Patents

Literature

1026 results about "Cl element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorine is a chemical element with symbol Cl and atomic number 17. The second-lightest of the halogens, it appears between fluorine and bromine in the periodic table and its properties are mostly intermediate between them. Chlorine is a yellow-green gas at room temperature.

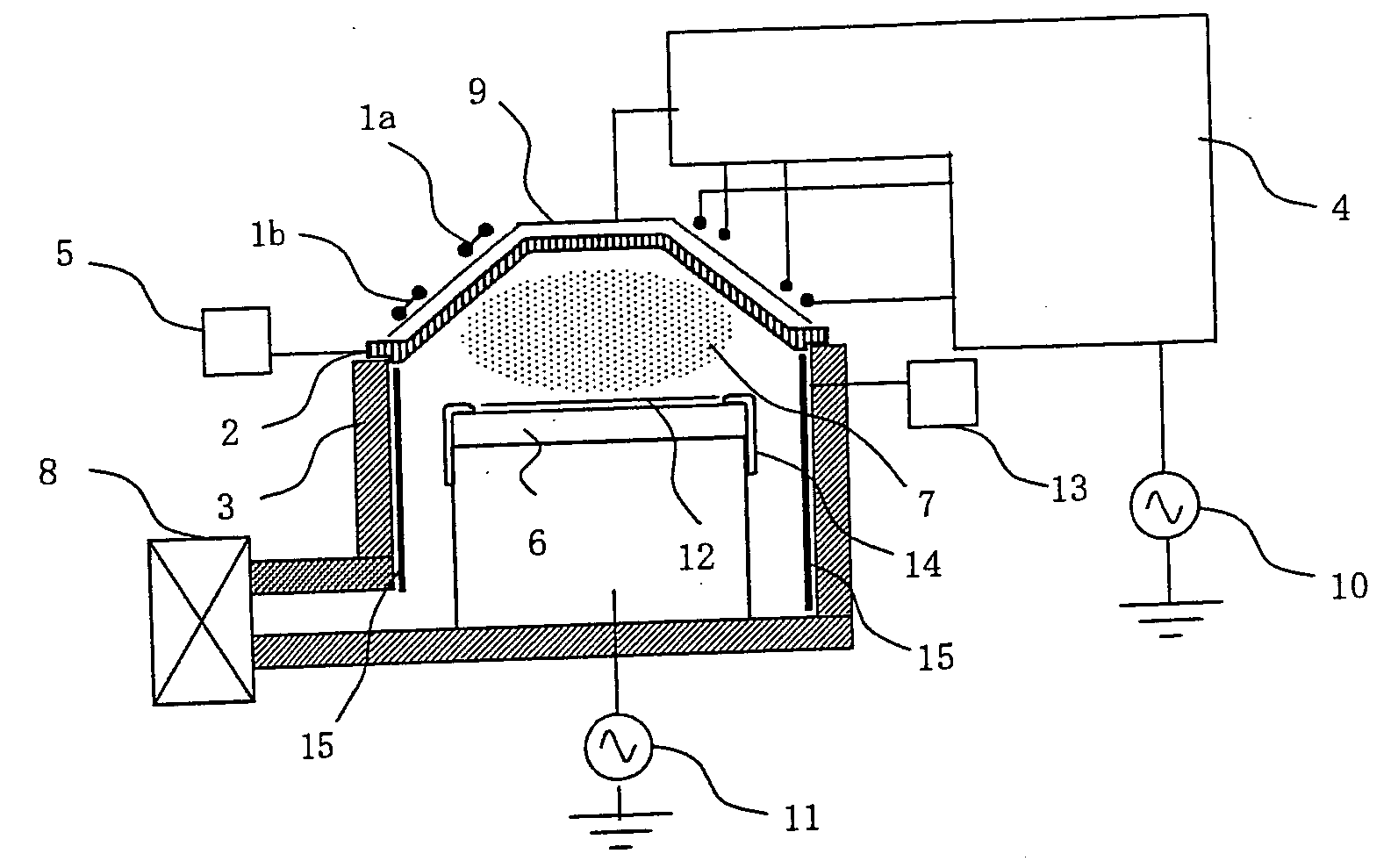

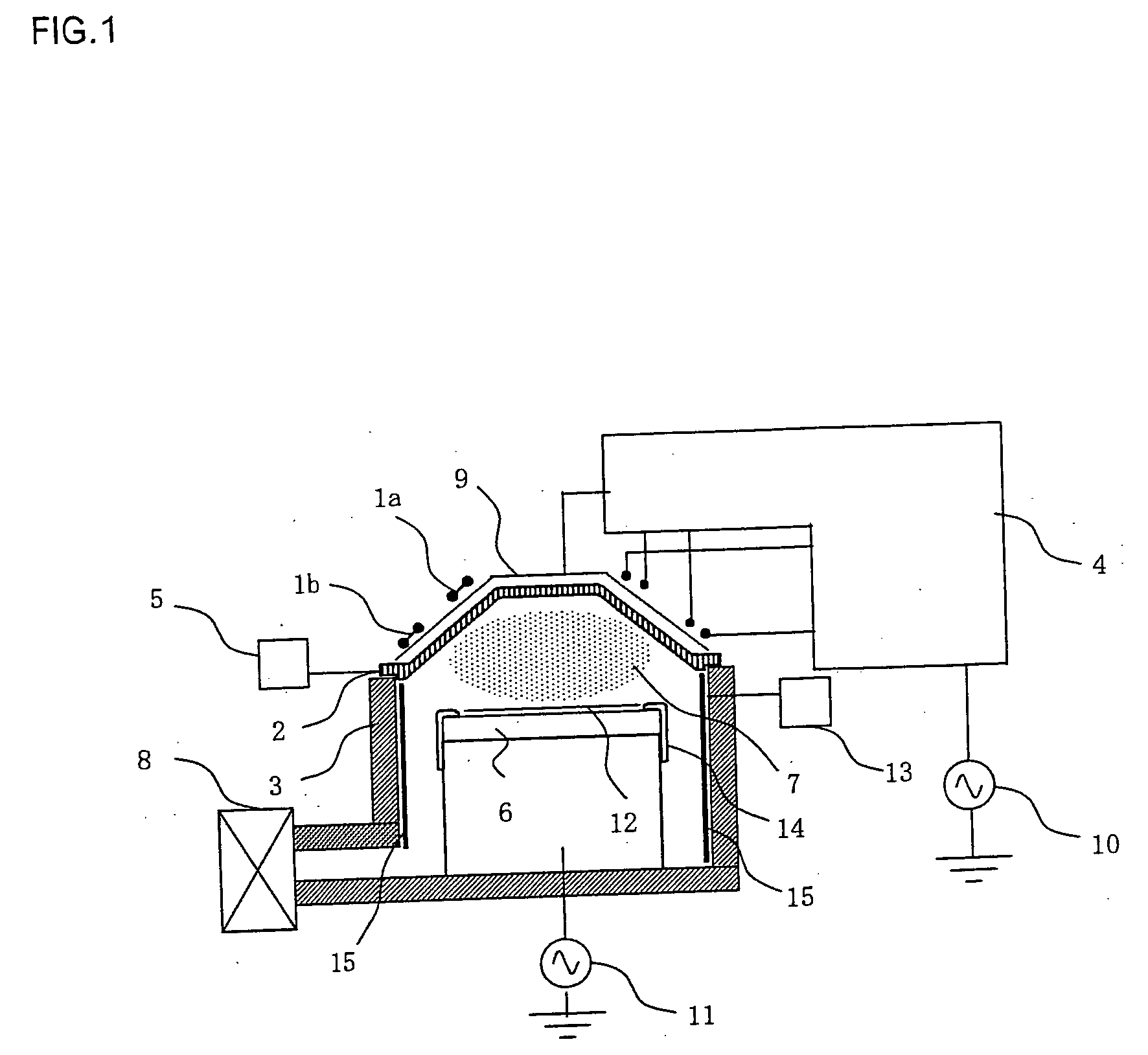

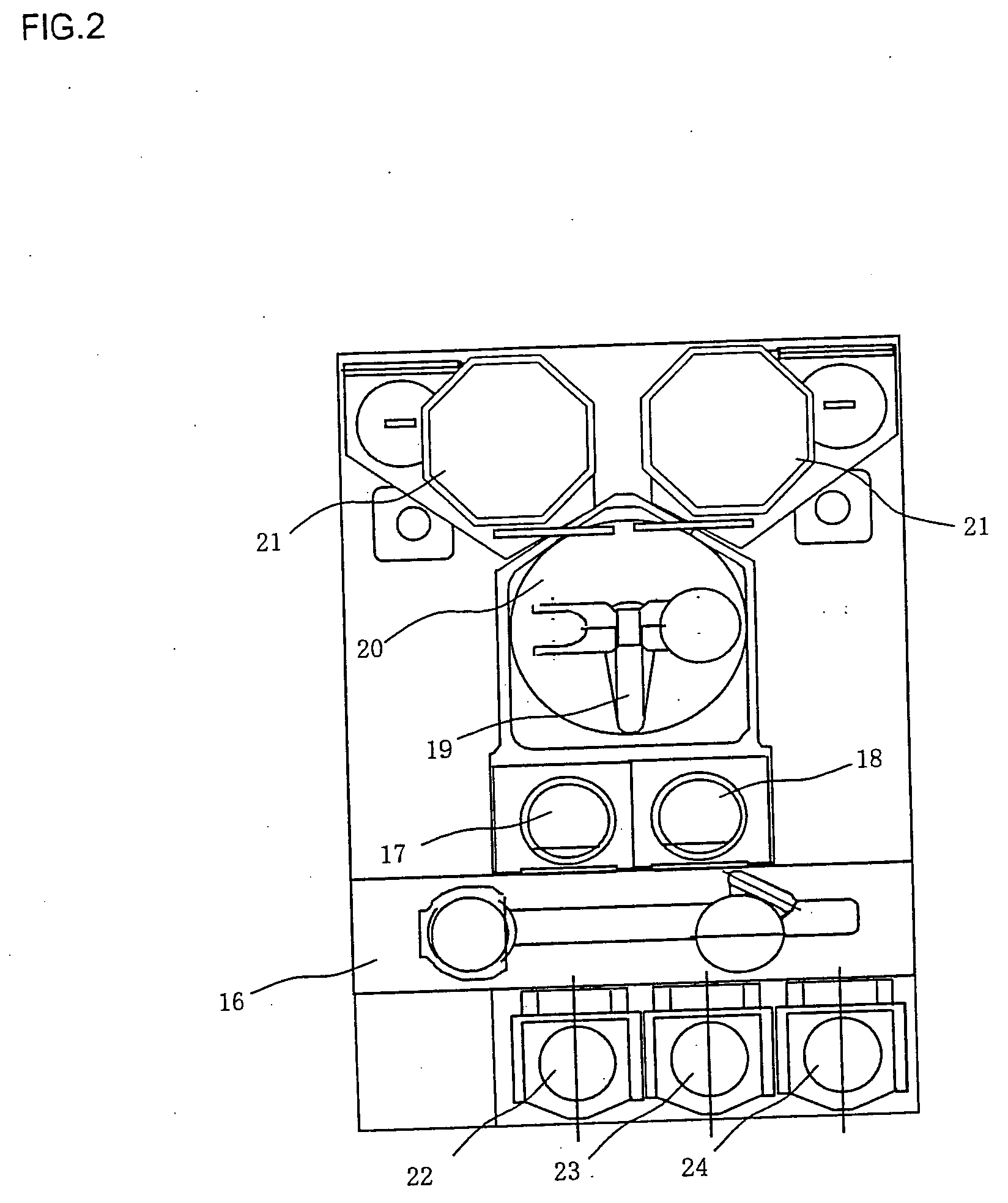

Method of cleaning etching apparatus

ActiveUS20060191555A1Clean interiorMaintain repeatabilityHollow article cleaningElectrostatic cleaningBoron trichlorideOxygen

To provide a cleaning method for an etching apparatus for a metal film that efficiently removes an etching residue deposited in an etching process chamber, assures the reproducibility of the etching performance, and keeps the etching process chamber in a low-dust-emission condition. Each time one workpiece with a metal film is etched (S1), the interior of the vacuum chamber is cleaned by replacing the workpiece with a dummy substrate (S2), performing a first step of plasma processing using oxygen (O2) and carbon tetrafluoride (CF4) to remove a carbon-based deposit pile (S3), and performing a second step of plasma processing using boron trichloride (BCl3) and chlorine (Cl2) to remove a residue that could not be removed by the first step and an etching residue of the metal film (S4).

Owner:HITACHI HIGH-TECH CORP

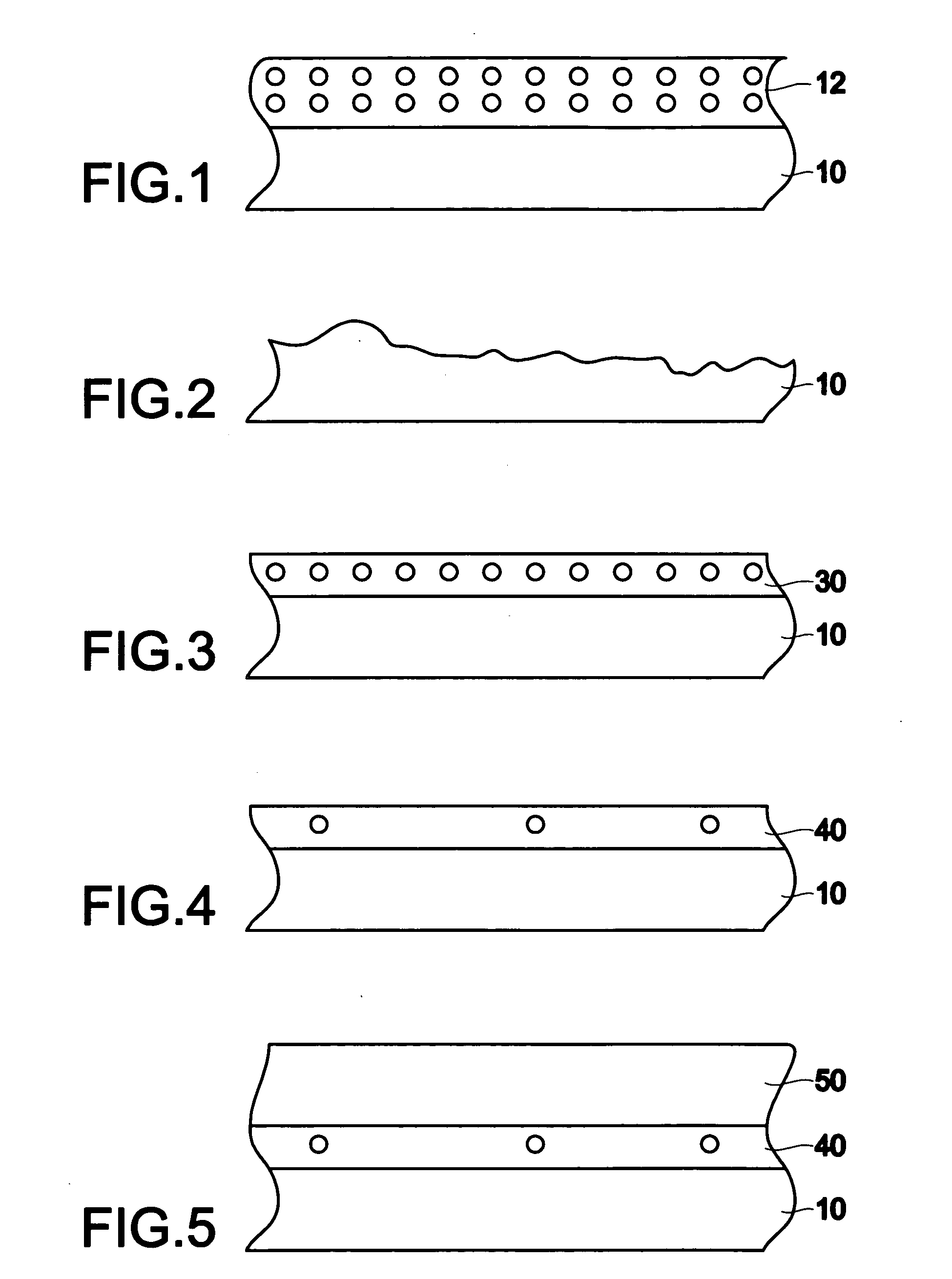

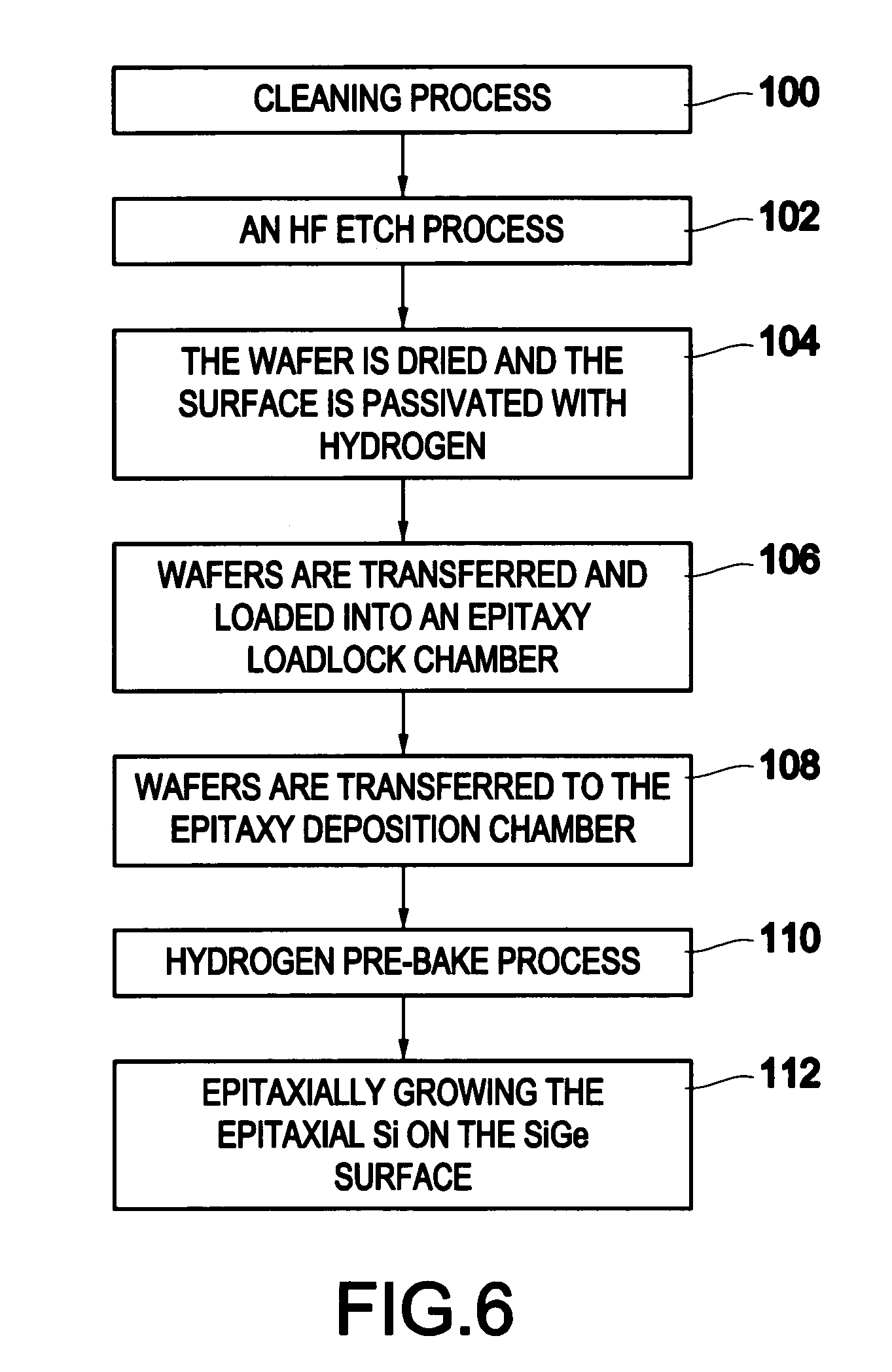

Method of preventing surface roughening during hydrogen pre-bake of SiGe substrates using chlorine containing gases

InactiveUS20050148162A1Prevent surfaceAvoid creatingPolycrystalline material growthSemiconductor/solid-state device manufacturingPartial oxidationSilicon on insulator

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves only a sub-monolayer of oxygen (typically 1×1013-1×1015 / cm2 of oxygen) at the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process in a chlorine containing environment which heats the silicon germanium, strained silicon, or thin silicon-on-insulator surface sufficiently to remove the remaining oxygen from the surface. By introducing a small amount of chlorine containing gases, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:IBM CORP

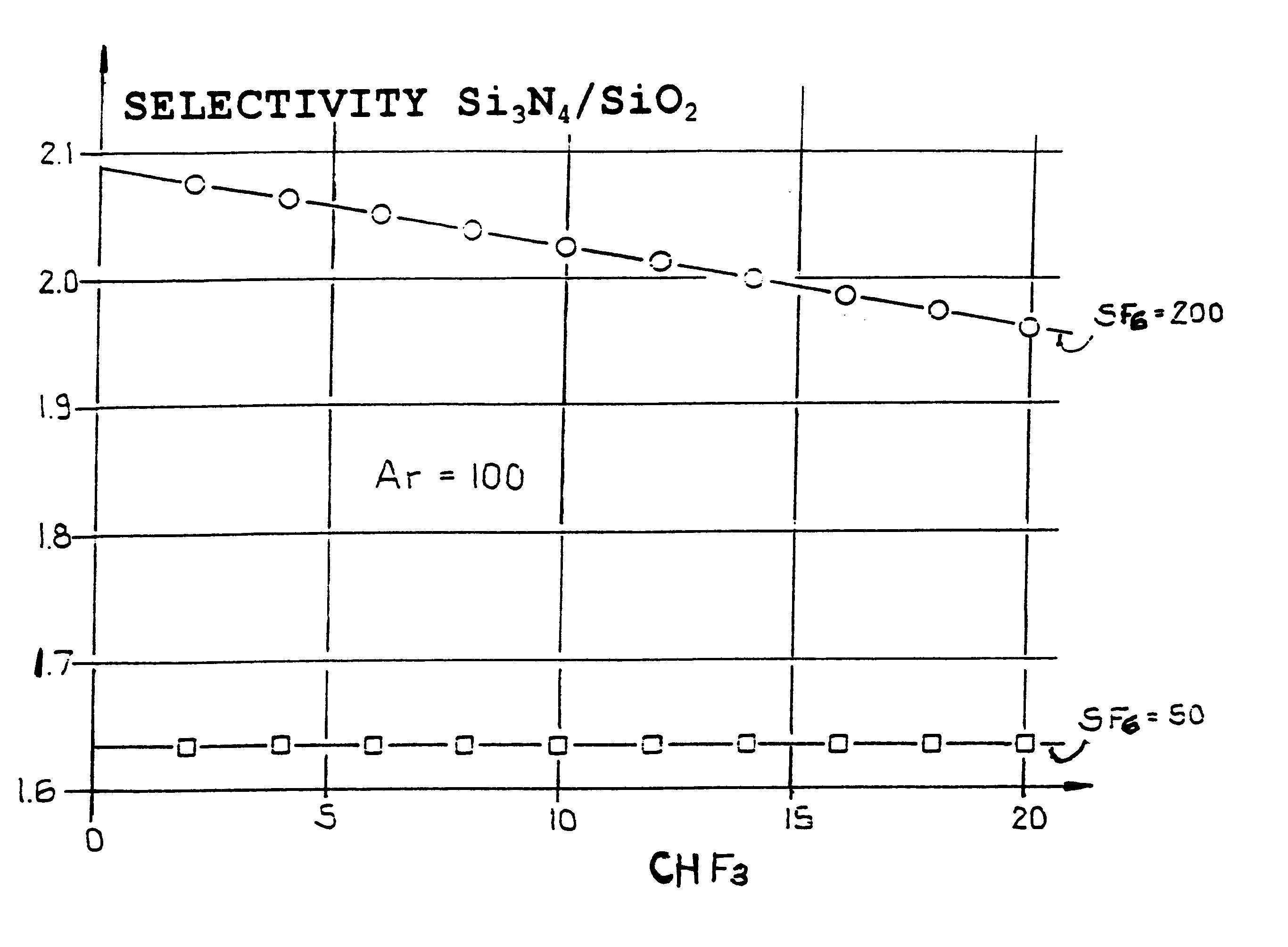

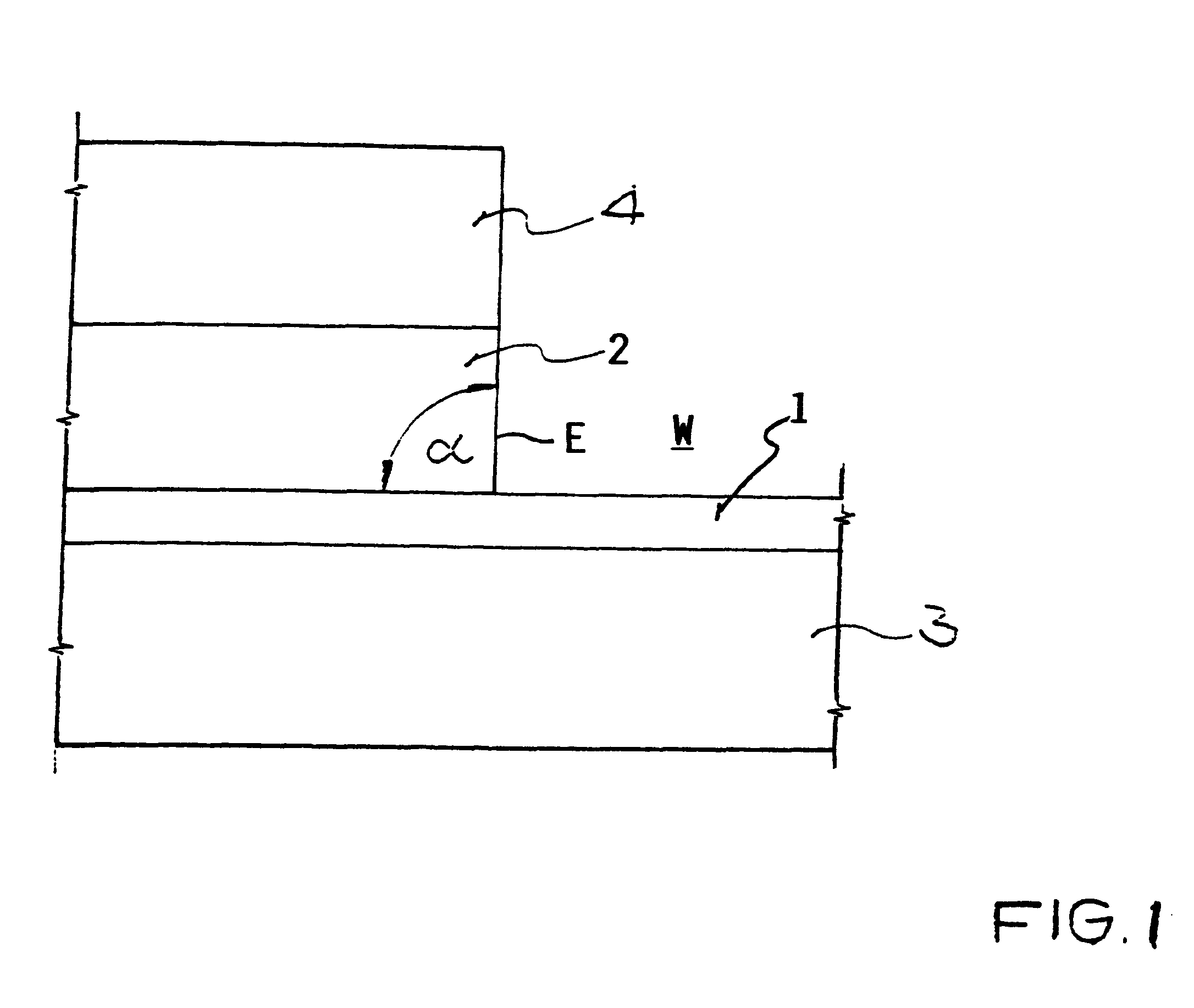

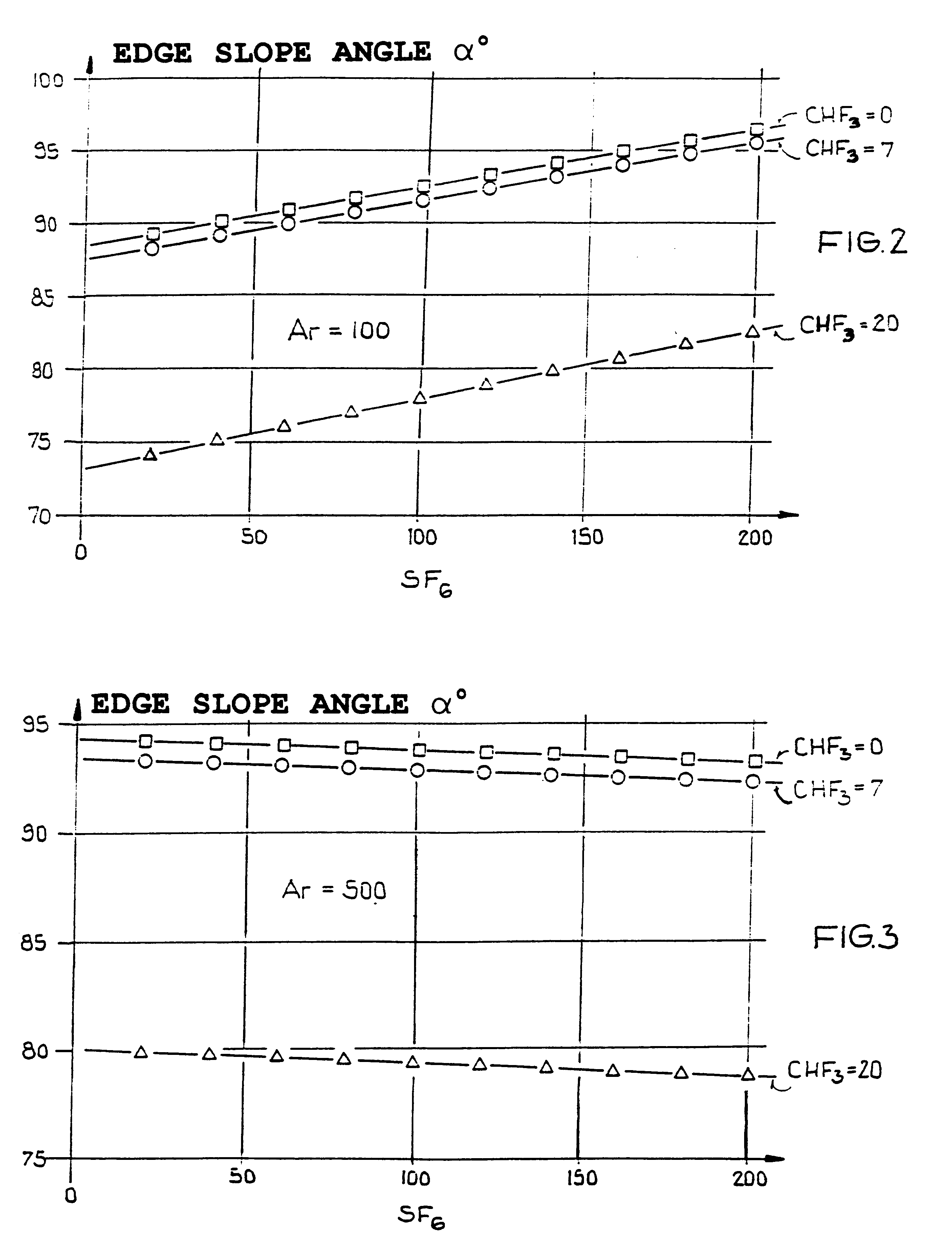

Method for anisotropic plasma-chemical dry etching of silicon nitride layers using a gas mixture containing fluorine

InactiveUS6569773B1Improve uniformityHigh atomic weightSemiconductor/solid-state device manufacturingSilicon oxideOxygen

An etching gas mixture containing CHF3, SF6 and a non-oxidizing gas such as Ar is used as an etching gas mixture for the anisotropic plasma-chemical dry-etching of a silicon nitride layer differentially or selectively relative to a silicon oxide layer. The gas mixture does not contain oxygen, chlorine, bromine, iodine or halides in addition to the above mentioned constituents, so that the process can be carried out in reactor systems equipped with oxidizable electrodes. By adjusting the gas flow rates or composition ratios of CHF3, SF6, and argon in the etching gas mixture, it is possible to adjust the resulting etching selectivity of silicon nitride relative to silicon oxide, and the particular edge slope angle of the etched edge of the remaining silicon nitride layer. A high etch rate for the silicon nitride is simultaneously achieved.

