolve Chroma ProblemsPurify effluent water qualityMultistage water/sewage treatmentContaminated groundwater/leachate treatmentNitrationAnaerobic reactor

The invention discloses a garbage percolate treatment method, and belongs to the technical field of waste resource treatment. The method adopts an anaerobic and aerobic mode to treat garbage percolate, and comprises the following steps that: the garbage percolate is collected in an adjusting tank; after the garbage percolate is evenly stirred, the pH is adjusted, and the garbage percolate is injected into an anaerobic reactor and subjected to anaerobic fermentation at a temperature of between 30 and 39 DEG C; the anaerobic effluent enters a primary aerobic system, the flow rate of the water in an aerobic tank reaches 0.2 to 1 meter per second under the action of an aeration device, then a biochemical environment with a high dispersion system and high transfer mass is formed in a reaction tank, and the wastewater is subjected to high-strength oxidation treatment; the garbage percolate enters a secondary aerobic system and is subjected to anaerobic, facultative aerobic and aerobic multi-level circulating treatment, and ammonia and nitrogen are fully discomposed and removed under the circular action of denitrification and nitration; the secondary aerobic effluent is subjected to coagulation treatment in a sedimentation tank, and the effluent color is solved; and the sludge is used for reflowing and fertilizing gardens and parks. By applying the method, the clean energy source which is methane can be acquired, and the aim of the garbage percolate can be treated at low cost.

Owner:JIANGNAN UNIV

High-efficiency multifunctional remover and preparation method thereof

ActiveCN104176810AImprove processing rateEfficient and thorough removalWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationLiquid productOrganic matter

The invention relates to a high-efficiency multifunctional remover and a preparation method thereof. The remover is prepared from 99-99.5mass% of sodium hypochlorite, 0.05-0.2mass% of potassium permanganate, 0.15-0.3mass% of potassium ferrate and 0.3-0.5mass% of polyferric sulfate. The preparation method of the remover comprises the following steps: adding 99-99.5mass% of sodium hypochlorite into a reaction kettle, stirring for dissolving sodium hypochlorite, adding 0.05-0.2mass% of potassium permanganate, stirring for 0.5-1h until complete dissolving, adding 0.15-0.3mass% of potassium ferrate, stirring and reacting for 0.5-1h, finally adding 0.3-0.5mass% of polyferric sulfate, and stirring for 0.5-1h until complete dissolving in order to obtain a purple red liquid product. The interaction of three strong oxidants, different timeliness to organic matters and the flocculation of polyferric sulfate allow the highest removal rate of organic pollutants to reach 95% and the cost to only account for 1 / 10 of the cost of an ordinary remover, so the remover provided by the invention has the advantages of high processing efficiency and low cost.

Owner:浙江杭海新城控股集团有限公司

Method for prevention and treatment of industrial pollution by comprehensively utilizing plant straw

InactiveCN107303578AIncrease production costReduce processing difficultySolid waste disposalTransportation and packagingSocial effectsHydrolysis

The invention provides a method for prevention and treatment of industrial pollution by comprehensively utilizing plant straw. The method includes the steps that the plant straw is smashed and added with water for high-temperature boiling treatment, and then hot water is used for washing; H2SO4 is added to solid matter after high-temperature boiling for continuous hydrolysis treatment, filtering is conducted after hydrolysis is completed, and hydrolyzed liquid is used as a raw material for manufacturing xylose; a NaOH solution is added into the hydrolyzed solid matter for high-temperature alkali cooking treatment and filtering is performed; the solid matter subjected to high-temperature alkali cooking treatment is used as a raw material for making paper or producing carboxymethylcellulose; and a HCl solution is added into the liquid subjected to high-temperature alkali cooking treatment for high-temperature acid cooking treatment, filtering is performed, the solid matter is used as a raw material for producing lignin, and filter liquor is evaporated into NaCl. By the adoption of the method, the plant straw is comprehensively utilized, pollution to the environment by making paper with the plant straw is removed, and the social effect and economic effect are good.

