Patents

Literature

36 results about "Trisilylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing a chlorine-free conformal sin film

ActiveUS20130189854A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistryEtching rate

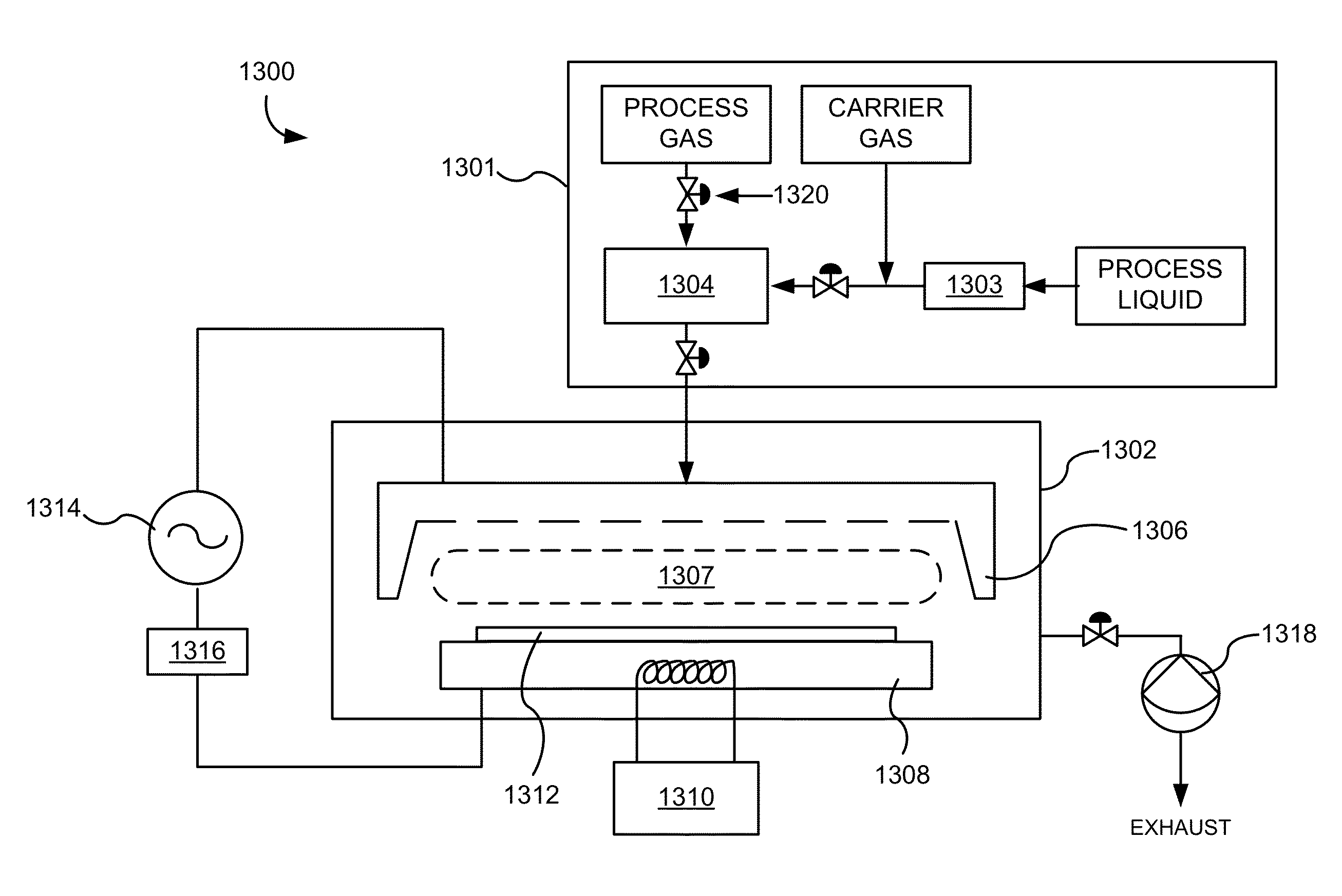

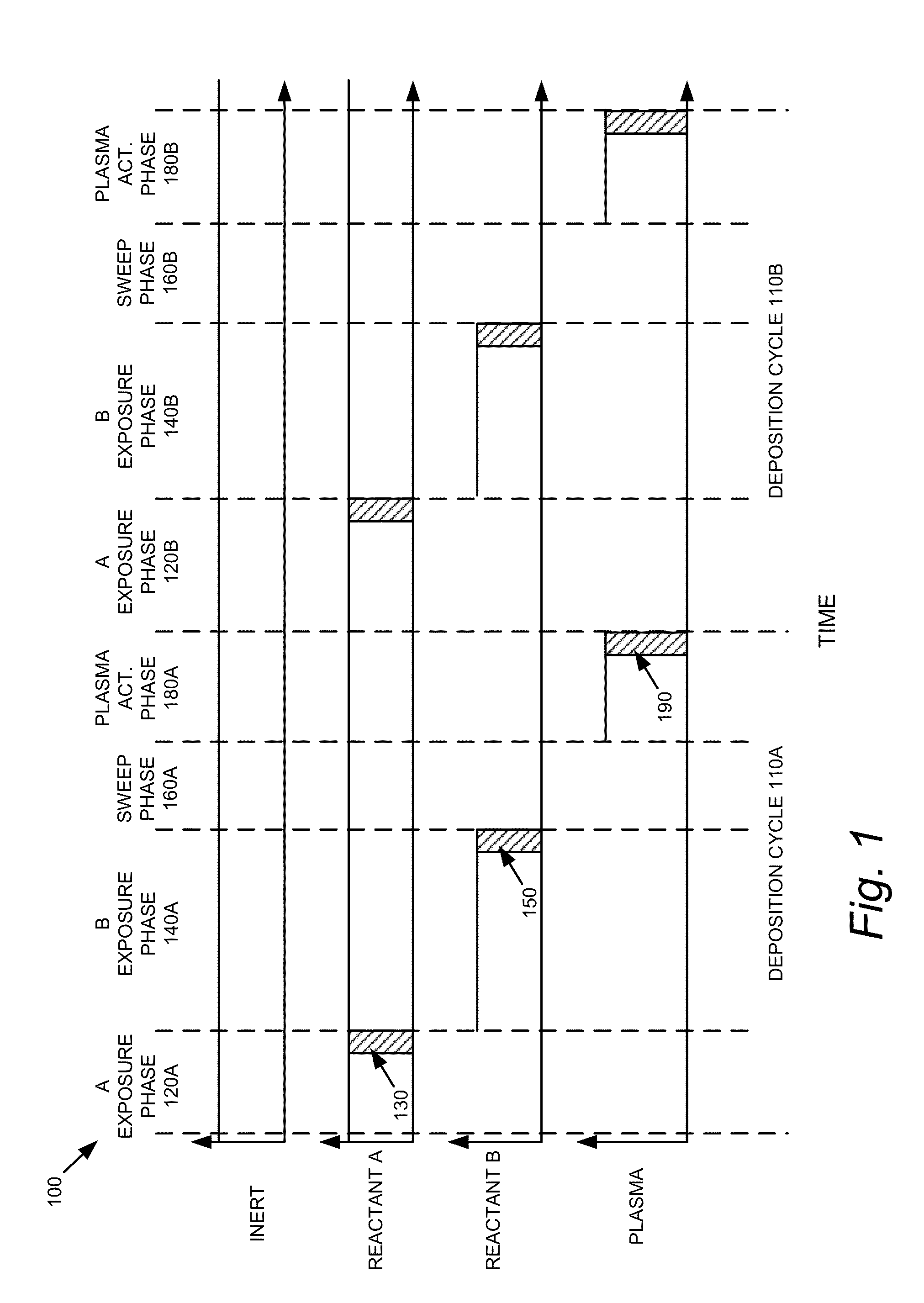

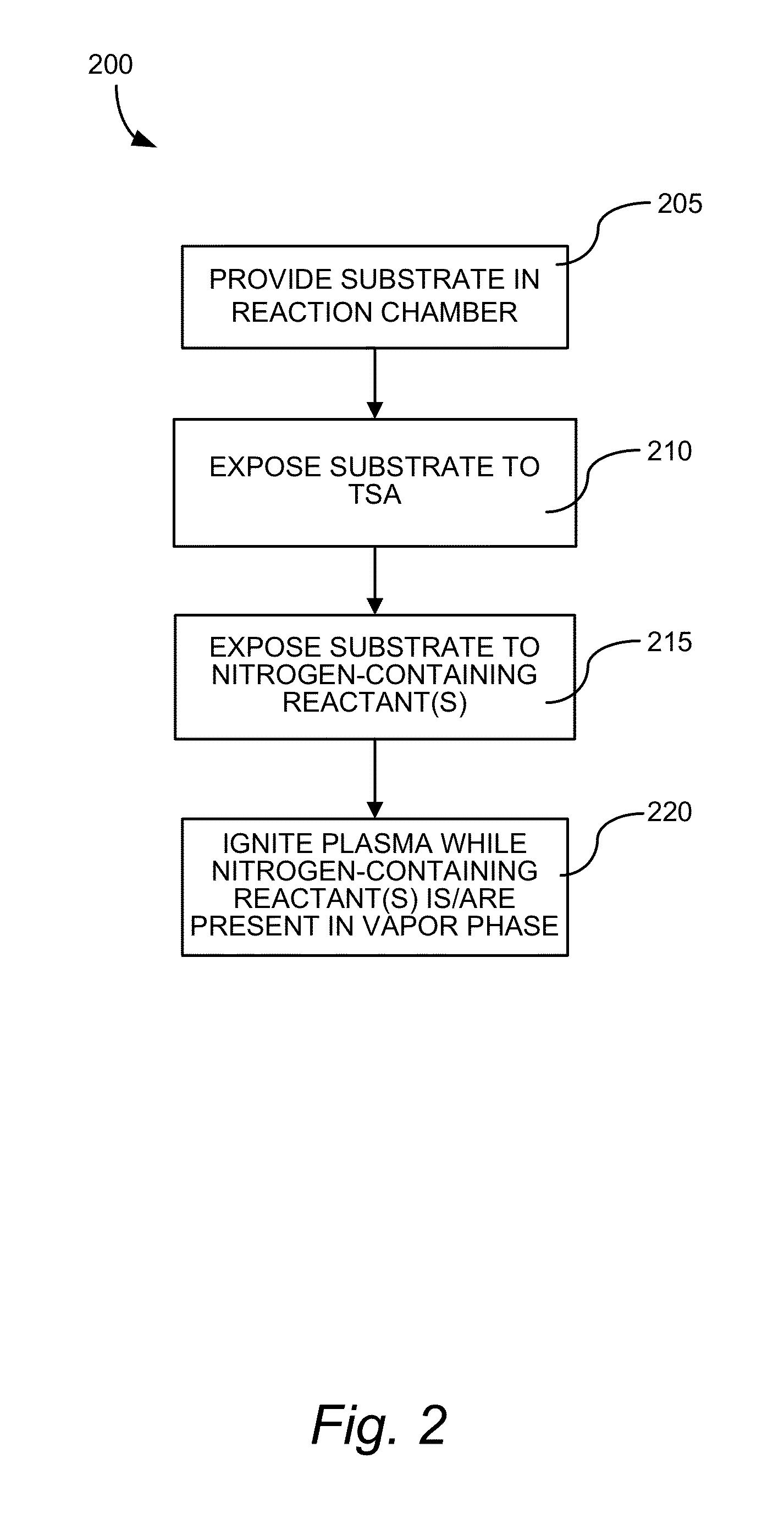

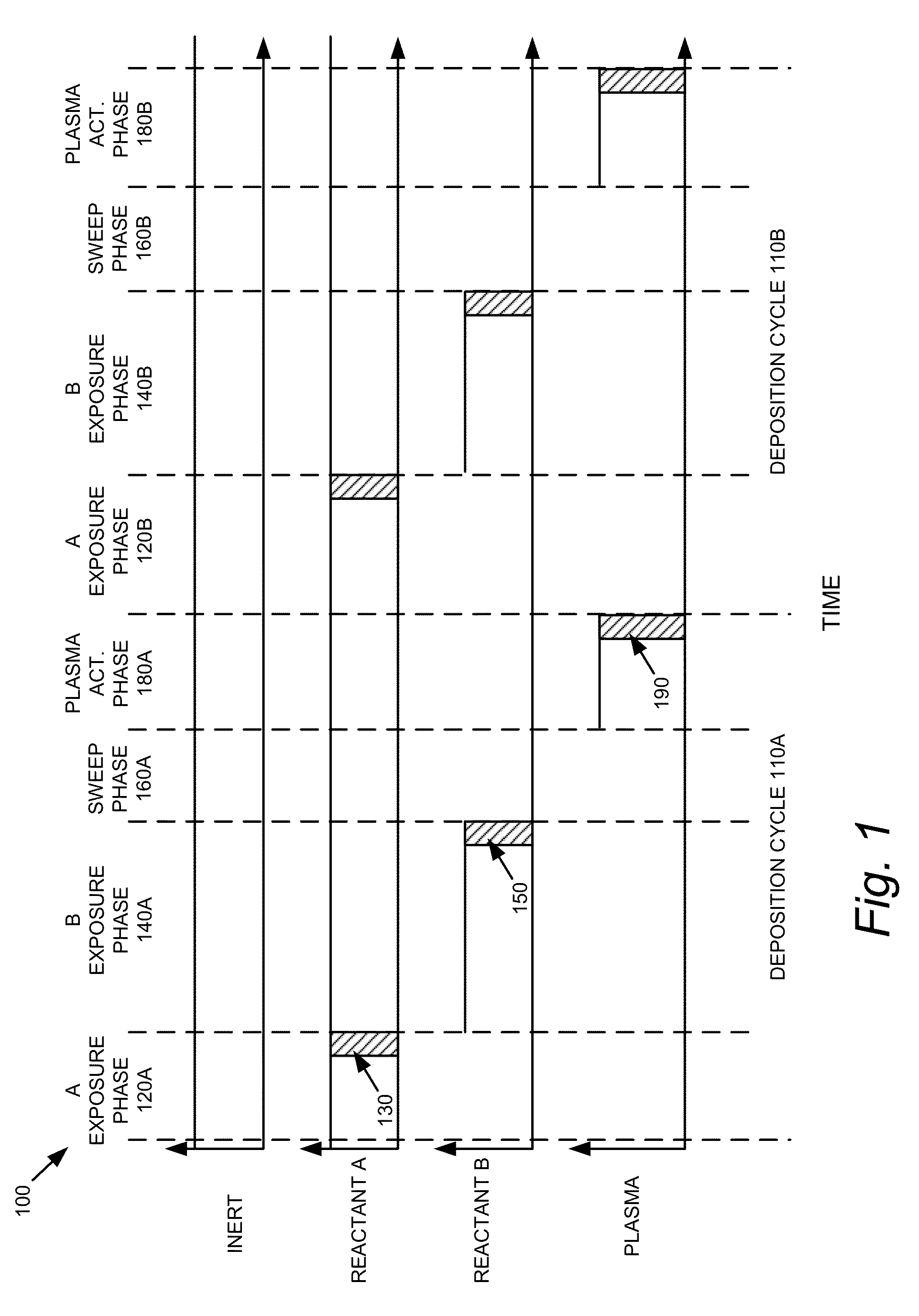

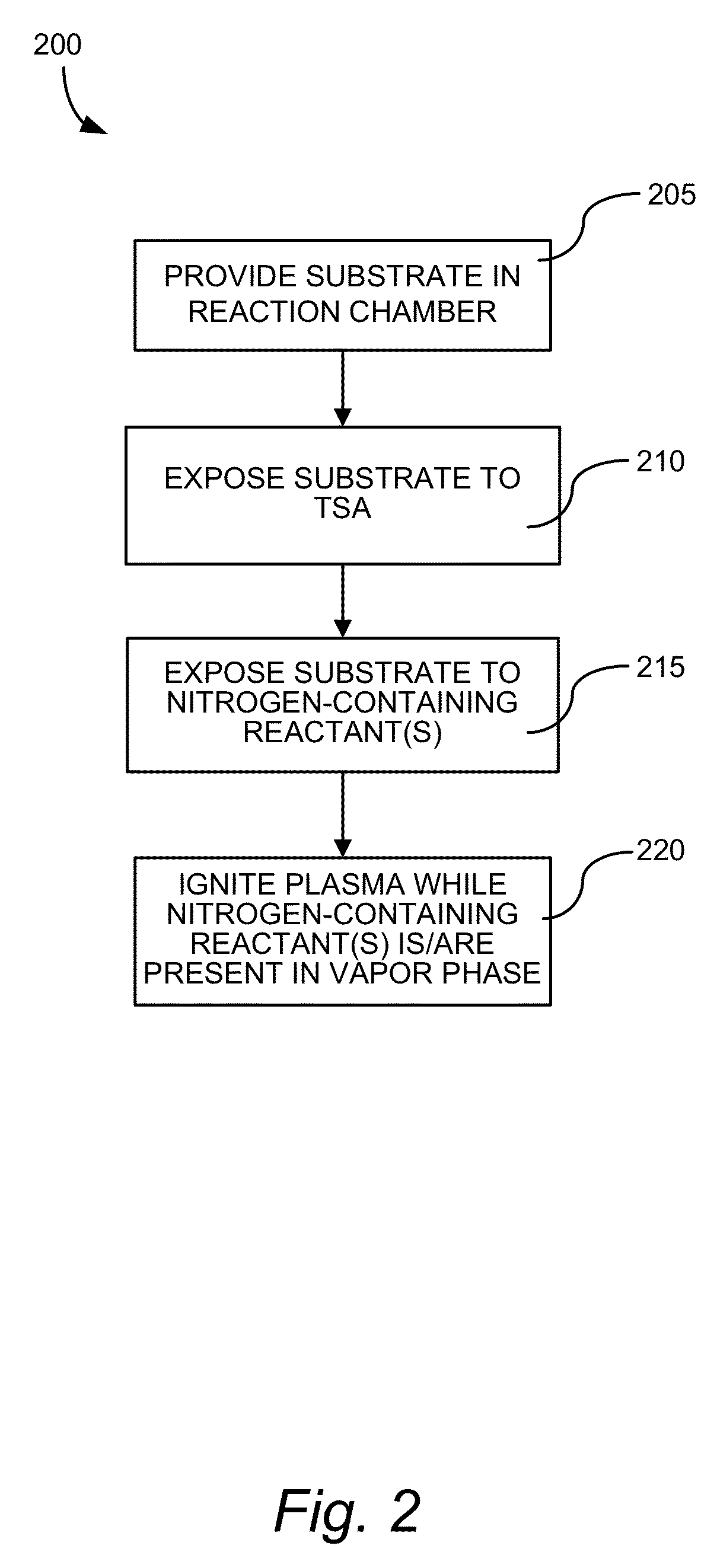

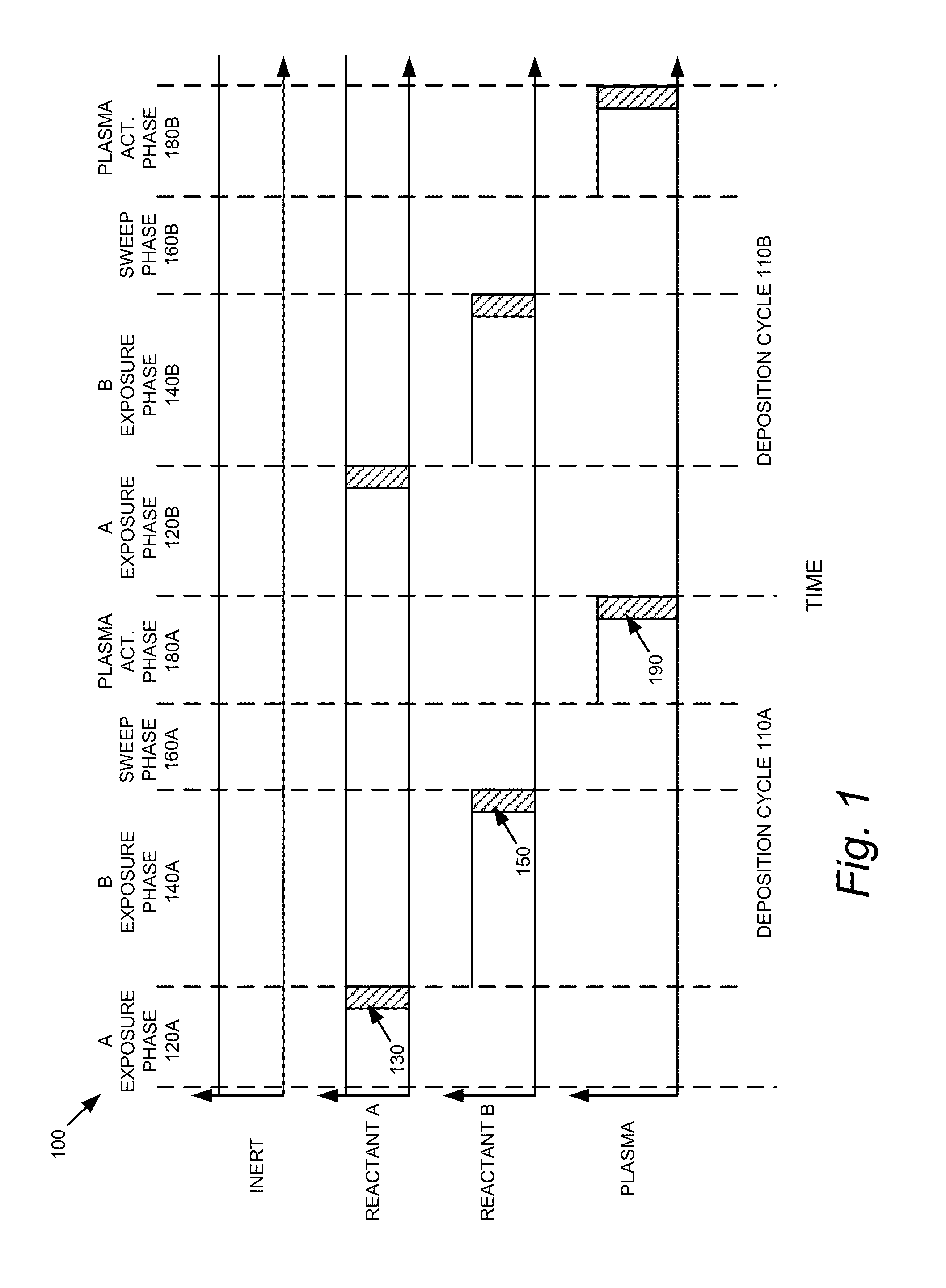

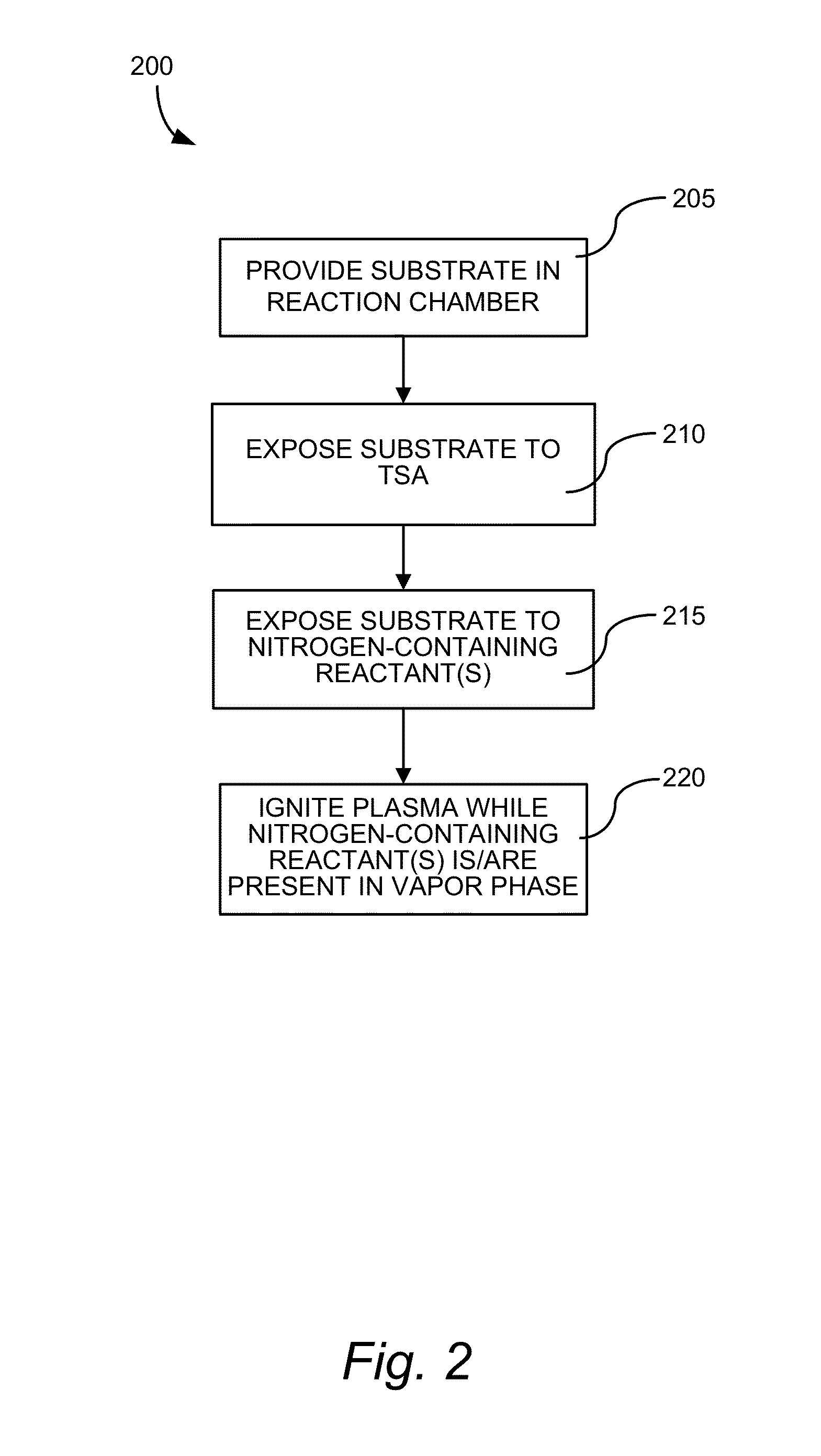

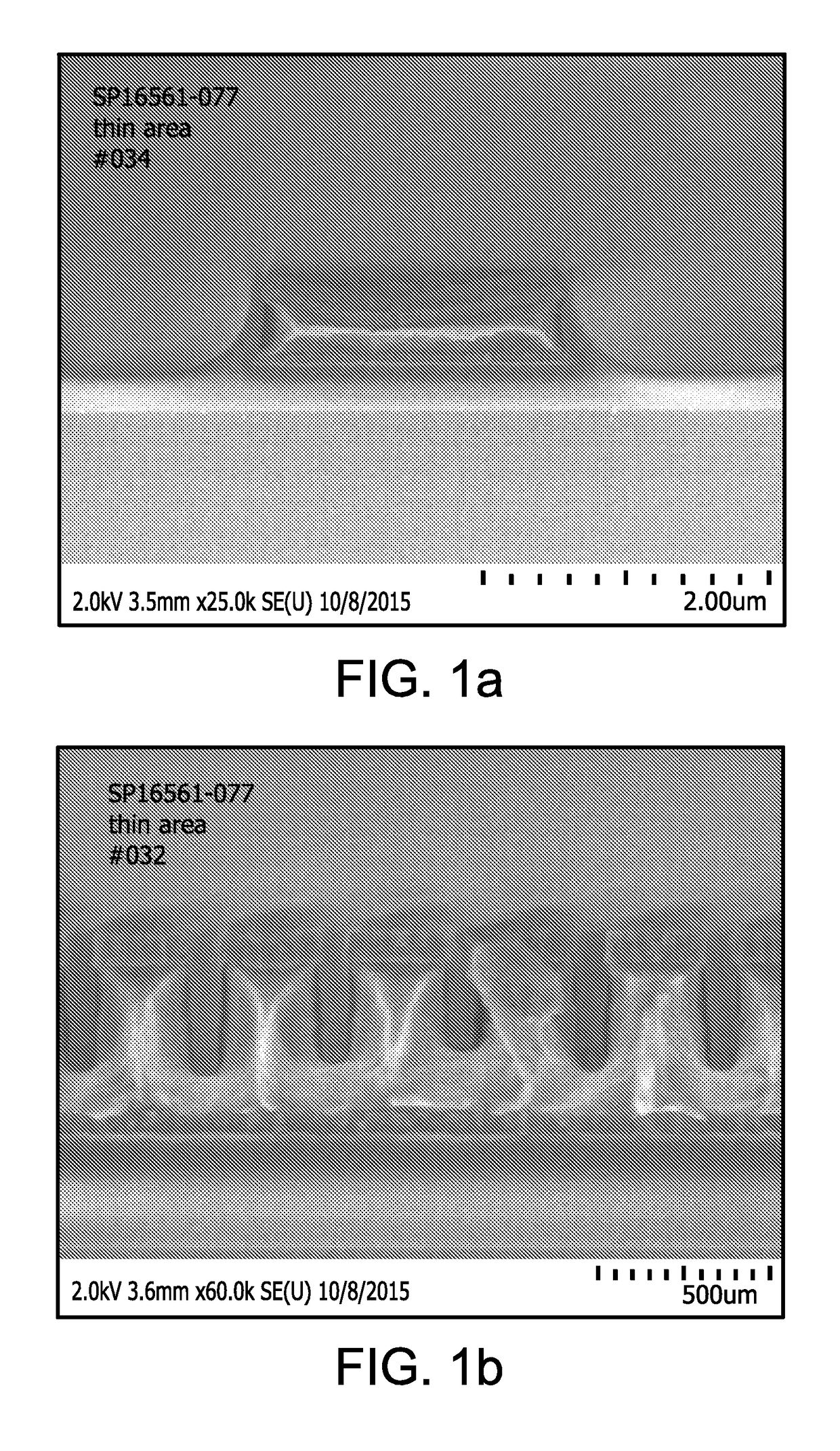

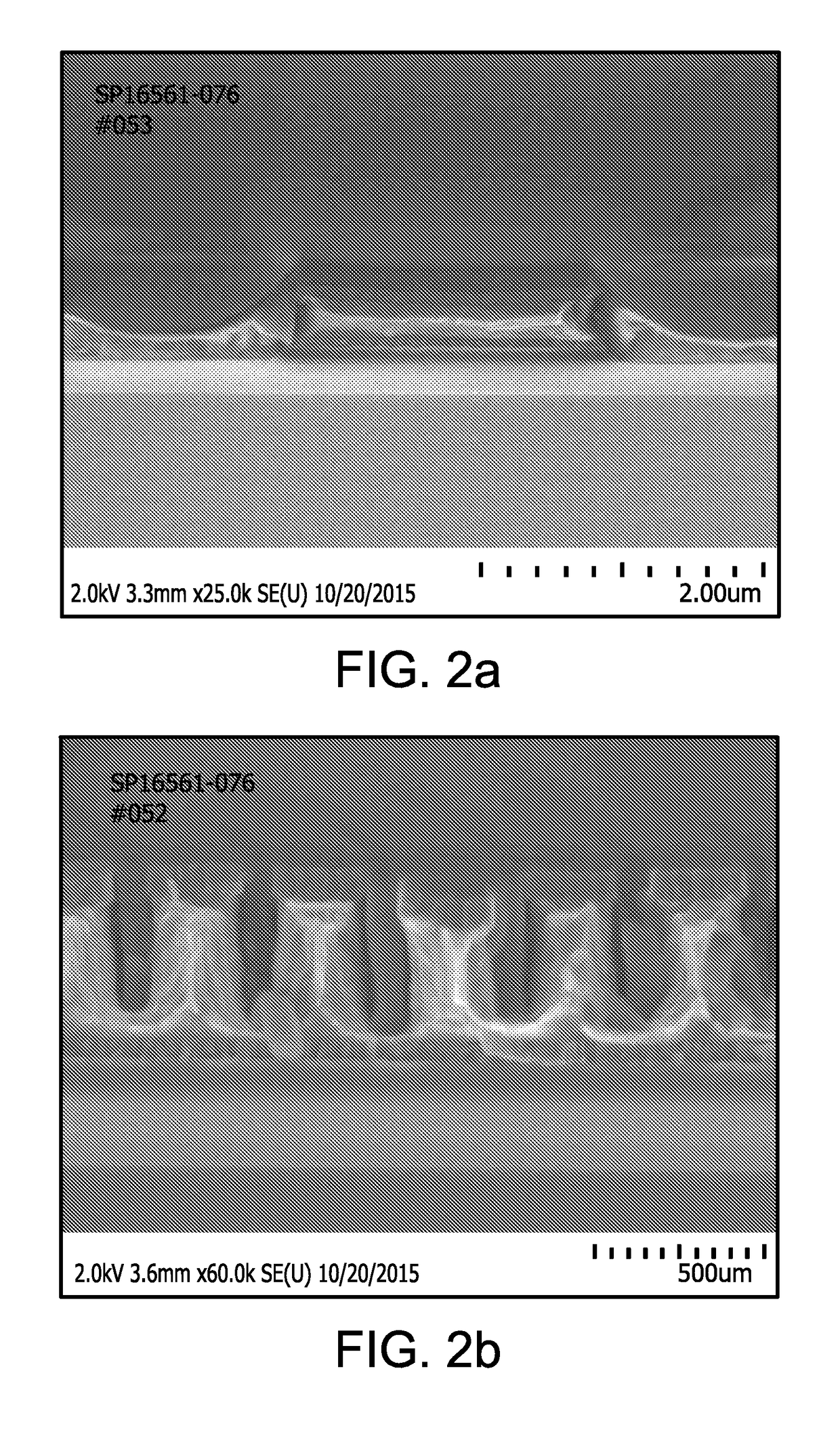

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

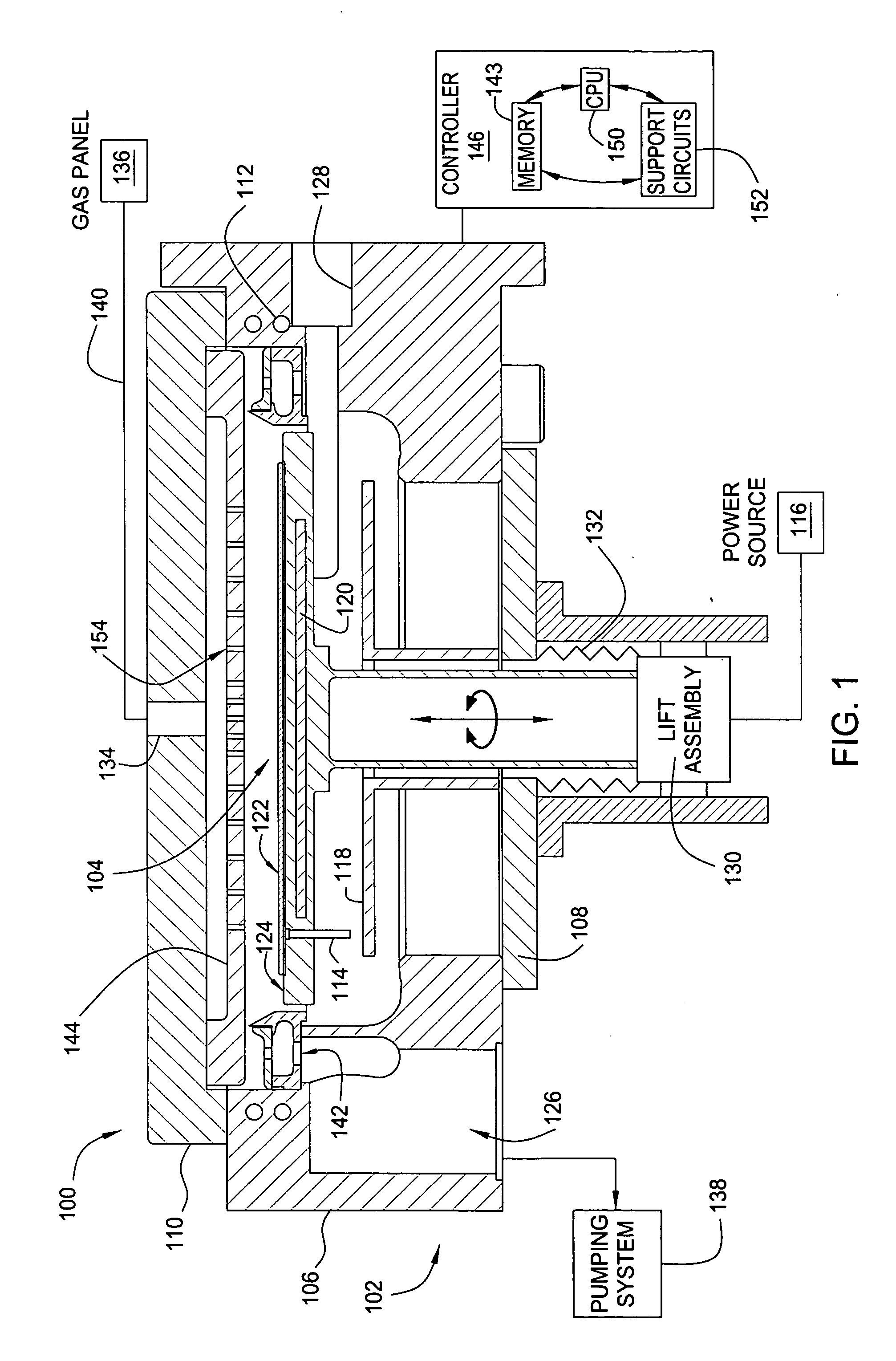

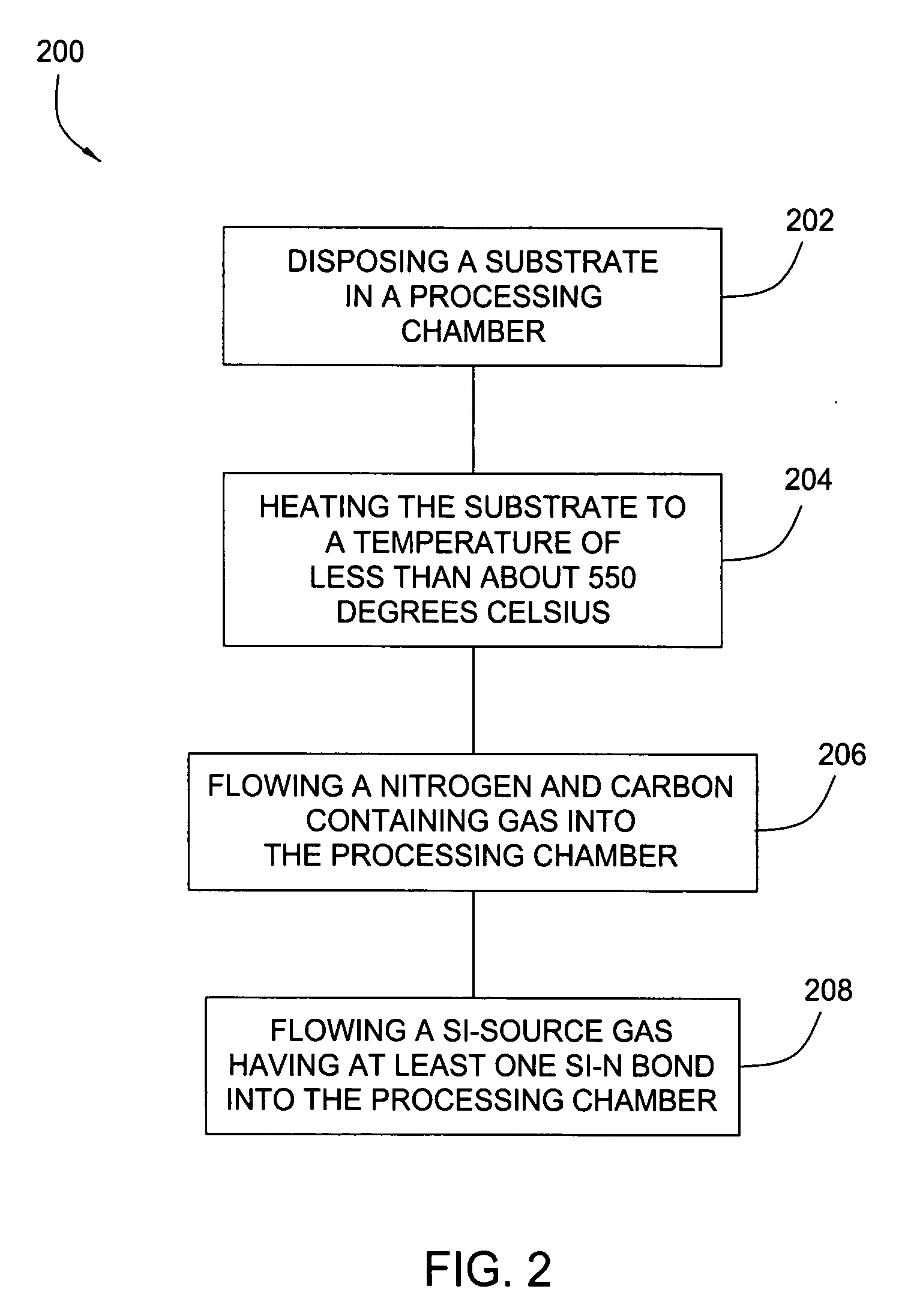

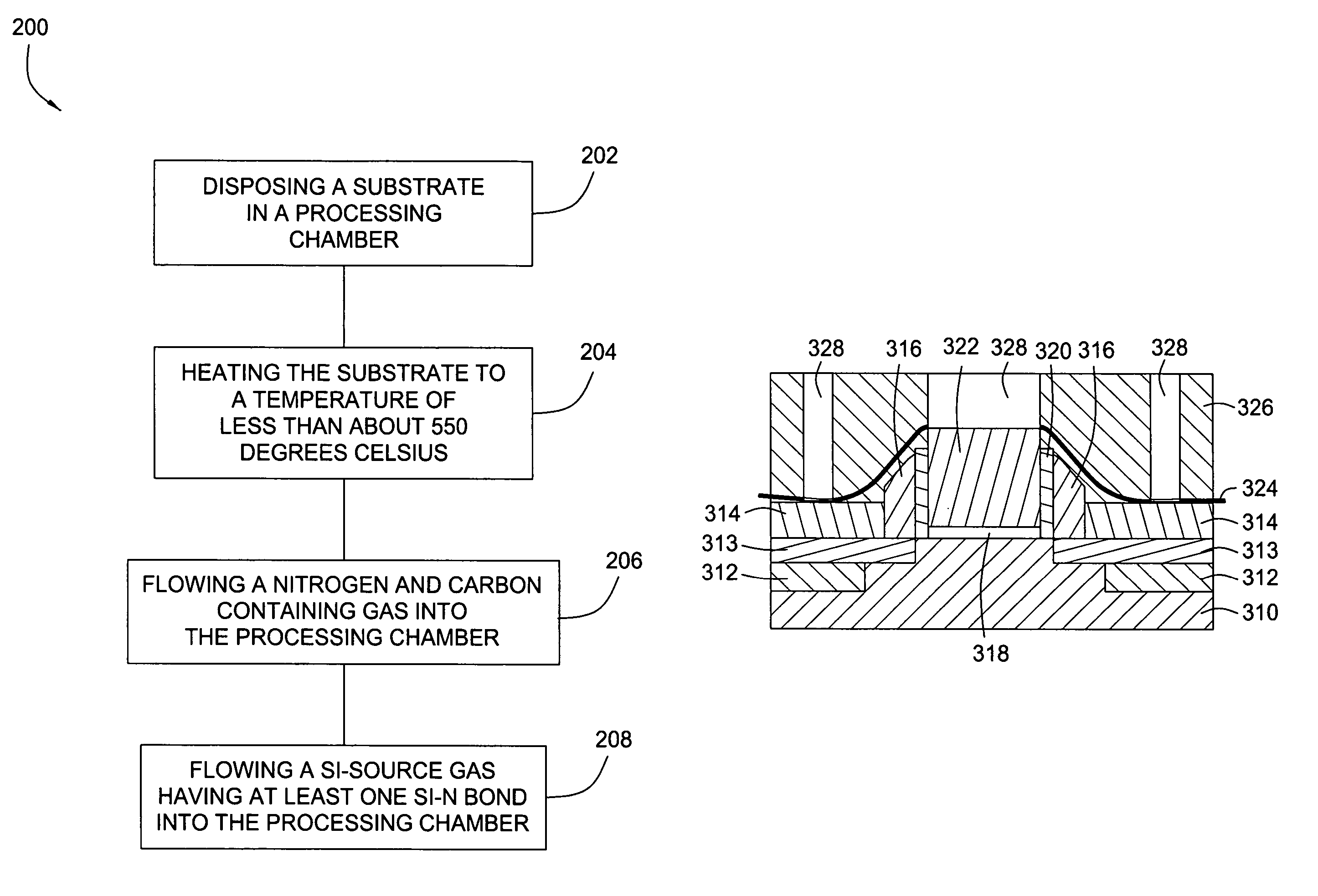

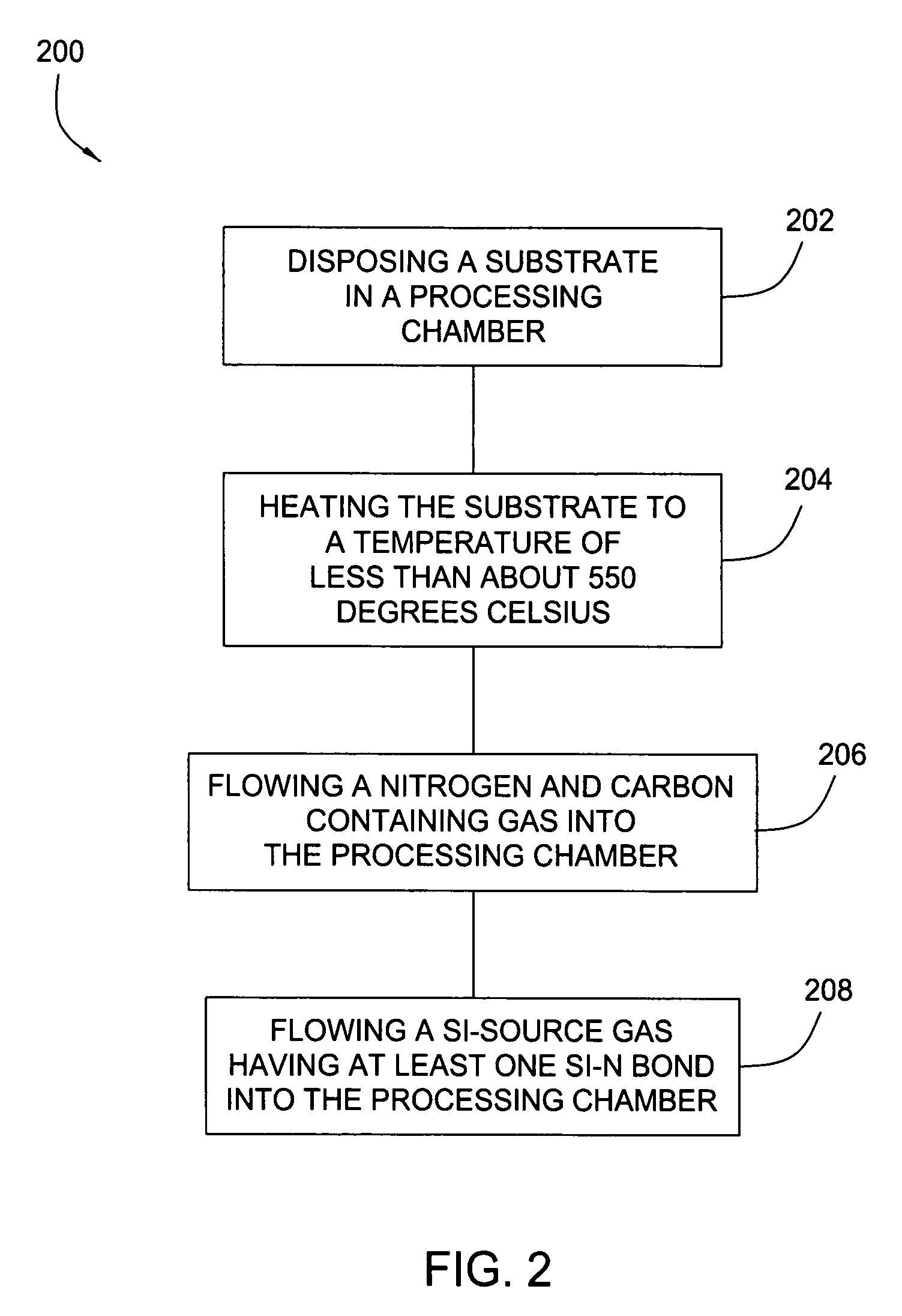

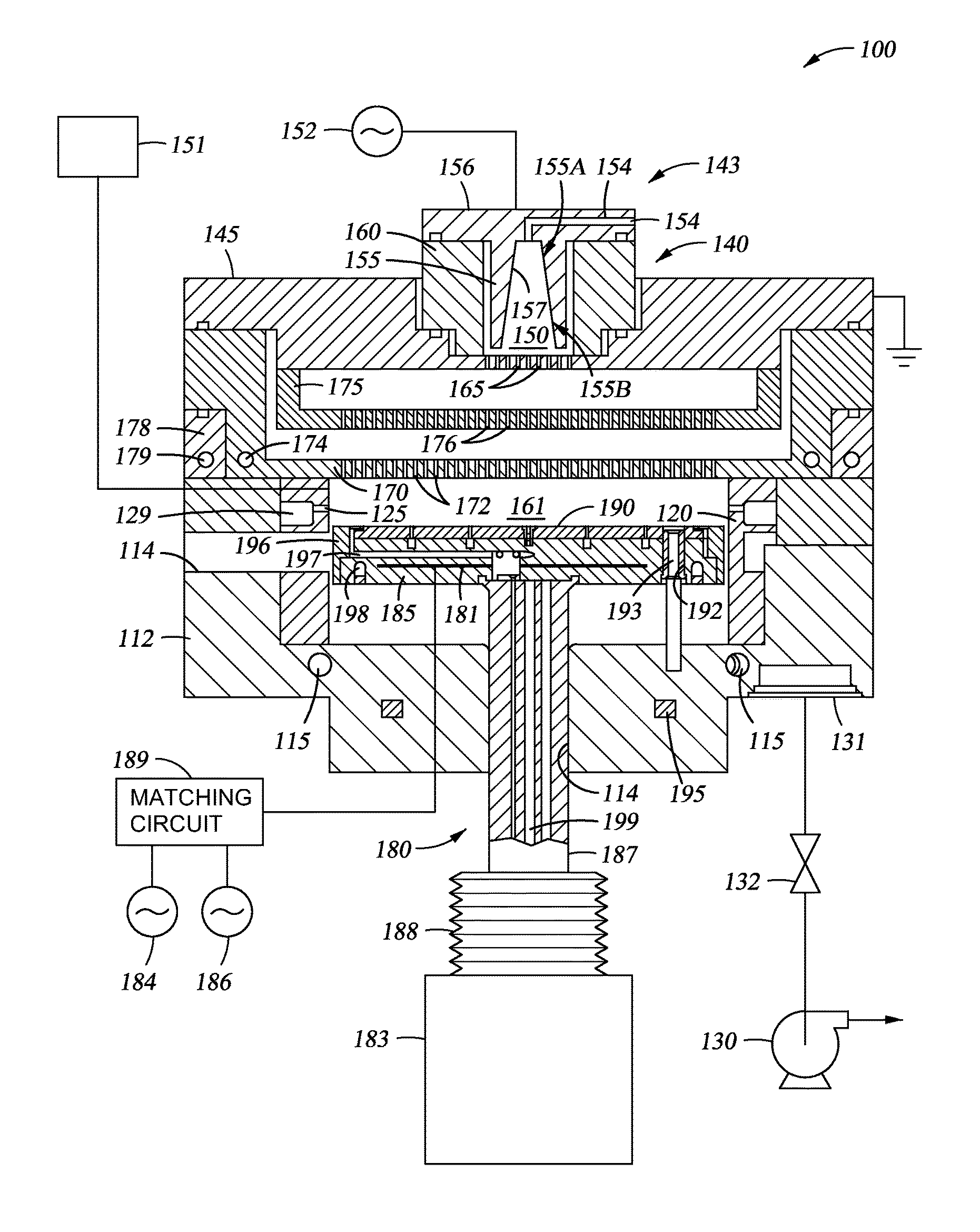

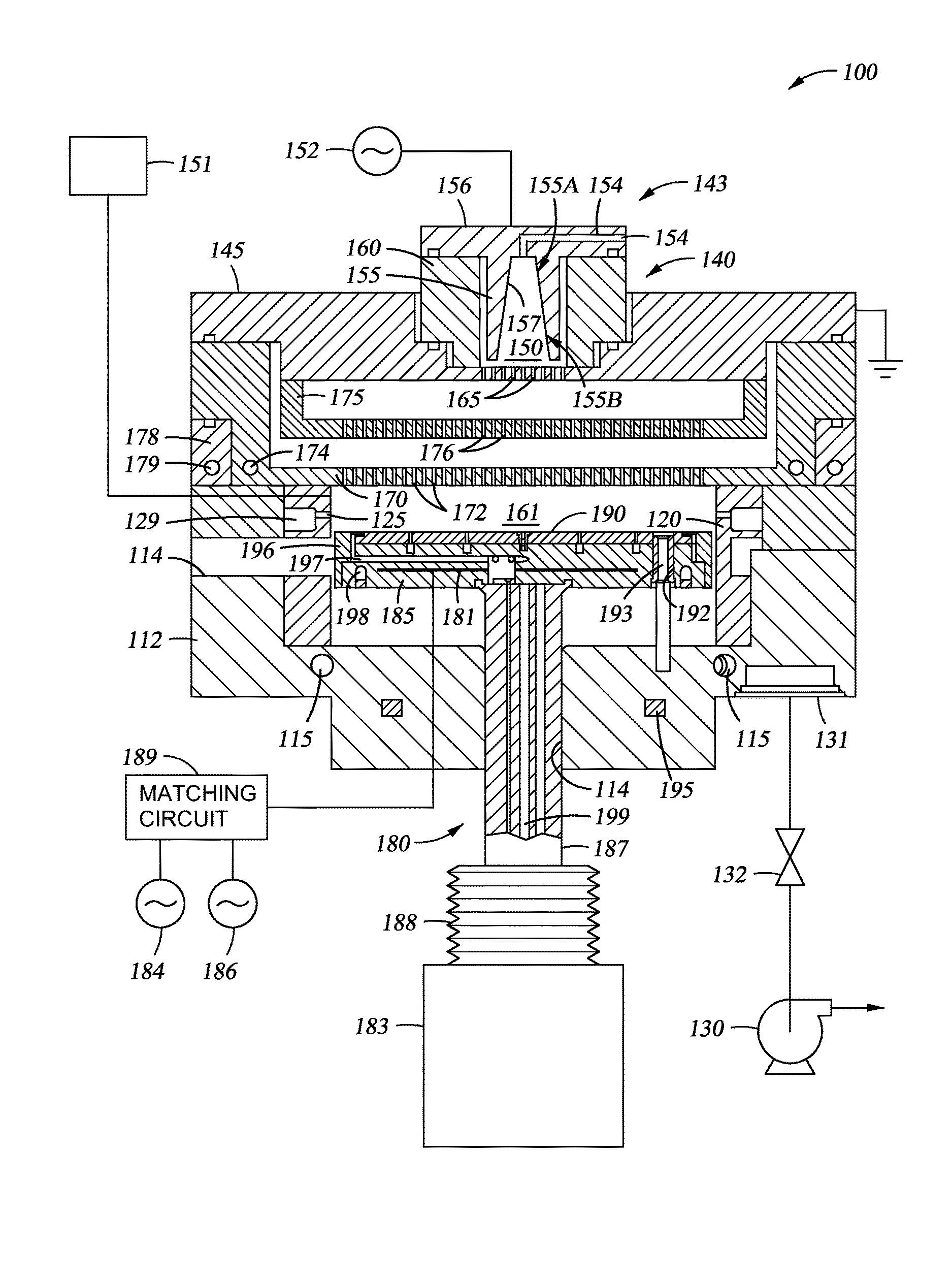

Method for silicon based dielectric chemical vapor deposition

InactiveUS20060286818A1TransistorSemiconductor/solid-state device manufacturingDielectricCelsius Degree

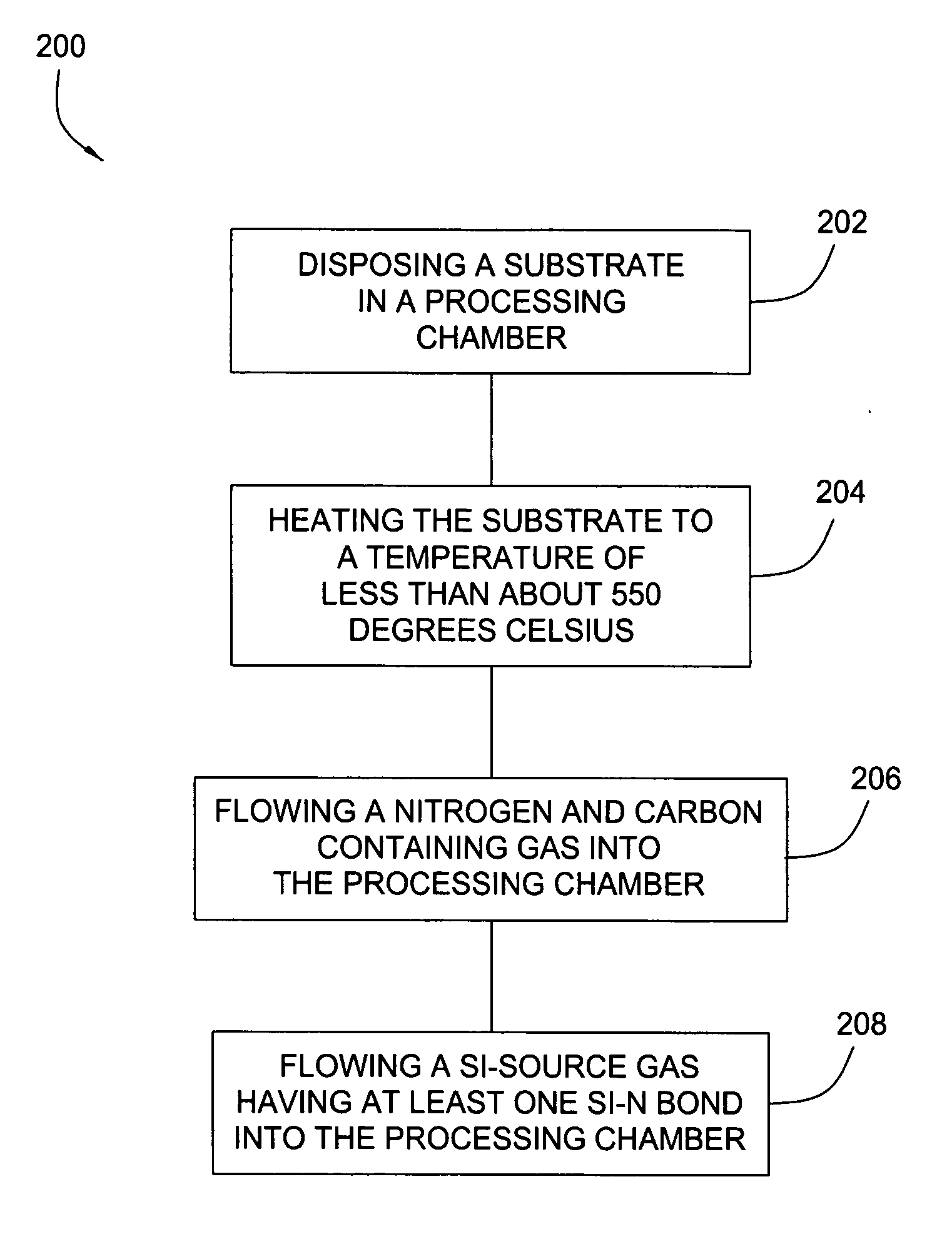

Embodiments of the invention generally provide a method for depositing silicon-containing films. In one embodiment, a method for depositing silicon-containing material film on a substrate includes flowing a nitrogen and carbon containing chemical into a deposition chamber, flowing a silicon-containing source chemical having silicon-nitrogen bonds into the processing chamber, and heating the substrate disposed in the chamber to a temperature less than about 550 degrees Celsius. In another embodiment, the silicon containing chemical is trisilylamine and the nitrogen and carbon containing chemical is (CH3)3—N.