Owner:ATMEL CORP +1

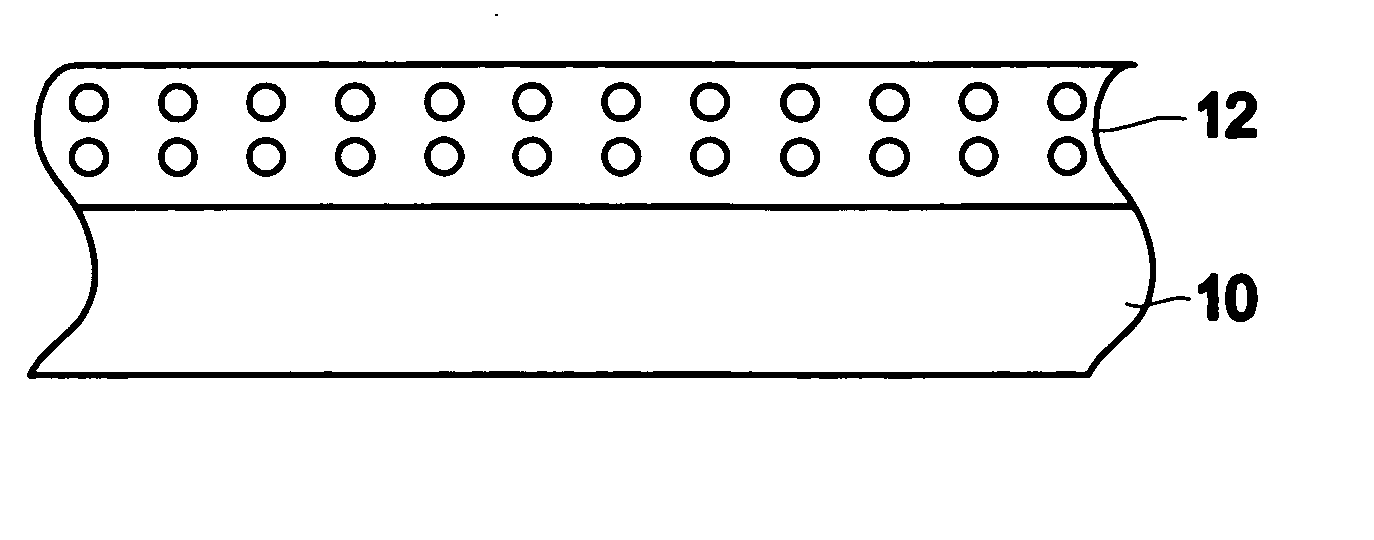

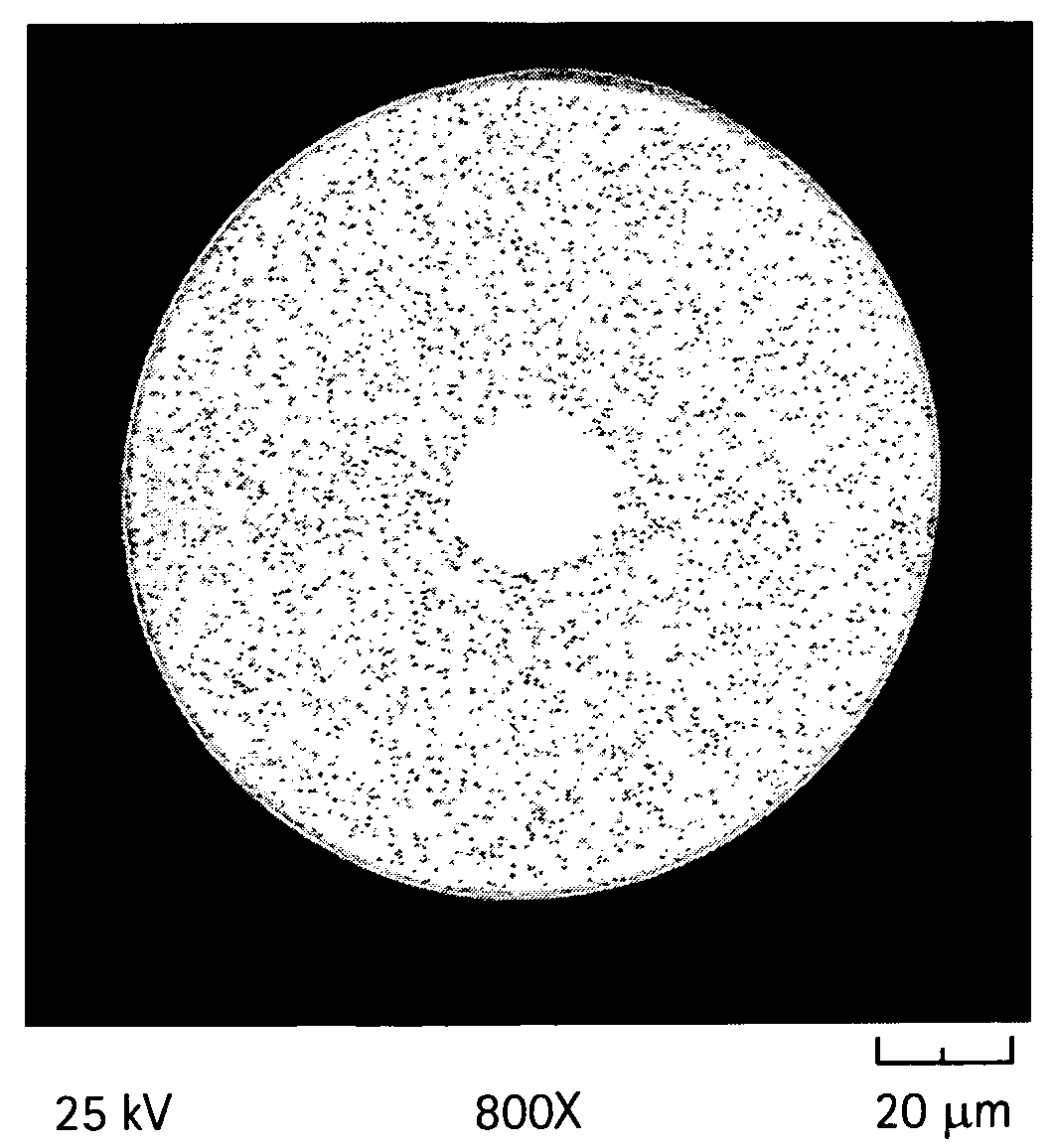

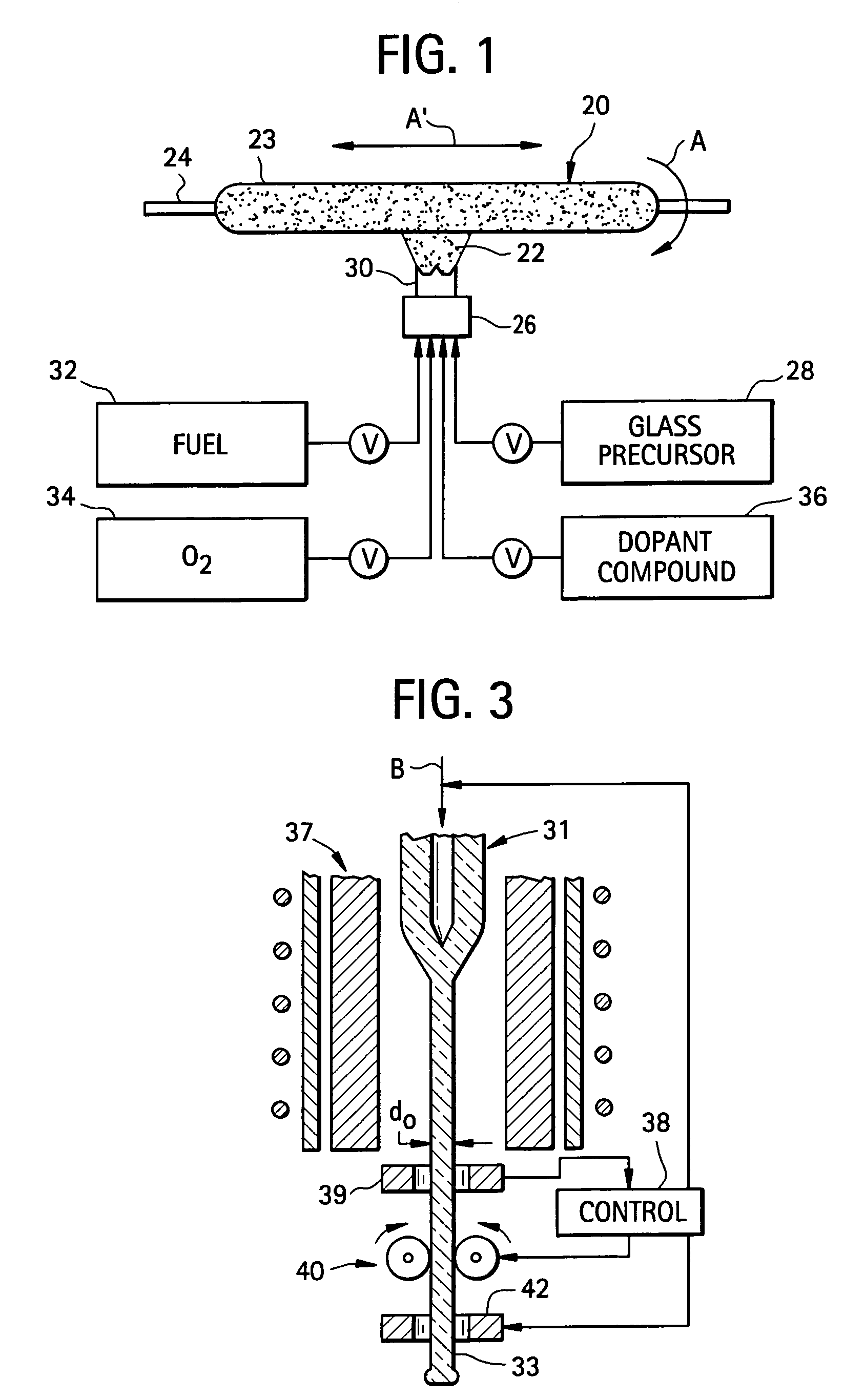

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

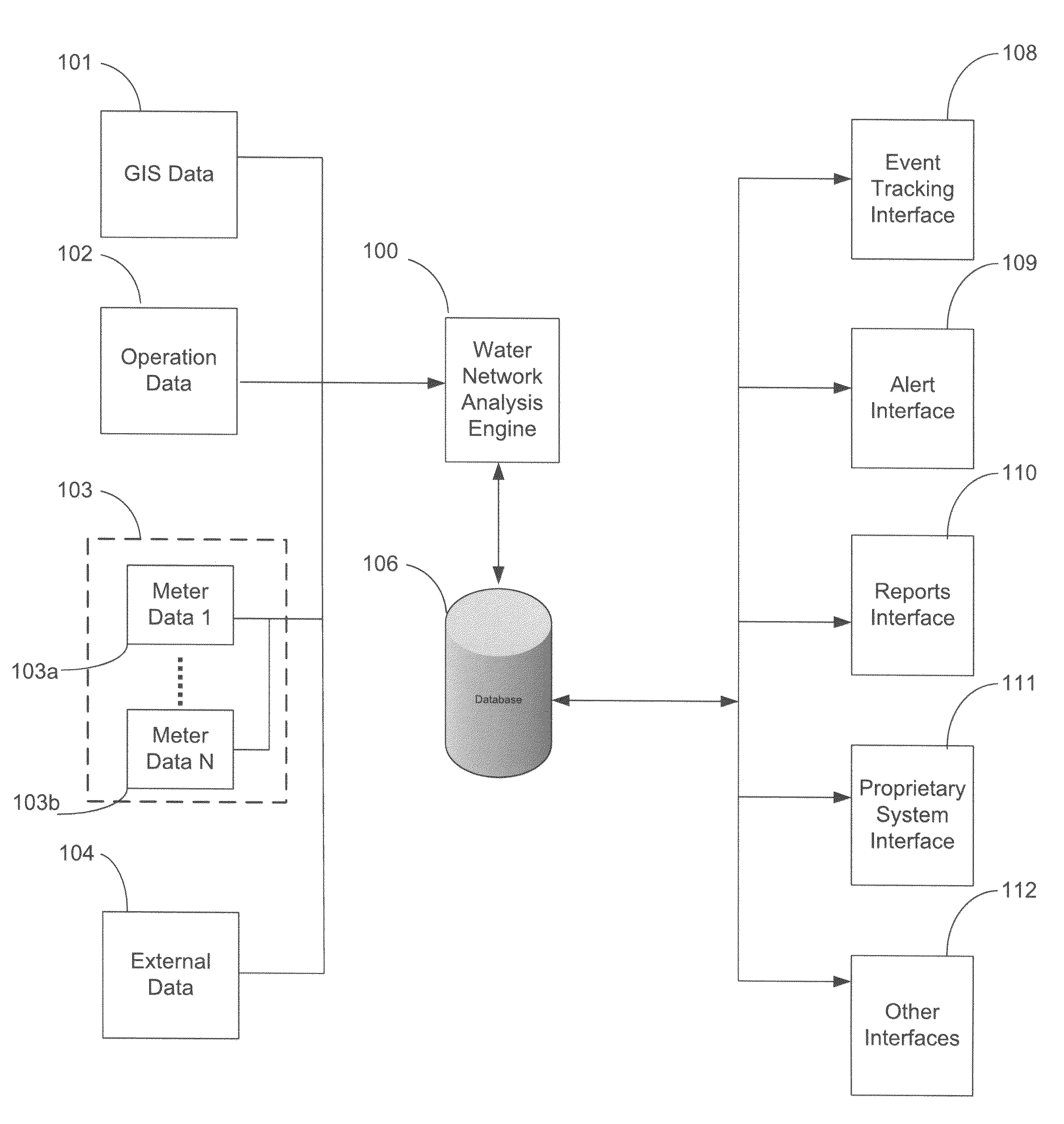

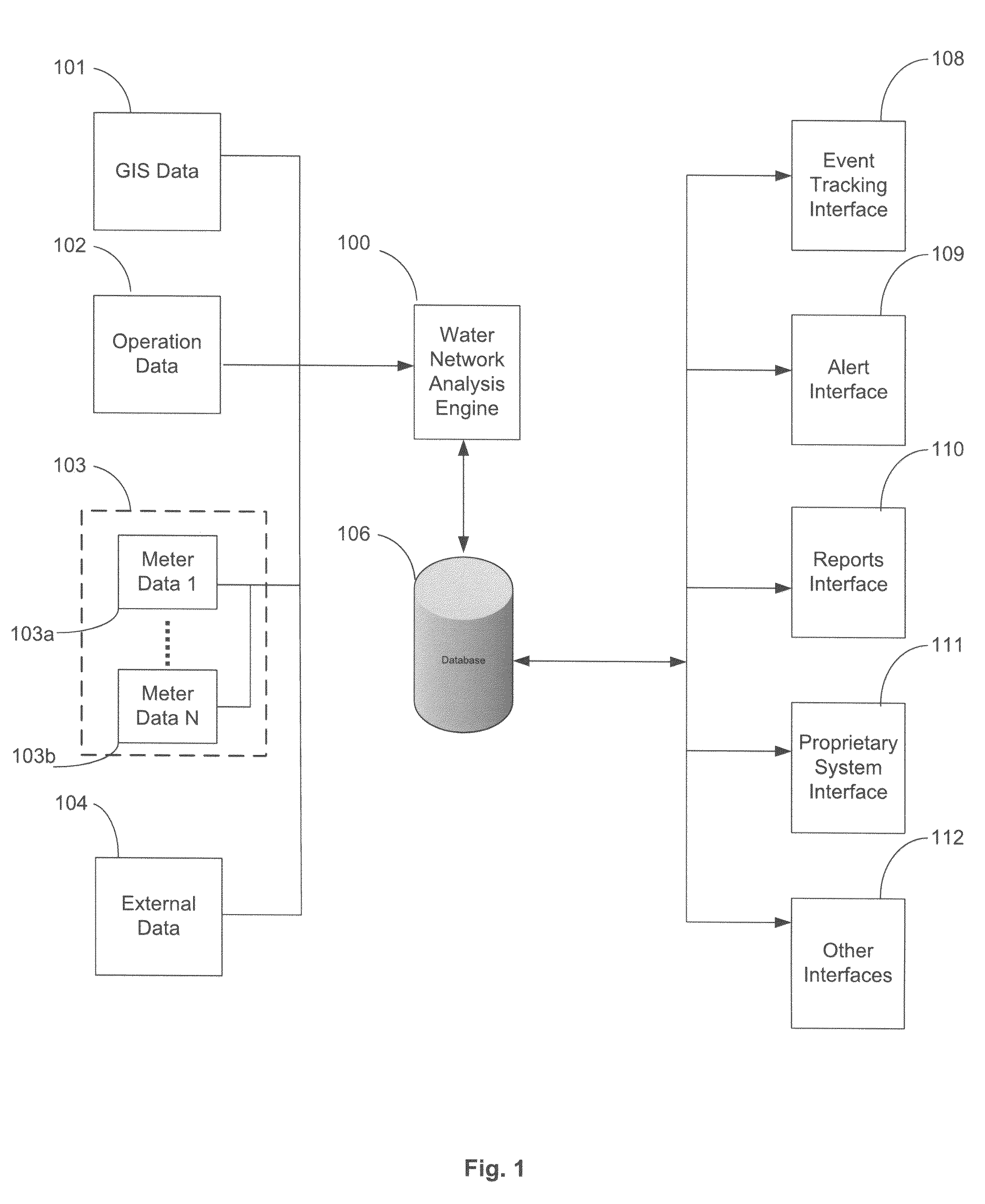

System and method for monitoring resources in a water utility network

ActiveUS7920983B1Easy to detectIncrease consumptionElectric signal transmission systemsTesting/calibration apparatusWater utilityUtility industry

A computerized method for monitoring a water utility network, the water utility network comprising a network of pipes for delivering water to consumers and a plurality of meters positioned within the pipes across the water distribution network. The method includes receiving meter data representing parameters measured by the meters, such as flow, pressure, chlorine level, pH and turbidity of the water being distributed through the pipes. The method also includes receiving secondary data from sources external to the meters and representing conditions affecting consumption of water in a region serviced by the water utility network such as weather and holidays. The meter and secondary data is analyzed using statistical techniques to identify water network events including leakage events and other events regarding quantity and quality of water flowing through the pipes and operation of the water network. The events are reported to users via a user interface.

Owner:TAKADU

Concentrated aqueous bromine solutions and their preparation

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

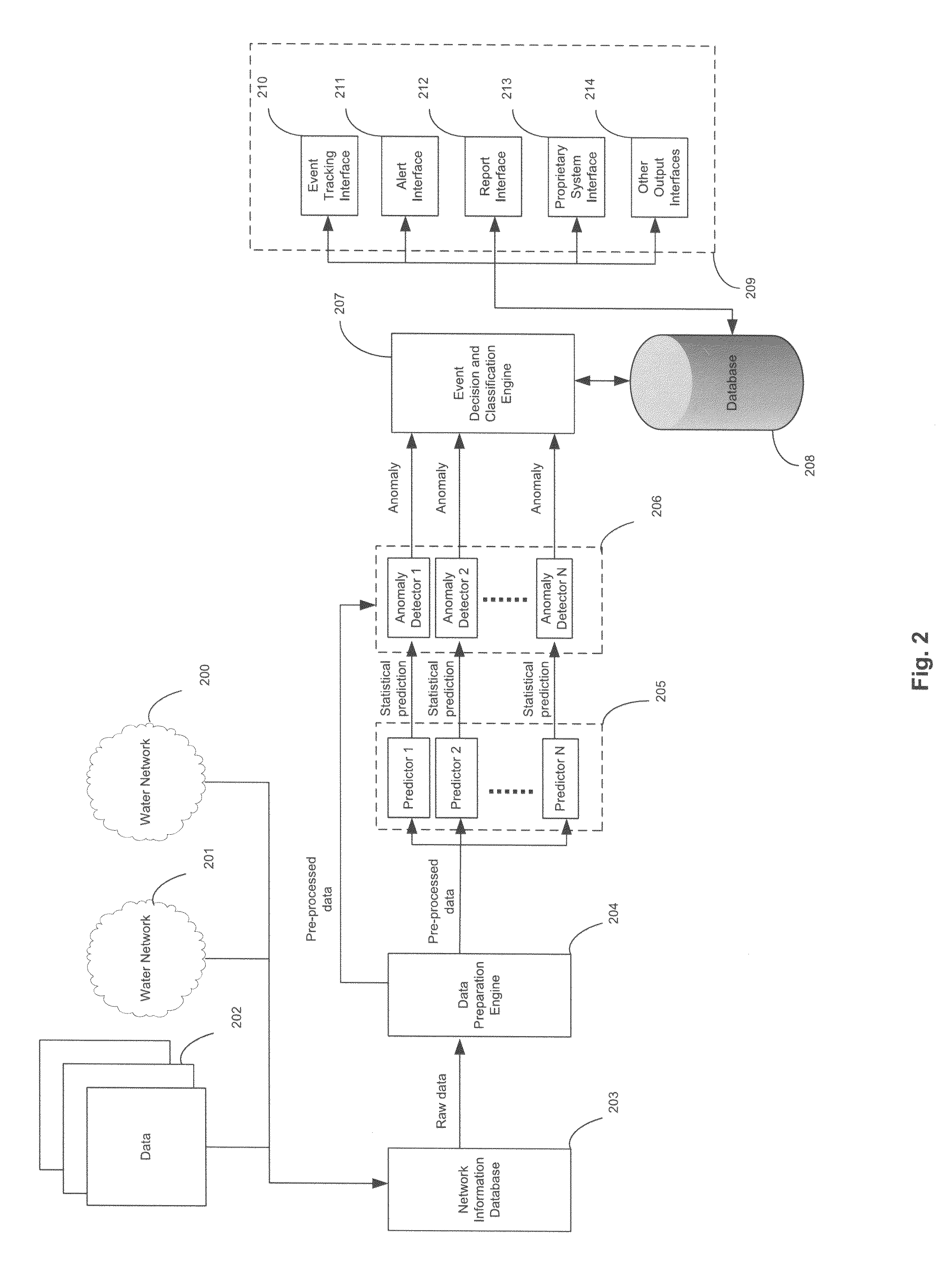

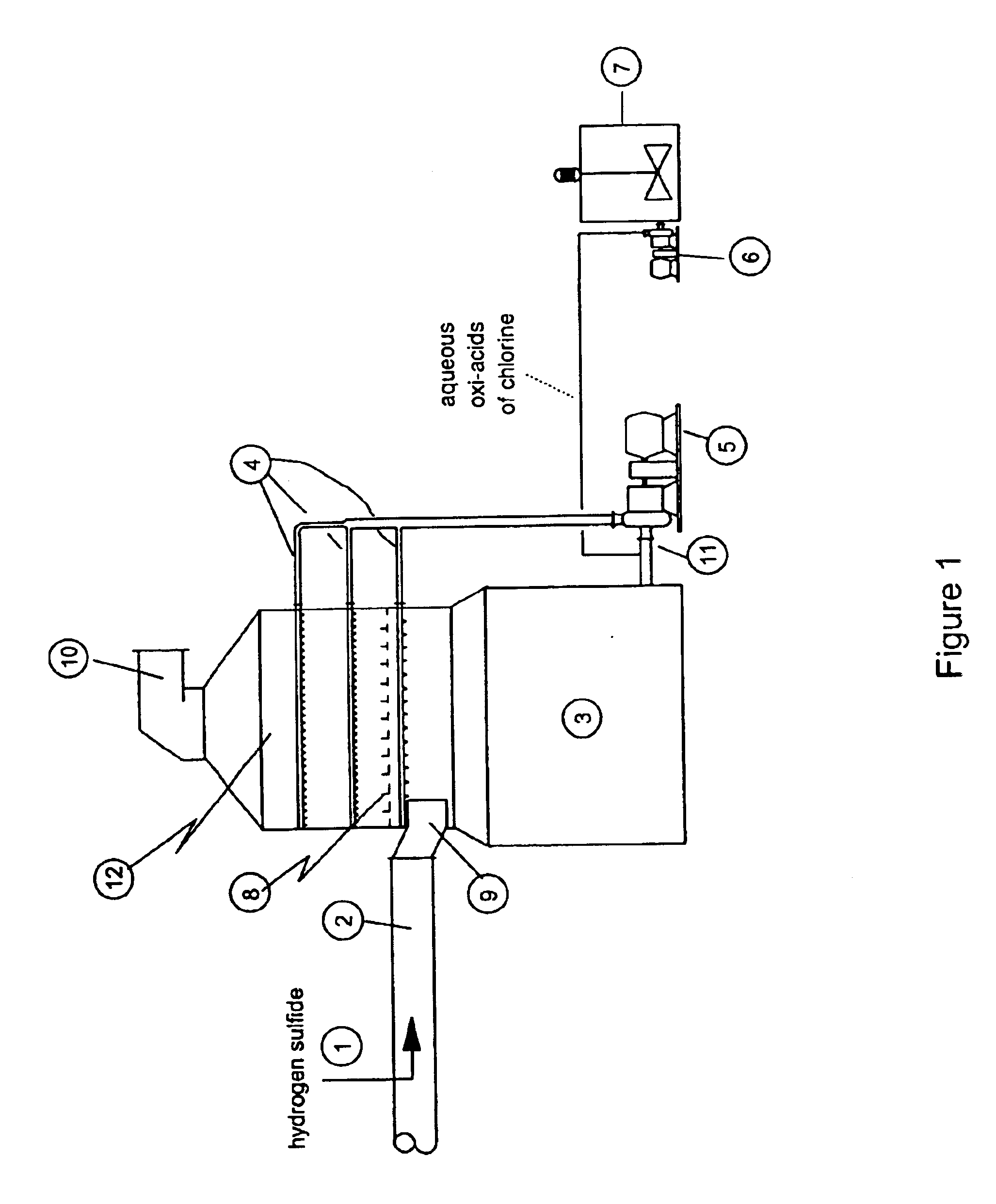

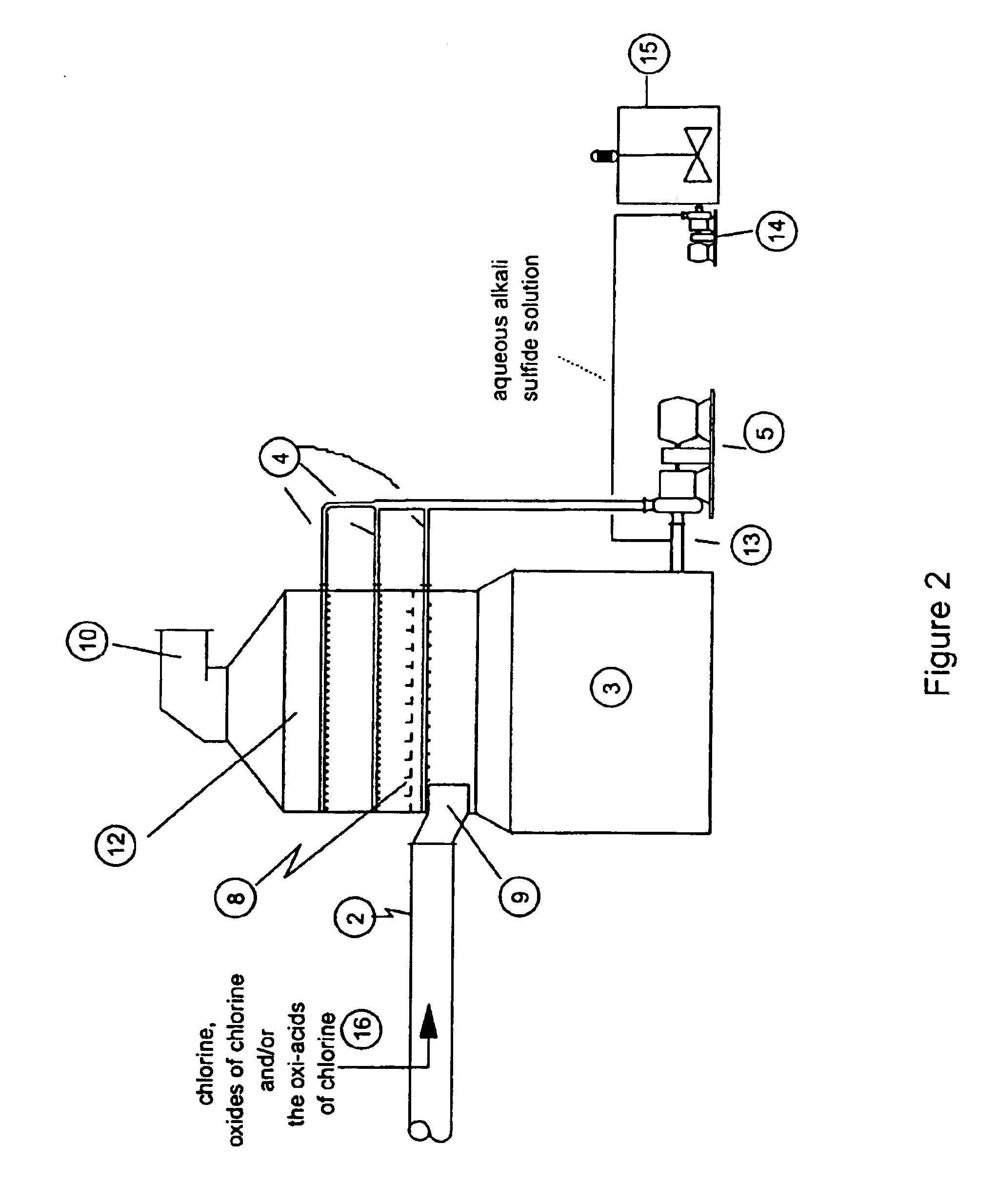

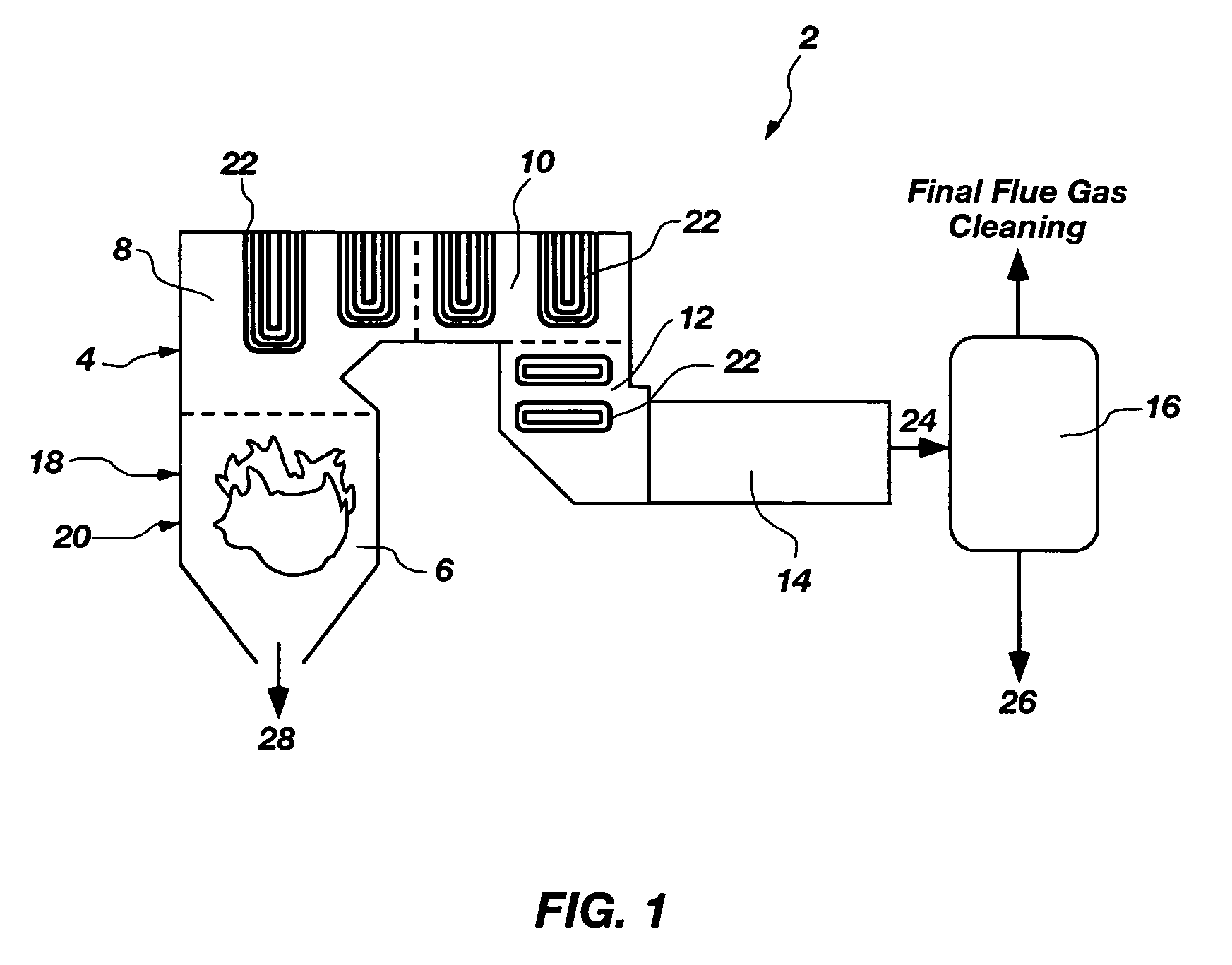

Method for controlling elemental mercury emissions

InactiveUS6855859B2Simple equipmentReduce oxidationGas treatmentExhaust apparatusElemental mercuryPrecipitation

Chlorine and sulfide species are separately introduced to a flue gas passing through a scrubber in order to remove the elemental and oxidized mercury from the gas through the precipitation of mercuric sulfide at near 100% efficiency.

