Patents

Literature

723 results about "Dichlorosilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dichlorosilane, or DCS as it is commonly known, is a chemical compound with the formula H₂SiCl₂. In its major use, it is mixed with ammonia (NH₃) in LPCVD chambers to grow silicon nitride in semiconductor processing. A higher concentration of DCS:NH₃ (i.e. 16:1), usually results in lower stress nitride films.

Low-temperature dielectric film formation by chemical vapor deposition

InactiveUS7994070B1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricWater vapor

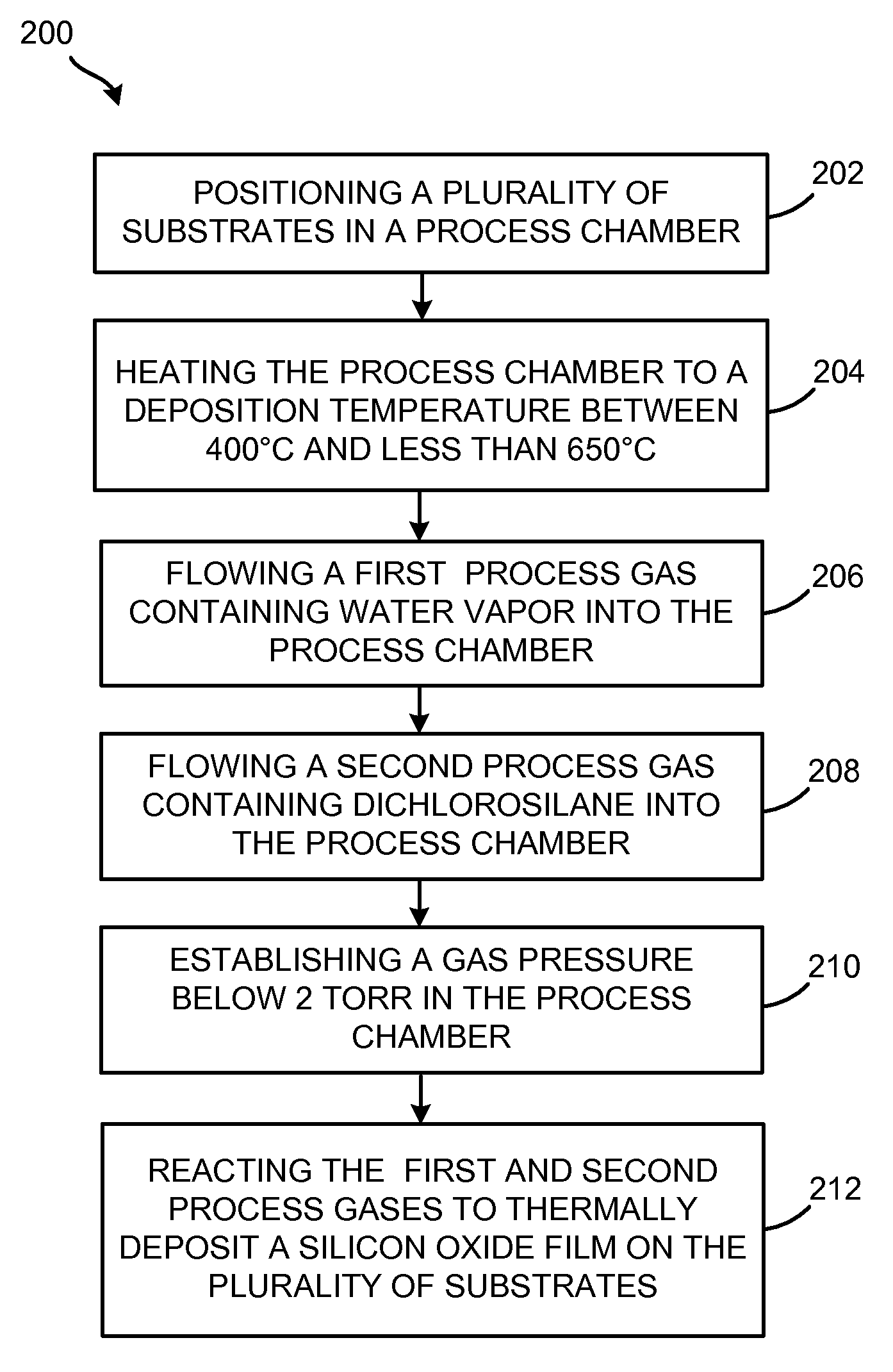

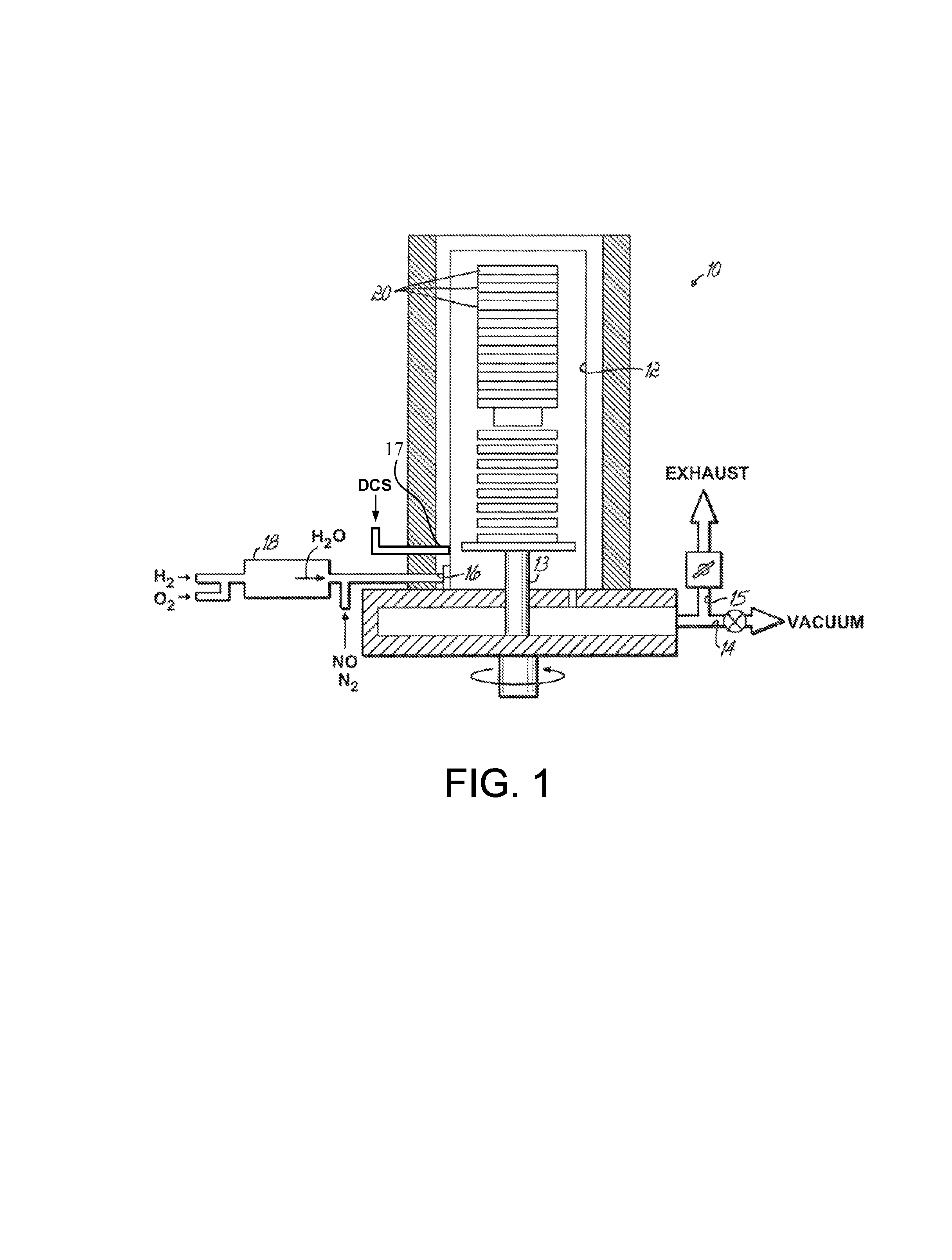

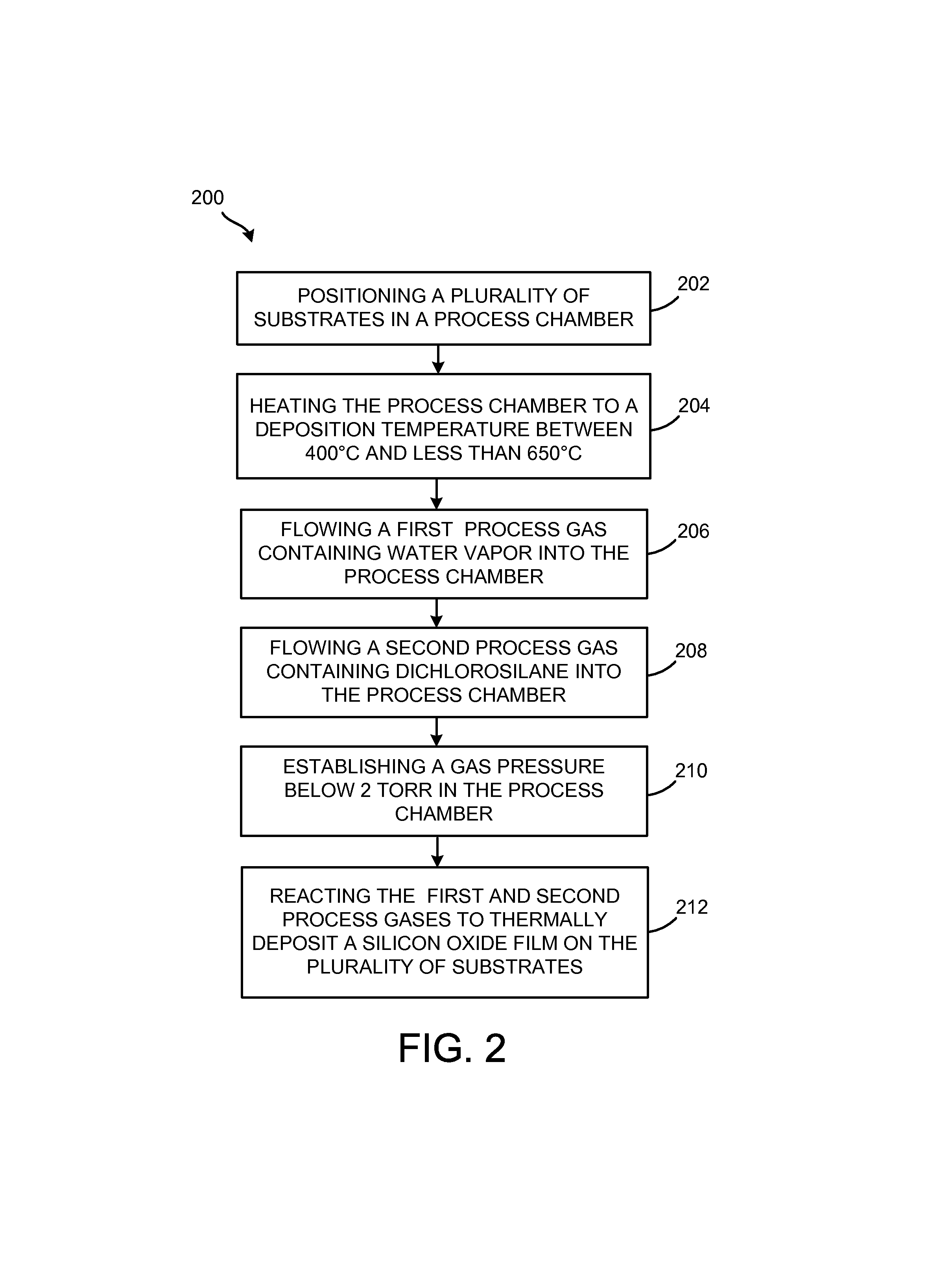

A method for depositing a dielectric film on a substrate includes positioning a plurality of substrates in a process chamber, heating the process chamber to a deposition temperature between 400° C. and less than 650° C., flowing a first process gas comprising water vapor into the process chamber, flowing a second process gas comprising dichlorosilane (DCS) into the process chamber, establishing a gas pressure of less than 2 Torr, and reacting the first and second process gases to thermally deposit a silicon oxide film on the plurality of substrates. One embodiment further includes flowing a third process gas comprising nitric oxide (NO) gas into the process chamber while flowing the first process gas and the second process gas; and reacting the oxide film with the third process gas to form a silicon oxynitride film on the substrate.

Owner:TOKYO ELECTRON LTD

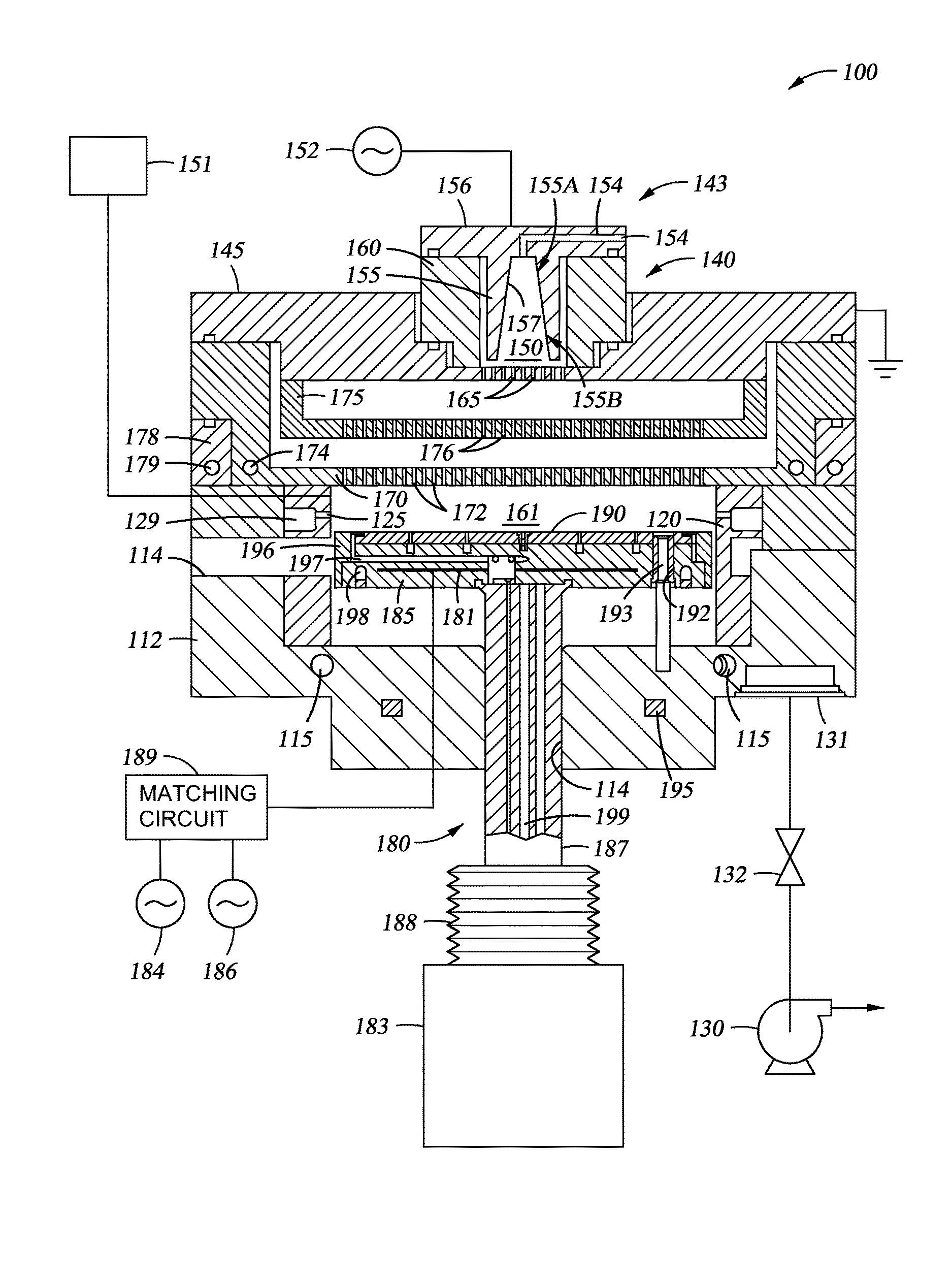

Low temperature silicon nitride films using remote plasma CVD technology

ActiveUS9583333B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCelsius DegreeRemote plasma

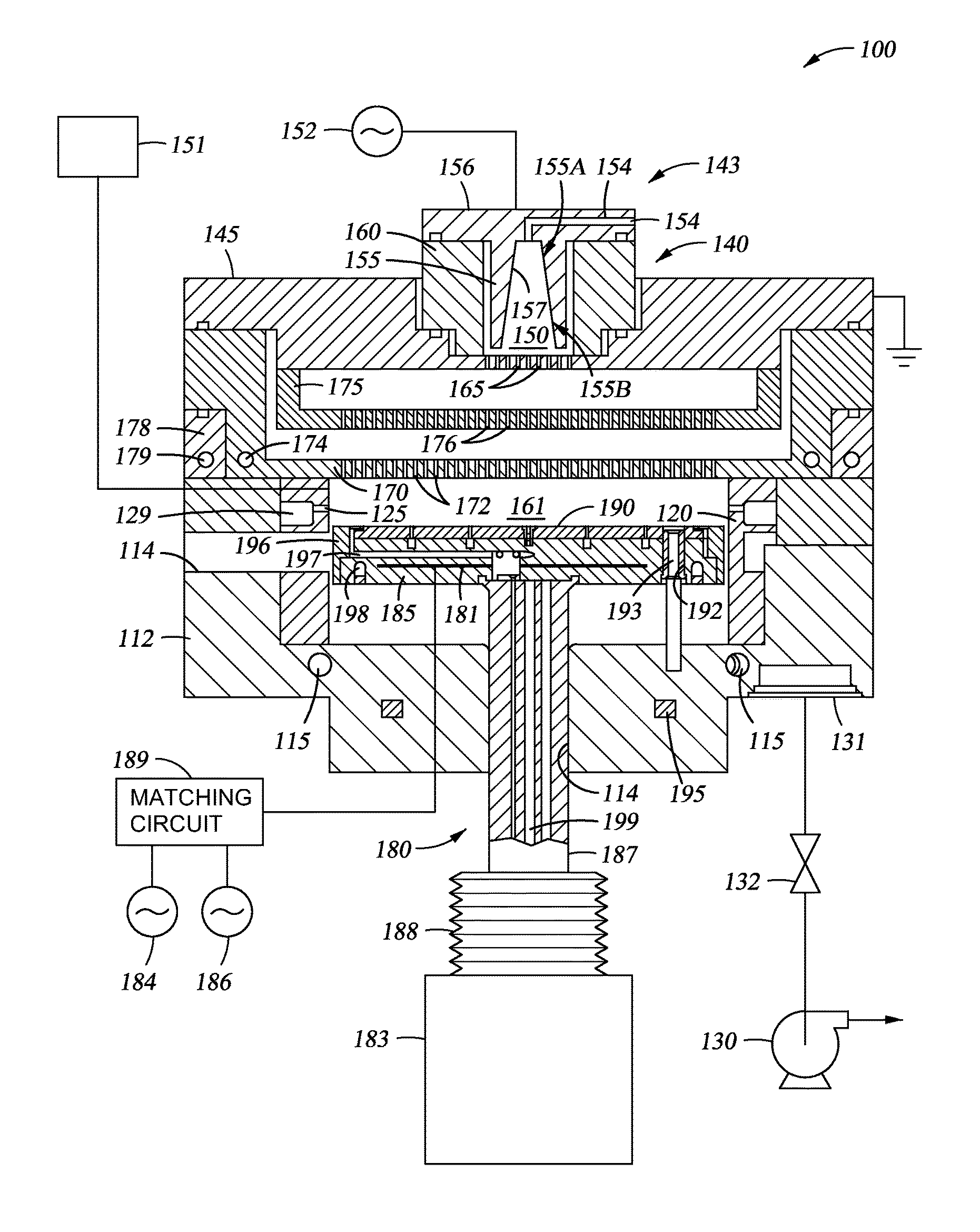

Embodiments of the present invention generally provide methods for forming a silicon nitride layer on a substrate. In one embodiment, a method of forming a silicon nitride layer using remote plasma chemical vapor deposition (CVD) at a temperature that is less than 300 degrees Celsius is disclosed. The precursors for the remote plasma CVD process include tris(dimethylamino)silane (TRIS), dichlorosilane (DCS), trisilylamine (TSA), bis-t-butylaminosilane (BTBAS), hexachlorodisilane (HCDS) or hexamethylcyclotrisilazane (HMCTZ).

Owner:APPLIED MATERIALS INC

Epitaxial deposition of doped semiconductor materials

ActiveUS7863163B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

A method for depositing a carbon doped epitaxial semiconductor layer comprises maintaining a pressure of greater than about 700 torr in a process chamber housing a patterned substrate having exposed single crystal material. The method further comprises providing a flow of a silicon source gas to the process chamber. The silicon source gas comprises dichlorosilane. The method further comprises providing a flow of a carbon precursor to the process chamber. The method further comprises selectively depositing the carbon doped epitaxial semiconductor layer on the exposed single crystal material.

Owner:ASM IP HLDG BV

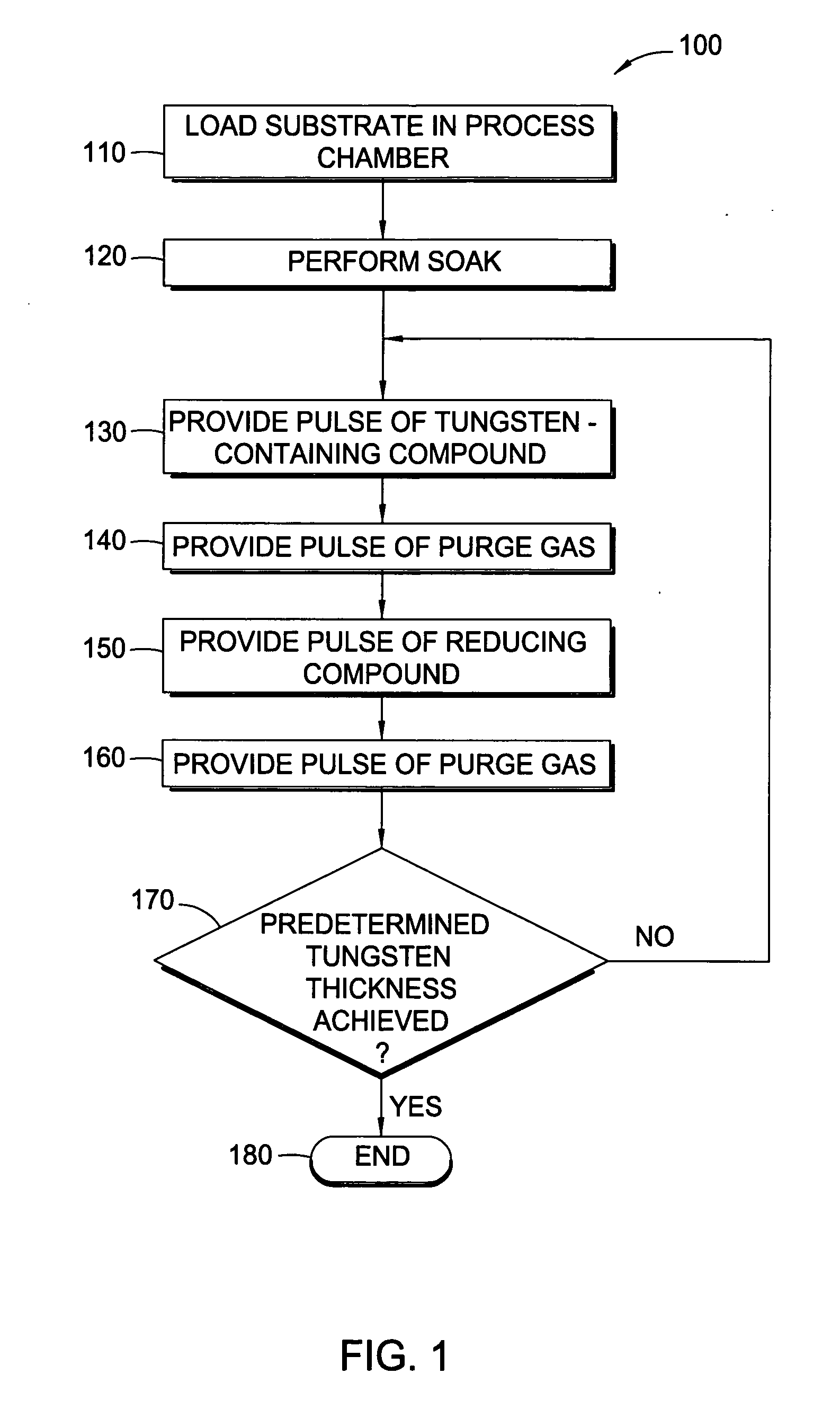

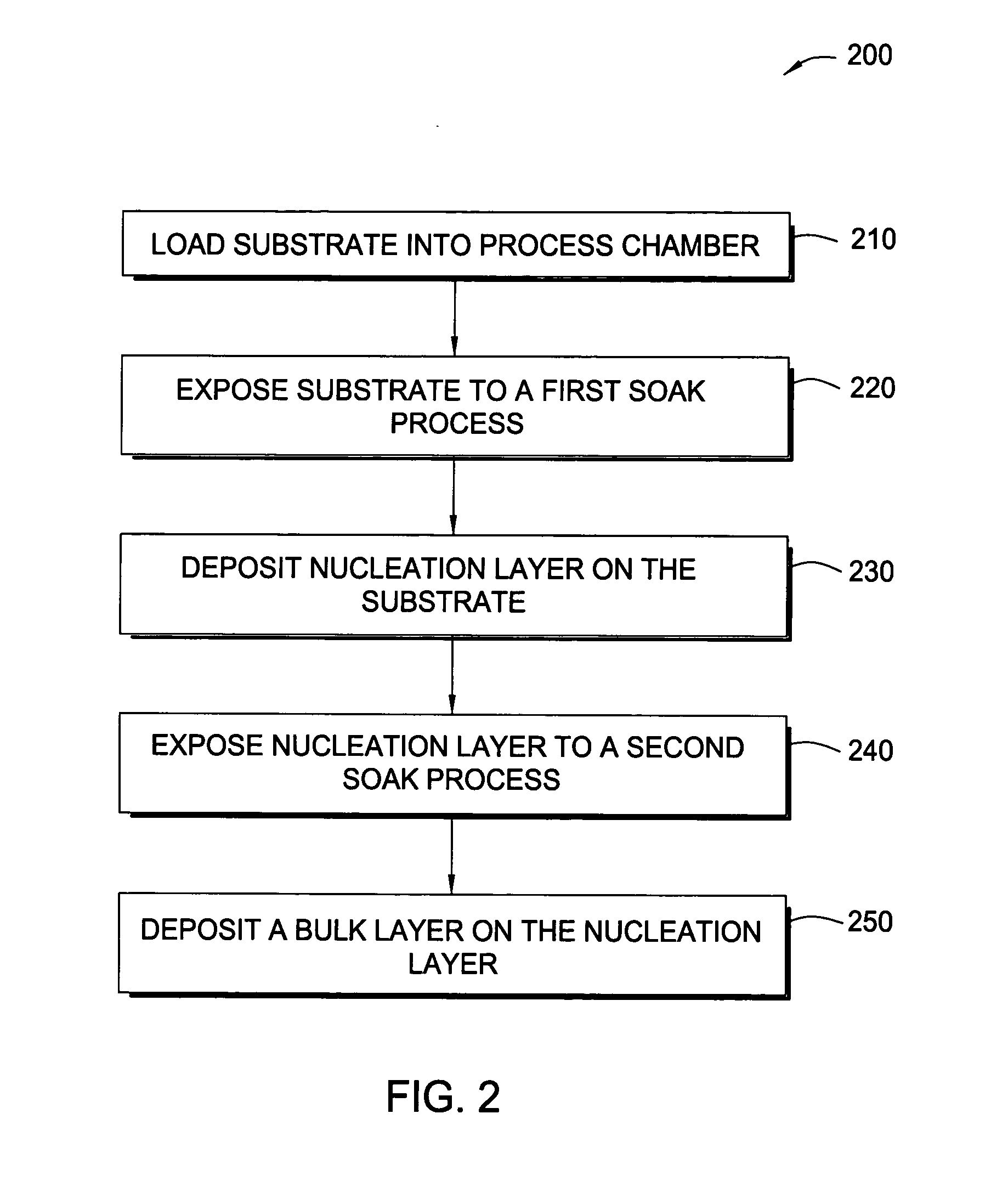

Methods for depositing tungsten layers employing atomic layer deposition techniques

InactiveUS7405158B2Solid-state devicesSemiconductor/solid-state device manufacturingDisilaneGas phase