Owner:APPLIED MATERIALS INC

Method for silicon based dielectric chemical vapor deposition

Embodiments of the invention generally provide a method for depositing silicon-containing films. In one embodiment, a method for depositing silicon-containing material film on a substrate includes flowing a nitrogen and carbon containing chemical into a deposition chamber, flowing a silicon-containing source chemical having silicon-nitrogen bonds into the processing chamber, and heating the substrate disposed in the chamber to a temperature less than about 550 degrees Celsius. In another embodiment, the silicon containing chemical is trisilylamine and the nitrogen and carbon containing chemical is (CH3)3—N.

Owner:APPLIED MATERIALS INC

Low temperature silicon nitride films using remote plasma CVD technology

ActiveUS9583333B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCelsius DegreeRemote plasma

Embodiments of the present invention generally provide methods for forming a silicon nitride layer on a substrate. In one embodiment, a method of forming a silicon nitride layer using remote plasma chemical vapor deposition (CVD) at a temperature that is less than 300 degrees Celsius is disclosed. The precursors for the remote plasma CVD process include tris(dimethylamino)silane (TRIS), dichlorosilane (DCS), trisilylamine (TSA), bis-t-butylaminosilane (BTBAS), hexachlorodisilane (HCDS) or hexamethylcyclotrisilazane (HMCTZ).

