A kind of synthetic method of trisilylamine

A technology of trisilyl amine and synthesis method, which is applied in the directions of silicon organic compounds, chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, etc. problems such as normal operation to achieve high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

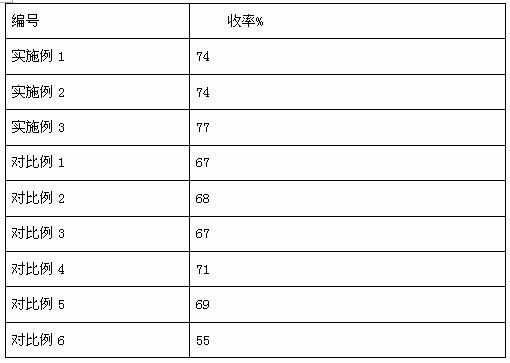

Examples

Embodiment 1

[0024] A synthetic method for trisilylamine, comprising the following steps:

[0025] 1) A method for synthesizing trisilylamine, which is prepared by using a catalytic distillation tower. The catalytic distillation tower is composed of a rectification section, a reaction section, a stripping section and a tower kettle connected in sequence from the top of the tower to the bottom of the tower. Its characteristics The preparation method includes the following steps: purging the catalytic distillation tower with an inert gas in advance, respectively simultaneously adding monochlorosilane and ammonia in gaseous form from the rectification section and the stripping section to the catalytic distillation tower for reaction. The molar ratio of chlorosilane and ammonia is 1:1.8, the space velocity of chlorosilane is 1 / h, the reaction pressure is 0.4MPa, and the reaction temperature of the distillation tower is 370°C. High-purity trisilylamine is obtained by known impurity removal and...

Embodiment 2

[0030] A synthetic method for trisilylamine, comprising the following steps:

[0031]1) A method for synthesizing trisilylamine, which is prepared by using a catalytic distillation tower. The catalytic distillation tower is composed of a rectification section, a reaction section, a stripping section and a tower kettle connected in sequence from the top of the tower to the bottom of the tower. Its characteristics The preparation method includes the following steps: purging the catalytic distillation tower with an inert gas in advance, respectively simultaneously adding monochlorosilane and ammonia in gaseous form from the rectification section and the stripping section to the catalytic distillation tower for reaction. The molar ratio of chlorosilane and ammonia is 1:1.2, the space velocity of chlorosilane is 0.5 / h, the reaction pressure is 0.2MPa, and the reaction temperature of the distillation tower is 350°C. High-purity trisilylamine is obtained by known impurity removal and...

Embodiment 3

[0036] A synthetic method for trisilylamine, comprising the following steps:

[0037] 1) A method for synthesizing trisilylamine, which is prepared by using a catalytic distillation tower. The catalytic distillation tower is composed of a rectification section, a reaction section, a stripping section and a tower kettle connected in sequence from the top of the tower to the bottom of the tower. Its characteristics The preparation method includes the following steps: purging the catalytic distillation tower with an inert gas in advance, respectively simultaneously adding monochlorosilane and ammonia in gaseous form from the rectification section and the stripping section to the catalytic distillation tower for reaction. The molar ratio of chlorosilane and ammonia is 1:3, the space velocity of chlorosilane is 2 / h, the reaction pressure is 1MPa, and the reaction temperature of the distillation tower is 420°C. The reaction product in the tower reactor is continuously drawn out, NH4C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com