Electrochemical sensor based on Co-MOF and heme-G-DNA concerted catalysis as well as preparation method and application of electrochemical sensor

A -G-DNA, synergistic catalysis technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of restricting the development of sensors, low specificity and stability, and achieve improved time efficiency and anti-interference ability, Strong electrical conductivity and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1. Preparation of signaling probe AuNPs-Co-MOF-hemin-G-DNA:

[0047] (1) Synthesis of Co-MOF:

[0048] Dissolve 0.06 M cobalt nitrate and 0.25 M 2-methylimidazole in 80 mL of methanol / ethanol (1:1) solution, slowly add 2-methylimidazole solution into the cobalt nitrate solution under vigorous stirring, and the resulting mixed solution Aging was performed at room temperature for 24 h; the obtained purple product was centrifuged at 10,000 rpm for 10 min and washed with ethanol, followed by vacuum drying at 60 °C for 12 h to obtain a purple powder Co-MOF. 6 mg of Co-MOF was ultrasonically dispersed in 1 mL of pure water to obtain a Co-MOF dispersion, which was stored at 4 °C.

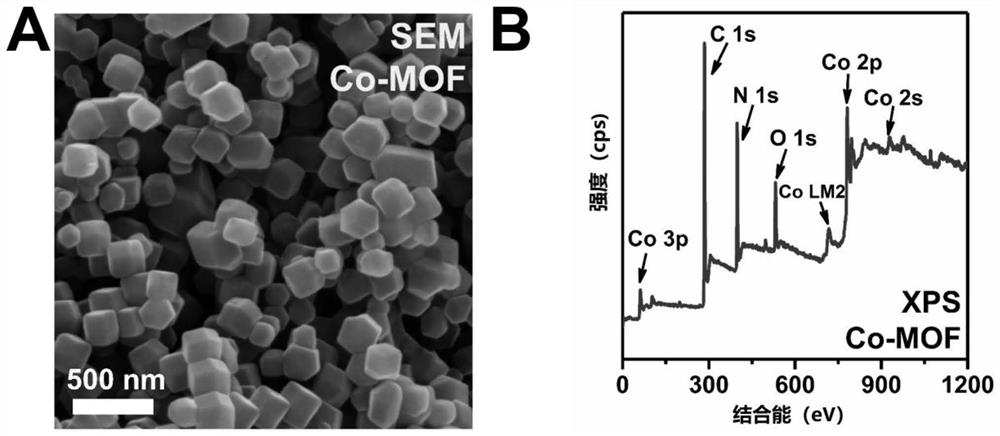

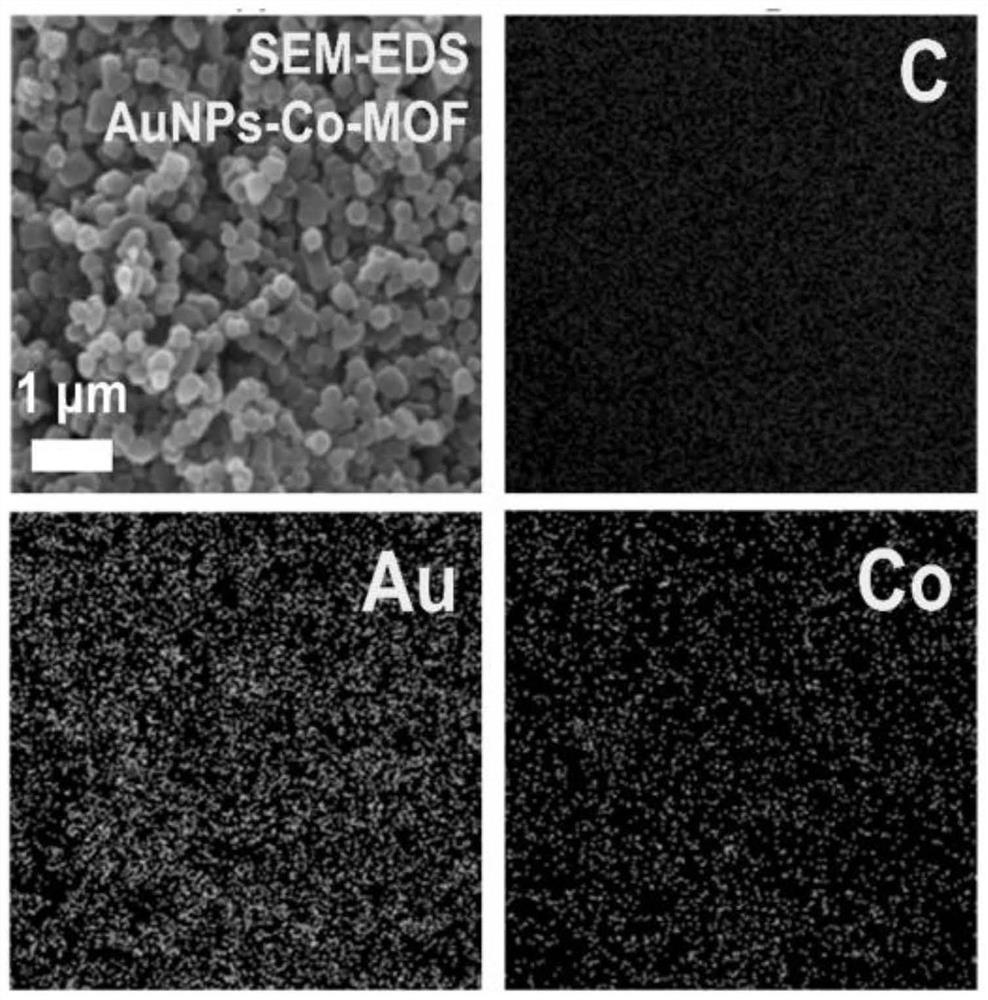

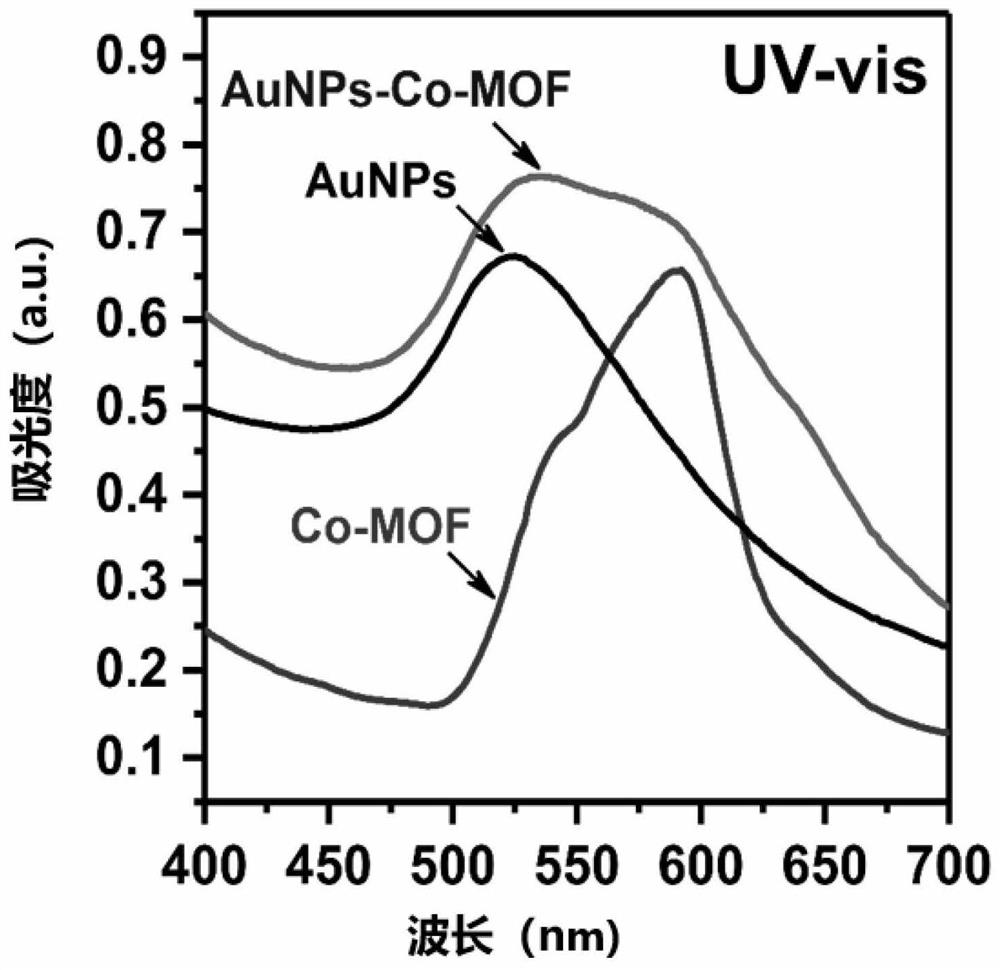

[0049] figure 1 is the characterization diagram of Co-MOF material; among them, A is the SEM image of Co-MOF material; B is the XPS spectrum of Co-MOF material. figure 1 The SEM image of A shows that the nanomaterial Co-MOF is in the shape of a regular rhombic dodecahedron. XPS results (...

Embodiment 2

[0060] Example 2. Preparation of DNAzyme-Au-N-CMK3 / SPCE:

[0061] (1) Preparation of N-CMK3 powder:

