Method for preparing trisilylamine at ultralow temperature

A technology of trisilylamine and ultra-low temperature, applied in the direction of nitrogen and non-metallic compounds, can solve the problems of difficult to complete the reaction, consume a lot of energy, and low yield, and achieve large market value, low cost, and high degree of raw material reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

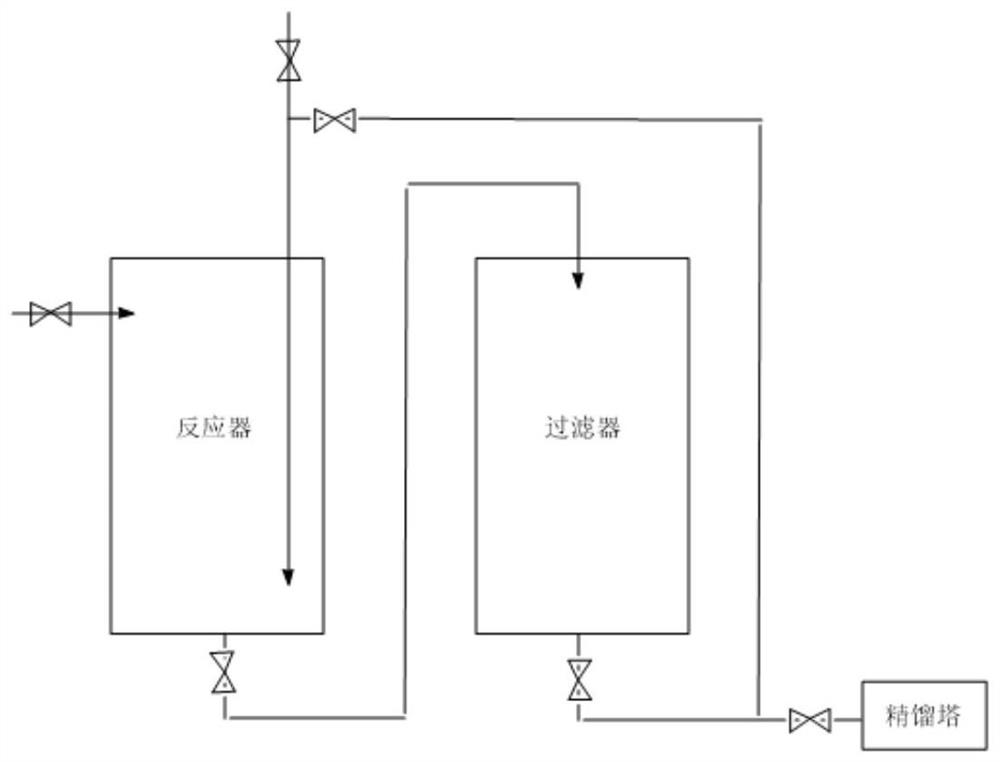

Method used

Image

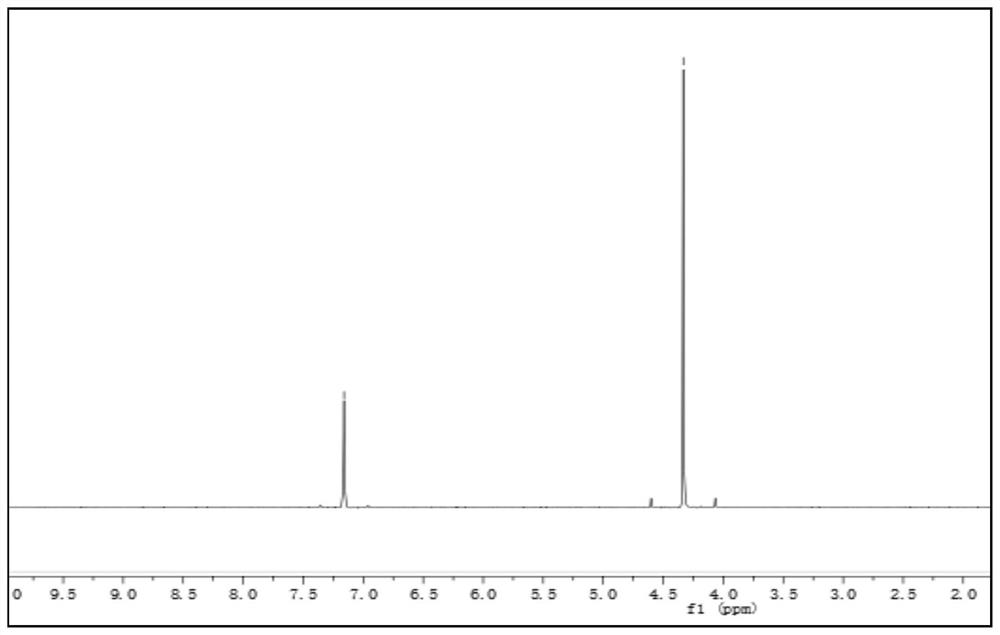

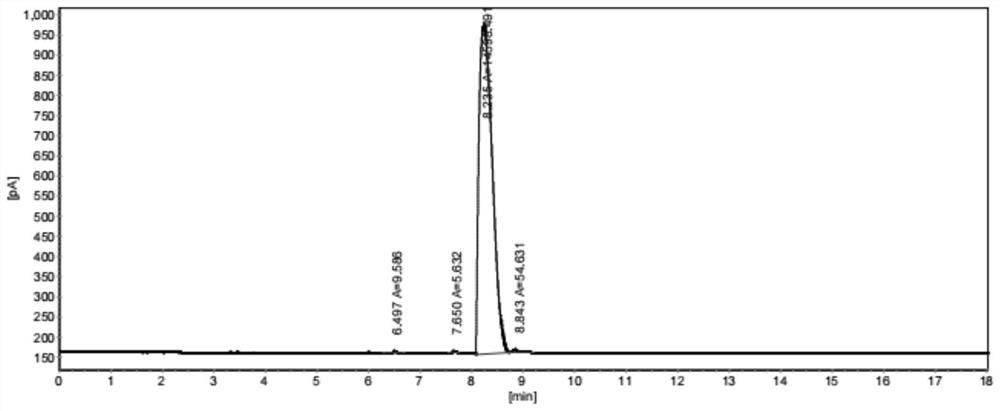

Examples

Embodiment 1

[0039] Slowly inject MCS gas into an ultra-low temperature reaction vessel equipped with a mechanical stirrer, then add dropwise liquefied ammonia, liquefied MCS and NH 3 The reaction is carried out at a molar ratio close to 1:1.2, the reaction generates a large amount of ammonium chloride solids, the solids are removed by filtration, the mother liquor is reintroduced into the ultra-low temperature reaction vessel, ammonia gas is added again, filtered again, and the mother liquor is introduced into the reaction vessel again, This cycle is repeated 5 times. When the online GC detects that there is only a small amount of MCS, the metal ion permeation membrane filtration is carried out, and the filtrate is directly introduced into the rectification device for purification.

[0040] The low temperature in the ultra-low temperature reaction is -65°C;

[0041] The amine source is added in the form of gaseous bubbling after mixing and diluting nitrogen (10%) with anhydrous ammonia; ...

Embodiment 2