Owner:刘从荡

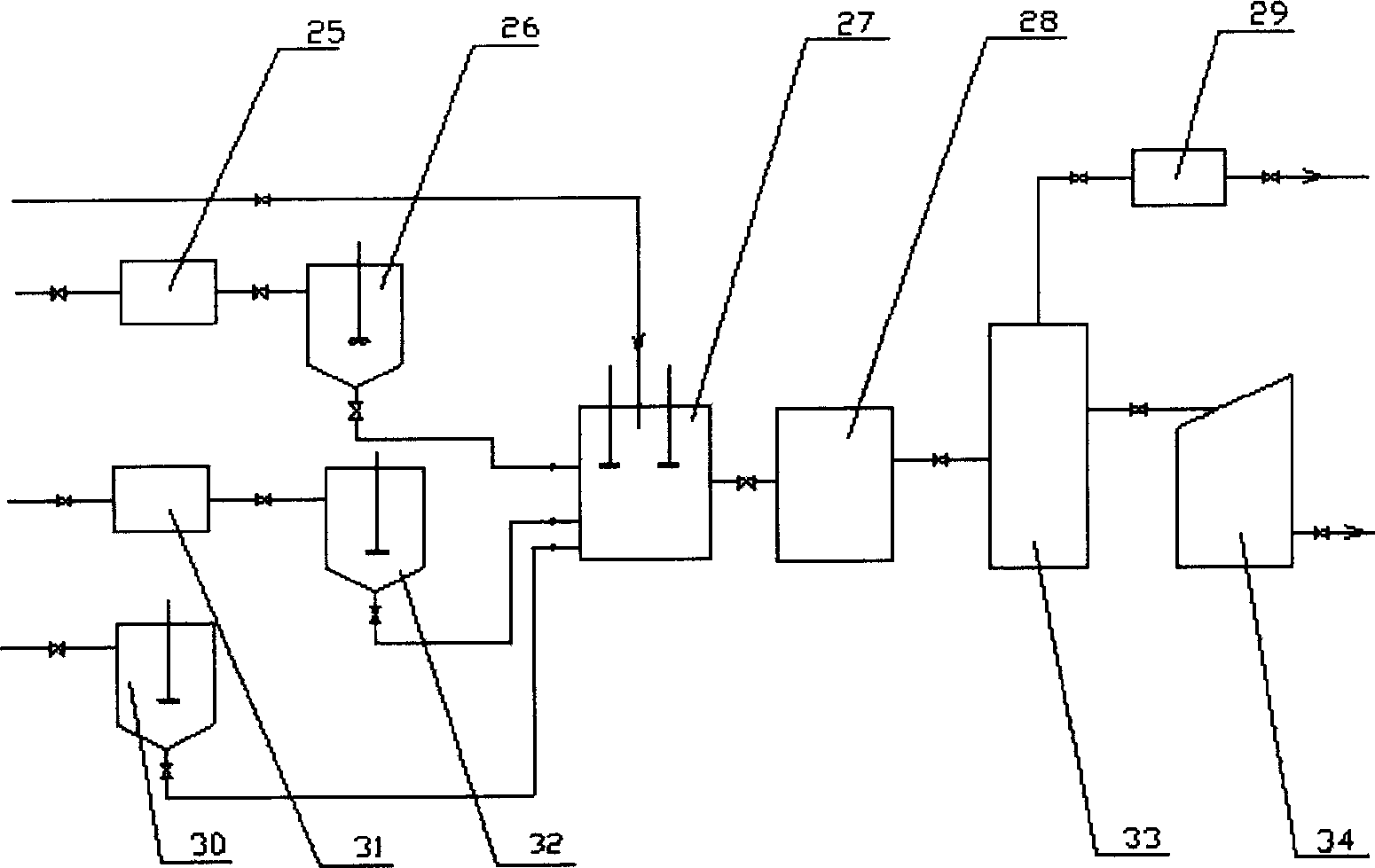

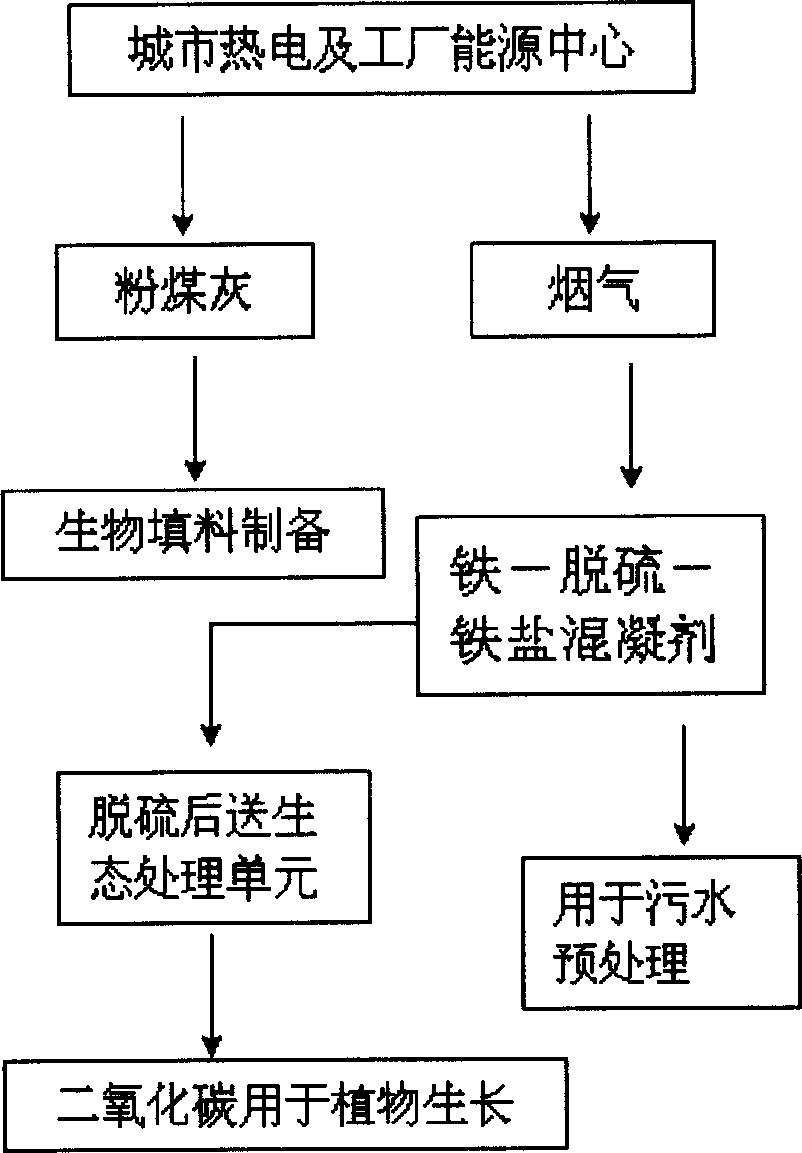

Method and apparatus for treating urban sewage by means of flue gas desulfurization of power plant and fly ash

InactiveCN1699208AImprove processing rateEasy to handleSolid waste disposalDispersed particle separationSlagReclaimed water

Disclosed is a method and apparatus for treating urban sewage by means of flue gas desulfurization of power plant and fly ash, which integrate the utilization of waste water, waste gas and waste slag in environmental engineering, by reutilizing industrial waste, the urban sewage water can be reused and meet the national standard for recycled water after ecological treatment, the problem of coal ash depositing is also solved.

