Treatment method for mixed organic waste gas containing chlorine, hydrogen chloride and oxynitride

A technology for nitrogen oxides and organic waste gas is applied in the treatment of hydrogen chloride and nitrogen oxides mixed organic waste gas and in the field of chlorine-containing gas. Treatment, achieving continuity and economic operational feasibility, effect to cover operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

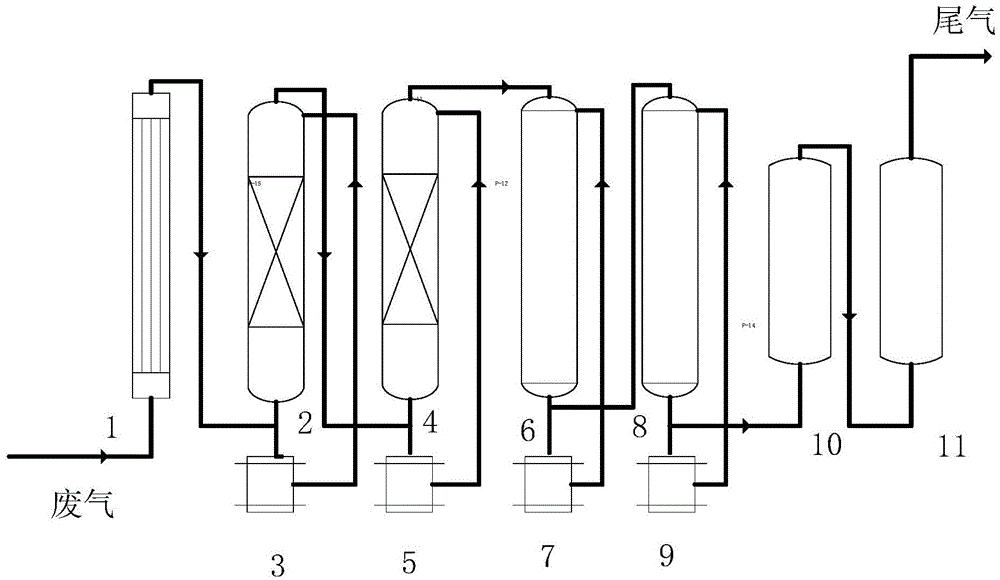

Image

Examples

Embodiment 1

[0050] 2,6-dichlorobenzonitrile is an intermediate of various herbicides and insecticides. The 2,6-dichlorobenzonitrile project of a factory produces chlorine gas and hydrogen chloride through chlorination, hydrolysis condensation, filtration, and rectification processes. , formic acid, nitric oxide, nitrogen dioxide, pyridine tail gas. Containing nitrogen oxides 56000mg / m 3 , Chlorine 68000mg / m 3 , hydrogen chloride 260000mg / m 3 , organic matter 8000mg / m 3 , exhaust gas at 500m 3 The flow rate per hour enters the condenser, the condensation temperature is 20°C, and the condensed waste gas enters the bottom of the first-stage packed tower, where the concentration of urea in the first packed tower is 15%, absorbing countercurrently with the waste gas from the bottom of the tower, and spraying Density is 50m 3 / m 2 h, the residence time of the waste gas is 18s, the absorption temperature is 50°C, the waste gas from the first packed tower enters the second packed tower from...

Embodiment 2

[0052] 2,4-Dichlorofluorobenzene is an intermediate in the synthesis of the broad-spectrum antibiotic ciprofloxacin. A company uses o-dichlorobenzene as raw material to synthesize 2,4-dichlorofluorobenzene through nitration, fluorination, chlorination, and rectification. The waste gas is mainly produced during the chlorination process, and its main components are chlorine, nitrogen oxides and Organic waste gas. Containing nitrogen oxides 3060mg / m 3 , Chlorine 7520mg / m 3 , hydrogen chloride 510mg / m 3 , organic waste gas 700mg / m 3 , exhaust gas at 200m 3 The flow rate of / h enters the condenser, the condensation temperature is 5°C, and the condensed exhaust gas enters the bottom of the first-stage packed tower. The urea concentration in the first packed tower is 10%, and it absorbs countercurrently with the tail gas from the bottom of the tower and sprays it. Density is 18m 3 / m 2 h, the waste gas residence time is 8s, the absorption temperature is 40°C, the tower diamete...

Embodiment 3

[0054] 1,2,4-Trichlorobenzene is an organic intermediate with a wide range of uses. It can be used not only as a solvent, but also as a raw material for the synthesis of medicines and pigments. A company uses 2,4-dinitrochlorobenzene to synthesize 1,2,4-trichlorobenzene by chlorination. During the synthesis process, there will be unreacted chlorine, nitrogen oxides and organic waste gas. Containing nitrogen oxides 4180mg / m 3 , Chlorine 6230mg / m 3 , hydrogen chloride 1620mg / m 3 , organic waste gas 4460mg / m 3 , exhaust gas at 100m 3 The flow rate of / h enters the condenser, the condensation temperature is 0°C, and the condensed exhaust gas enters the bottom of the first-stage packed tower. The urea concentration in the first packed tower is 10%, and it is absorbed countercurrently with the tail gas from the bottom of the tower and sprayed. Density is 24m 3 / m 2 h, the waste gas residence time is 11s, the absorption temperature is 45°C, the diameter of the packed tower is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com