[0053]The MCS gas is slowly introduced into the ultra-low temperature reaction vessel equipped with a mechanical stirrer, and then the liquefied ammonia gas is added dropwise. The liquefied MCS and NH3 react at a molar ratio close to 1:1.3, and the reaction generates a large amount of ammonium chloride solid. Filter to remove solids, re-introduce the mother liquor into the ultra-low temperature reaction vessel, add ammonia gas again, filter again, and guide the mother liquor into the reaction vessel again, and cycle like this for 5 times. When the online GC detects that there is only a small amount of MCS left, the metal ion is adsorbed. Osmotic membrane filtration, the filtrate is directly introduced into the rectification device for purification.

[0054] The low temperature in the ultra-low temperature reaction is -65°C;

[0055] The amine source is added in the form of gaseous bubbling after mixing and diluting nitrogen (50%) with anhydrous ammonia;

[0056] The membrane ...

Embodiment 3

[0067] The MCS gas is slowly introduced into the ultra-low temperature reaction vessel equipped with a mechanical stirrer, and then the liquefied ammonia gas is added dropwise. The liquefied MCS and NH3 react at a molar ratio close to 1:1.4, and the reaction generates a large amount of ammonium chloride solid. Filter to remove solids, re-introduce the mother liquor into the ultra-low temperature reaction vessel, add ammonia gas again, filter again, and guide the mother liquor into the reaction vessel again, and cycle like this for 5 times. When the online GC detects that there is only a small amount of MCS left, the metal ion is adsorbed. Osmotic membrane filtration, the filtrate is directly introduced into the rectification device for purification.

[0068] The low temperature in the ultra-low temperature reaction is -75°C;

[0069] The added amine source can be mixed and diluted with nitrogen (90%) and anhydrous ammonia in gaseous bubbling form;

[0070] The membrane filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com