Owner:DALIAN UNIV OF TECH

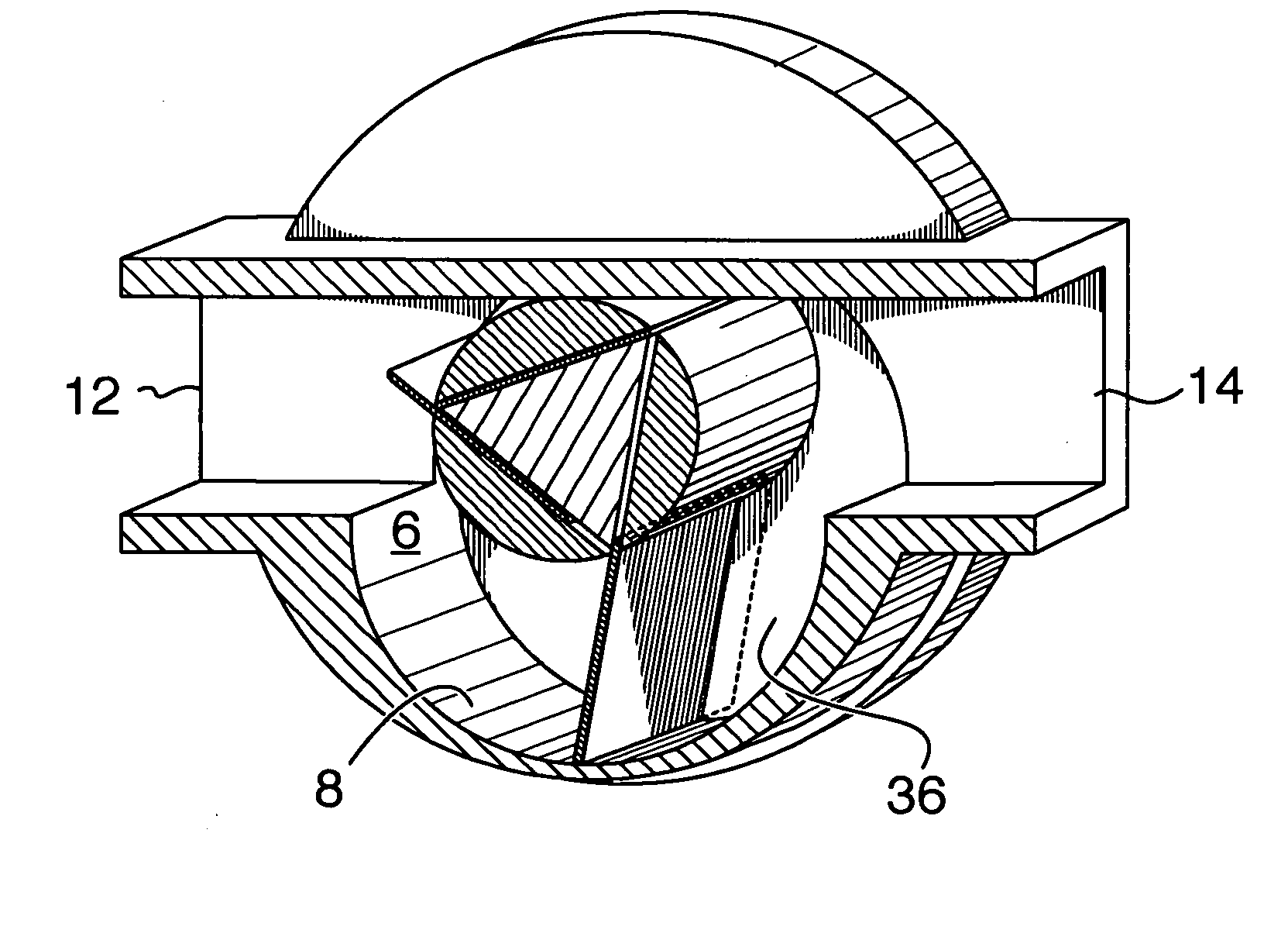

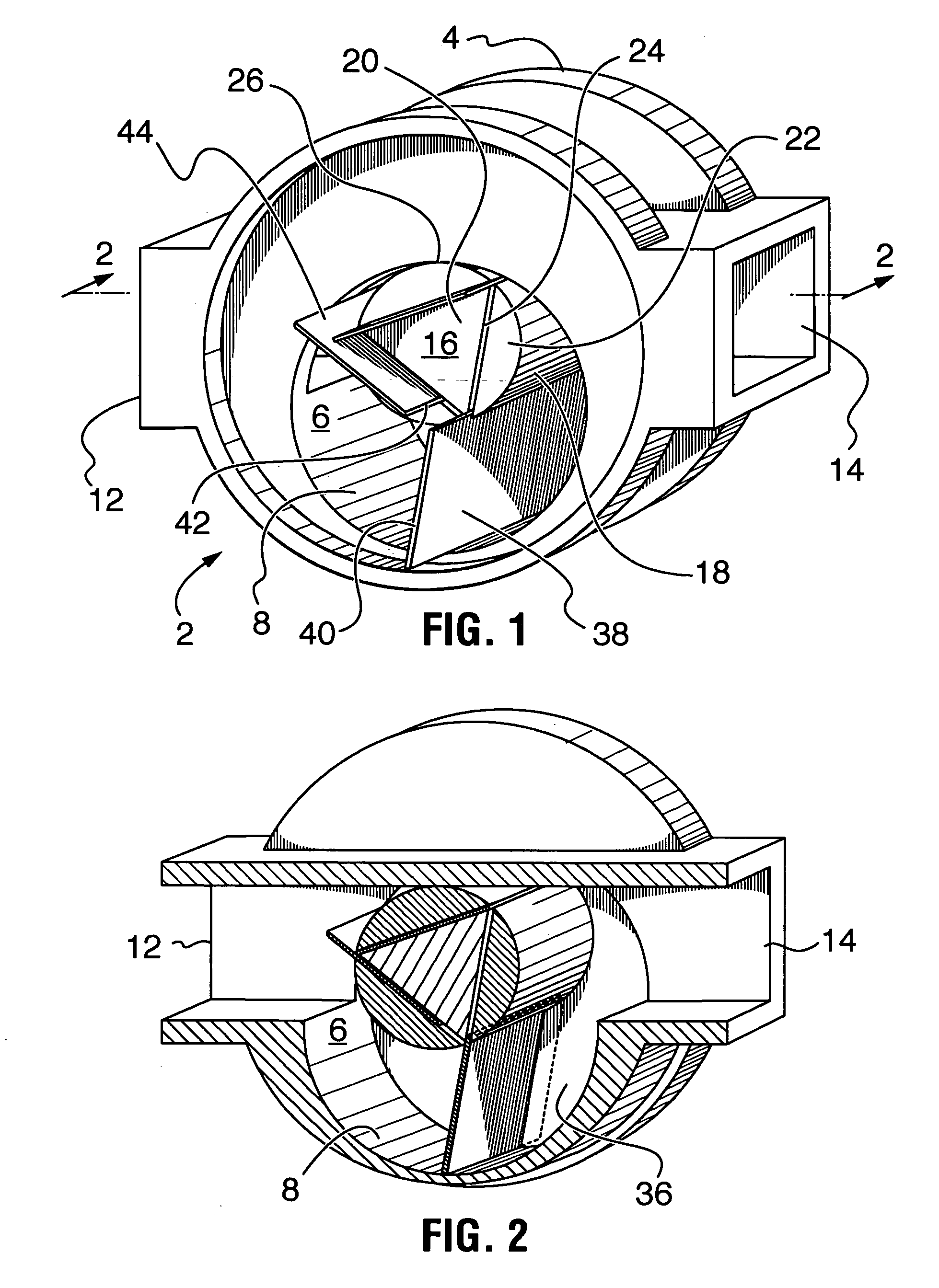

Fluid cannon positive displacement pump

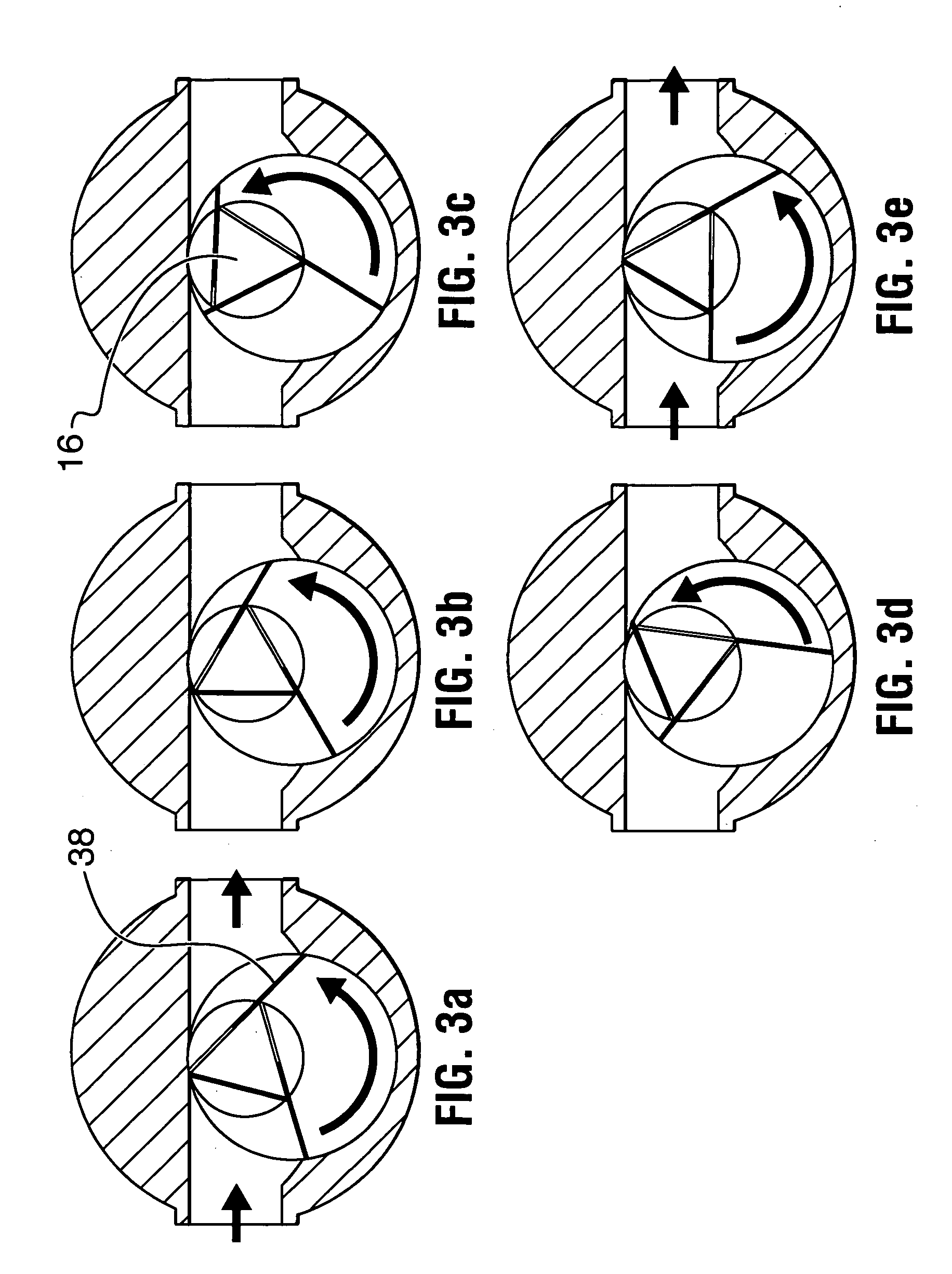

ActiveUS6896502B1Great vane surface areaImprove processing rateOscillating piston enginesRotary piston pumpsEngineeringPositive displacement pump

A positive displacement pump comprising a casing having an interior chamber and an inlet and an outlet oppositely spaced within the chamber. A rotor with a cylindrical outer surface is secured in offset position within the chamber. An end disk is secured to each end of the rotor. Three planar vanes are provided, each having sides and inner and outer edges. The sides of the vanes are seated within the end disk slots. The outer edges of the vanes are in constant contact with the side wall of the chamber. The inner edges of the vanes are constantly movably seated in the rotor slots during operation of the pump. The slots in the rotor within which the vanes are seated are formed along a chord when the rotor is viewed in lateral cross section and are orientated so that their planes lie at 60° angles to the planes of adjacent slots.