Owner:THE BABCOCK & WILCOX CO

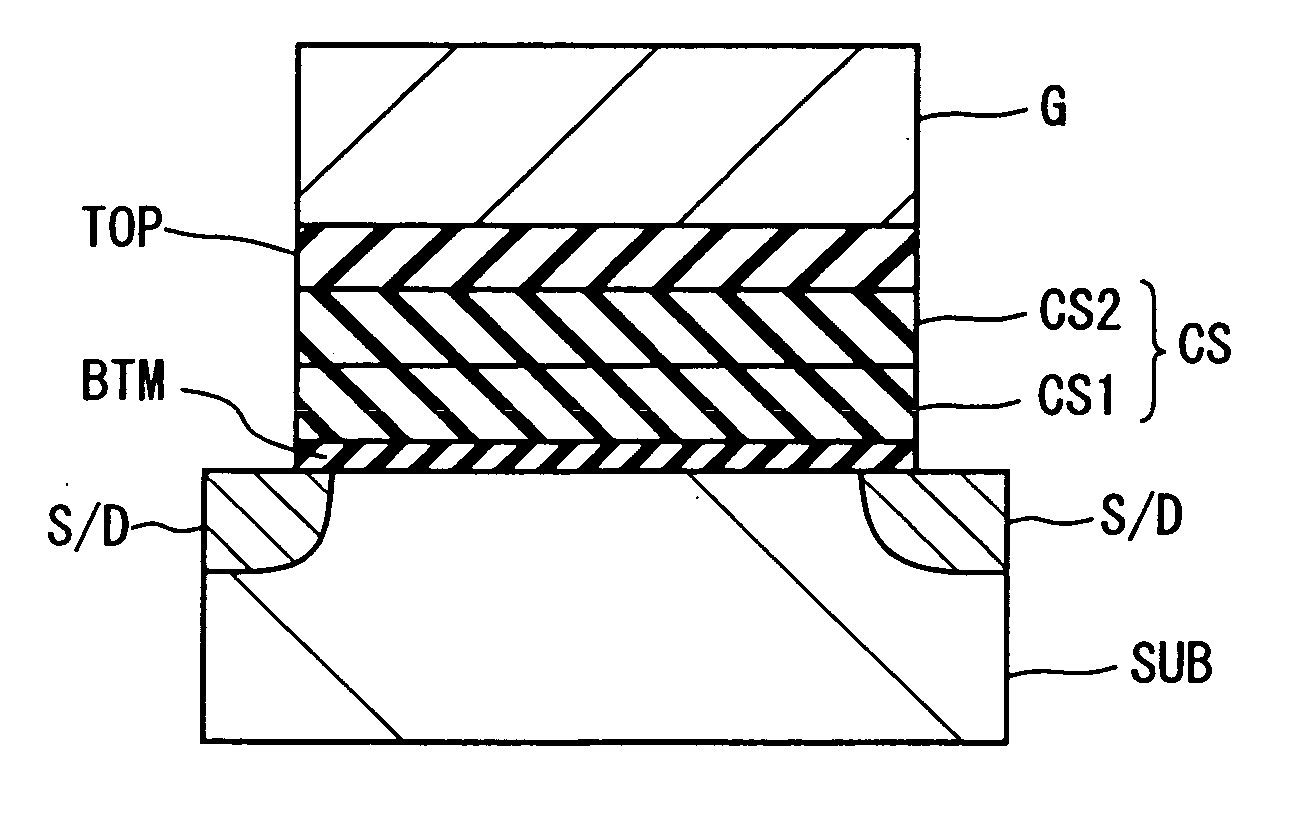

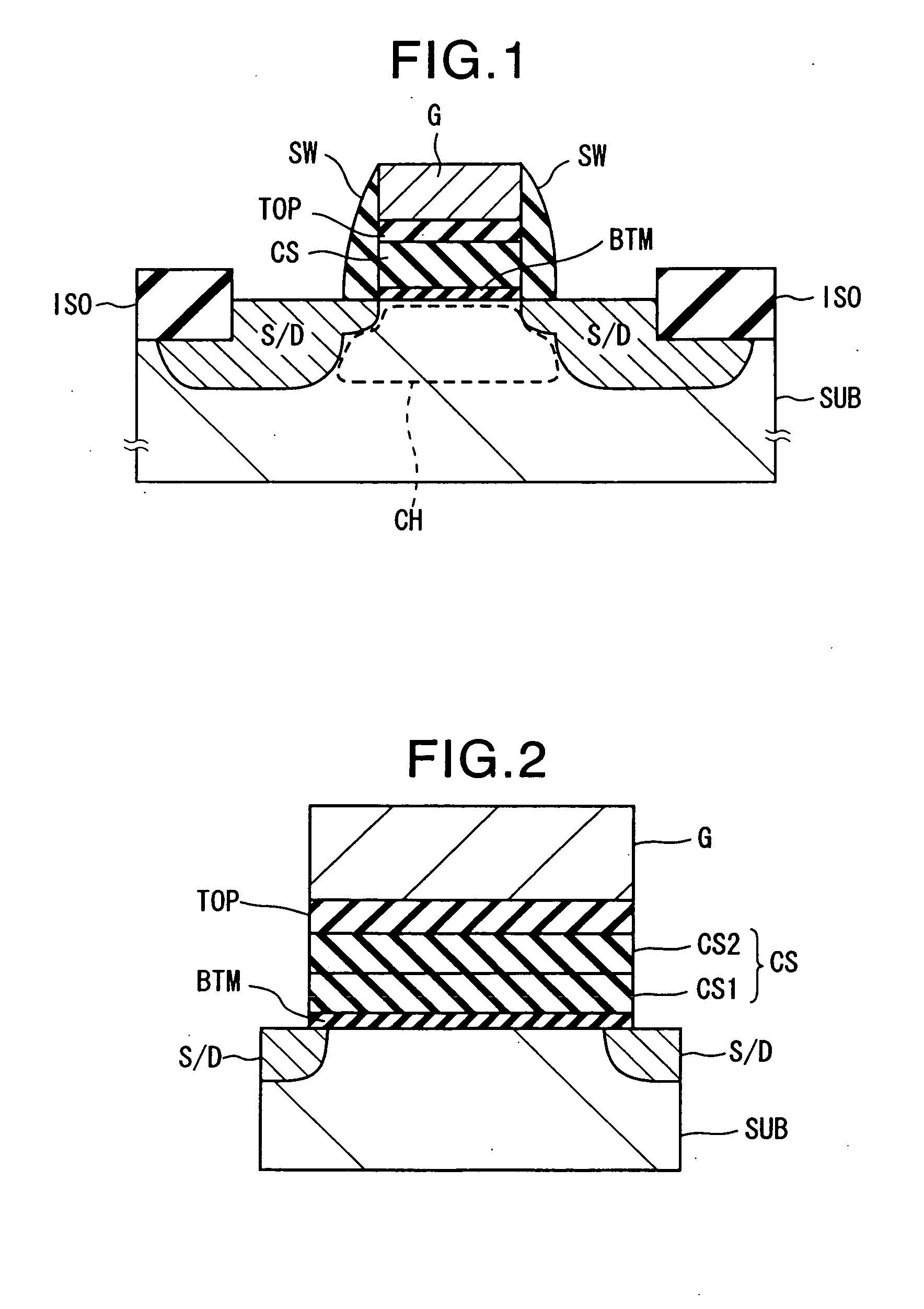

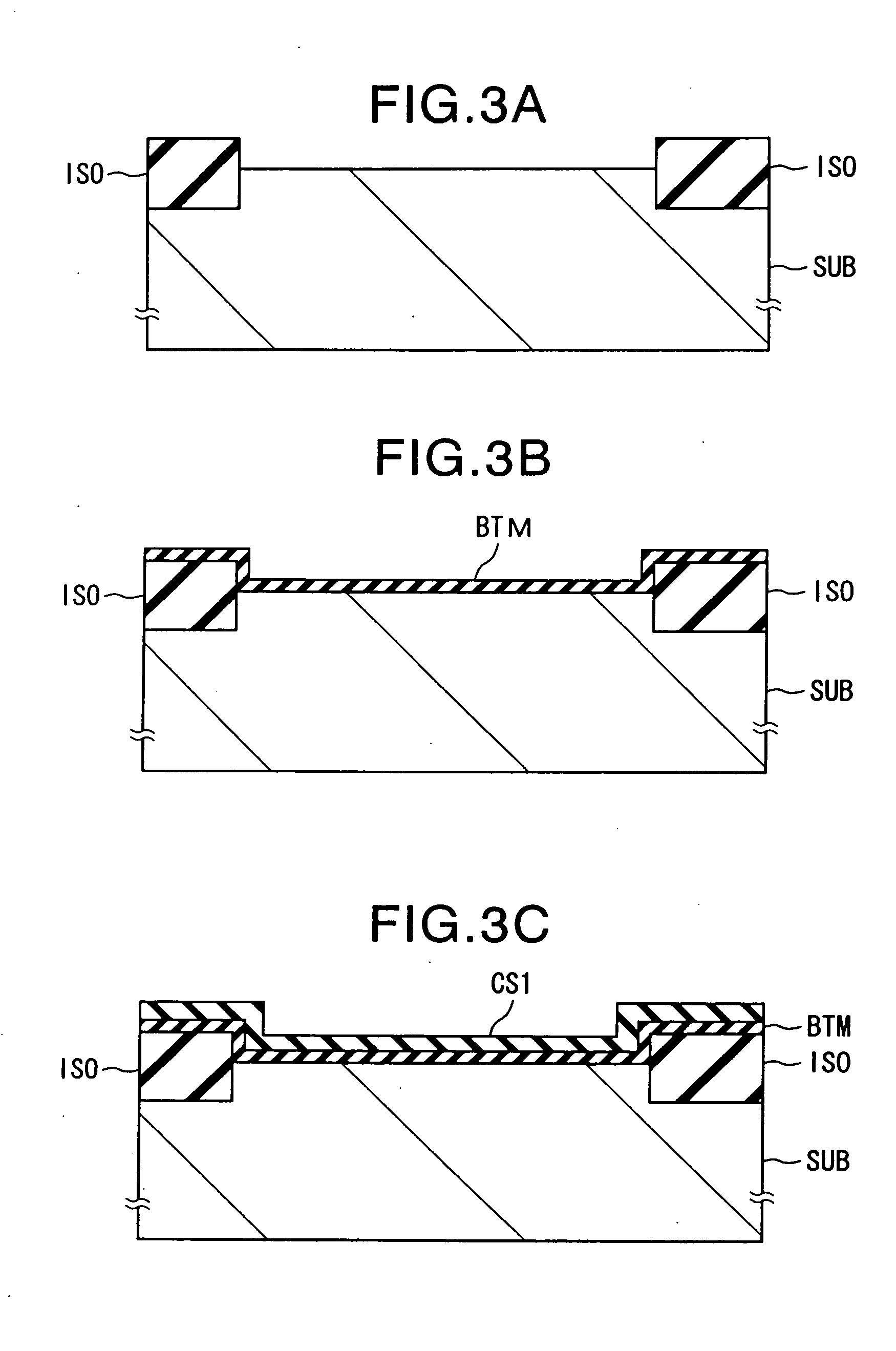

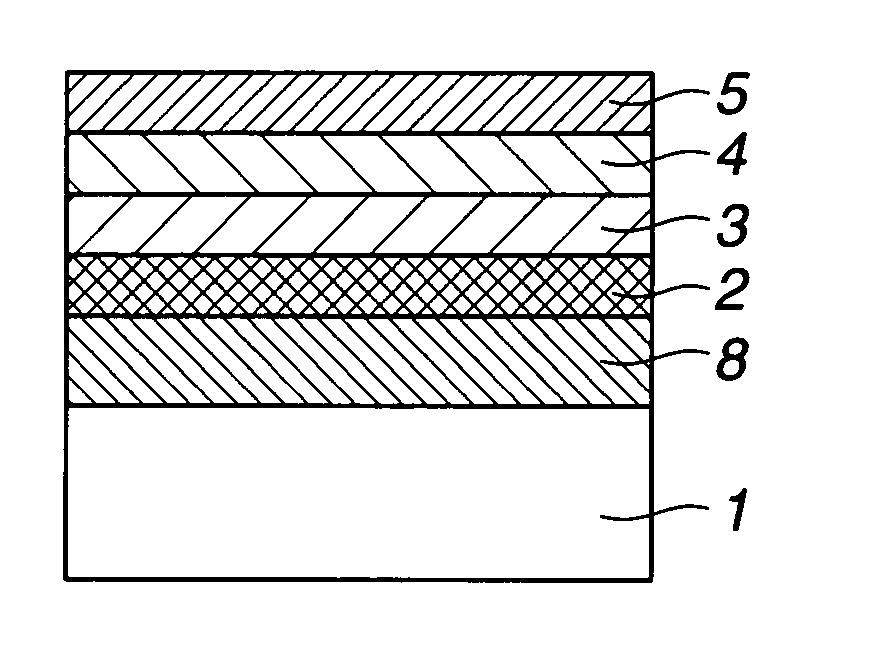

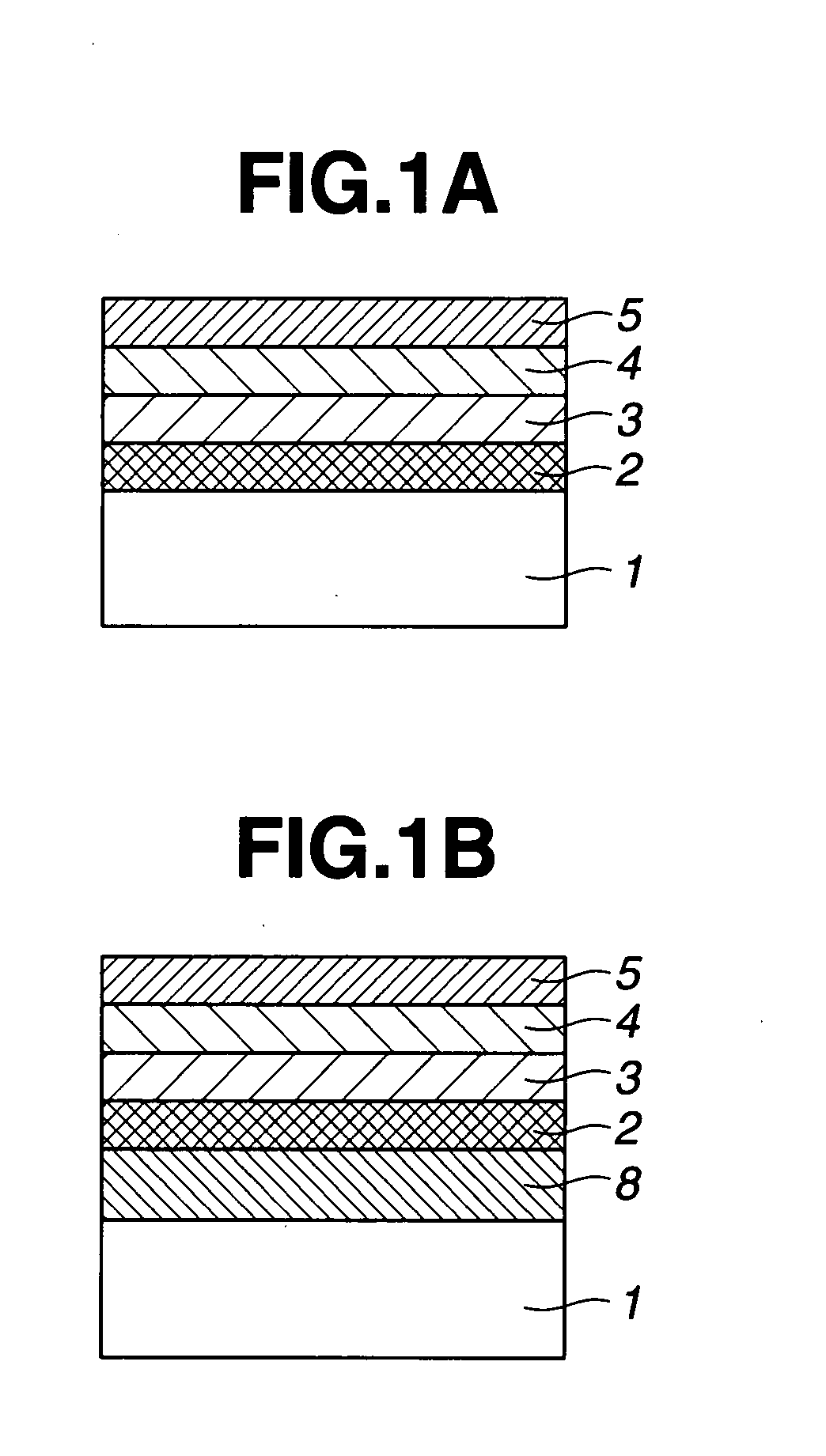

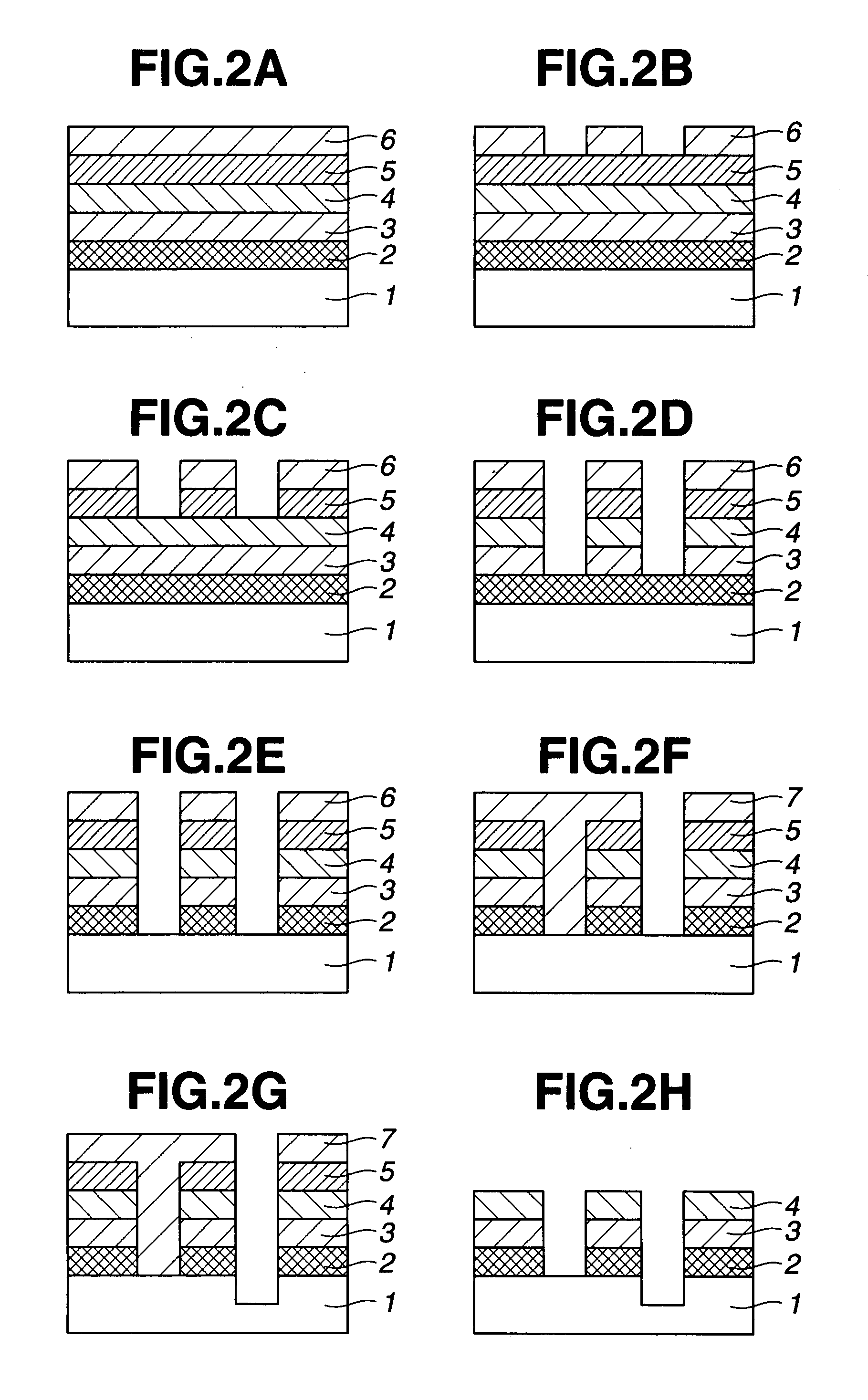

Non-volatile semiconductor memory device and method for producing same

InactiveUS20050230766A1Reduce voltageIncrease speedTransistorSolid-state devicesVolumetric Mass DensityChemical vapor deposition

The memory device has a plurality of dielectric films including charge storage layers CS having a charge holding capability therein and stacked on an active region of a semiconductor SUB and electrodes G on the plurality of dielectric films. Each charge storage layer CS includes a first nitride film CS1 made of silicon nitride or silicon oxynitride and a second nitride film CS2 made of silicon nitride or silicon oxynitride and having a higher charge trap density than the first nitride film CS1. The first nitride film CS1 is formed by chemical vapor deposition using a first gas which contains a first silicon-containing gas containing chlorine with a predetermined percent composition and a nitrogen-containing gas as starting materials. The second nitride film CS2 is formed by chemical vapor deposition using a second gas which contains a second silicon-containing gas having a lower chlorine percent composition than the above predetermined percent composition and a nitrogen-containing gas as starting materials.

Owner:SONY CORP

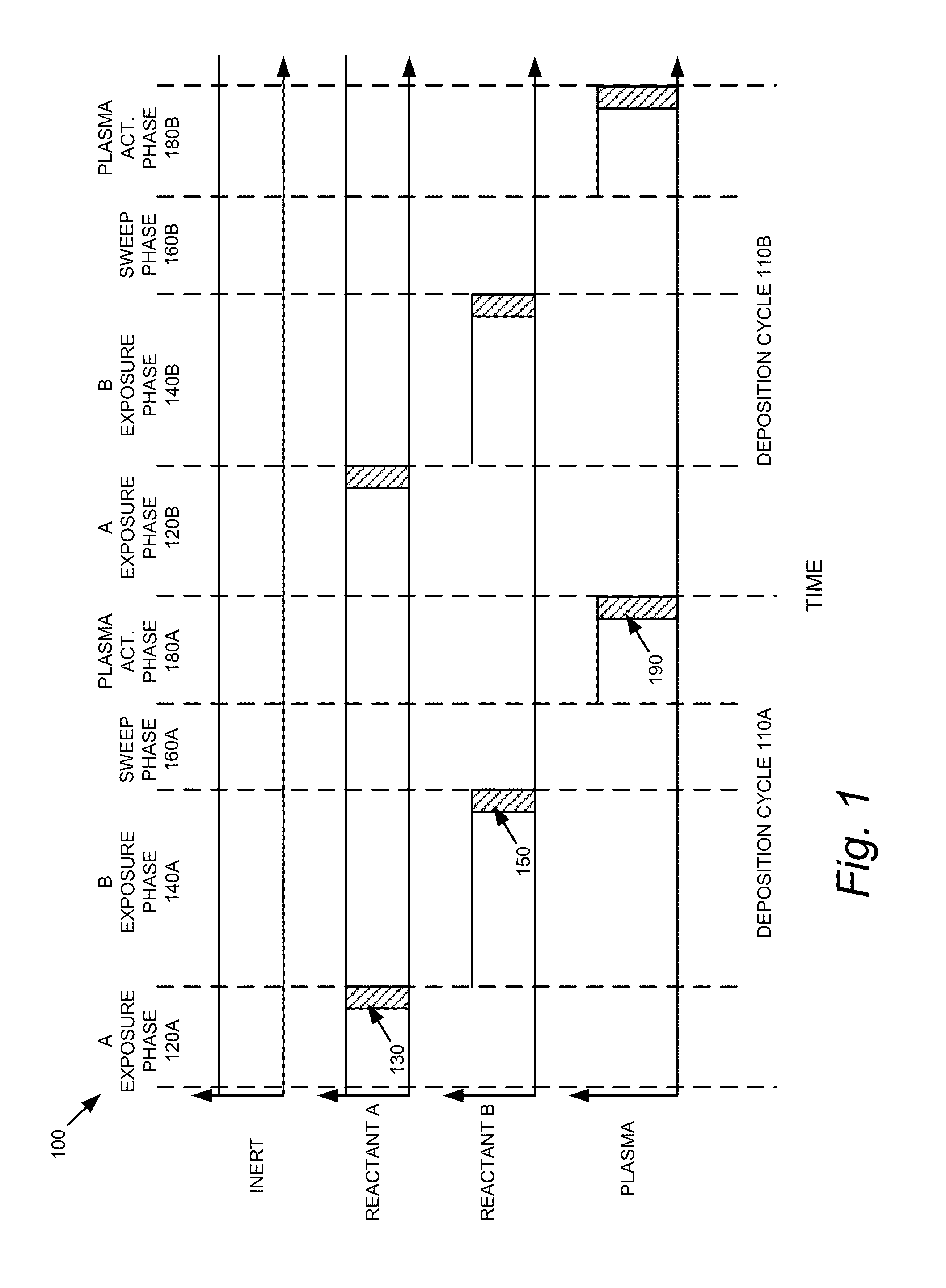

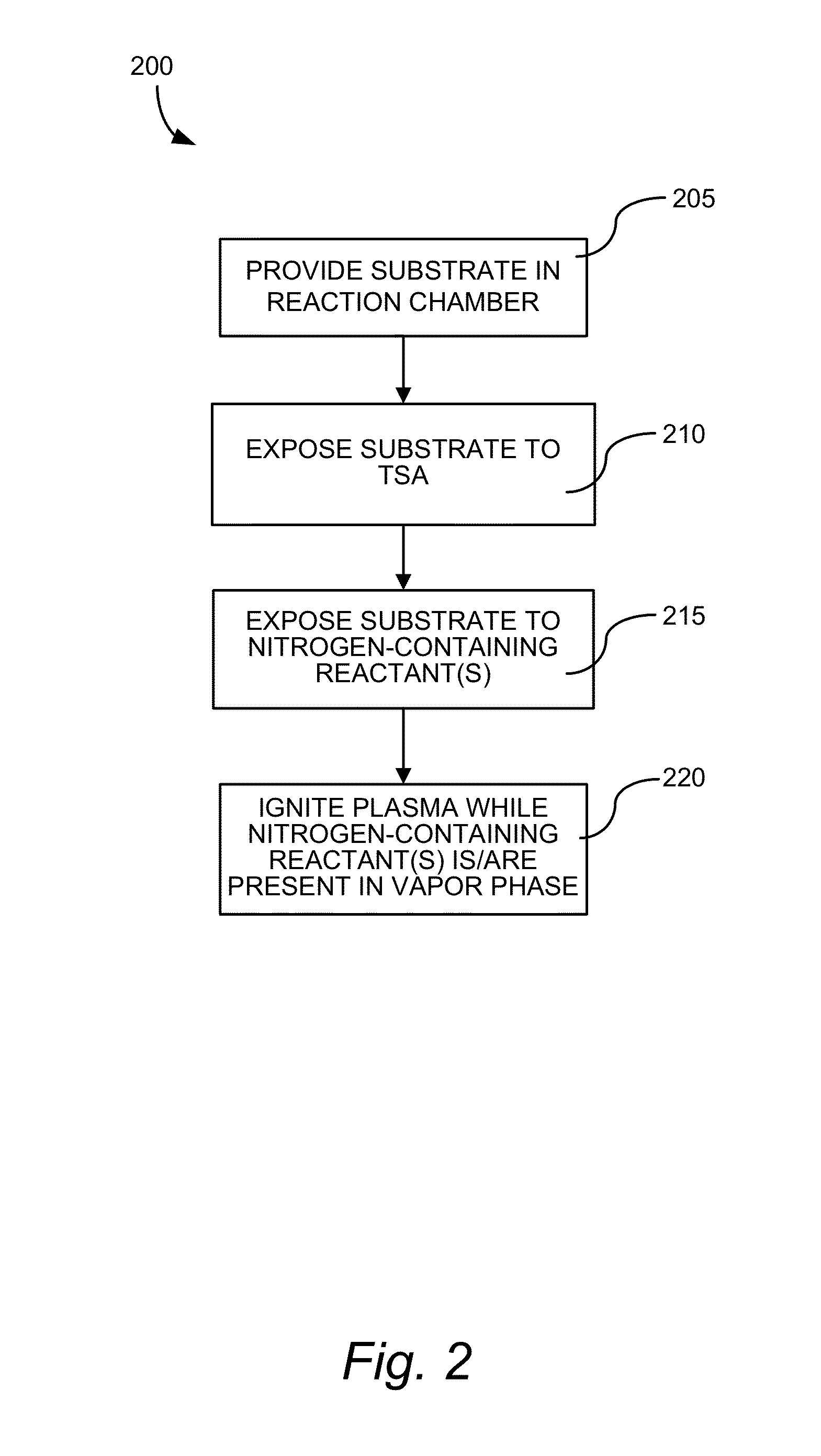

Method for depositing a chlorine-free conformal sin film

ActiveUS20140141626A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorine.freeChemistry

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

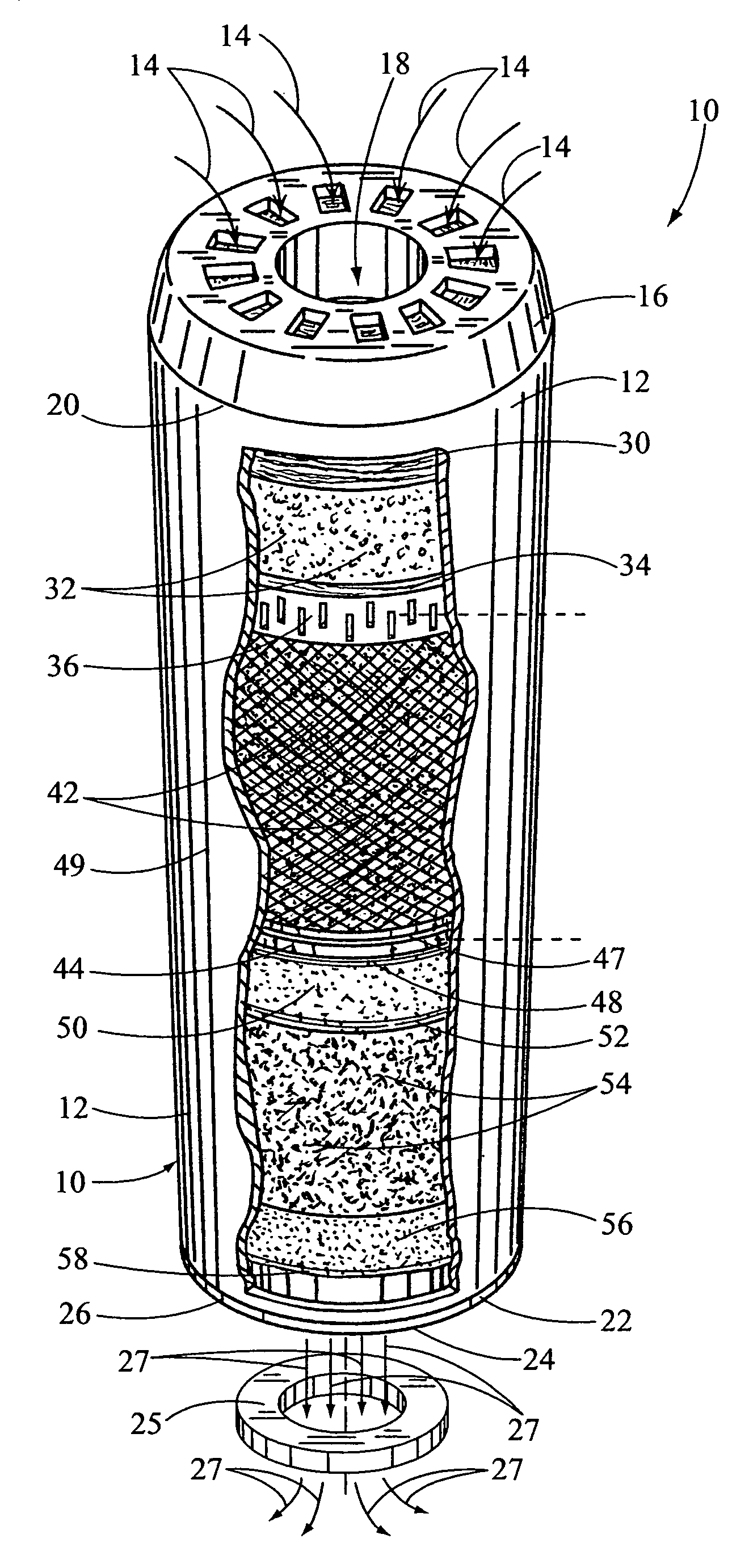

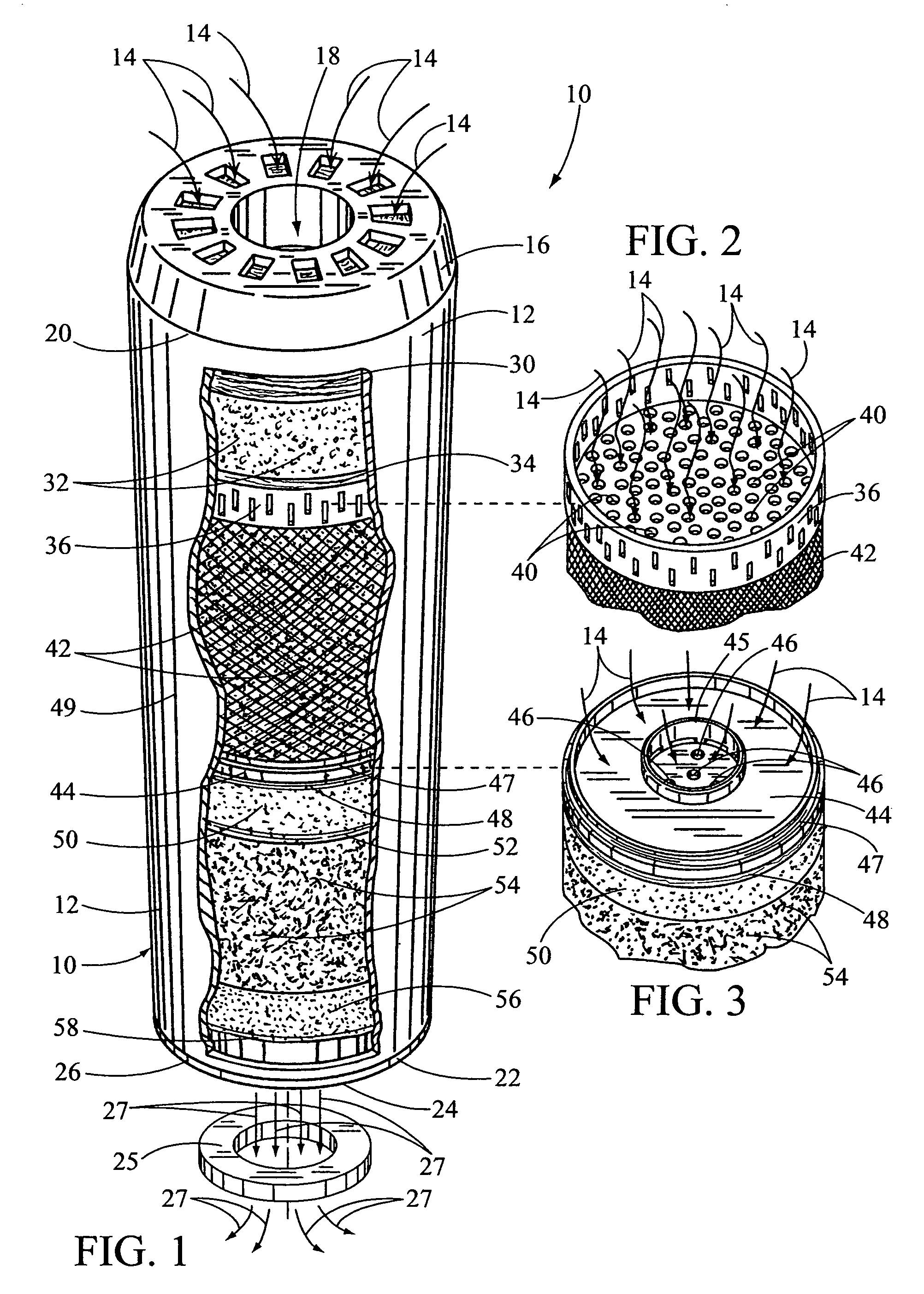

Drinking water filter used with tap water and other water sources

InactiveUS7156994B1Save spaceEliminate needTreatment involving filtrationWater/sewage treatment by ion-exchangeWater sourceFiltration

A drinking water filter for filtering major water contaminates from tap water and other drinking water sources. The water filter a cylindrical cartridge for receiving a plurality of sponge filters used as dividers between different layers of filtration material and along a length of the cartridge. The sponge filters are designed to remove large and small sediments in the water from 1 to 100 microns in size and greater when the water is introduced through the cartridge. The layers of filtration material includes a layer of granulated zinc and copper alloy, a fine mesh carbon block, a layer of granulated ion exchange resin, a layer of granulated activated carbon and layer of granulated activated calcite. The carbon block and the granulated carbon material is used for removing chlorine, odor, color, cysts, protozoa and organic contaminants such as pesticides, herbicides, arsenic, mercury, and trihalomnethanes. The zinc and copper alloy is used for removing chlorine and heavy metals in the water and reducing bacteria in the water. The calcite is used to raise the pH in the filtered water when the pH is below neutral.

Owner:ARCHER VIRGIL L

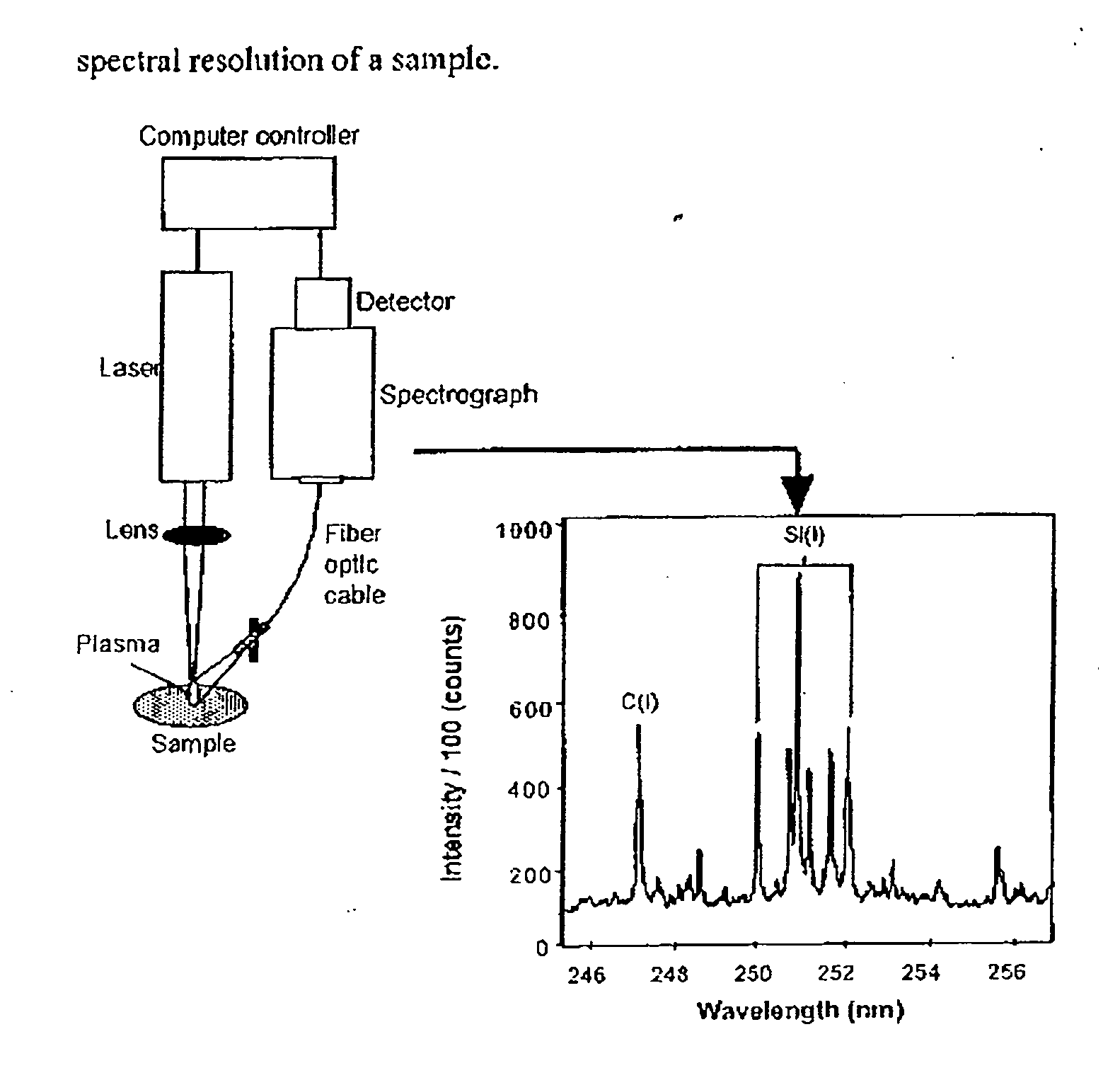

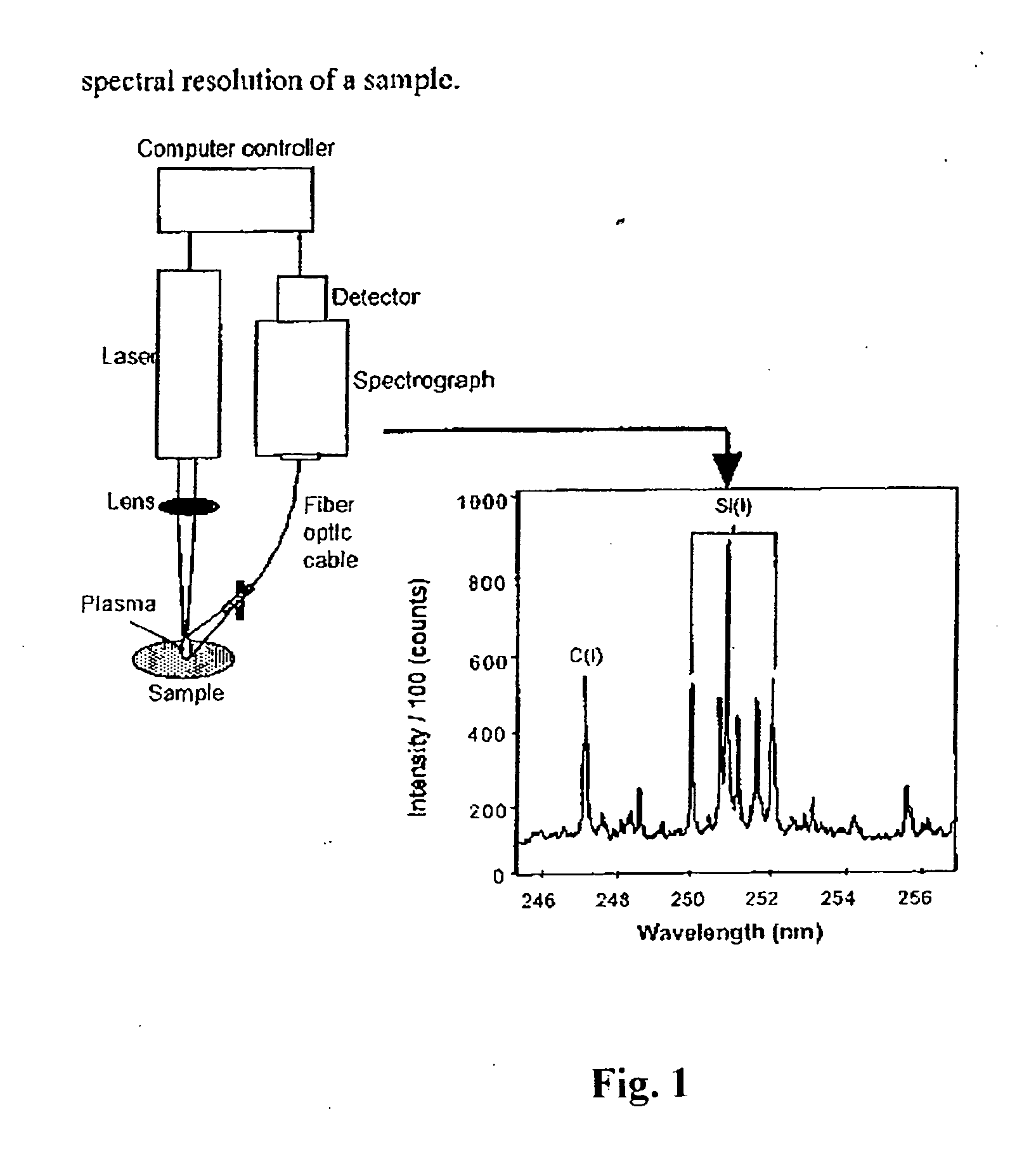

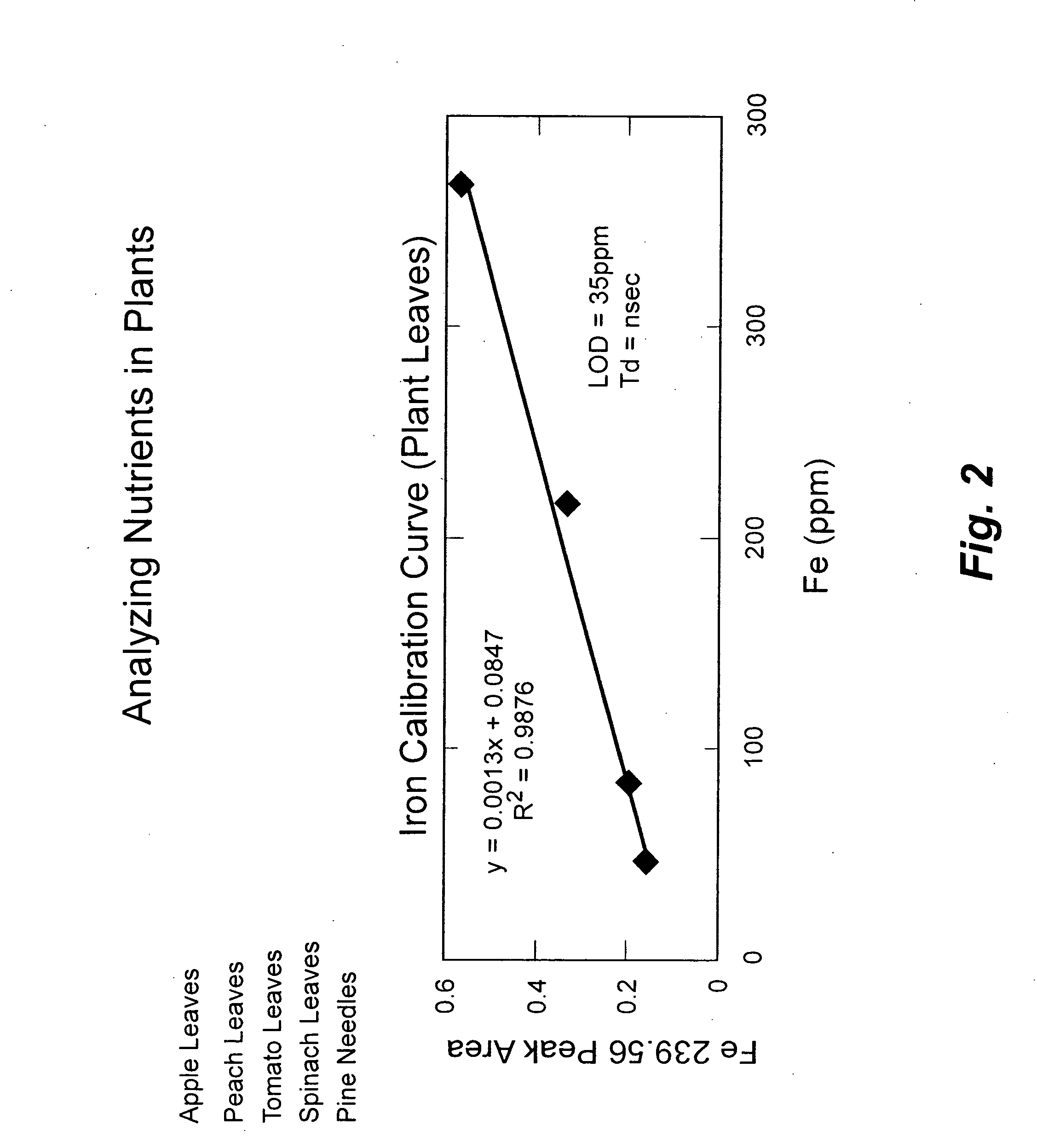

Measuring nutrients in plants and soils by laser induced breakdown spectroscopy

A process for analyzing the nutrient status of plant matter and / or soil for one or more nutrients selected from among calcium, potassium, nitrogen, sulfur, phosphorus, magnesium, chlorine, iron, boron, manganese, zinc, copper, nickel and molybdenum is described and includes contacting said plant matter and / or soil with a laser source capable of inducing breakdown of the sample whereby an emission from said sample occurs; and, analyzing said spectral emission for determination of an amount of said one or more nutrients. A process for analyzing the heavy metal content of plant matter and / or soil, or of fertilizers or soil amendments is also described.