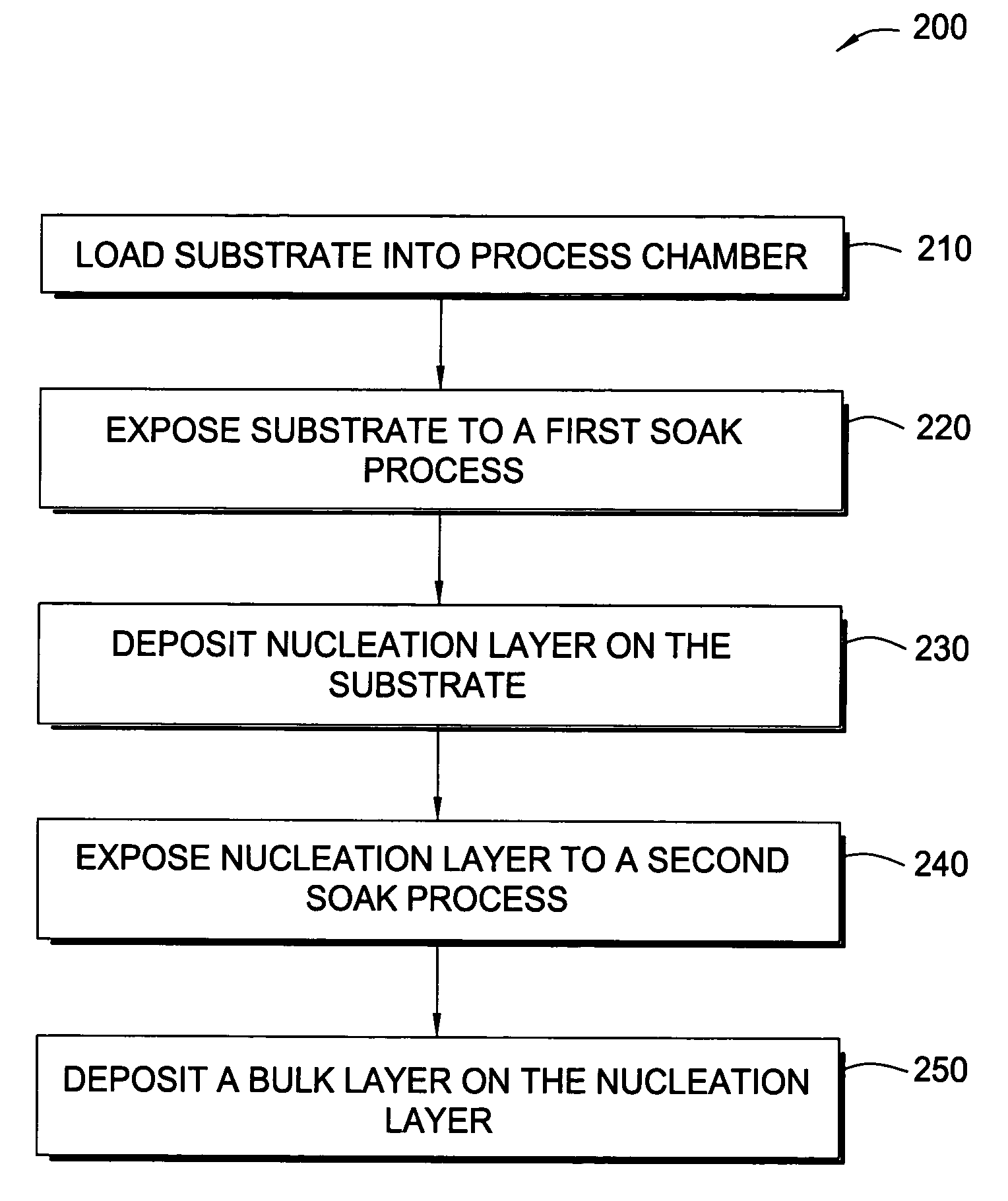

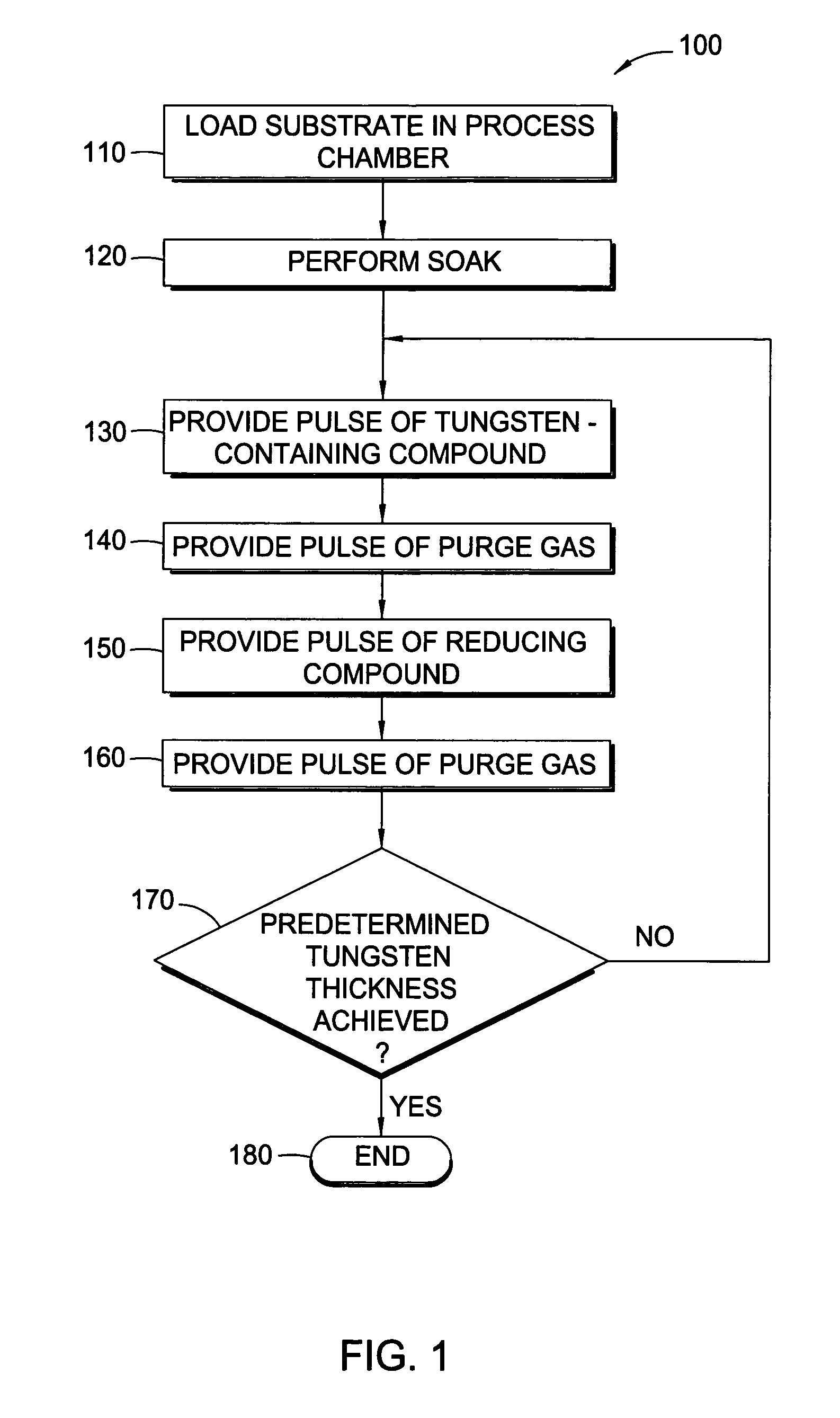

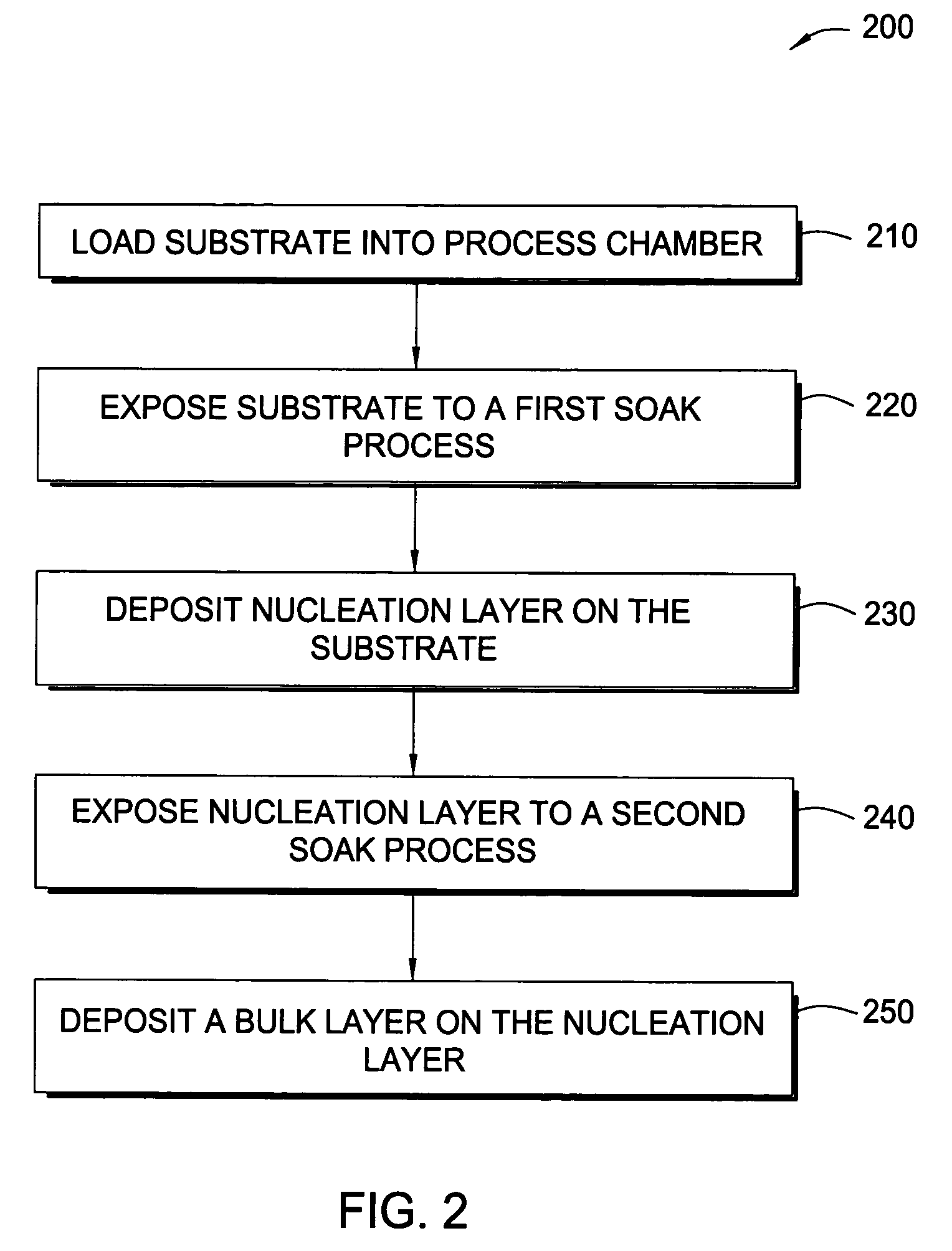

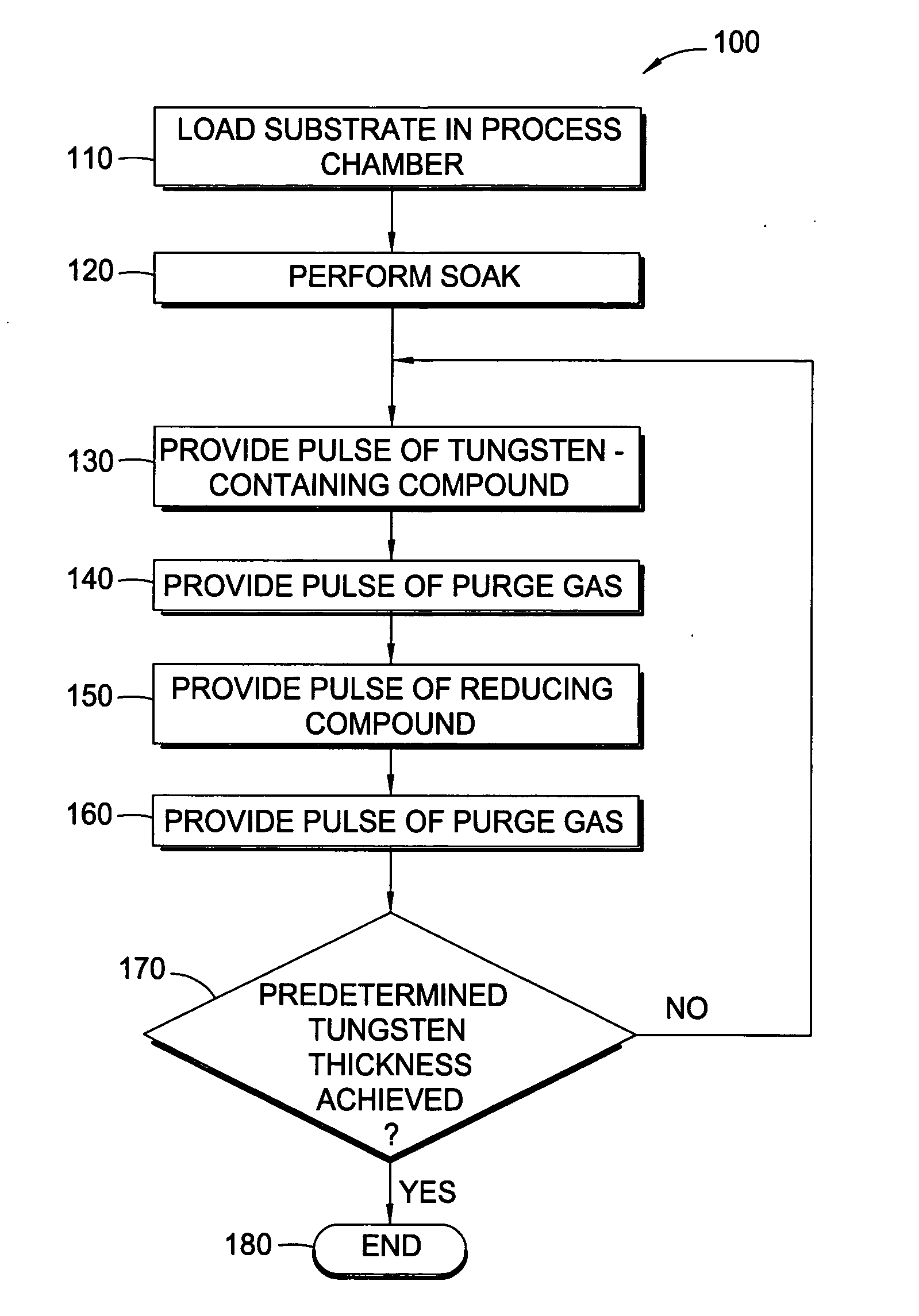

In one embodiment of the invention, a method for forming a tungsten-containing layer on a substrate is provided which includes positioning a substrate containing a barrier layer disposed thereon in a process chamber, exposing the substrate to a first soak process for a first time period and depositing a nucleation layer on the barrier layer by flowing a tungsten-containing precursor and a reductant into the process chamber. The method further includes exposing the nucleation layer to a second soak process for a second time period and depositing a bulk layer on the nucleation layer. In one example, the barrier layer contains titanium nitride, the first and second soak processes independently comprise at least one reducing gas selected from the group consisting of hydrogen, silane, disilane, dichlorosilane, borane, diborane, derivatives thereof and combinations thereof and the nucleation layer may be deposited by an atomic layer deposition process or a pulsed chemical vapor deposition process while the bulk layer may be deposited by a chemical vapor deposition process or a physical vapor deposition process.

Owner:APPLIED MATERIALS INC

Methods for depositing tungsten layers employing atomic layer deposition techniques

InactiveUS20060009034A1Solid-state devicesSemiconductor/solid-state device manufacturingDisilaneGas phase

In one embodiment of the invention, a method for forming a tungsten-containing layer on a substrate is provided which includes positioning a substrate containing a barrier layer disposed thereon in a process chamber, exposing the substrate to a first soak process for a first time period and depositing a nucleation layer on the barrier layer by flowing a tungsten-containing precursor and a reductant into the process chamber. The method further includes exposing the nucleation layer to a second soak process for a second time period and depositing a bulk layer on the nucleation layer. In one example, the barrier layer contains titanium nitride, the first and second soak processes independently comprise at least one reducing gas selected from the group consisting of hydrogen, silane, disilane, dichlorosilane, borane, diborane, derivatives thereof and combinations thereof and the nucleation layer may be deposited by an atomic layer deposition process or a pulsed chemical vapor deposition process while the bulk layer may be deposited by a chemical vapor deposition process or a physical vapor deposition process.

Owner:APPLIED MATERIALS INC

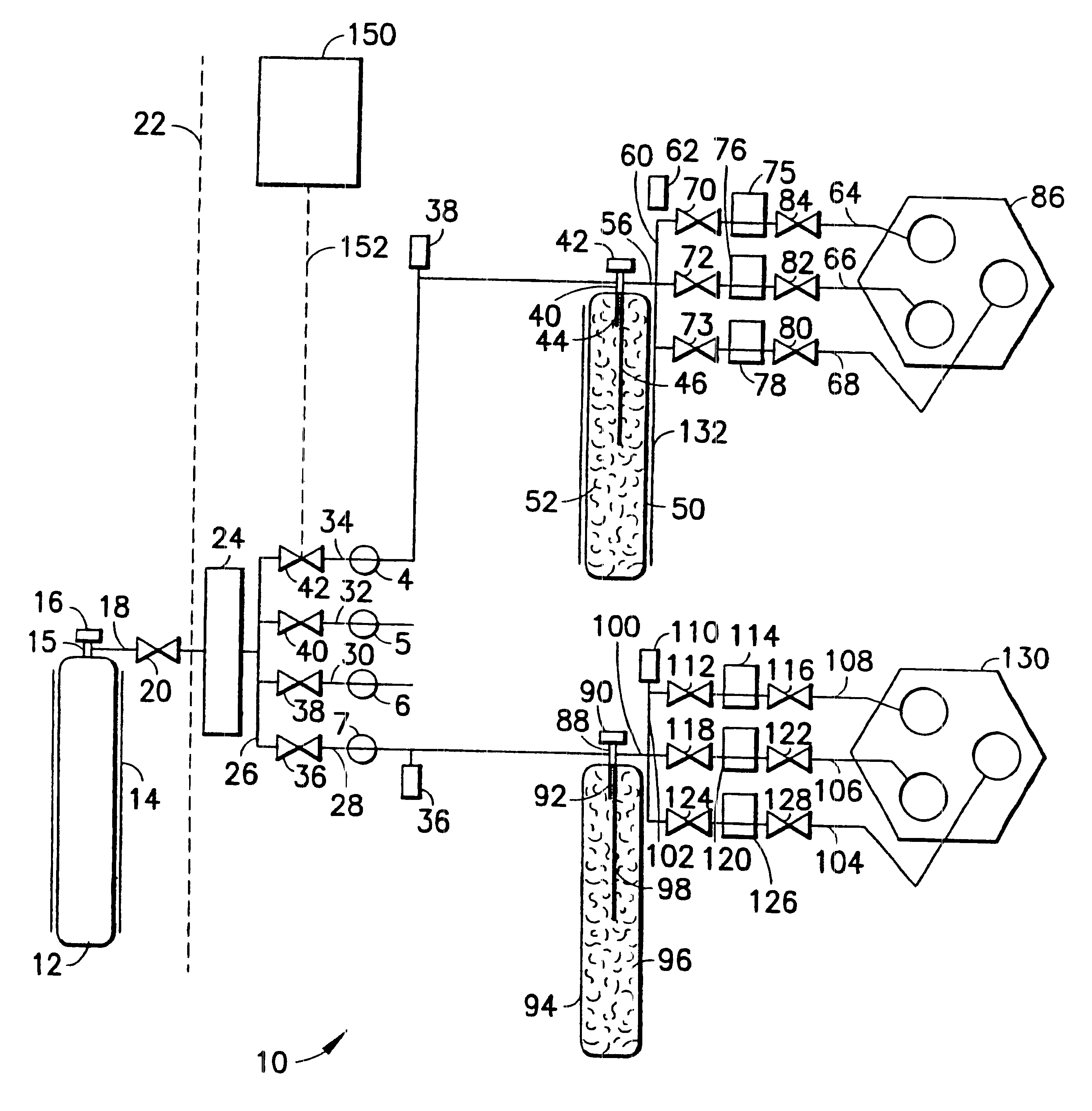

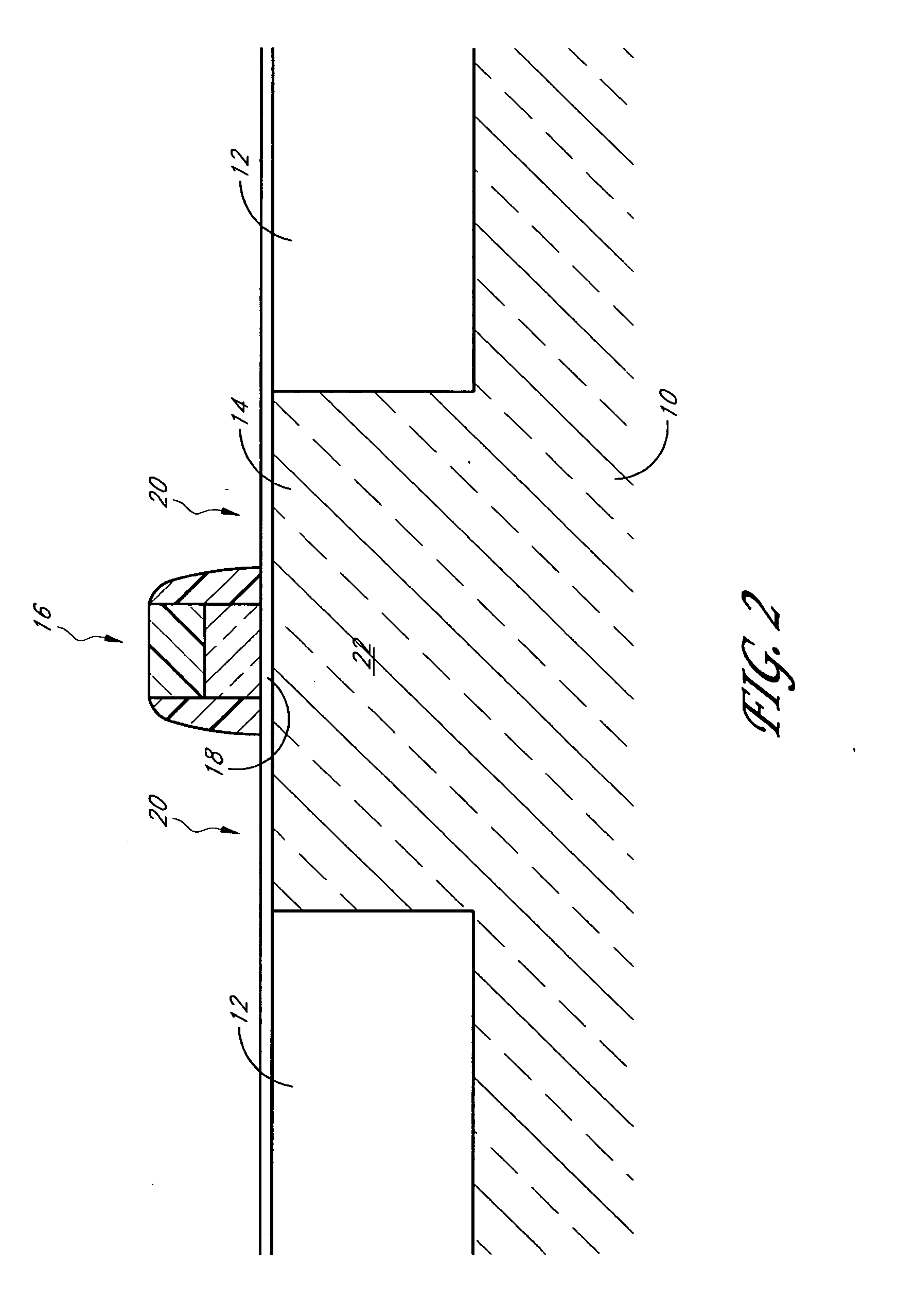

Fluid distribution system and process, and semiconductor fabrication facility utilizing same

A fluid distribution system for supplying a gas to a process facility such as a semiconductor manufacturing plant. The system includes a main fluid supply vessel coupled by flow circuitry to a local sorbent-containing supply vessel from which fluid, e.g., low pressure compressed gas, is dispensed to a fluid-consuming unit, e.g., a semiconductor manufacturing tool. A fluid pressure regulator is disposed in the flow circuitry or the main liquid supply vessel and ensures that the gas flowed to the fluid-consuming unit is at desired pressure. The system and associated method are particularly suited to the supply and utilization of liquefied compressed gases such as trimethylsilane, arsine, phosphine, and dichlorosilane.

Owner:ENTEGRIS INC

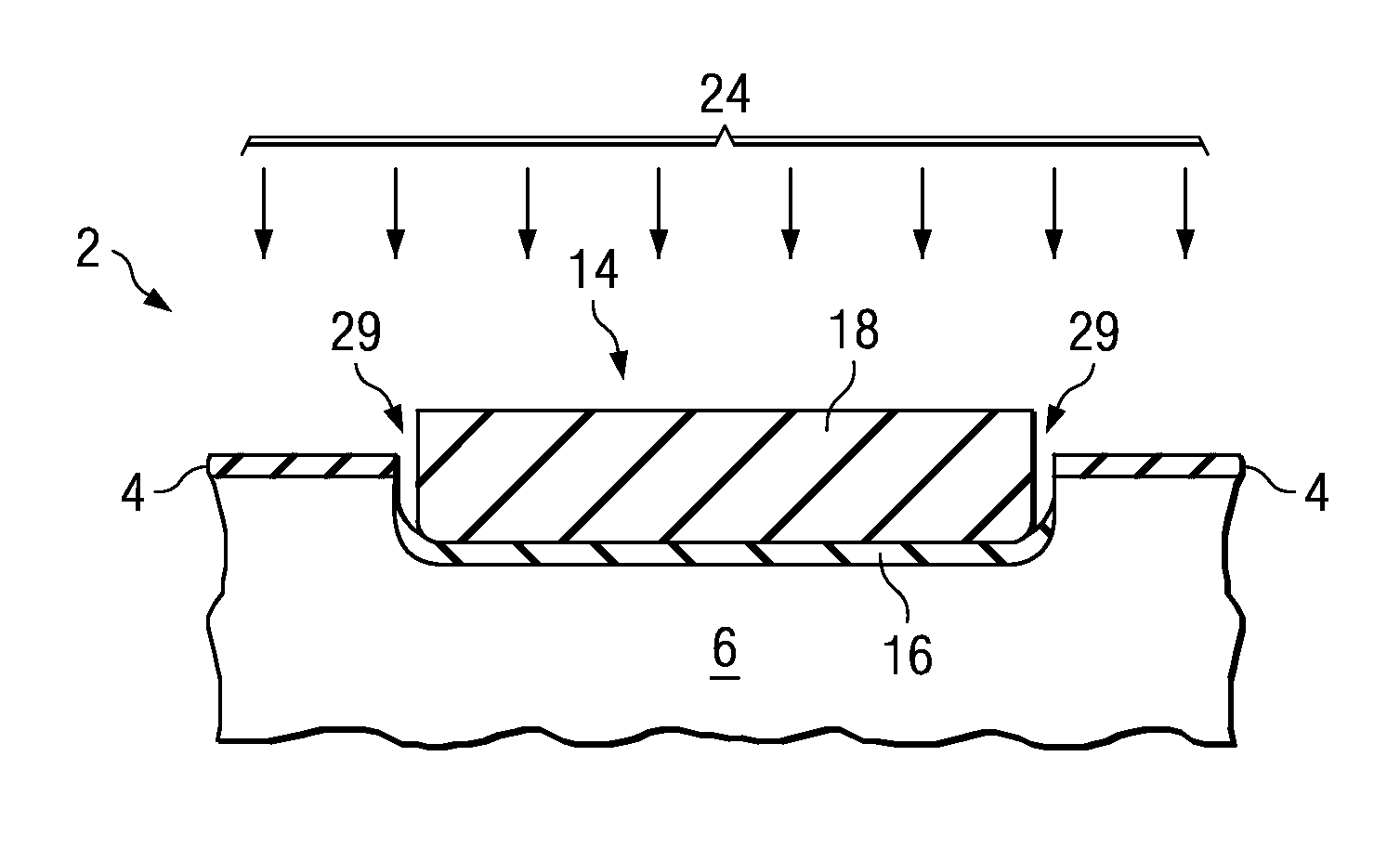

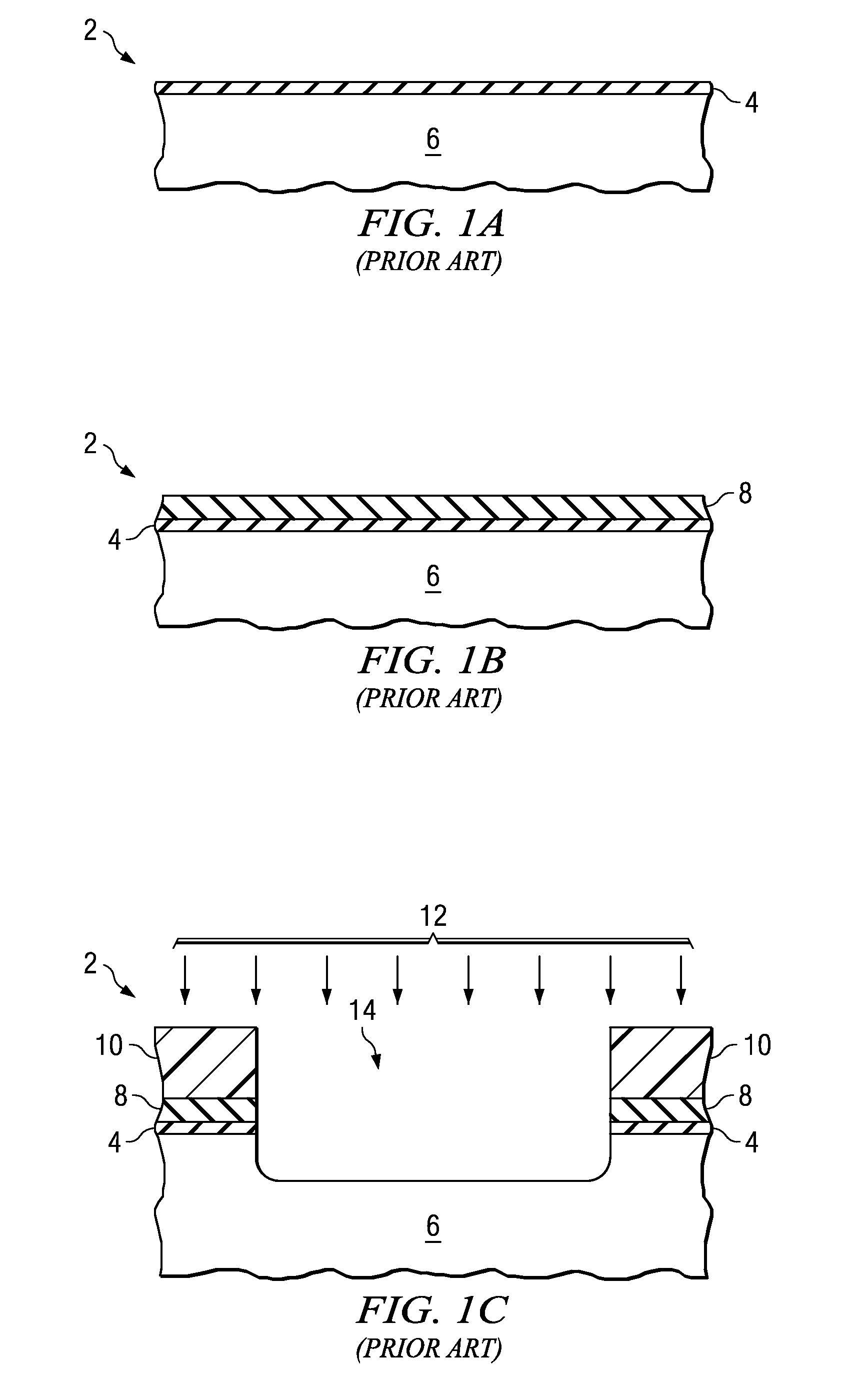

Method of forming reliable copper interconnects

InactiveUS6211084B1Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectSilanes

The adhesion of a diffusion barrier or capping layer to Cu and / or Cu alloy interconnect members is significantly enhanced by treating the exposed surface of the Cu and / or Cu alloy interconnect members with a silane or dichlorosilane plasma to form a layer of copper silicide thereon prior to depositing the capping layer. Embodiments include electroplating or electroless plating Cu or a Cu alloy to fill a damascene opening in a dielectric interlayer, chemical mechanical polishing, treating the exposed surface of the Cu or Cu alloy interconnect member in a silane or dichlorosilane plasma to form the copper silicide layer and depositing a capping layer of silicon nitride thereon.