Owner:1564330 ONTARIO

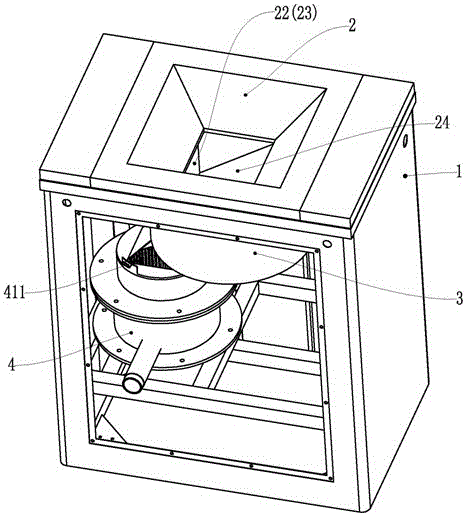

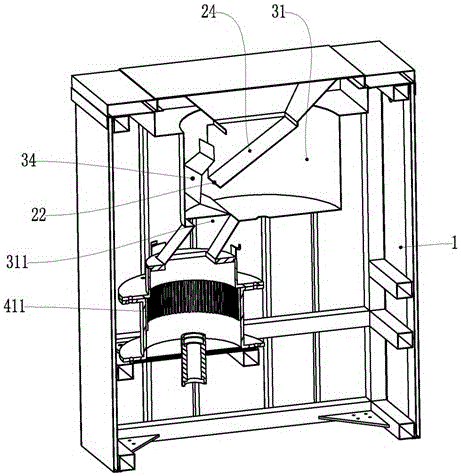

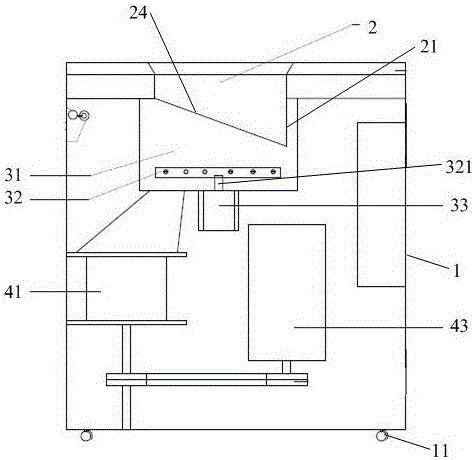

Commercial Waste Food Disposer

ActiveCN103394503BSpeed up entryImprove processing rateSolid waste disposalGrain treatmentsEngineeringFood waste

Owner:邓燕钧

Wastewater treatment agent as well as preparation method and use method thereof

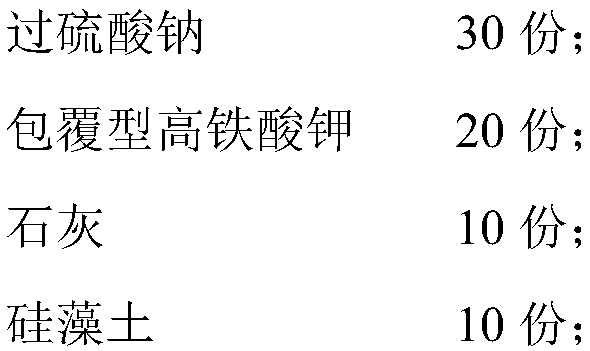

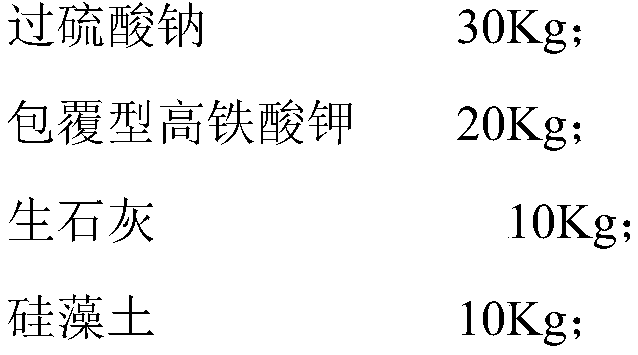

ActiveCN108190976AEasy to handlePromote flocculation and sedimentationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionCompound aPotassium

The invention relates to a wastewater treatment agent as well as a preparation method and a use method thereof. The wastewater treatment agent comprises a compound A and a compound B; the compound A comprises the following components in part by weight: 20 parts of iron carbon sphere particles and 10 parts of citric acid; the compound B comprises the following components in part by weight: 30 partsof sodium persulfate, 20 parts of encapsulation-type potassium ferrate, 10 parts of lime and 10 parts of diatomite; and the mass ratio of the compound A to the compound B is 1:(2-6). In addition, theinvention further provides the preparation method and the use method of the wastewater treatment agent. According to the wastewater treatment agent prepared by the preparation method provided by theinvention and a method for wastewater treatment by the wastewater treatment agent, the treatment time of wastewater can be effectively shortened, and the degradation rates of various substances in thewastewater are improved.

Owner:SHIJIAZHUANG YUANSHENGYUAN ENVIRONMENTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com