Owner:LOS ALAMOS NATIONAL SECURITY

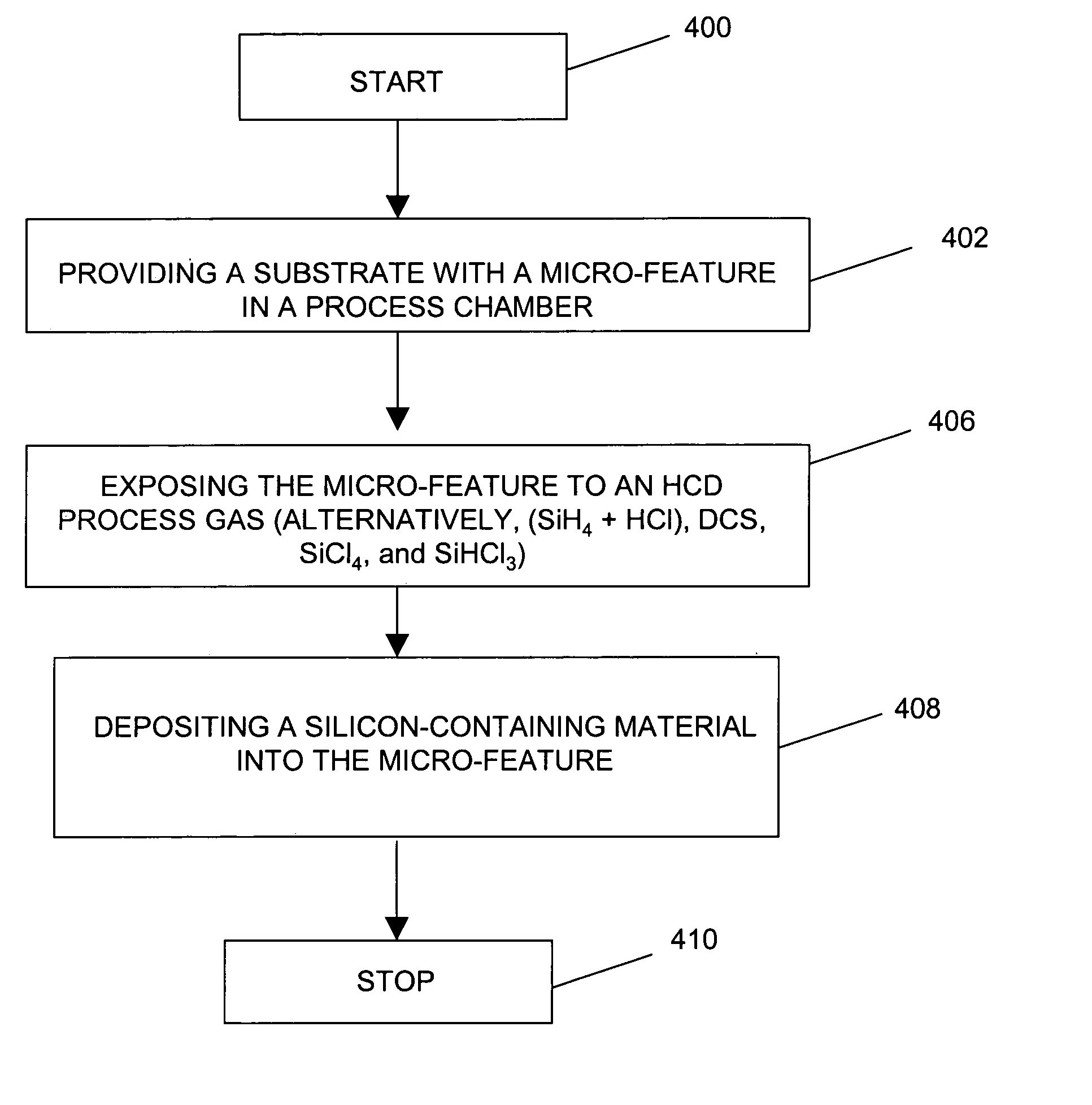

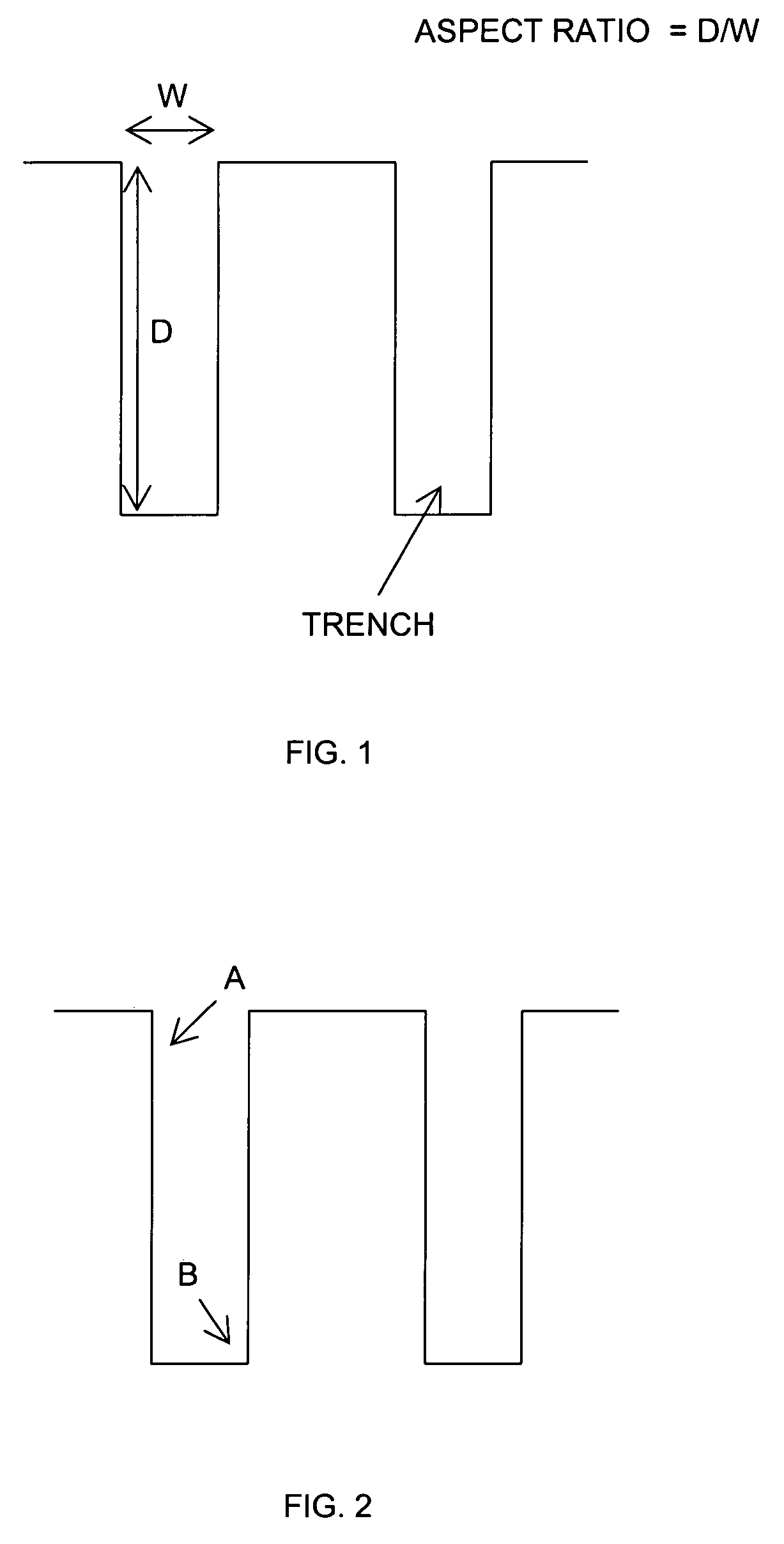

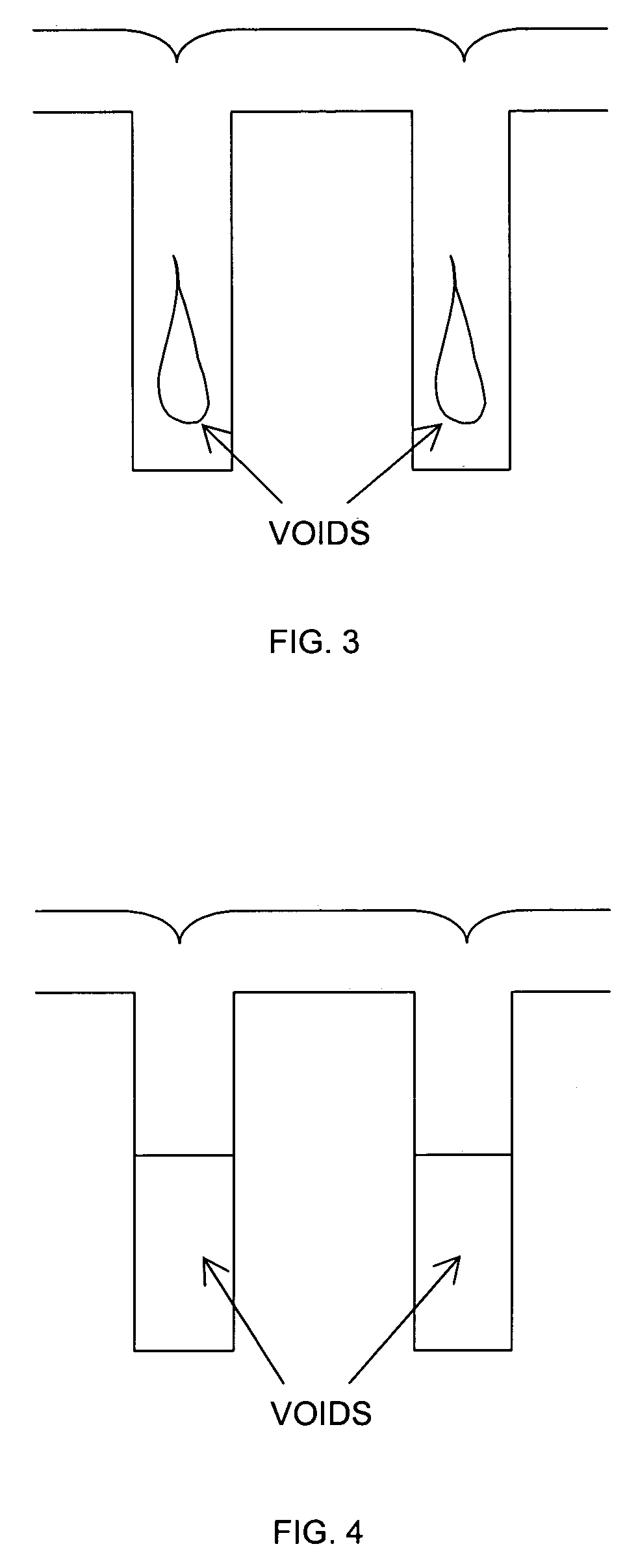

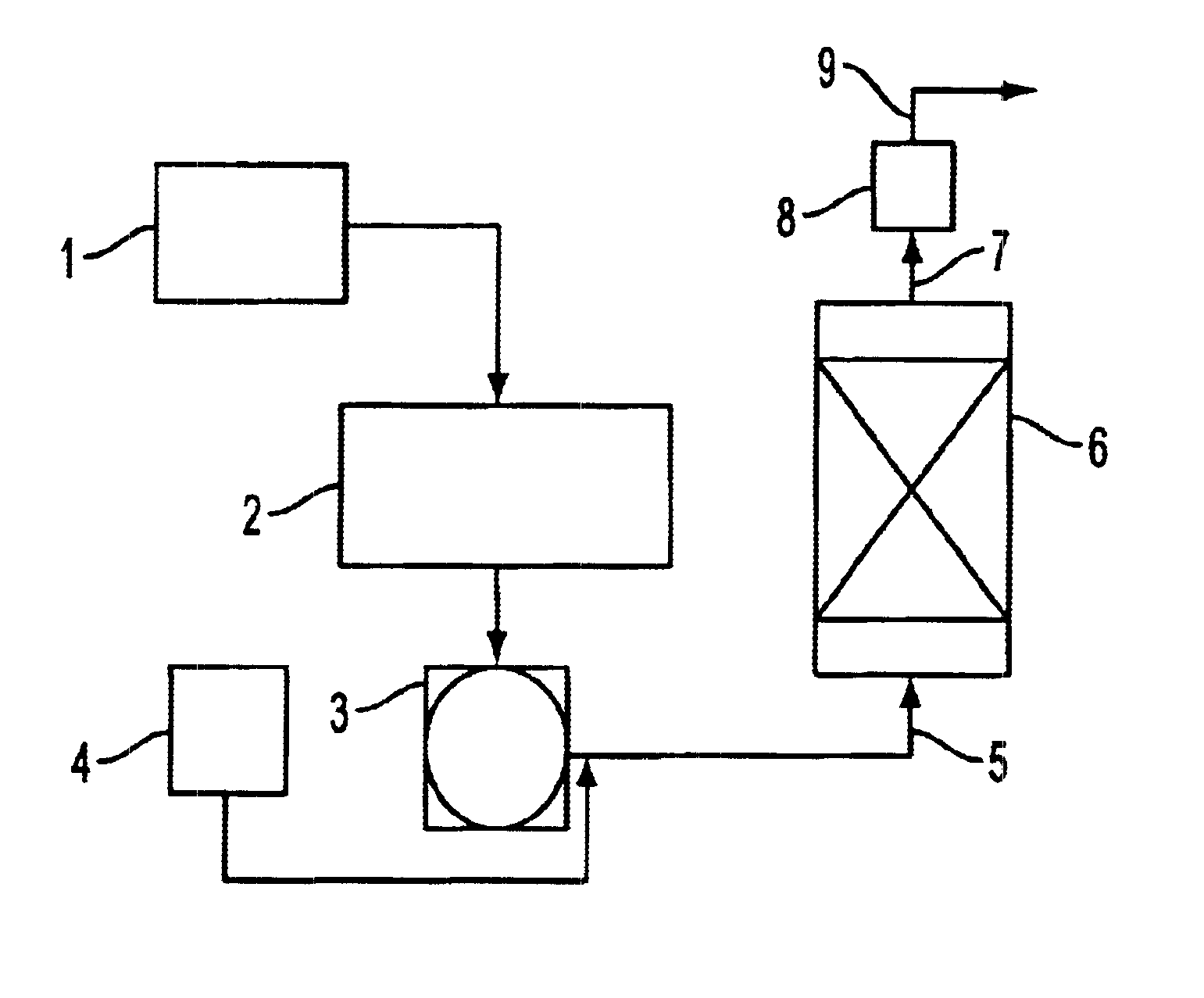

Micro-feature fill process and apparatus using hexachlorodisilane or other chlorine-containing silicon precursor

ActiveUS7205187B2Inhibition formationIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneDeposition process

A method is provided for depositing a silicon-containing film in a micro-feature on a substrate by a low pressure deposition process in a processing system. A silicon-containing film can be formed in a micro-feature by providing a substrate in a process chamber of a processing system, and exposing a hexachlorodisilane (HCD) process gas to the substrate. A processing tool containing a processing system for forming a silicon-containing film in a micro-feature using a silicon and chlorine-containing gas such as a HCD process gas is provided. Alternatively, the micro-feature can be exposed to DCS, SiCl4, and SiHCl3 gases. Alternatively, the micro-feature can be exposed to (SiH4+HCl).

Owner:TOKYO ELECTRON LTD

Harm-removing agent and method for rendering halogen-containing gas harmless and uses thereof

InactiveUS6649082B2Low abilityImprove abilitiesGas treatmentDecorative surface effectsAlkaline earth metalSulfur dioxide

Owner:SHOWA DENKO KK

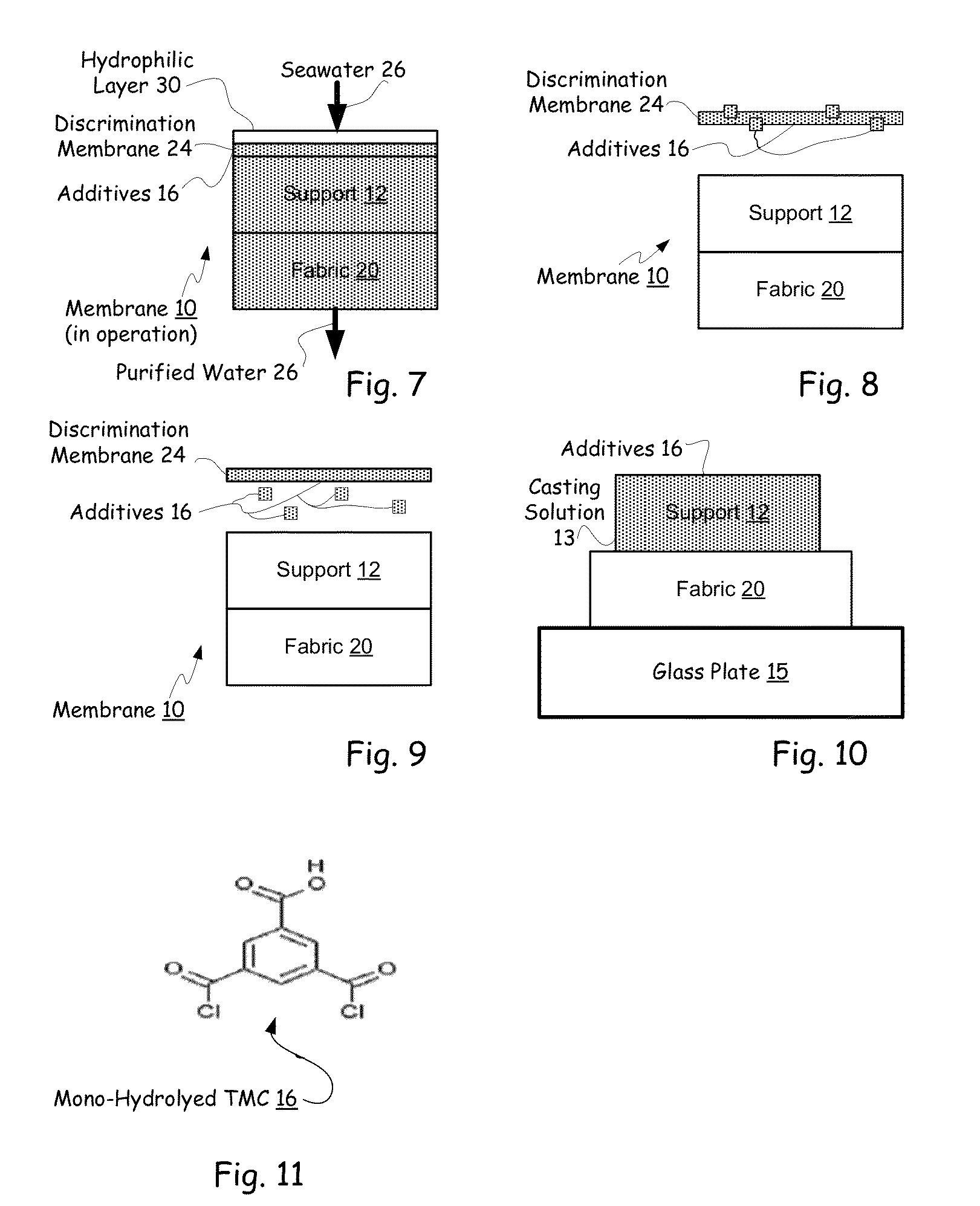

Hybrid TFC RO membranes with nitrogen additives

ActiveUS8567612B2Inhibits biofilm formationMembranesWater/sewage treatment bu osmosis/dialysisChloramine BAlkaline earth metal

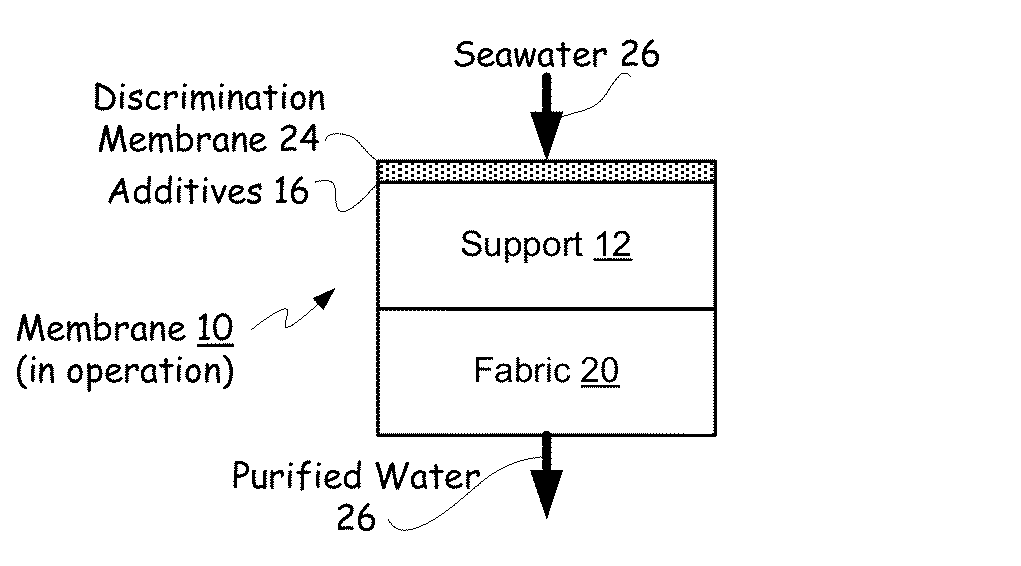

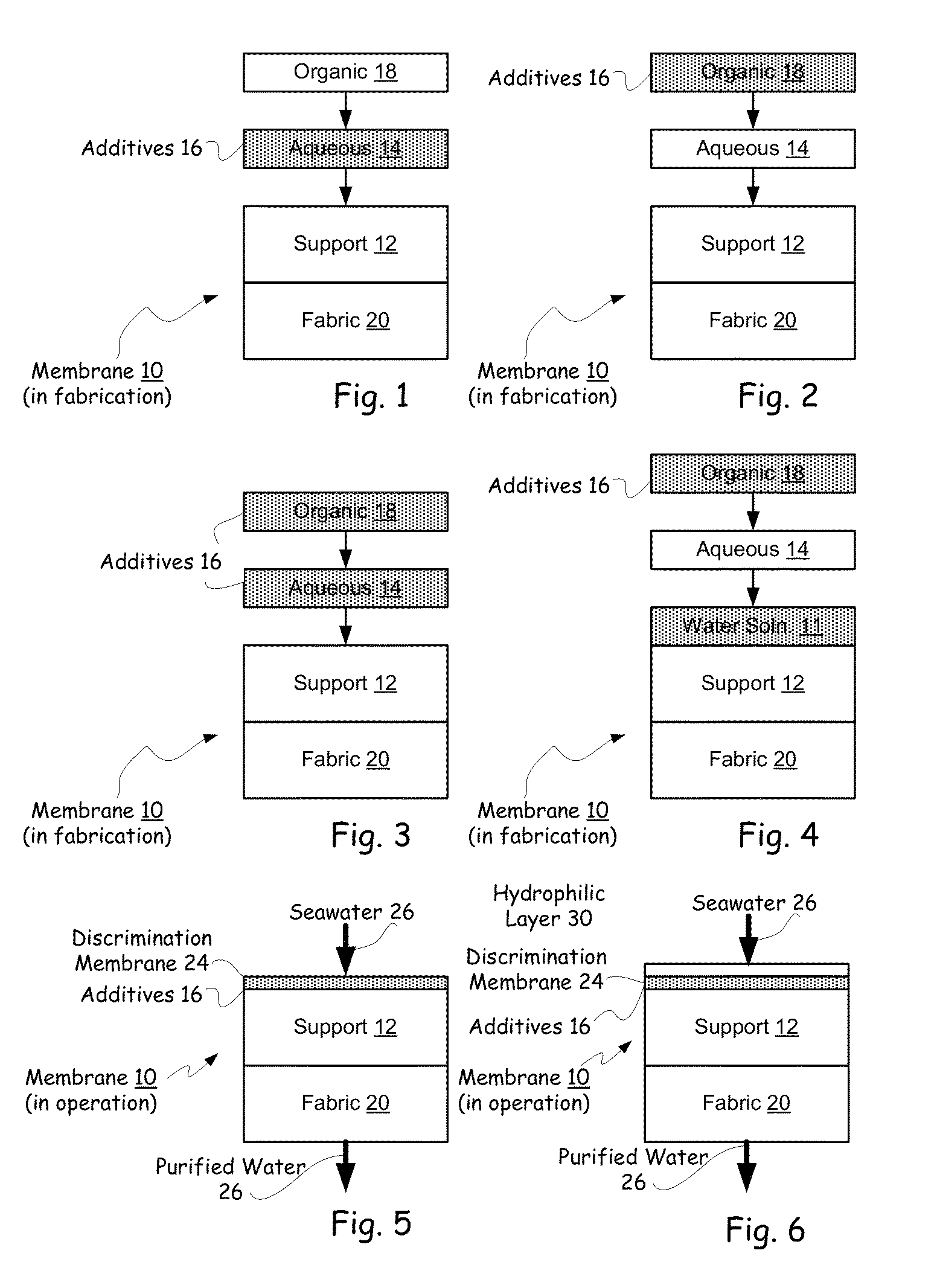

RO membranes using chlorinated water as a feed stream maybe protected from damage by the chlorine with a protective layer including reactive nitrogen which forms chloromines on the surface of the membrane that reduce chlorine penetration. This protective layer also provides substantial anti-fouling capabilities, whether used with a chlorinated or unchlorinated feed stream because the chloramines are anti-bacterial. Although chlorine is lost in use, the anti-fouling layer or coating can be recharged with additional chlorine without damaging the discrimination layer. The anti-fouling layer or coating may be advantageously used with Thin film composite, TFC, membranes for use in forward and reverse osmosis may include nanoparticles, monohydrolyzed and / or di-hydrolyzed TMC, and / or alkaline earth alkaline metal complexes or other additives.

Owner:NANOH2O

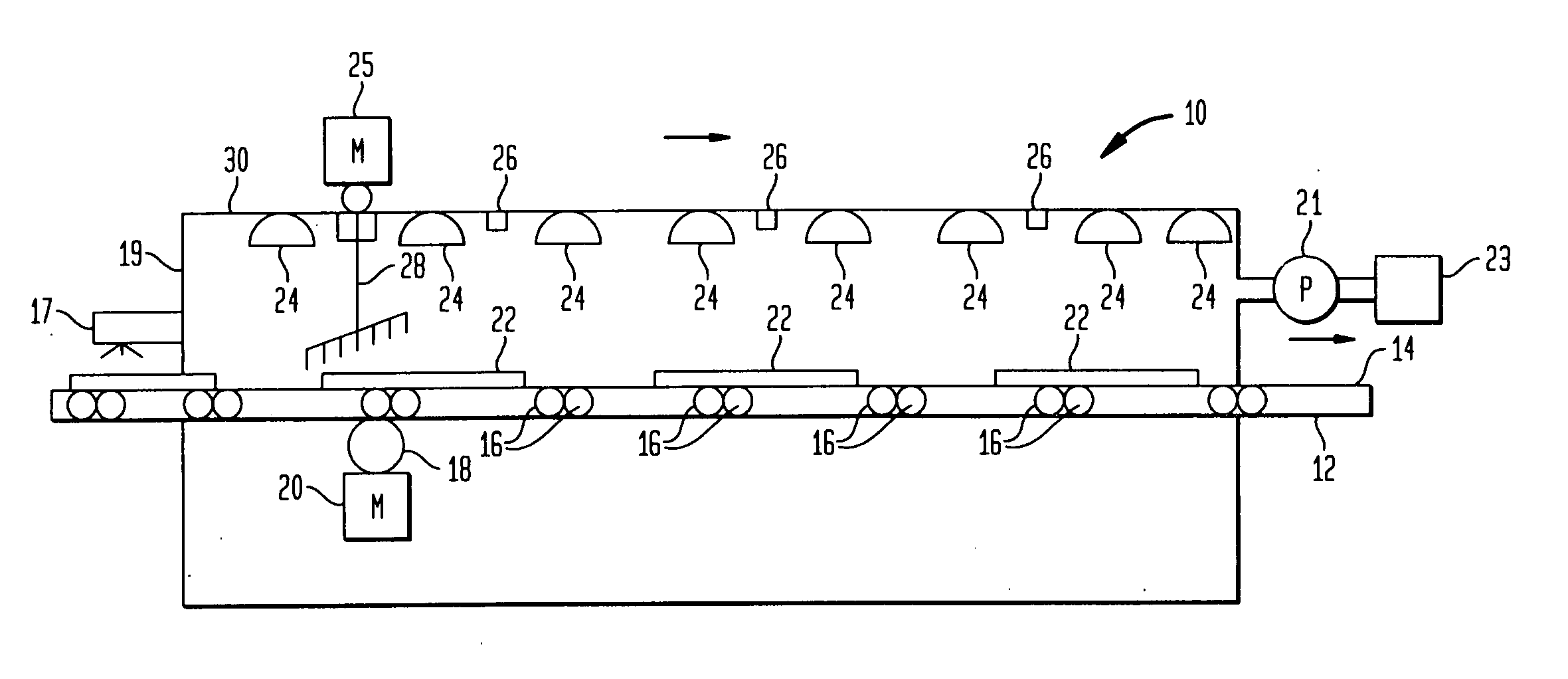

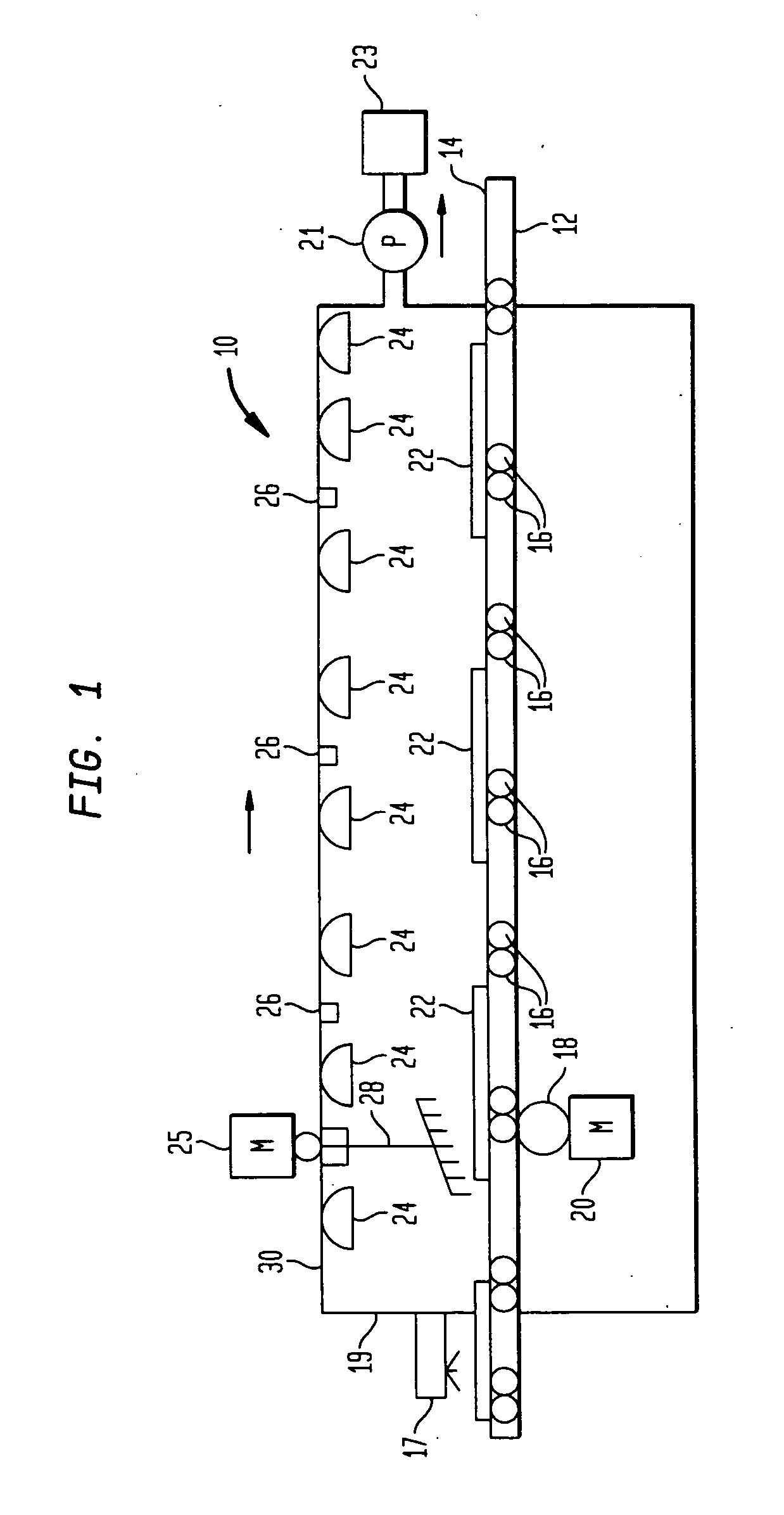

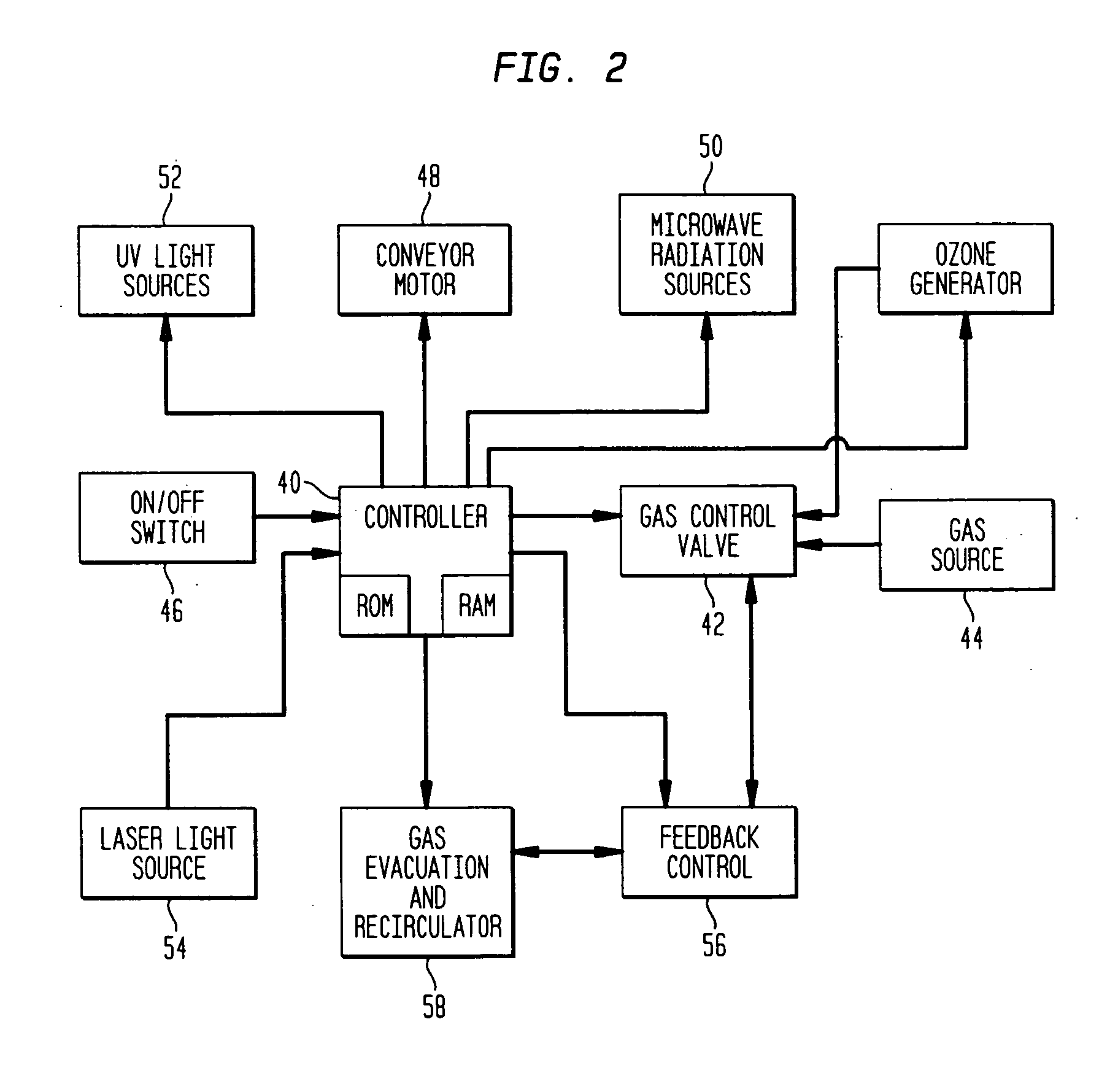

Sanitizing device and method for sanitizing articles

The invention provides an apparatus for sanitizing a plurality of articles, which comprises a housing enclosing a sanitizing zone, the housing having a seal for preventing leakage of gas or fluid from the sanitizing zone; a pump for introducing an antimicrobial fluid into the sanitizing zone; and a pump for withdrawing the fluid from the sanitizing zone. The device also includes at least one high power microwave source and at least one ultraviolet irradiating source, or a microwave source that also generates ultraviolet radiation. Preferably, the gas is a halogen, such as chlorine, bromine, or iodine, or a gas or fluid containing chlorine or bromine ions, but it can be ozone or another gas which kills bacteria, microbes, viruses, and other pathogens. The fluid can also be sprayed droplets or vaporized sodium hypochlorite, or similar antiseptic agent.