Owner:GLOBALFOUNDRIES INC

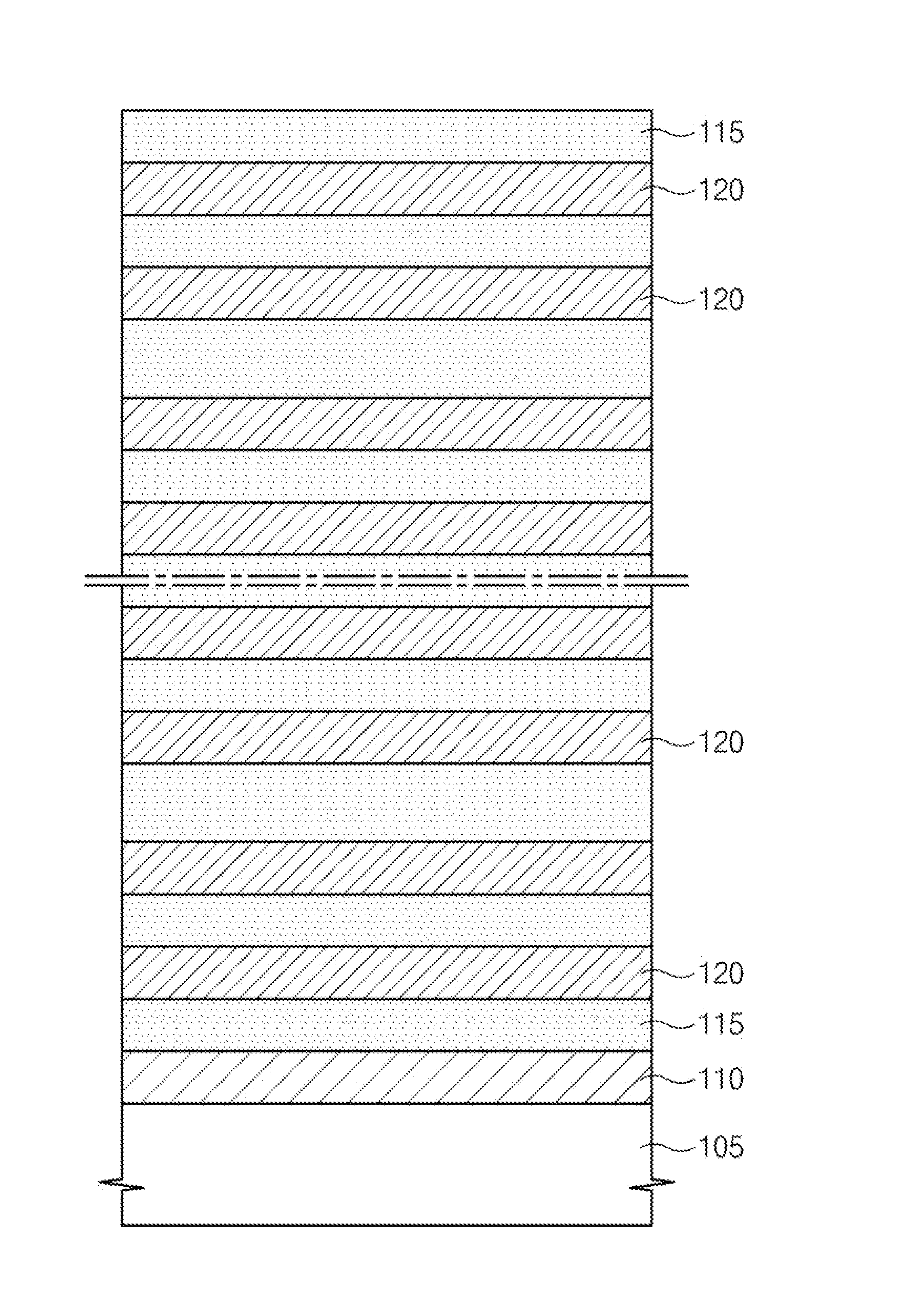

Formation of silicon nitride film

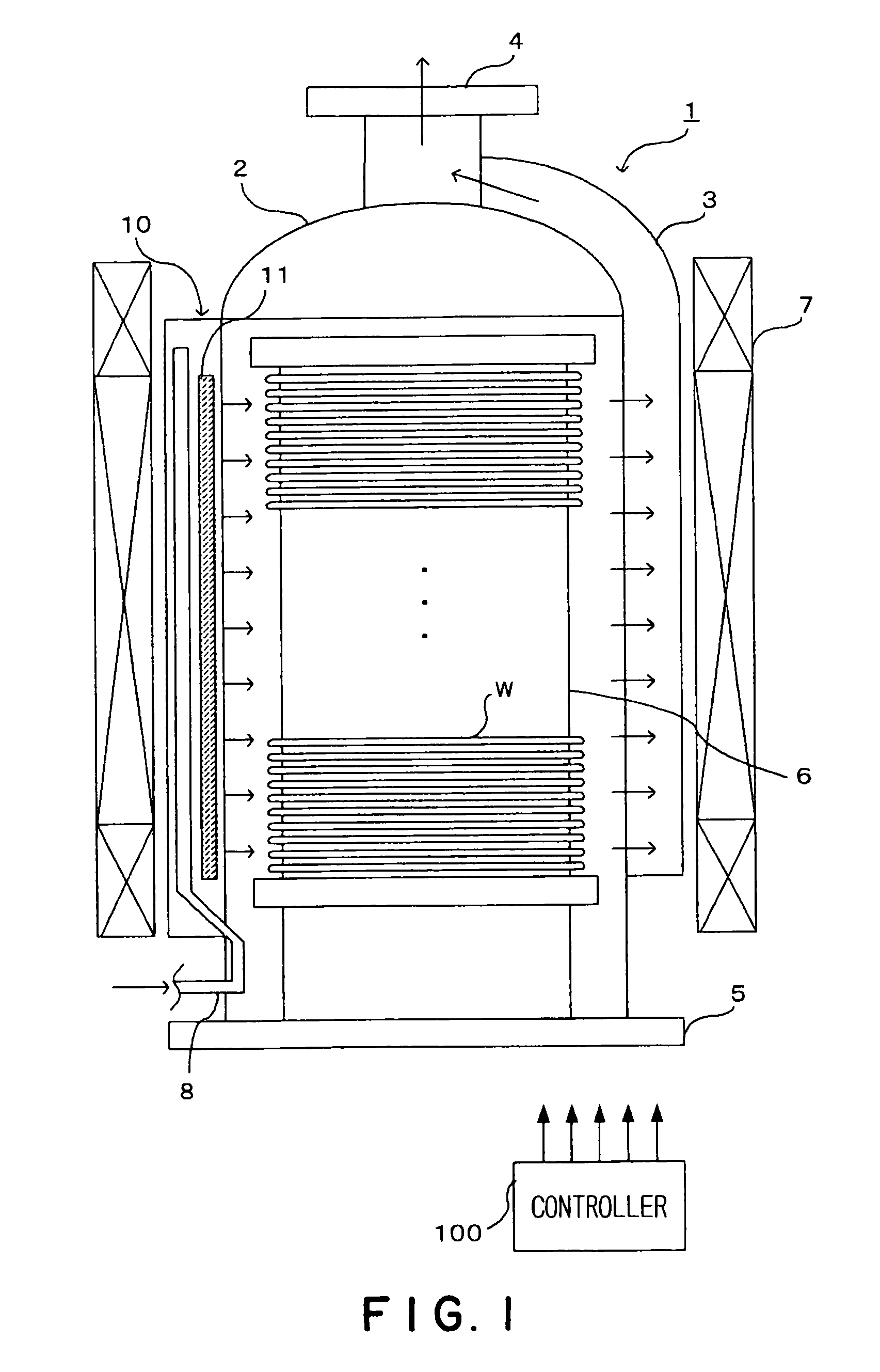

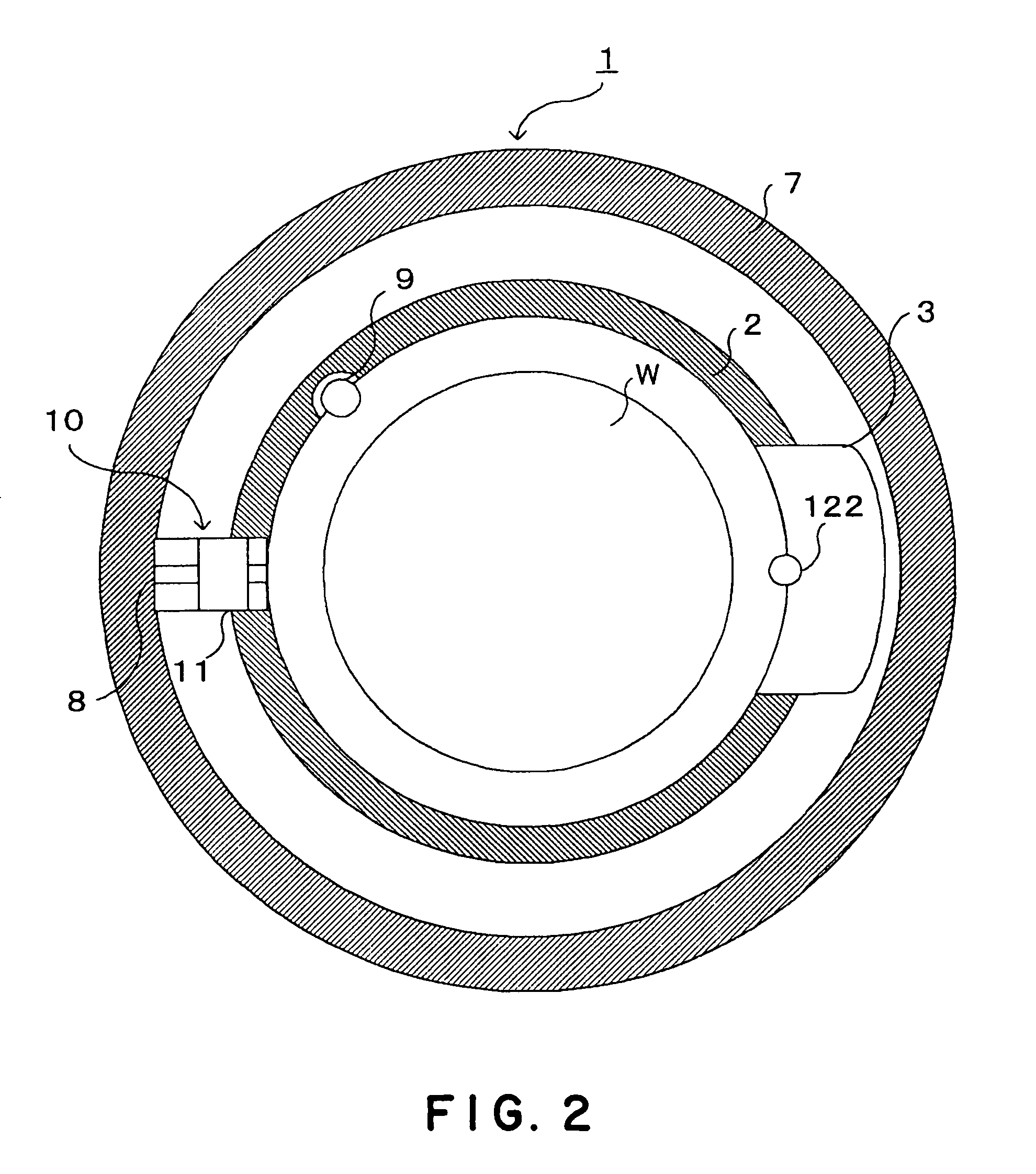

ActiveUS7625609B2Increase pressureLow process temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingChemical species

Owner:TOKYO ELECTRON LTD

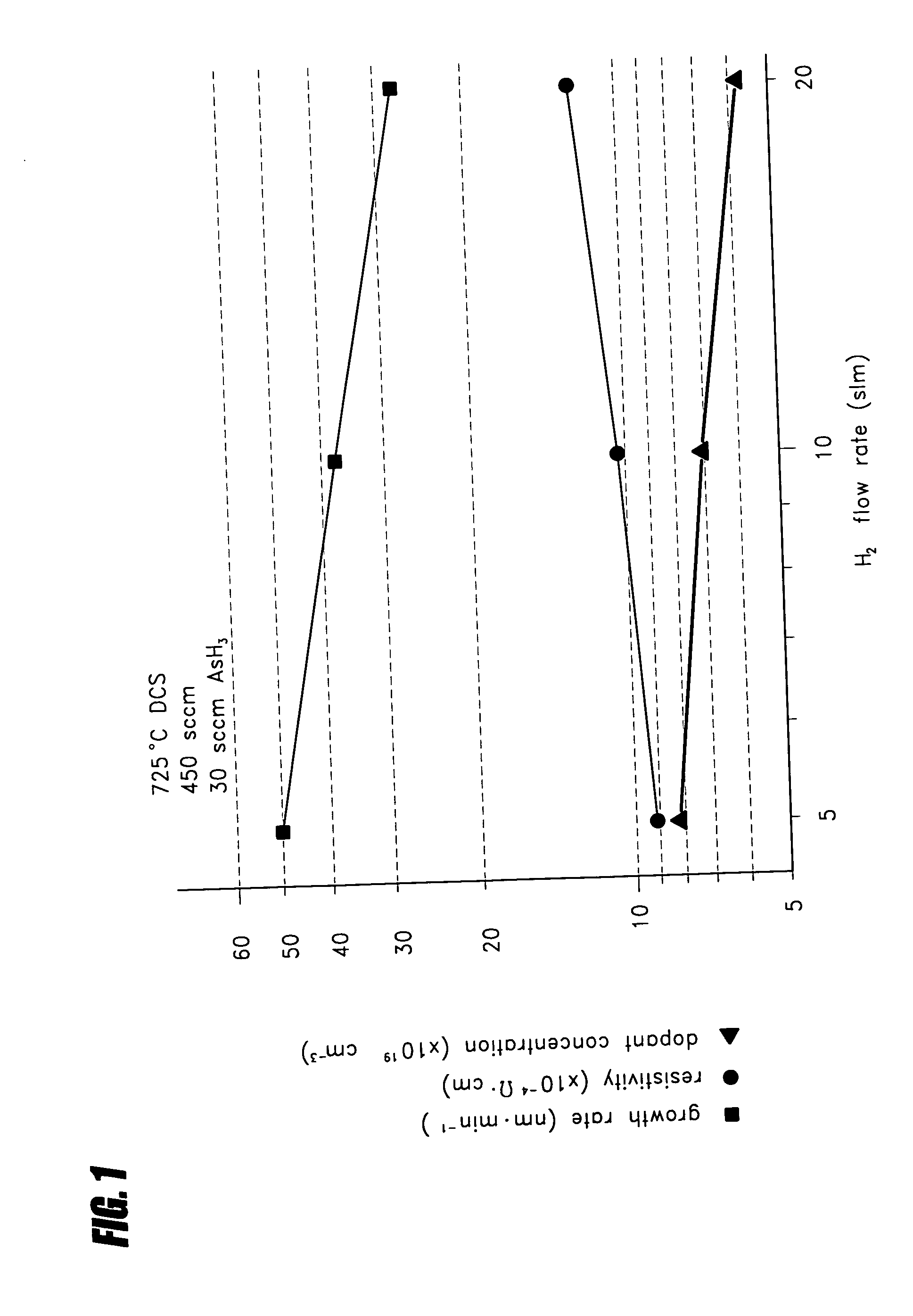

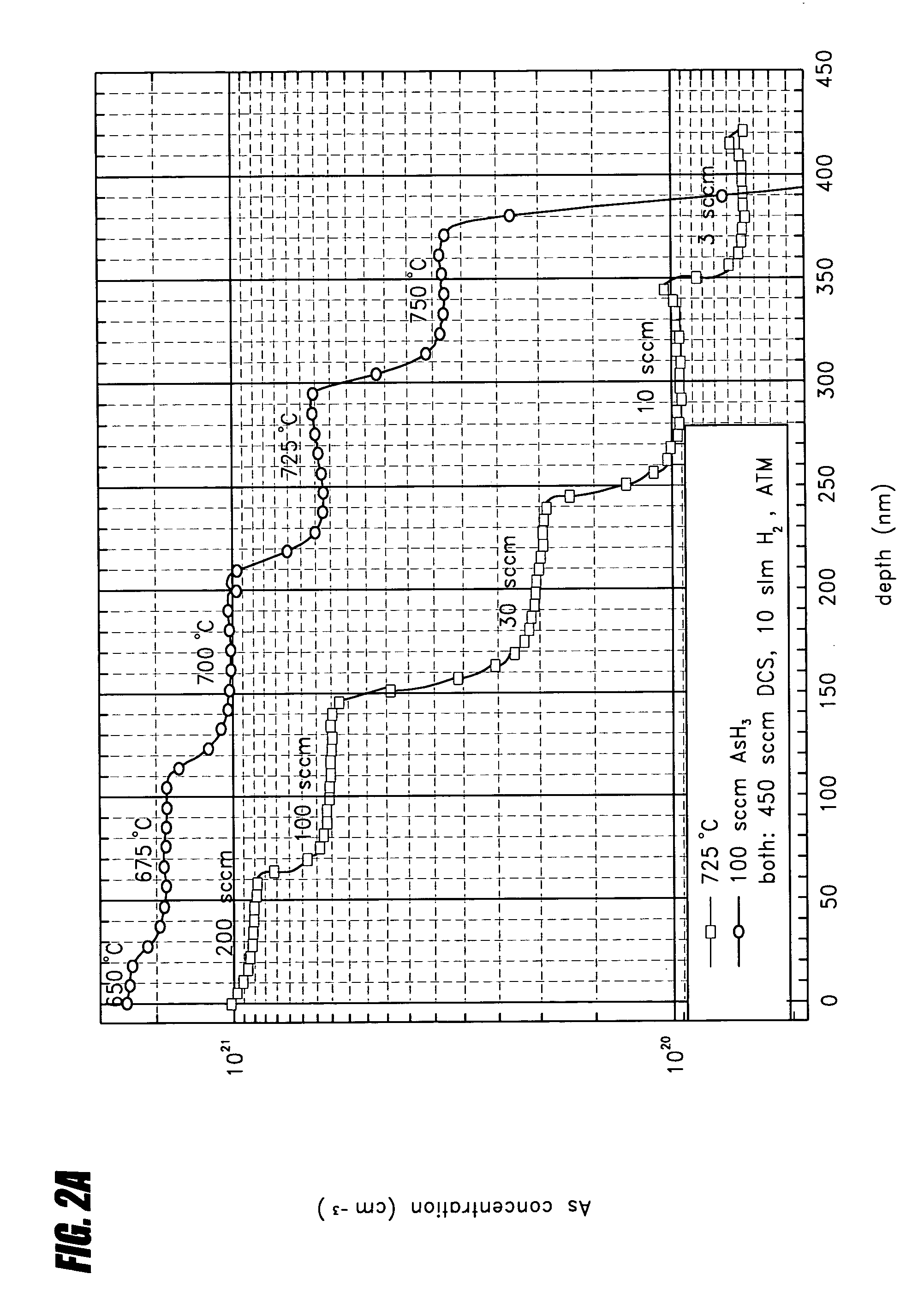

In situ doped epitaxial films

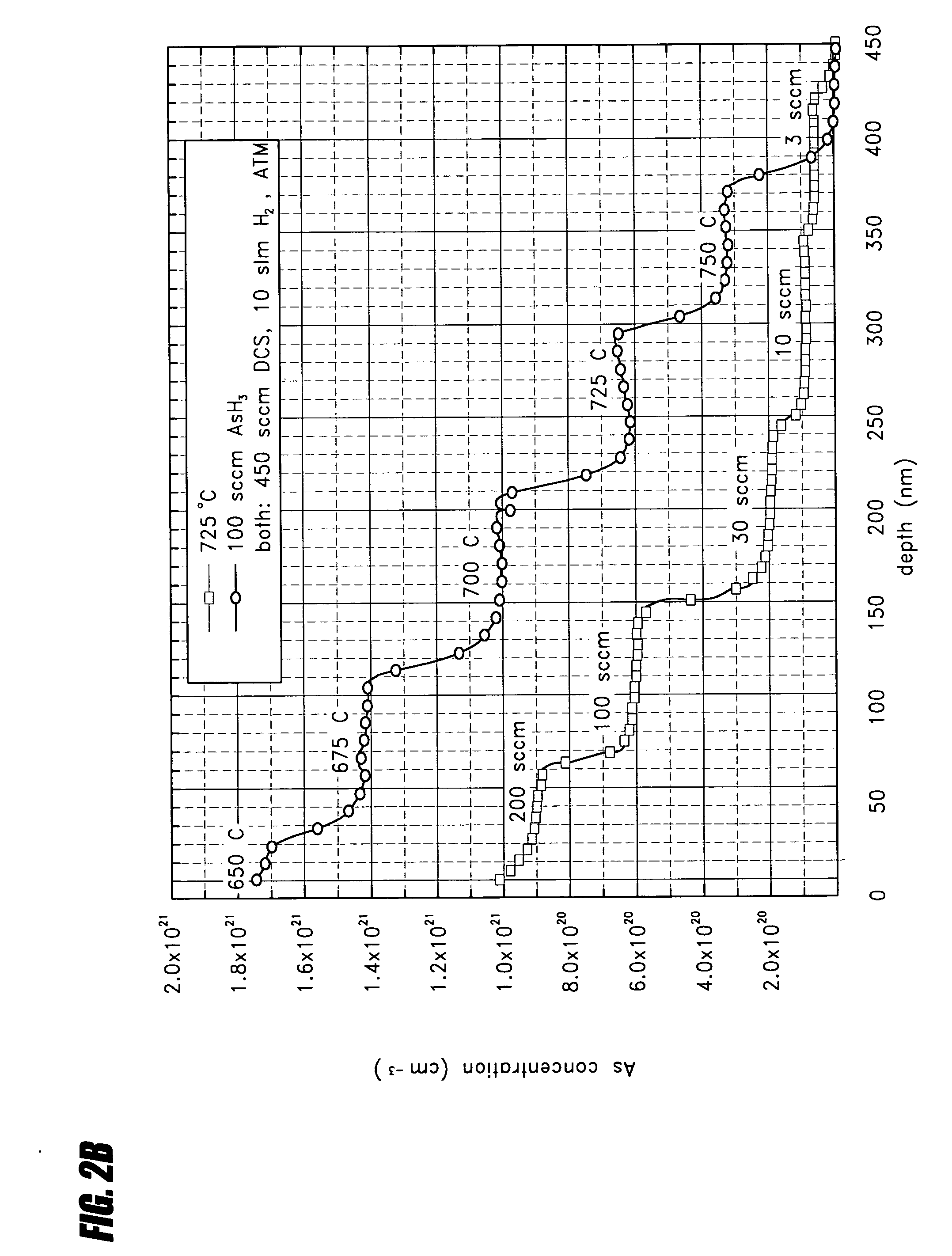

InactiveUS20050250298A1Slow deposition rateReduce the probability of depositionPolycrystalline material growthFrom solid stateDopantIn situ doping

A method for depositing an in situ doped epitaxial semiconductor layer comprises maintaining a pressure of greater than about 80 torr in a process chamber housing a patterned substrate. The method further comprises providing a flow of dichlorosilane to the process chamber. The method further comprises providing a flow of a dopant hydride to the process chamber. The method further comprises selectively depositing the epitaxial semiconductor layer on single crystal material on the patterned substrate at a rate of greater than about 3 nm min−1.

