Fluidized bed reactor, fluidized bed reaction apparatus, and methane water-vapour reforming method

A fluidized bed reactor, methane steam technology, applied in chemical instruments and methods, inorganic chemistry, chemical/physical processes, etc., can solve the problem of rapid decline of catalyst activity, reduce energy consumption and hydrogen consumption, improve reaction degree, avoid the effect of unnecessary decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

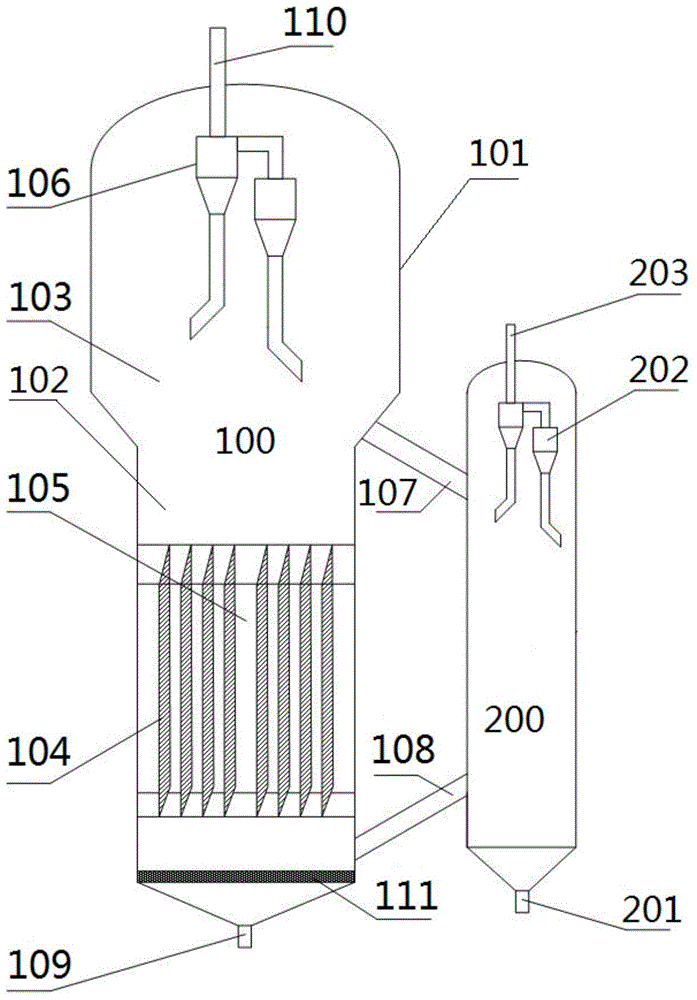

[0084] This embodiment adopts figure 1 Shown fluidized bed reactor, wherein:

[0085] (1) The reaction zone of the fluidized bed reactor is a cylinder with an inner diameter of 160mm and a height of 1200mm, the angle between the outer contour line of the expanding diameter zone and the horizontal plane is 60°, and the settling zone is a cylinder with an inner diameter of 240mm and a height of 400mm cylinder;

[0086] (2) In the reaction zone, 20 metal foam plates (produced by Beijing Zhongshi Qiangye Foam Metal Co., Ltd.) are arranged at equal intervals along the longitudinal direction. The metal foam plates are formed of nickel and tungsten, and the weight ratio of nickel to tungsten is 1 : 0.1, the thickness of the foam metal plate is 2mm, the average pore diameter of the pores on the foam metal plate is 1mm, the porosity of the foam metal plate is 95% by volume), the minimum distance between the upper end surface of the foam metal plate and the top of the reaction zone is ...

Embodiment 2

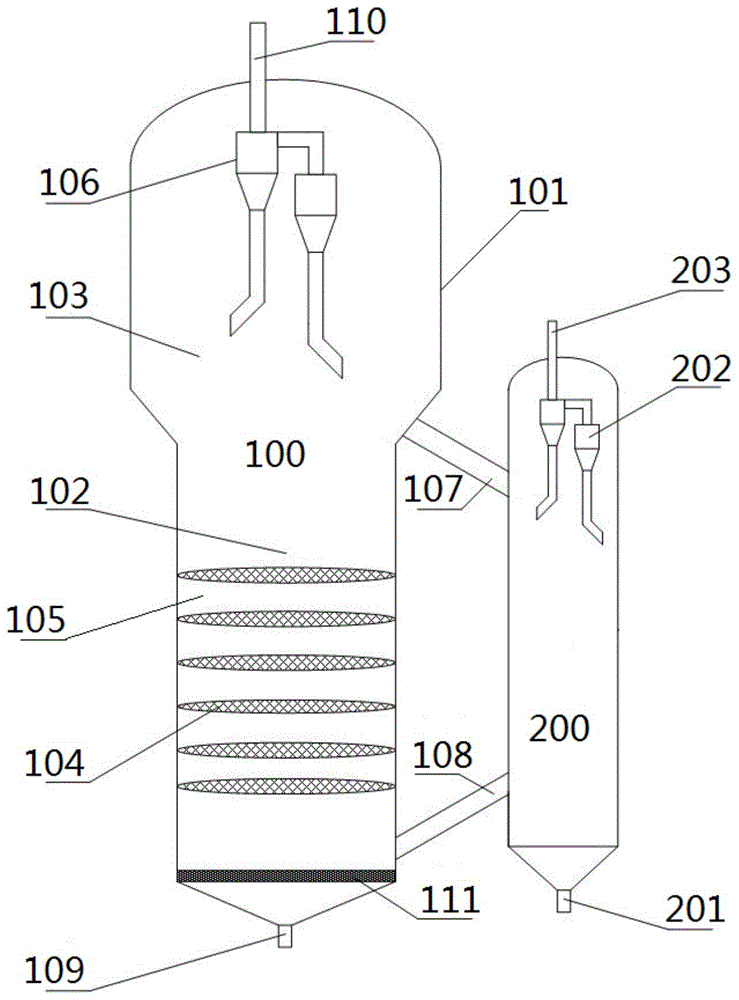

[0096] Adopt the method identical with embodiment 1 to produce hydrogen, difference is:

[0097] (1) In the reaction zone, 20 metal foam plates (produced by Beijing Zhongshi Qiangye Foam Metal Co., Ltd., inactive foam metal plates formed of copper) are arranged at uniform intervals along the horizontal direction. Loaded with nickel and tungsten, wherein the loading of nickel is 10% by weight, the weight ratio of nickel to tungsten is 1:0.2, the thickness of the inactive foam metal plate is 5mm, and the average of the pores on the inactive foam metal plate The pore diameter is 2mm, the porosity is 95%), the side wall of the metal foam plate is connected with the inner wall of the reaction zone;

[0098] (2) Filling fluidizable particles between the metal foam plates and between the metal foam plates and the inner wall of the reaction zone, the fluidizable particles are calcium oxide particles with a volume average particle diameter of 70 μm.

[0099] Methane is steam reformed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com