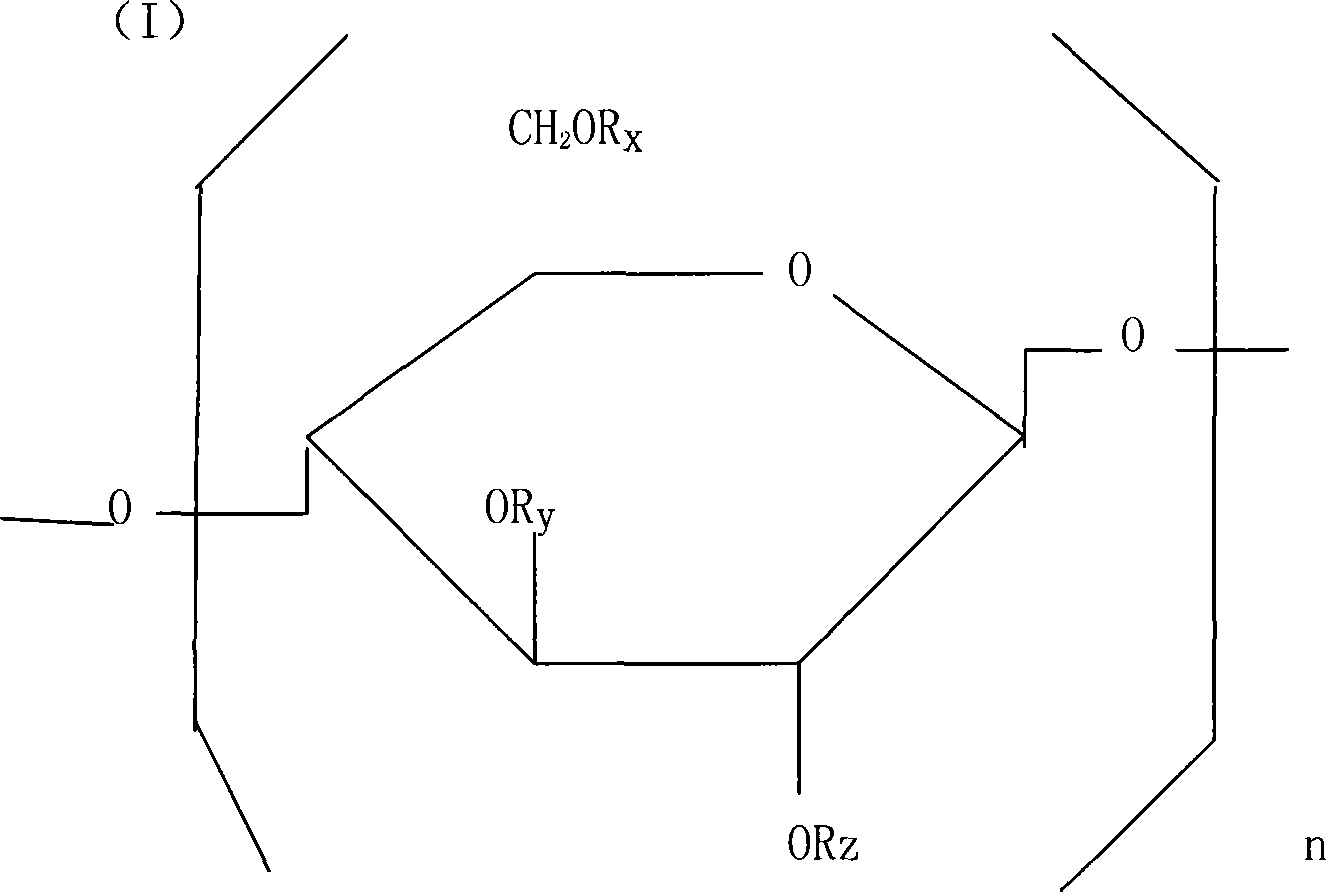

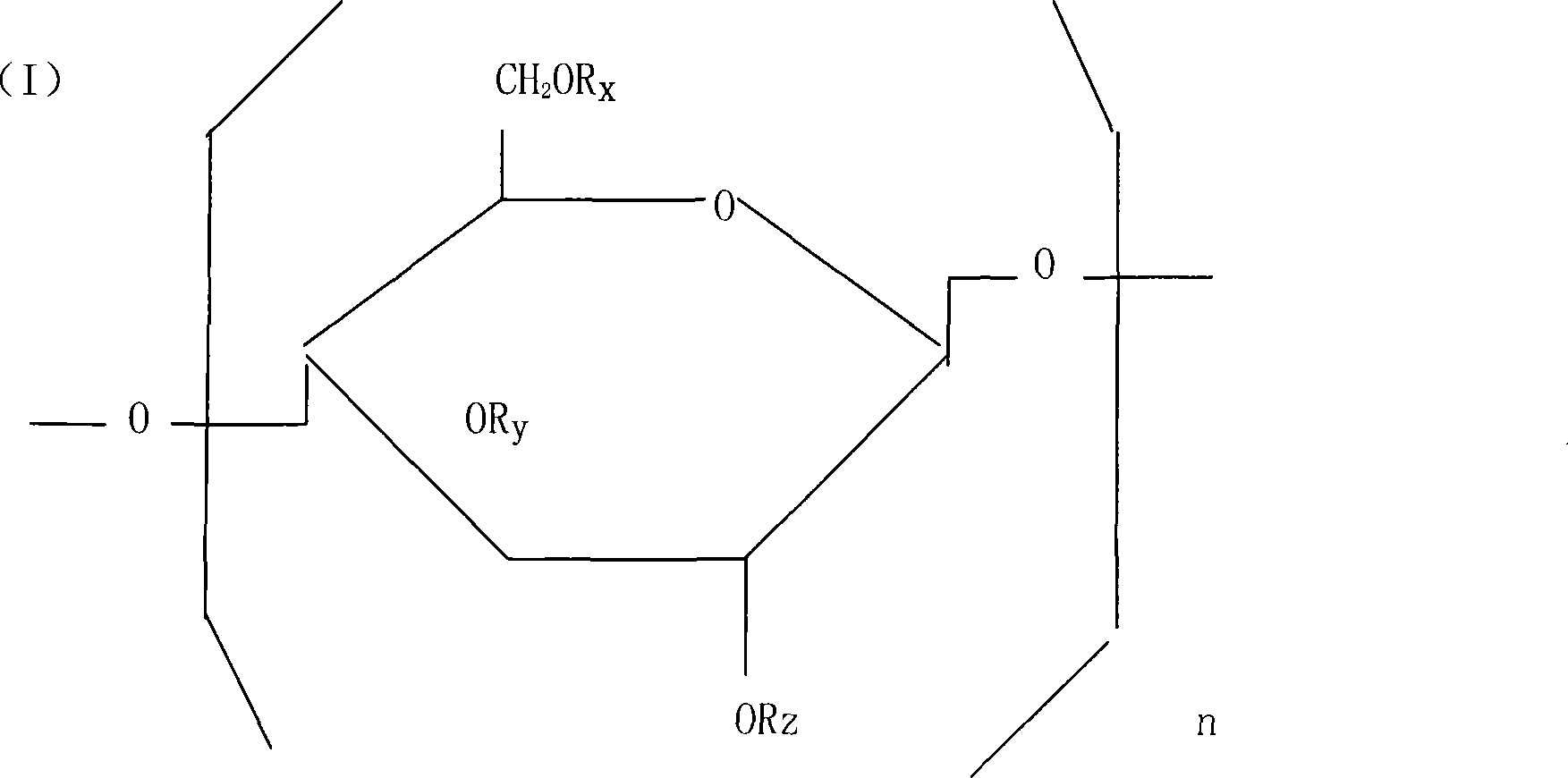

Ultra-high substitution carboxymethyl cellulose sodium and its preparation method and application

A technology of sodium carboxymethyl and cellulose, applied in the application, food preparation, chemical instruments and methods, etc., can solve the problems of incomplete alkalization etherification, unsatisfactory product performance indicators, low production efficiency, etc., and achieve excellent results. , Superior suspension stability, the effect of improving acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