Owner:APPLIED MATERIALS INC

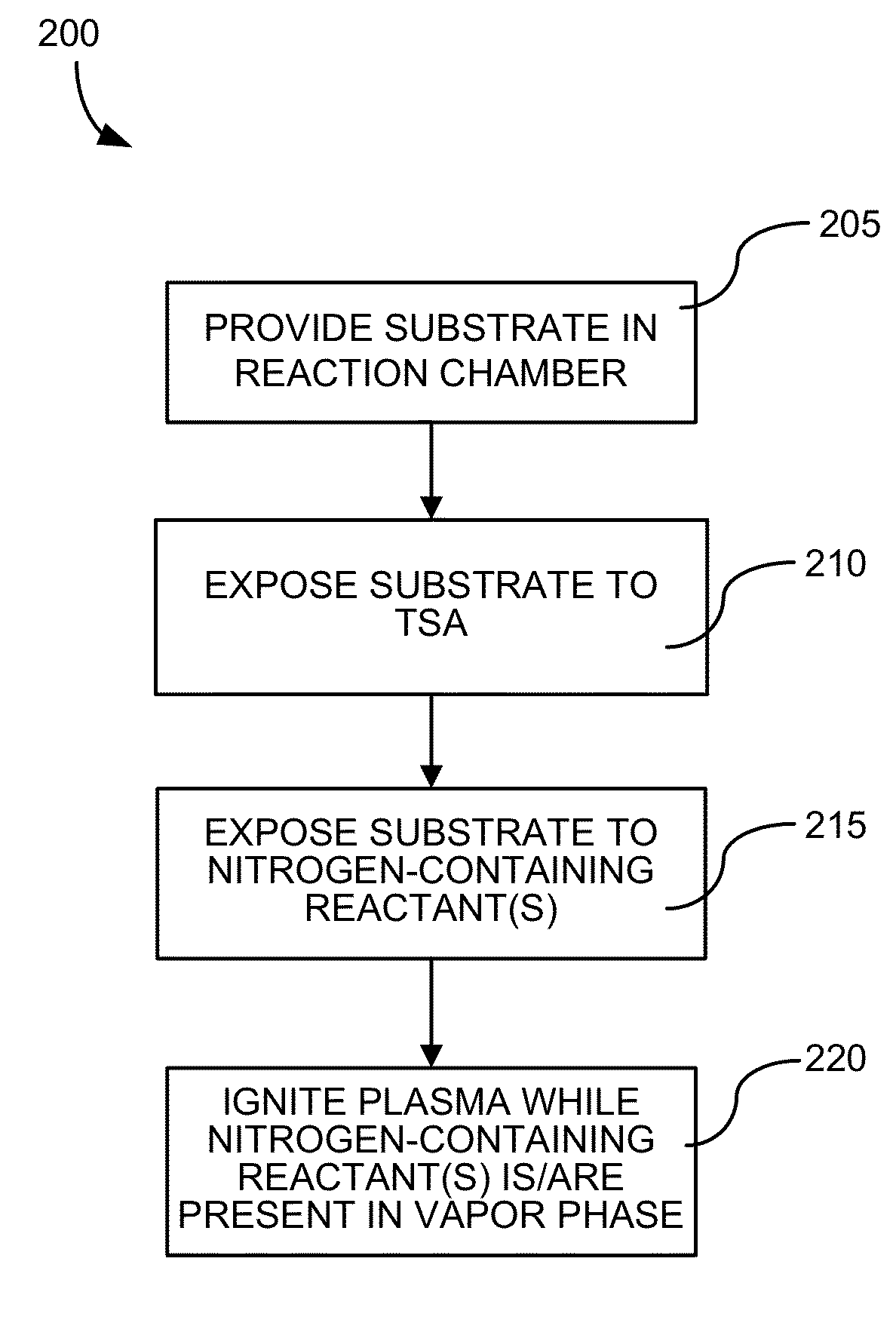

Method for depositing a chlorine-free conformal sin film

ActiveUS8592328B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistryEtching rate

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

Method for depositing a chlorine-free conformal sin film

ActiveUS20140141626A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorine.freeChemistry

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

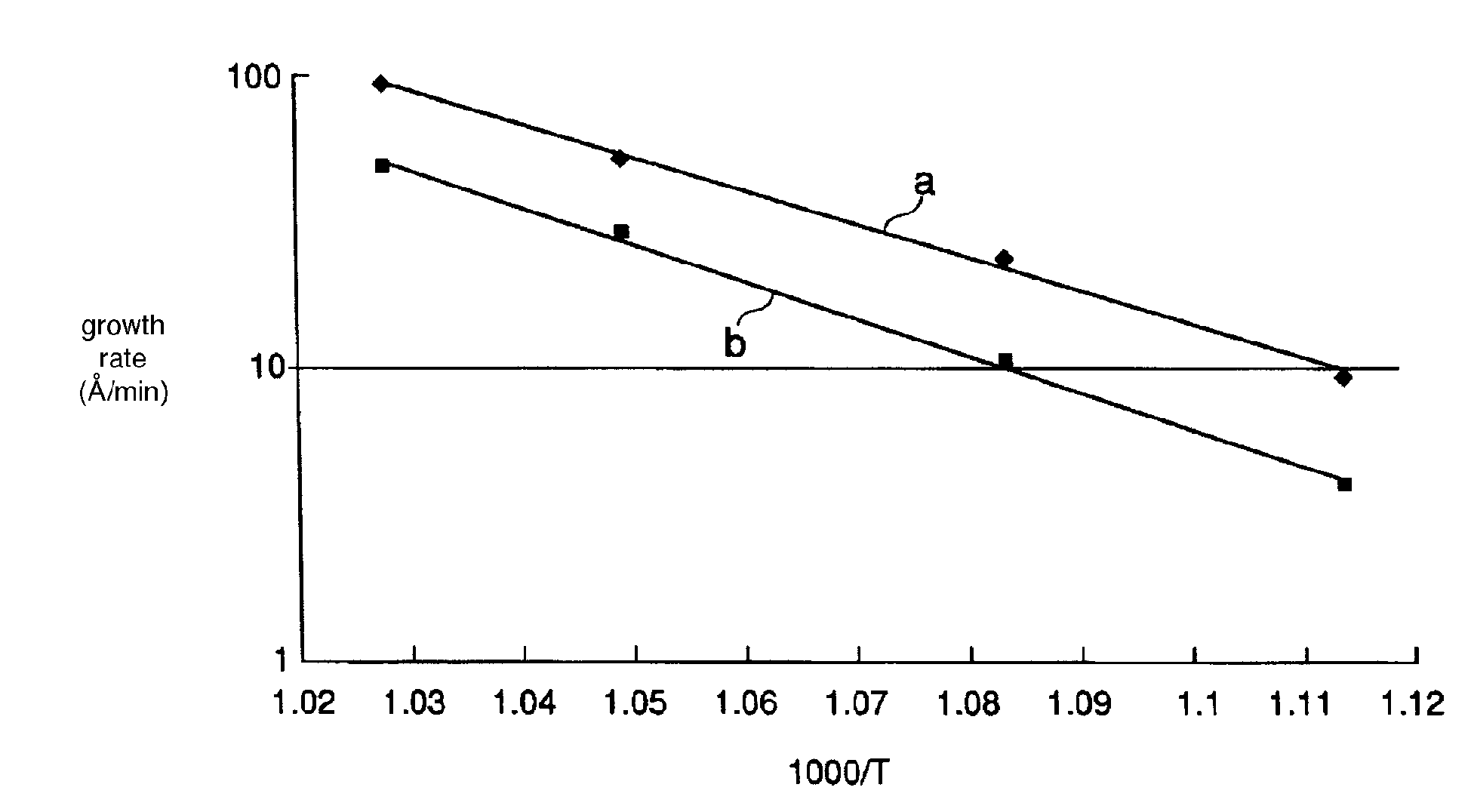

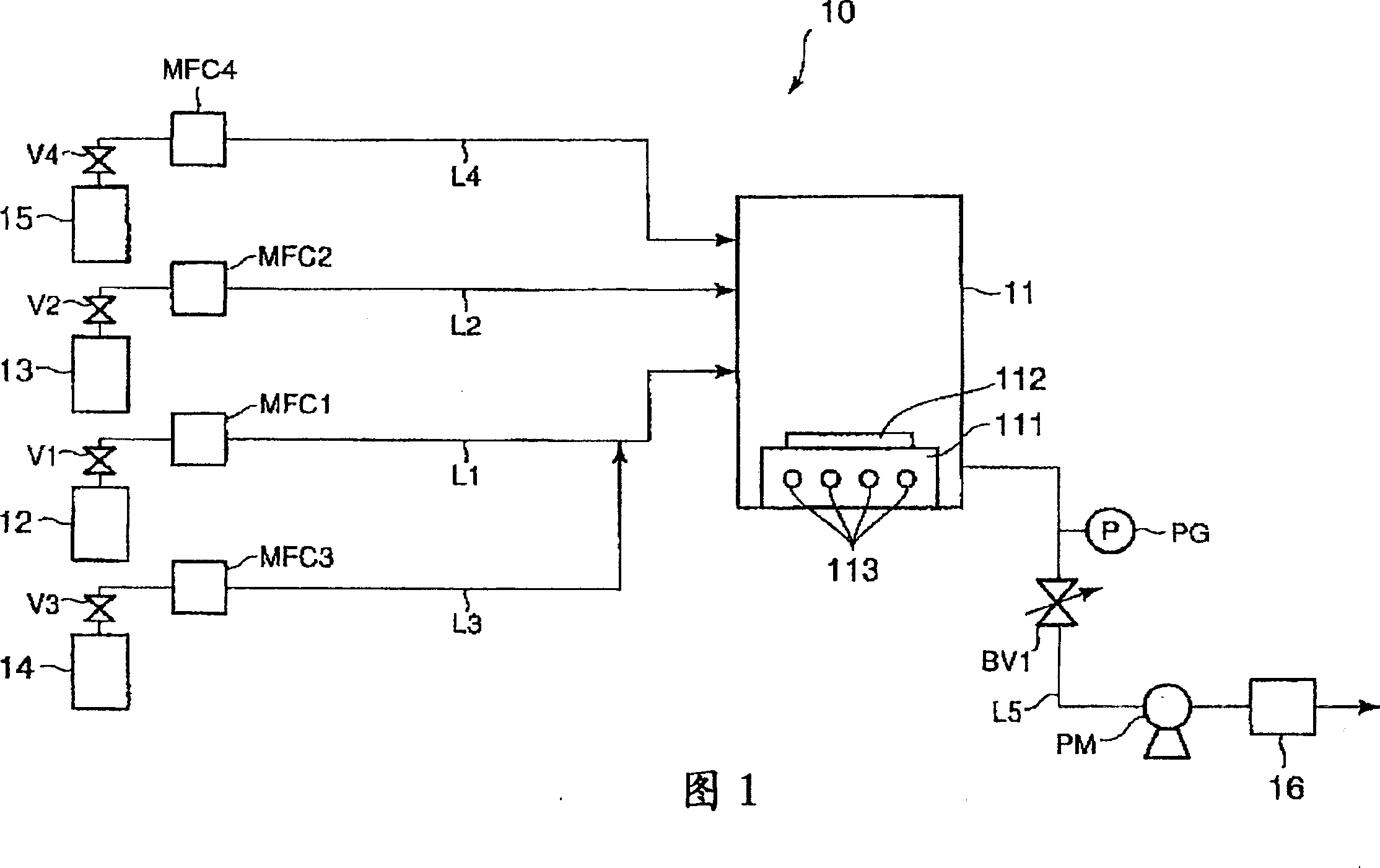

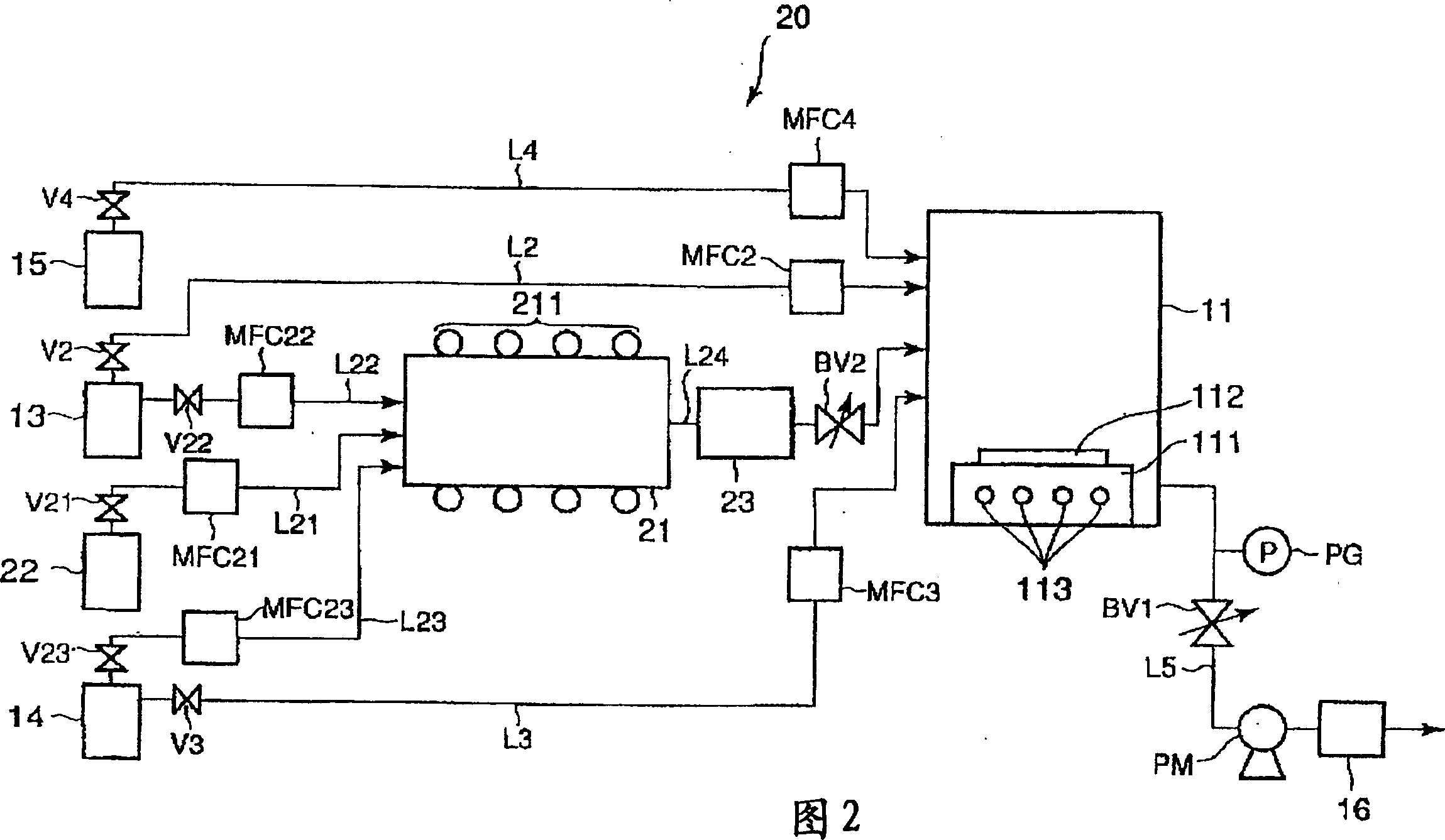

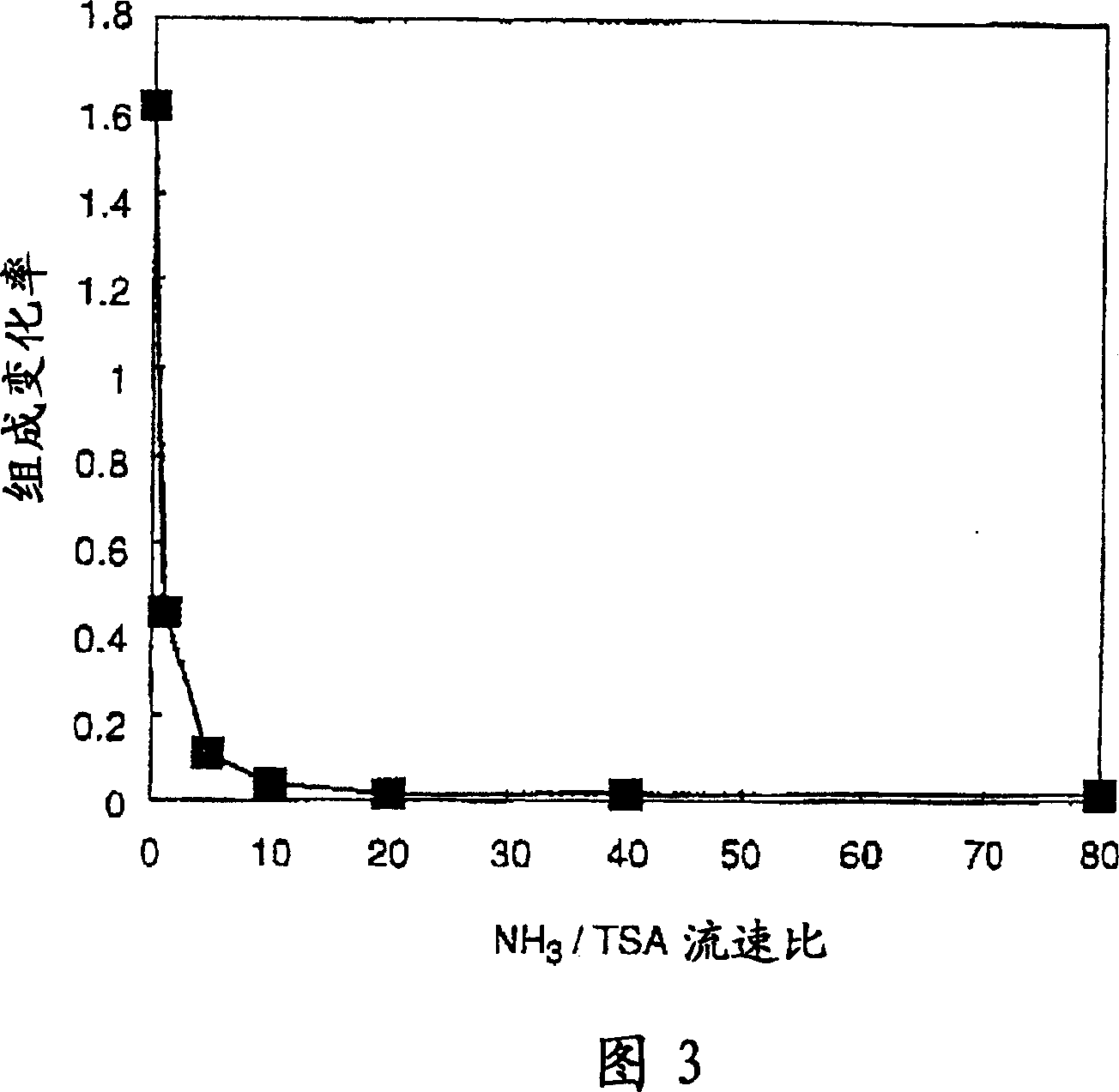

Methods for producing silicon nitride films and silicon oxynitride films by thermal chemical vapor deposition

ActiveUS20050100670A1Quality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilyleneThermal chemical vapor deposition

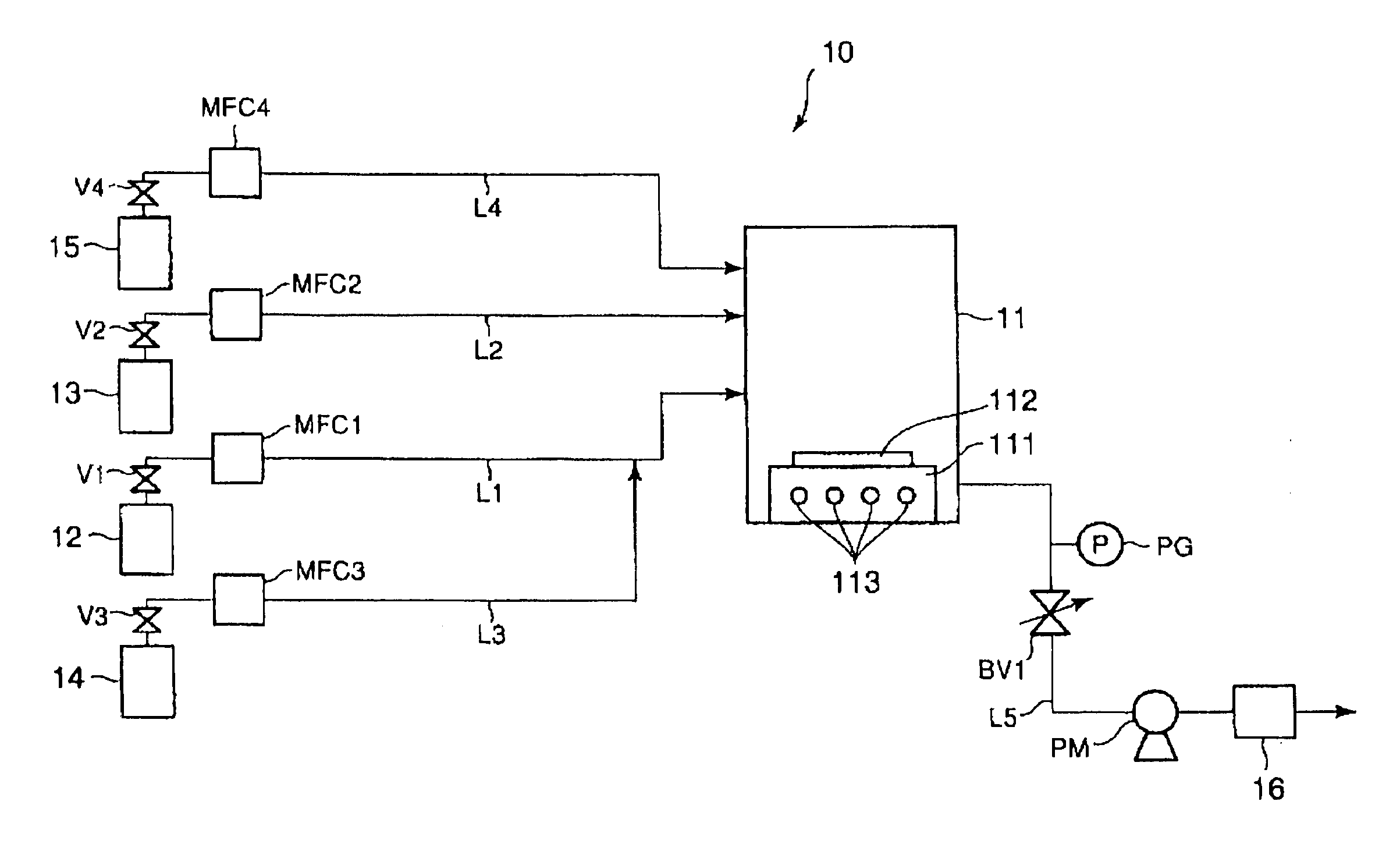

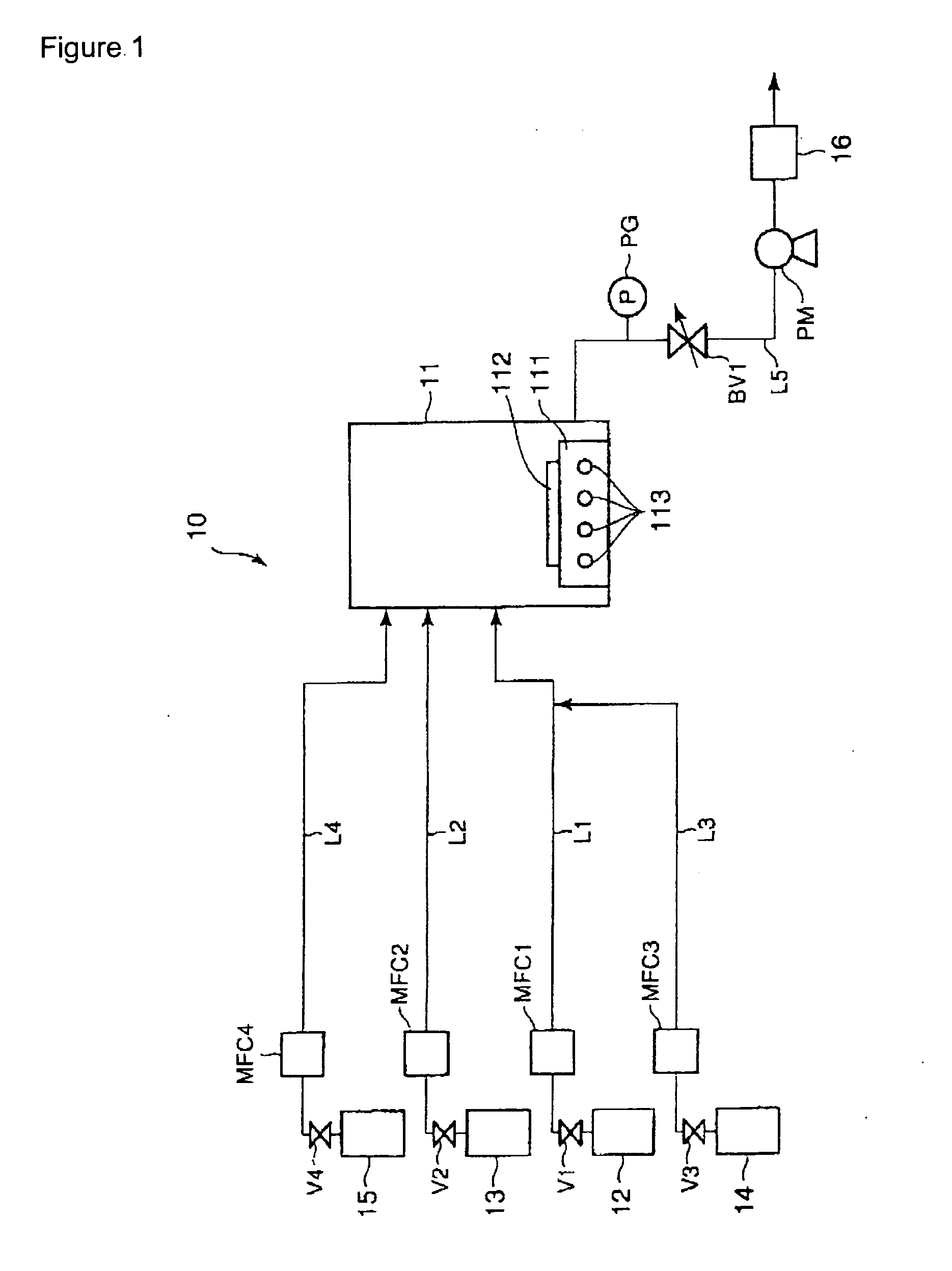

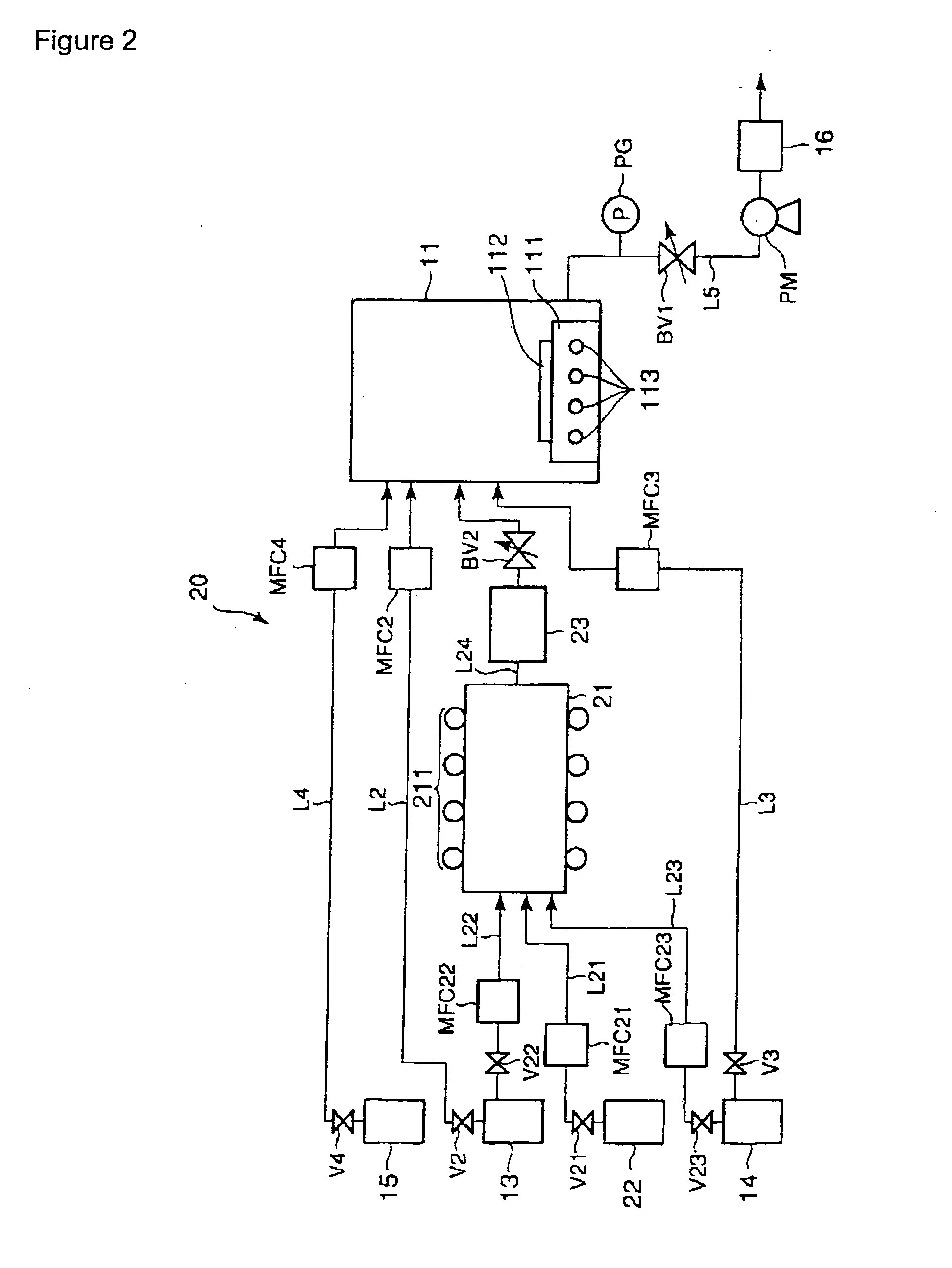

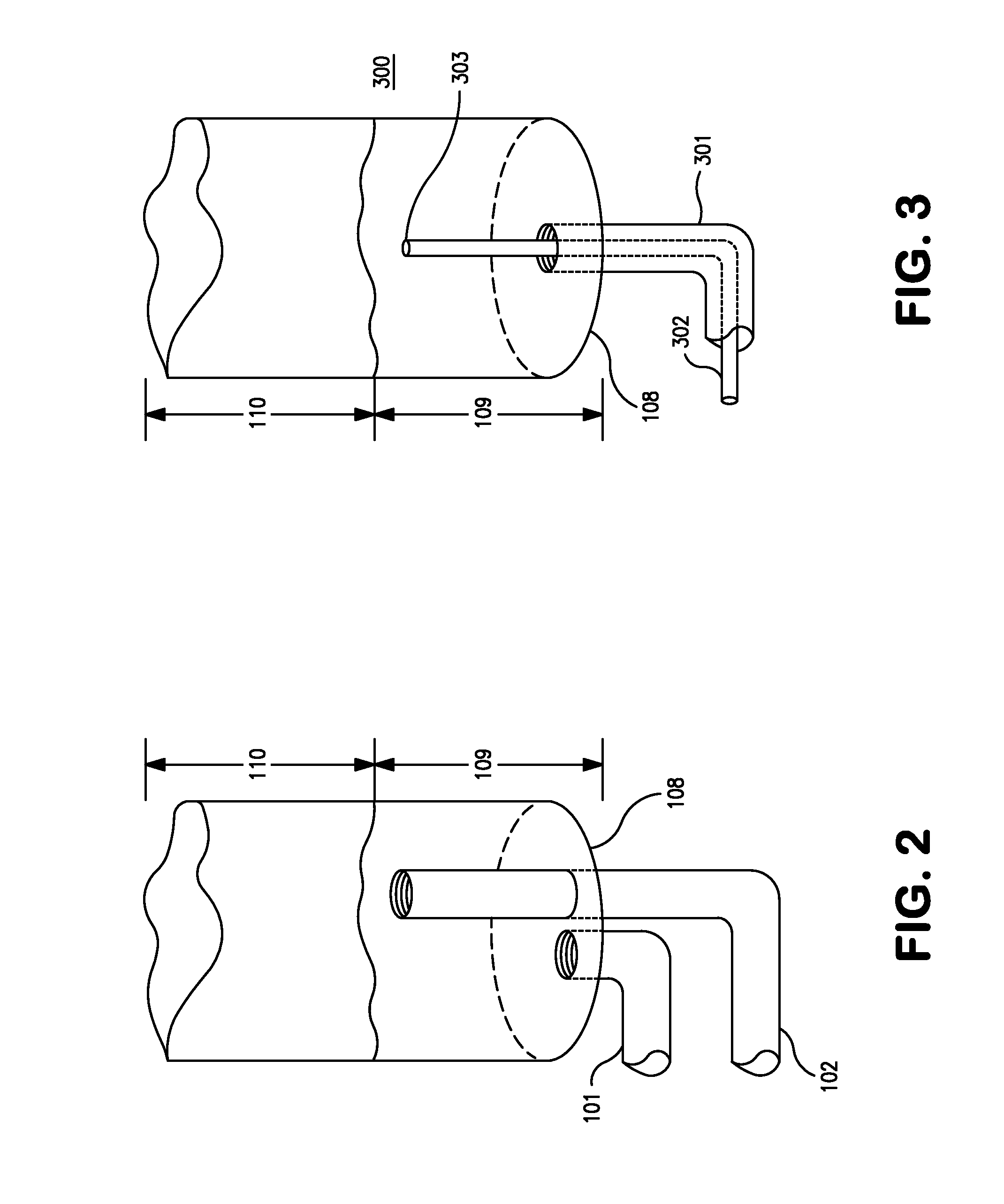

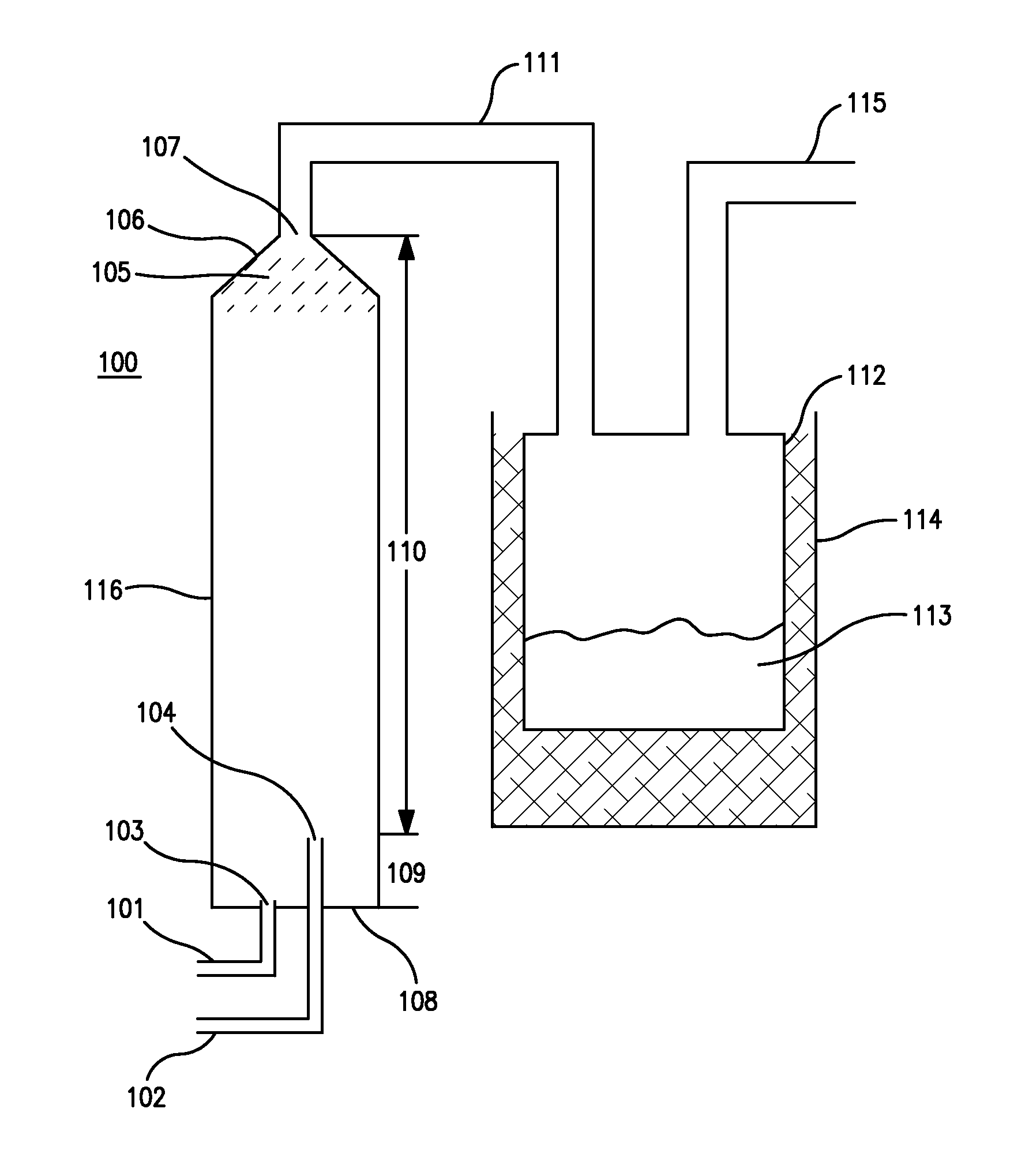

Silicon nitride film is formed on substrate (112) by feeding trisilylamine and ammonia into a CVD reaction chamber (11) that contains a substrate (112). The ammonia gas / trisilylamine gas flow rate ratio is set to a value of at least about 10 and / or the thermal CVD reaction is run at a temperature no greater than about 600° C. Silicon oxynitride is obtained by introducing an oxygen source gas into the CVD reaction chamber (11). This method avoids the production of ammonium chloride and / or the incorporation of carbonaceous contaminants which are detrimental to the quality of the deposited film.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

