Methods for producing silicon nitride films and silicon oxynitride films by thermal chemical vapor deposition

A technology of silicon nitride thin film and silicon nitride oxide, which is applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, electrical components, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

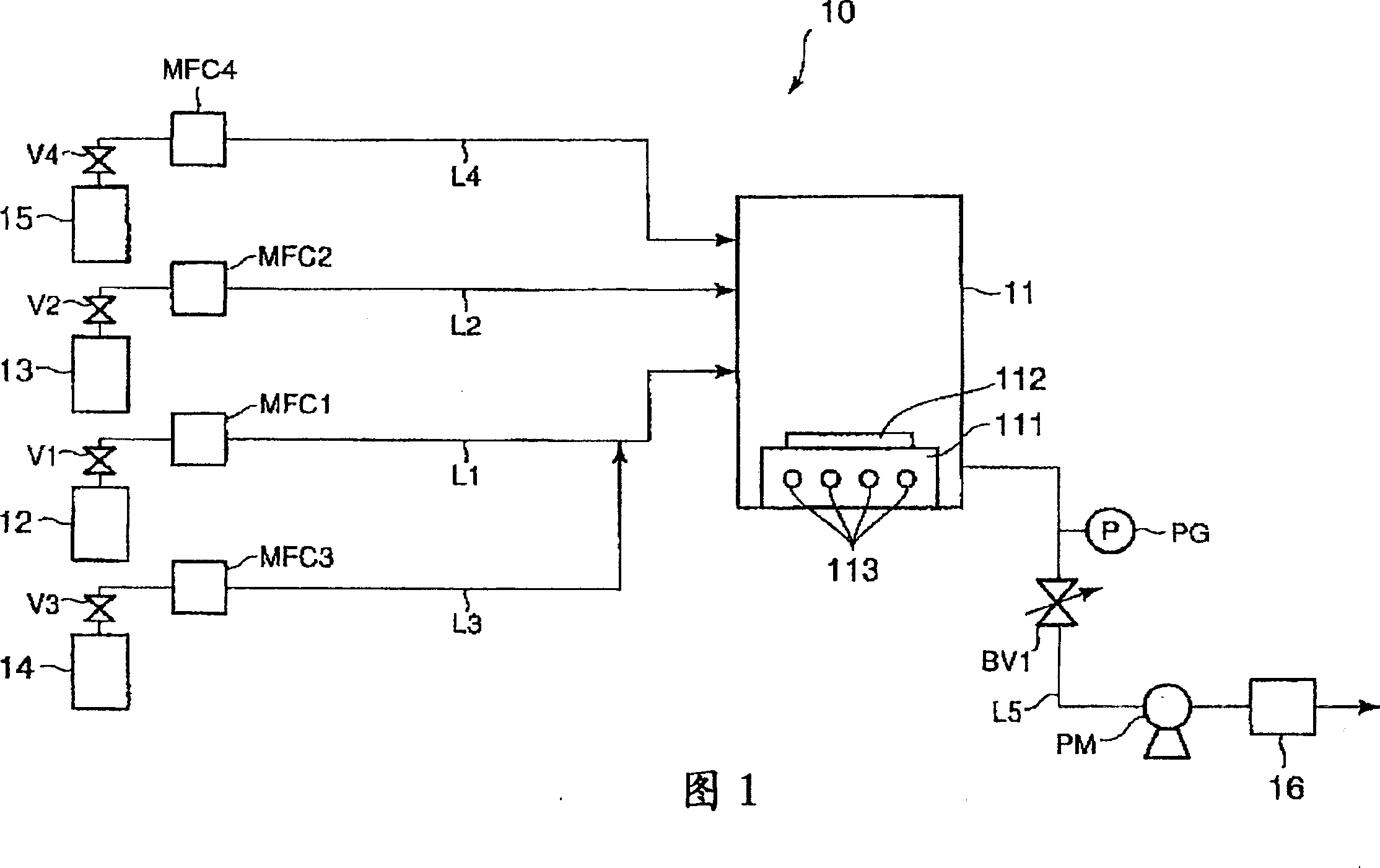

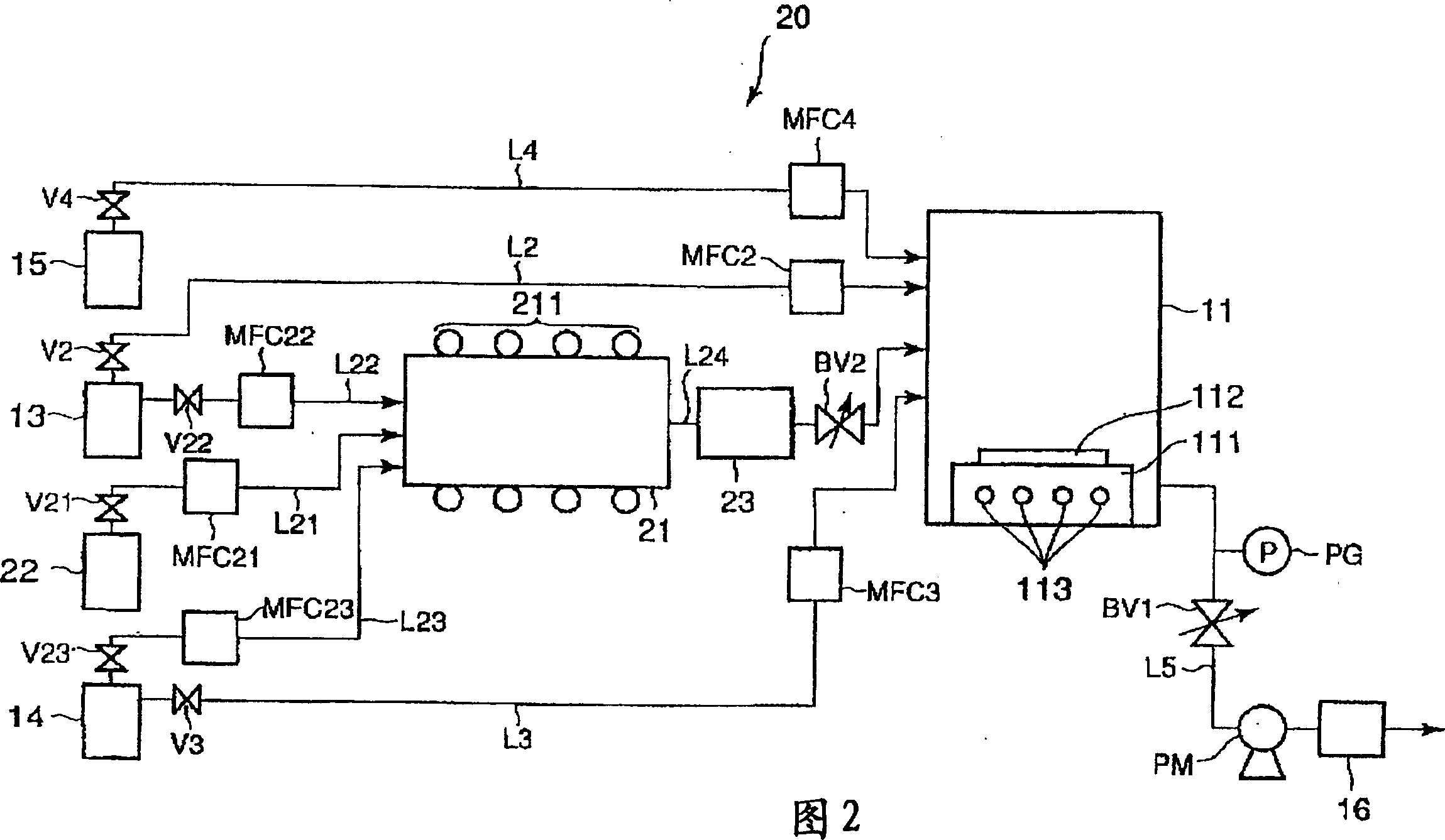

[0070] The oxygen source gas source 15 used in the preparation process of the silicon oxynitride film includes a sealed container containing the oxygen source gas. An oxygen source gas is introduced from its source 15 and into the CVD reaction chamber 11 through an oxygen source gas feed line L4. A shut-off valve V4 is installed in the feed pipe L4 and a flow rate controller such as a mass flow controller MFC4 is installed downstream thereof. The oxygen source gas is controlled to a predetermined flow rate by a mass flow controller MFC4 and introduced into the CVD reaction chamber 11 .

[0071] The outlet of the CVD reaction chamber 11 is connected to an exhaust gas treatment device 16 through a line L5. The waste gas treatment device 16 removes substances such as by-products and unreacted materials, and the gas purified by the waste gas treatment device 16 is discharged from the system. In the line L5 are installed a pressure sensor PG, a pressure regulator such as a butter...

Embodiment 1

[0082] A fabrication facility as shown in Figure 1 (but without the oxygen source gas feed system) was used in this example. Ammonia gas and TSA gas were introduced into a CVD reaction chamber in which a silicon substrate was placed, and a silicon nitride film was formed on the silicon substrate under the following conditions.