Owner:ASM AMERICA INC

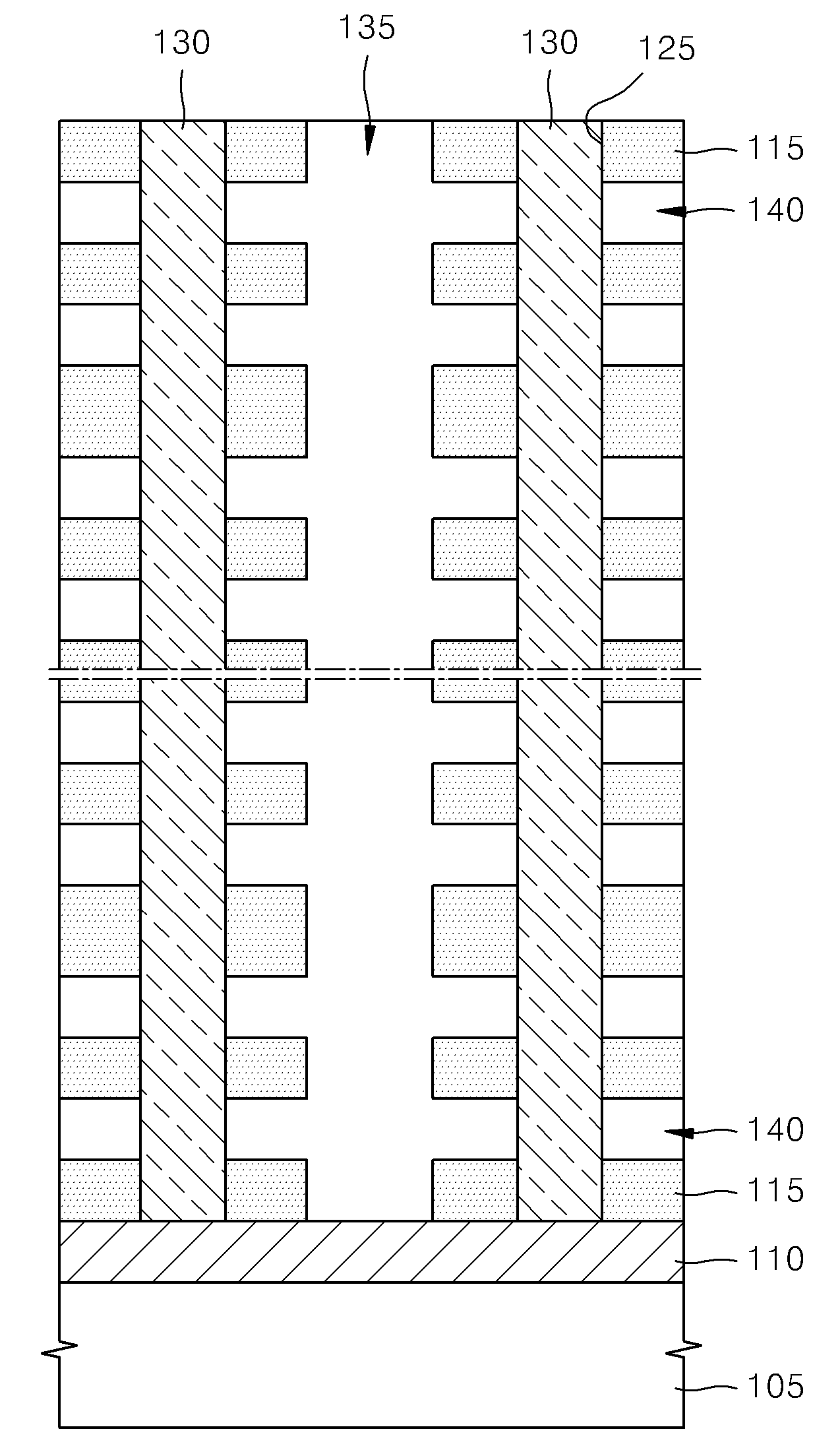

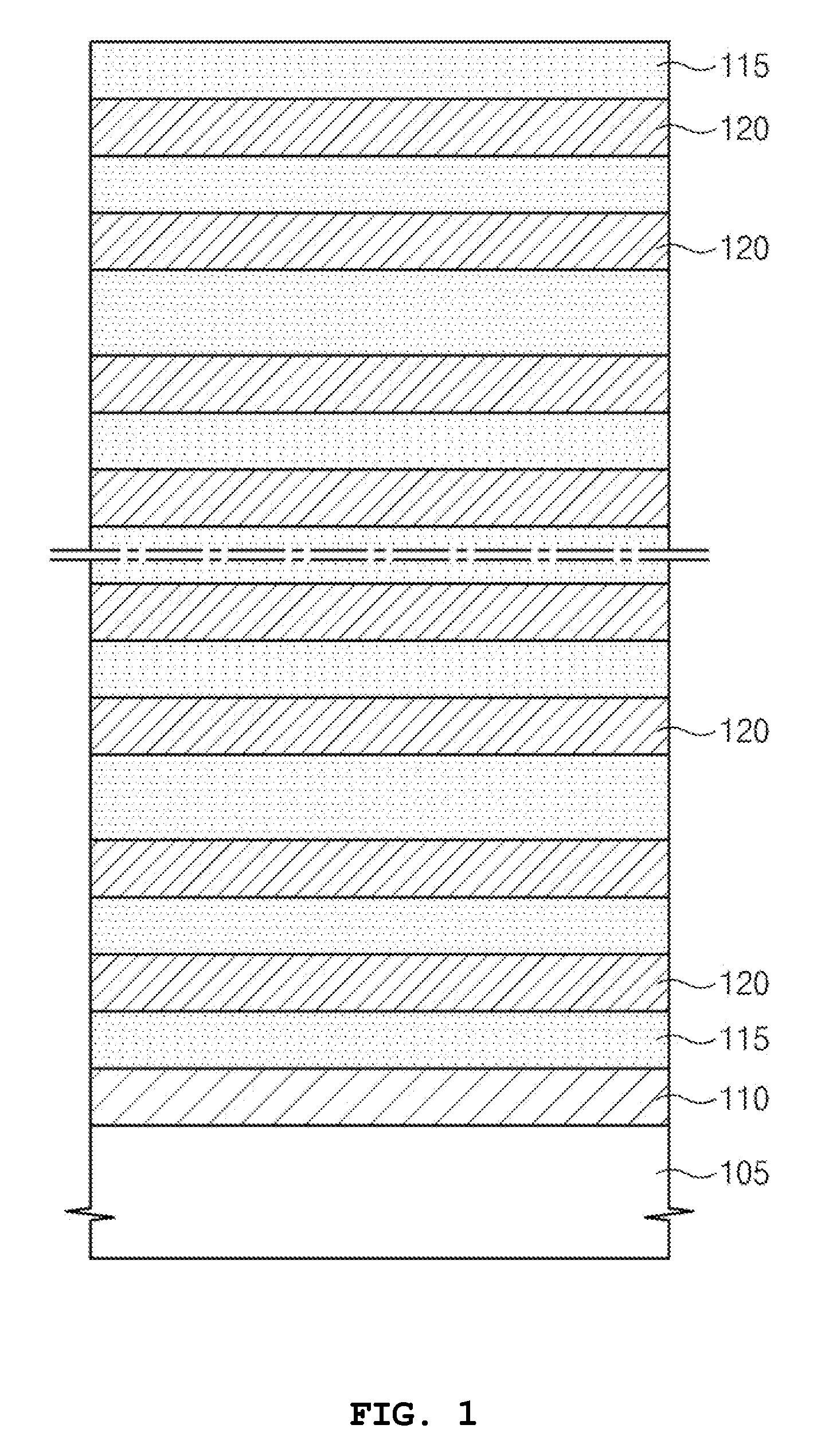

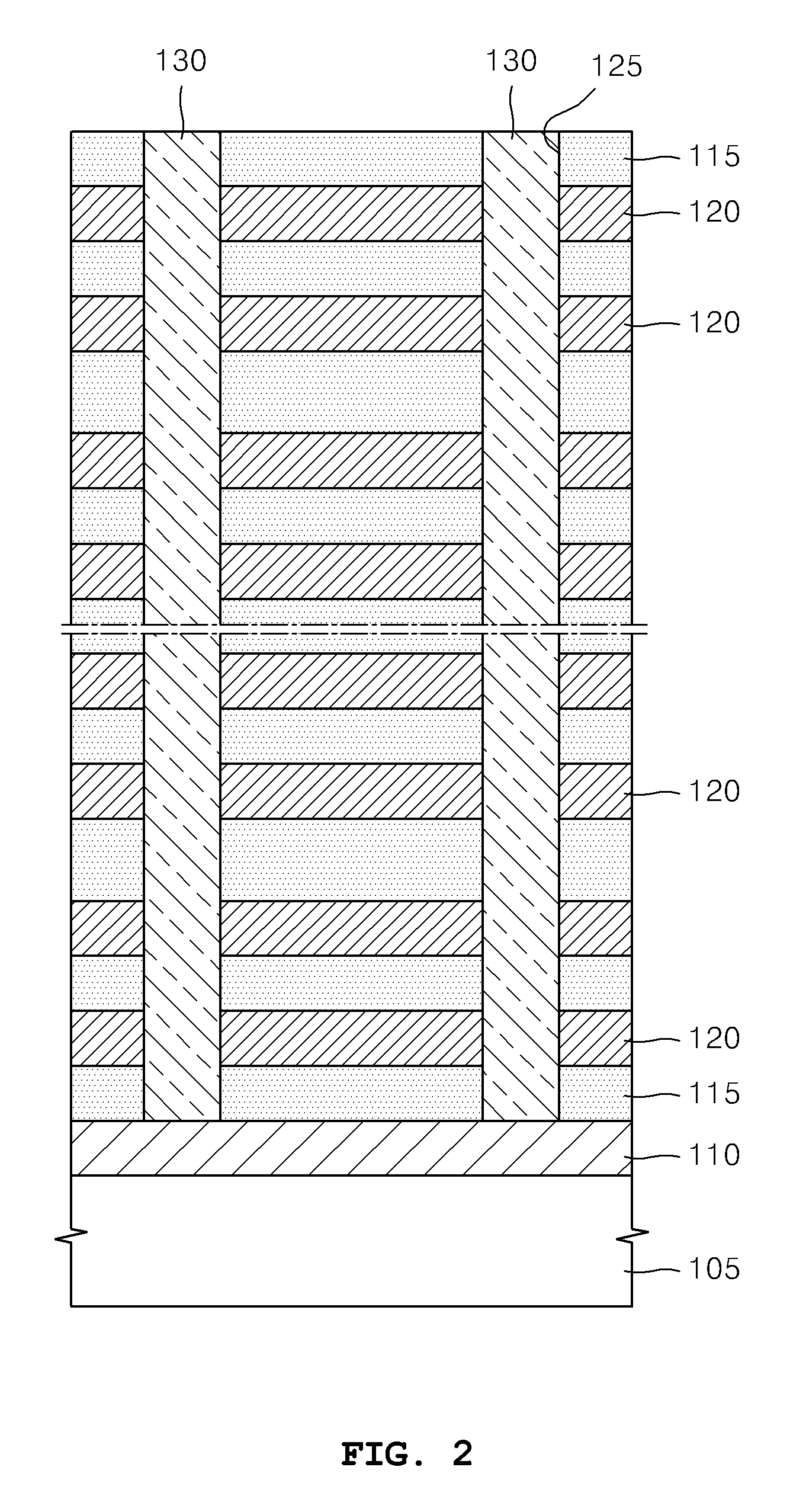

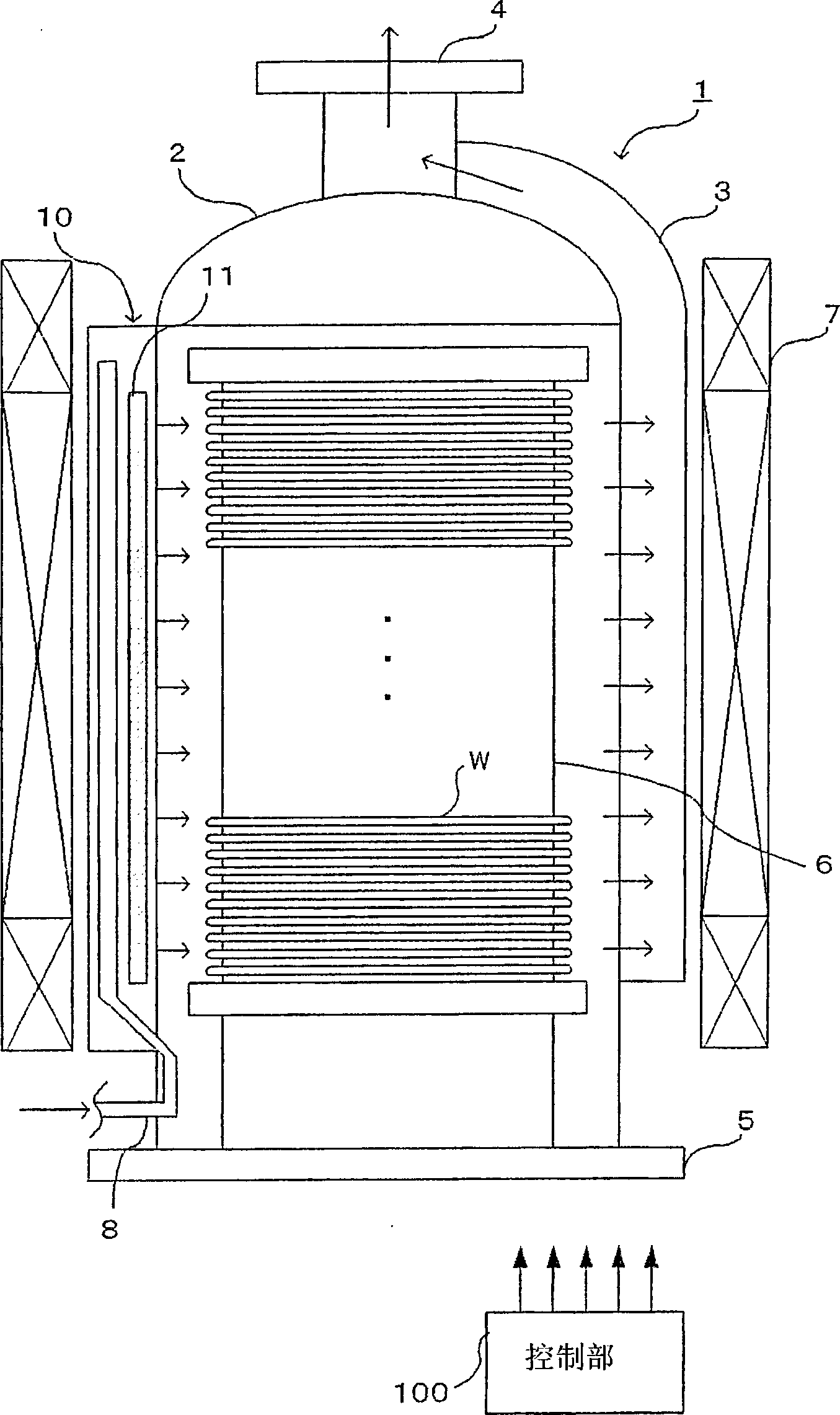

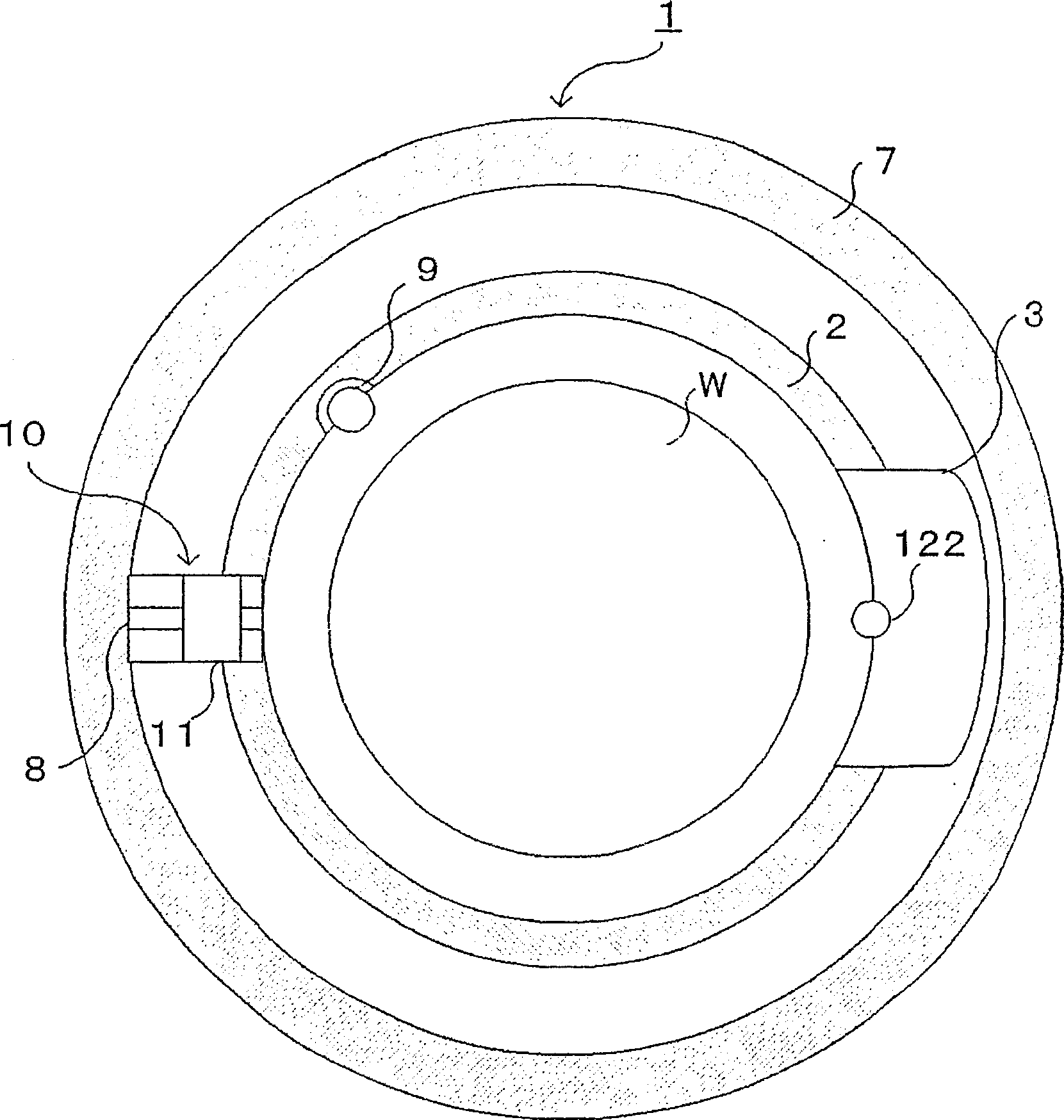

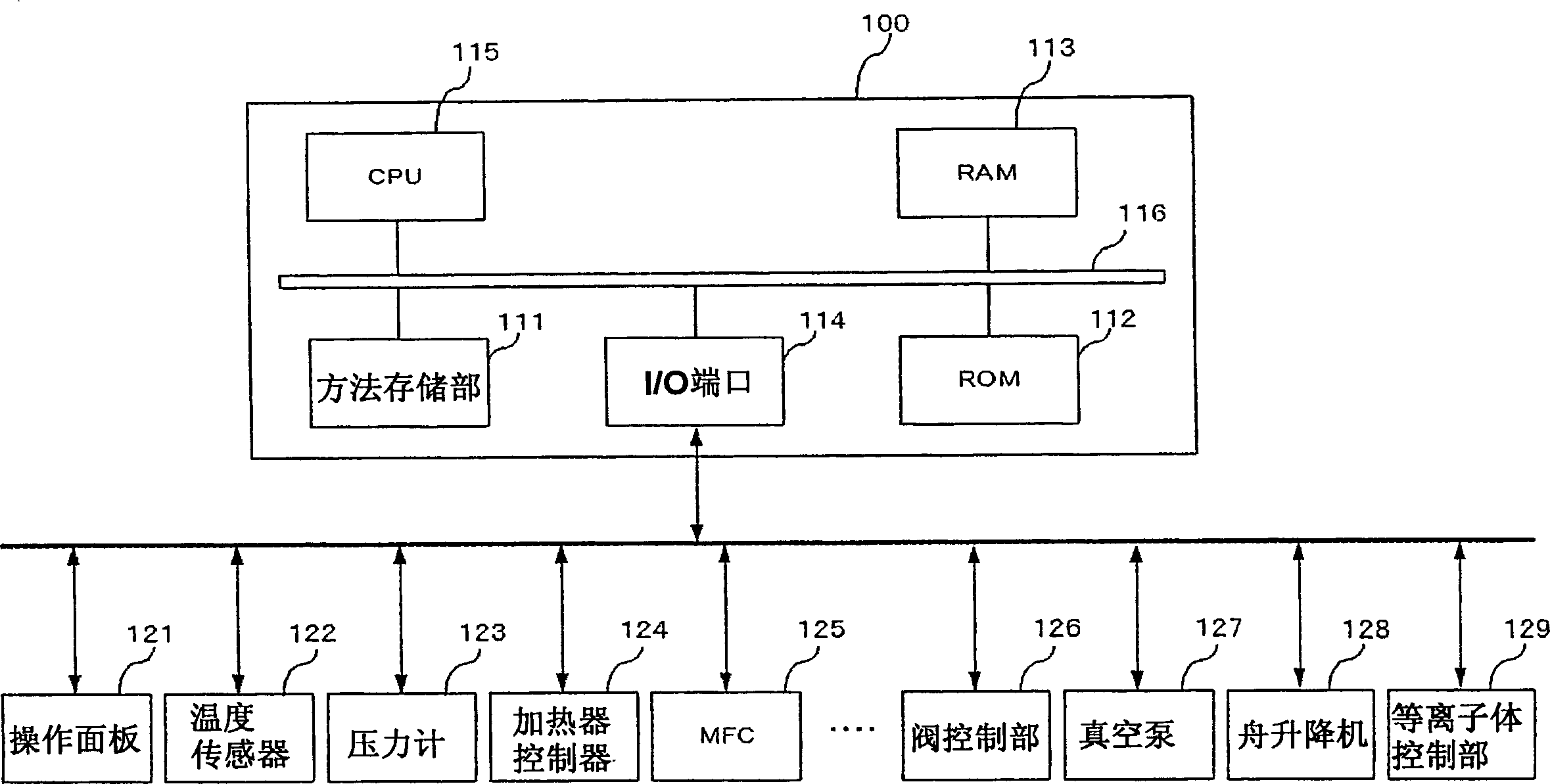

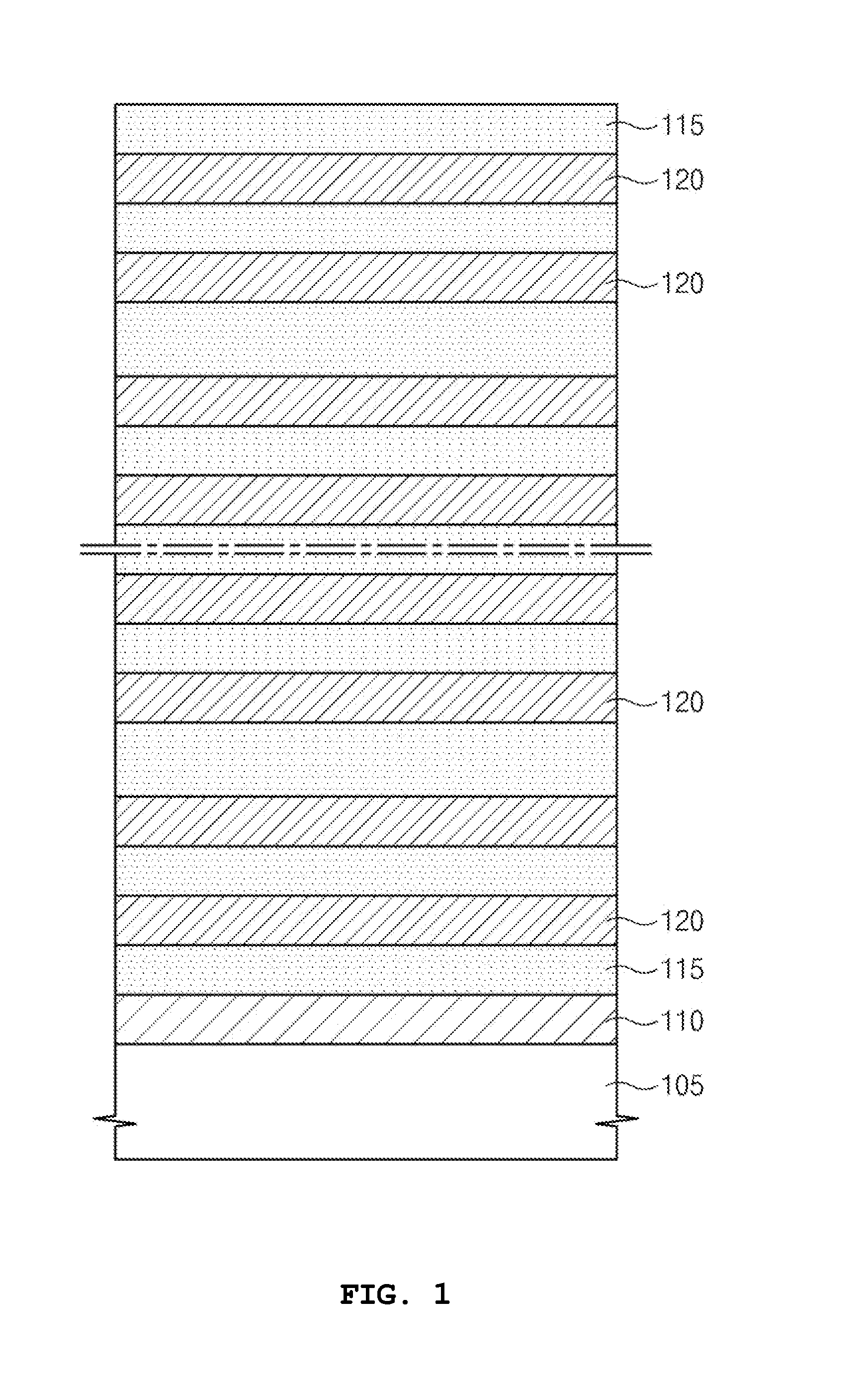

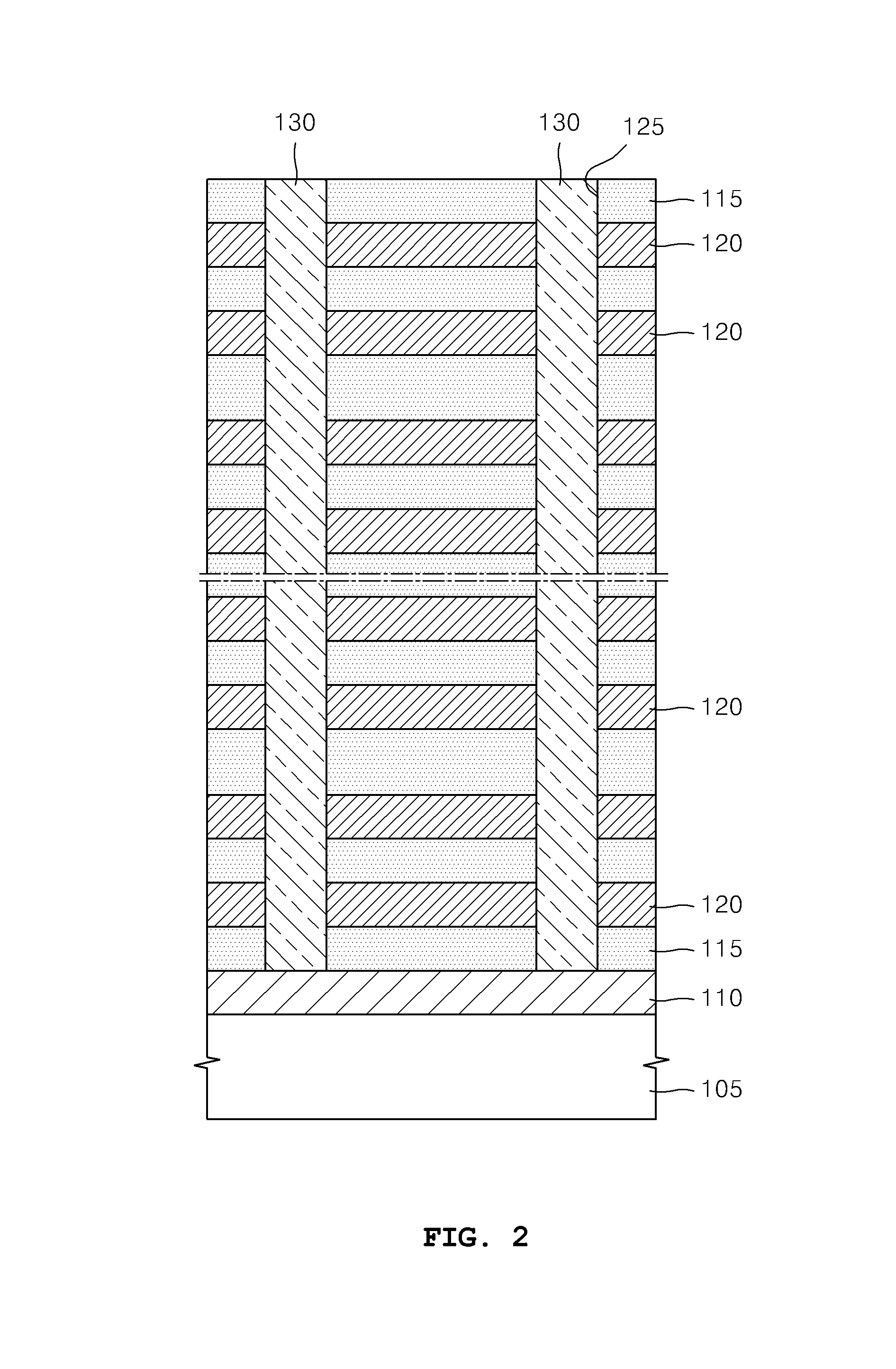

Method and apparatus for manufacturing three-dimensional-structure memory device

ActiveUS9425057B2Lower the volumeAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDichlorosilane

A method for manufacturing a memory device having a vertical structure according to one embodiment of the present invention comprises: a step for alternatingly laminating one or more insulation layers and one or more sacrificial layers on a substrate; a step for forming a penetration hole for penetrating the insulation layer and the sacrificial layer; a step for forming a pattern for filling up the penetration hole; a step for forming an opening for penetrating the insulation layer and the sacrificial layer; and a step for removing the sacrificial layer by supplying an etchant through the opening, wherein the step for laminating the insulation layer includes a step for depositing a first silicon oxide film by supplying to the substrate at least one gas selected from the group consisting of SiH4, Si2H6, Si3H8, Si4H10, and the step for laminating the sacrificial layer includes a step for depositing a second silicon oxide film by supplying dichlorosilane (SiCl2H2) to the substrate.

Owner:EUGENE TECH CO LTD

Formation of silicon nitride film by using atomic layer deposition method

ActiveCN1841676ALow wet etch rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical speciesDichlorosilane

Owner:TOKYO ELECTRON LTD

Method and apparatus for manufacturing three-dimensional-structure memory device

ActiveUS20130171827A1Lower the volumeAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon monoxide

A method for manufacturing a memory device having a vertical structure according to one embodiment of the present invention comprises: a step for alternatingly laminating one or more insulation layers and one or more sacrificial layers on a substrate; a step for forming a penetration hole for penetrating the insulation layer and the sacrificial layer; a step for forming a pattern for filling up the penetration hole; a step for forming an opening for penetrating the insulation layer and the sacrificial layer; and a step for removing the sacrificial layer by supplying an etchant through the opening, wherein the step for laminating the insulation layer includes a step for depositing a first silicon oxide film by supplying to the substrate at least one gas selected from the group consisting of SiH4, Si2H6, Si3H8, Si4H10, and the step for laminating the sacrificial layer includes a step for depositing a second silicon oxide film by supplying dichlorosilane (SiCl2H2) to the substrate.