Owner:WEN SHEREE H

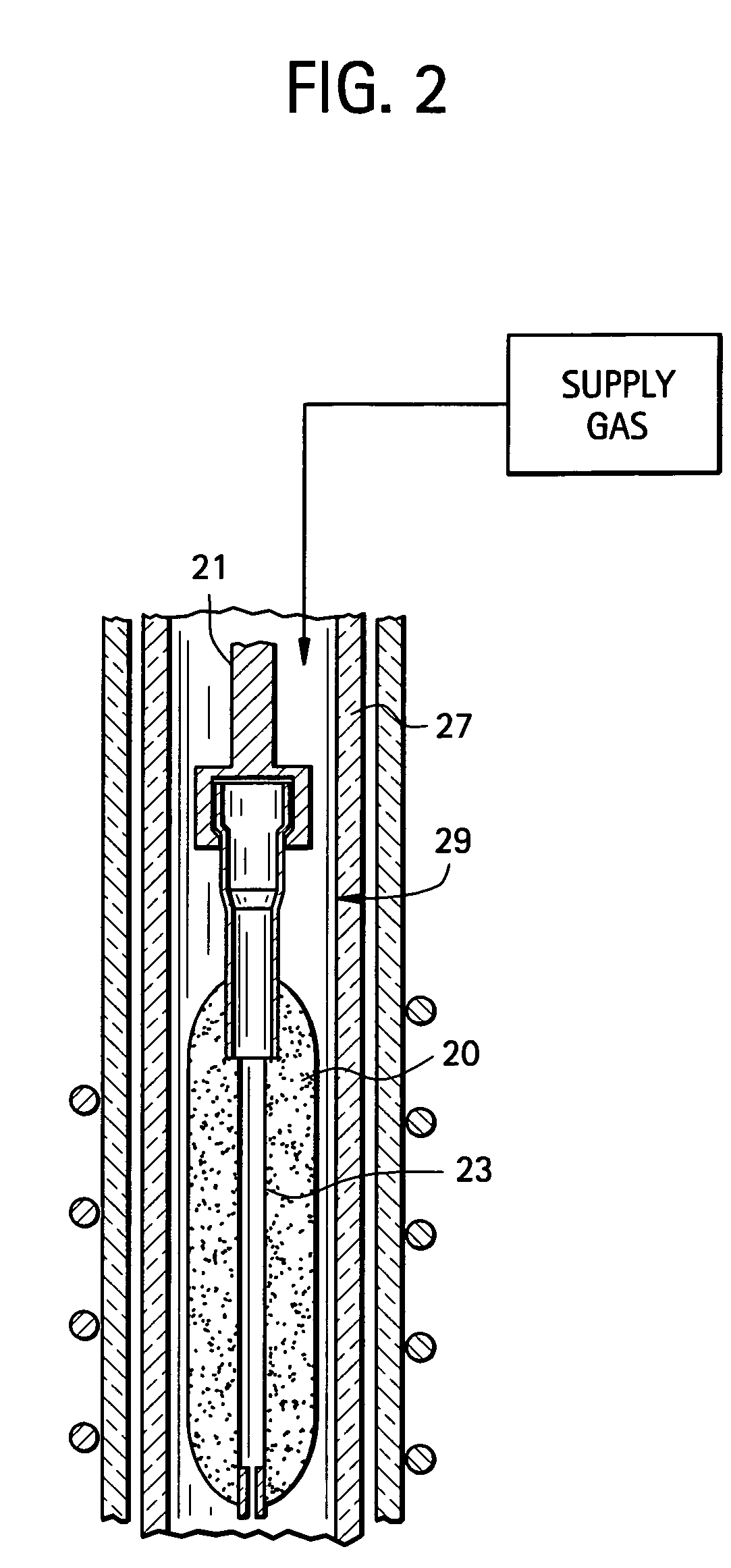

Optical fiber containing alkali metal oxide

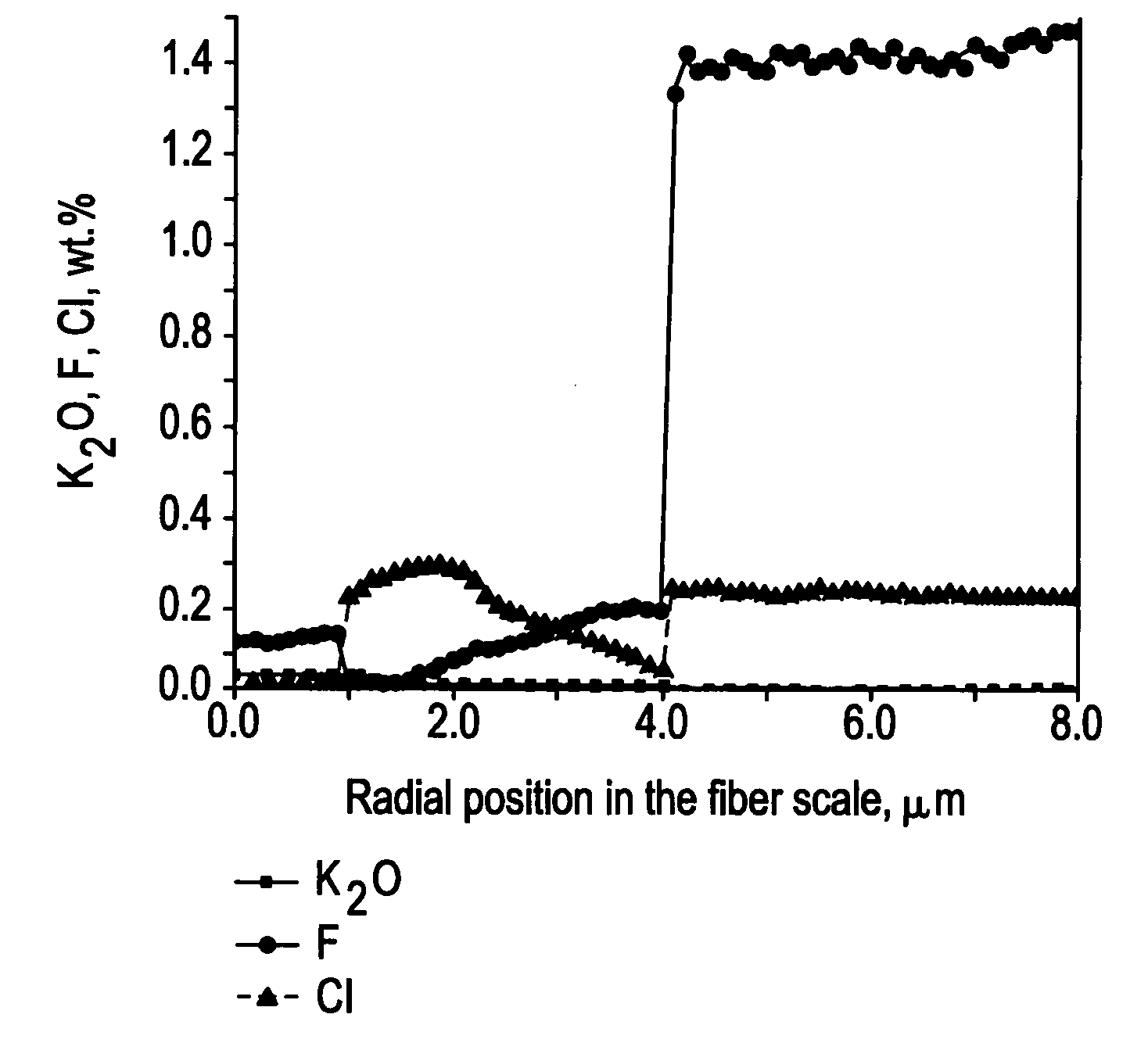

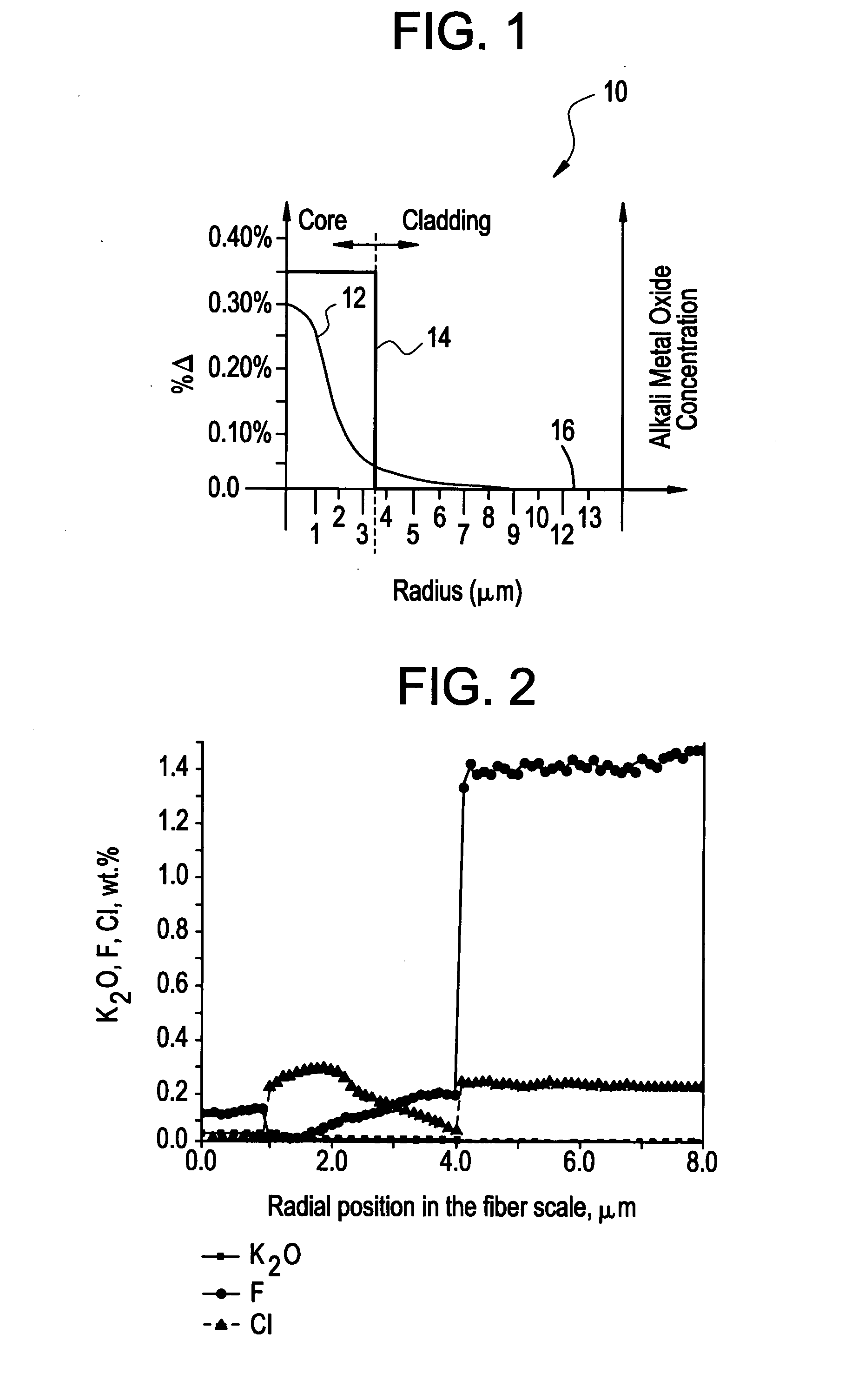

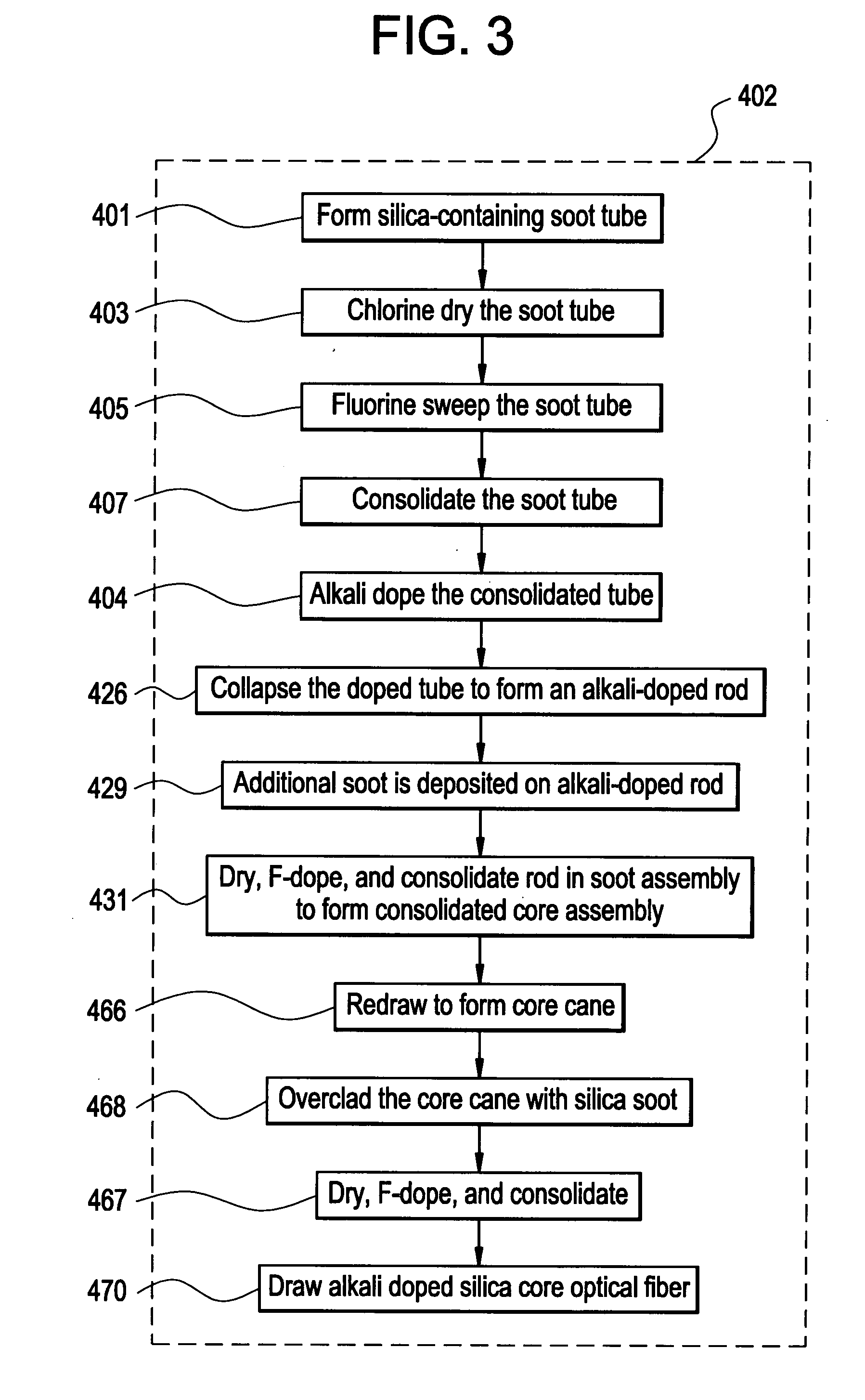

ActiveUS20070297735A1Reduce lossReduce concentrationGlass making apparatusOptical fibre with multilayer core/claddingDopantAlkali metal oxide

Disclosed is an optical fiber having a silica-based core comprising an alkali metal oxide selected from the group consisting of K2O, Na2O, LiO2, Rb2O, Cs2O and mixtures thereof in an average concentration in said core between about 50 and 500 ppm by weight, said core further comprising chlorine and fluorine, wherein the average concentration of fluorine in said core is greater than the average concentration of alkali metal oxide in said core and the average concentration of chlorine in said core is greater than the average concentration of alkali metal oxide in said core; and a silica-based cladding surrounding and directly adjacent the core. By appropriately selecting the concentration of alkali metal oxide dopant in the core and the cladding, a low loss optical fiber may be obtained.

Owner:CORNING INC

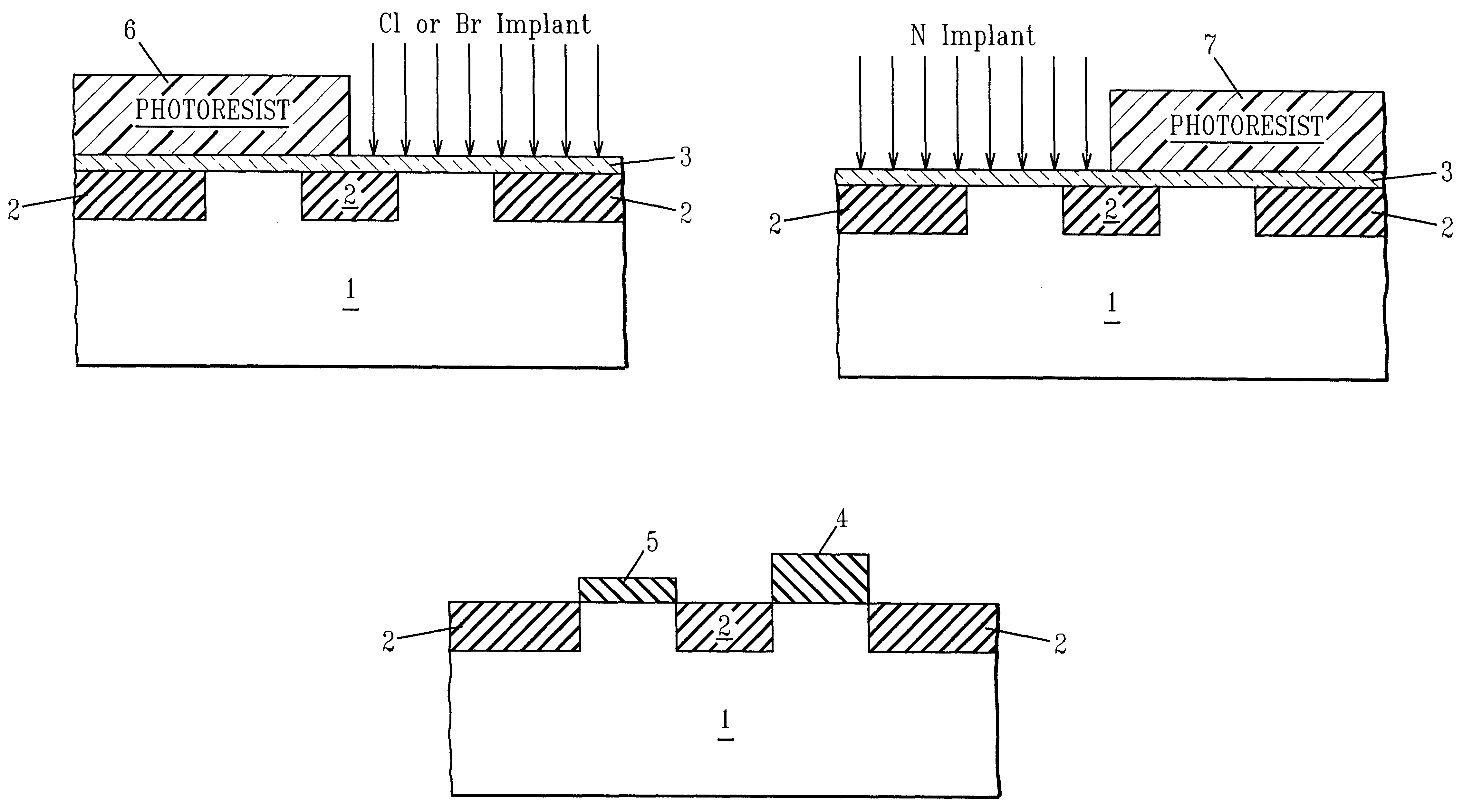

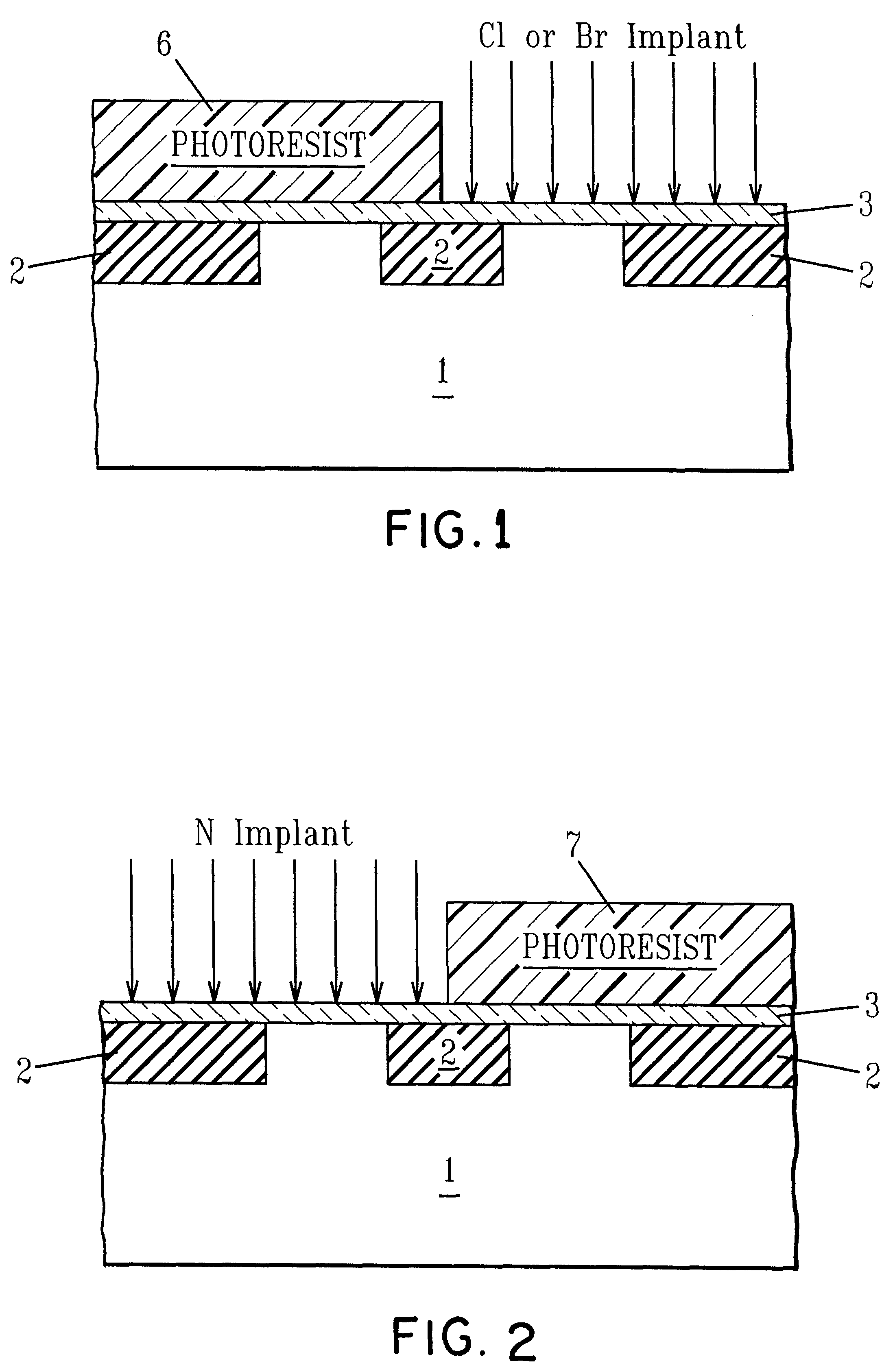

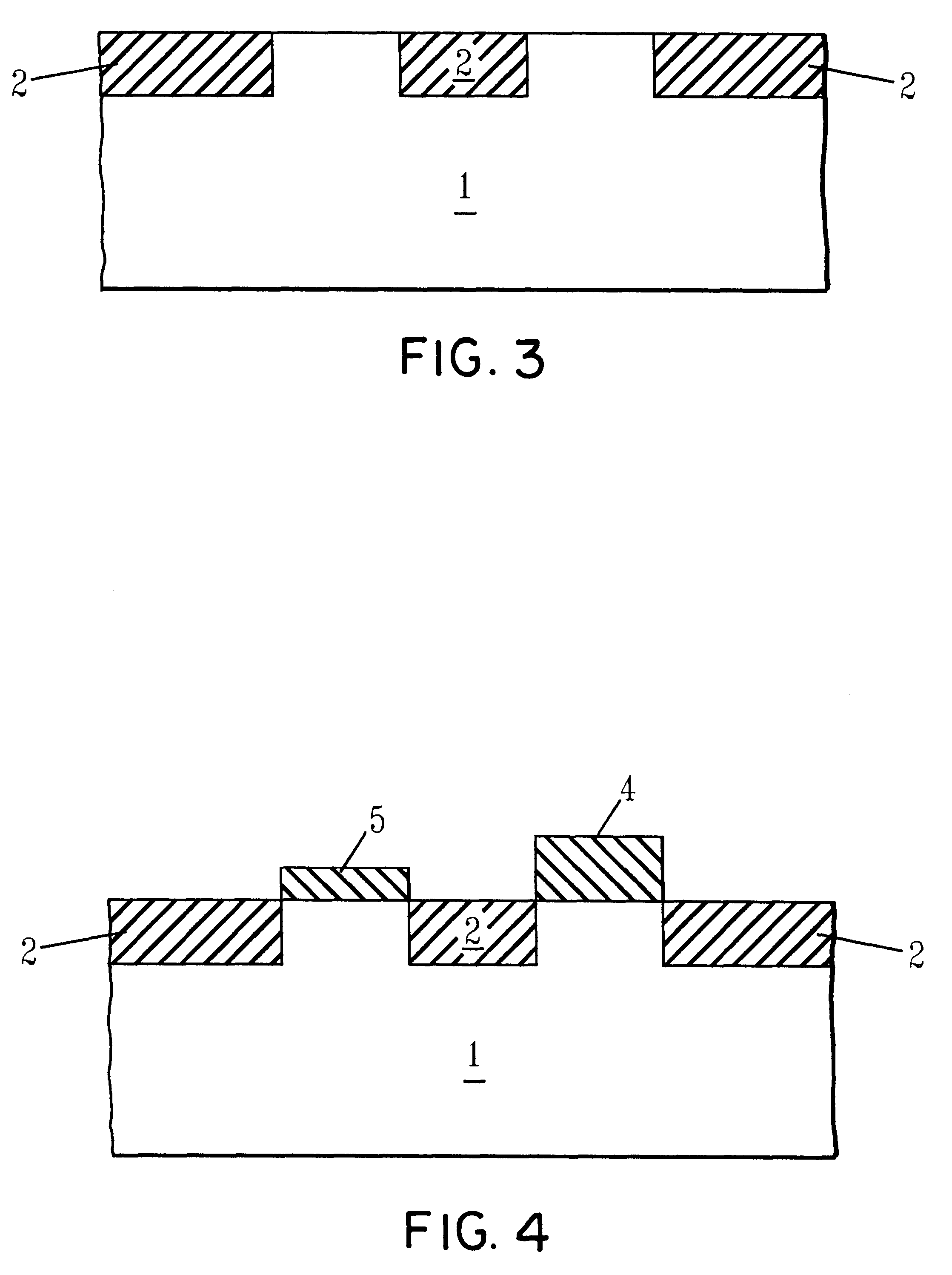

Method for fabricating different gate oxide thicknesses within the same chip

InactiveUS6335262B1Increase rangeSlow and reduced rateSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureBromine

Owner:GLOBALFOUNDRIES INC

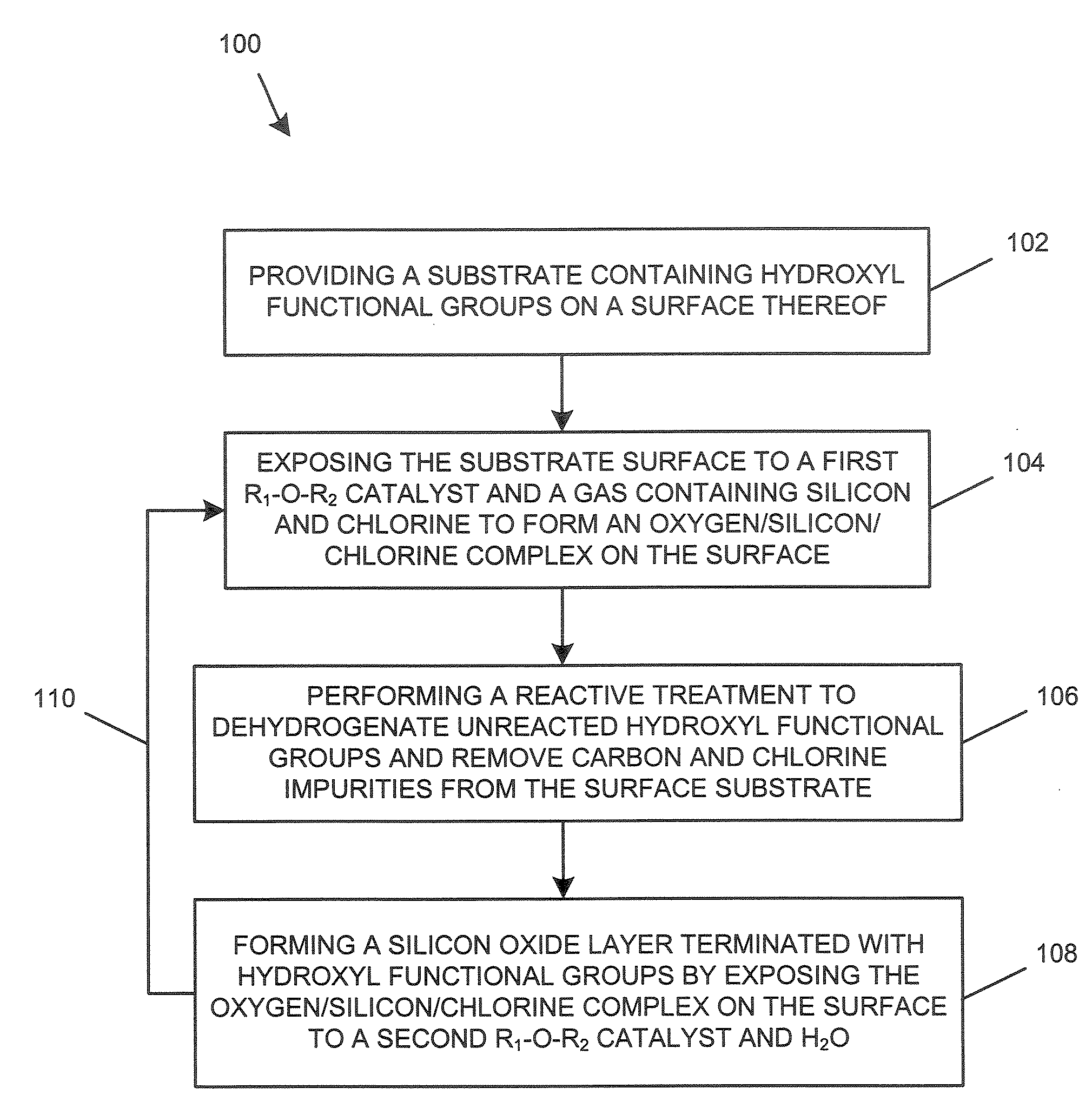

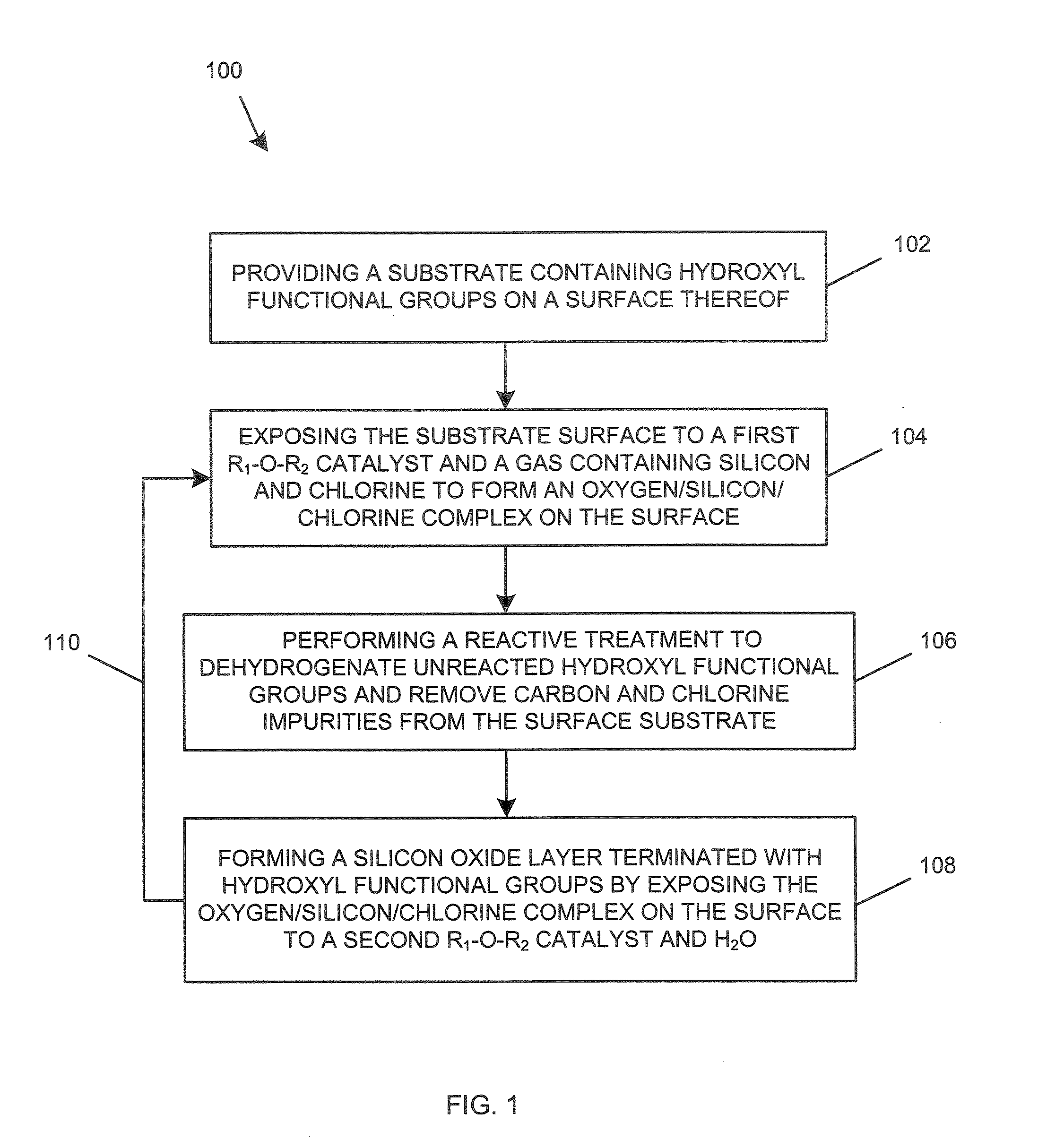

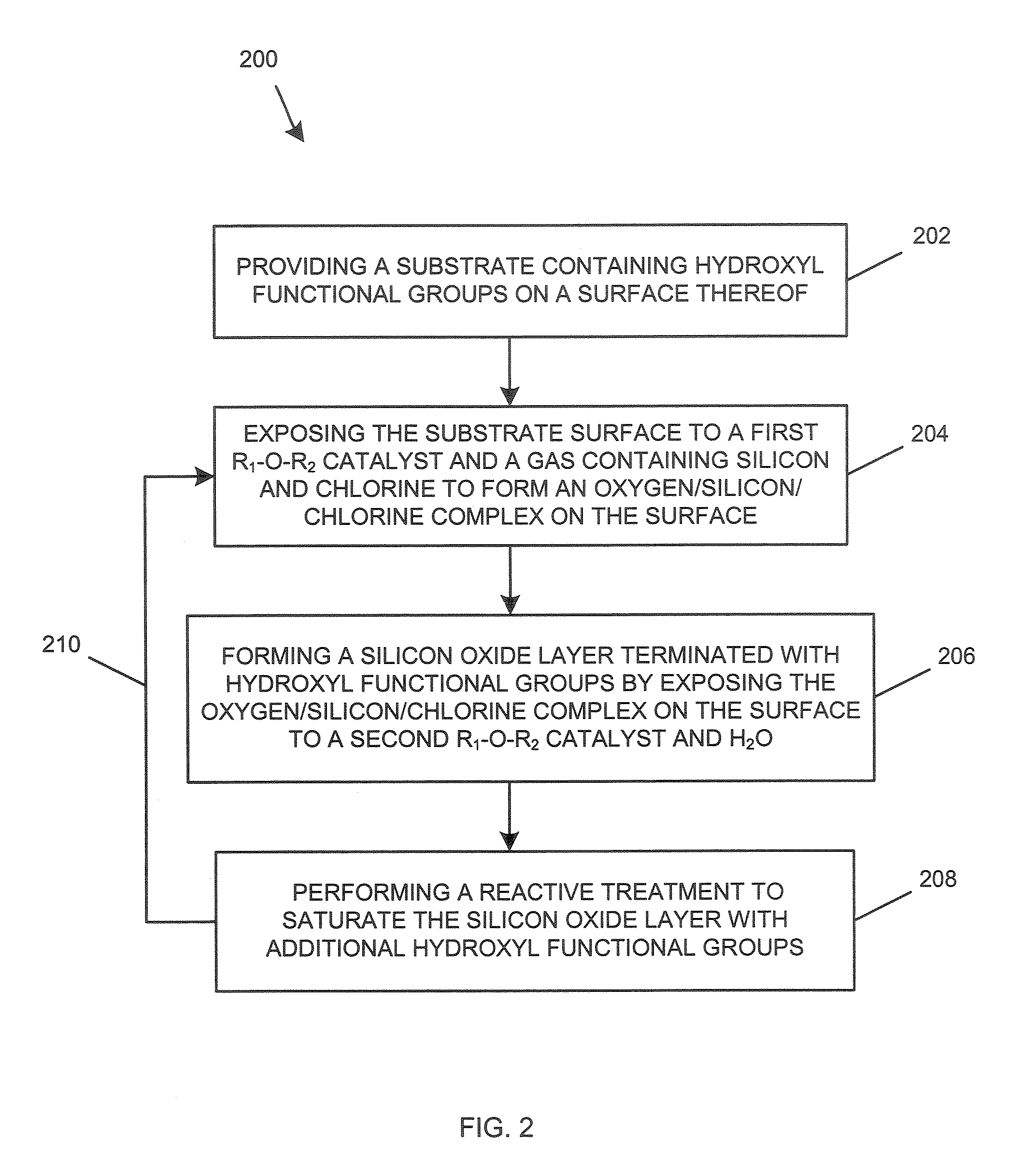

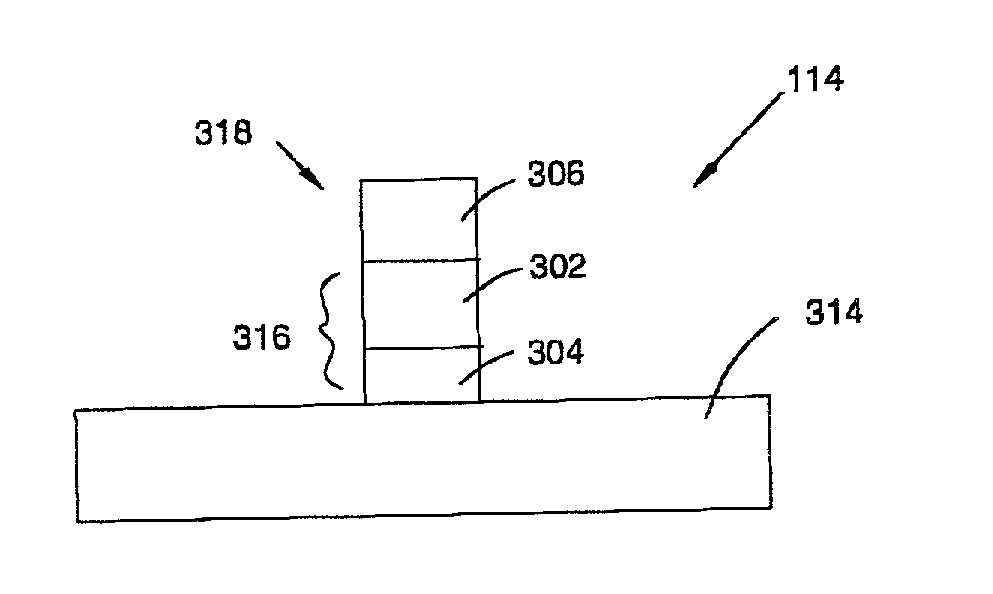

Catalyst-assisted atomic layer deposition of silicon-containing films with integrated in-situ reactive treatment

ActiveUS20080241358A1Reduces and eliminates needReduce and eliminate needVacuum evaporation coatingSolid-state devicesAtomic layer depositionSilicon

A method is provided for low temperature catalyst-assisted atomic layer deposition of silicon-containing films such as SiO2 and SiN. The method includes exposing a substrate surface containing X—H functional groups to a first R1—X—R2 catalyst and a gas containing silicon and chlorine to form an X / silicon / chlorine complex on the surface, and forming a silicon-X layer terminated with the X—H functional groups by exposing the X / silicon / chlorine complex on the substrate surface to a second R1—X—R2 catalyst and a X—H functional group precursor. The method further includes one or more integrated in-situ reactive treatments that reduce or eliminate the need for undesired high-temperature post-deposition processing. One reactive treatment includes hydrogenating unreacted X—H functional groups and removing carbon and chlorine impurities from the substrate surface. Another reactive treatment saturates the silicon-X layer with additional X—H functional groups.

Owner:TOKYO ELECTRON LTD

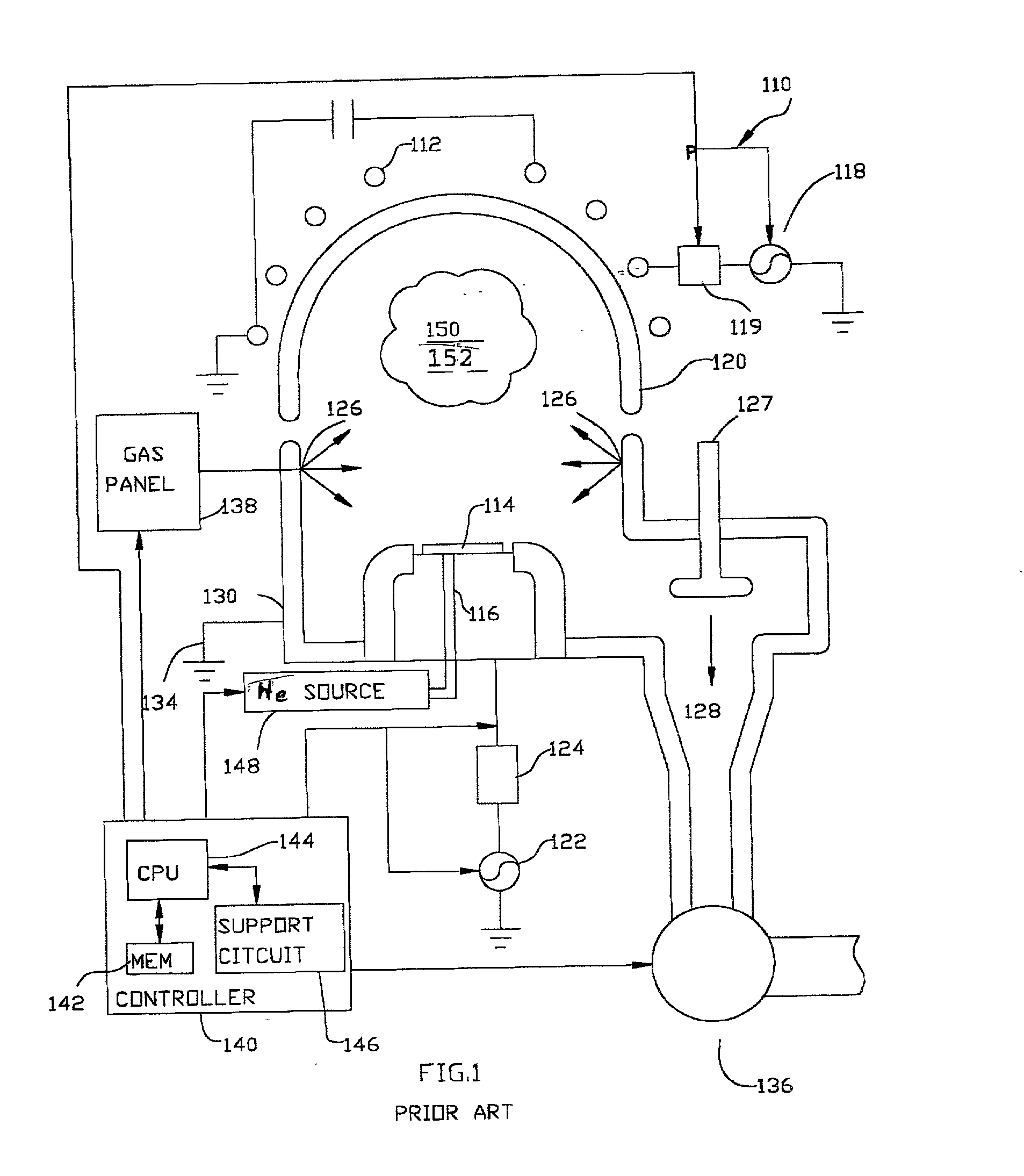

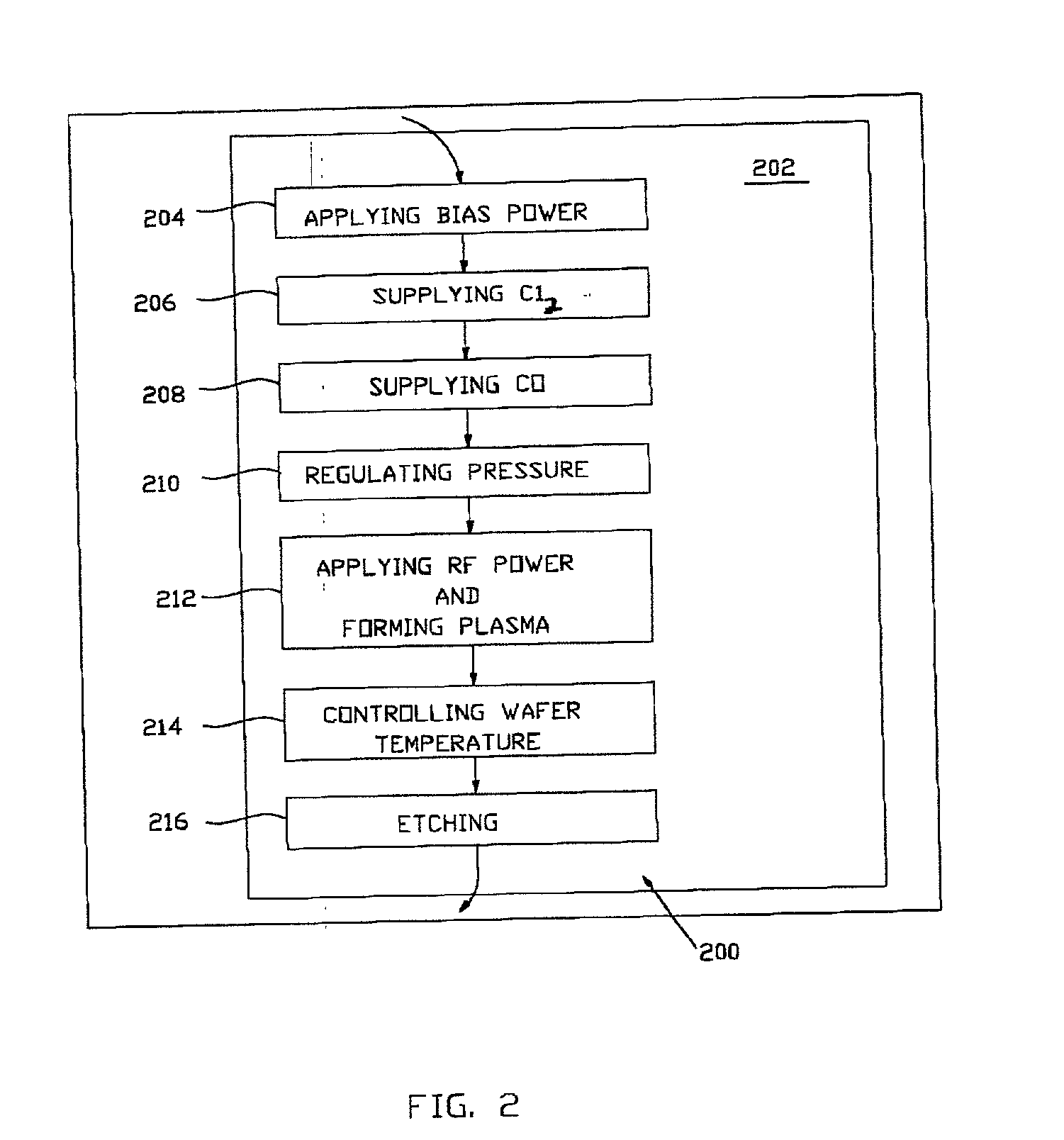

Method of plasma etching of high-K dielectric materials with high selectivity to underlying layers

InactiveUS20030170986A1Easy to understandSemiconductor/solid-state device manufacturingChamber pressureDielectric permittivity

A method of etching high dielectric constant materials using halogen gas and reducing gas chemistry. An embodiment of the method is accomplished using a 20 to 300 sccm of chlorine and 2 to 200 sccm of carbon monoxide, regulated to a total chamber pressure of 2-100 mTorr to etch a hafnium oxide layer.

Owner:APPLIED MATERIALS INC

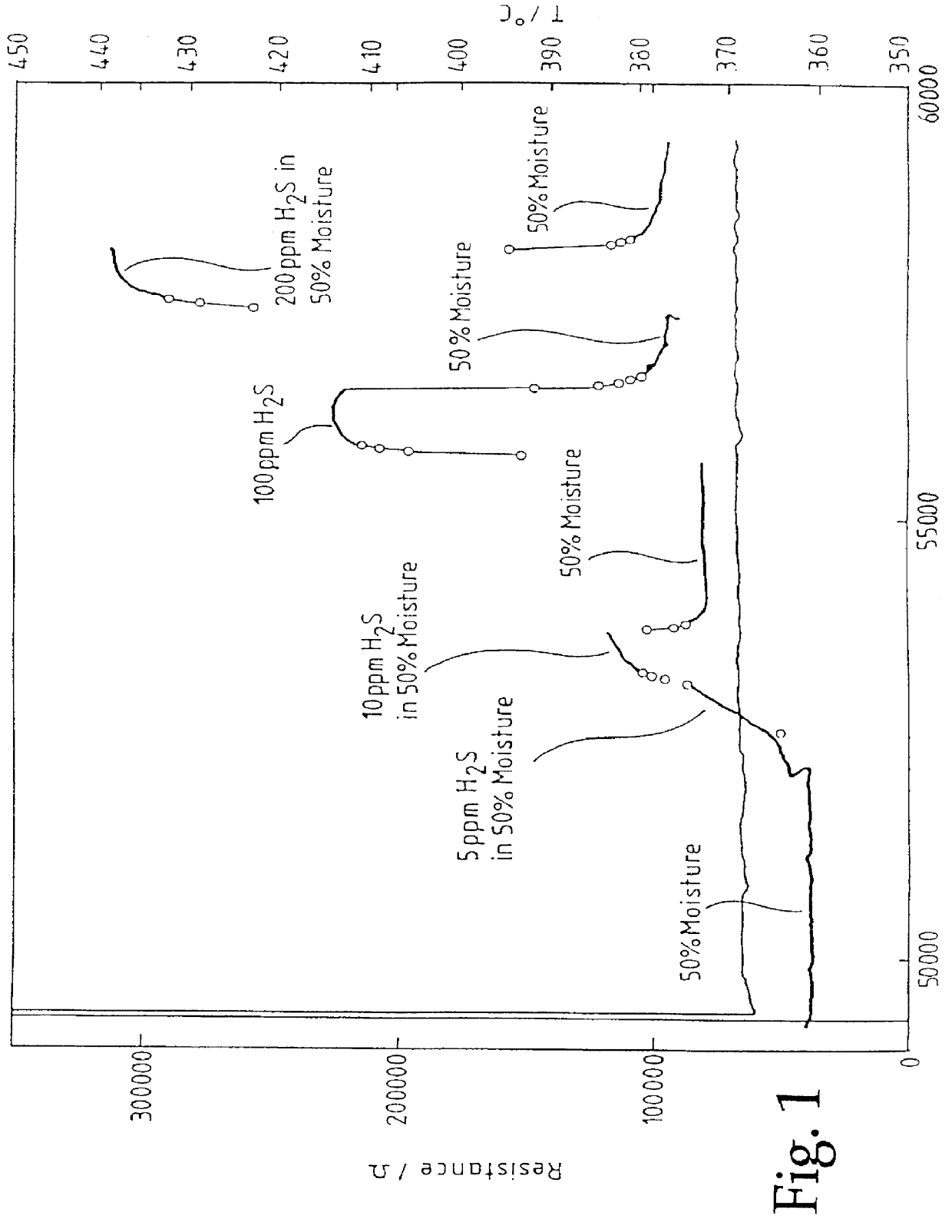

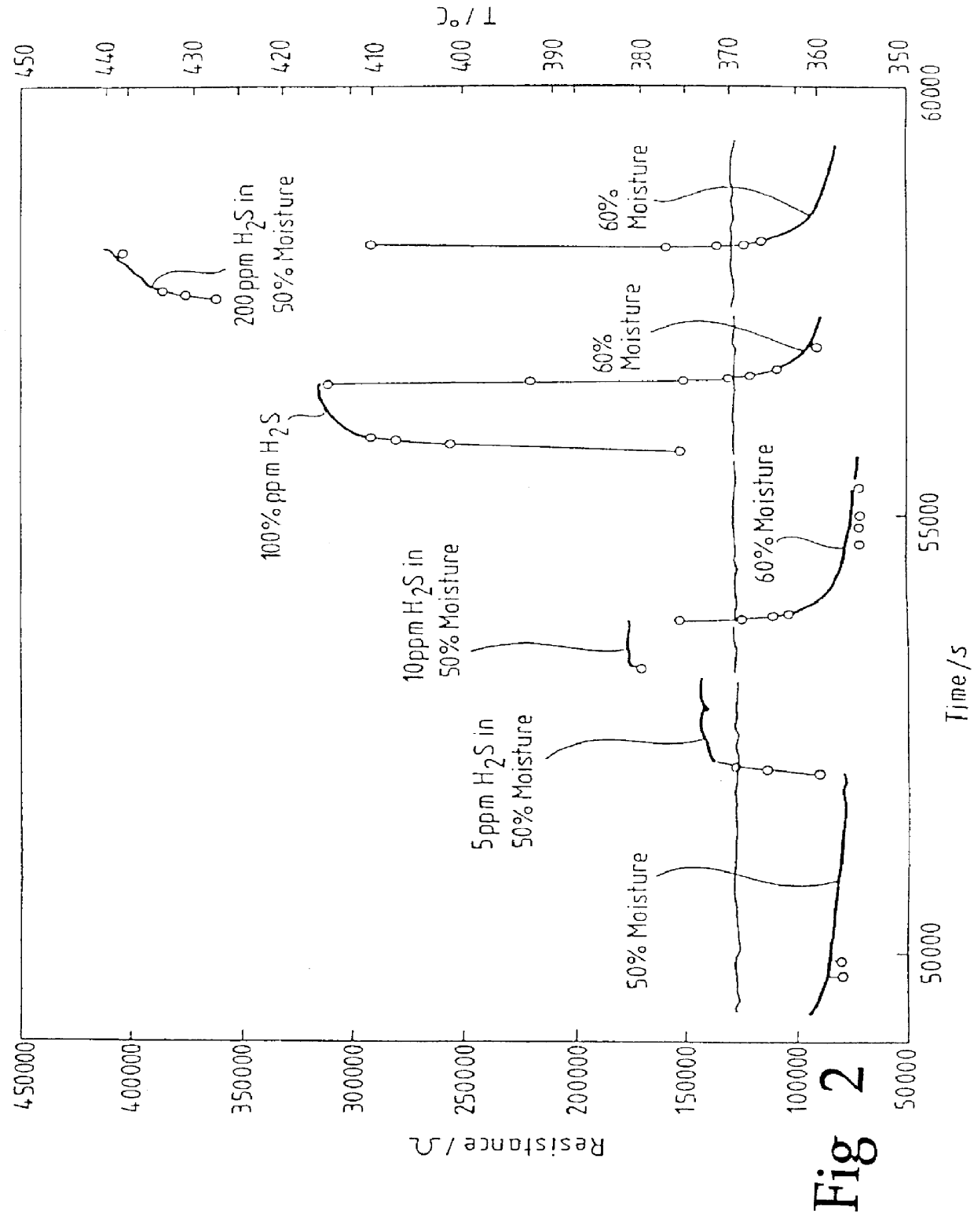

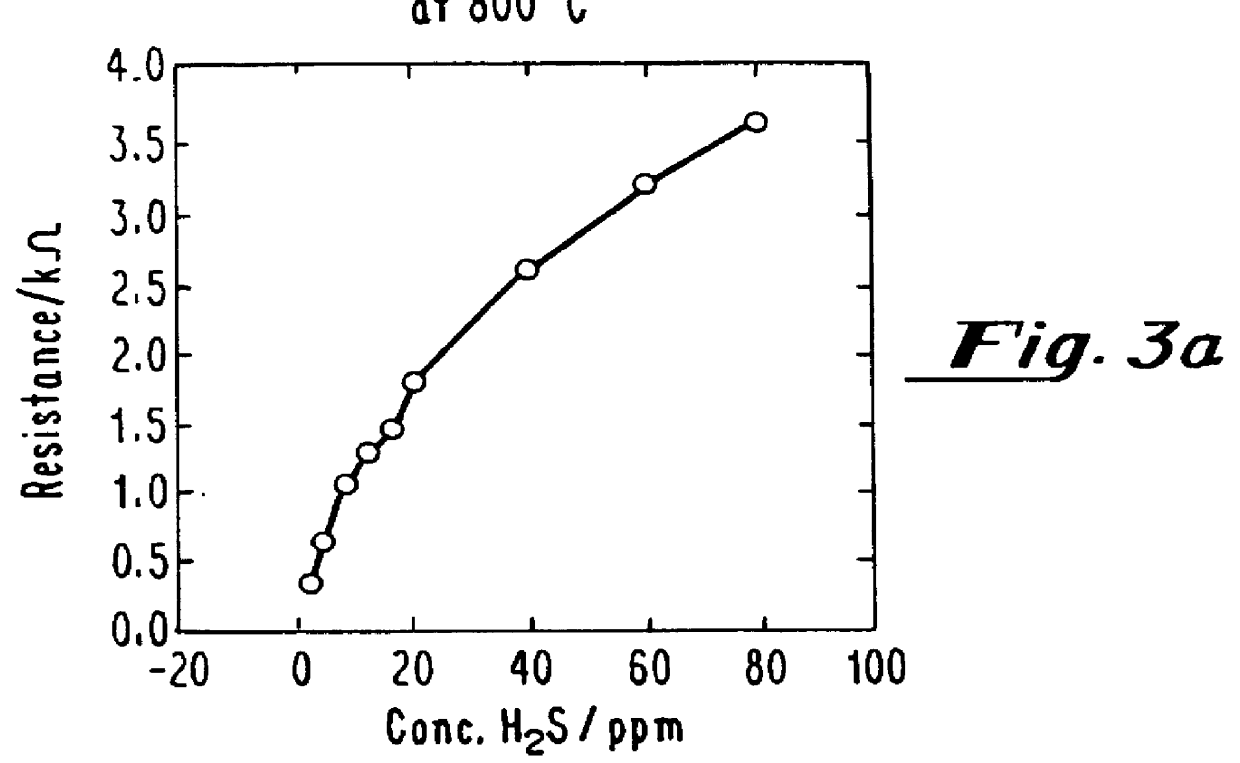

Semiconducting oxide gas sensors

InactiveUS6046054AShort stabilization timeGreatly reduced baseline driftFuel testingBiological testingAmmoniaPartial pressure

The selectivity of response of resistive gas sensors to specific gases or vapors is improved by the selection of specified gas-sensitive materials which are not previously known for the applications described, which include detection of hydrocarbons in the presence of CO, H2S, SO2, chlorine, NO2, CO2 (especially in low concentrations), CFC's, ammonia, free oxygen by determination of partial pressures, and numerous organic gases and vapors.

Owner:CAPTEUR SENSORS & ANALYZERS +1

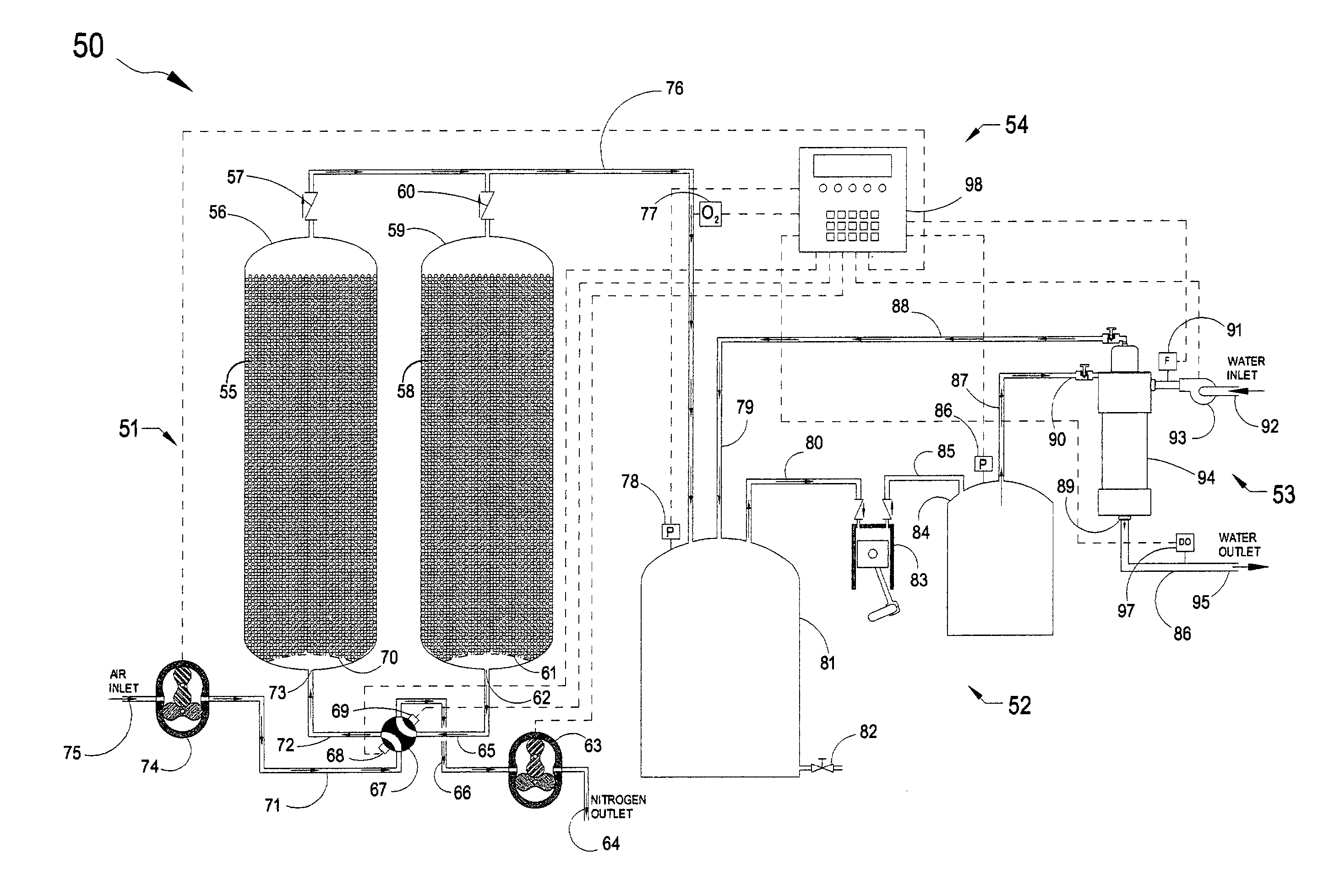

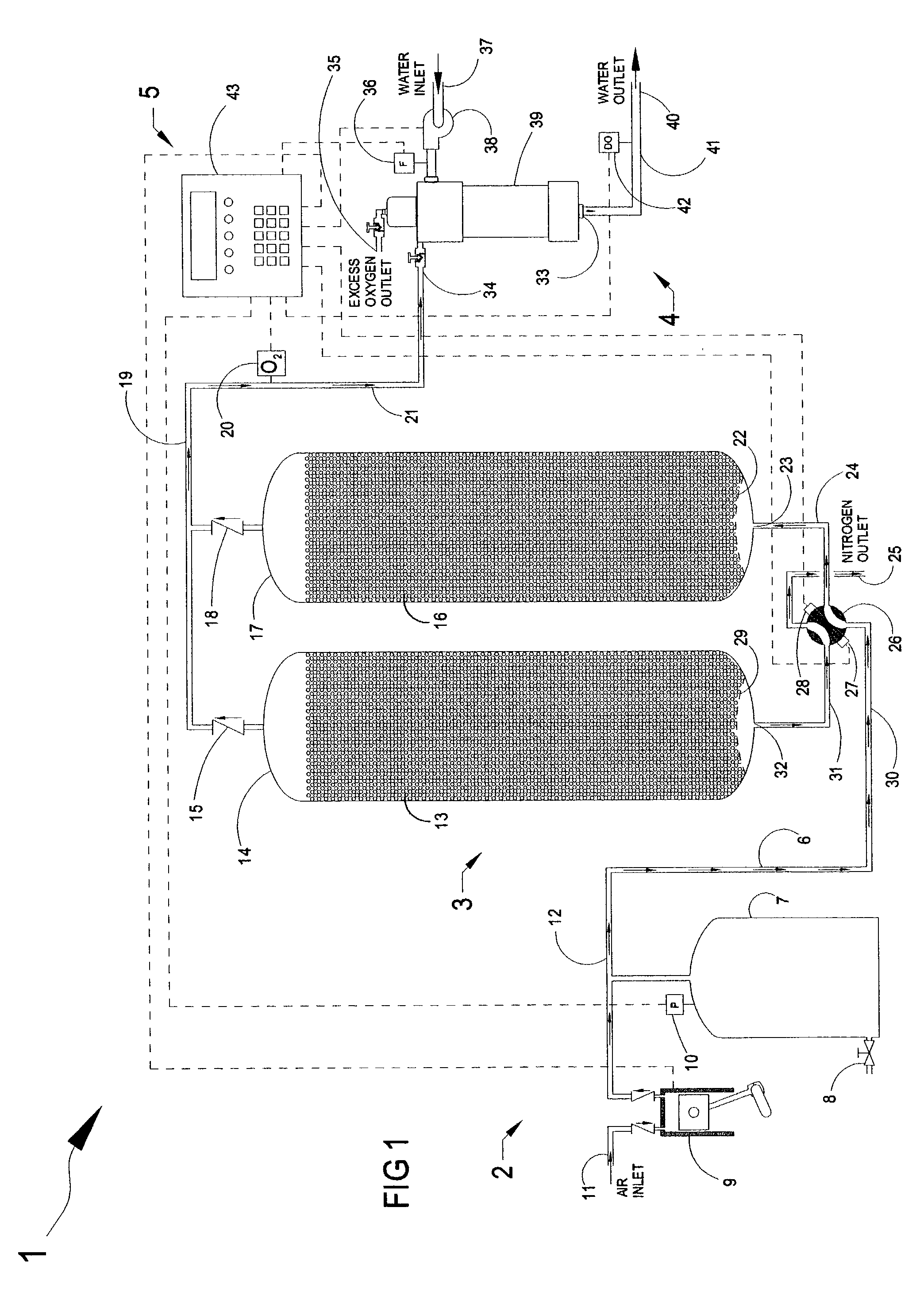

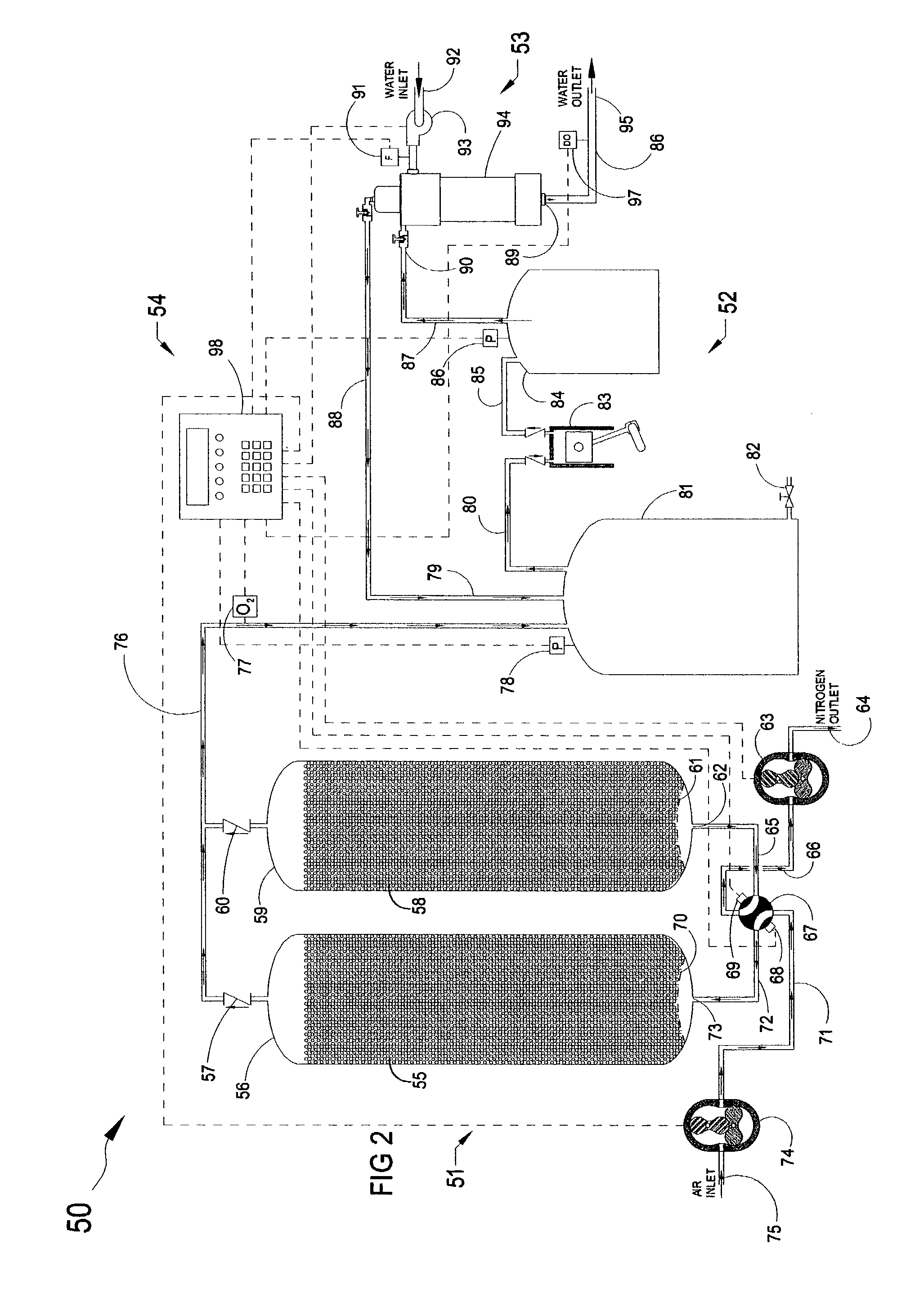

Methods and apparatus for supplying high concentrations of dissolved oxygen and ozone for chemical and biological processes

InactiveUS6962654B2Liquid separation auxillary apparatusFlow mixersHigh concentrationOrganismal Process

A method and apparatus for supplying dissolved gases (such as oxygen, ozone, chlorine etc.) for chemical and biological processes is described. The methods and apparatus described are particularly suitable for use in the biodegradation of organic matter (such as in municipal and industrial wastewater treatment), and other uses. The apparatus may comprise a dissolved gas supply system.