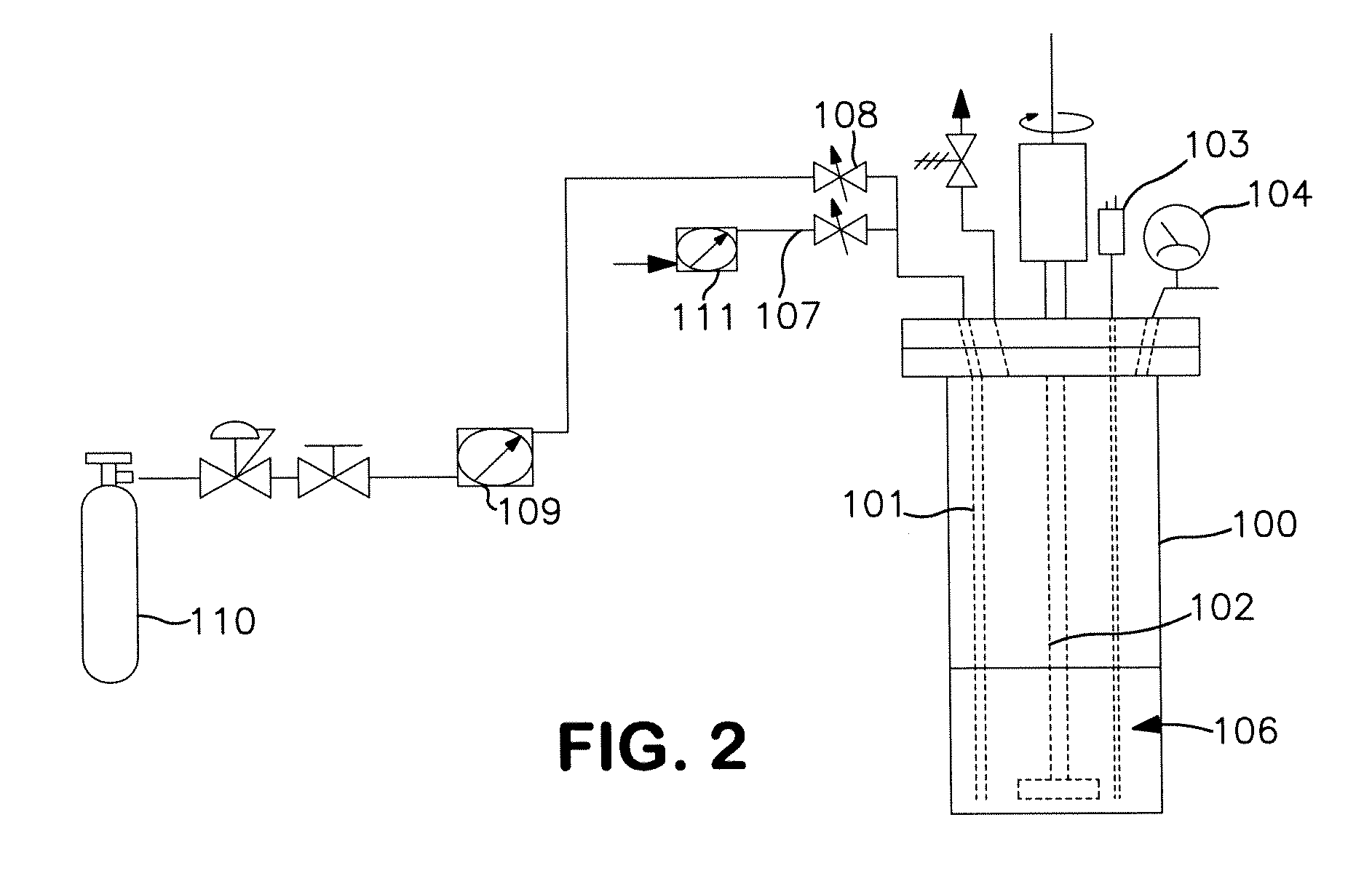

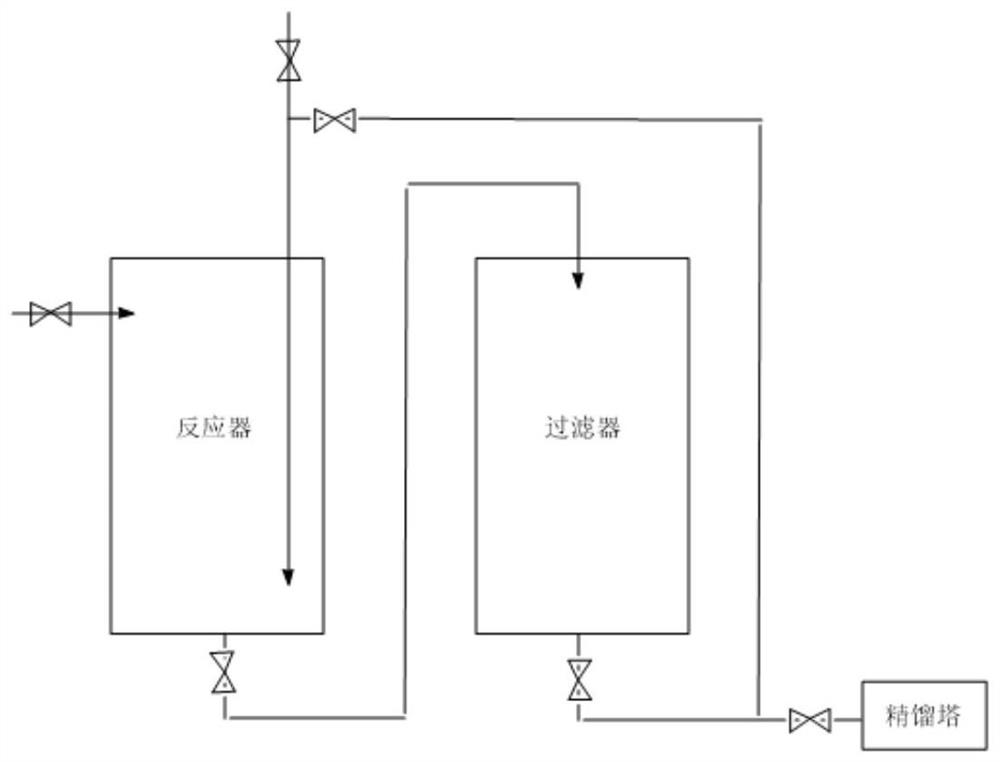

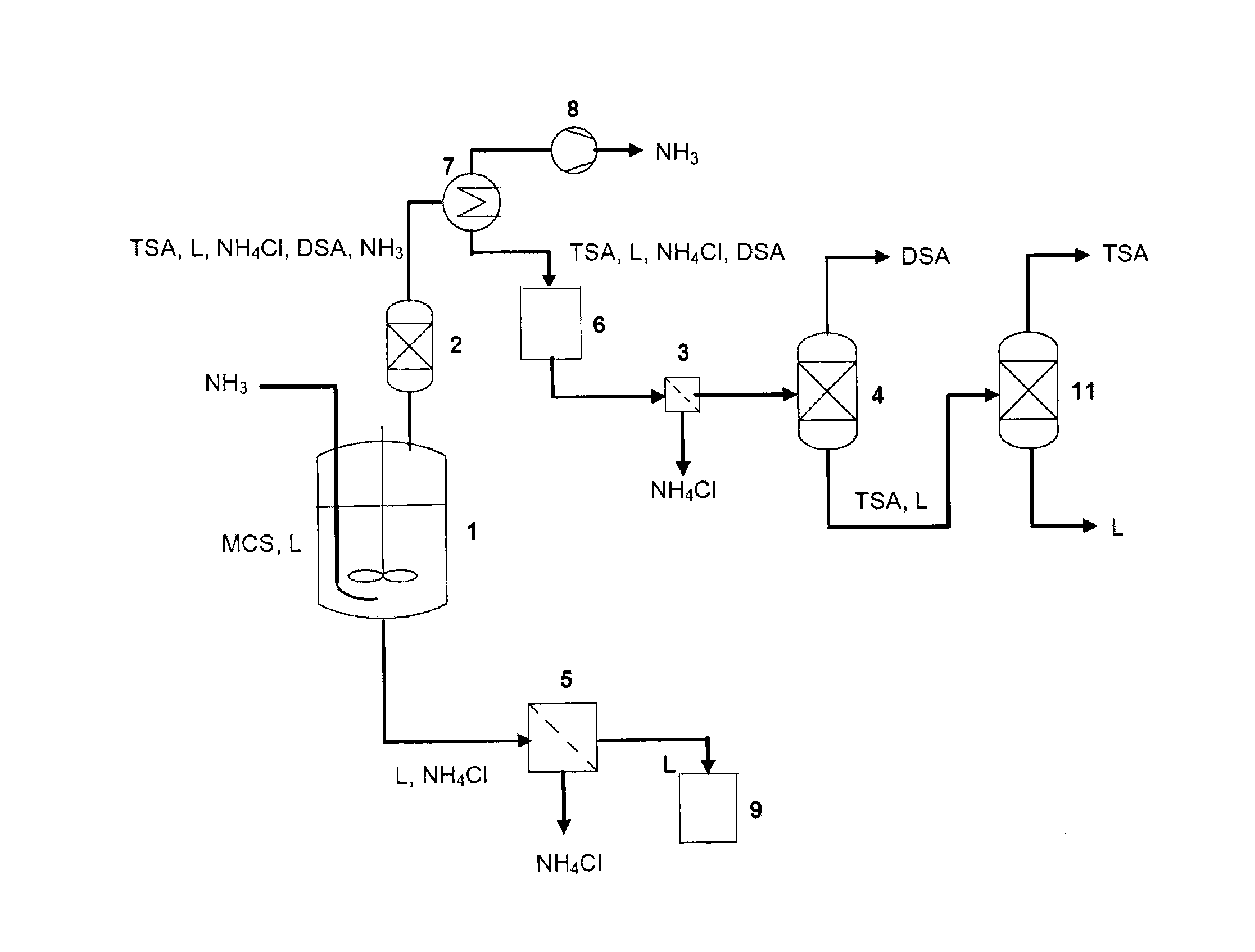

Apparatus and method for the condensed phase production of trisilylamine

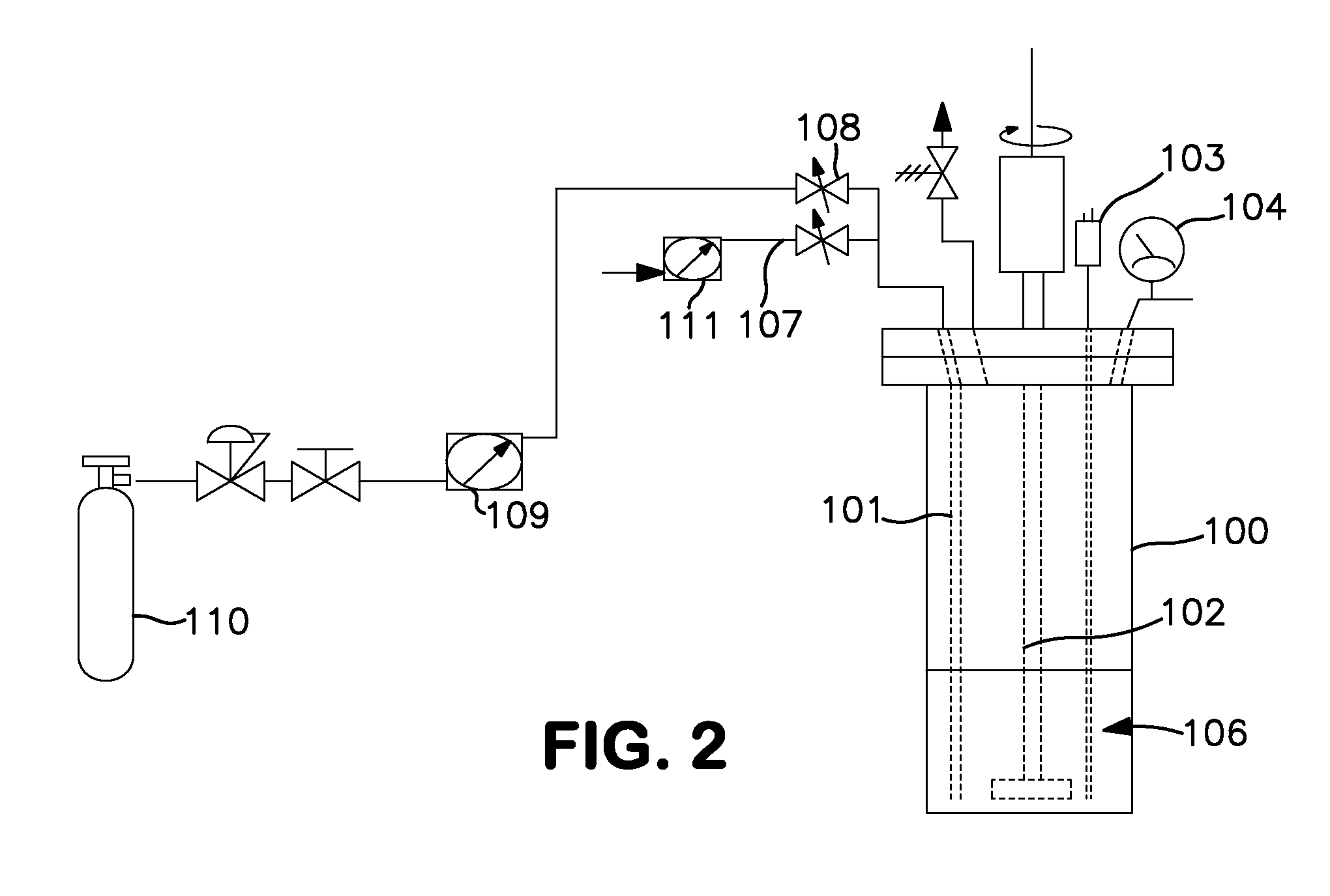

ActiveUS20130089487A1Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsDistillationSynthesis methods

