Movable chemical vapor deposition method of silicon nitride thin film

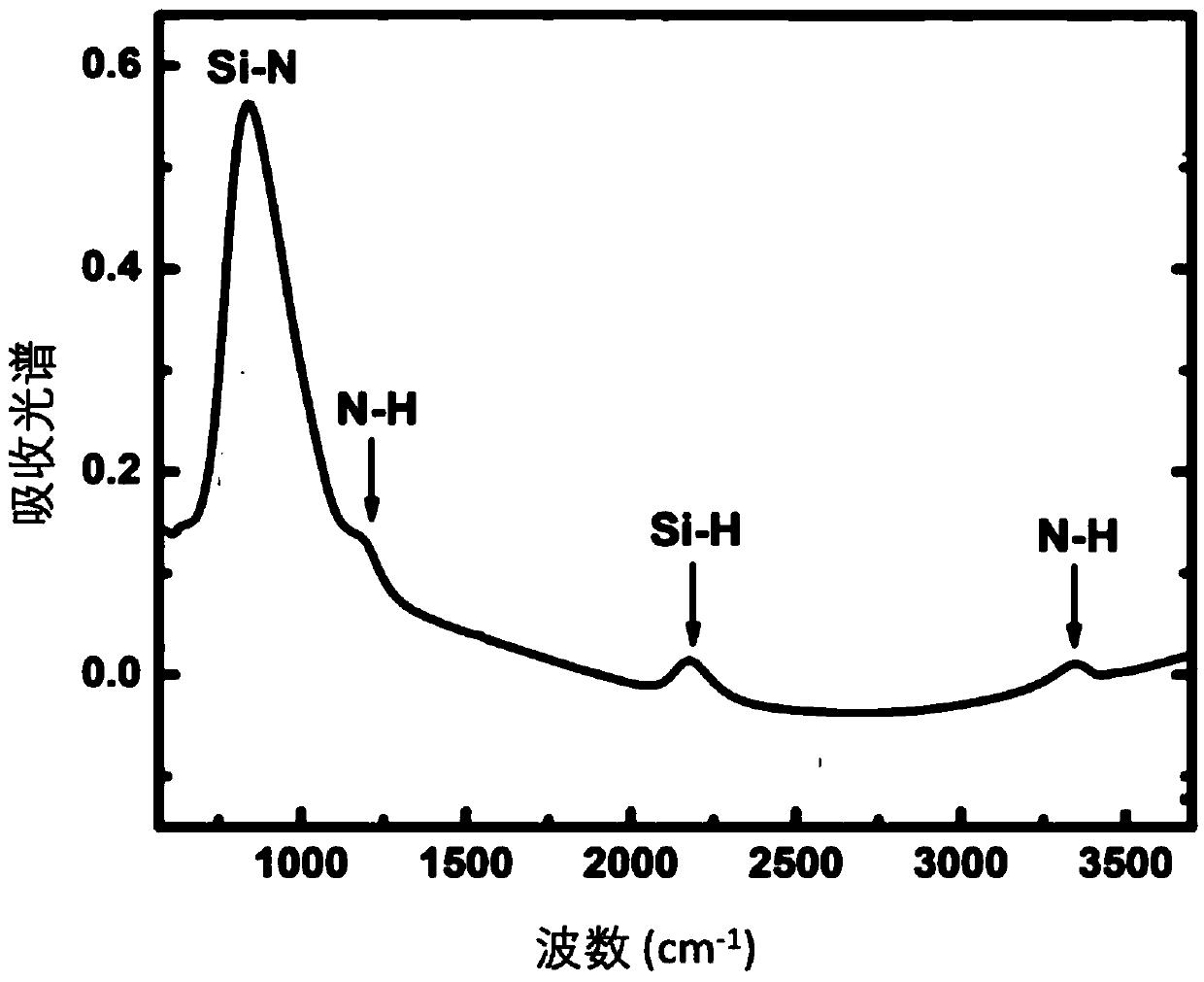

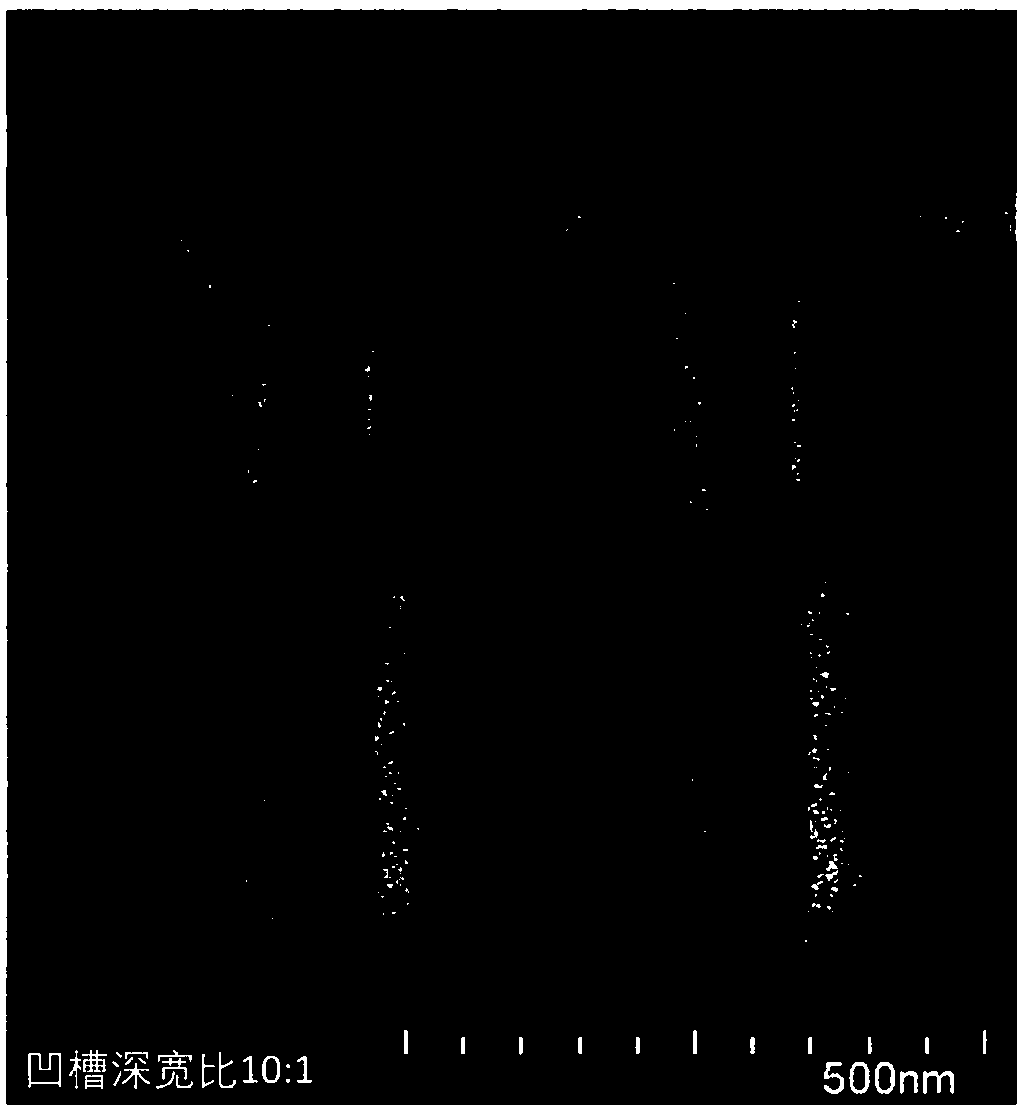

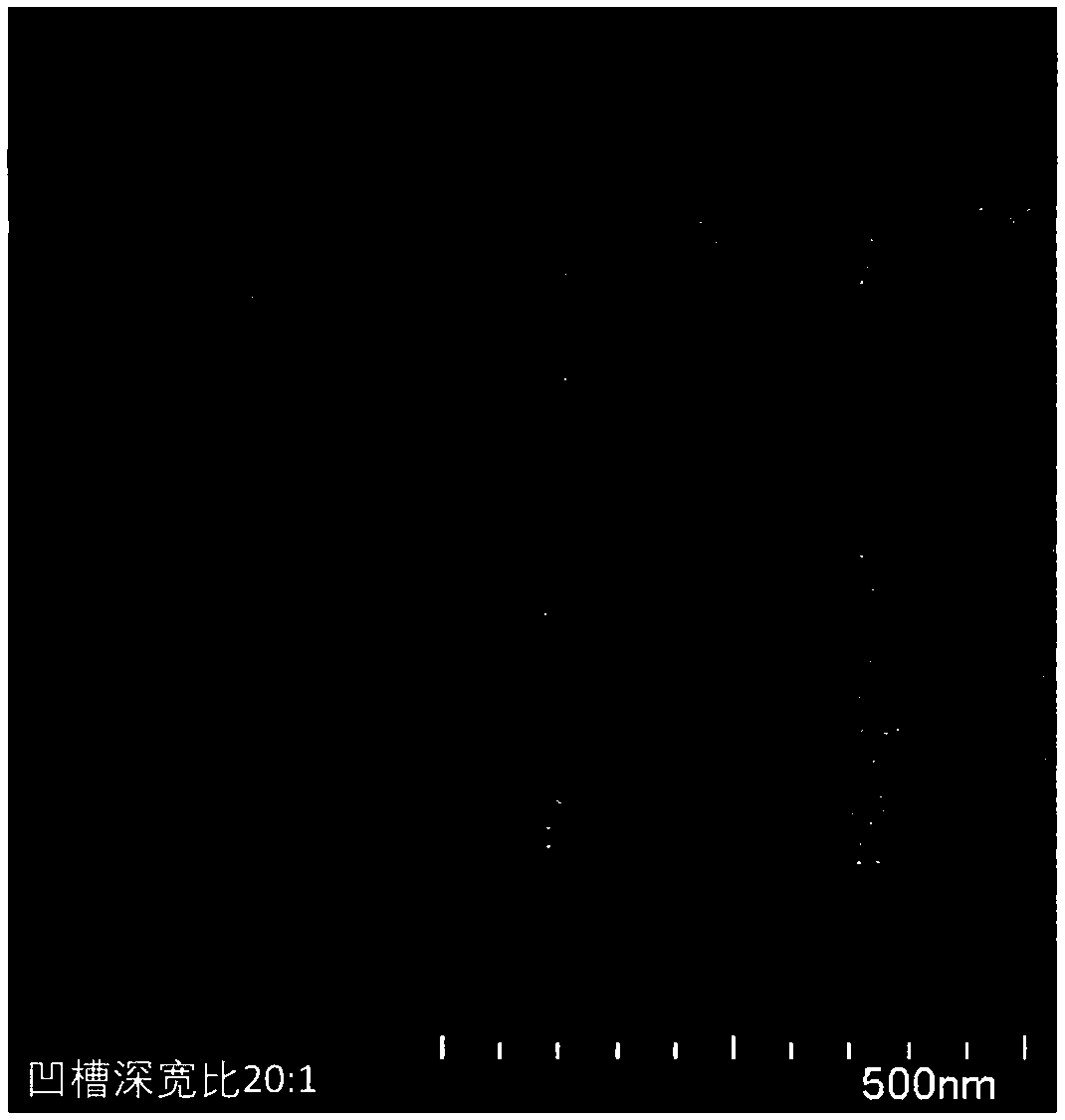

A technology of silicon nitride thin film and vapor deposition, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing H-Si bond density and high ratio, and achieve low wet etching rate, good uniformity, The effect of high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] At a temperature of 20°C, the cyclosilane is reacted with a nitrogen-containing compound, and is deposited to a medium resistivity (that is, a resistivity of 8-12Ω·cm, such as 8Ω·cm, 10Ω·cm, cm, 12Ω·cm) single crystal silicon wafer substrate and silicon pattern wafer, a flowable silicon nitride film is formed until the groove of the substrate is filled, and then annealed at 700°C for 3 hours to finally obtain a dense Silicon nitride film.