Owner:HYDROTREAT

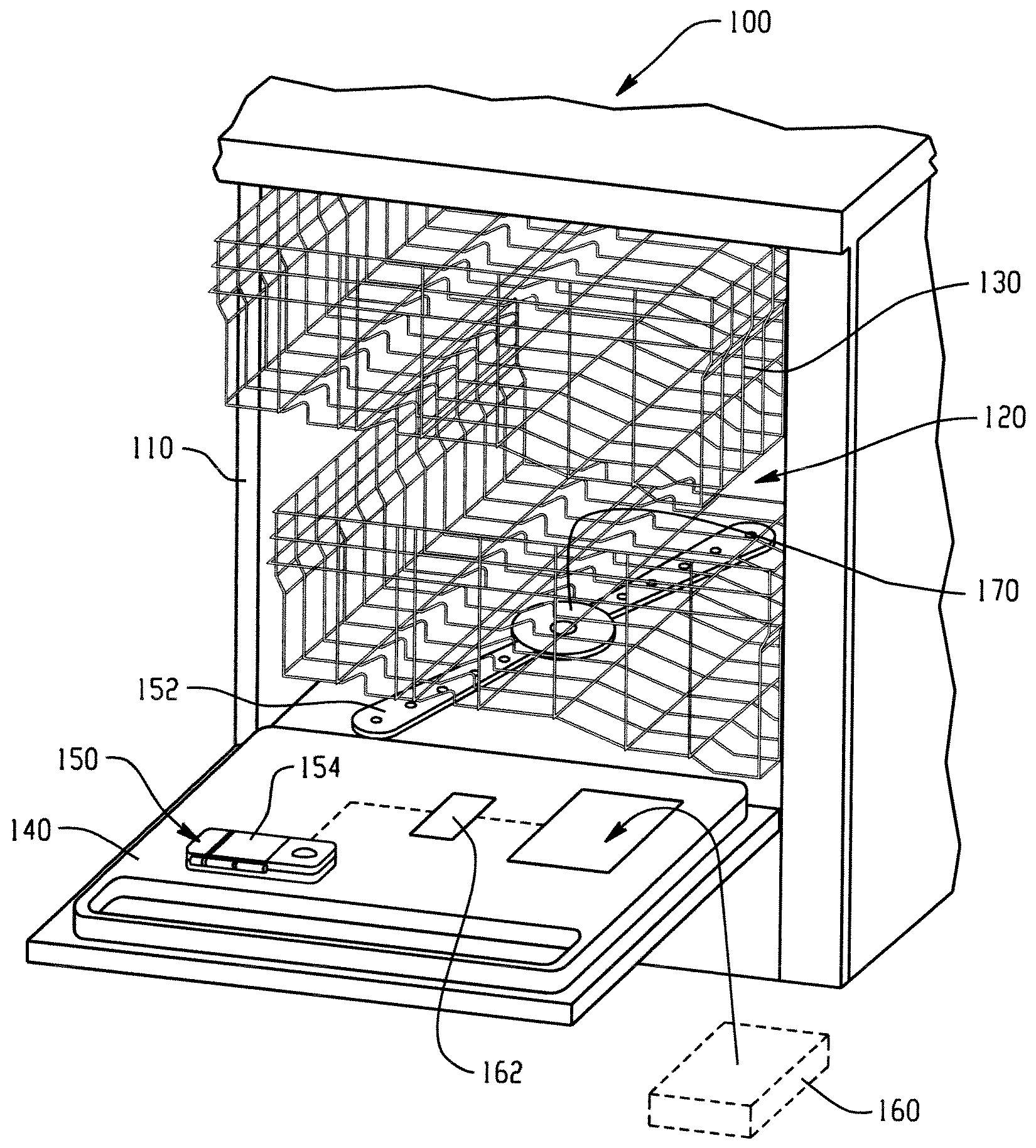

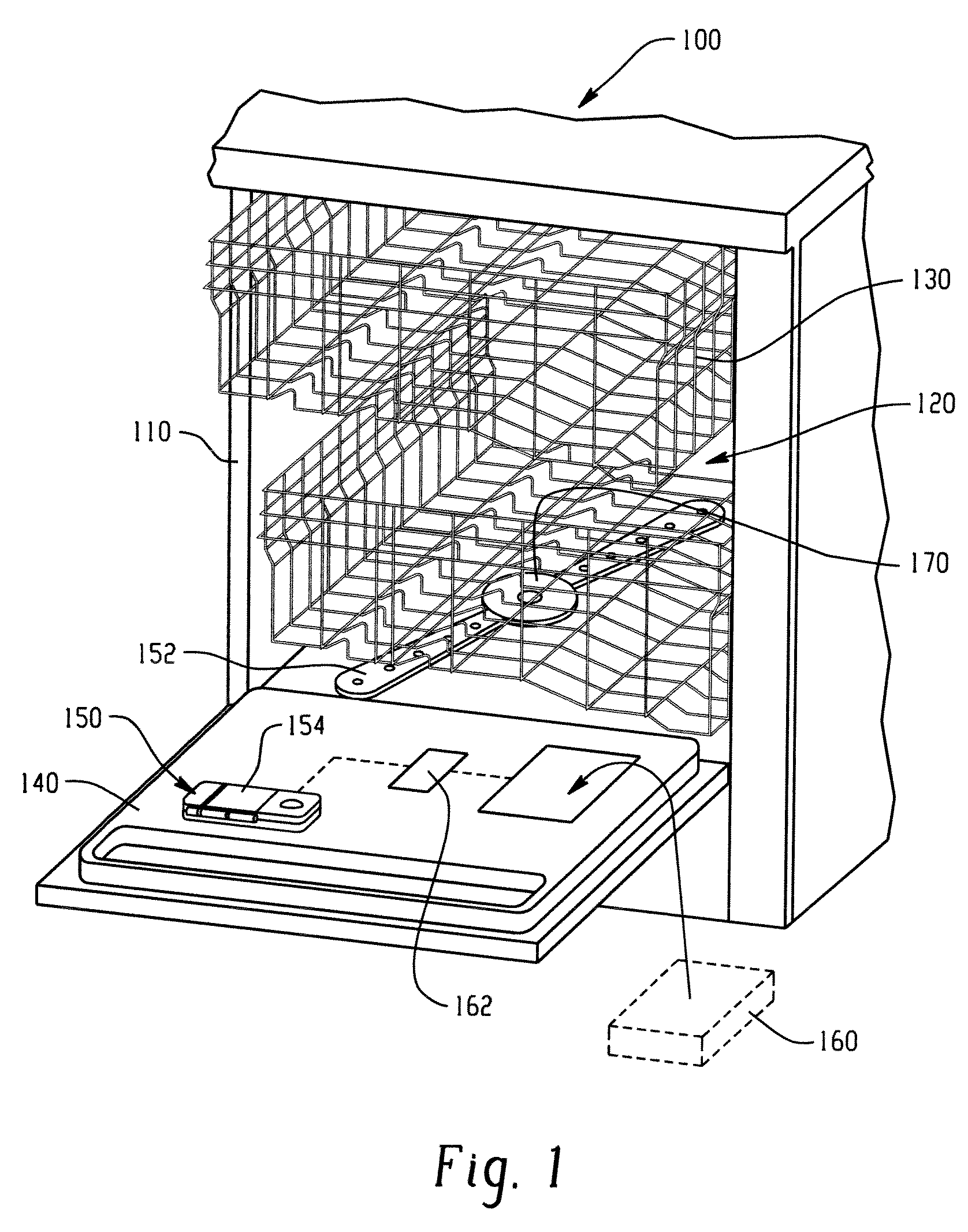

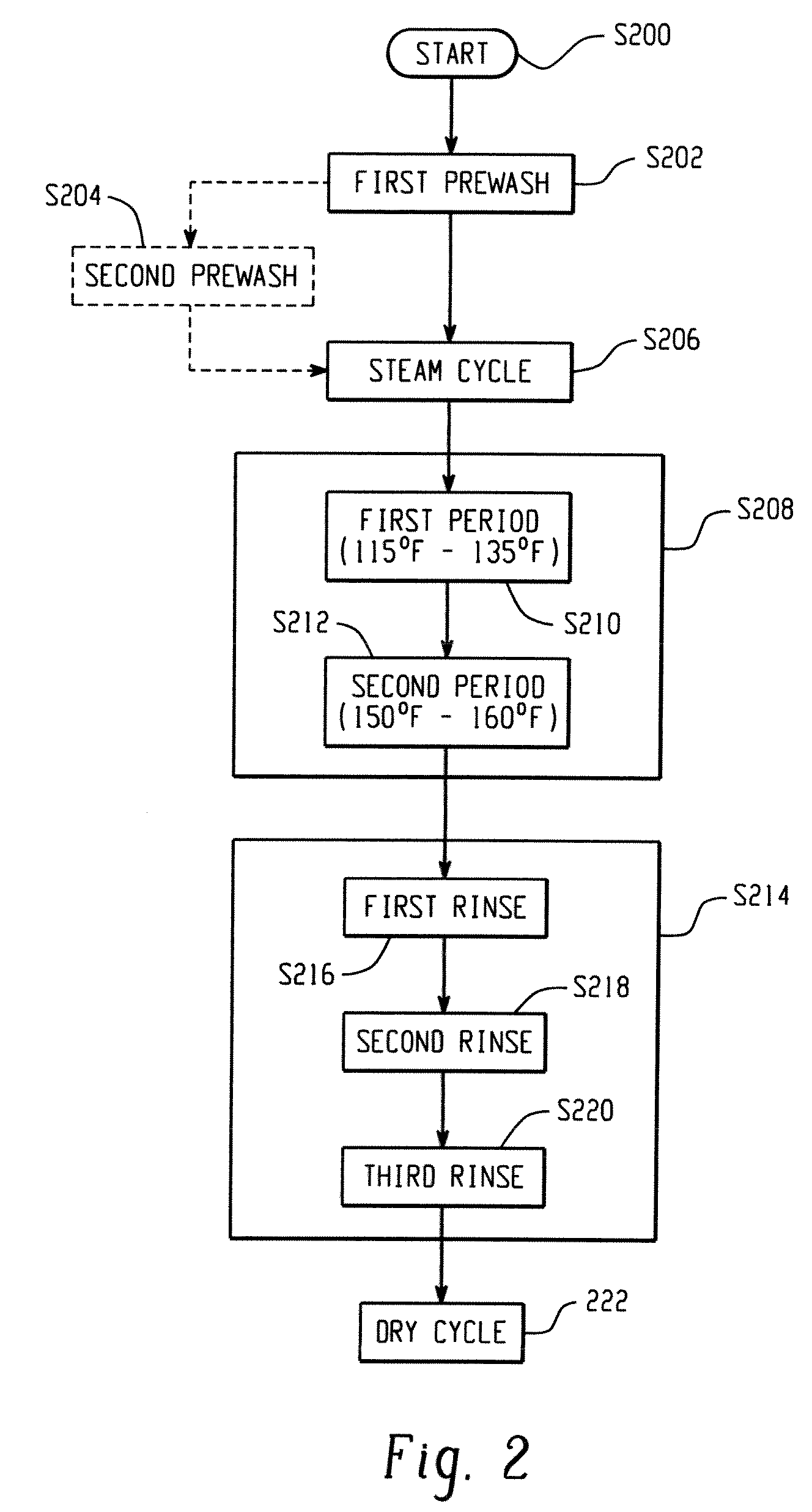

Deep clean cycle

InactiveUS20110000511A1Improve performanceSelectively energizing the heaterWashing processesAutomatic washing/rinsing machine detectionEngineeringEnzyme

A dishwasher includes a housing, a wash chamber in the housing that receives kitchenware therein, a detergent dispenser for introducing a detergent into the wash chamber, and a heater for raising temperature in the wash chamber. The dishwasher further includes a controller for selectively controlling water supply to and from the dish chamber. The controller establishes a temperature of the wash fluid circulating in the wash chamber during the first period in a range from about 115° F. (46° C.) to about 135° F. (58° C.) to enhance the wash performance of enzyme-based detergents and establishes a temperature of the wash fluid during a second period in the range from about 150° F. (65° C.) to about 160° F. (72° C.) to enhance wash performance of a chlorine-based detergent. A method of washing kitchenware contained in the dishwasher comprises (i) removing loose soil on the kitchenware in at least one pre-wash cycle, (ii) washing the kitchenware in a main wash cycle, and (iii) rinsing the kitchenware in at least one rinse cycle. The main wash cycle comprises the actions of (i) washing the kitchenware in a first temperature range for enzyme-based detergent for a first period and (ii) washing the kitchenware in a second temperature range for chlorine-based detergent for a second period.

Owner:GENERAL ELECTRIC CO

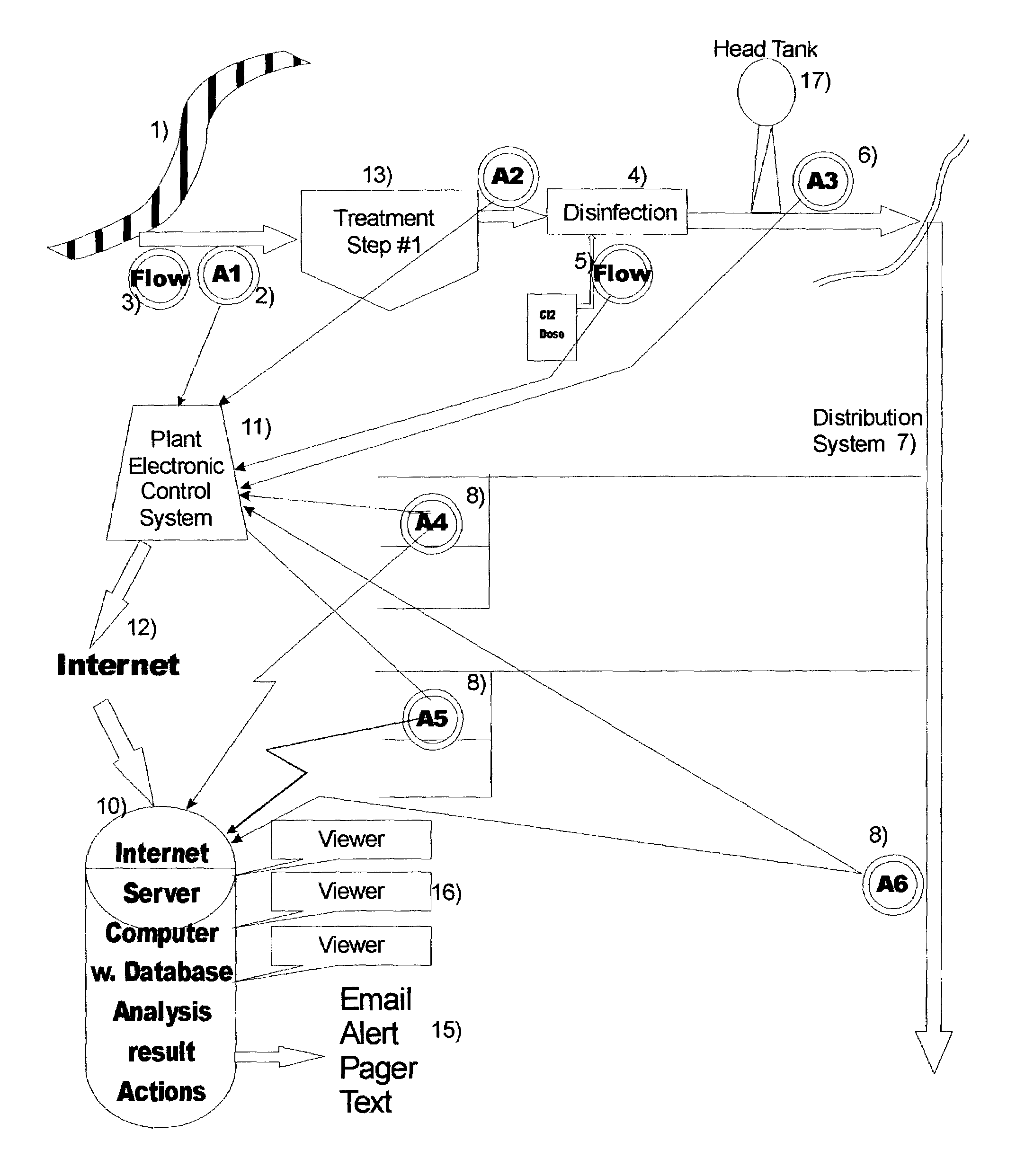

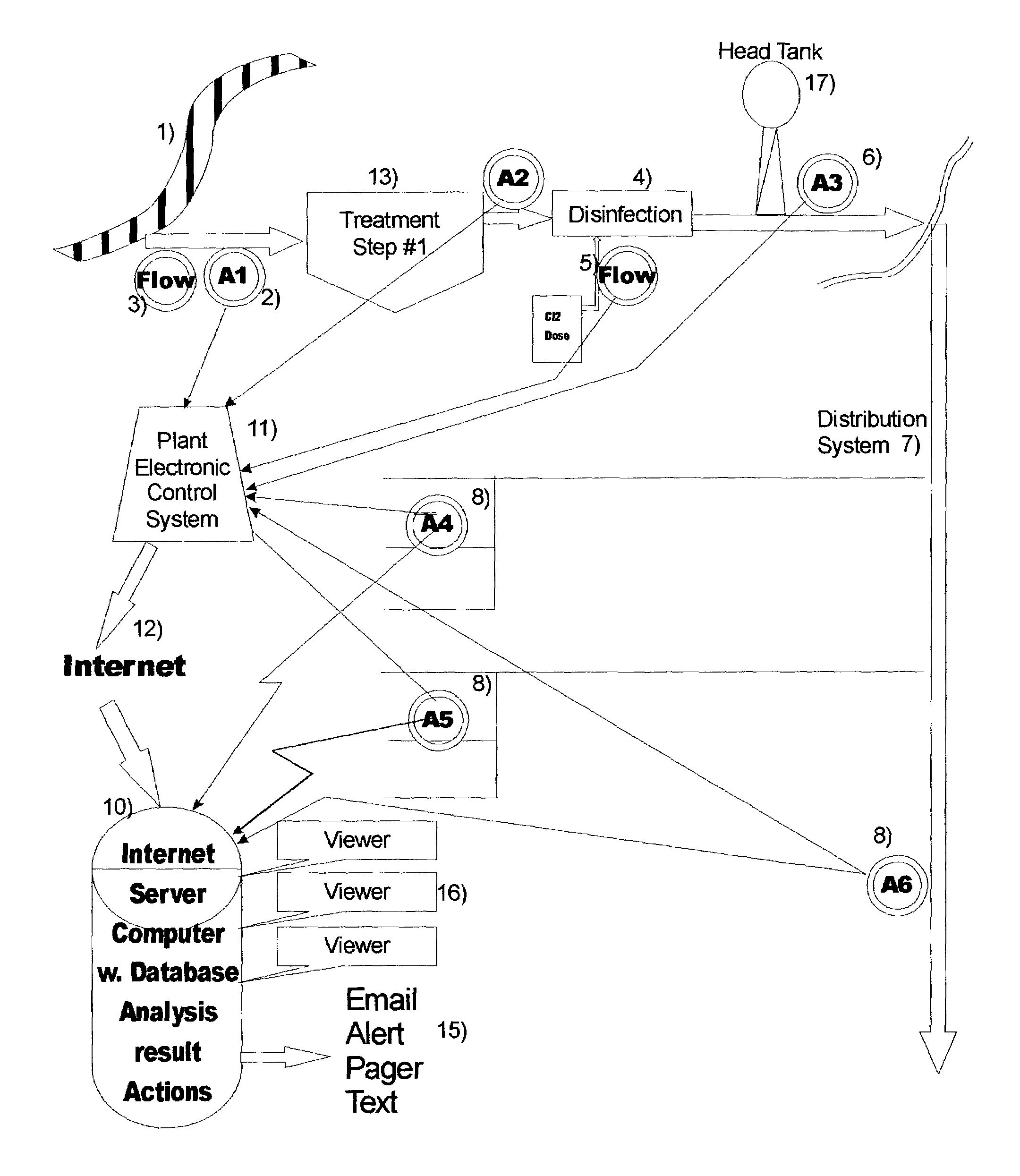

Anti-terrorism water quality monitoring system

InactiveUS7454295B2Prevent hackingRule out the possibilityGeneral water supply conservation2D-image generationChloramine BChlorine dioxide

An Anti-Terrorism water quality monitoring system for continuously monitoring a potable water treatment system and related potable water distribution network that provides potable water to a municipality, city, housing development or other potable water consumer. The system includes the collection of data from the water distribution system and from the water treatment facility and from advanced separation processes which are integrated into analytical instruments. The data collected are stored in a remote database on a remote server computer or bank of computers and accessible by Homeland Security or its designated agency. Preferred parameters of monitoring include the turbidity and disinfectant such as chlorine, hypochlorous acid, sodium hypochlorite, calcium hypochlorite, ozone, chlorine dioxide, chloramines, hydrogen peroxide, peracetic acid.

Owner:HACH CO

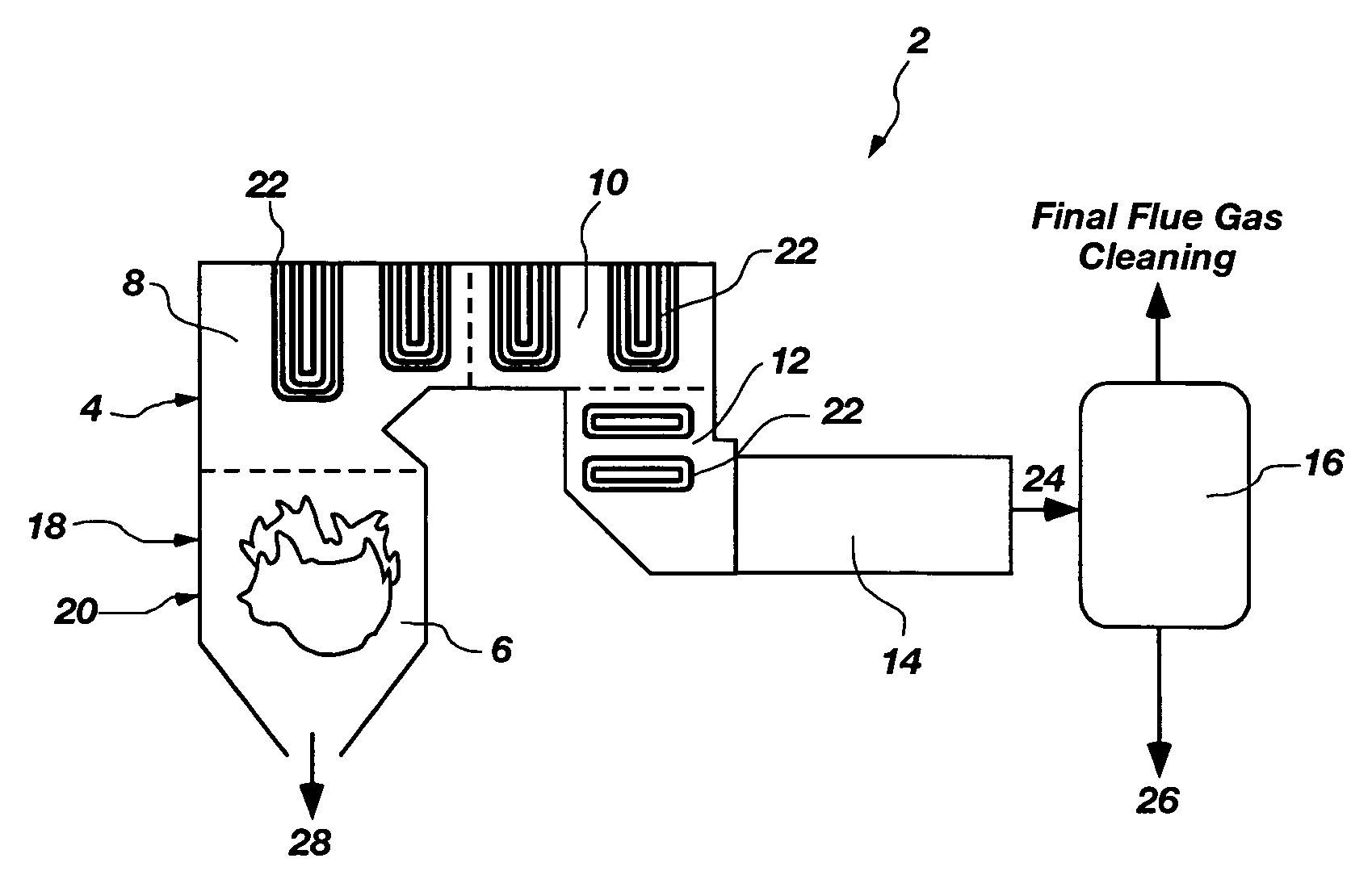

Method for oil shale pollutant sorption/NOx reburning multi-pollutant control

A method of decreasing pollutants produced in a combustion process. The method comprises combusting coal in a combustion chamber to produce at least one pollutant selected from the group consisting of a nitrogen-containing pollutant, sulfuric acid, sulfur trioxide, carbonyl sulfide, carbon disulfide, chlorine, hydroiodic acid, iodine, hydrofluoric acid, fluorine, hydrobromic acid, bromine, phosphoric acid, phosphorous pentaoxide, elemental mercury, and mercuric chloride. Oil shale particles are introduced into the combustion chamber and are combusted to produce sorbent particulates and a reductant. The at least one pollutant is contacted with at least one of the sorbent particulates and the reductant to decrease an amount of the at least one pollutant in the combustion chamber. The reductant may chemically reduce the at least one pollutant to a benign species. The sorbent particulates may adsorb or absorb the at least one pollutant. A combustion chamber that produces decreased pollutants in a combustion process is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

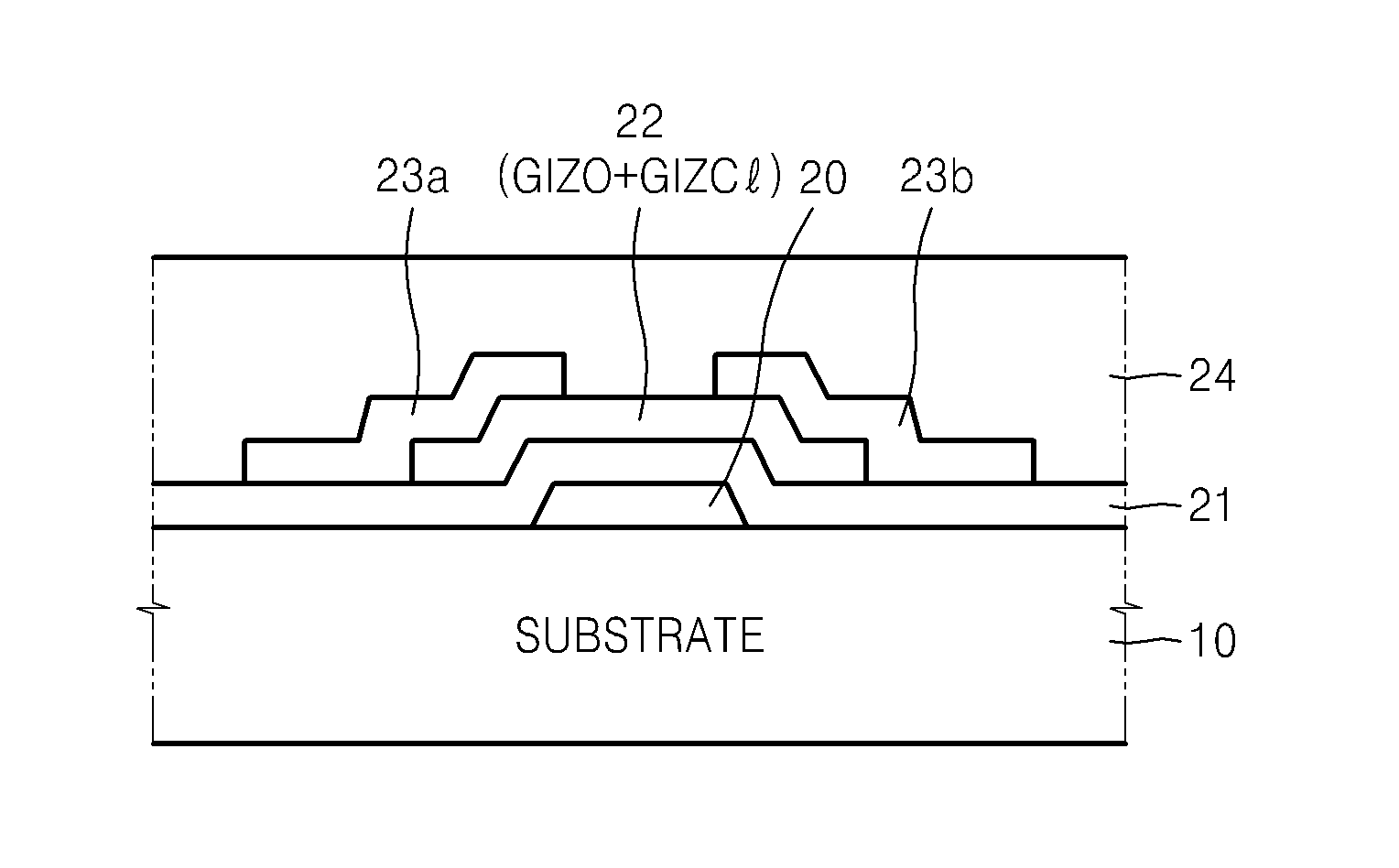

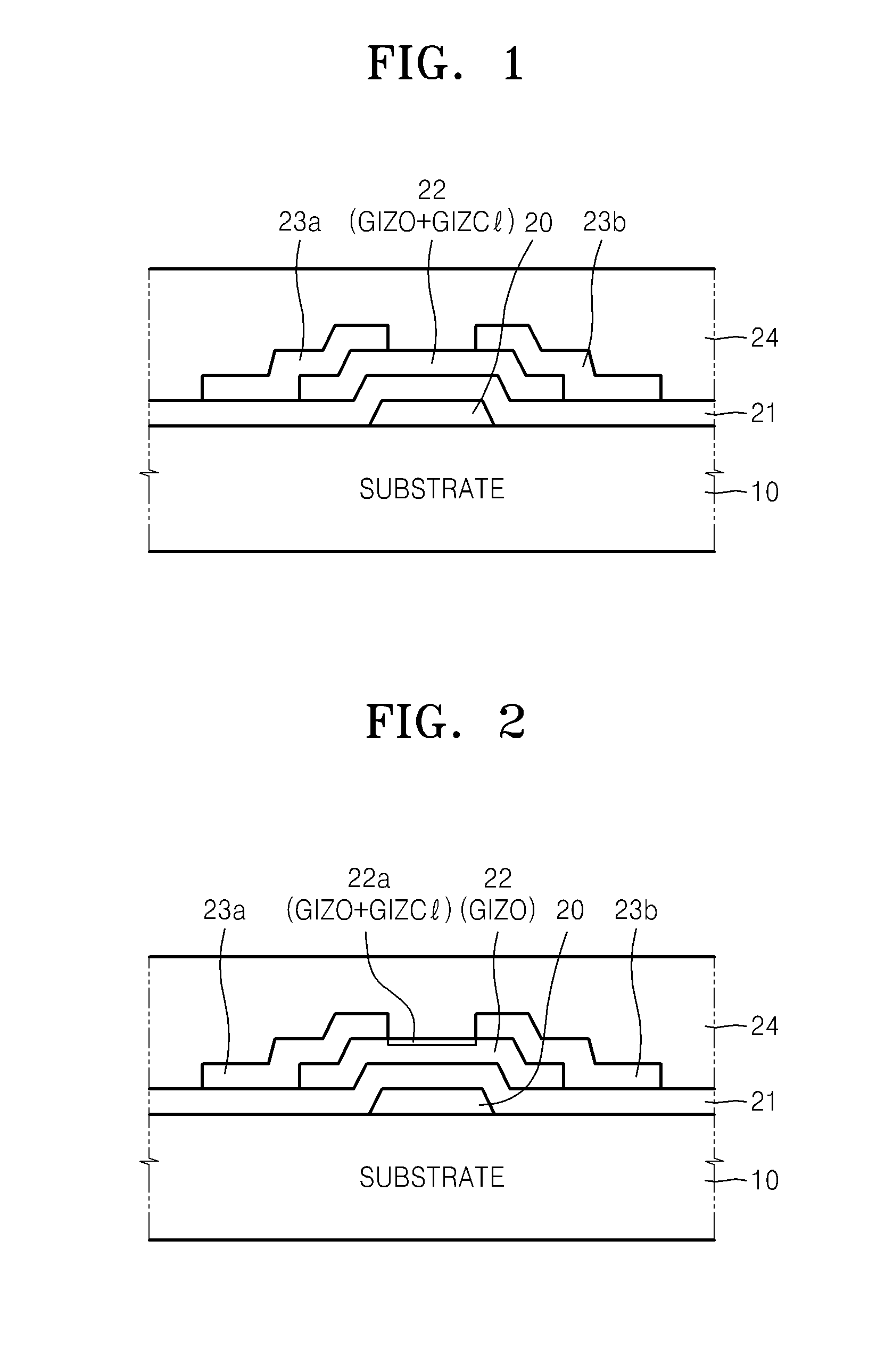

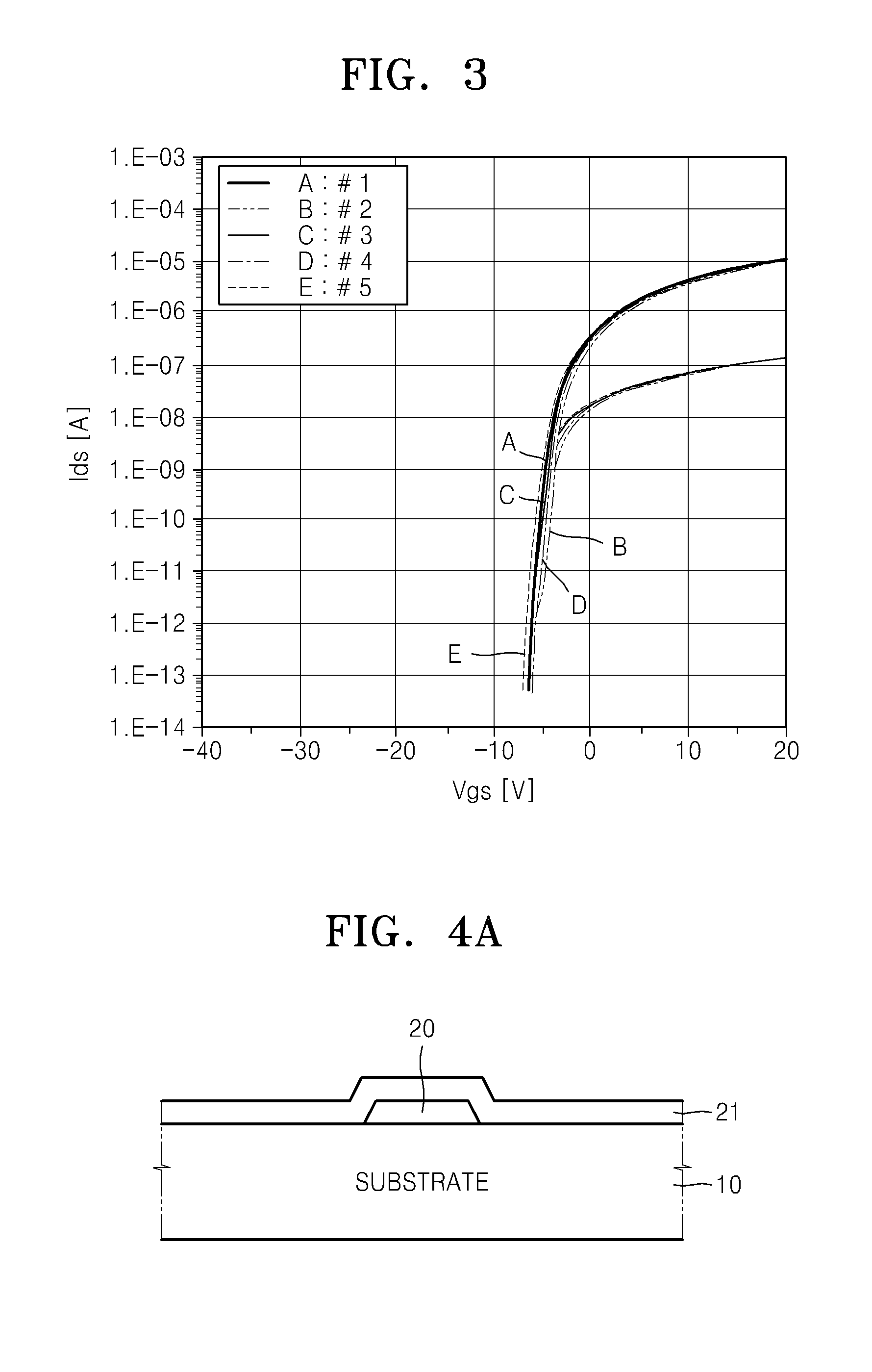

ZnO-BASED THIN FILM TRANSISTOR AND METHOD OF MANUFACTURING THE SAME

InactiveUS20080283831A1Avoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPlasma Gases