Owner:EUGENE TECH CO LTD

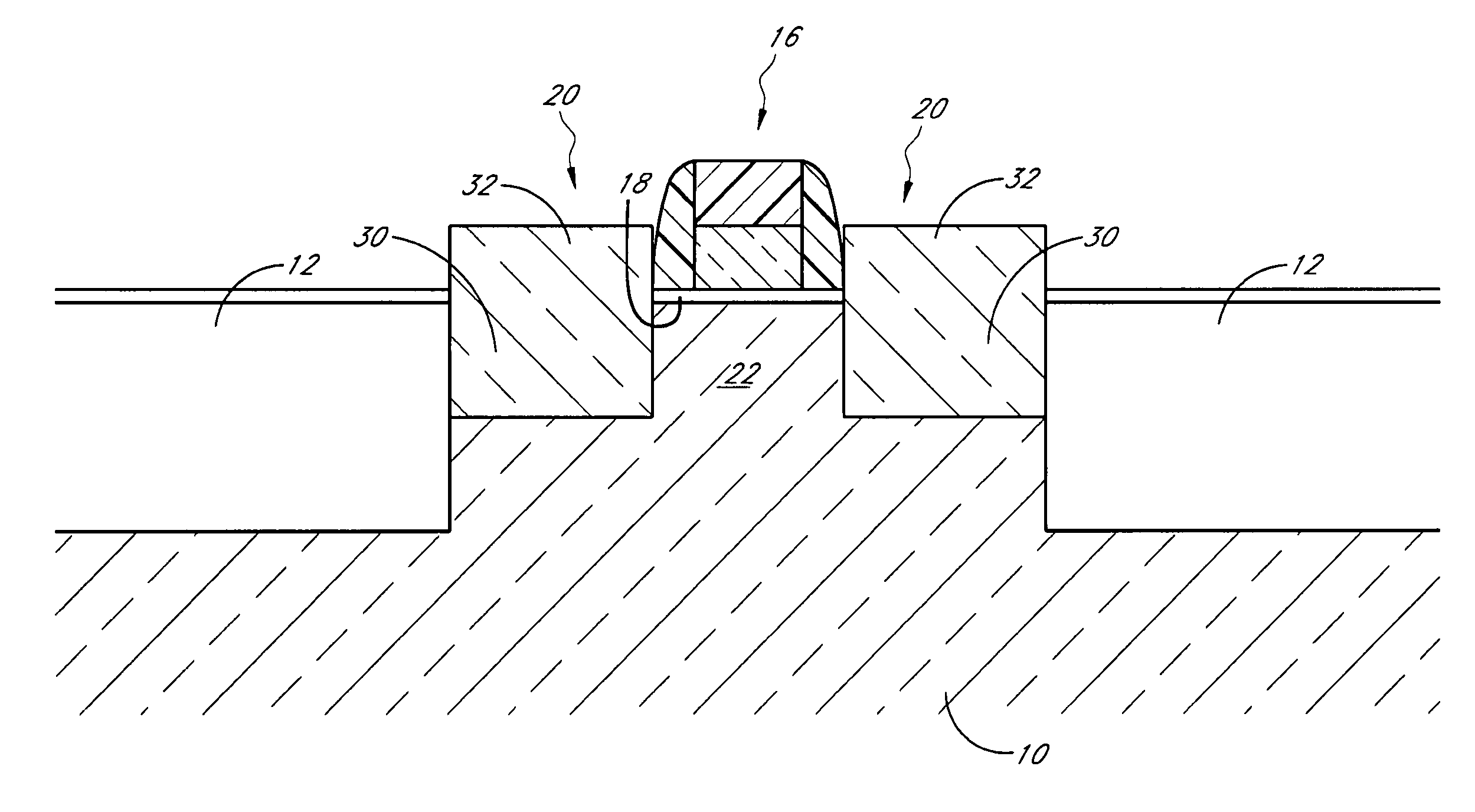

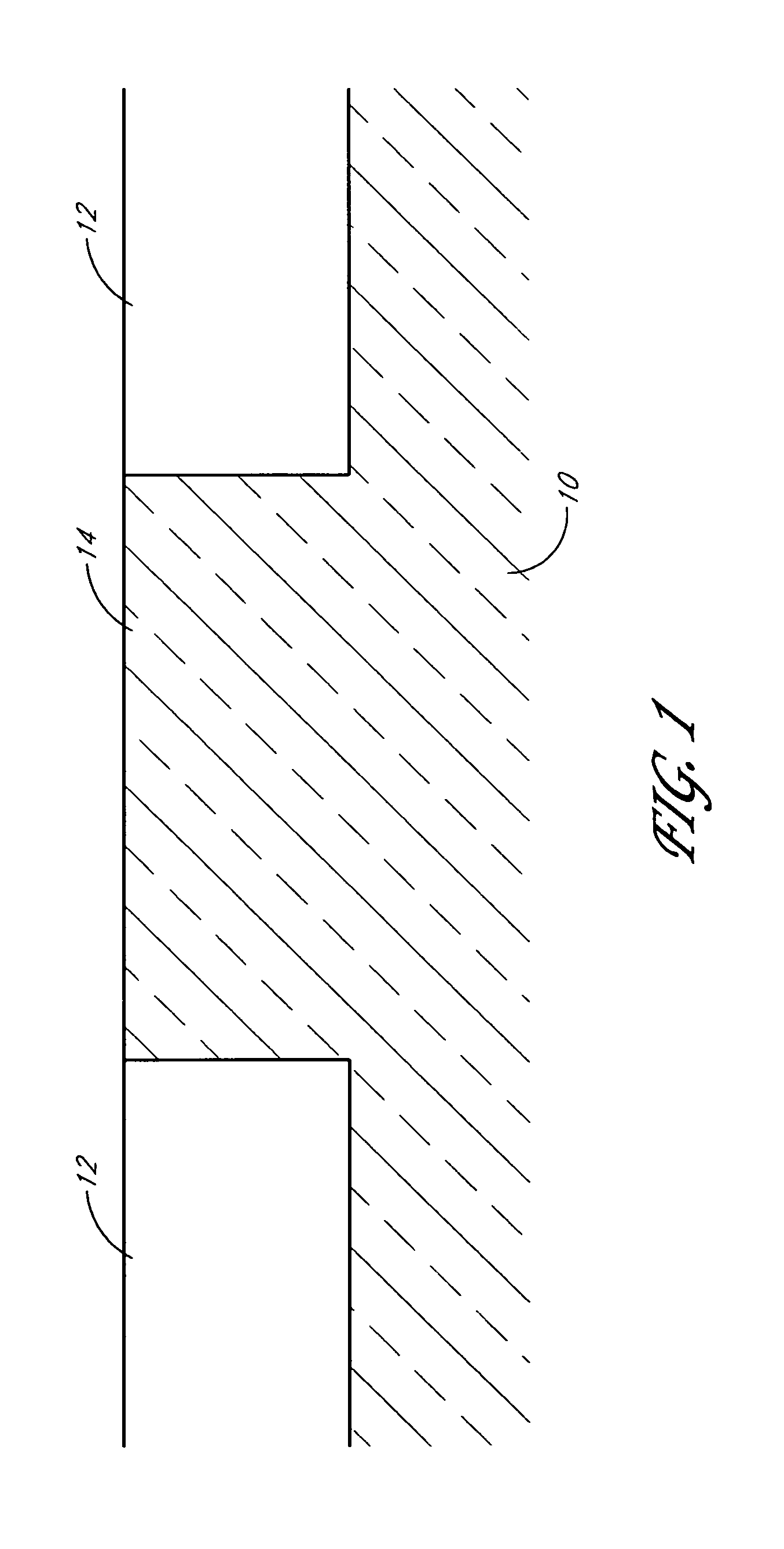

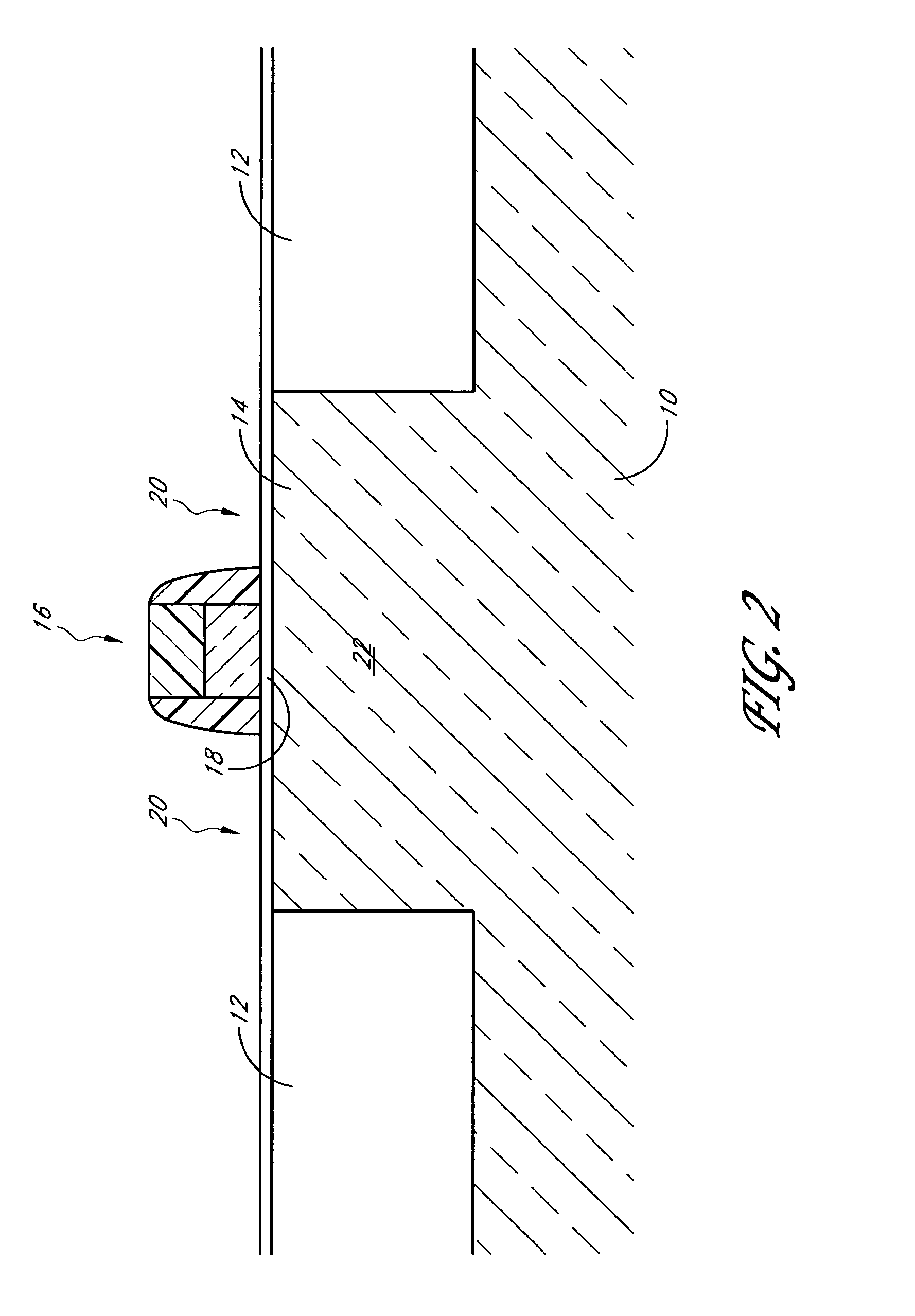

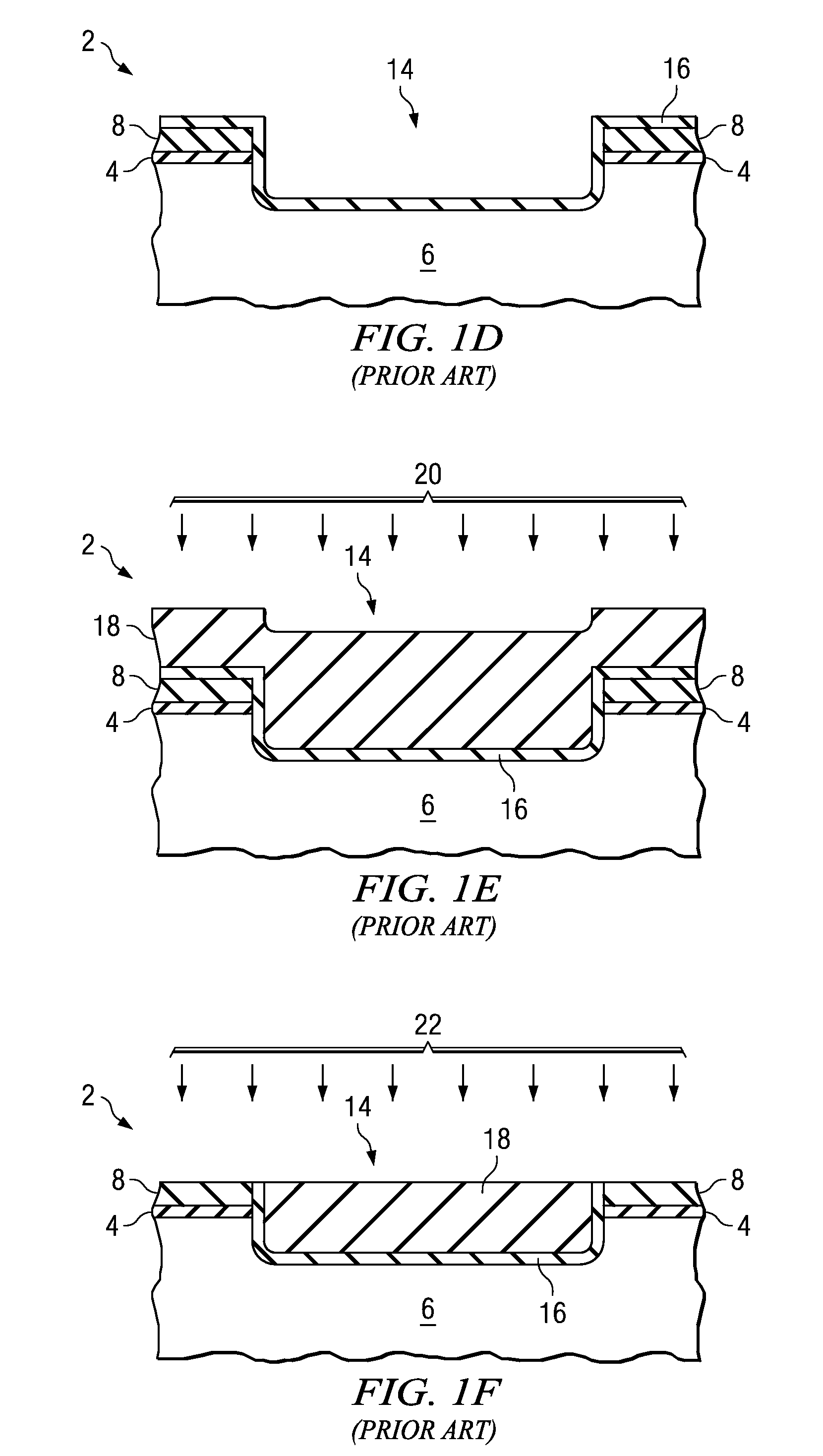

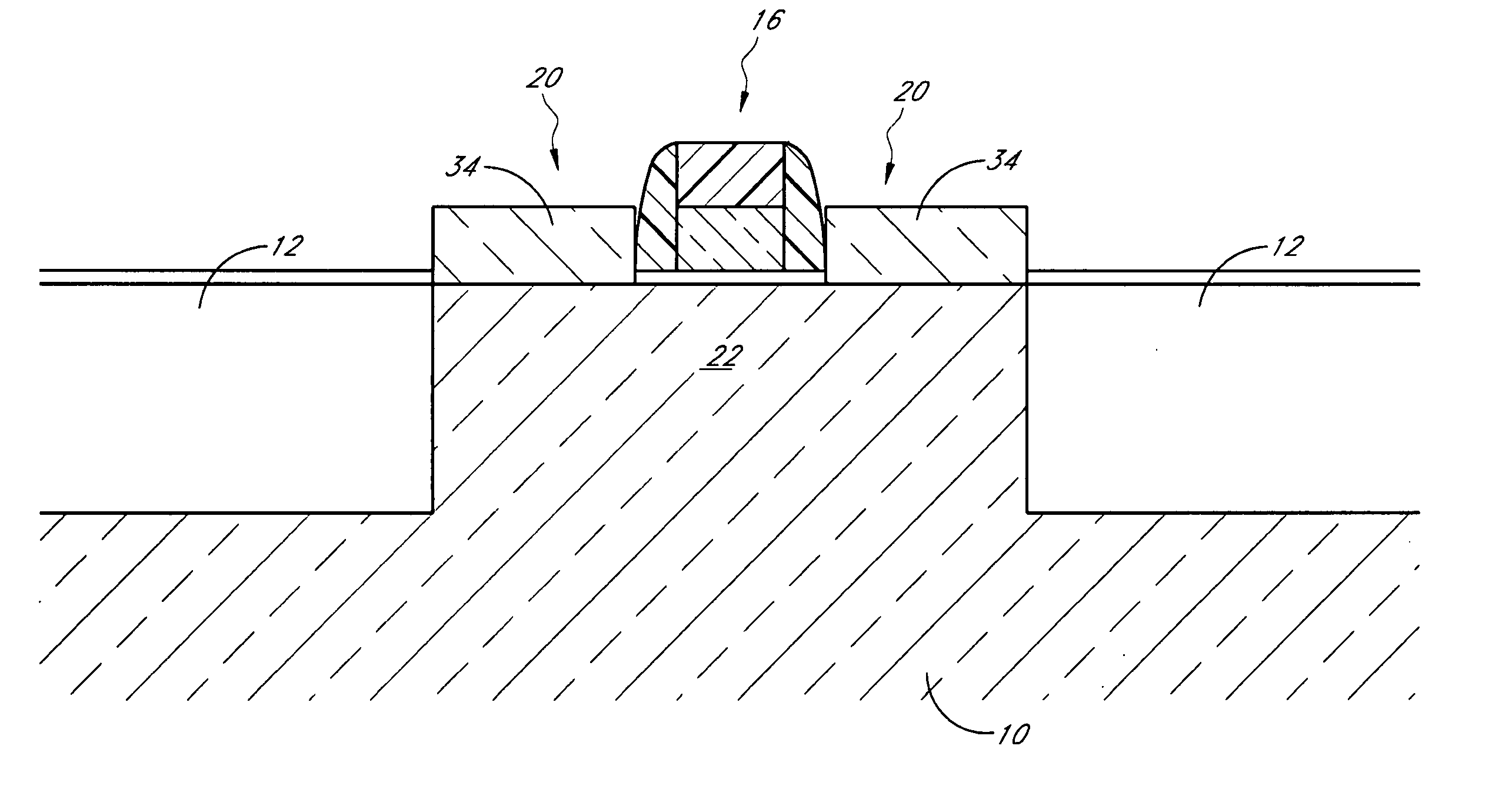

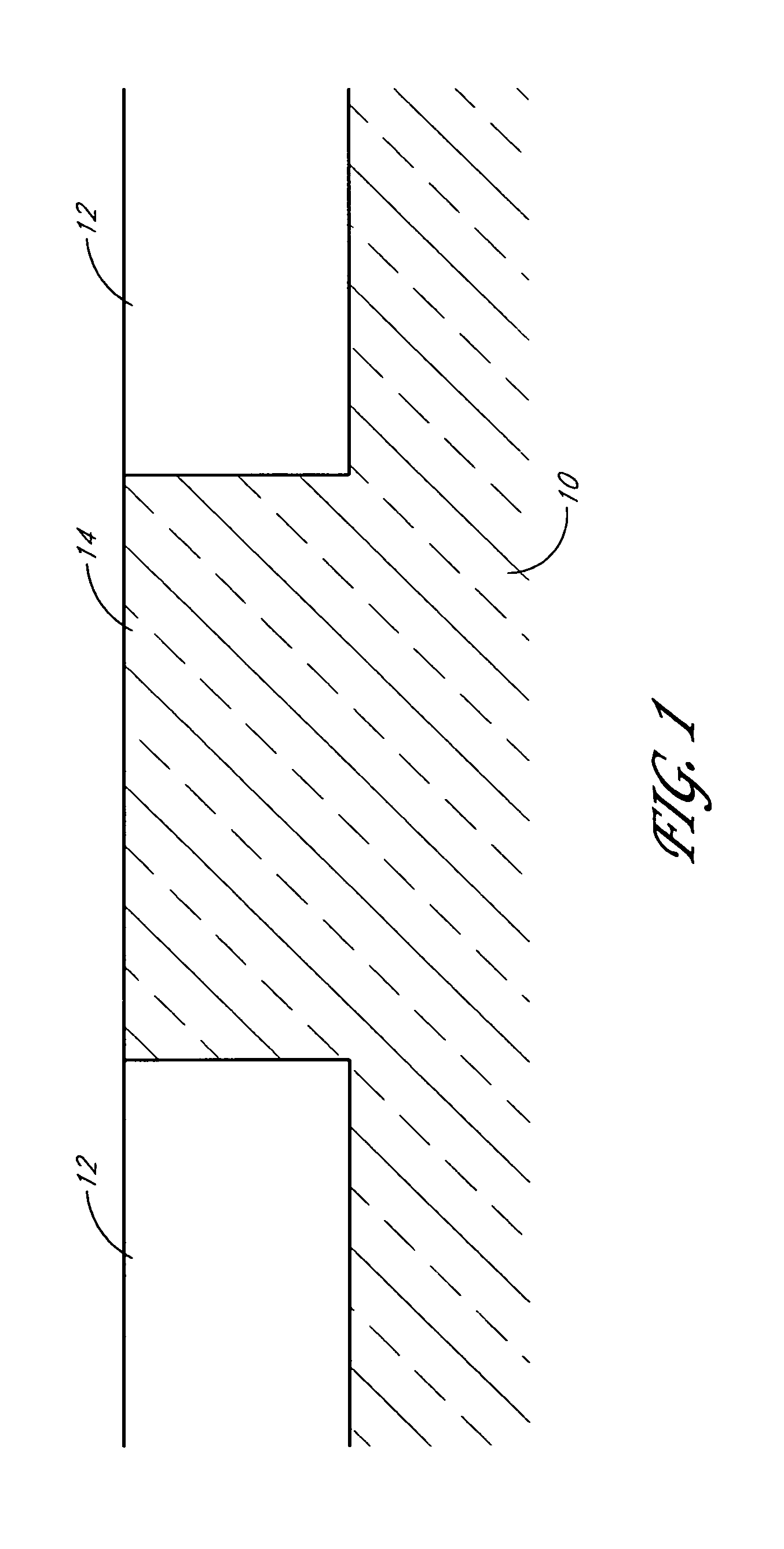

Highly selective liners for semiconductor fabrication

A method for manufacturing an isolation structure is disclosed that protects the isolation structure during etching of a dichlorosilane (DCS) nitride layer. The method involves the formation of a bis-(t-butylamino)silane-based nitride liner layer within the isolation trench, which exhibits a five-fold greater resistance to nitride etching solutions as compared with DCS nitride, thereby allowing protection against damage from unintended over-etching. The bis-(t-butylamino)silane-based nitride layer also exerts a greater tensile strain on moat regions that results in heightened carrier mobility of active regions, thereby increasing the performance of NMOS transistors embedded therein.