[0062] 2.0 g urea, 2.5 g sucrose and 1 g SBA-15 were dissolved in 20 mL of a mixed solution of water and ethanol with a volume ratio of 1:1. After continuous stirring for 2 h, the mixture was heated in an oven at 80 °C for 12 h. Subsequently, transfer the dried powder to a tube furnace, raise the temperature to 800 °C at a rate of 10 °C / min, and perform pyrolysis under nitrogen for 4 h. After the pyrolysis product is cooled to room temperature, use a mass fraction of 10 % HF solution was etched for 24 h to remove the silica template, and then centrifuged at 10,000 rpm for 10 min, washed with pure water and ethanol and dried at 80 °C to obtain N-CMK3 powder.

[0063] (2) Preparation of Au-N-CMK3 / SPCE:

[0064] 5 mg of N-CMK3 was ultrasonically dispersed in 1 mL of pure water for 1 h, and 20 μL of the dispersion was drop-coated on the surface of SPCE, and dried with an infrare...

Embodiment 3

[0072] Example 3. Preparation of an electrochemical sensor based on Co-MOF and heme-G-DNA synergistic catalysis:

[0073] Take 10 μL of different concentrations of Pb 2+ The standard solution was added dropwise to the sensor DNAzyme-Au-N-CMK3 / SPCE prepared in Example 2, and reacted at room temperature for 80 minutes. Among them, Pb 2+ The presence of DNAzyme can be cleaved into two free fragments at the "rA" site, so that Pb 2+ been specifically identified. In order to achieve electrochemical signal amplification, after washing the electrode with PBS, 10 μL of the signal probe AuNPs-Co-MOF-hemin-G-DNA obtained in Example 1 was coated on the sensor and incubated for 60-120 min. The pairing principle makes the G-DNA part that has not formed a quadruplex structure form a complementary chain with the DNAzyme fixed on the surface of the substrate after cleavage, and finally wash the electrode surface with PBS. Coated AuNPs-Co-MOF-hemin-G-DNA on DNAzyme-Au-N-CMK3 / SPCE and used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com