[0083] Ammonia flow rate: 40sccm

[0084] TSA gas flow rate: 0.5sccm

[0085] Pressure in CVD reaction chamber: 1 Torr

[0086] Reaction temperature: 640°C

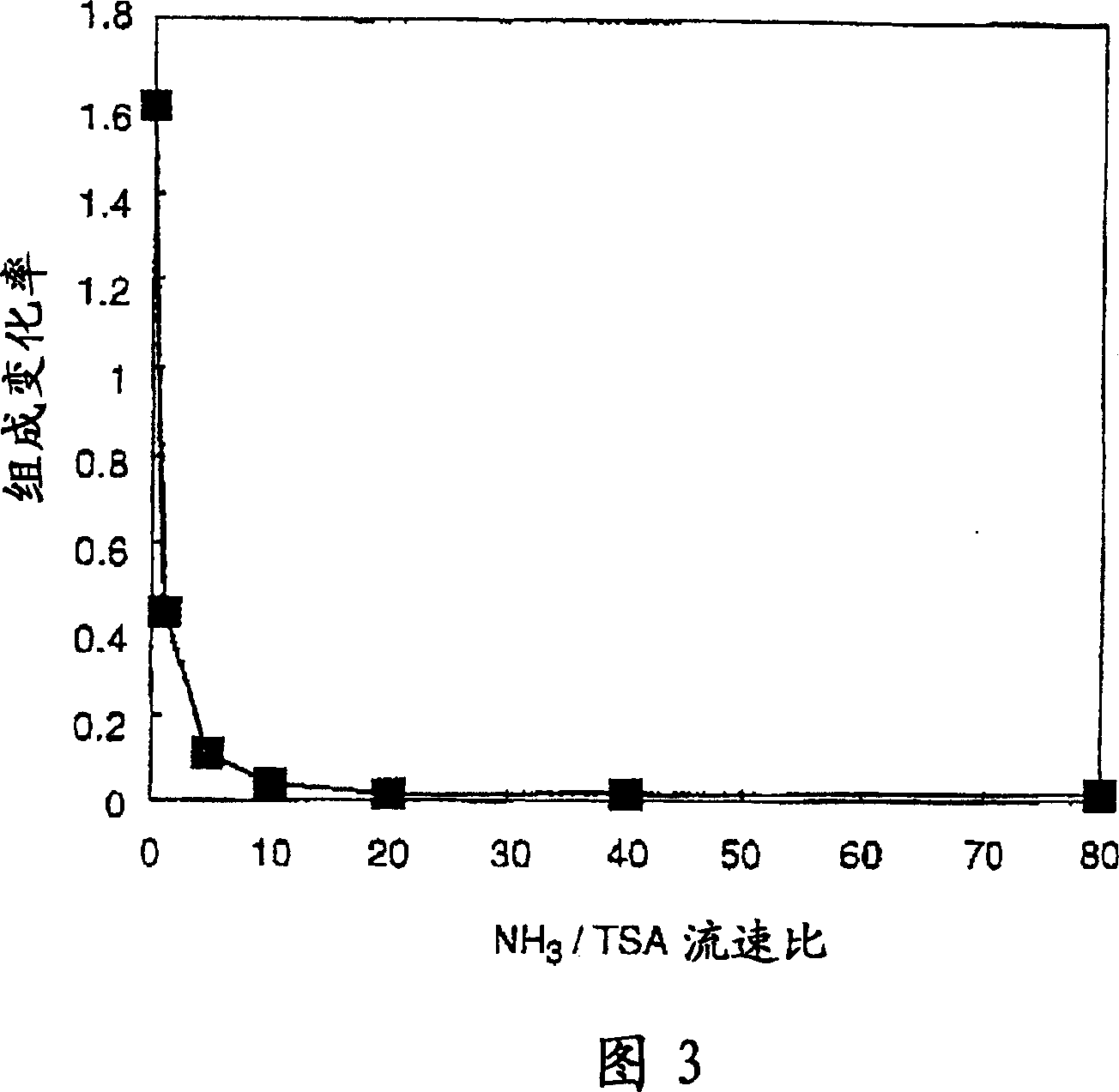

[0087] The composition of the obtained silicon nitride film was determined by Auger spectroscopy to be Si 0.81 N. The deposition (growth) rate of the silicon nitride film was 17 angstroms / minute. NH in this example 3 / TSA flow rate ratio was 80, and a stable film composition was obtained.

Embodiment 2

[0089] A fabrication facility as shown in Figure 1 (but without the oxygen source gas feed system) was used in this example. Ammonia gas and TSA gas were introduced into a CVD reaction chamber in which a silicon substrate was placed, and a silicon nitride film was formed on the silicon substrate under the following conditions.

[0090] Ammonia flow rate: 40sccm

[0091] TSA gas flow rate: 4sccm

[0092] Pressure in CVD reaction chamber: 1 Torr

[0093] Reaction temperature: 560°C

[0094] The composition of the obtained silicon nitride film was determined by Auger spectroscopy to be Si 1.04 N. The deposition (growth) rate of the silicon nitride film was 6 angstroms / minute. NH in this example 3 / TSA flow rate ratio was 10, and a stable film composition was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com