Owner:TEXAS INSTR INC

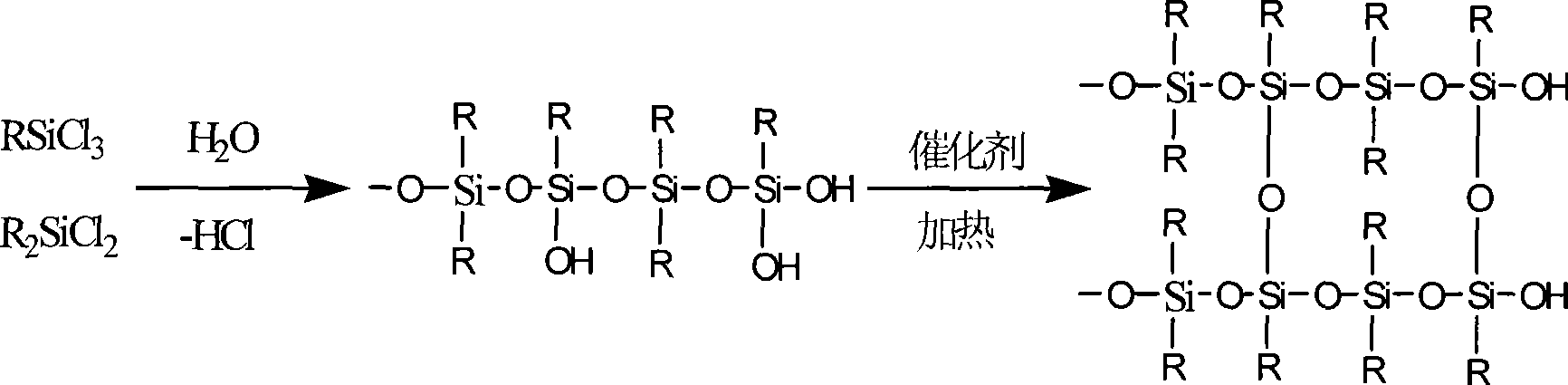

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

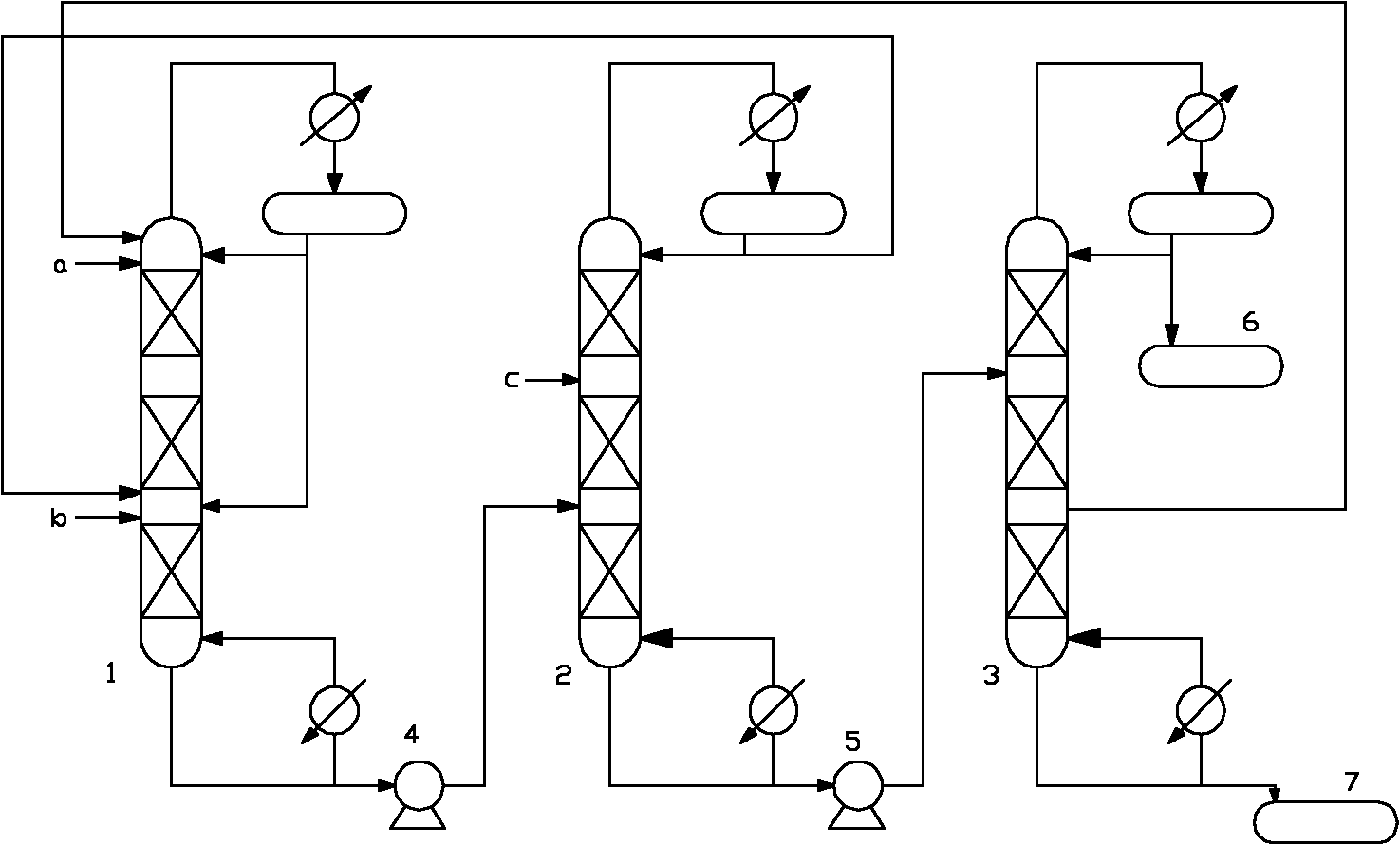

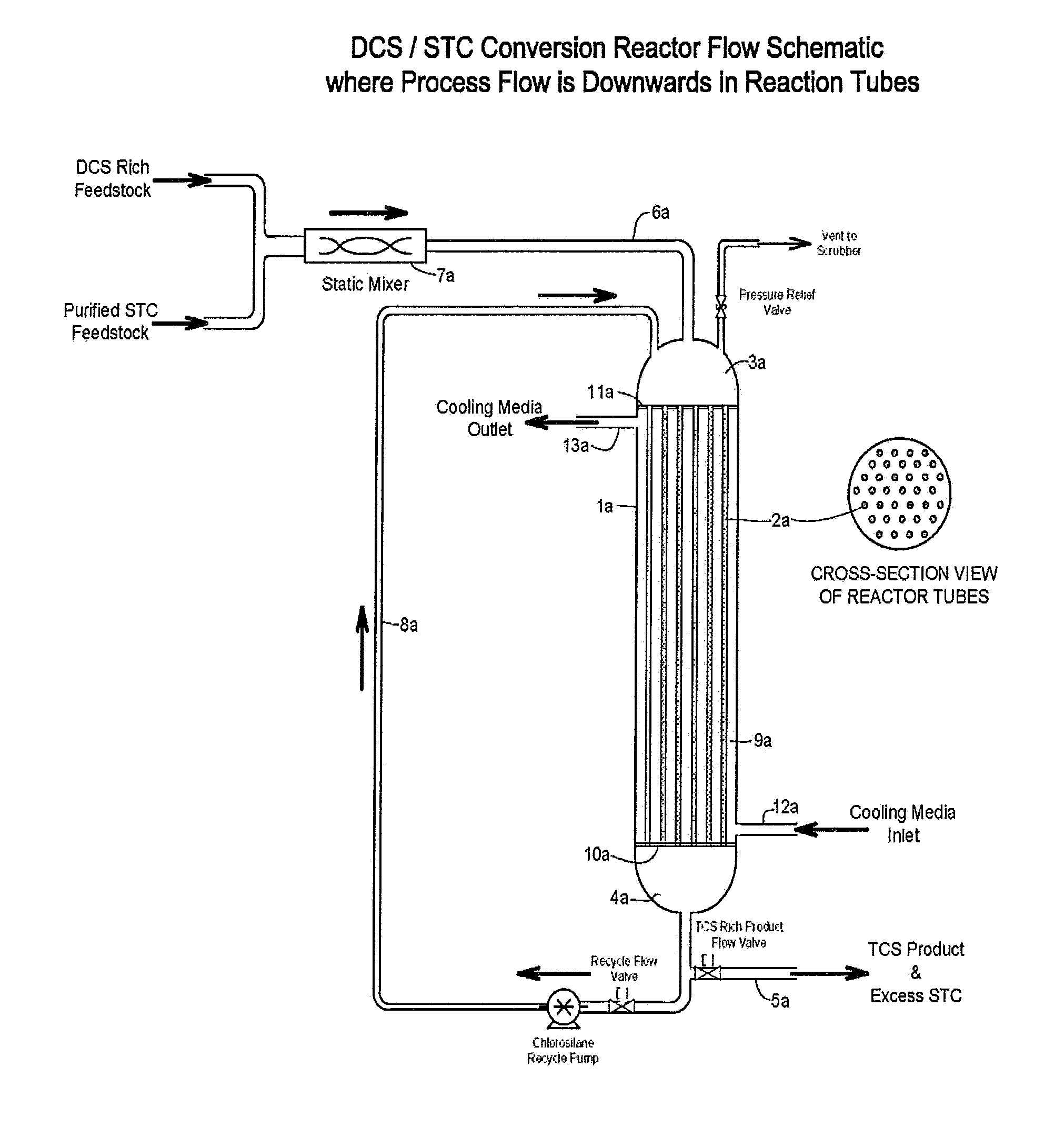

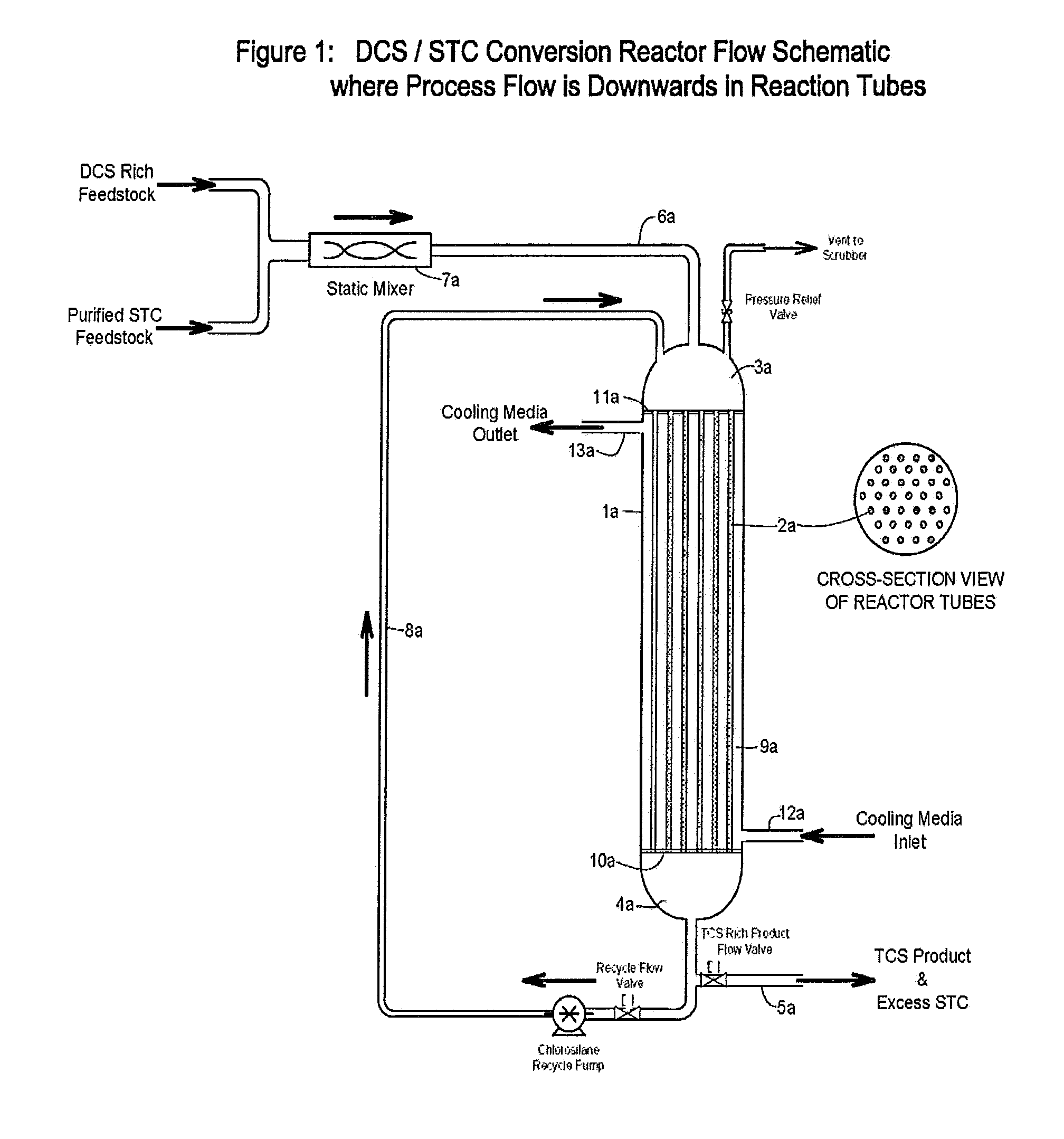

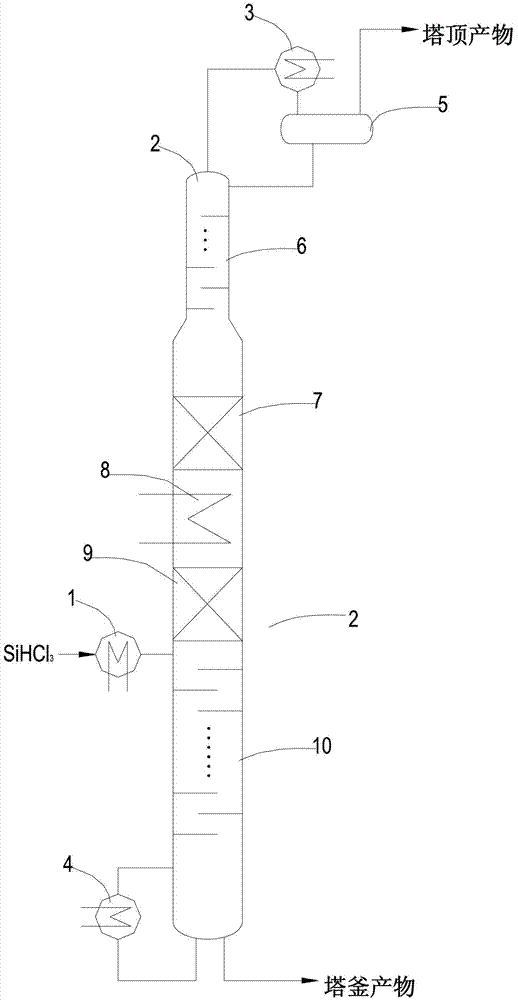

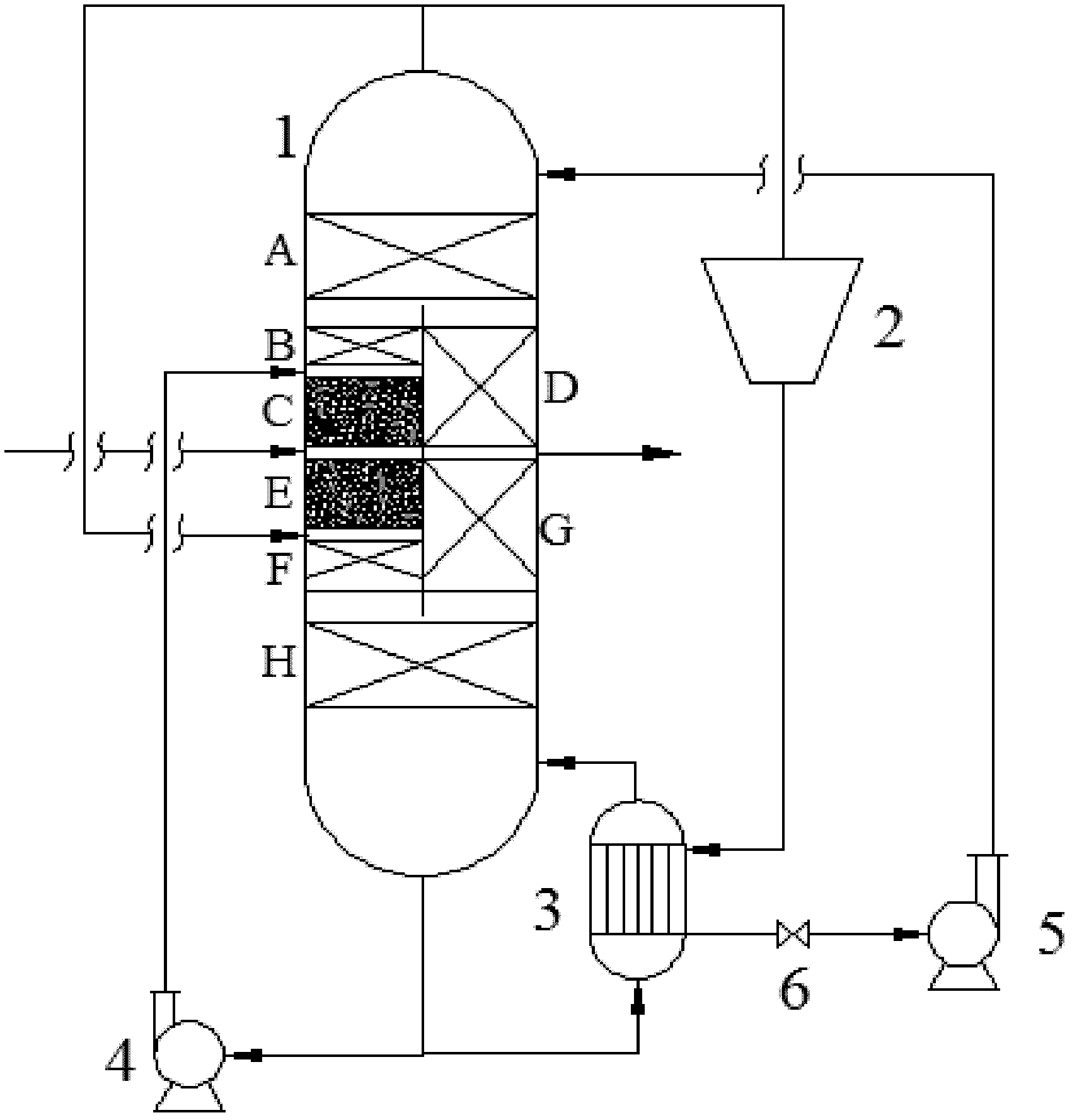

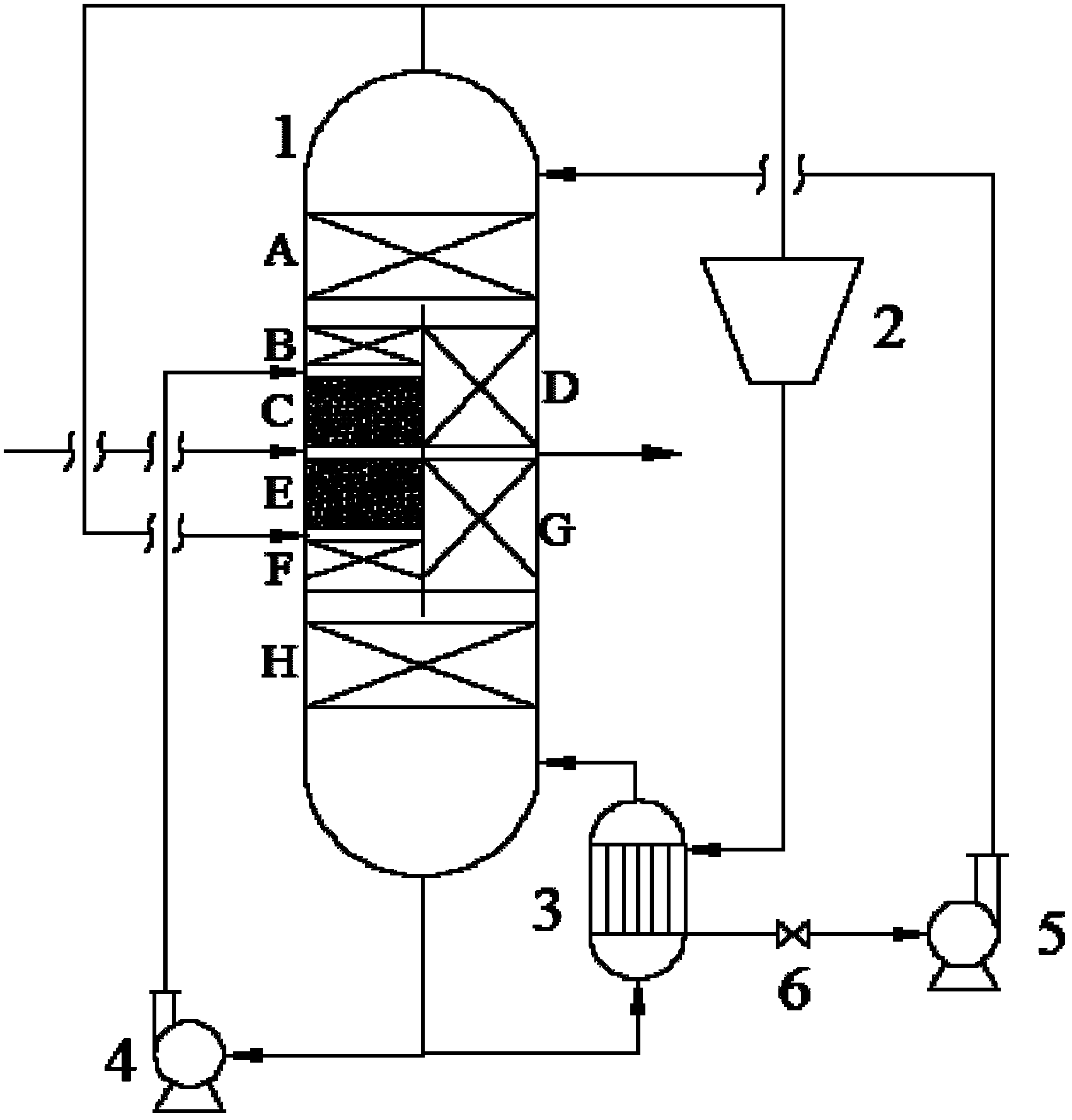

Method and apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction

ActiveCN101955187AResolve enrichmentIncrease profitChemical industryHalogenated silanesDichlorosilaneTower

The invention relates to a method and an apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction. The method comprises the following steps of: reacting dichlorosilane with silicon tetrachloride in the upper middle part of a reaction rectification tower, obtaining incompletely reacted dichlorosilane at the top of the reaction rectification tower; reflowing at the top of the tower and in the middle of the tower, obtaining a mixture of dichlorosilane, trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a light-end removal tower to remove a light component, obtaining the dichlorosilane at the top of the light-end removal tower; reflowing to the reaction rectification tower for recycling, obtaining a mixture of trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a heavy-end removal tower to separate the trichlorosilane from the silicon tetrachloride, wherein the trichlorosilane at the top of the heavy-end removal tower is a product; and taking out the silicon tetrachloride at the side line of the lower part of the tower, entering the reaction rectification tower for recycling, and obtaining excessive silicon tetrachloride at the bottom of the tower. In the invention, by utilizing the proportionate reaction, the utilization ratio of the raw materials is enhanced; the problem of dichlorosilane and silicon tetrachloride enrichment is solved; and the final conversion ratio of the dichlorosilane is ensured to reach 100 percent theoretically.

Owner:TIANJIN UNIV

Process for producing trichlorosilane

InactiveUS20090060819A1Reduce kilogramLower requirementChemical/physical/physico-chemical stationary reactorsMetal/metal-oxides/metal-hydroxide catalystsBoiling pointDichlorosilane

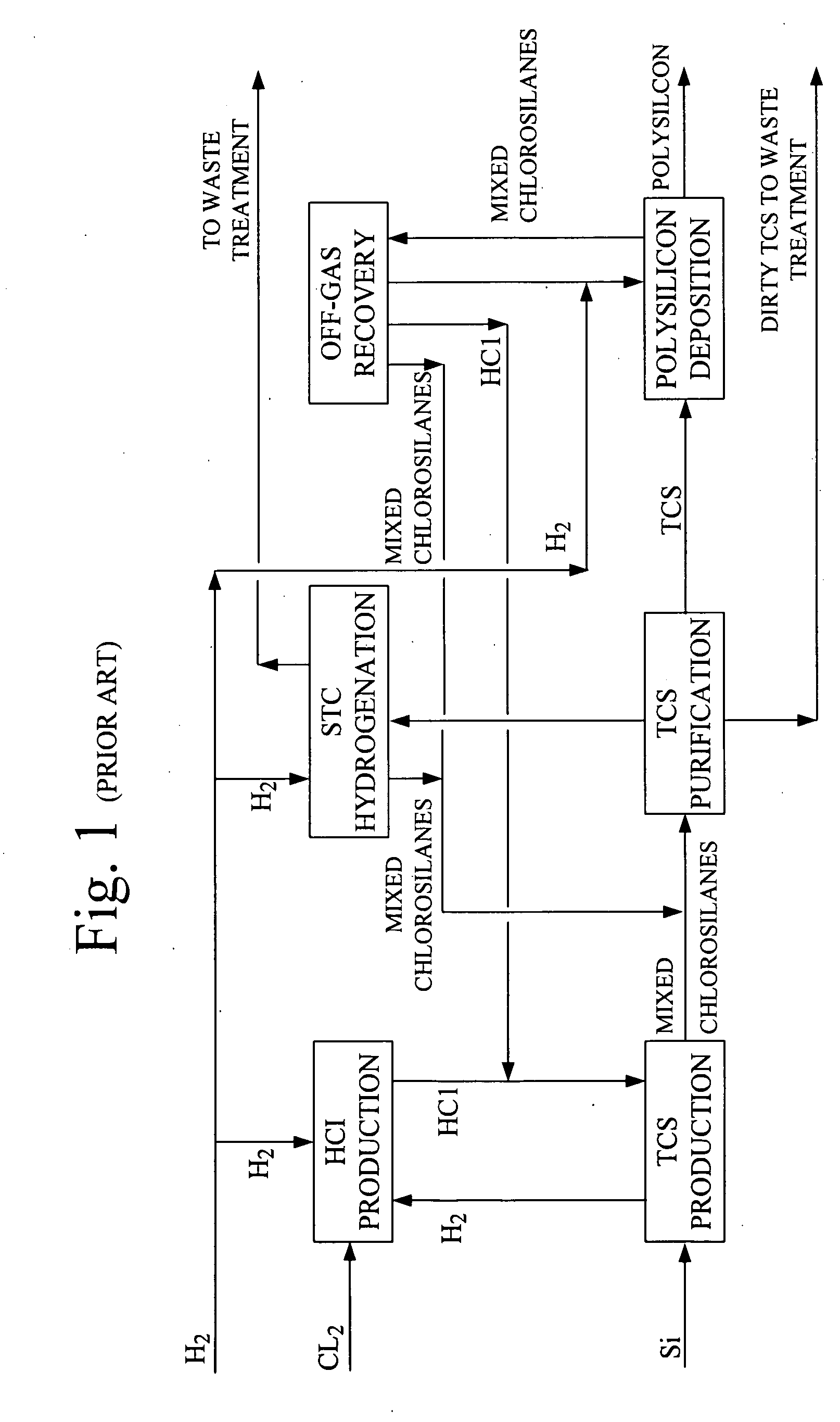

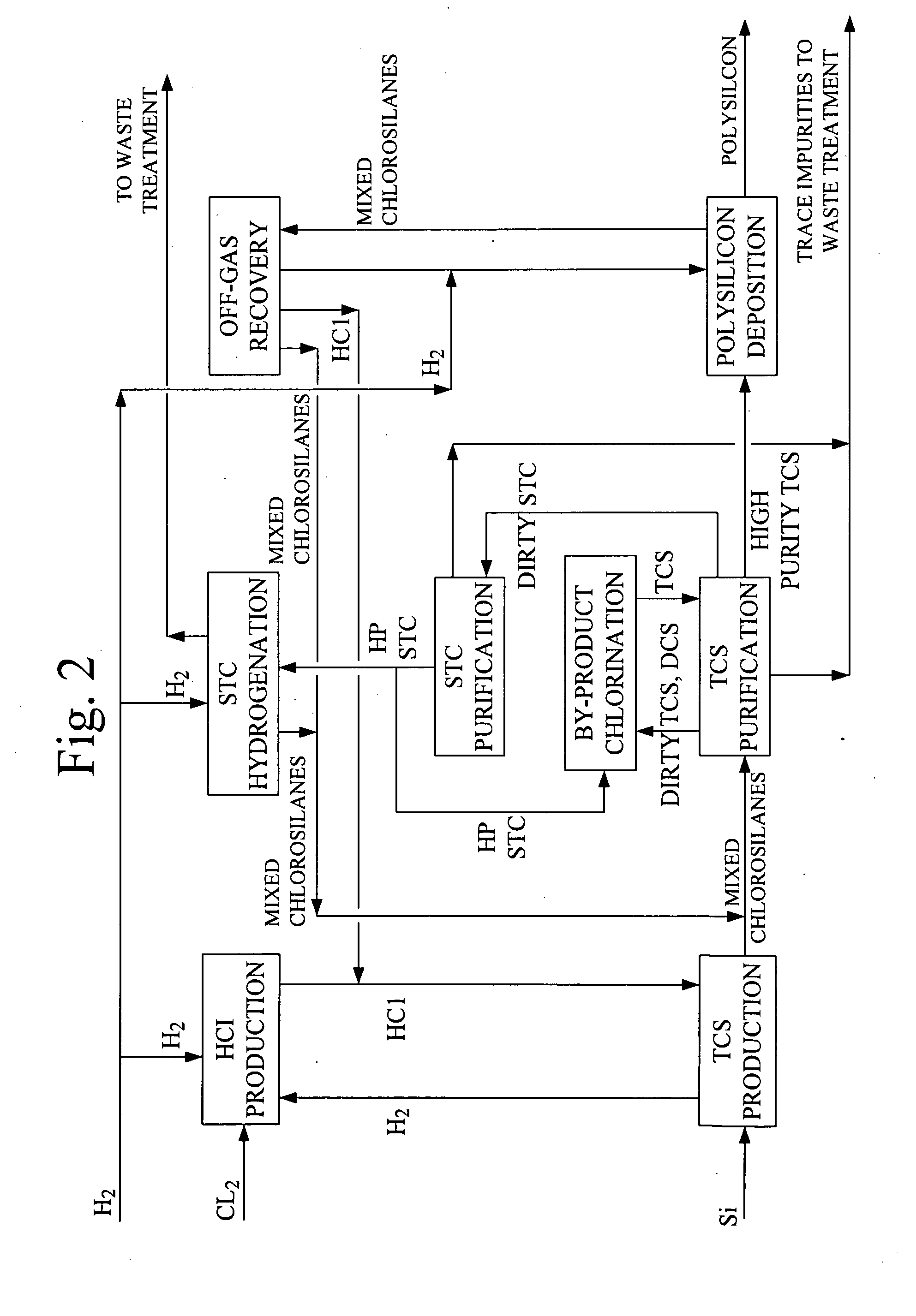

A process for preparing high purity trichlorosilane (TCS) utilizing contaminated by-products of primary reaction products hydrogen chloride, metallurgical or chemical grade silicon stock, and / or by-products of the improved Siemens process, including “dirty” TCS containing low boiling impurities such as dichlorosilane (DCS) and “dirty” STC containing high boiling impurities. The “dirty” STC is first purified and a portion is reacted with “dirty” TCS containing DCS to produce additional TCS feedstock for the TCS purification process. Another portion of the purified STC is hydrogenated and converted back to TCS providing another feedstock to the TCS purification process. Overall net yield of high purity TCS produced is increased over established practice.

Owner:DYNAMIC ENG

Epitaxial deposition of doped semiconductor materials

ActiveUS20070161216A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsDichlorosilane

A method for depositing a carbon doped epitaxial semiconductor layer comprises maintaining a pressure of greater than about 700 torr in a process chamber housing a patterned substrate having exposed single crystal material. The method further comprises providing a flow of a silicon source gas to the process chamber. The silicon source gas comprises dichlorosilane. The method further comprises providing a flow of a carbon precursor to the process chamber. The method further comprises selectively depositing the carbon doped epitaxial semiconductor layer on the exposed single crystal material.

Owner:ASM IP HLDG BV

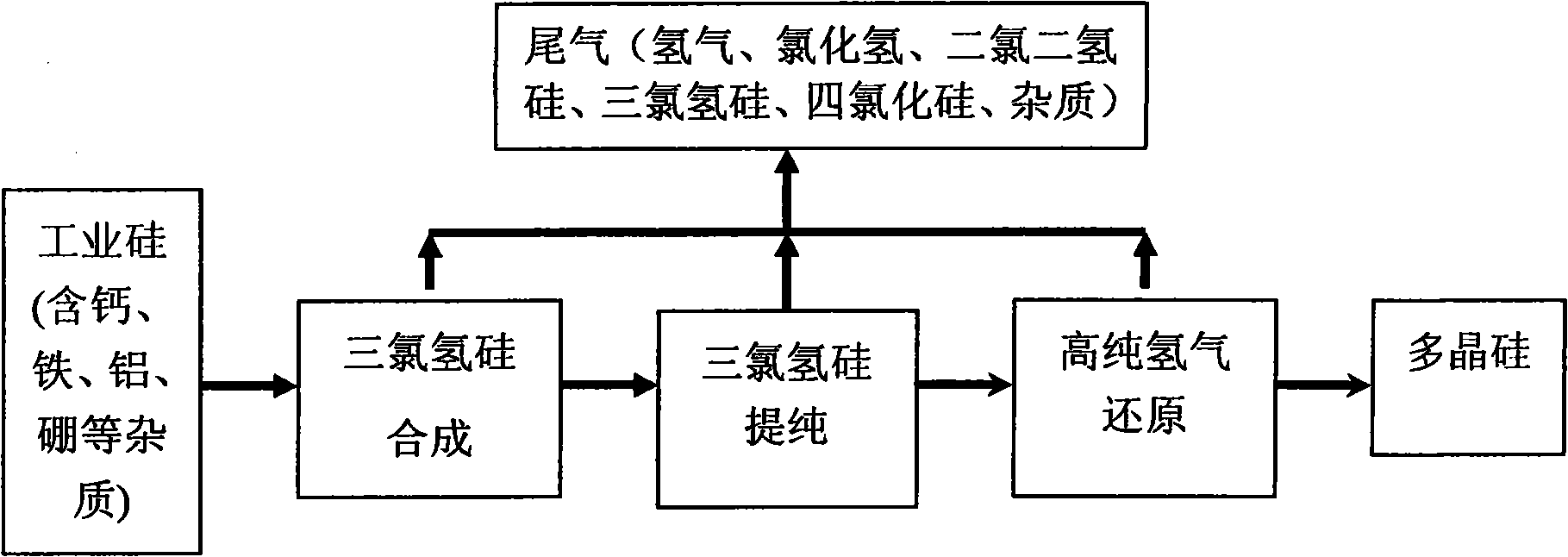

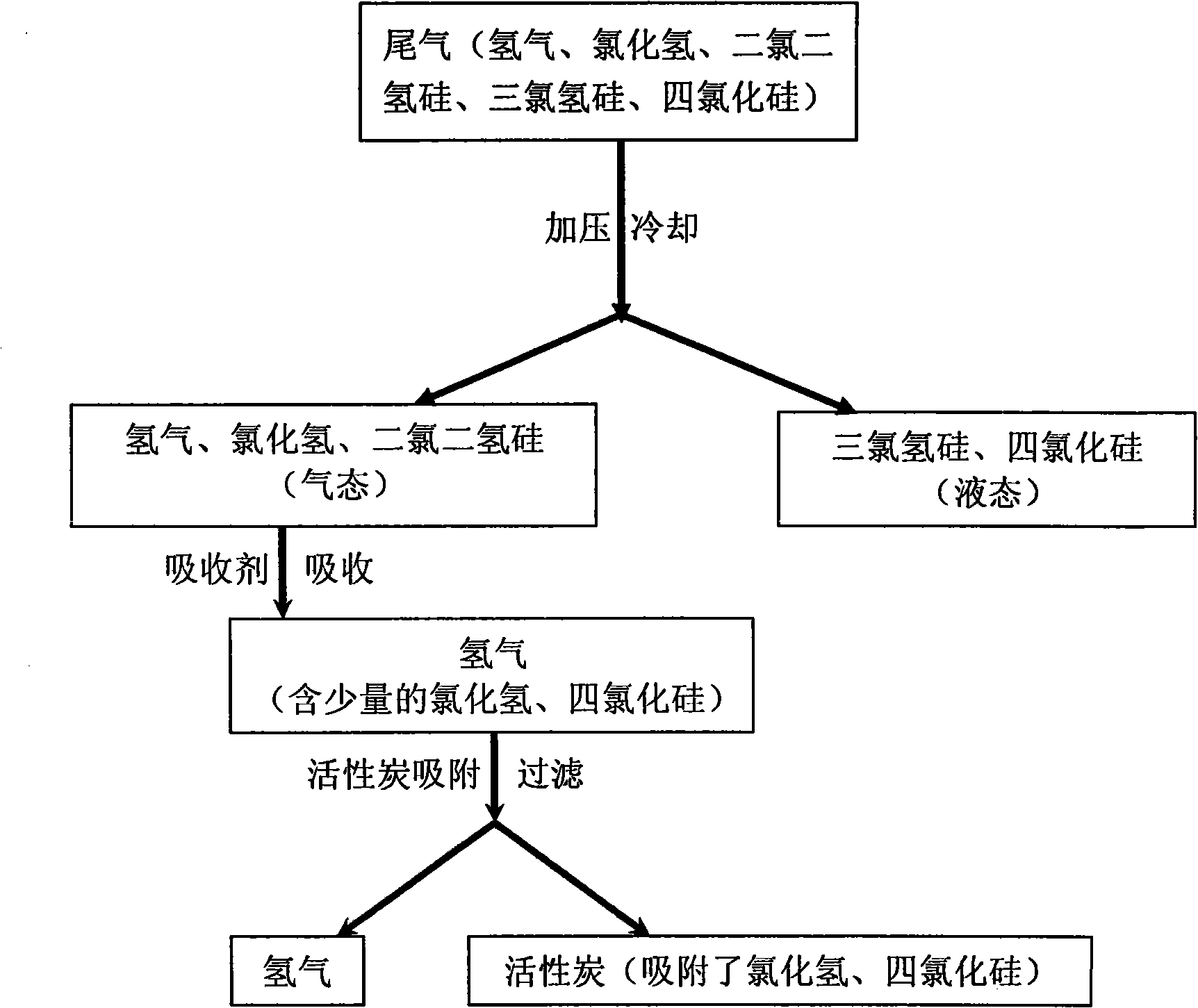

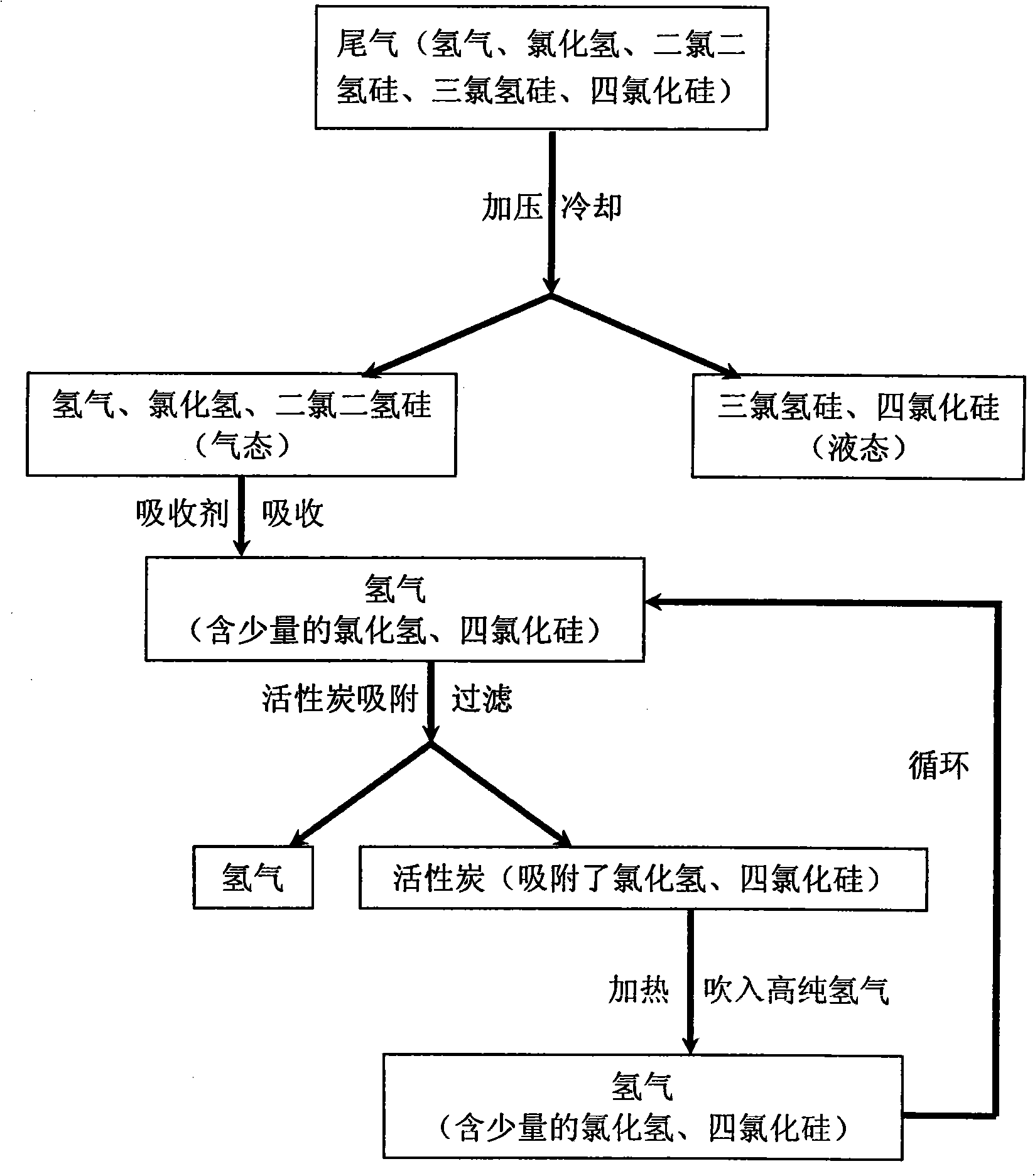

Method for reclaiming hydrogen from tail gas from polysilicon production

ActiveCN101327912AOvercome and eliminate the disadvantages of recycling technologyOvercome and eliminate shortcomingsHydrogen separation using liquid contactDispersed particle separationRecovery methodLiquid state

The invention relates to a hydrogen recovery method in the exhaust generated by producing polysilicon. The exhaust mainly comprises hydrogen, chlorine hydride, dichlorosilane, trichlorosilane and tetrachlorosilane. The method comprises the following steps: pressurizing and cooling the exhaust in order to turn trichlorosilane and tetrachlorosilane to liquid state while hydrogen, chlorine hydride and dichlorosilane still being gas state, so that the gas hydrogen, chlorine hydride and dichlorosilane can be separated from the liquid trichlorosilane and tetrachlorosilane by gas liquid separation; dissolving the gas chlorine hydride and dichlorosilane into the liquid tetrachlorosilane by passing gas hydrogen, chlorine hydride and dichlorosilane through the liquid tetrachlorosilane, so that separating the hydrogen from chlorine hydride and dichlorosilane. The invention recovers the hydrogen in the exhaust by dry treatment and the hydrogen can be reused in the polysilicon production, which makes good use of the material, reduces pollutants, settles the problem of environmental pollution, improves the product quality and reduces the cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

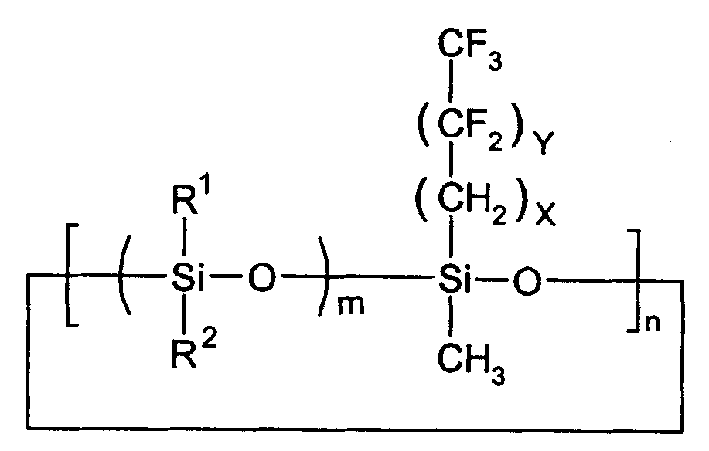

Mixed fluorinated cyclosiloxane, preparing method and use thereof

InactiveCN1456564AEasy to control molecular weightEasy to control molecular weight distributionSilicon organic compoundsDichlorosilaneAlkali metal

A mixed fluoric cyclosiloxane is prepared through mixing fluoric alkylmethyl dichlorosilane with dihydroxy dichlorosidane and reacting on metallic oxide or carbonate of alkali metal for dechlorination. It can be used to cynthesize fluoric polysiloxane for preparing F-Si lubricant, F-Si rubber, or hydroxy F-Si oil.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

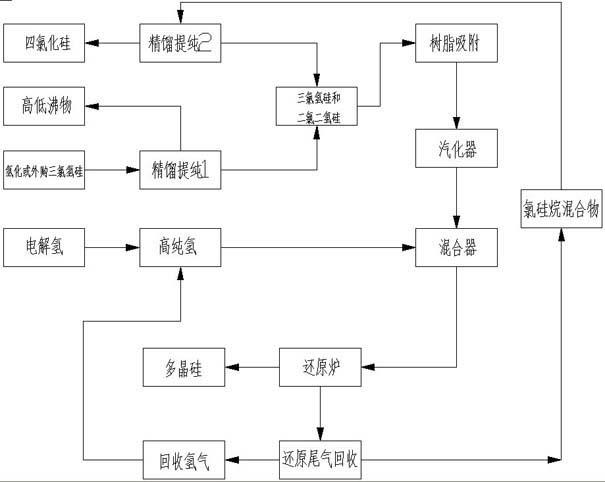

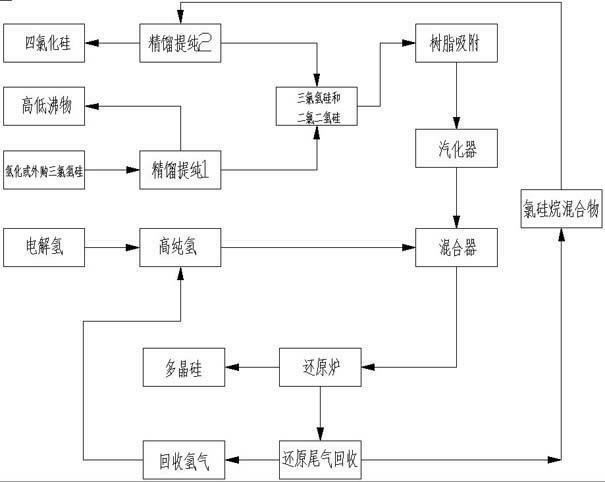

Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

InactiveCN102642834ASolve processing problemsReduce investmentSiliconPhysical chemistryMixed materials

The invention discloses a method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon. After trichlorosilane produced by hydrogenation of silicon tetrachloride or purchased outside is rectified and purified, the rectified and purified trichlorosilane is mixed with recycled trichlorosilane and dichlorosilane mixed materials, the volume percent of dichlorosilane in the mixed raw materials is controlled to be between 3% and 15%, preferably between 5% and 10%, then impurity removal by adsorption and vaporization operation are performed, vaporized chlorosilane mixed gas and high-purity hydrogen are mixed according to mole ratio of 1:2 to 1:10, preferably 1:4 to 1:6, and finally the vaporized chlorosilane mixed gas and the high-purity hydrogen enter into a reduction furnace to produce the polycrystalline silicon. After reactions, tail gas undergoes low-temperature condensation recycle, chlorosilane obtained by recycle is sent to a rectification process to perform separation of silicon tetrachloride and impurities, and the trichlorosilane and dichlorosilane mixed raw materials are obtained. The method makes full use of byproduct dichlorosilane in the polycrystalline silicon production process to improve sedimentation velocity of silicon and reduce power consumption and material consumption, simultaneously can reduce treatment cost and loss of silicon, and improves trichlorosilane utilization rate.