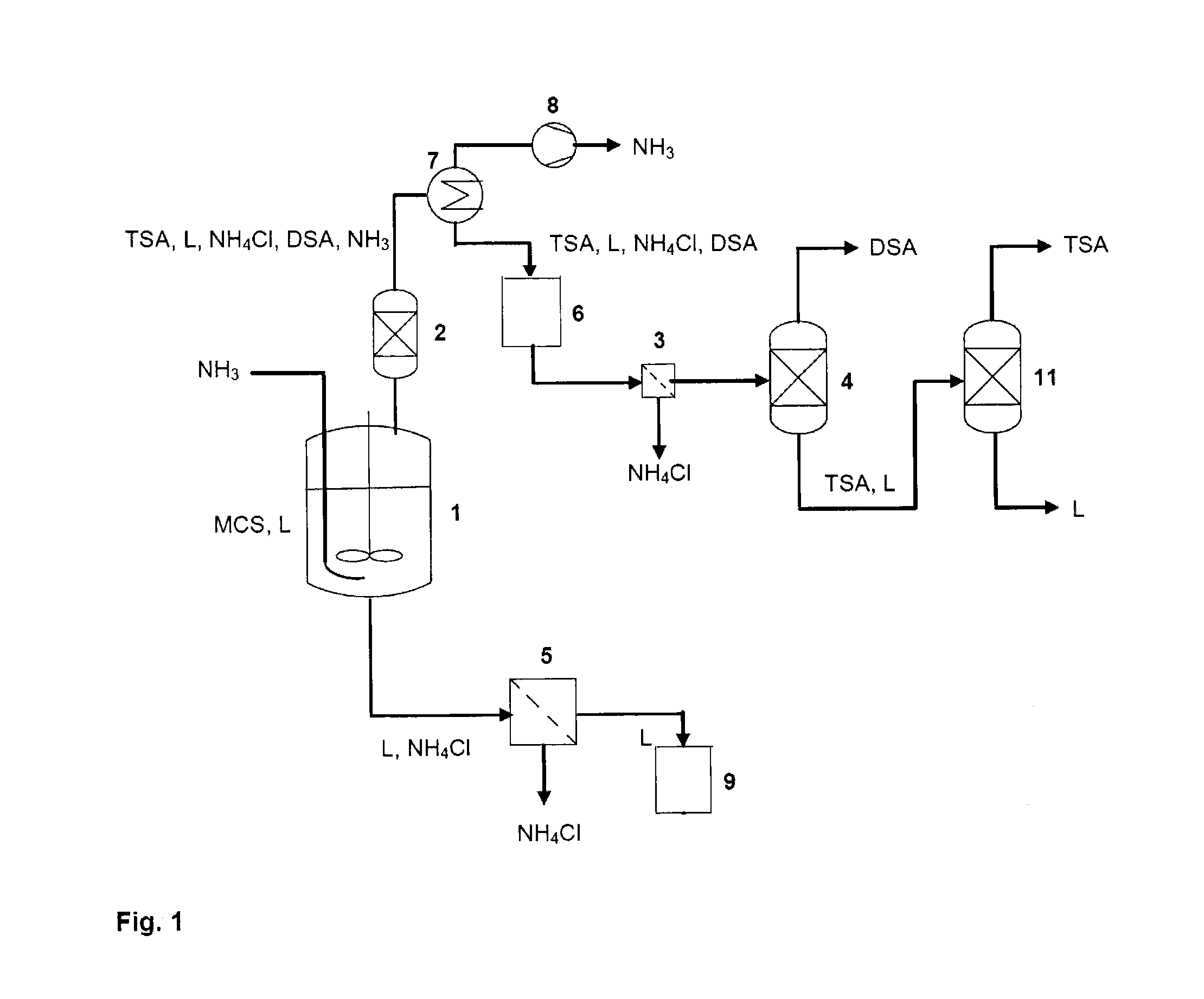

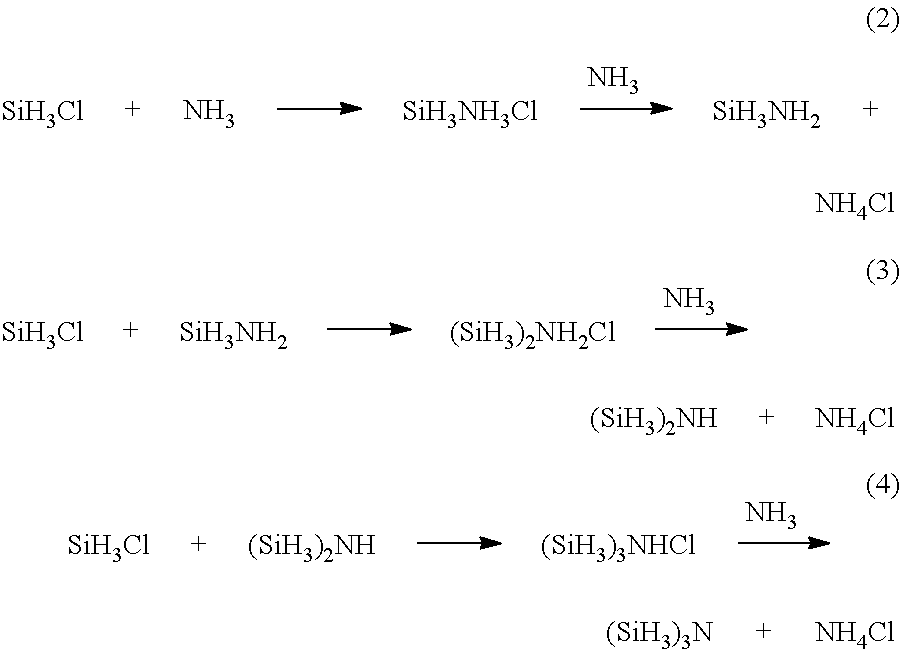

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

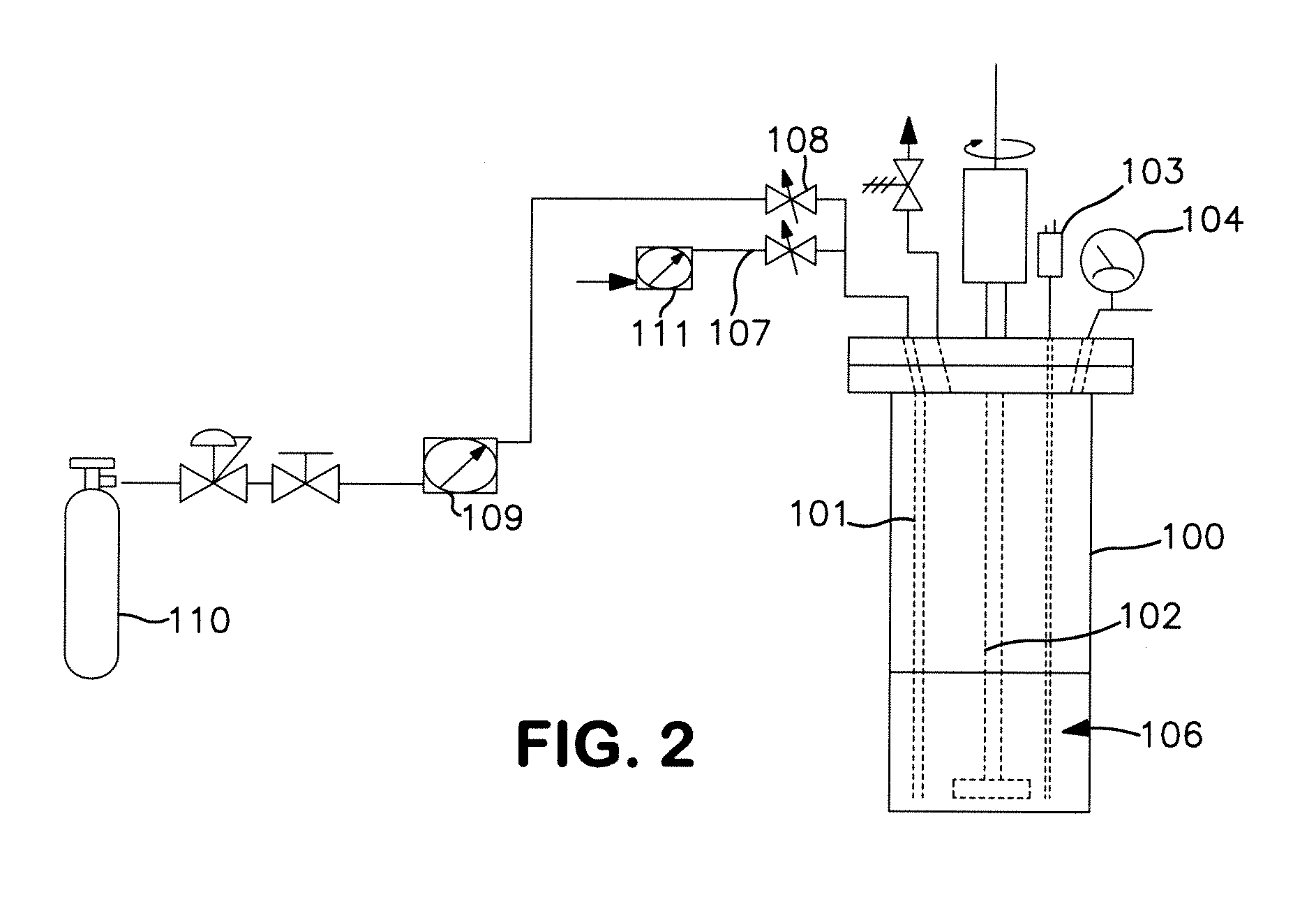

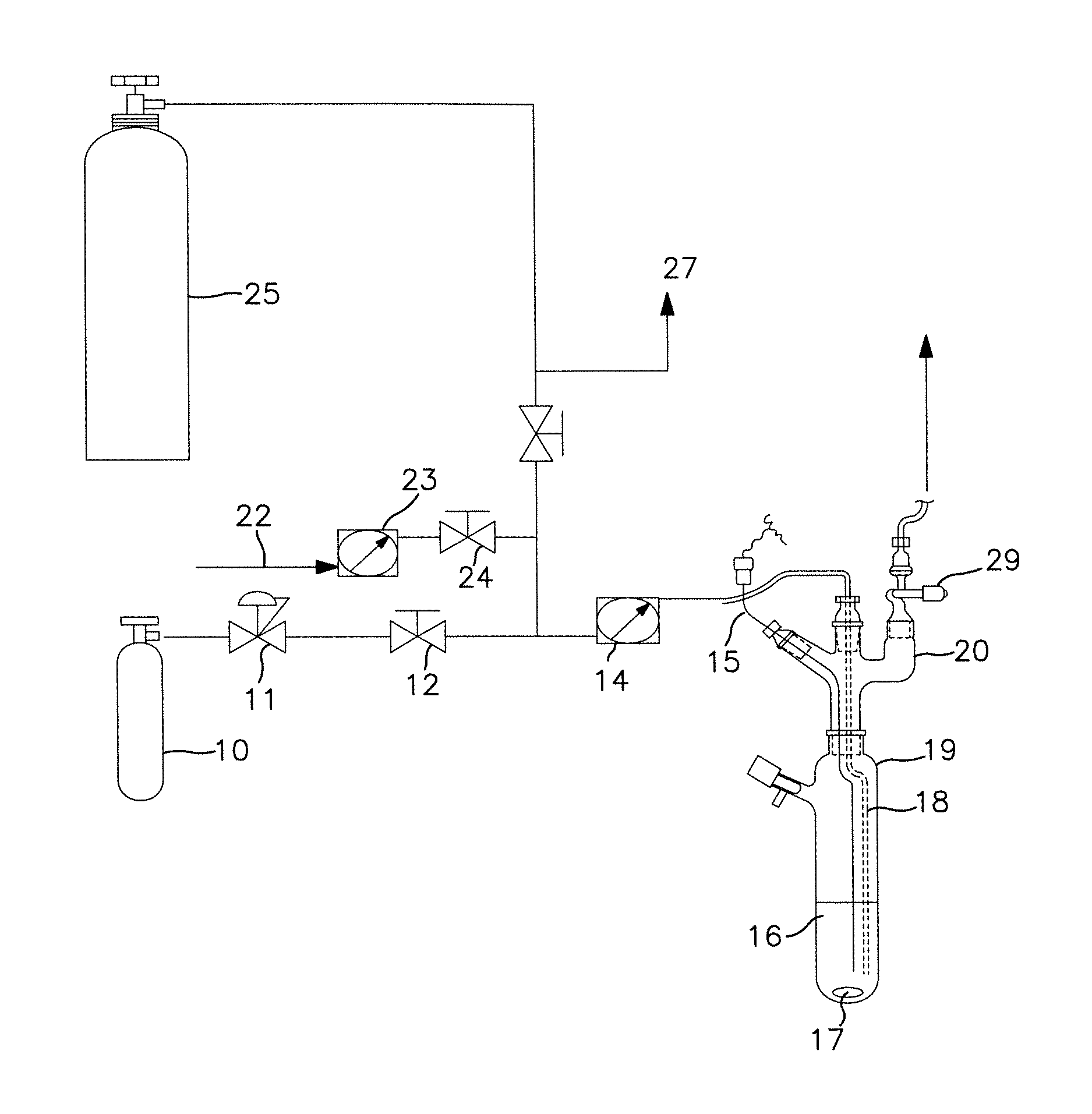

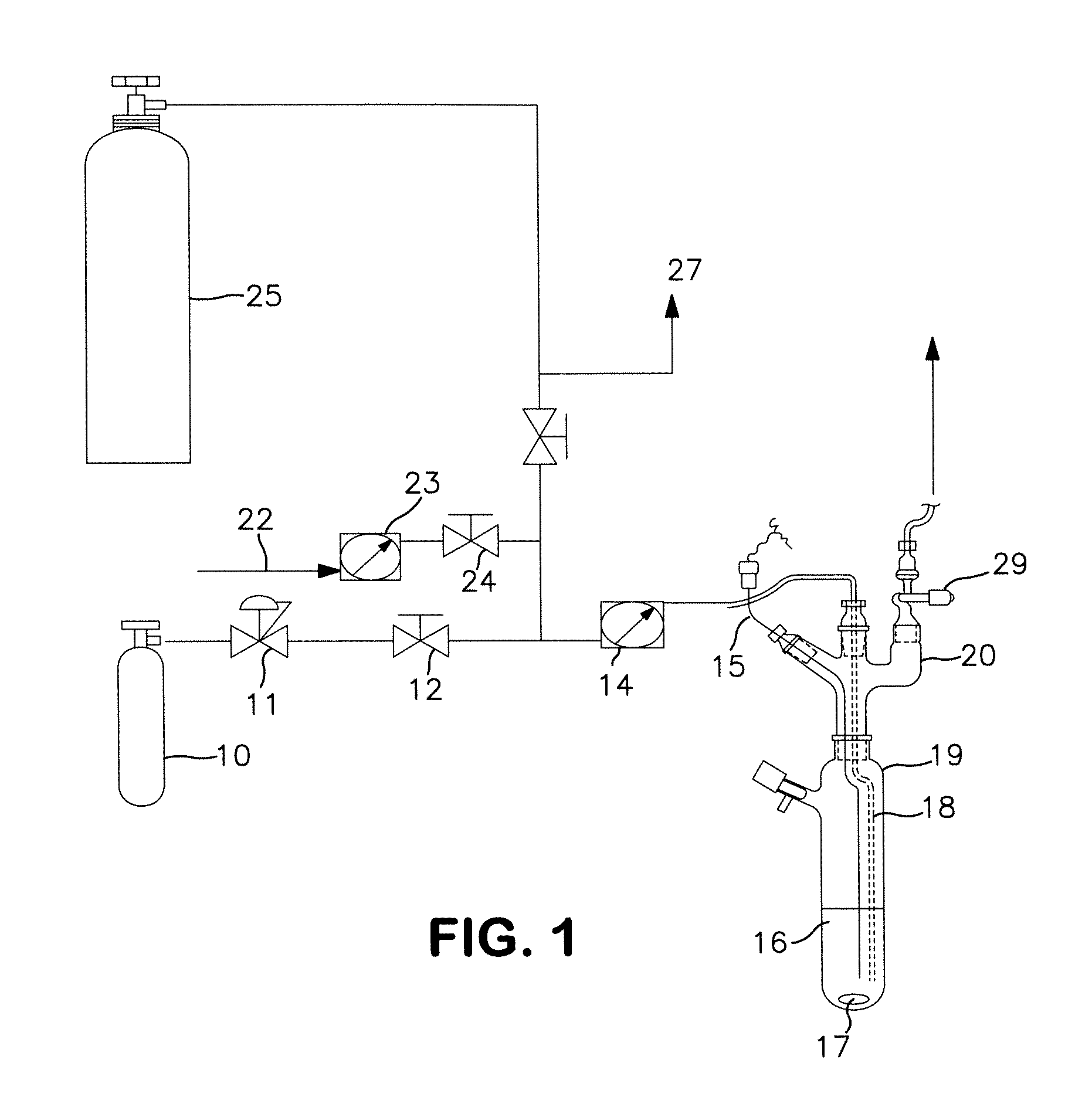

Apparatus and method for the production of trisilylamine

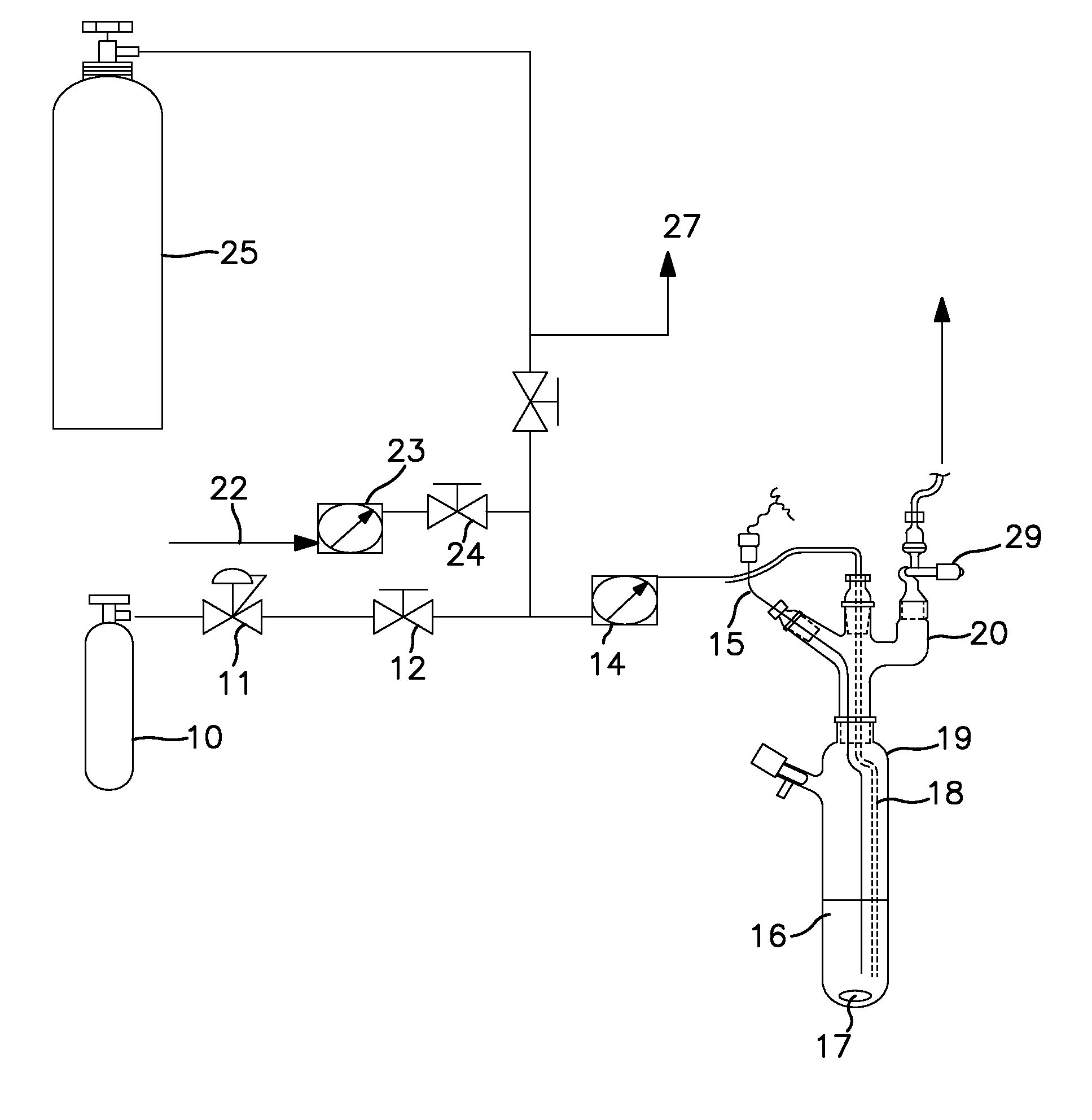

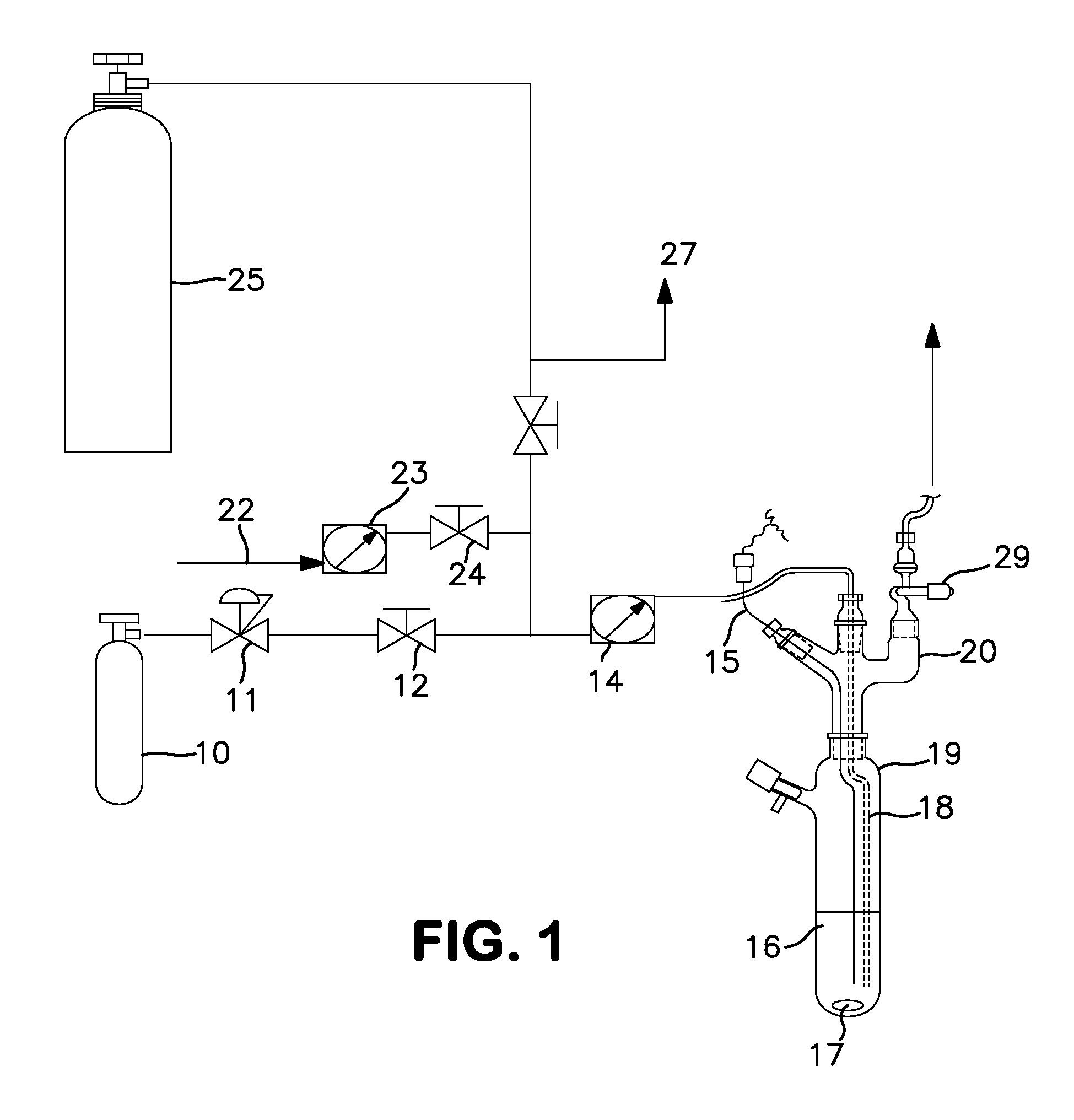

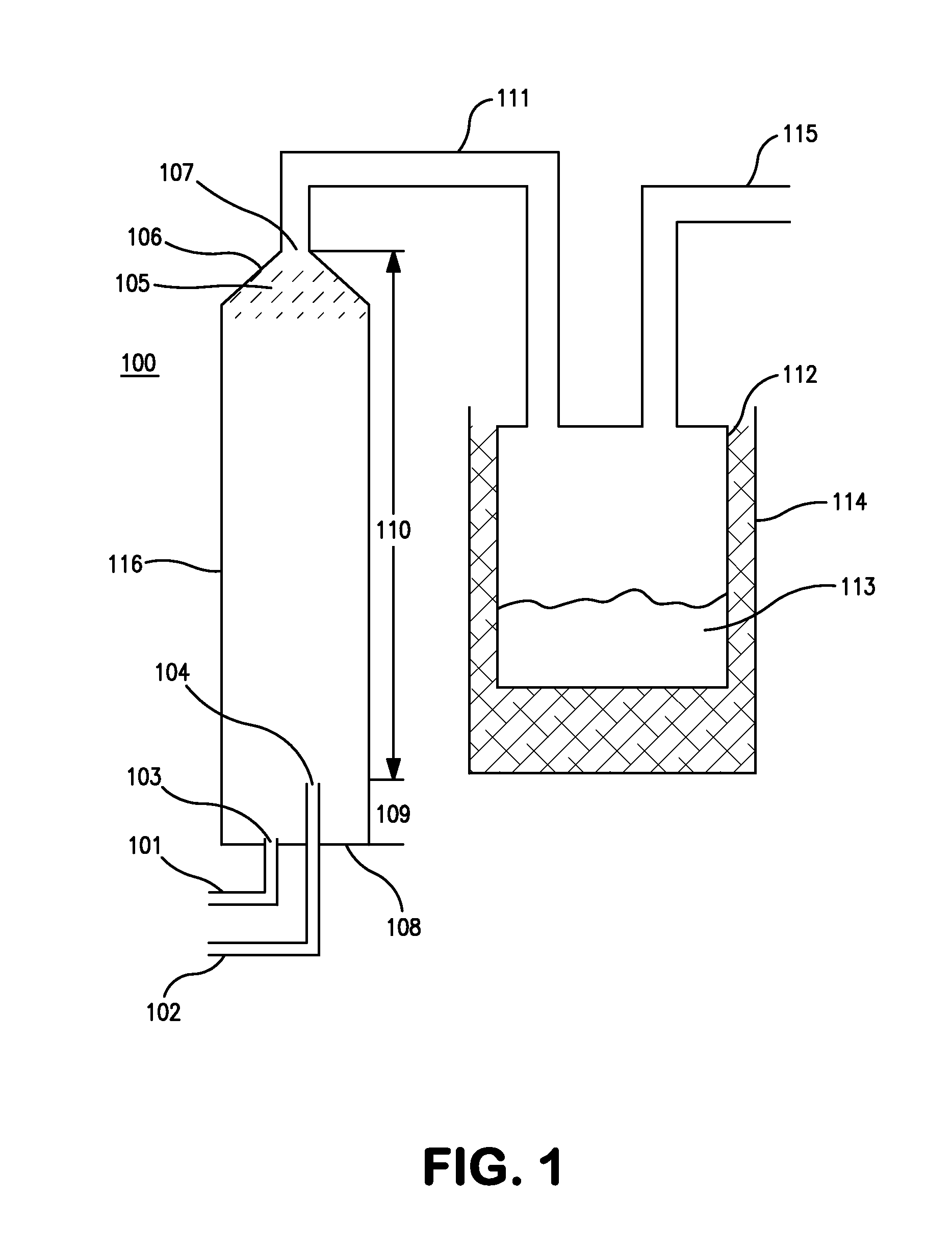

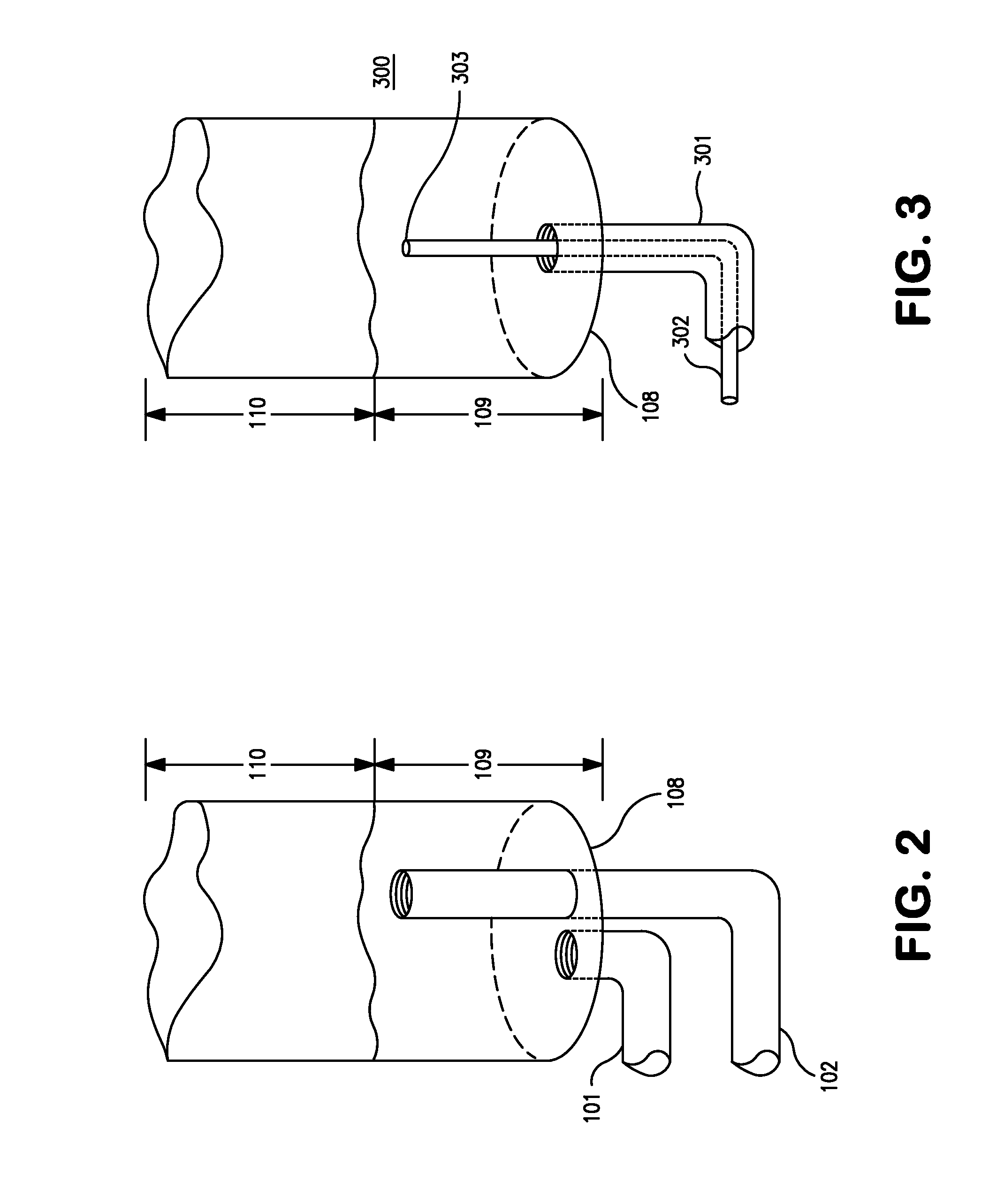

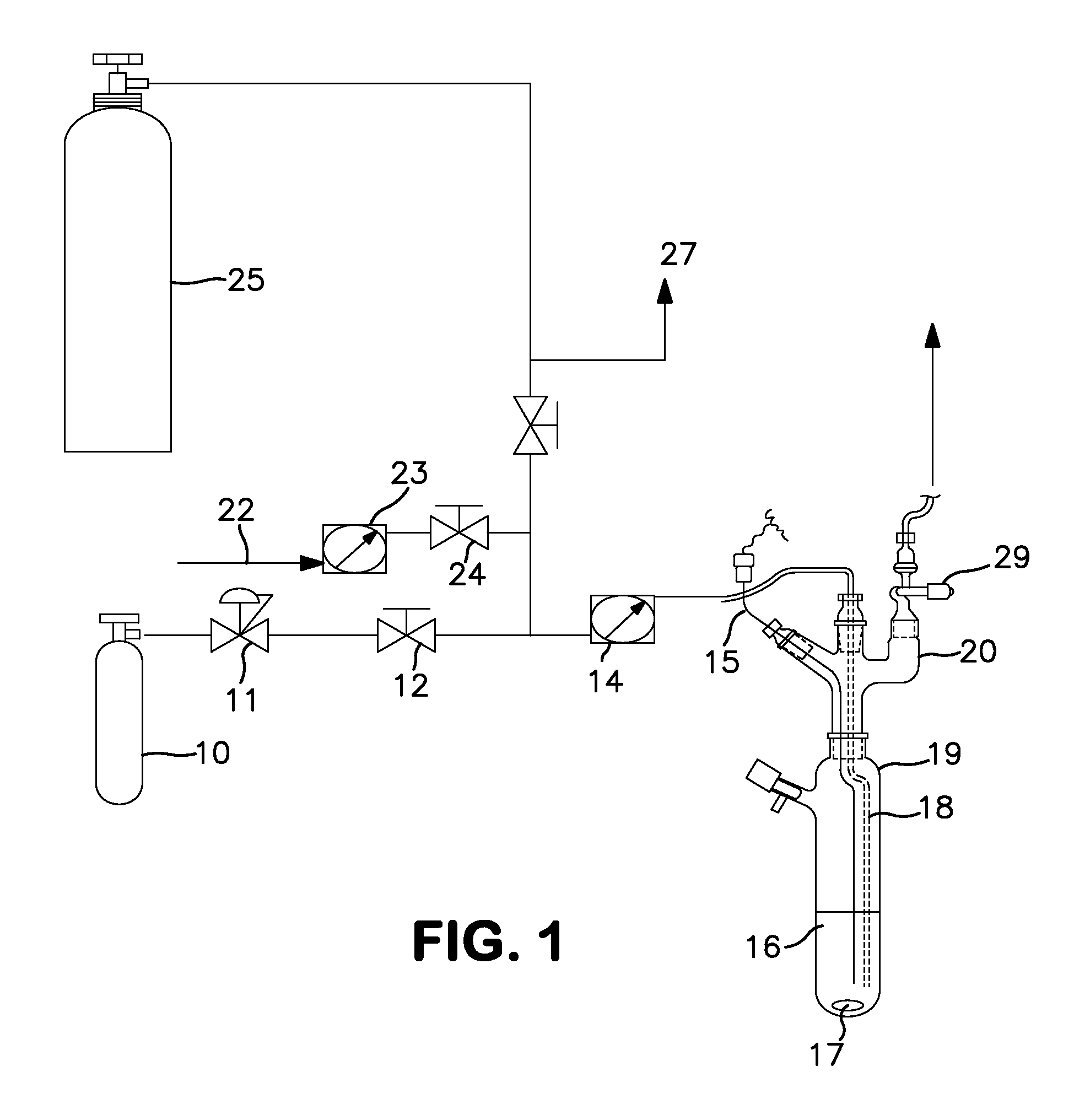

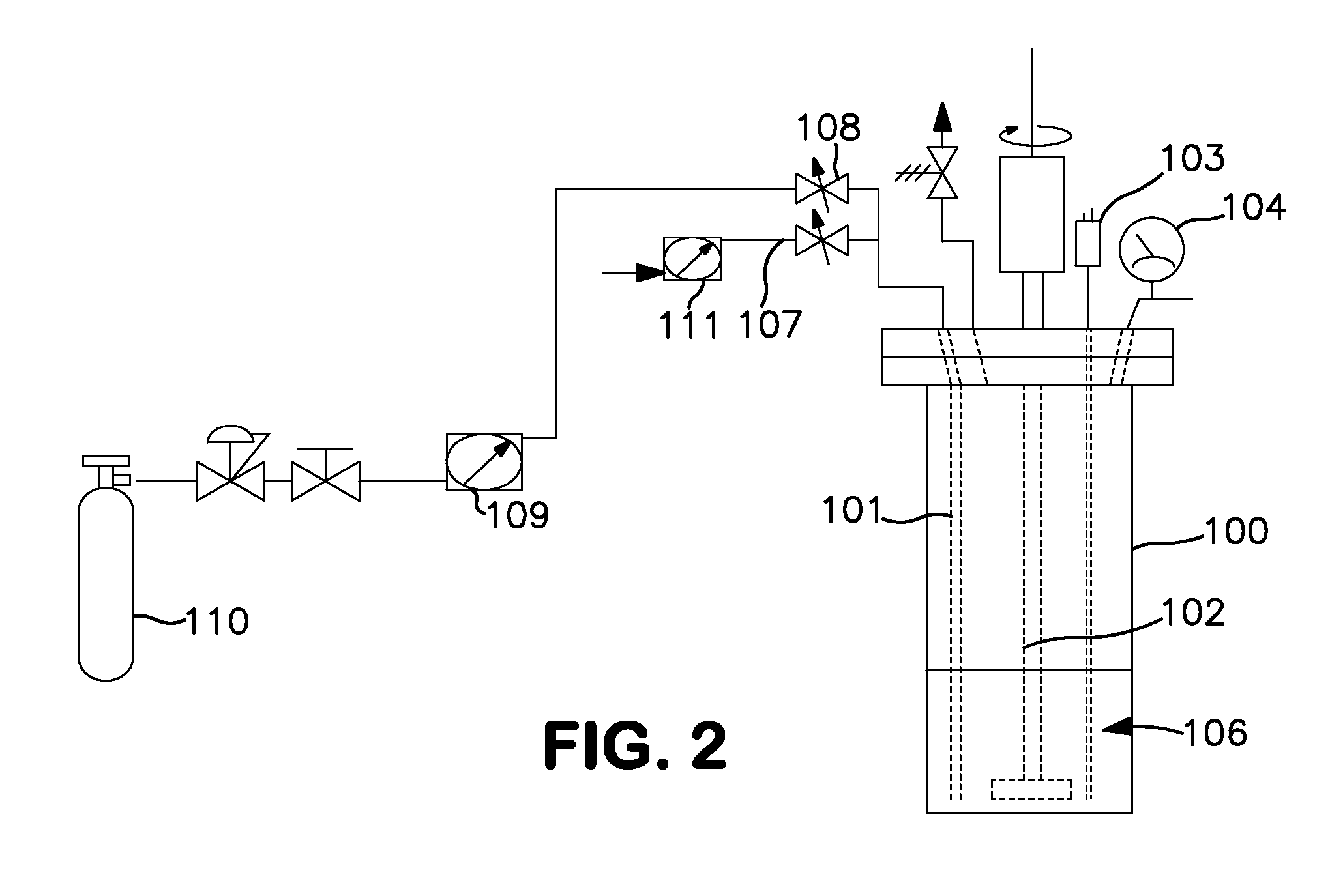

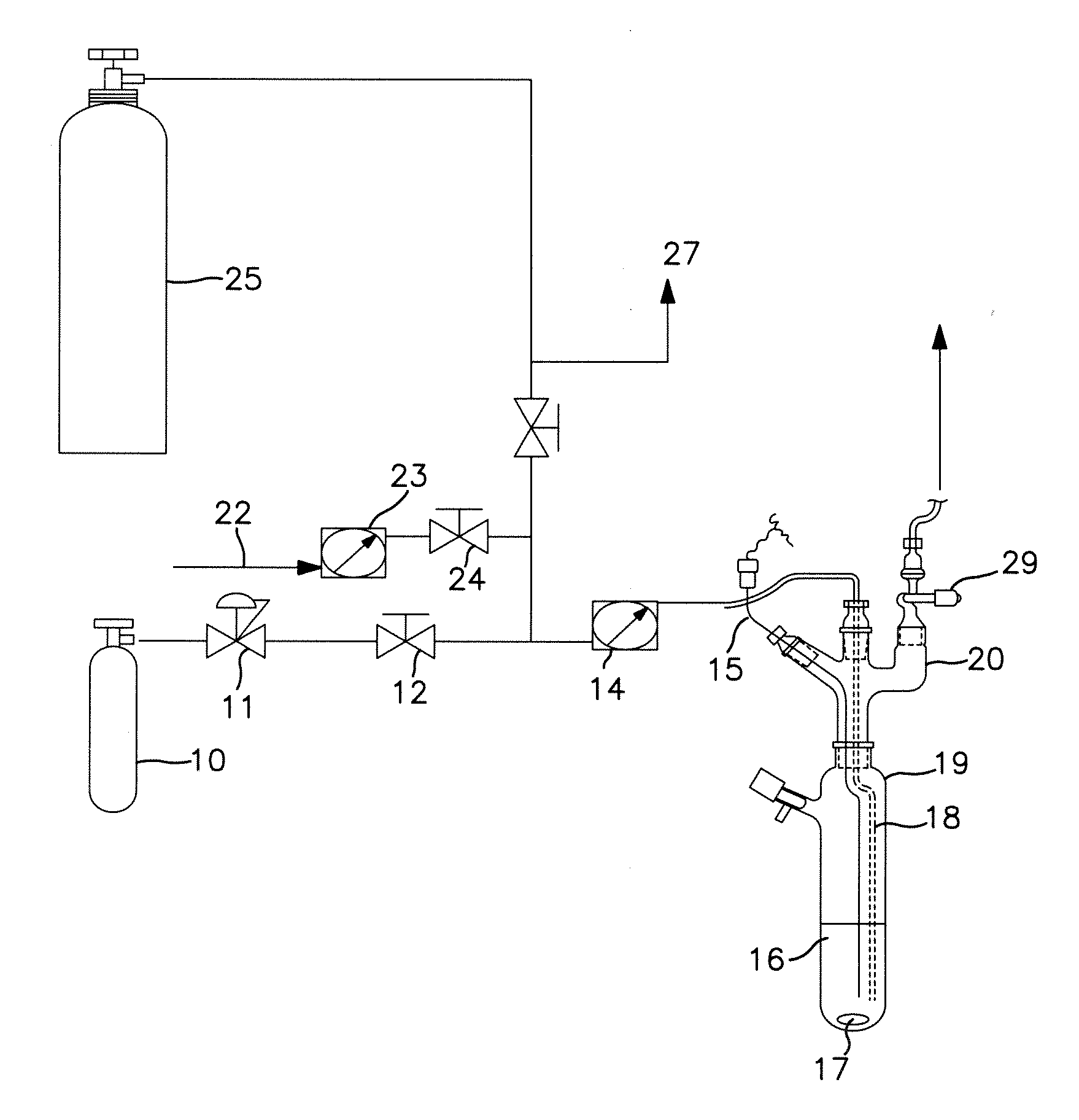

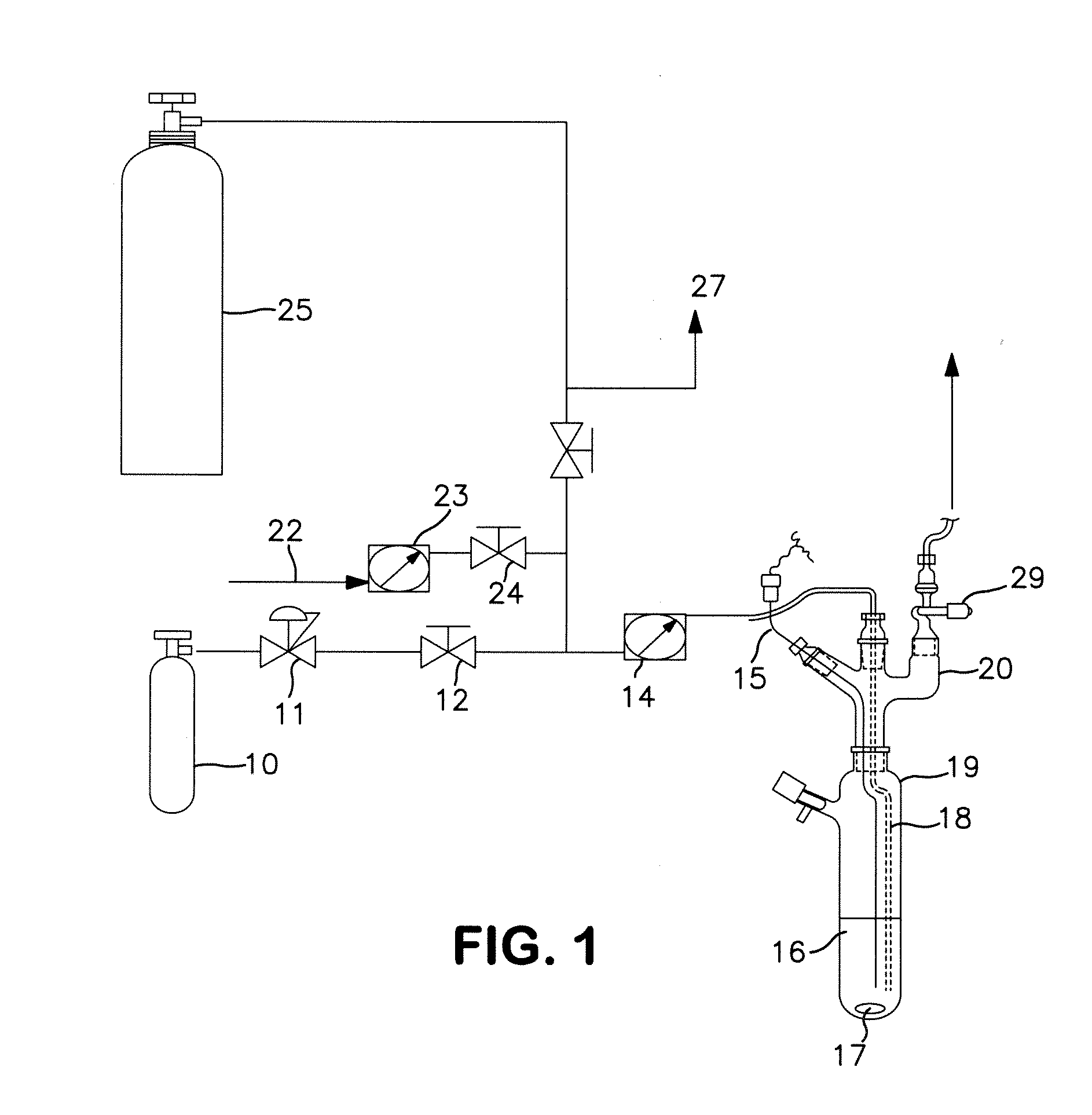

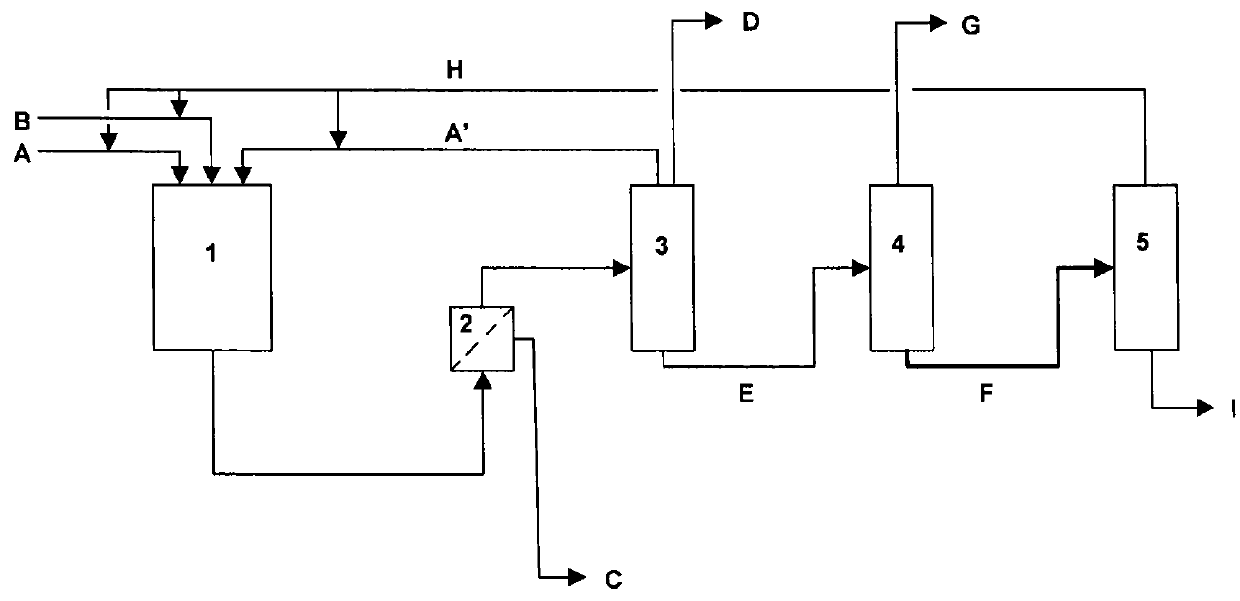

ActiveUS20100310443A1Increase volumeHigh volume high efficiency synthesisGroup 4/14 element organic compoundsPressurized chemical processReaction zoneProduct gas

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Preparation process of trisilylamine

ActiveUS20110178322A1Low costEasy to separateSilicon organic compoundsChemical/physical/physico-chemical processesLow oxygenAtmosphere

Provided is a preparation process of trisilylamine capable of preparing high-purity trisilylamine more easily at a lower cost. More specifically, provided is a preparation process of trisilylamine, comprising a step of thermally decomposing perhydropolysilazane under an oxygen-free or low oxygen atmosphere.