A ZnO-based thin film transistor (TFT) is provided herein, as is a method of manufacturing the TFT. The ZnO-based TFT has a channel layer that comprises ZnO and ZnCl, wherein the ZnCl has a higher bonding energy than ZnO with respect to plasma. The ZnCl is formed through the entire channel layer, and specifically is formed in a region near THE surface of the channel layer. Since the ZnCl is strong enough not to be decomposed when exposed to plasma etching gas, an increase in the carrier concentration can be prevented. The distribution of ZnCl in the channel layer, may result from the inclusion of chlorine (Cl) in the plasma gas during the patterning of the channel layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Photomask blank

ActiveUS20070248897A1Improve conductivityEnsure stabilityVacuum evaporation coatingSputtering coatingNitrogenOxygen

A photomask blank has a light-shielding film composed of a single layer of a material containing a transition metal, silicon and nitrogen or a plurality of layers that include at least one layer made of a material containing a transition metal, silicon and nitrogen, and has one or more chrome-based material film. The high transition metal content ensures electrical conductivity, preventing charge-up in the photomask production process, and also provides sufficient chemical stability to cleaning in photomask production. The light-shielding film has a good resistance to dry etching of the chrome-based material film in the presence of chlorine and oxygen, thus ensuring a high processing accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

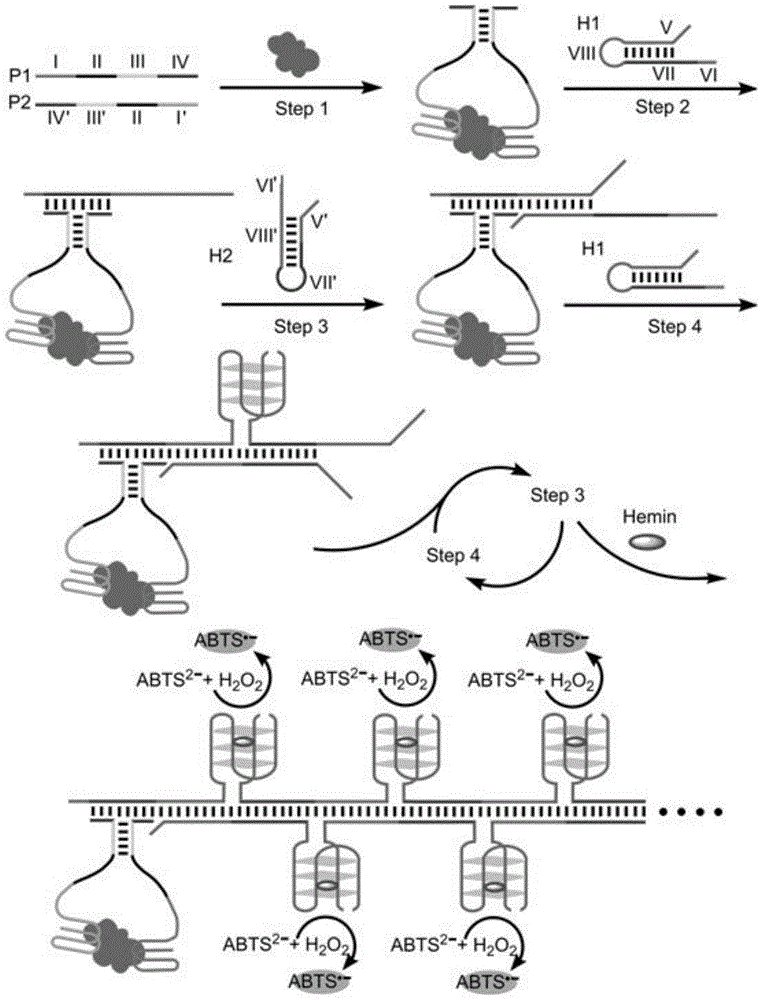

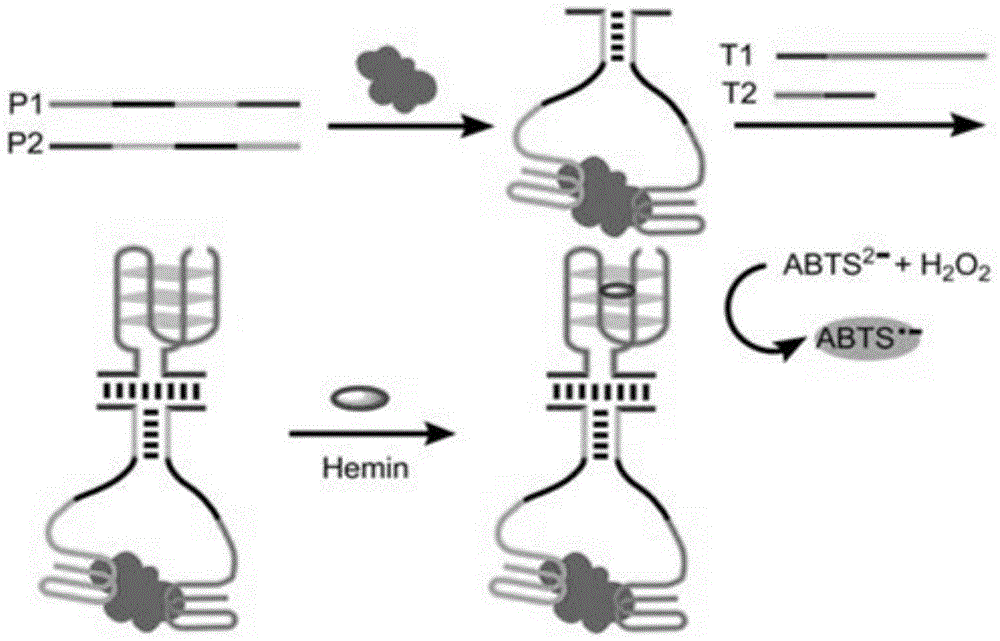

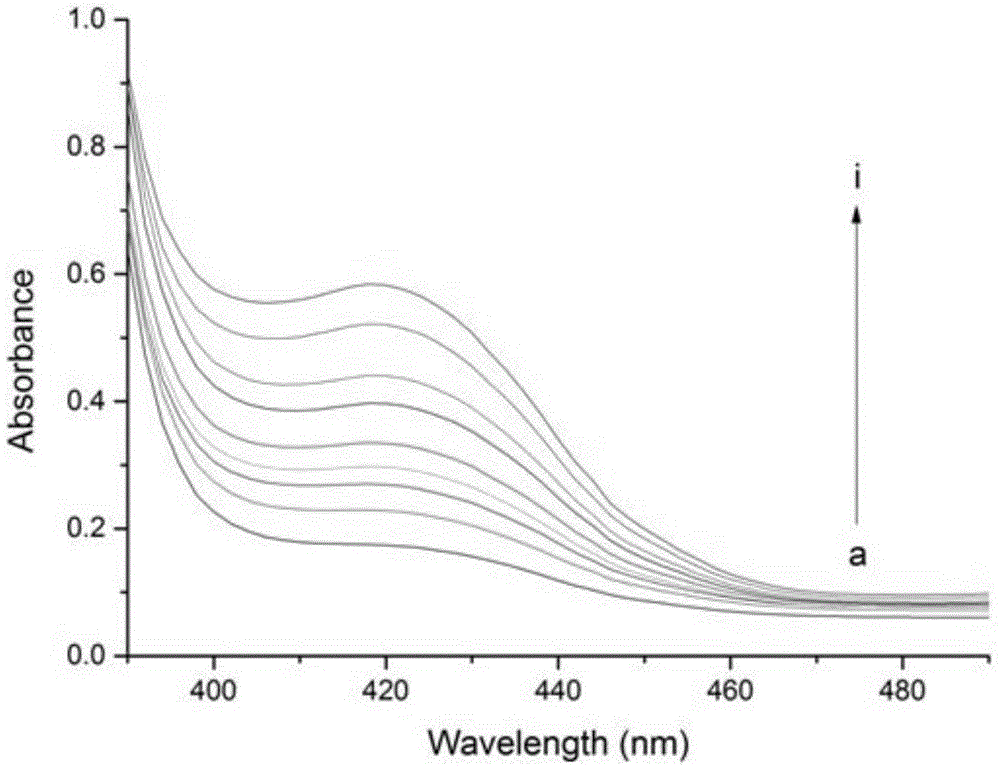

Probe based on G-quadruplex-chlorine heme DNA enzyme and application of probe

InactiveCN105018474AAchieving magnified detectionExcellent long-term storage stabilityMicrobiological testing/measurementDNA/RNA fragmentationProtein detectionHeme

The invention provides a probe based on a G-quadruplex-chlorine heme DNA enzyme and a method for detecting protein. The method for detecting the protein facilitates detecting operation and is low in cost and free of marking. The probe has the advantages of being high in sensitivity and low in background noise. When the protein is detected, the detecting operation is easy, consumed time is short, cost is low, and the problems that a method for detecting the protein in the prior art is long in consumed time, high in cost and complex in detecting probe manufacturing are solved.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

Peroxide and chlorine test strip

InactiveUS6087089AAddressing Insufficient SensitivityAccurate and reliable quantitative determinationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMicrobiological testing/measurementHigh concentrationCellulose

A composition, method, and test device for quantitatively determining the oxidant concentration of a test sample are disclosed. The test device includes a test pad having a suitable carrier matrix incorporating an indicator reagent composition capable of interacting with an oxidant to produce a detectable and measurable response for oxidant over a wide concentration range of oxidant. An indicator reagent composition contains: (a) an iodide salt, (b) a buffer, and (c) a water-soluble polymer, preferably a cellulose-based polymer. An indicator reagent composition is incorporated into a carrier matrix, like filter paper, to provide a test pad useful in a dry phase oxidant assay of a test sample, especially for test samples containing a high concentration of oxidant, like chlorine or a peroxide.

Owner:INTEGRATED BIOMEDICAL TECH INC AN INDIANA

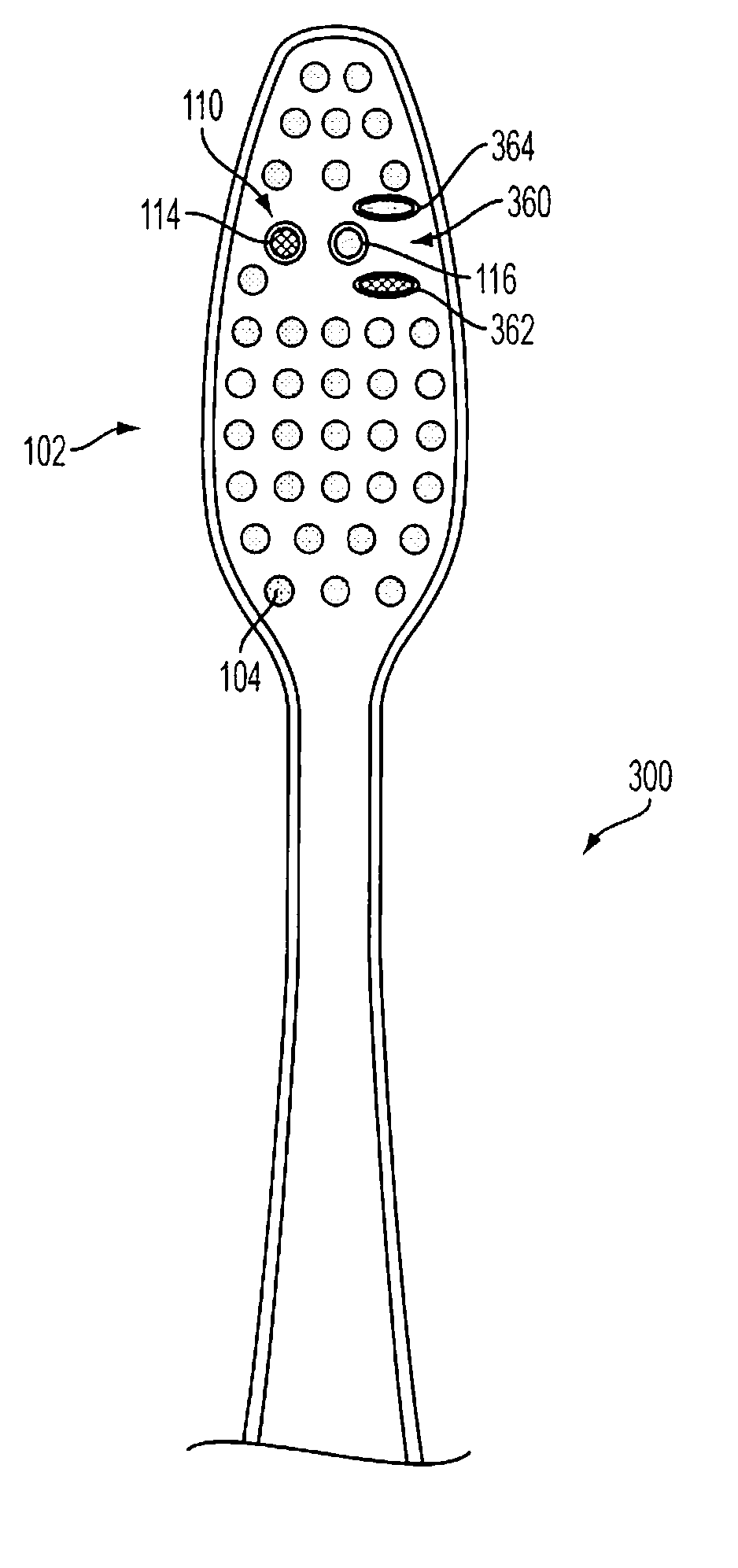

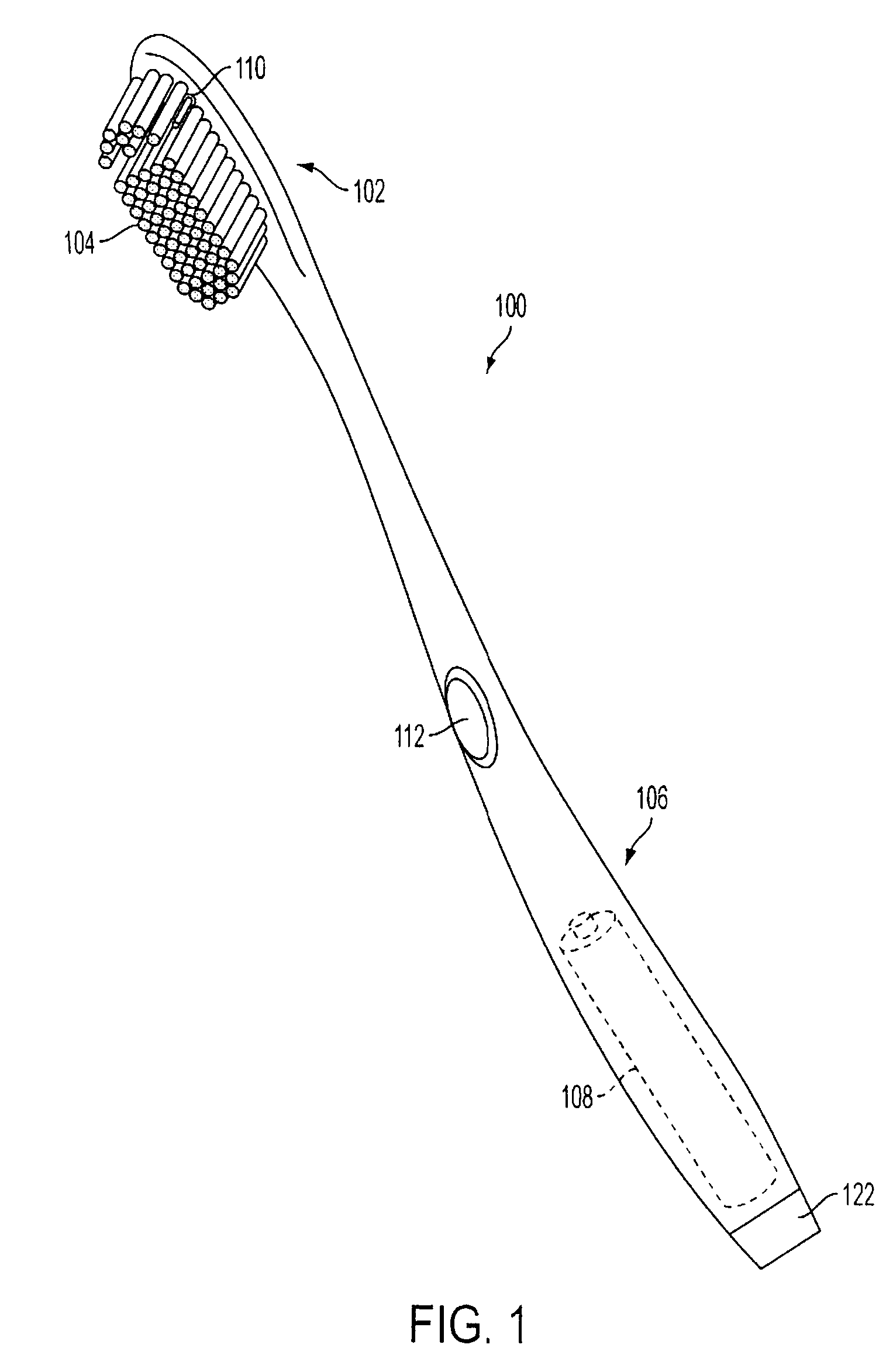

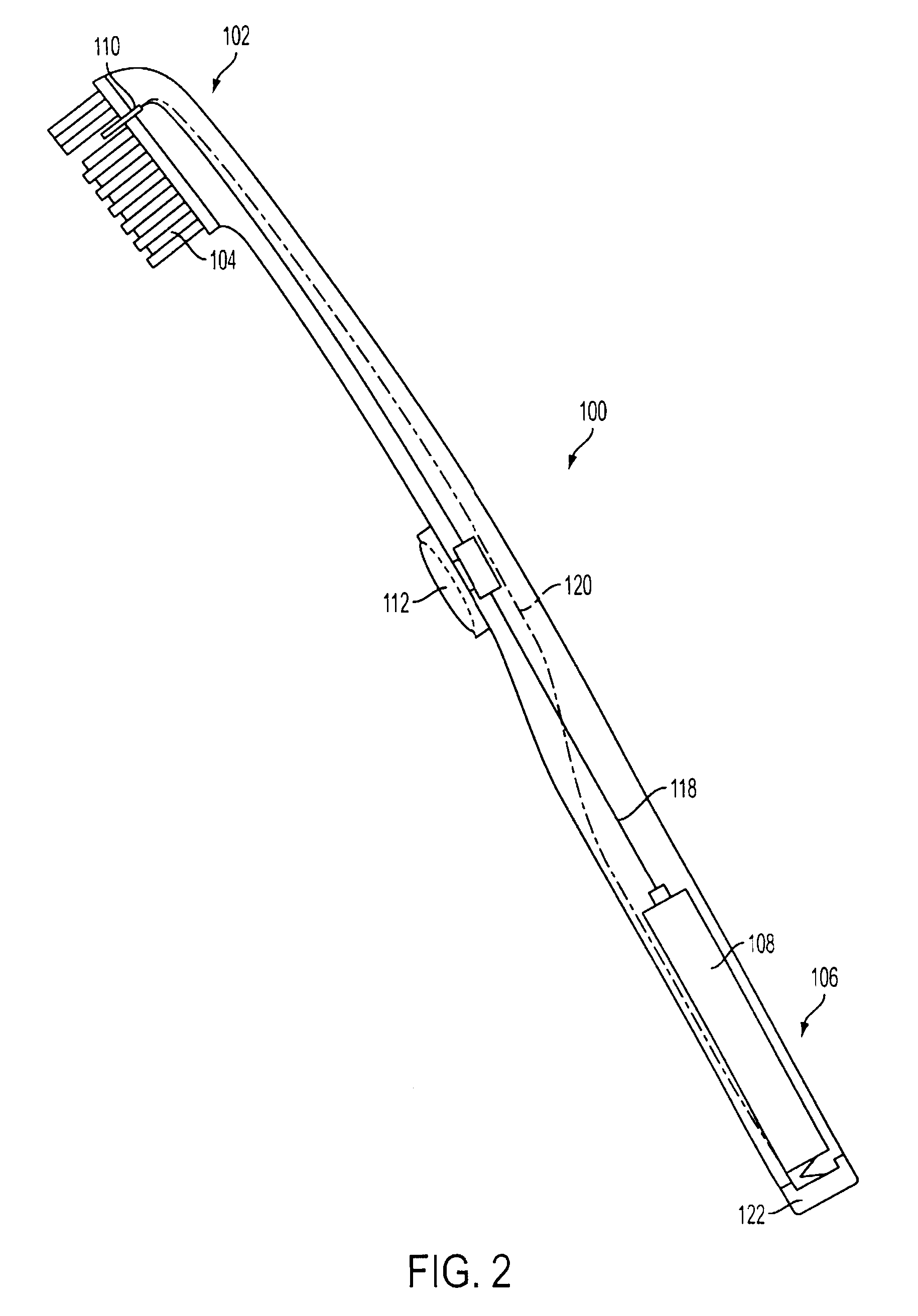

Generating a chemical agent in situ

A device for generating a chemical agent in situ on an as-needed basis via the application of an electrical potential across a pair of conductors in communication with an electrolyte. The device may be a toothbrush that generates chemical agents in a user's mouth by applying an electrical potential to an electrolyte such as saliva and / or a dentifrice located therein. The chemical agents may include ozone, hydrogen peroxide, peroxide, chlorine and / or hypochlorite. The toothbrush may include a voltage source and a first set of electrodes for applying an electrical potential to the electrolyte. The toothbrush may also include a second set of electrodes disposed about an anode of the first set of electrodes. The first and second sets of anodes cooperate to produce ions, peroxides, ozone and / or other chemical agents via the application of electrical potential to the electrolyte.

Owner:COLGATE PALMOLIVE CO

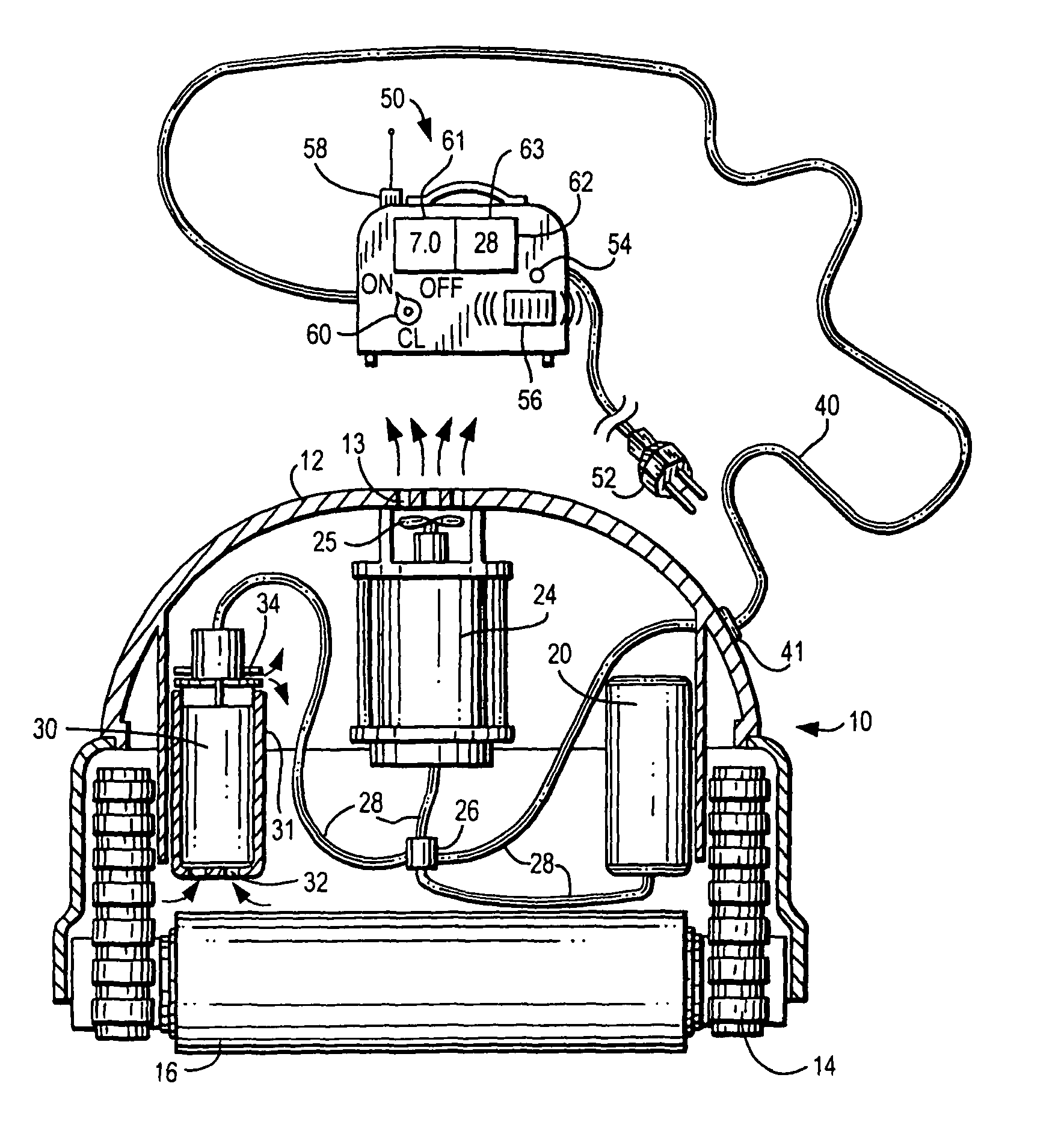

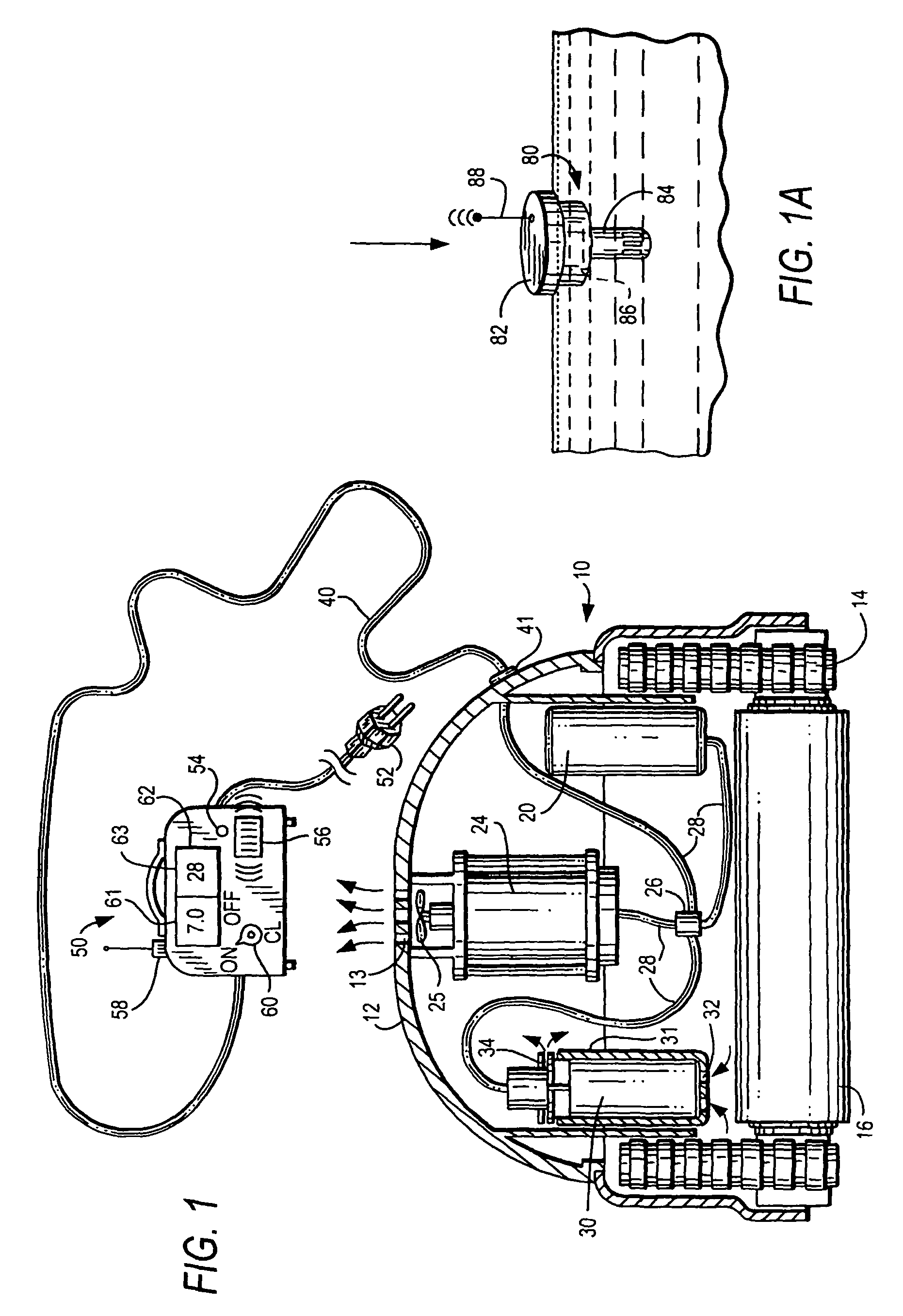

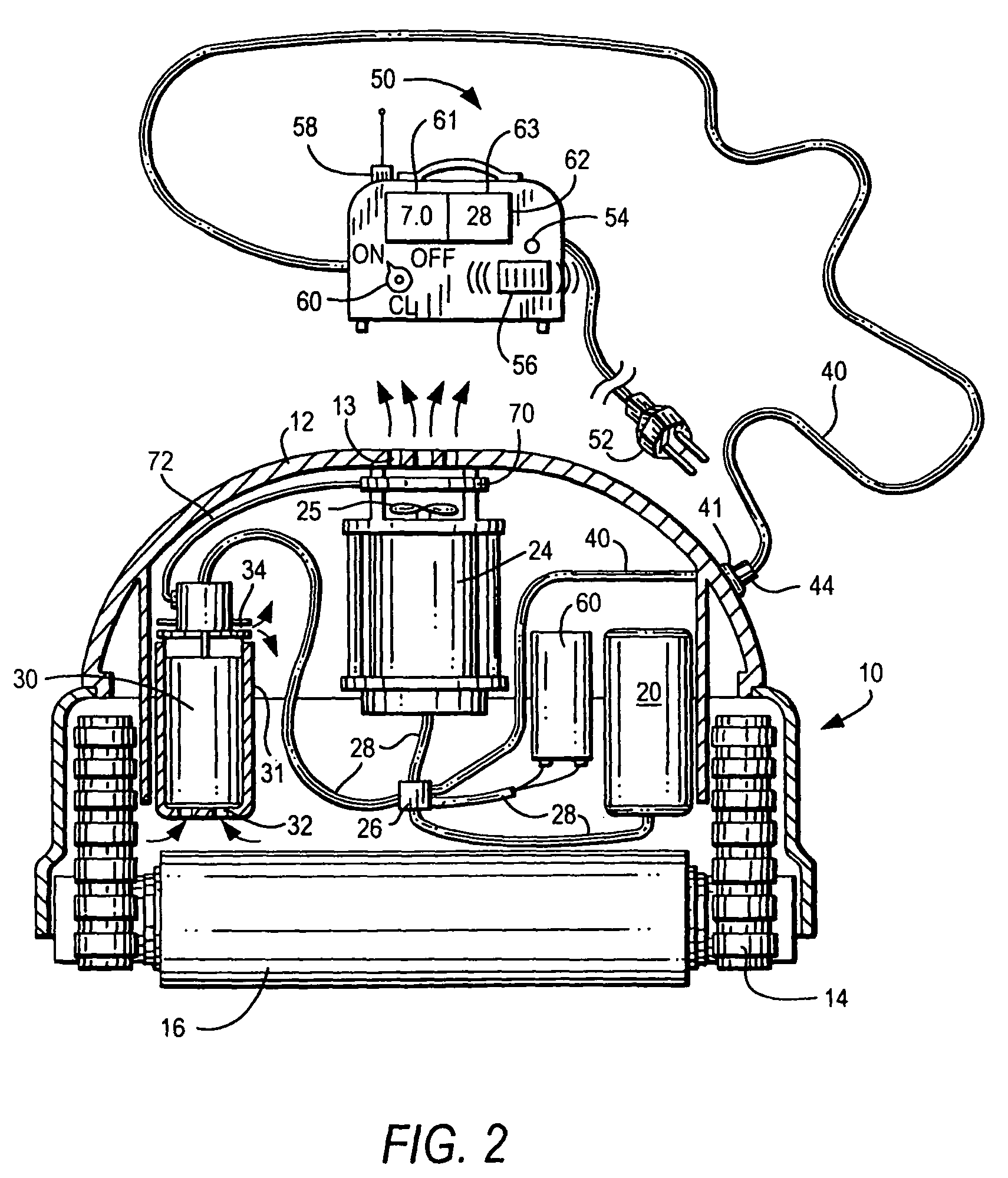

Method and appartus for operation of pool cleaner with integral chlorine generator

InactiveUS8007653B2Eliminate needEasy to useCellsPhotography auxillary processesMarine engineeringSalt water

An automated self-propelled pool cleaner having a housing, a water pump for moving water through the housing, drive means for moving the pool cleaner over the surface of the salt water pool to be cleaned, and an integral electrochemical chlorine generator mounted in the housing, includes a processor / controller that is programmed to activate the chlorine generator, the pump and drive means in predetermined operational sequences that minimize wear and tear on the water pump and drive means, while at the same time distribute and maintain a safe level of sanitizing chlorine in the pool, to thereby obviate the need for an in-line chlorinator or other chemical additive treatments; an optional automated sensor device can be provided to activate a secondary maintenance program which enables the pool cleaner to operate over prolonged periods of time as the sole means for filtering and sanitizing the pool water. An electrochemical cell manual mounting system permits the cell to be secured in place for operation and manually removed for maintenance, repair or replacement by the user without special tools or training.

Owner:AQUA PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com