Formation of silicon nitride film by using atomic layer deposition method

一种氮化硅膜、硅氮化物的技术,应用在涂层、气态化学镀覆、金属材料涂层工艺等方向,能够解决不能实现应力强度、氮化硅膜湿蚀刻速率大、氮化硅膜膜应力低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

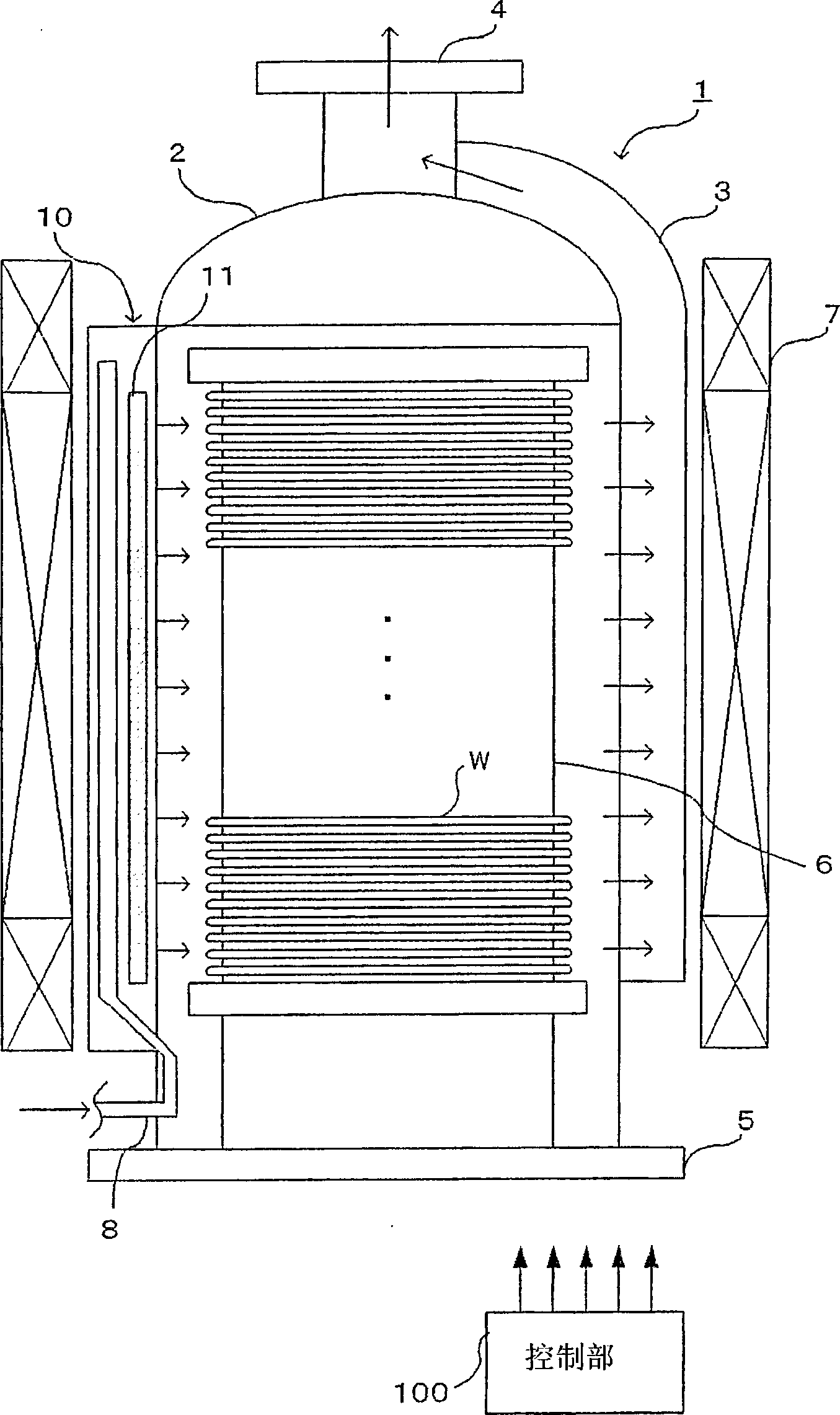

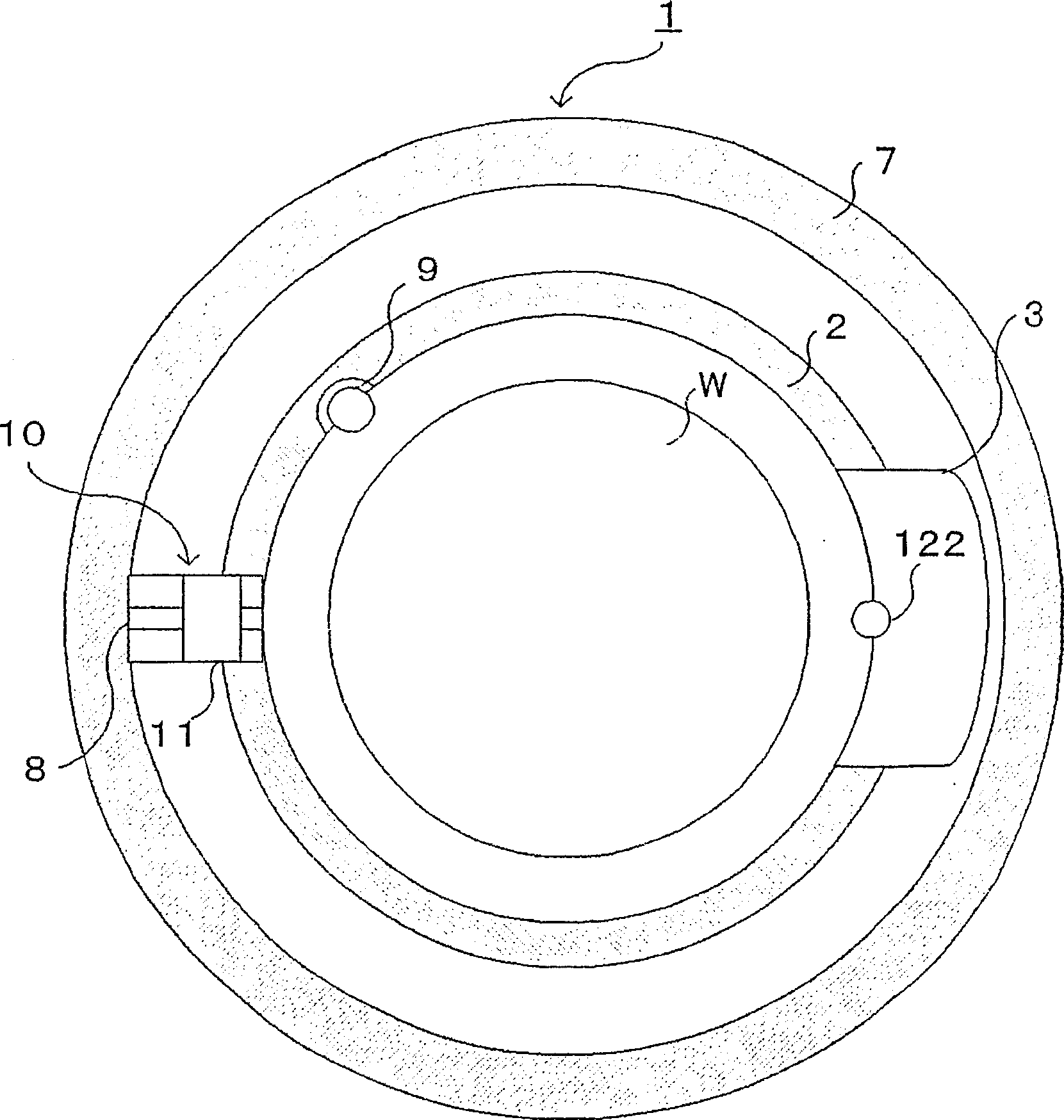

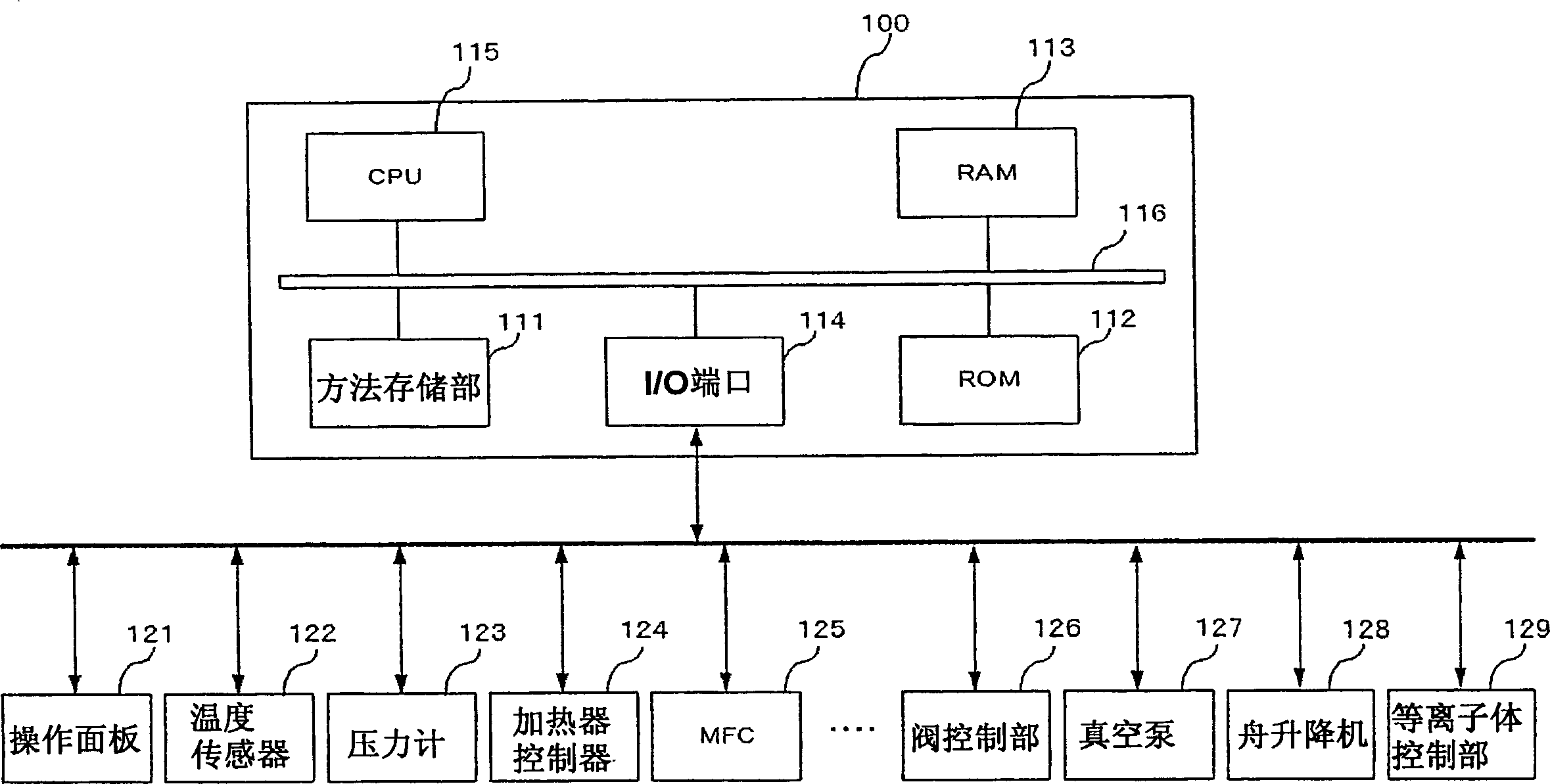

[0023] Preferred embodiments of the present invention will be described below with reference to the drawings. In the exemplary embodiments described below, a batch type vertical processing apparatus is used as the silicon nitride film forming apparatus.

[0024] Such as figure 1 As shown, the longitudinal direction of the processing device 1 has a substantially cylindrical reaction tube 2 facing the vertical direction. The reaction tube 2 is made of a material excellent in heat resistance and corrosion resistance, for example, quartz.

[0025] The exhaust unit 3 is disposed on one side of the reaction tube 2 and is used to exhaust the gas in the reaction tube 2 . The exhaust part 3 is provided on the side wall of the reaction tube 2 and communicates with the reaction tube 2 through an opening (not shown) extending upward along the reaction tube 2 . The upper end of the exhaust part 3 is connected to the exhaust port 4 arranged at the upper part of the reaction tube 2 . An ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com