Owner:SHIN ETSU CHEM IND CO LTD

Apparatus and method for the production of trisilylamine

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for producing silicon nitride films

ActiveUS8357430B2Improve film propertiesIncrease resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenGas phase

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

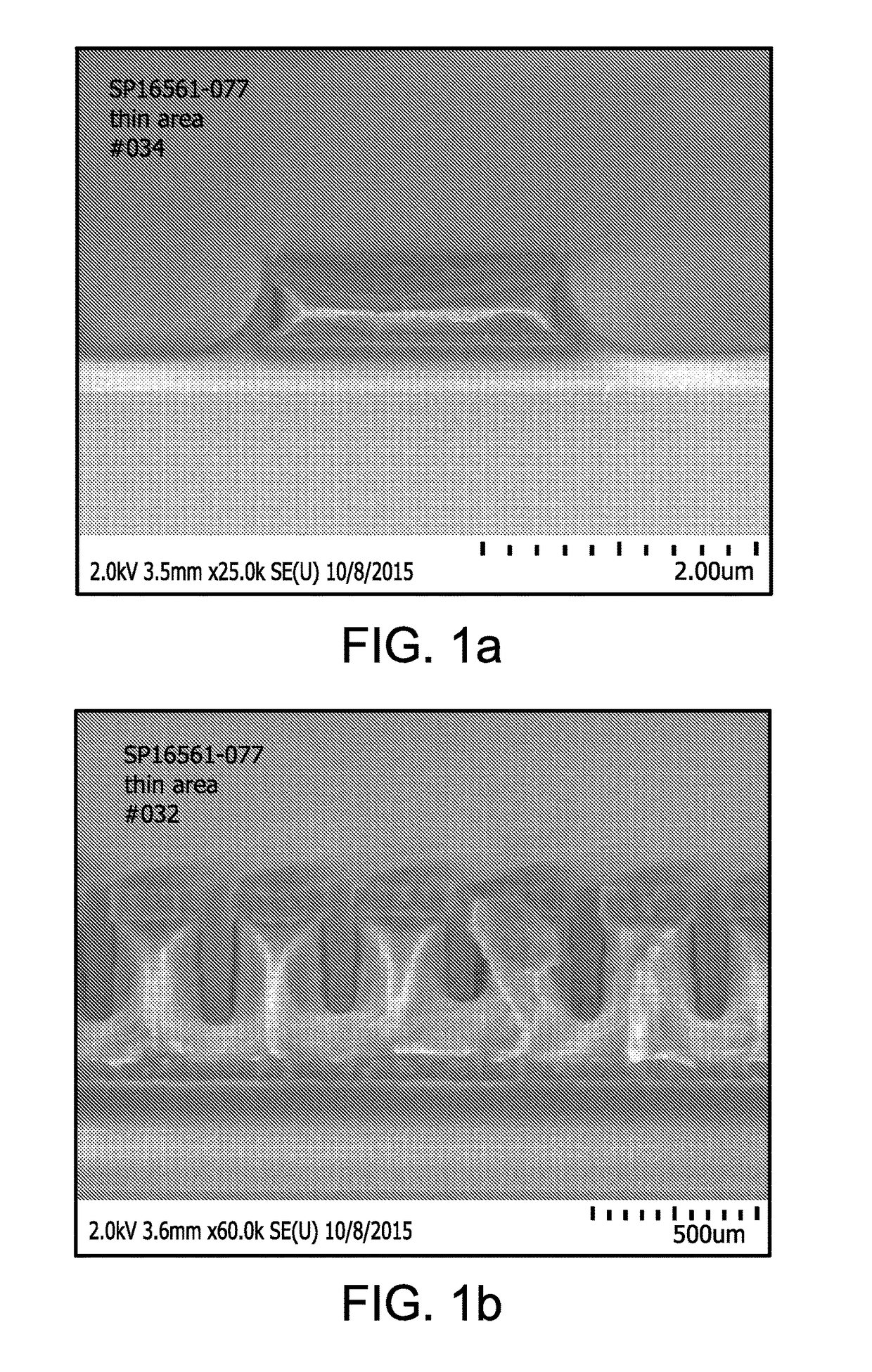

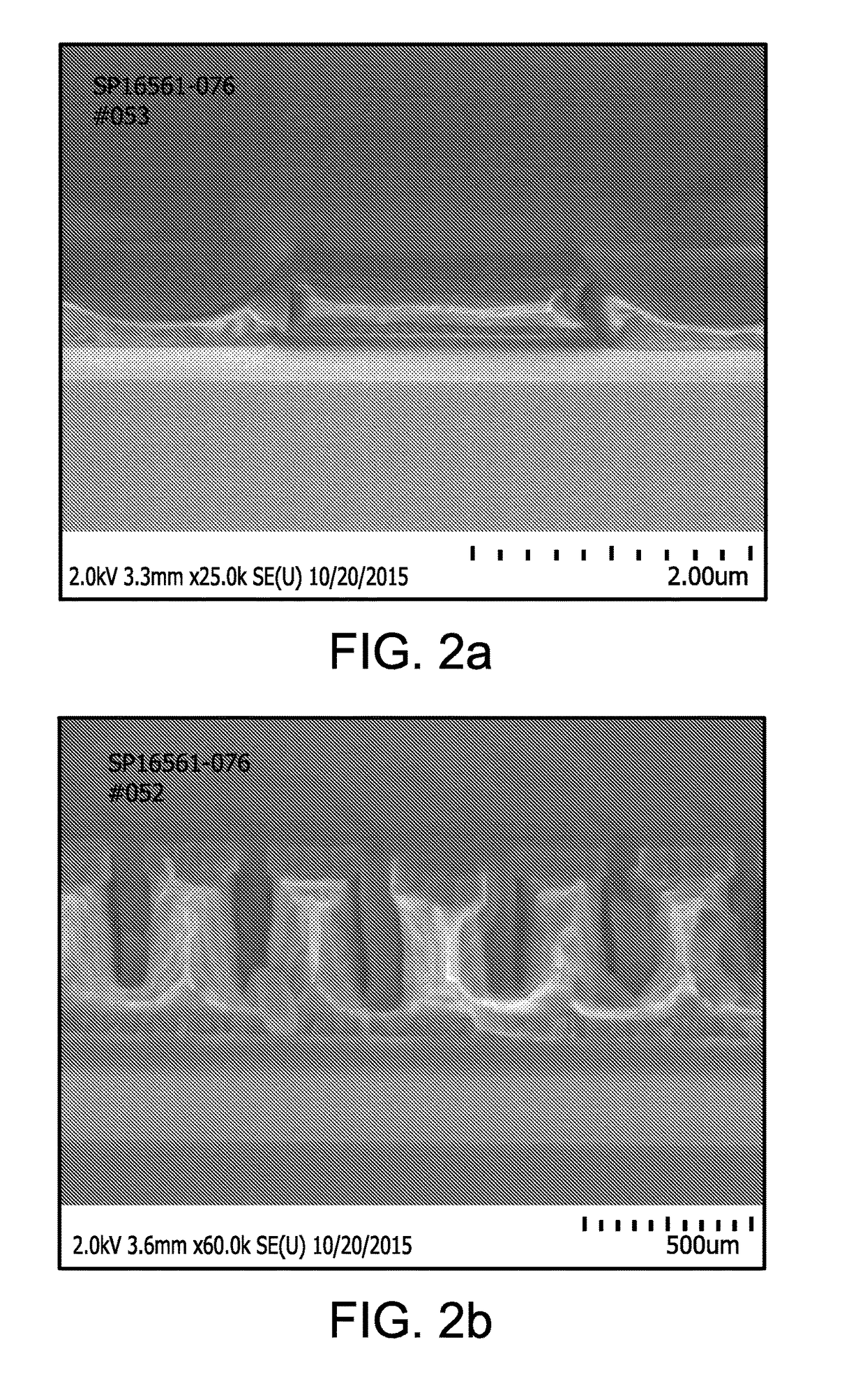

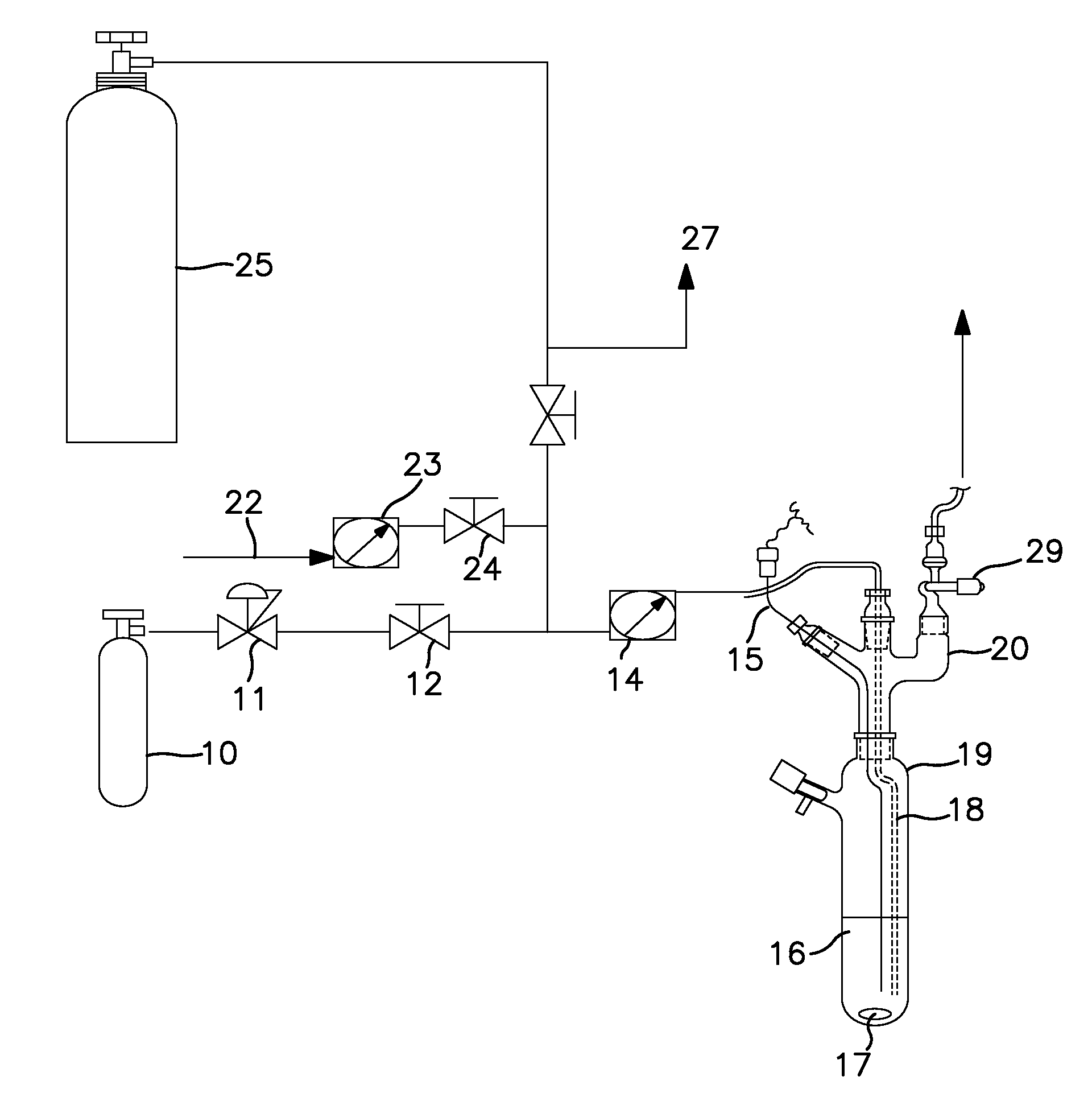

Compositions and methods using same for deposition of silicon-containing film

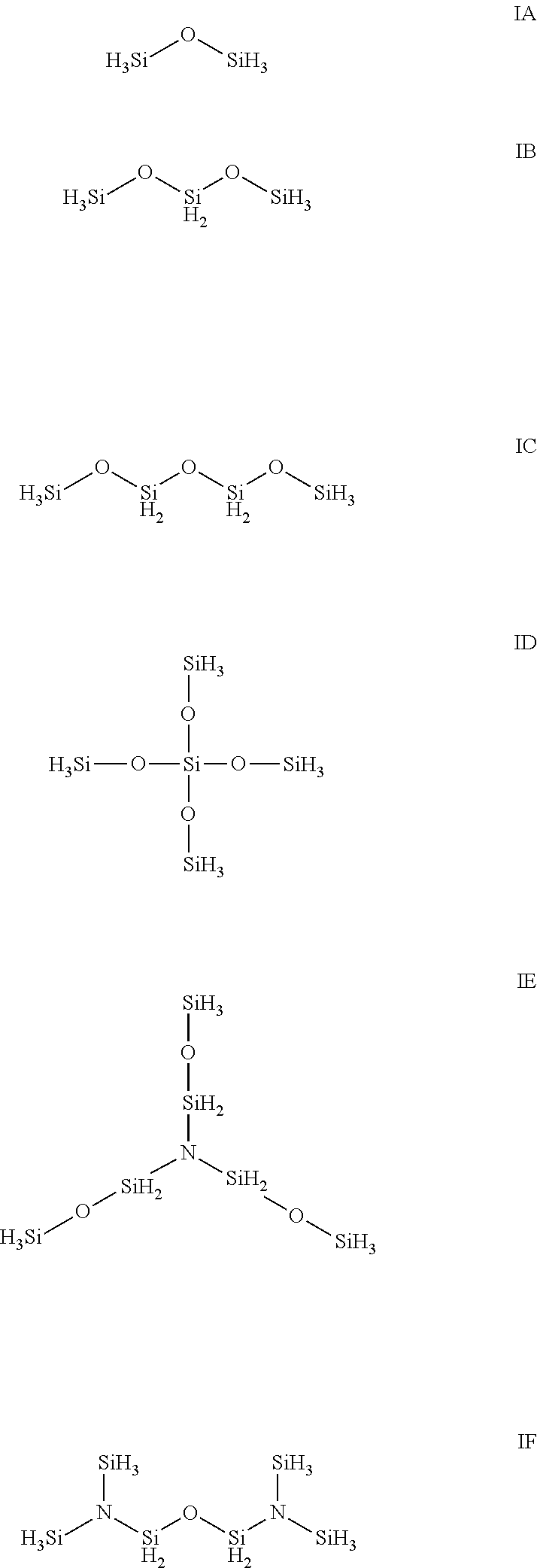

ActiveUS20170335449A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilane compoundsTrisilazane

Described herein are compositions and methods using same for forming a silicon-containing film such as without limitation a silicon oxide, silicon nitride, silicon oxynitride, a carbon-doped silicon nitride, or a carbon-doped silicon oxide film on at least a surface of a substrate having a surface feature. In one aspect, the composition comprises at least one compound is selected from the group consisting of a siloxane, an trisilylamine-based compound, an organoaminodisilane compound, and a cyclic trisilazane compound.