Owner:雅安永旺硅业有限公司

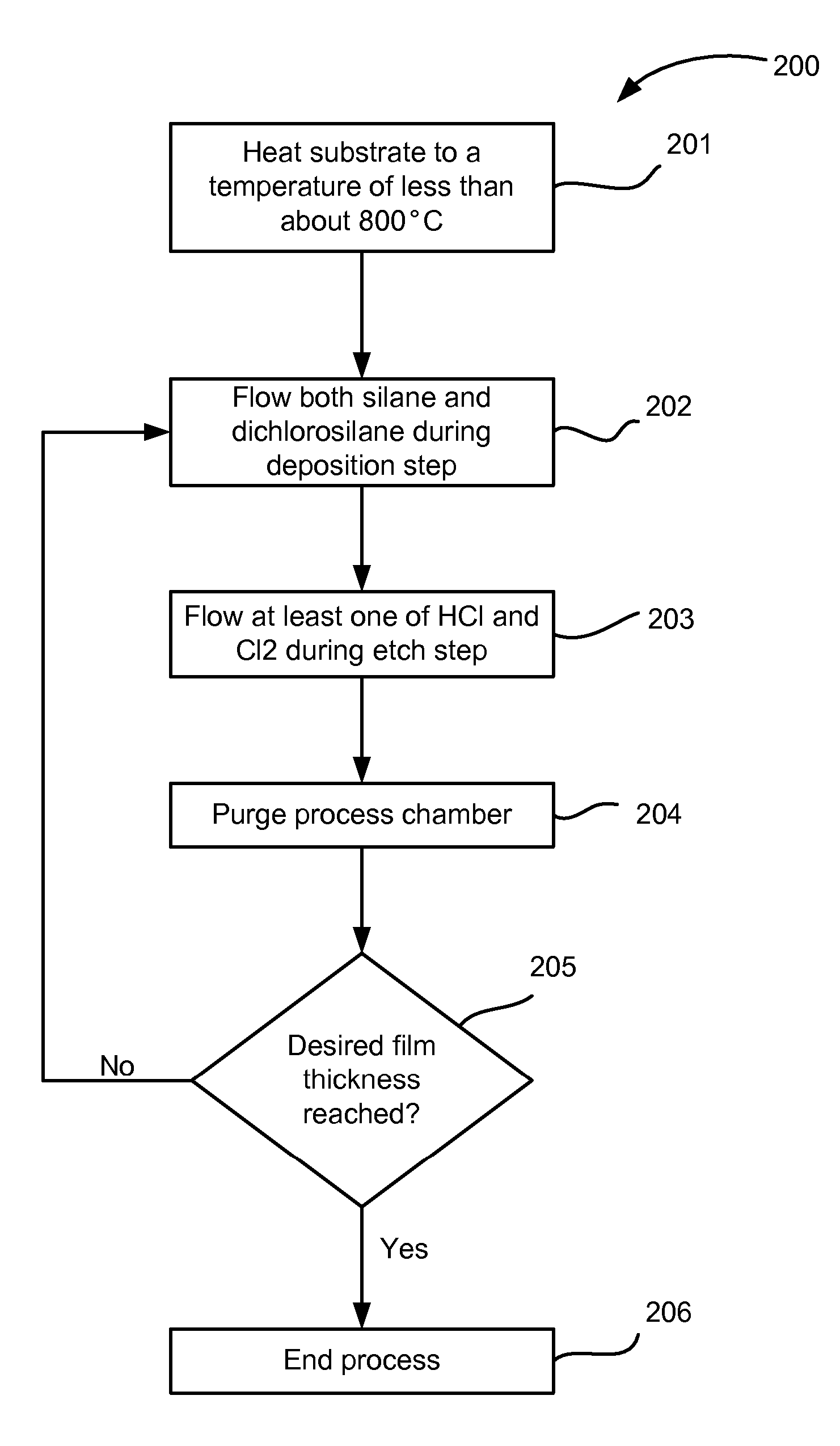

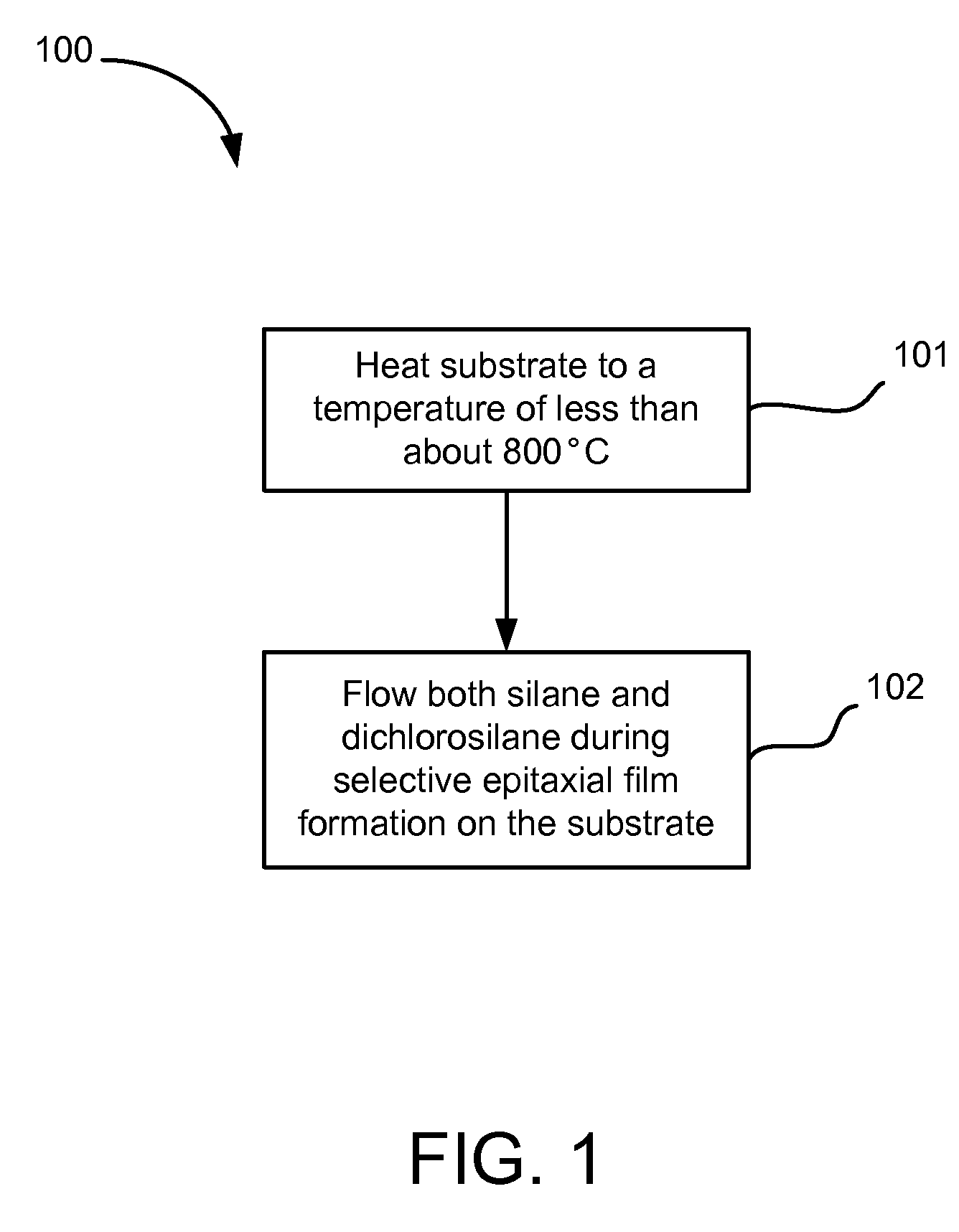

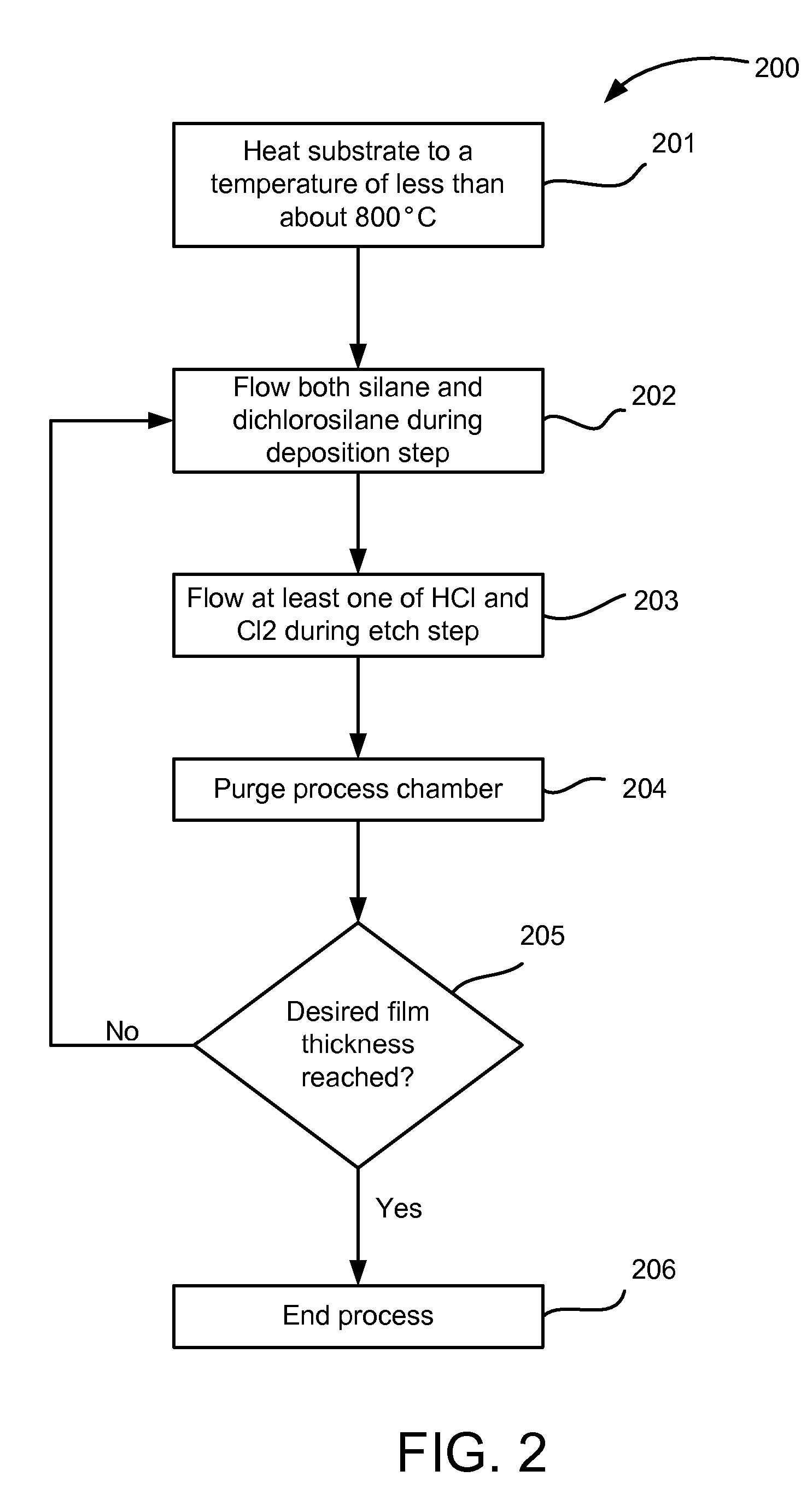

Methods of controlling morphology during epitaxial layer formation

ActiveUS20080026549A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSilanesDichlorosilane

A first aspect of the invention provides a method of selectively forming an epitaxial layer on a substrate. The method includes heating the substrate to a temperature of less than about 800° C. and employing both silane and dichlorosilane as silicon sources during epitaxial film formation. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

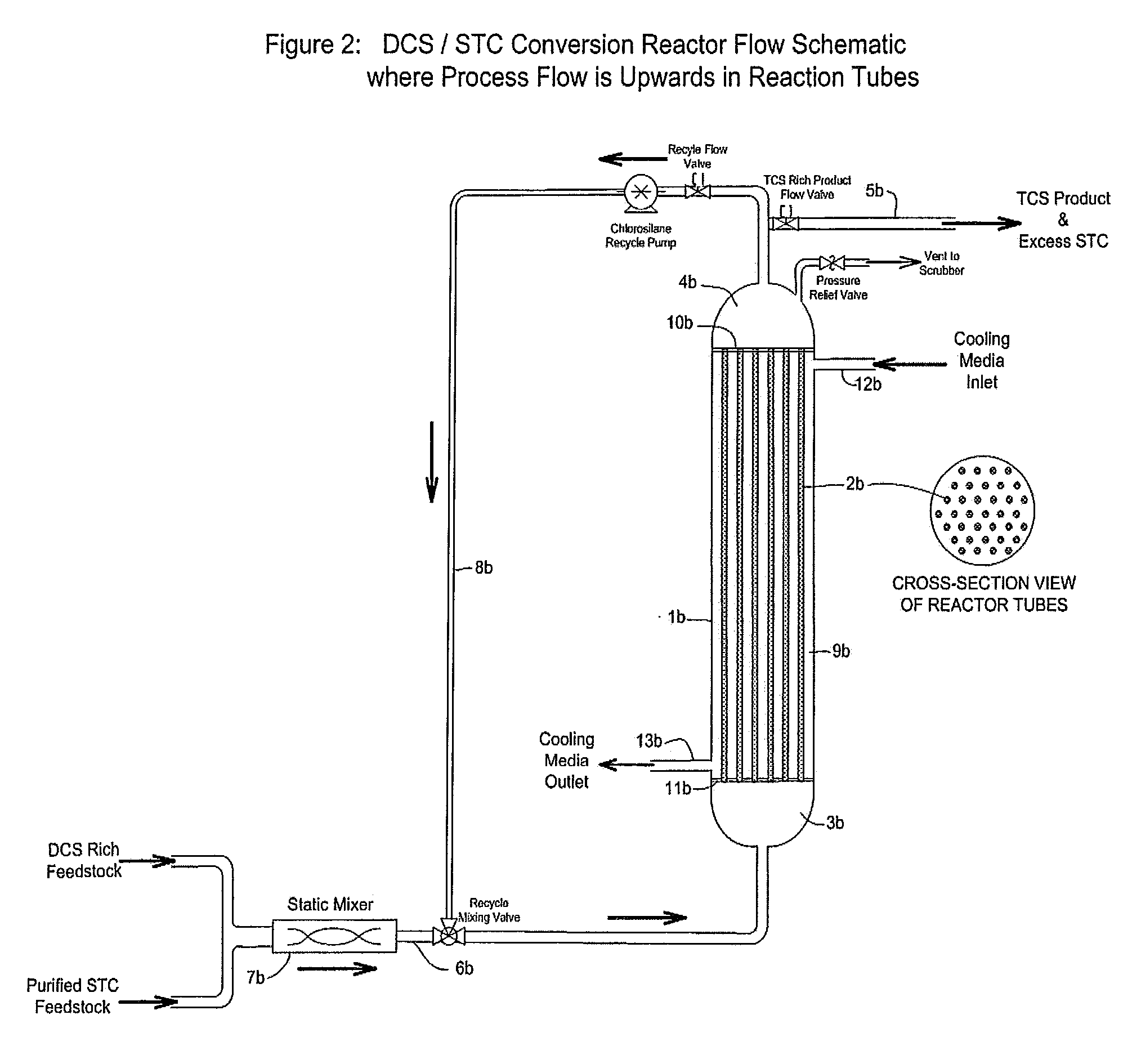

Enhancements for a chlorosilane redistribution reactor

The present invention includes a process and means for using two isolated by-products from the reaction of at least one of metallurgical silicon and silicon tetrachloride with at least one of anhydrous hydrogen chloride and hydrogen to produce trichlorosilane. The two isolated by-products are dichlorosilane and silicon tetrachloride. The present process reduces chlorosilane waste and improves efficiency of overall process for production of trichlorosilane for use in chemical vapor deposition of polysilicon for electronic and solar applications. The present invention further includes a chemical reactor for the reacting dichlorosilane with silicon tetrachloride to produce additional trichlorosilane.