[0063] The cyclosilane is cyclopentasilane, cyclohexasilane, cyclooctylsilane or trimethylsilylcyclotrisilazane. The nitrogen-containing compound is ammonia, nitrogen / hydrogen mixed gas, hydrazine or nitrogen trifluoride. A pre-deposition treatment is performed on the above-mentioned single crystal silicon wafer substrate in advance, and the specific pre-deposition treatment may be plasma treatment, heat treatment, chemical treatment, ultraviolet light exposure, and electron beam bombardment.

[0064] The film deposition described ...

Embodiment 2

[0066] The difference from Example 1 is that the flowable silicon nitride film is annealed at 900° C. for 1 h, and finally a dense silicon nitride film is obtained. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 5000 mg / min, the flow rate of nitrogen-containing compound is 1000 sccm, and the in-situ plasma power density is 3.5 W / cm 2 , the pressure is 12Torr.

Embodiment 3

[0068] The difference from Example 1 is that the flowable silicon nitride film is treated with ultraviolet light for 12 minutes, and then cured by bombardment with nitrogen-containing ion beams at 400°C. Repeat the above steps until a dense silicon nitride film with a certain thickness is obtained. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 2000 mg / min, the flow rate of nitrogen-containing compound is 600 sccm, and the in-situ plasma power density is 0.3W / cm 2 , the pressure is 5Torr.

[0069] The resulting dense silicon nitride film was immersed in a 10:1 hydrofluoric acid solution for wet etching rate measurement, and the wet etching rate was less than 10 times that of the silicon nitride film prepared by LPCVD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com