Owner:VERSUM MATERIALS US LLC

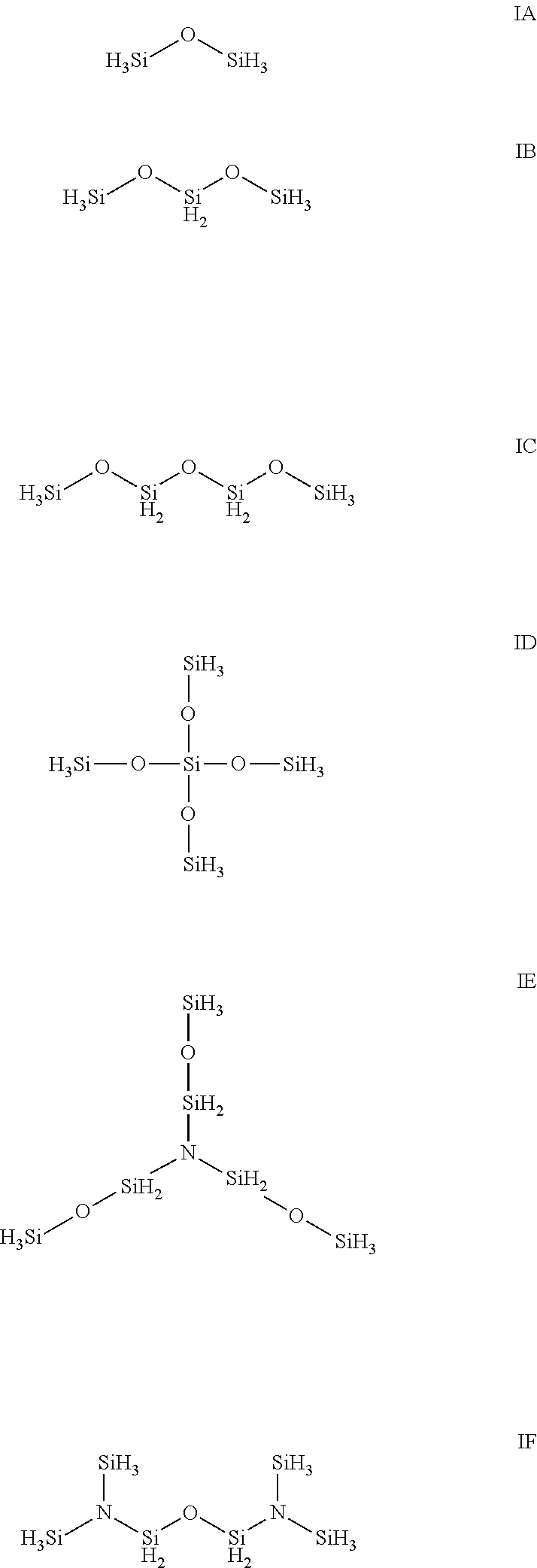

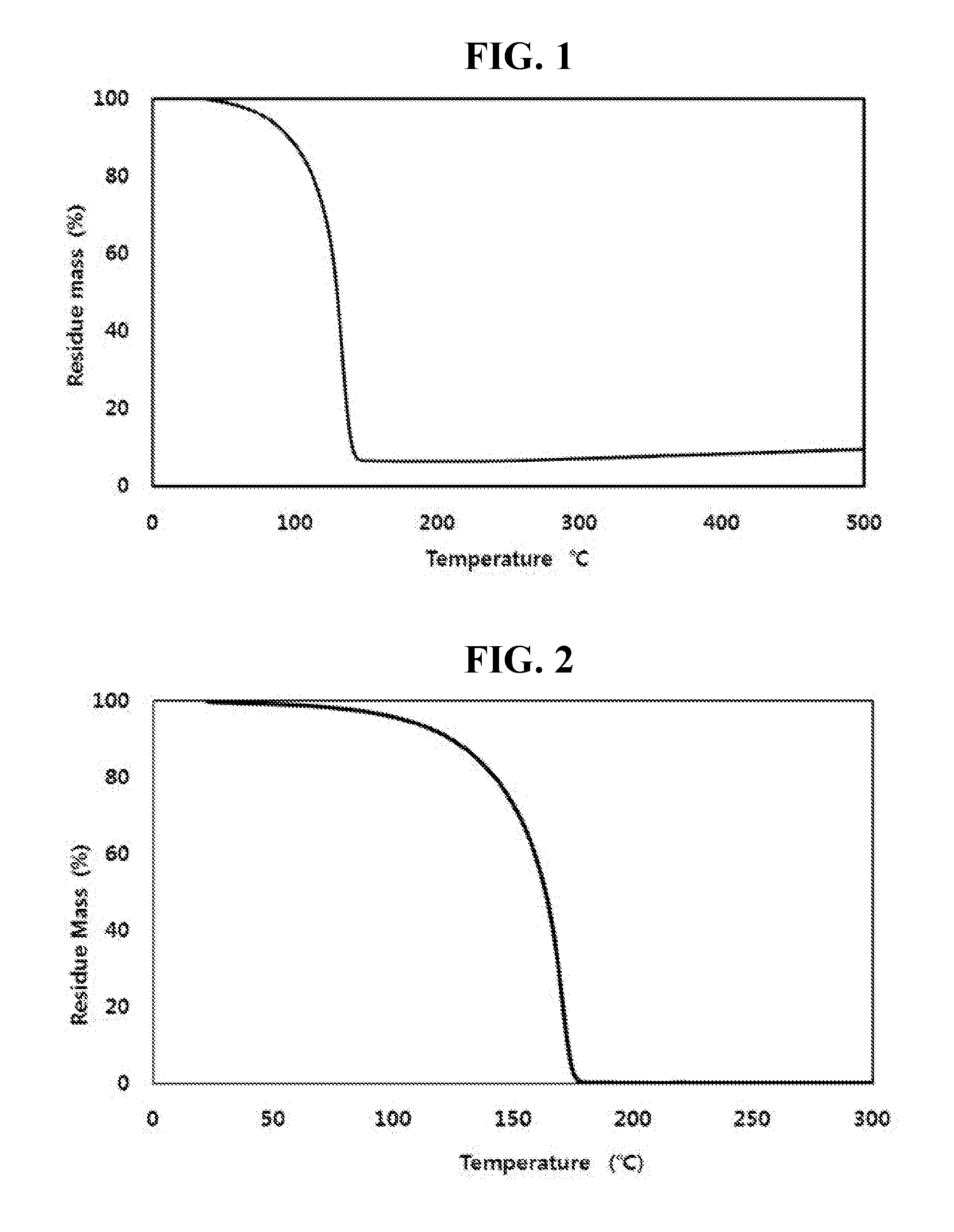

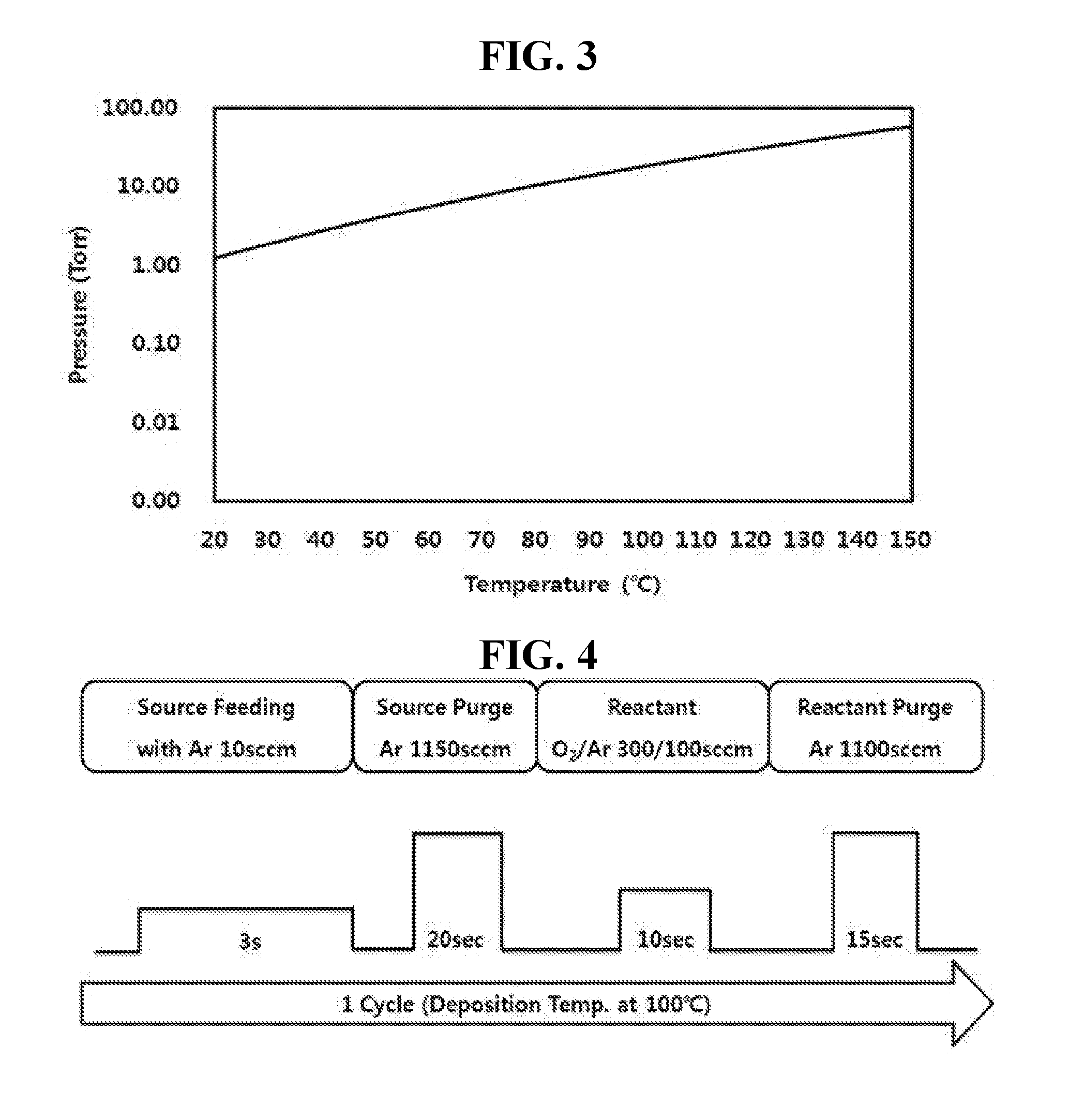

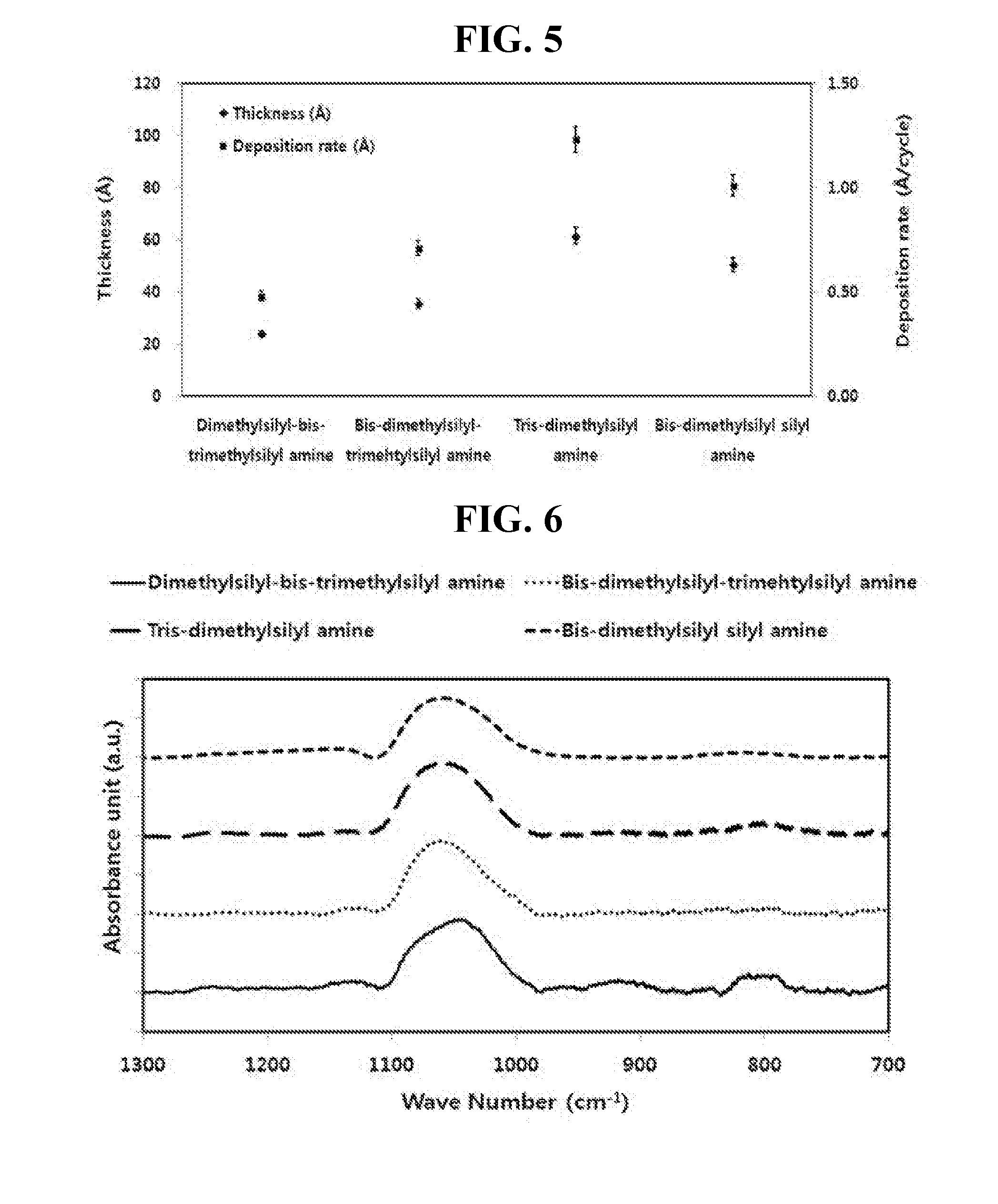

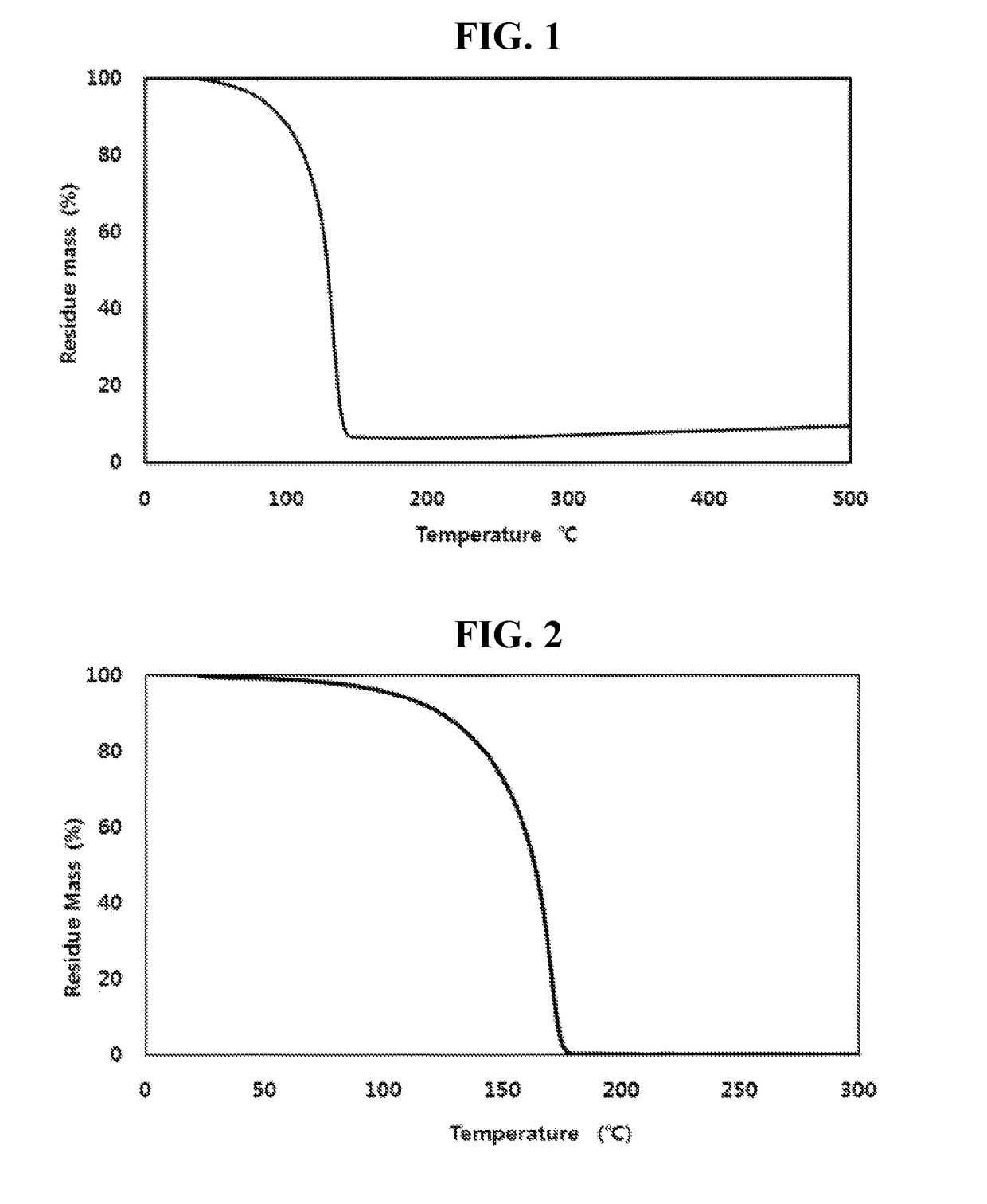

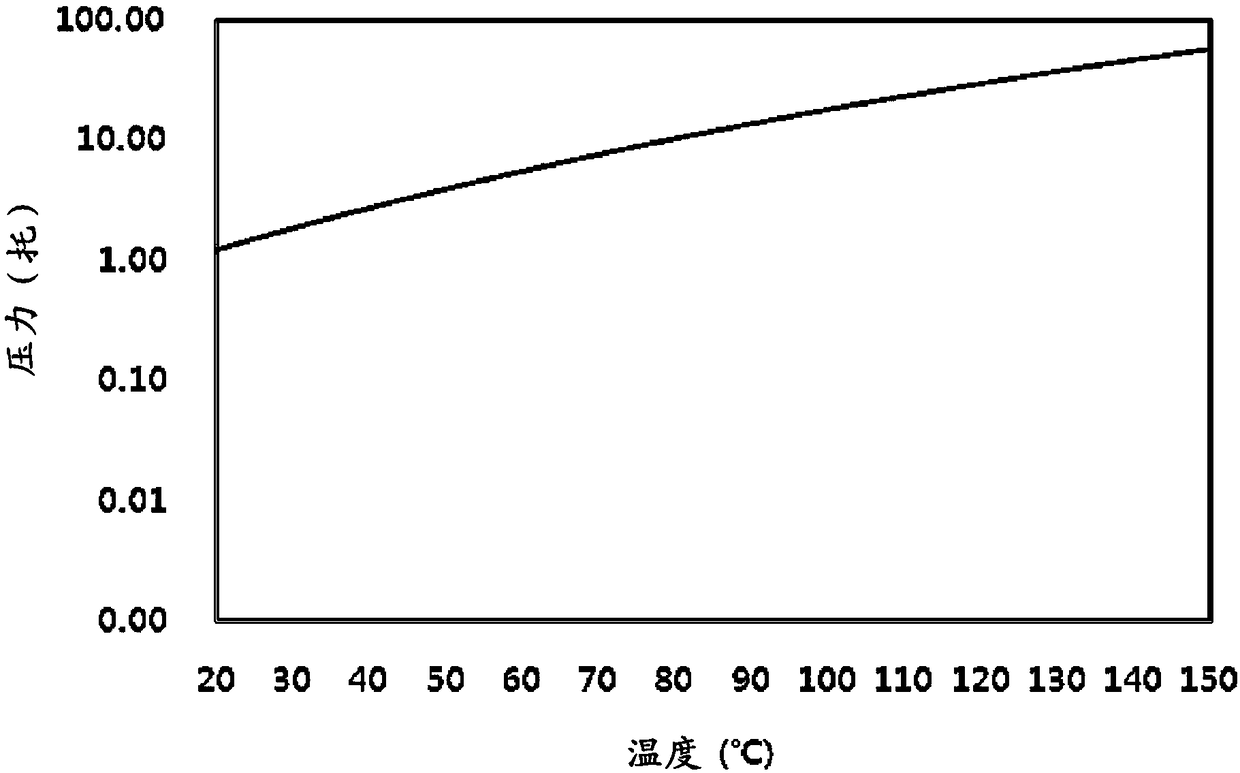

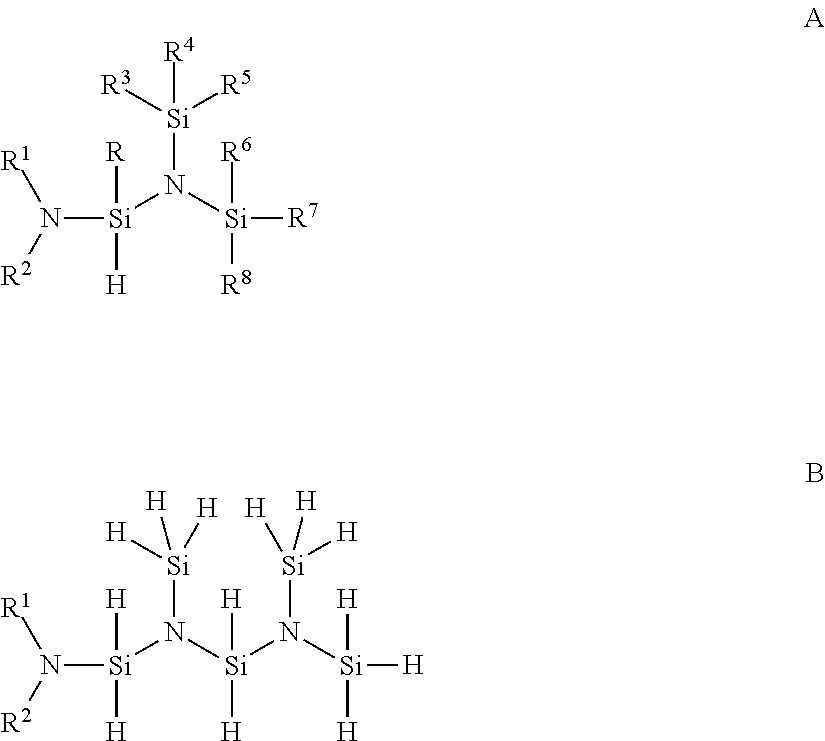

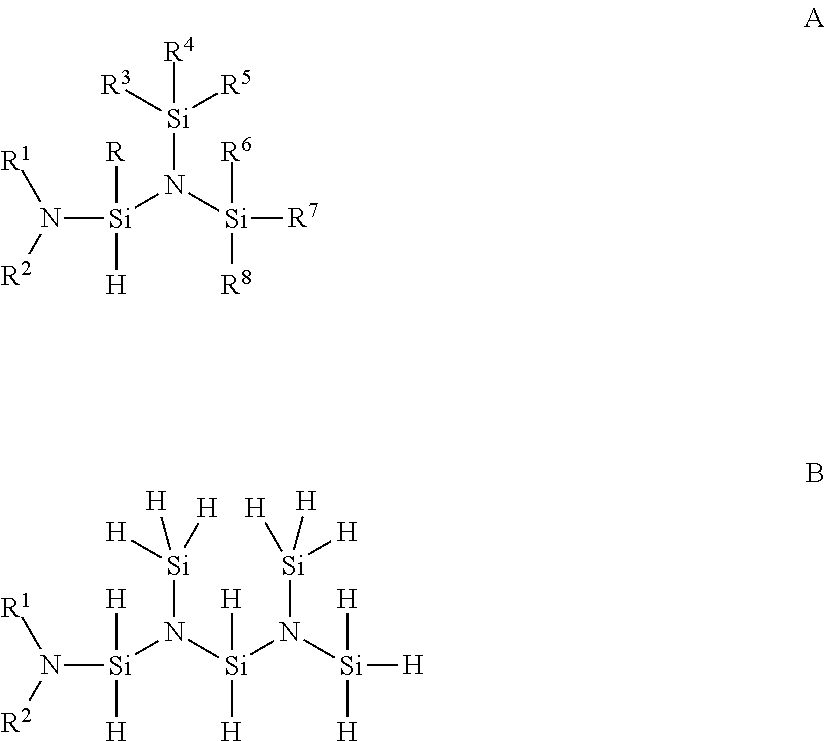

Novel trisilyl amine derivative, method for preparing the same and silicon-containing thin film using the same

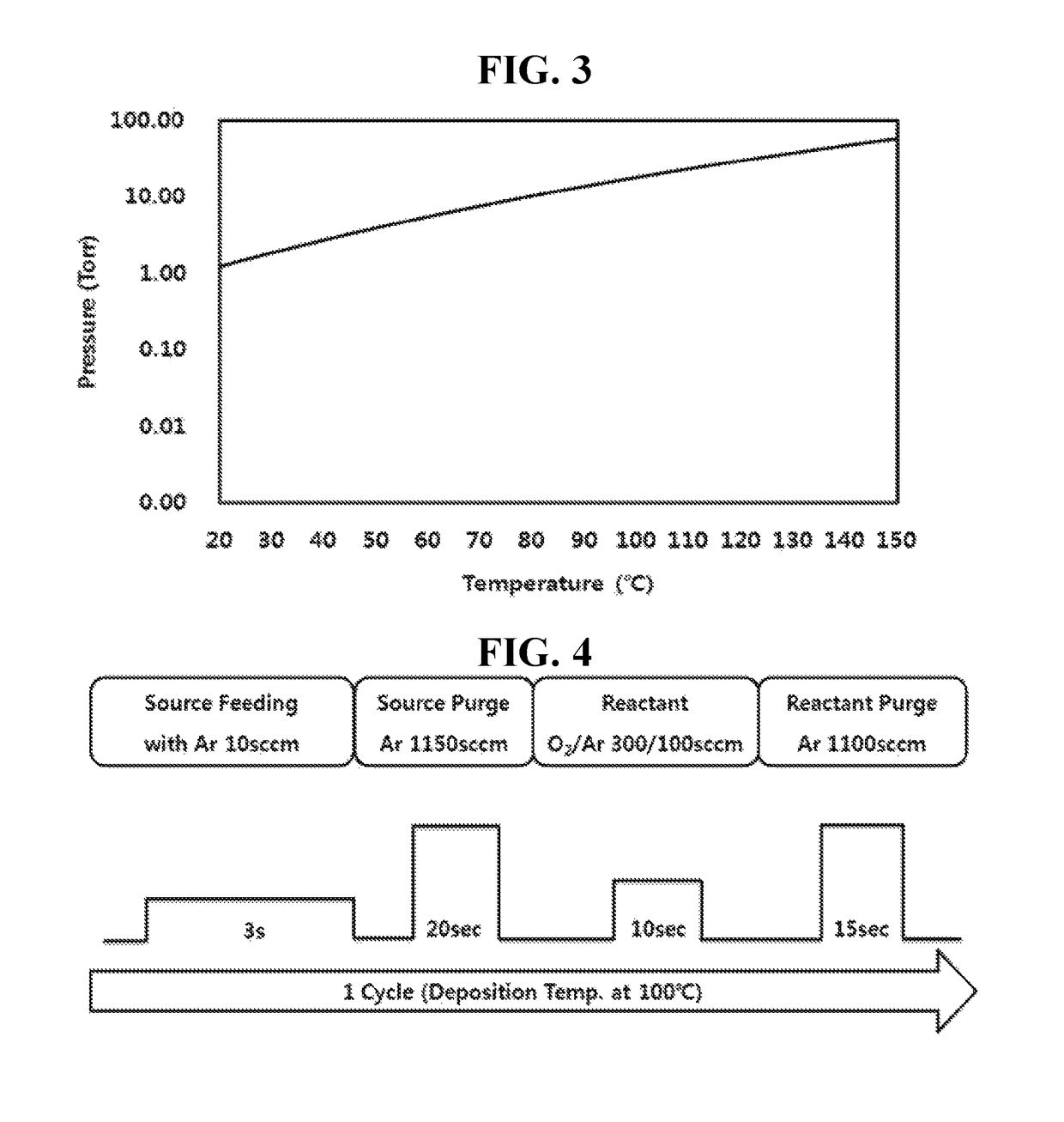

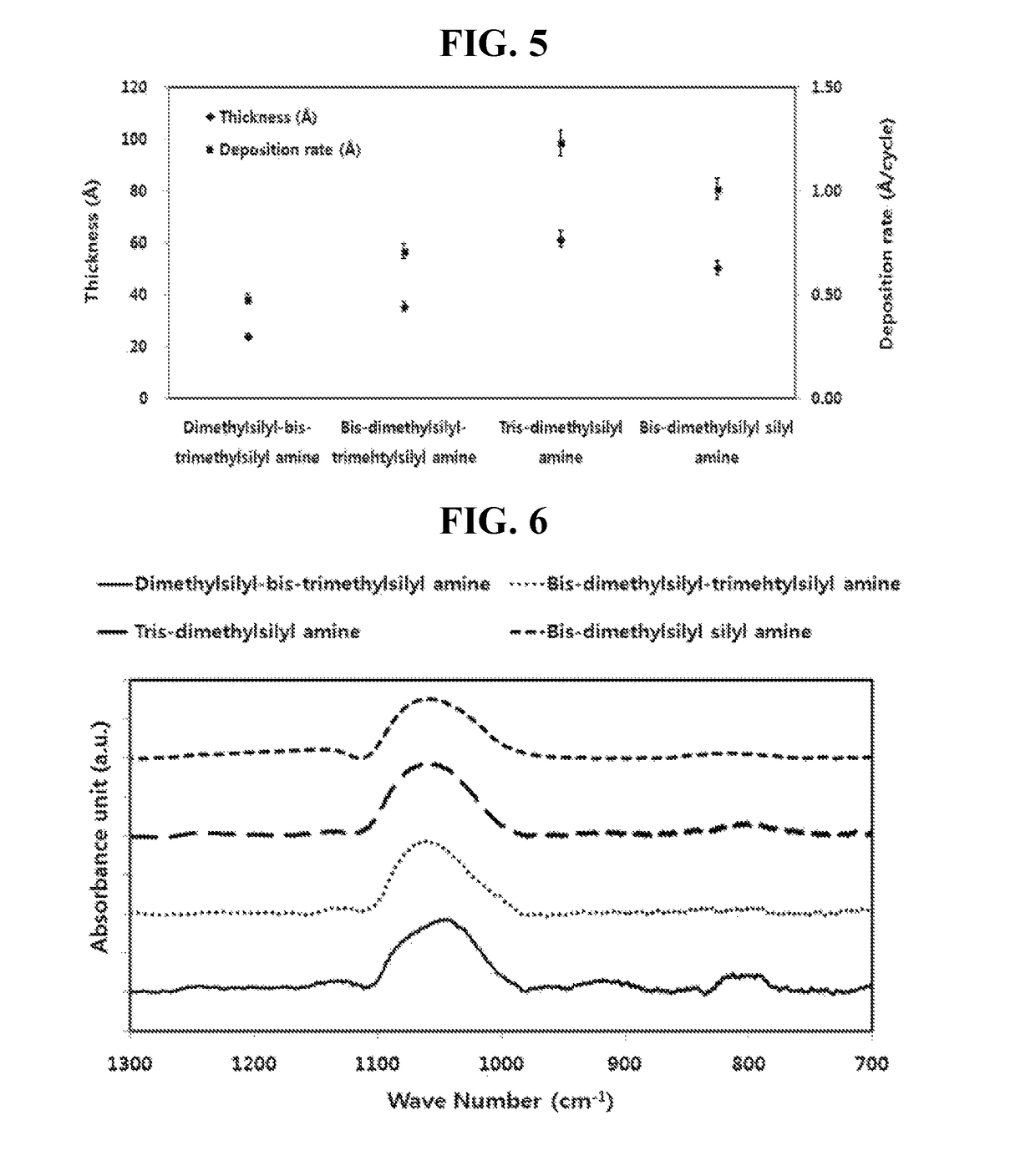

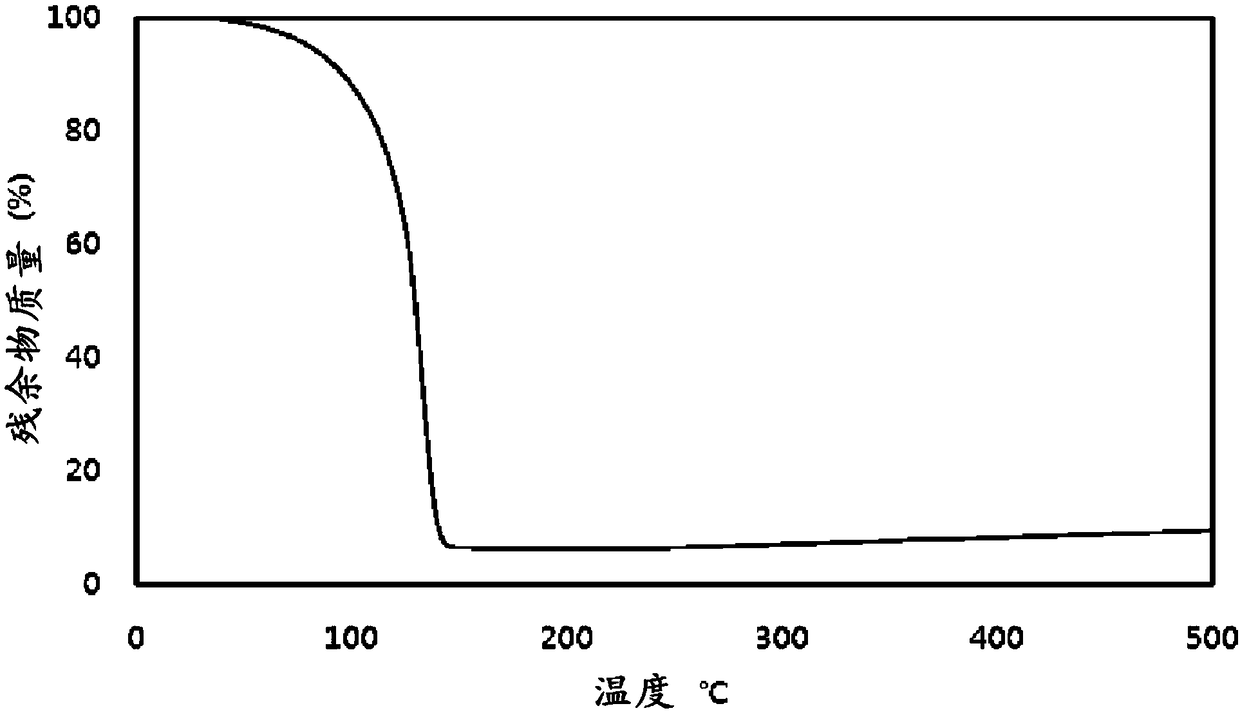

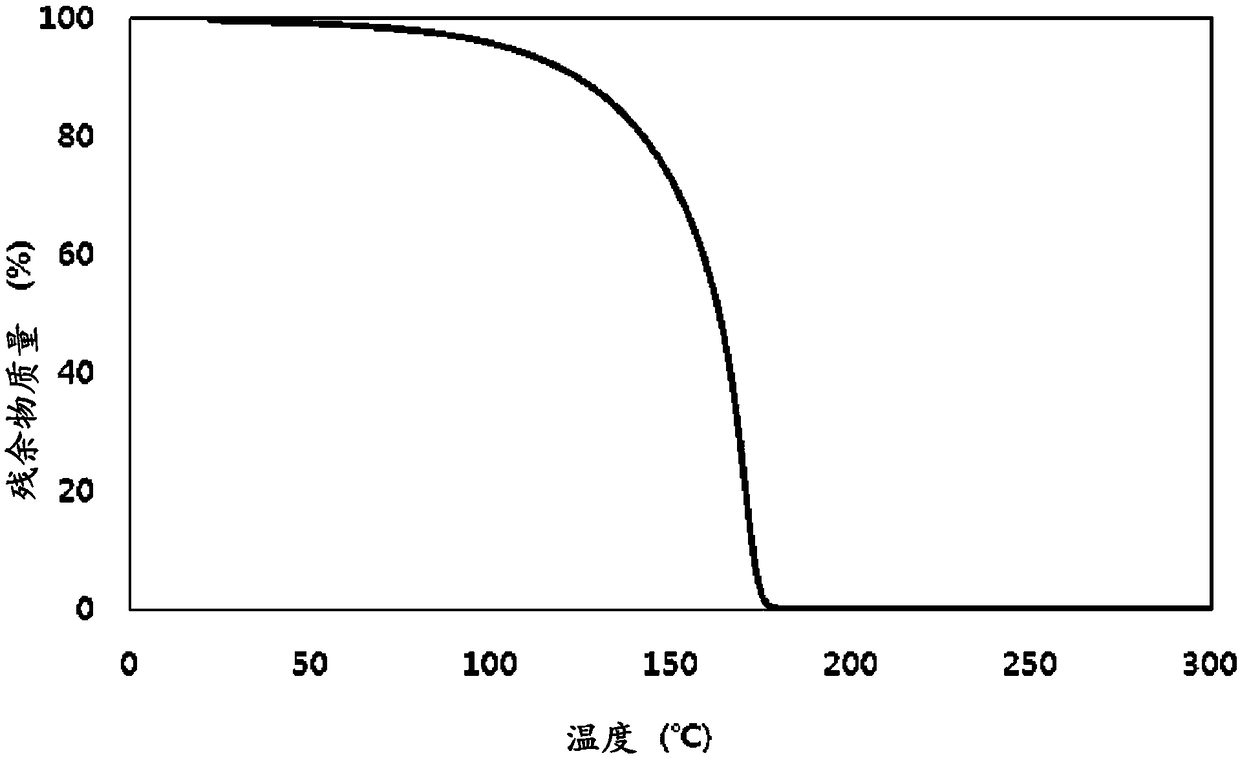

ActiveUS20160333030A1Improve thermal stabilityImprove responseGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingLiquid stateRoom temperature

Provided are a novel trisilyl amine derivative, a method for preparing the same, and a silicon-containing thin film using the same, wherein the trisilyl amine derivative, which is a compound having thermal stability, high volatility, and high reactivity and being present in a liquid state at room temperature and under pressure where handling is possible, may form a high purity silicon-containing thin film having excellent physical and electrical properties by various deposition methods.

Owner:DNF

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS8568682B2Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsSilyleneDistillation

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS20130216463A1Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsDistillationSynthesis methods

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS20140050647A1Increased formationSilicon hydridesNitrogen and non-metal compoundsSilyleneDistillation

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis process that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This process facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Preparation process of trisilylamine

ActiveUS8461367B2Easy to getEasy to separate and purifySilicon organic compoundsChemical/physical/physico-chemical processesLow oxygenAtmosphere

Provided is a preparation process of trisilylamine capable of preparing high-purity trisilylamine more easily at a lower cost. More specifically, provided is a preparation process of trisilylamine, comprising a step of thermally decomposing perhydropolysilazane under an oxygen-free or low oxygen atmosphere.

Owner:SHIN ETSU CHEM CO LTD

Methods for producing silicon nitride films and silicon oxynitride films by thermal chemical vapor deposition

InactiveCN100347834CQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseThermal chemical vapor deposition

Silicon nitride film is formed on substrate by feeding trisilylamine and ammonia into a CVD reaction chamber that contains a substrate. The ammonia gas / trisilylamine gas flow rate ratio is set to a value of at least about 10 and / or the thermal CVD reaction is run at a temperature no greater than about 600° C. Silicon oxynitride is obtained by introducing an oxygen source gas into the CVD reaction chamber. This method avoids the production of ammonium chloride and / or the incorporation of carbonaceous contaminants which are detrimental to the quality of the deposited film.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

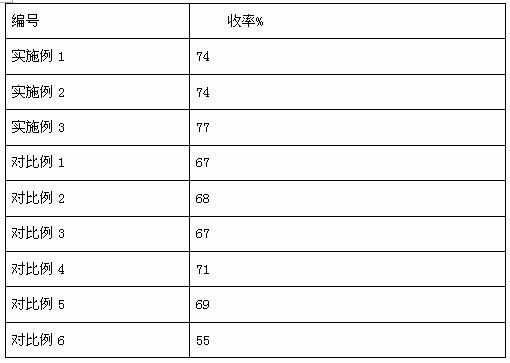

Method for preparing trisilylamine at ultralow temperature

ActiveCN113912029AIncrease responsivenessLow costNitrogen and non-metal compoundsPhysical chemistryOrganic chemistry

The invention relates to the technical field of trisilylamine preparation, in particular to a method for preparing trisilylamine at an ultralow temperature. According to the method for preparing the trisilylamine at the ultralow temperature without participation of the solvent, by-products generated in the reaction can be easily removed through filtration of a metal ion adsorption permeable membrane, the GC purity of the trisilylamine finally obtained through the reaction reaches 99.5%, the yield reaches 85% or above (based on ammonia gas), and the purity of metal ions contained in the product reaches 6N level; and the device is simple and convenient, the raw material reaction degree is high, the cost is lower, the market value is great, and the industrial production benefit is better.

Owner:ZHEJIANG BRITECH CO LTD

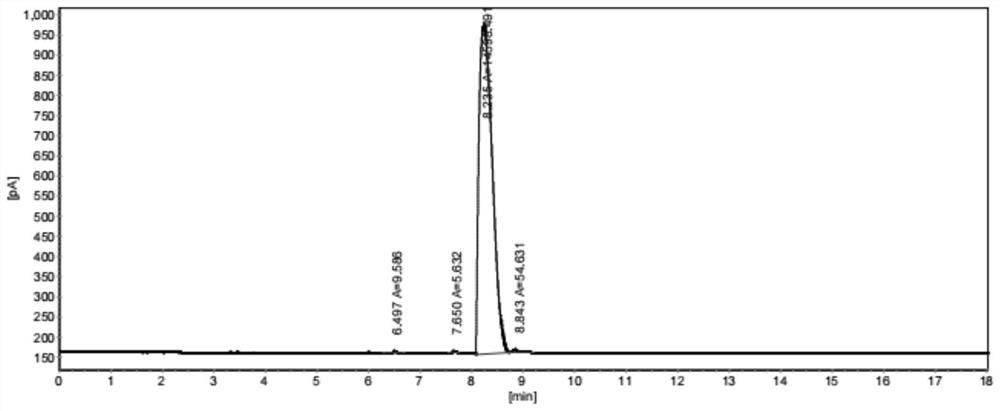

A kind of synthetic method of trisilylamine

ActiveCN108586515BHigh puritySilicon organic compoundsChemical industryPhysical chemistryReaction temperature

The invention provides a synthesis method of trimethylsilylamine, which is characterized in that the preparation method includes the following steps: purging a catalytic distillation tower with inert gas in advance, and simultaneously removing monochlorosilane and ammonia from the rectification tower in gaseous form. Section and stripping section are continuously added to the catalytic distillation tower for reaction. The molar ratio of monochlorosilane and ammonia is 1:1.2-3, the space velocity of monochlorosilane is 0.5-2 / h, and the reaction pressure is 0.2-1MPa. The distillation tower The reaction temperature is 350°C-420°C. The reaction product from the tower reactor is continuously taken out, NH4Cl is separated, and then high-purity trimethylsilylamine is obtained through the impurity removal and refining technology known in the industry.