Owner:DYNAMIC ENG

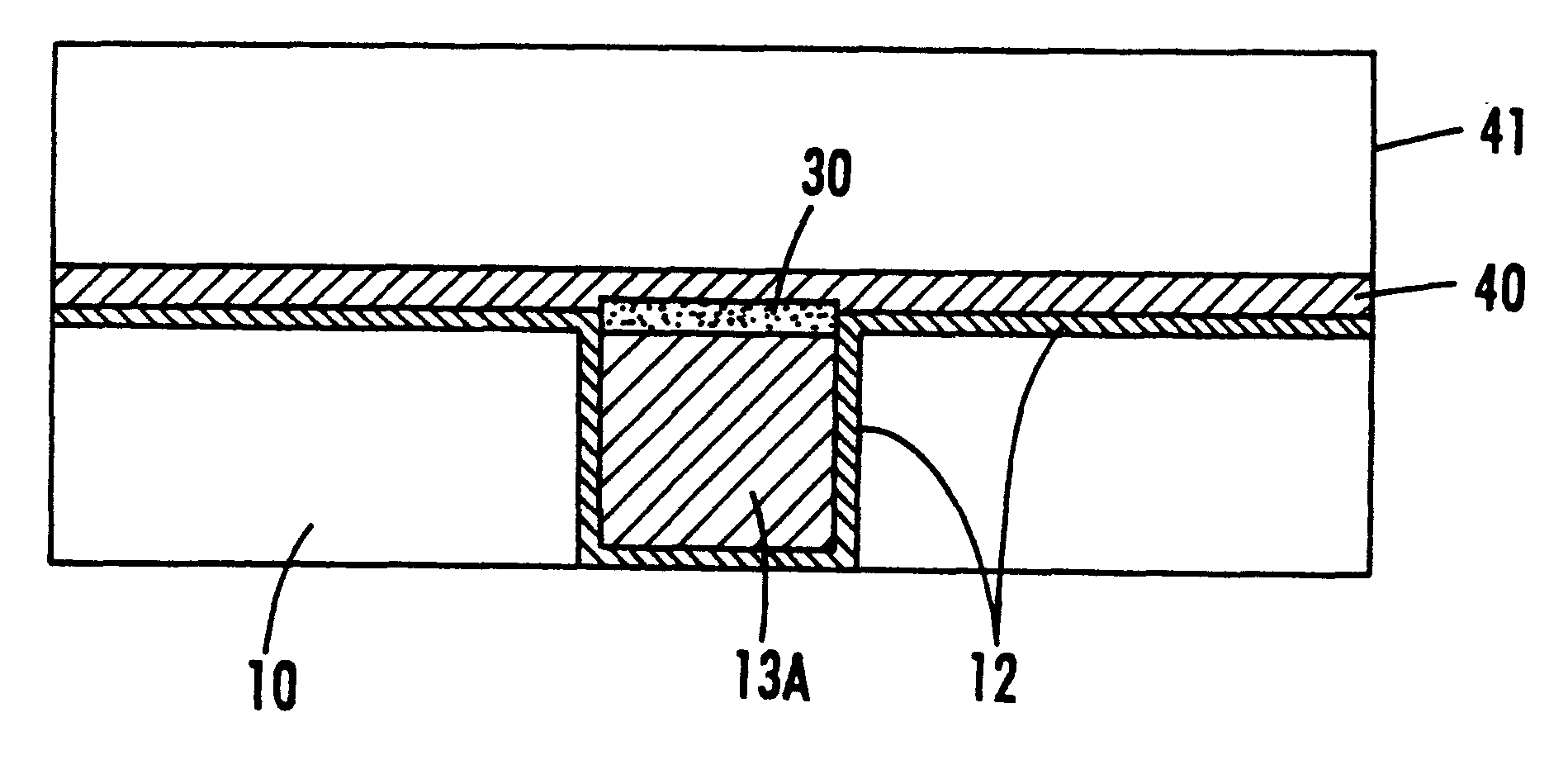

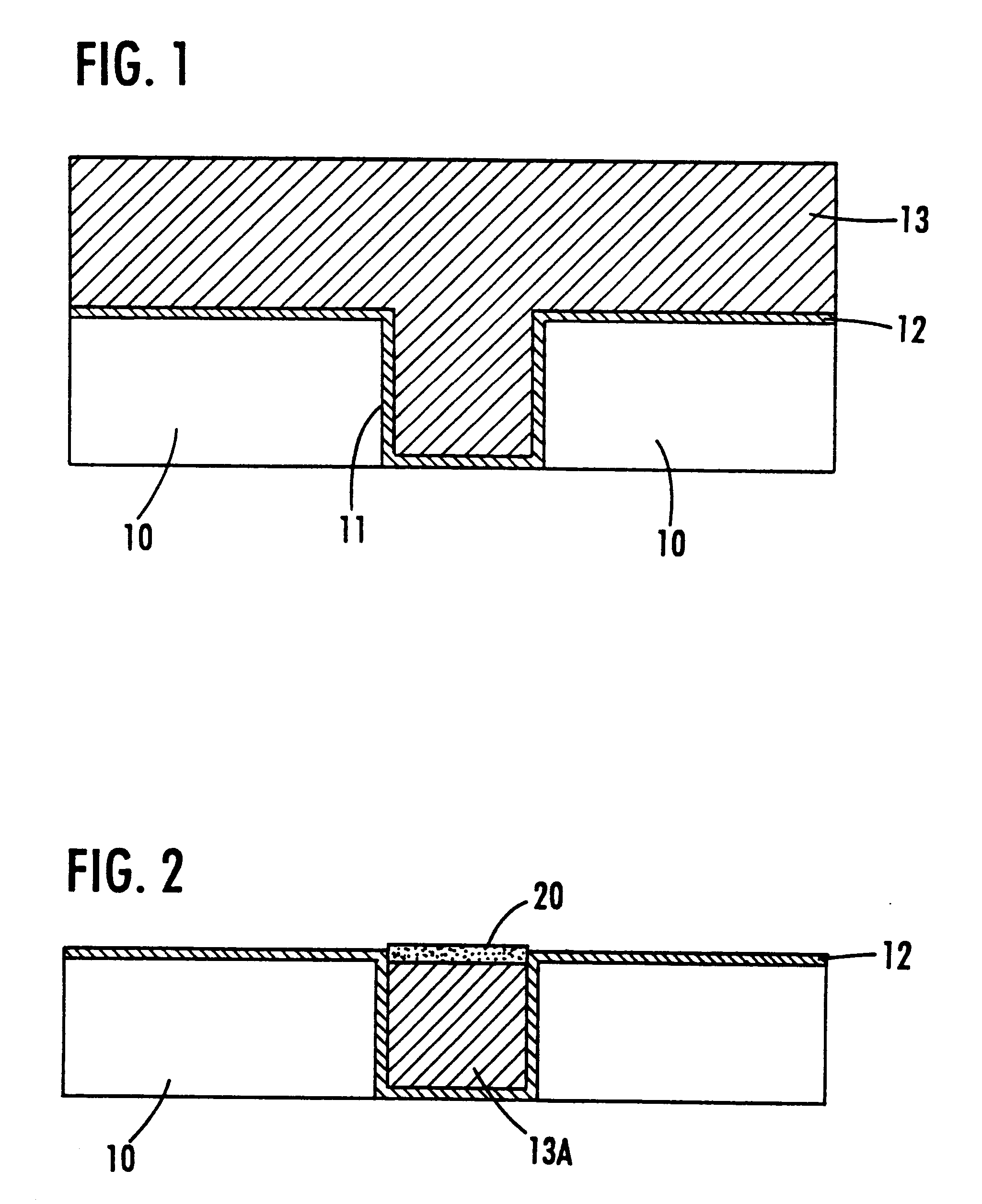

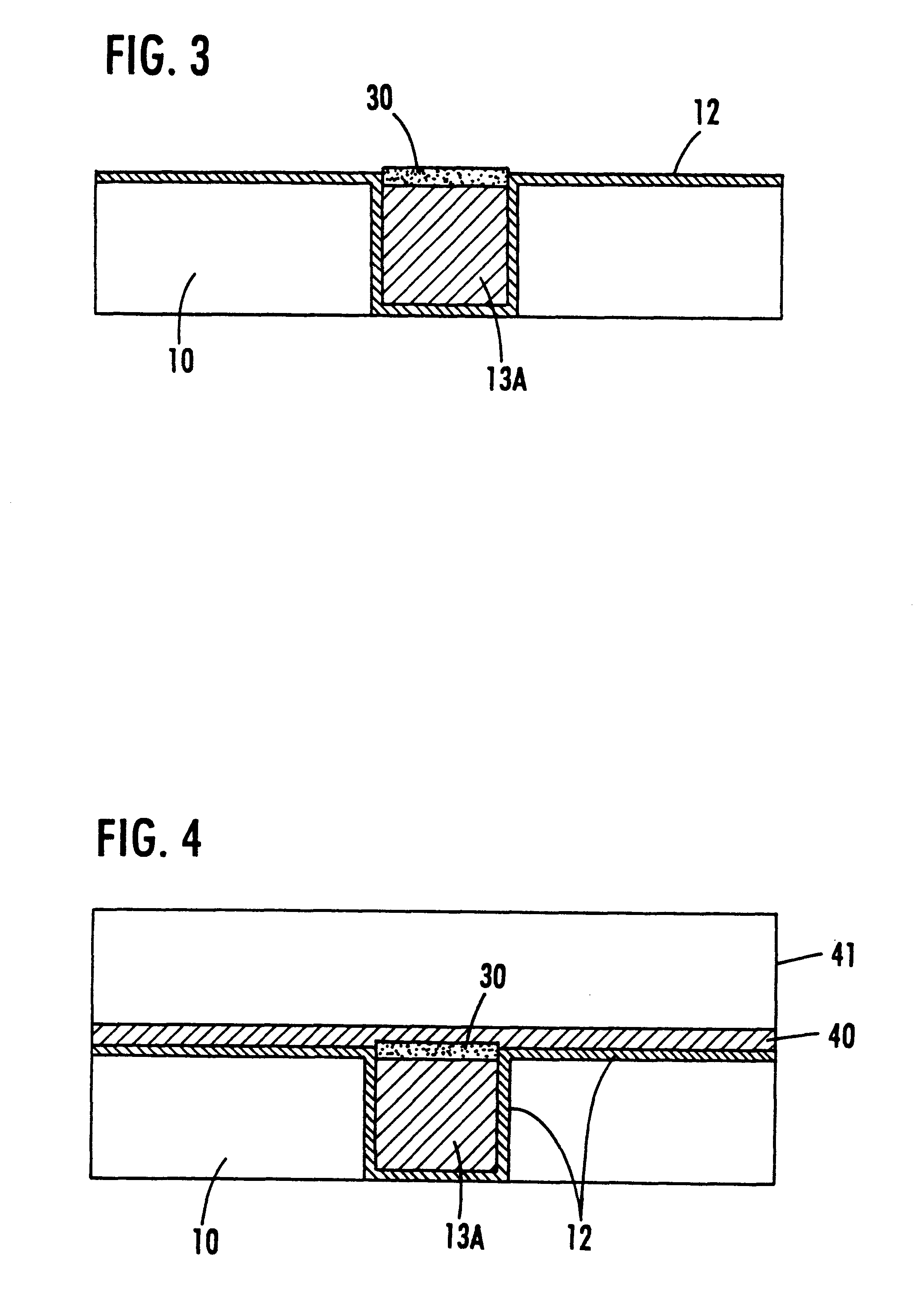

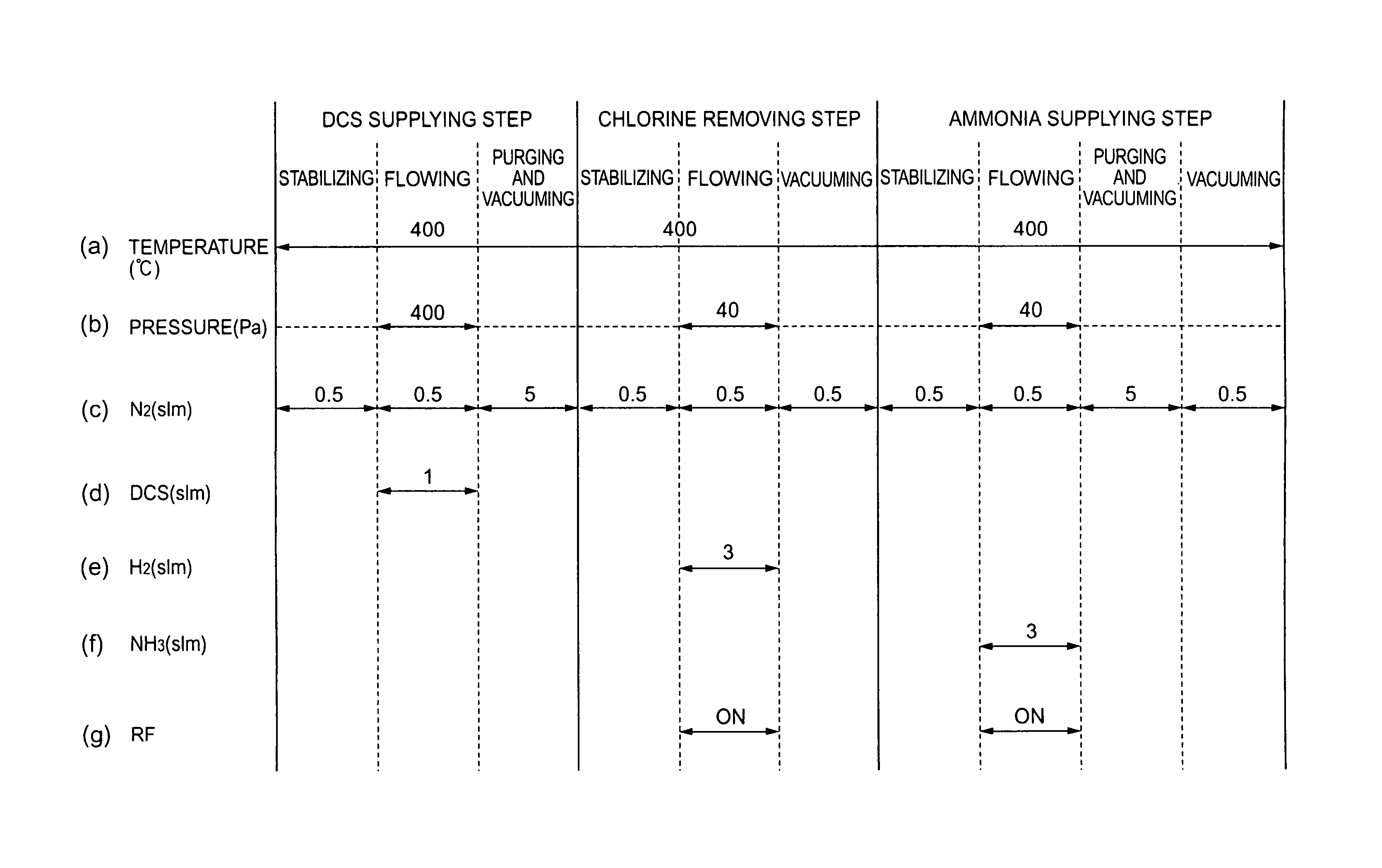

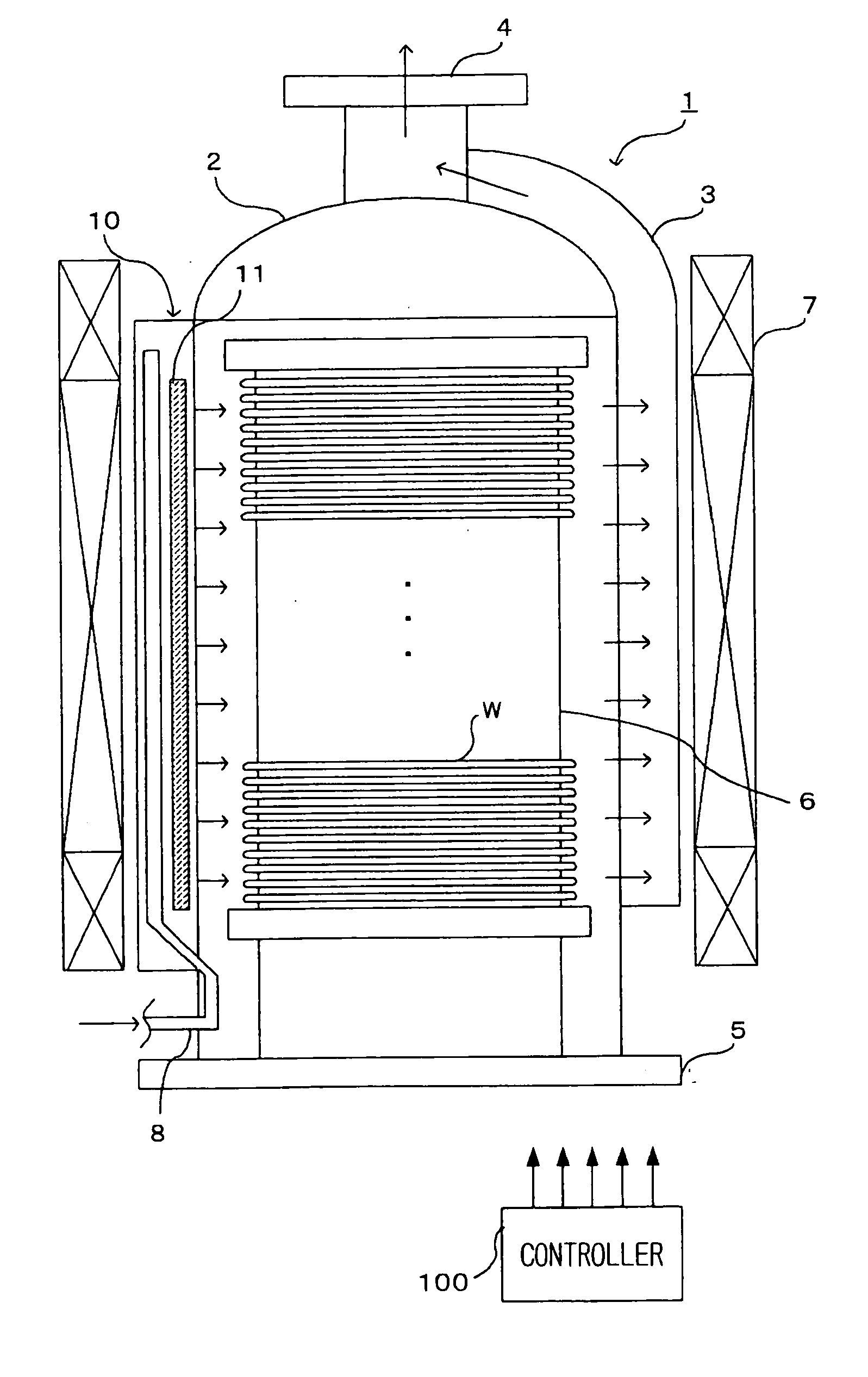

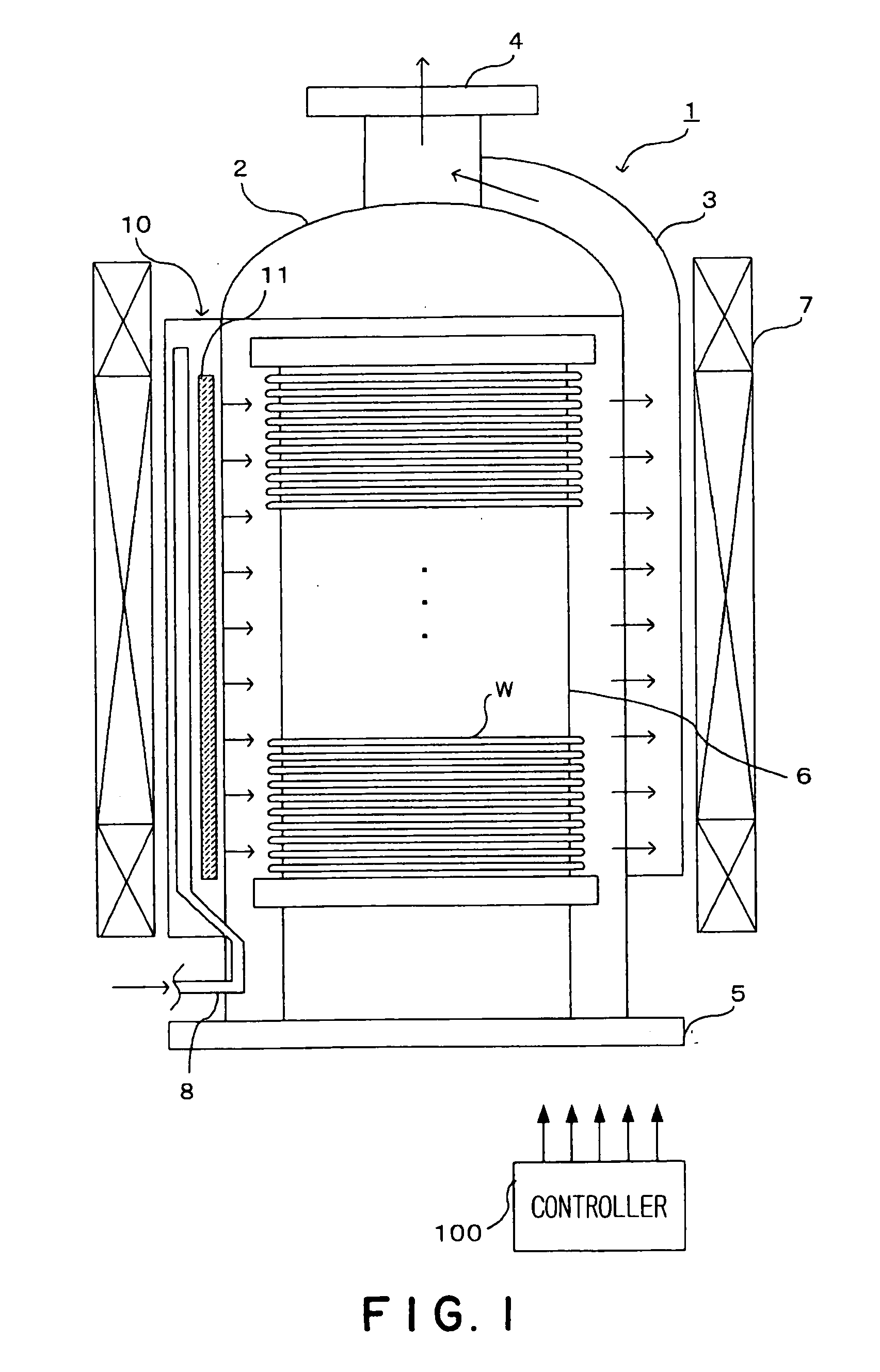

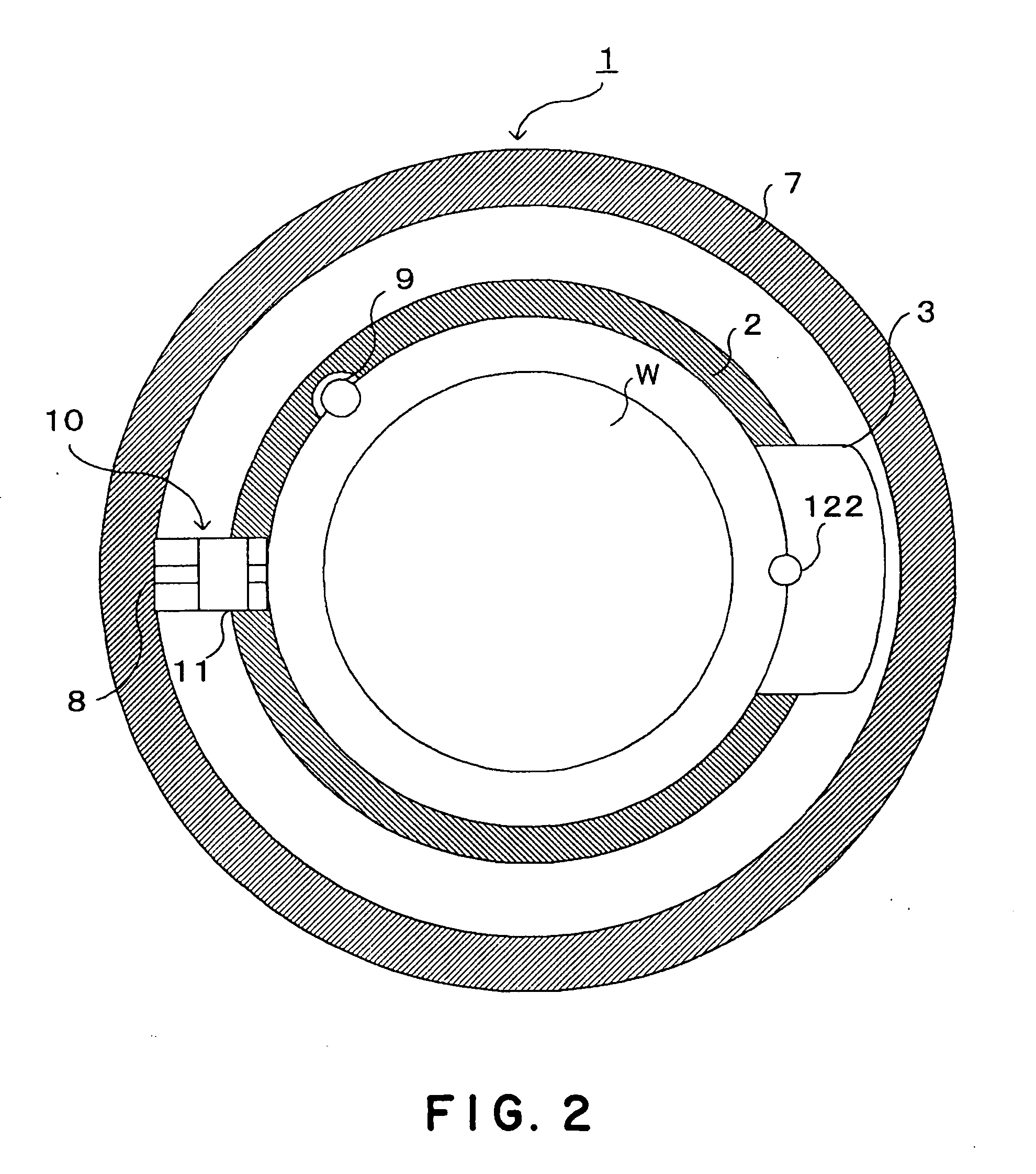

Formation of silicon nitride film

ActiveUS20060216418A1Increase pressureLow process temperatureLiquid surface applicatorsSemiconductor/solid-state device manufacturingWaferingChemical species

Disclosed is a method of forming a silicon nitride film which can form a silicon nitride film having a high film stress at a low process temperature. The method includes the steps of (a) supplying dichlorosilane into a reaction chamber containing a process object, thereby allowing chemical species originated from dichlorosilane as a precursor to be adsorbed on the process object; (b) hydrogenating chlorine contained in the chemical species, thereby removing the chlorine from the chemical species; and (c) supplying ammonia radicals into the reaction chamber, thereby nitriding the chemical species, from which the chlorine has been removed, by the ammonia radicals to, deposit resultant silicon nitride on the process object, wherein the steps (a), (b) and (c) are performed repeatedly for plural times in that order, thereby a silicon nitride film of a desired thickness is formed on a semiconductor wafer.

Owner:TOKYO ELECTRON LTD

Preparation method of organic silicon modified polyester wire enamel

InactiveCN102161860AImprove the disadvantages that the heat resistance performance is not good enoughGood storage stabilityPolyester coatingsPolyesterSilanes

The invention discloses a preparation method of organic silicon modified polyester wire enamel. Divalent alcohol, trihydric alcohol and dibasic acid are combined into polyester of low polymerization in a molar ratio of 1: (0.08-0.2): (0.95-1); dialkyl dichlorosilane or dialkyl dioxolane silane and alkyl trichlorosilane or alkyl trialkoxysilane are combined into organic silicon resin prepolymer solution; then the organic silicon resin prepolymer solution reacts with resin of low polymerization; and a solvent and a film forming assistant are added to blend into the organic silicon modified polyester wire enamel. The heat-resistant degree of the polyester wire enamel is effectively improved, and production process is simple and reliable; the organic silicon modified polyester wire enamel can be produced at normal pressure and common vacuum degree, and the storage stability of the product is good; and the solvent with small toxicity is used for replacing phenol solvents so as to lower product toxicity.

Owner:GUANGDONG HENGBAOCHANG ELECTRICAL TECH +1

Production method of silane

The invention discloses a production method of silane. The production method comprises the following steps of: heating trichlorosilane to 70-90 DEG C by using a preheater; feeding heated trichlorosilane into a first reaction region of a reaction rectifying tower, and performing a first step catalytic disproportionation reaction of trichlorosilane in the first reaction region to generate dichlorosilane and silicon tetrachloride; feeding silicon tetrachloride generated in the first reaction region into the stripping section of the reaction rectifying tower, separating, purifying and discharging from a tower kettle; raising dichlorosilane generated in the first reaction region to a second reaction region of the reaction rectifying tower, and performing a second step catalytic disproportionation reaction to generate trichlorosilane and silane; refluxing the trichlorosilane generated in the second reaction region into the first reaction region, mixing with trichlorosilane heated by using the preheater, and continually performing the first step catalytic disproportionation reaction; and raising silane generated in the second reaction region into the rectifying section of the reaction rectifying tower, separating, purifying and discharging from the tower top of the reaction rectifying tower to obtain silane.

Owner:覃攀

Method of preparing dimethyl dichloro silicane using organic silicon high boiling point substance

InactiveCN1590389ALoose requirementsImprove securityGroup 4/14 element organic compoundsBoiling pointDichlorosilane

A process for preparing dimethyl dichlorosilane from the high-boiling-point residue generated in synthesizing methyl chlorosilane includes filling catalyst in gas preheater, passing chloromethane (or hydrogen chloride) gas through it, carrying catalyst into reactor while introducing said residue to it, and separating dimethyl dichlorosilane from the cooled substance at tower top.

Owner:PETROCHINA CO LTD

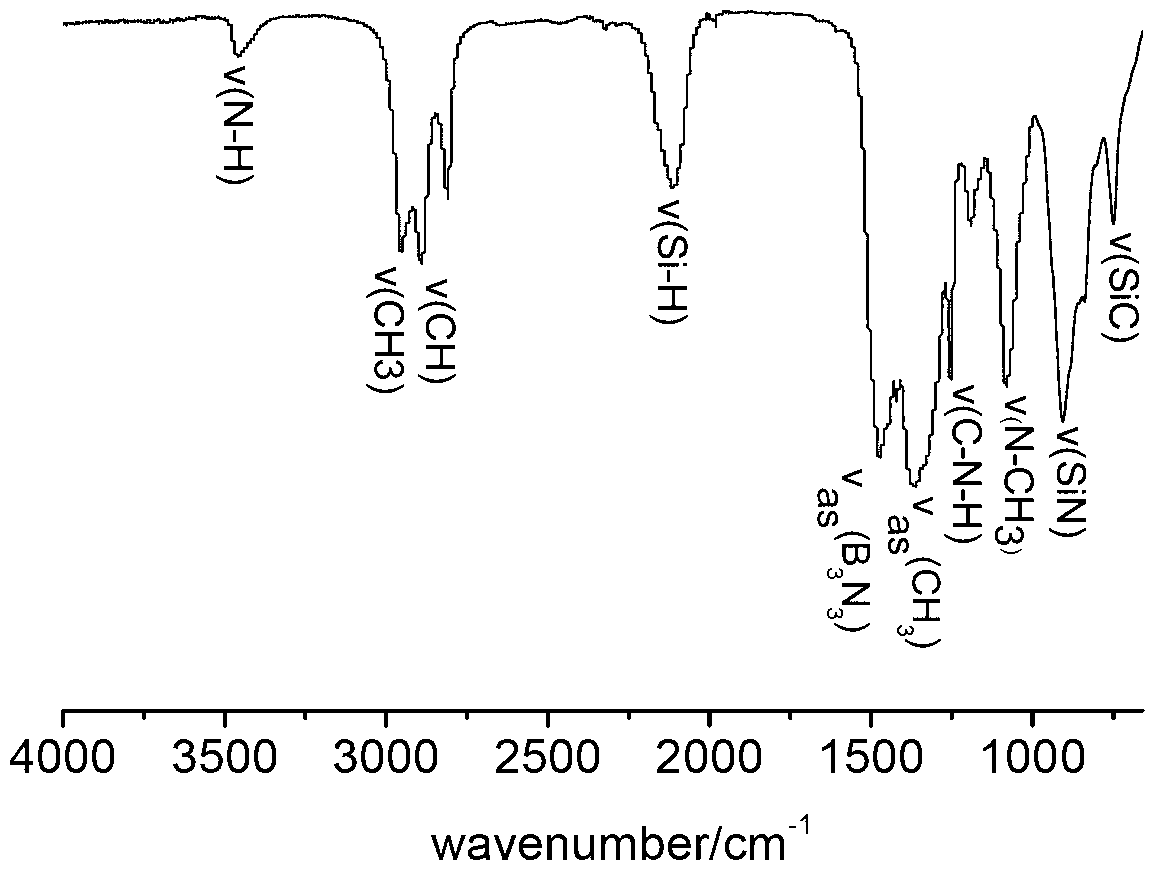

Preparation method for SiBN(C) ceramic fiber precursor

The invention relates to a preparation method for a SiBN(C) ceramic fiber precursor. The preparation method comprises the steps of synthesizing SiBN(C) ceramic fiber precursor molecules by using methyl dichlorosilane (MeHSiCl2), hexamethyl disilazane (HMDZ), boron trichloride (BCl3) and methylamine (CH3NH2) at a temperature ranging from-40 DEG C to-80 DEG C; removing toluene from an anhydrous toluene solution of the SiBN(C) ceramic fiber precursor molecules; heating to a temperature of 130-300 DEG C to obtain a prepolymer; then adding active group-terminated polydimethylsiloxane or active group-terminated long carbon chain molecules; keeping for 10-100 h at the temperature of 130-300 DEG C; defoaming and melt-spinning. Aiming at the problems of large friability, low strength and the like of the SiBN(C) ceramic fiber precursor, the SiBN(C) ceramic fiber precursor with excellent flexibility is prepared by employing a copolymerization method, thereby providing a foundation for continuous and integrated preparation of SiBN(C) ceramic fibers.

Owner:DONGHUA UNIV

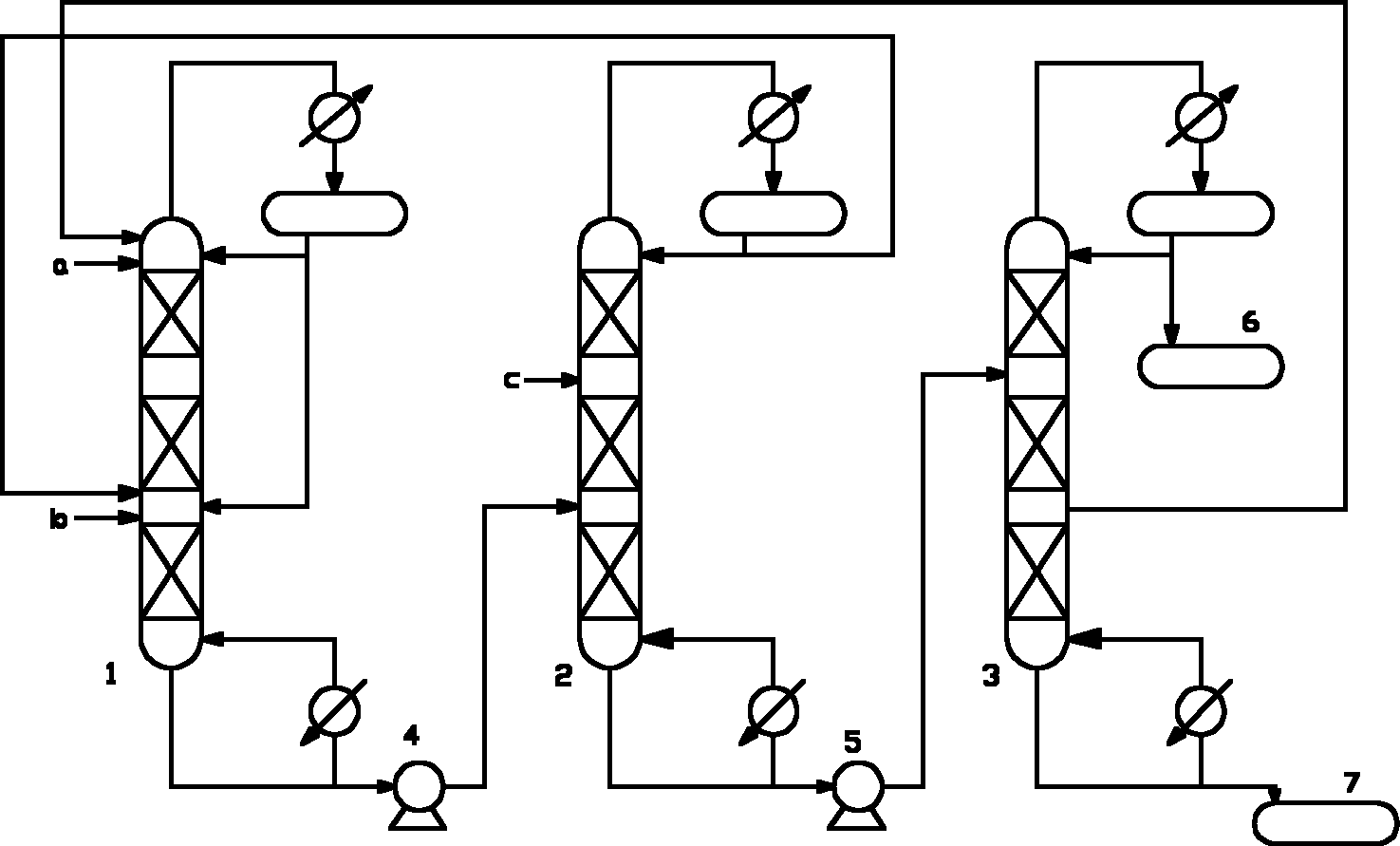

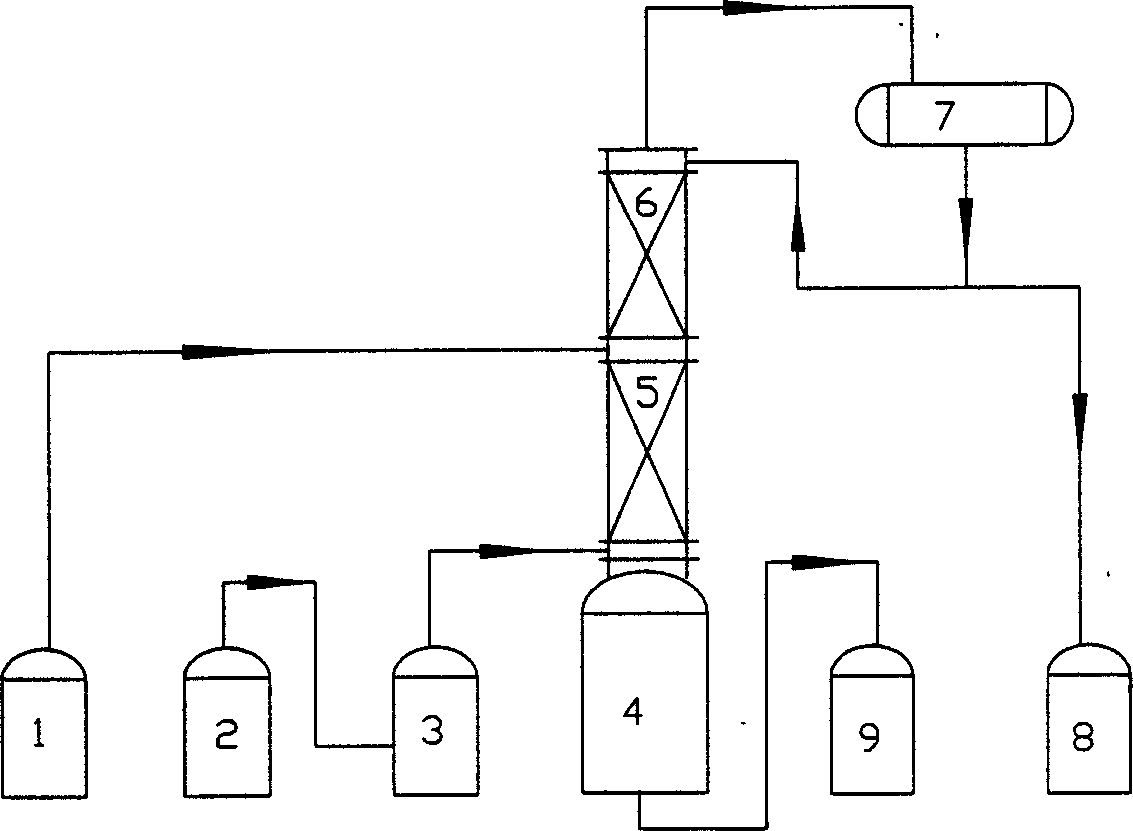

Reactive distillation device for preparing trichlorosilane from mixed chlorosilane and method for device

InactiveCN102491341AIncrease profitResolve enrichmentChemical industryHalogenated silanesPartial gravityReactive distillation

The invention relates to a reactive distillation device preparing trichlorosilane from mixed chlorosilane and a method for the reactive distillation device. The method comprises the following steps of: feeding mixed chlorosilane raw materials at a middle position of an upper reaction section C and a lower reaction section E, obtaining dichlorosilane on the top of a tower, and making partial dichlorosilane return to the lower part of the lower reaction section E under the gravity and serve as a feed to enter the tower; obtaining silicon tetrachloride at the bottom of the tower, and returning partial silicon tetrachloride serving as a feed to the tower through the upper part of the upper reaction section C by using a feed liquid circulating pump at the bottom of the tower; extracting a trichlorosilane product in the middle of the tower; pressurizing and heating the partial dichlorosilane extracted on the top of the tower through a compressor, performing heat exchange with the partial silicon tetrachloride extracted at the bottom of the tower, returning the heated silicon tetrachloride to the bottom of the tower for refluxing, and returning the cooled dichlorosilane to the top of the tower for refluxing through a throttling valve and the feed liquid circulating pump on the top of the tower. The traditional reactive distillation equipment and subsequent separation and purification equipment are integrated in a dividing-wall tower, the process flow is simplified, the equipment investment is saved, and energy consumption is reduced.

Owner:TIANJIN UNIV

Refractive index-adjustable MDT silicone resin and preparation method thereof

ActiveCN102898649AAdjustable refractive indexReduce the refractive index differenceOther chemical processesRefractive indexSolvent

The invention relates to the field of organic polymer chemistry and provides a refractive index-adjustable MDT silicone resin and a preparation method thereof. The refractive index-adjustable MDT silicone resin solves the problem that the existing MDT silicone resin has a small refractive index thereby leading to a large difference between refractive indexes of the silicone resin and a polymer and thus an organic silicon polymer packaging material reinforced by the existing MDT silicone resin has poor optical properties and a semiconductor lighting device adopting the organic silicon polymer packaging material has low optical efficiency. The preparation method comprises that hexamethyldisiloxane as a blocking agent, bifunctional organic dichlorosilane as a D chain unit source, and trifunctional organic trichlorosilane as a T chain unit source undergo a co-hydrolytic condensation reaction in the presence of a water-acetone-toluene mixed solution as a solvent under the self-catalysis effect of hydrochloric acid produced by chlorosilane hydrolysis to produce the refractive index-adjustable MDT silicone resin. The refractive index-adjustable MDT silicone resin improves optical properties of a MDT silicone resin-reinforced high-refractive index organic silicon polymer packaging material and also improves mechanical properties of the packaging material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Surface treatment of nanoparticles to control interfacial properties and method of manufacture

InactiveUS20050222325A1Material nanotechnologySynthetic resin layered productsPersonal care3-mercaptopropyltrimethoxysilane

A surface treated particle comprising a plurality of inorganic, metallic, semi-metallic, and / or metallic oxide particles and a star-graft copolymer with looped and / or linear polymeric structure on a star-graft copolymer, obtainable by a heterogeneous polymerization reaction in the particle surface proximity, encapsulating at least a portion of said particles and a method for making the same. The surface treatment comprises: Si (w, x, y, z), where: w, x, y, and z are mole percent tetrafunctional, trifunctional, difunctional, and monofunctional monomeric units, respectively; w, x, y, and z are about 0-50, 0-50, 5-99, and 0-5, respectively; w is tetraethylorthosilicate; x is selected from the group consisting of γ-glycidoxypropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, methyltrimethoxysilane, n-propyltrimethoxysilane, isobutyltrimethoxysilane, n-hexyltrimethoxysilane, n-octyltrimethoxysilane, n-octadecyltrimethoxysilane, phenyltrimethoxysilane, 3-(trimethoxysilyl)propylsuccinic anhydride, heptadecafluorotrimethoxysilane, 3-isocyanatopropyltrimethoxysilane, 2-(diphenylphosphino)ethyltrimethoxysilane, 3-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane, n-(trimethoxysilylpropyl)EDTA, pentafluorophenylpropyltrimethoxysilane, trifluoropropyltrimethoxysilane, and the triethoxy-containing counterparts of these monomers; y is selected from the group consisting of dicyclohexyldimethoxysilane, diethyldiethoxysilane, dimethyldichlorosilane, dimethyldiethoxysilane, dimethyldimethoxysilane, diphenyldiethoxysilane, diphenyldimethoxysilane, di-n-hexyldichlorosilane, n-hexylmethyldichlorosilane, methyldodecyldiethoxysilane, n-octylmethyldimethoxysilane, and the diethoxy-containing counterparts of these monomers; and z is selected form the group consisting of n-octadecyldimethylmethoxysilane, triethylsilanol, trimethylethoxysilane, trimethylmethoxysilane, and the ethoxy-containing counterparts of these monomers. Product(s) per se, defined as surface treated ZnO and / or TiO2, and the use of the product(s) per se in personal care formulations are excluded.

Owner:NANOPHASE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com