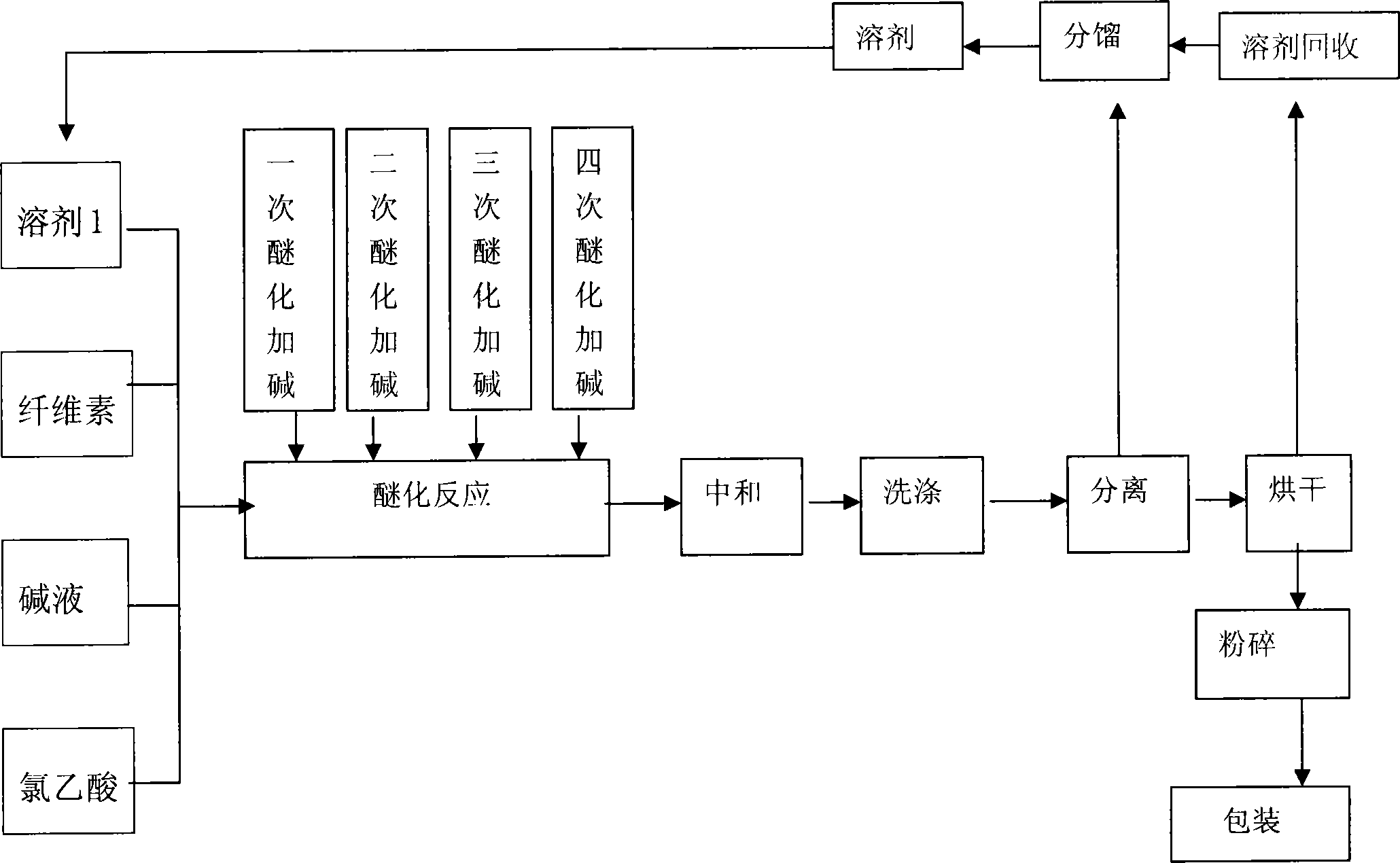

Method used

Image

Examples

Embodiment 1

[0030] Carry out following steps successively and carry out the preparation of extra-highly substituted cellulose carboxymethyl sodium:

[0031] (1) inject 4.8 tons of composite solvent (composed of 71%-87% isopropanol, 10%-20% ethanol, 3%-9% water) into the reactor;

[0032] (2) The reaction kettle was heated to 20°C, vacuumed, the manhole cover was opened, 400kg of caustic soda was put in, the temperature was raised to 70°C, and the temperature was continuously stirred for 20 minutes;

[0033] (3) Then lower the temperature to 22°C, vacuumize, open the manhole cover, put in 540kg of refined cotton, keep the constant temperature at 22°C, and continuously stir for 90 minutes;

[0034](4) Throwing 430 kg of chloroacetic acid with a concentration of 96.5% into the reactor, constant temperature at 28° C., stirring continuously for 40 minutes, then raising the temperature to 55° C., performing etherification for the first time at a constant temperature, and etherification at a con...

Embodiment 2

[0040] Carry out following steps successively and carry out the preparation of extra-highly substituted cellulose carboxymethyl sodium:

[0041] (1) 7.8 tons of composite solvents are injected into the reactor;

[0042] (2) The reaction kettle was heated to 20°C, vacuumed, the manhole cover was opened, 430kg of caustic soda was put in, the temperature was raised to 70°C, and the constant temperature was continuously stirred for 20 minutes;

[0043] (3) Then lower the temperature to 22°C, vacuumize, open the hole cover, put in 580kg of refined cotton, keep the temperature at 28°C, and stir continuously for 90 minutes;

[0044] (4) 440kg of chloroacetic acid with a concentration of 96.5% was dropped into the reactor, kept at a constant temperature of 30° C., and continuously stirred for 40 minutes;

[0045] (5) Then, the temperature was raised to 60° C., and the first etherification was carried out at a constant temperature for 40 minutes.

[0046] (6) After 40 minutes, 42kg o...

Embodiment 3

[0051] Carry out following steps successively and carry out the preparation of extra-highly substituted cellulose carboxymethyl sodium:

[0052] (1) Inject 6.9 tons of composite solvent in the reactor;

[0053] (2) Heat up the reaction kettle to 20°C, vacuumize, open the manhole cover, put in 420kg of caustic soda, heat up to 70°C, and keep stirring at constant temperature for 20min;

[0054] (3) Then lower the temperature to 22-18°C, vacuumize, open the hole cover, put in 560kg of refined cotton, keep the temperature at 26°C, and stir continuously for 90 minutes;

[0055] (4) 430kg of chloroacetic acid of 96.5% is dropped into the reaction kettle, constant temperature 29 ℃, continuous stirring 40min;

[0056] (5) Then the temperature was raised to 58° C., and the first etherification was carried out at a constant temperature for 40 minutes;

[0057] (6) After 40 minutes, 38kg of lye is sprayed into the reaction kettle by the pressurized pump through the annular porous spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com