Owner:ZHEJIANG BRITECH CO LTD

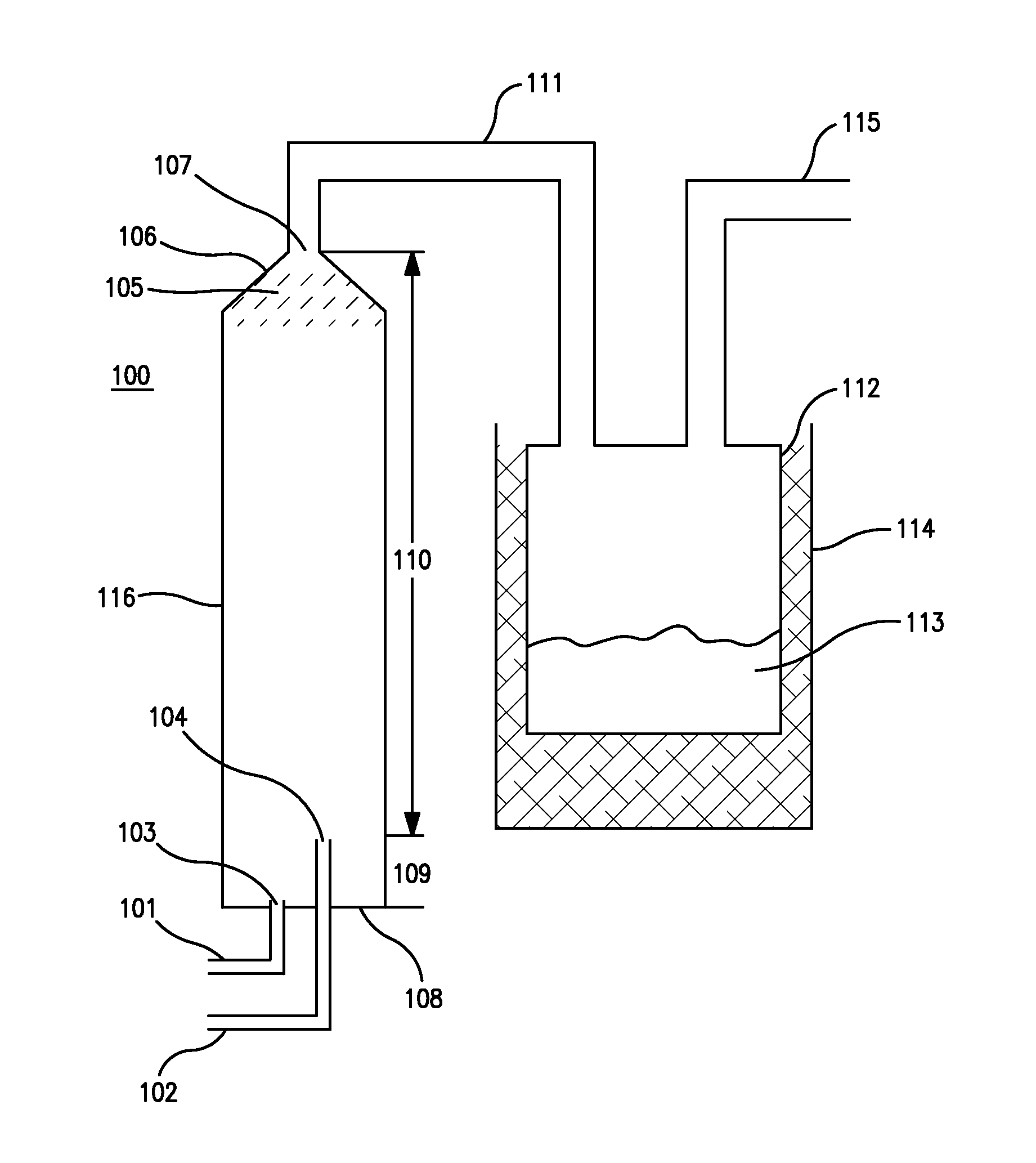

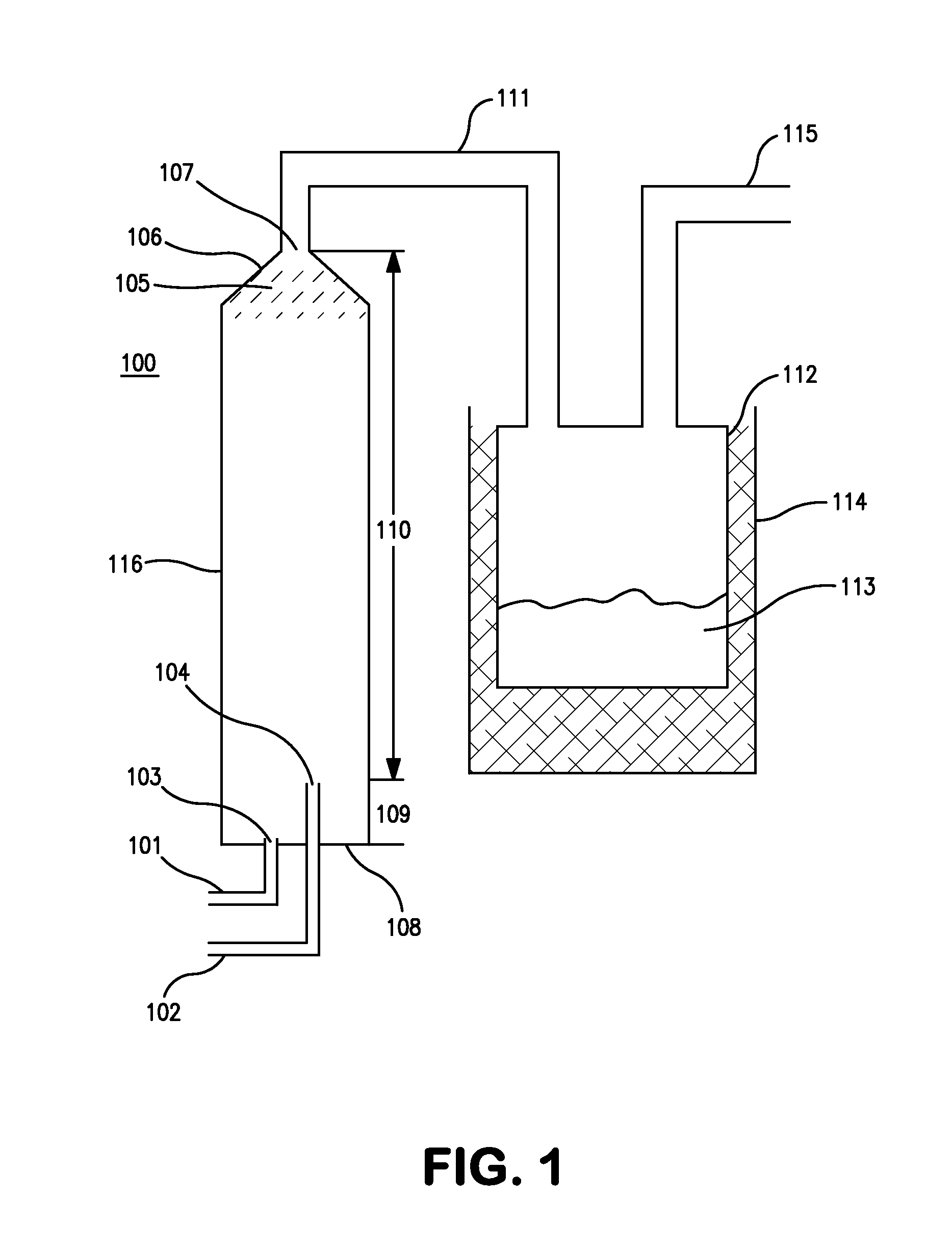

Process for producing pure trisilylamine

InactiveUS20150259206A1Group 4/14 element organic compoundsChemical/physical/physico-chemical stationary reactorsLiquid stateSolvent

A process for producing trisilylamine in the liquid phase by charging monochlorosilane in the liquid state in a solvent at elevated temperature, and reacting the monochlorosilane with NH3 in a stoichiometric excess is provided. Additionally provided is a production unit for carrying out the process.

Owner:EVONIK DEGUSSA GMBH

Compositions and methods using same for deposition of silicon-containing film

ActiveUS10106890B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilane compoundsTrisilazane

Compositions and methods using same for forming a silicon-containing film such as without limitation a silicon oxide, silicon nitride, silicon oxynitride, a carbon-doped silicon nitride, or a carbon-doped silicon oxide film on at least a surface of a substrate having a surface feature. In one aspect, the composition comprises at least one compound is selected from the group consisting of a siloxane, an trisilylamine-based compound, an organoaminodisilane compound, and a cyclic trisilazane compound.

Owner:VERSUM MATERIALS US LLC

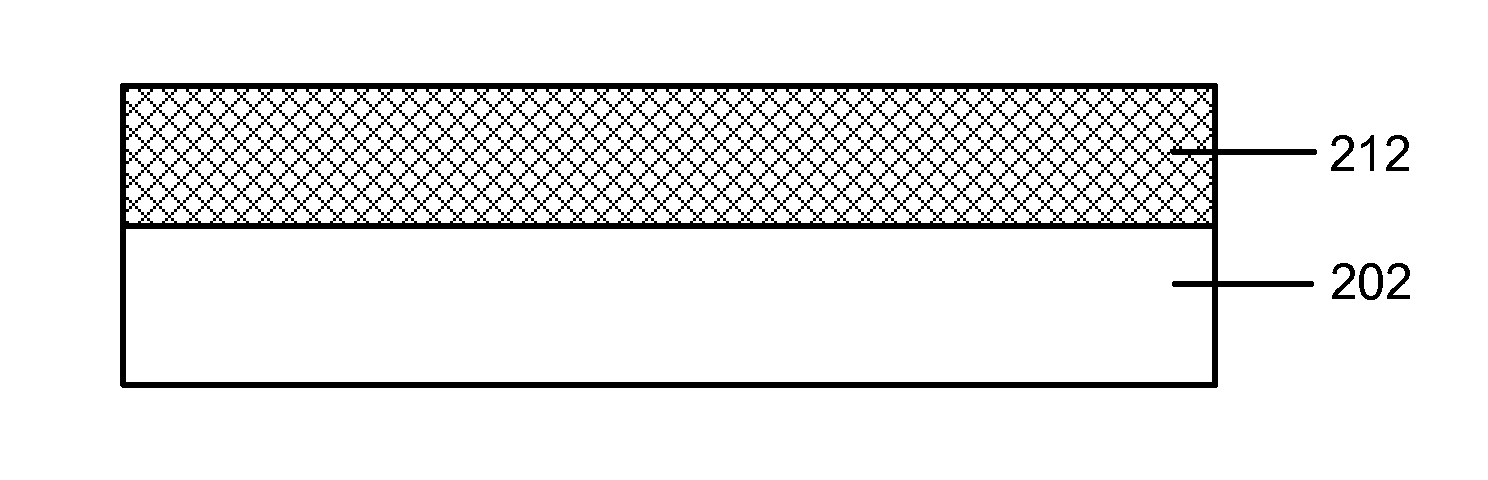

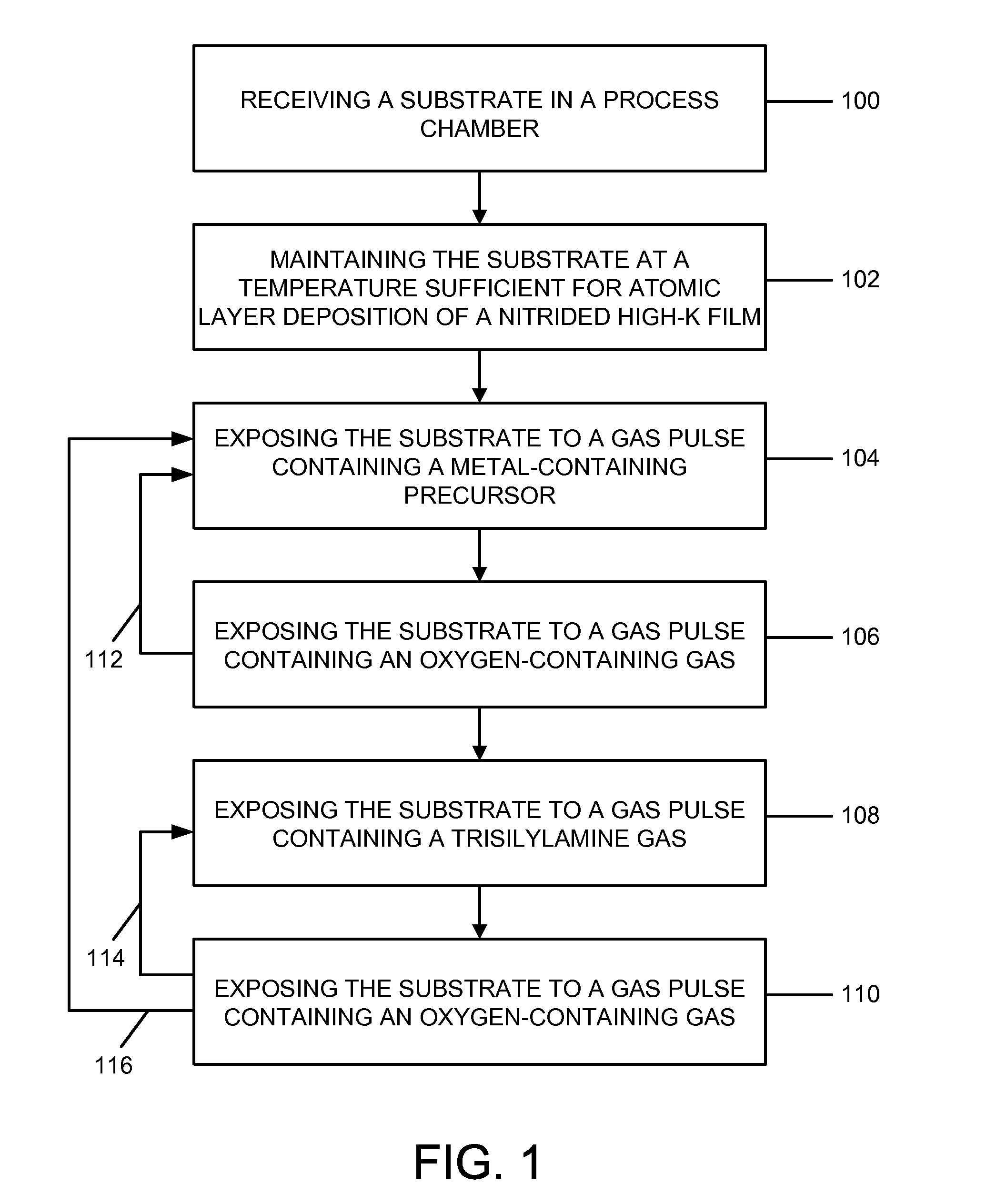

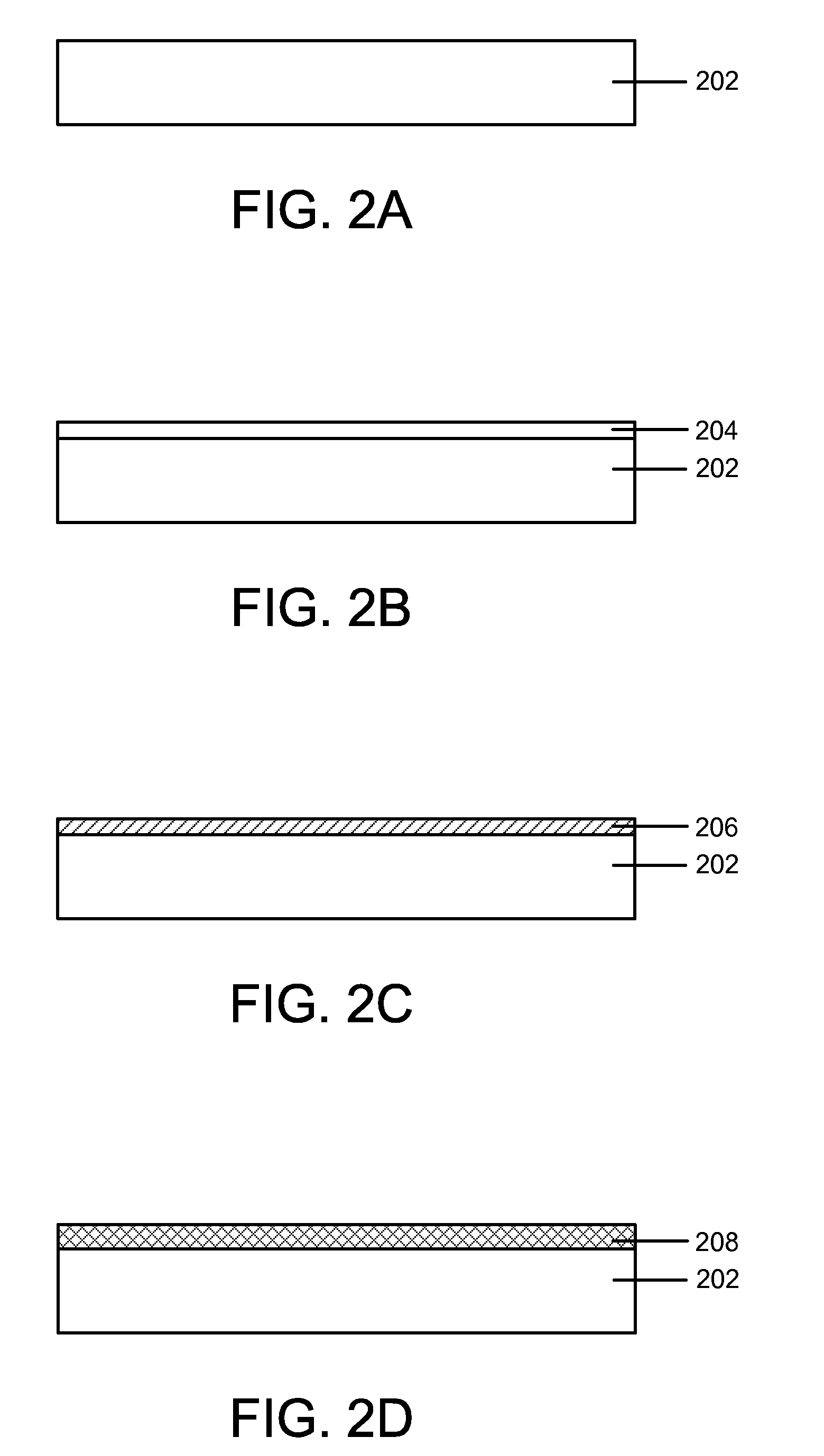

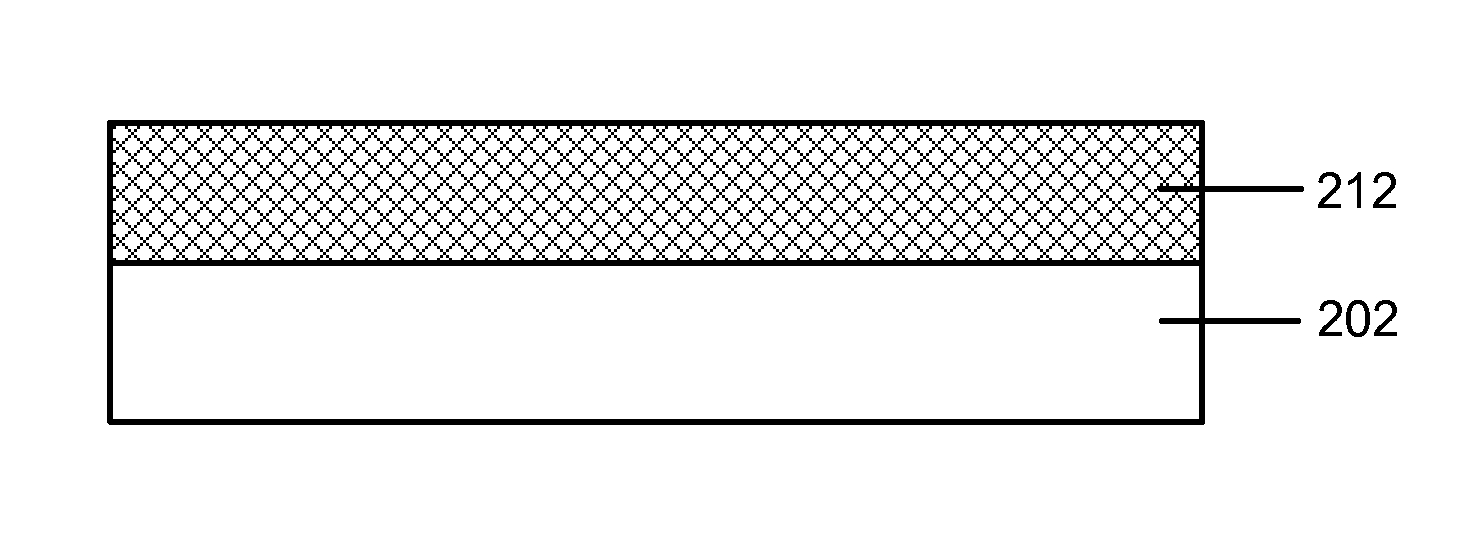

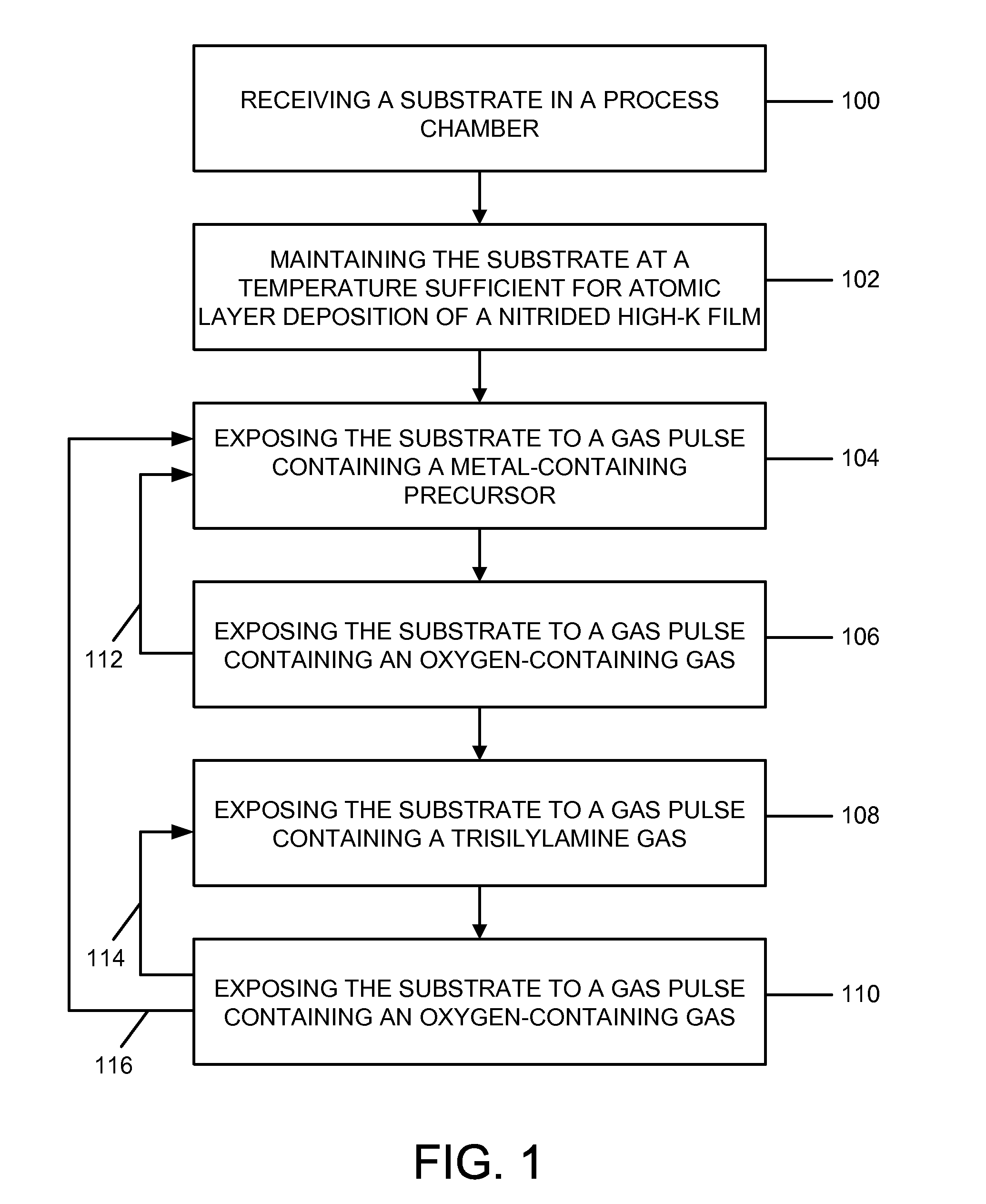

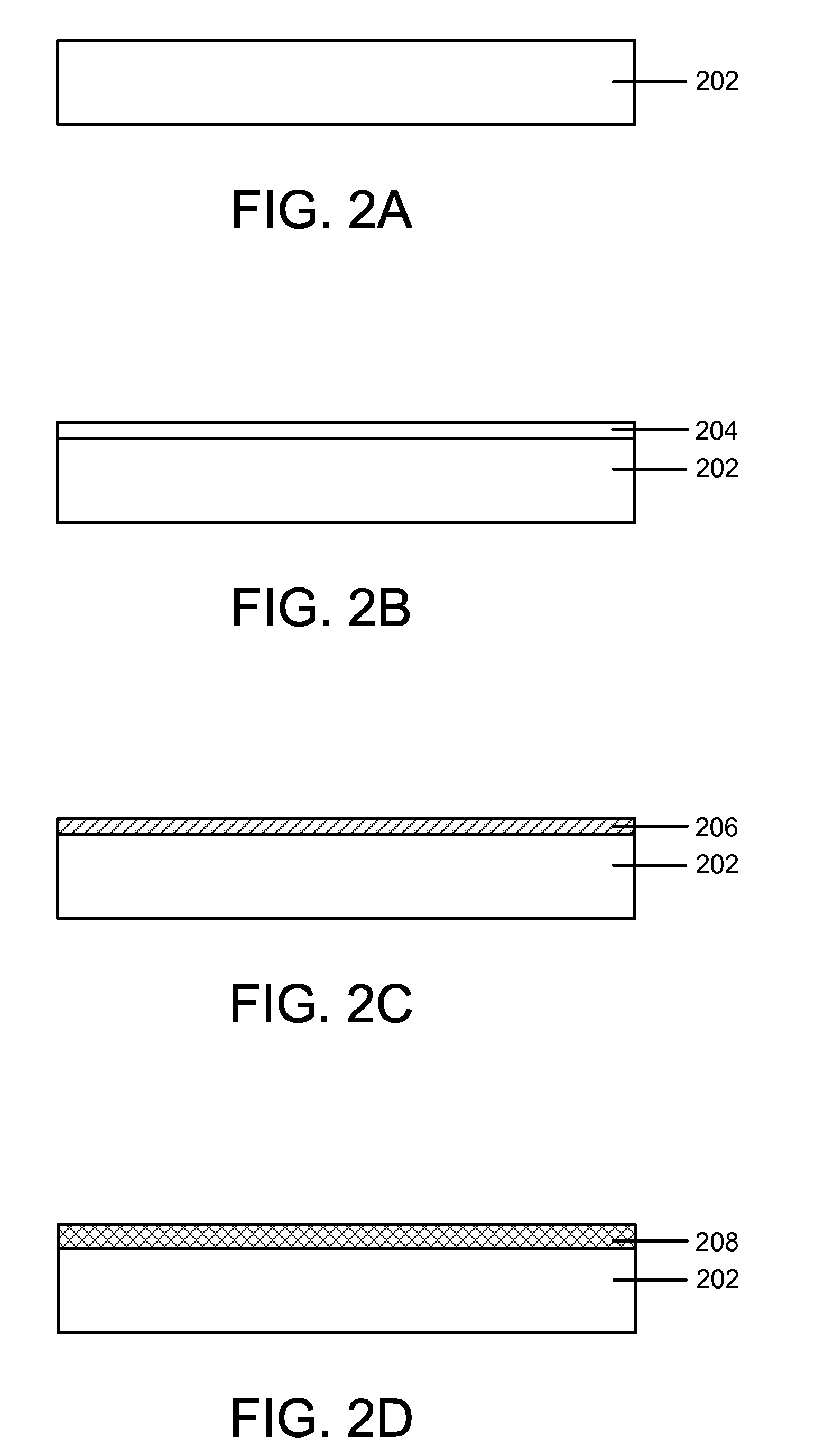

Nitridation of atomic layer deposited high-k dielectrics using trisilylamine

ActiveUS20140017907A1Avoid insufficient temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricSilylene

A method is provided for forming a nitrided high-k film in an atomic layer deposition process (ALD) process. The method includes receiving a substrate in a process chamber, maintaining the substrate at a temperature sufficient for ALD of a nitrided high-k film, and depositing the nitrided high-k film on the substrate by exposing the substrate to a gas pulse sequence that includes, in any order: a) exposing the substrate to a gas pulse comprising a metal-containing precursor, b) exposing the substrate to a gas pulse comprising an oxygen-containing gas, and c) exposing the substrate to a gas pulse comprising trisilylamine gas, where the exposing the substrate to the trisilylamine gas yields the nitrided high-k film that includes nitrogen and that is substantially free of silicon, and repeating the gas pulse sequence. A trisilylamine gas exposure may also be used to nitride a deposited high-k film.

Owner:AIR LIQUIDE AMERICA INC +1

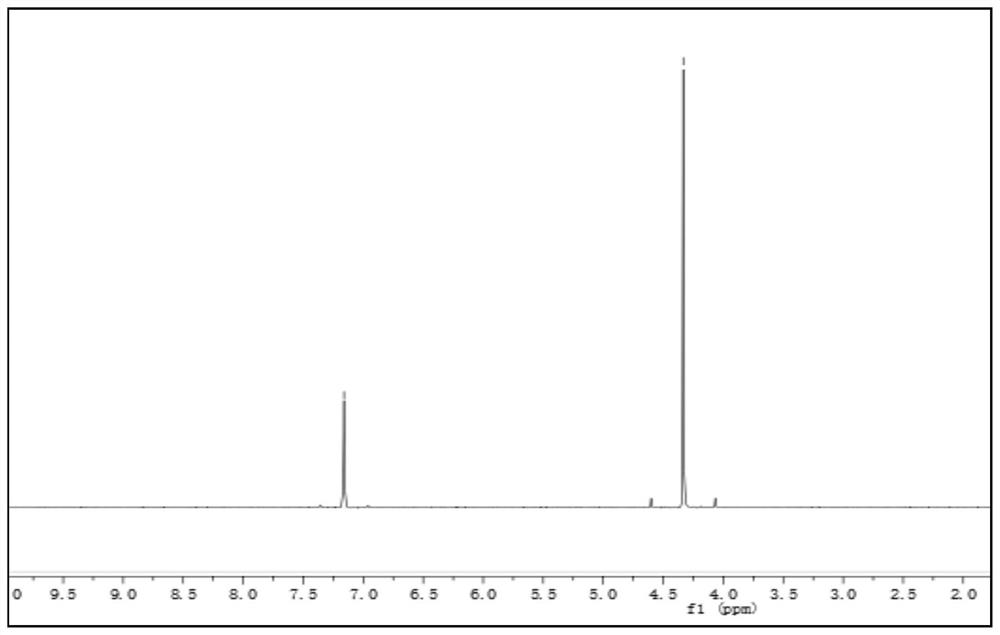

High purity trisilylamine, methods of making, and use

ActiveUS20200262849A1Improved propertyHigh puritySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilanesCombinatorial chemistry

A composition, comprising: trisilylamine and less than 5 ppmw of halogen. A method of making a silylamine comprising combining ammonia and a compound comprising aminosilane functionality, where the compound comprising aminosilane functionality is according to formula (I) R1 N(R2)a(SiH3)2−a (I), where R1 is an organic polymer, a C-1-20 hydrocarbyl group or —SiR331, where R3 is C1-6 hydrocarbyl, R2 is a C-1-20 hydrocarbyl group, H, or -SiR331 , where R3 is as defined above, subscript a is 0 or 1, provided that R1 and R2 may be the same or different except if R1 is phenyl, R2 is not phenyl, under sufficient conditions to cause a reaction to form a silylamine and a byproduct.

Owner:NATA SEMICON MATERIALS CO LTD

Nitridation of atomic layer deposited high-k dielectrics using trisilylamine

ActiveUS9064694B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNitrogen

A method is provided for forming a nitrided high-k film in an atomic layer deposition process (ALD) process. The method includes receiving a substrate in a process chamber, maintaining the substrate at a temperature sufficient for ALD of a nitrided high-k film, and depositing the nitrided high-k film on the substrate by exposing the substrate to a gas pulse sequence that includes, in any order: a) exposing the substrate to a gas pulse comprising a metal-containing precursor, b) exposing the substrate to a gas pulse comprising an oxygen-containing gas, and c) exposing the substrate to a gas pulse comprising trisilylamine gas, where the exposing the substrate to the trisilylamine gas yields the nitrided high-k film that includes nitrogen and that is substantially free of silicon, and repeating the gas pulse sequence. A trisilylamine gas exposure may also be used to nitride a deposited high-k film.

Owner:AIR LIQUIDE AMERICA INC +1

Trisilyl amine derivative, method for preparing the same and silicon-containing thin film using the same

ActiveUS10202407B2Improve thermal stabilityImprove responseGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingLiquid stateRoom temperature

Provided are a novel trisilyl amine derivative, a method for preparing the same, and a silicon-containing thin film using the same, wherein the trisilyl amine derivative, which is a compound having thermal stability, high volatility, and high reactivity and being present in a liquid state at room temperature and under pressure where handling is possible, may form a high purity silicon-containing thin film having excellent physical and electrical properties by various deposition methods.

Owner:DNF

Novel trisilyl amine derivative, method for preparing the same and silicon-containing thin film using the same

ActiveCN108794521AImprove thermal stabilityImprove responseGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingLiquid stateRoom temperature

Owner:DNF

Trisilylamine derivatives as precursors for high growth rate silicon-containing films

ActiveUS11078569B2Silicon organic compoundsChemical vapor deposition coatingPhysical chemistryPerylene derivatives

Owner:VERSUM MATERIALS US LLC

Production of trisilylamine from monochlorosilane and ammonia by use of inert solvent

ActiveUS9359205B2Efficient conversionSilicon organic compoundsChemical/physical/physico-chemical stationary reactorsSolventNH3 compound

The present invention relates to a specific process for producing trisilylamine from monochlorosilane and ammonia in the liquid phase. The invention further relates to a plant wherein such a process can be carried out with advantage.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com