A flowable chemical vapor deposition method of a silicon oxide film

A flow chemistry and vapor deposition technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as high proportion, inability to meet actual needs, and reduction of H-Si bond density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

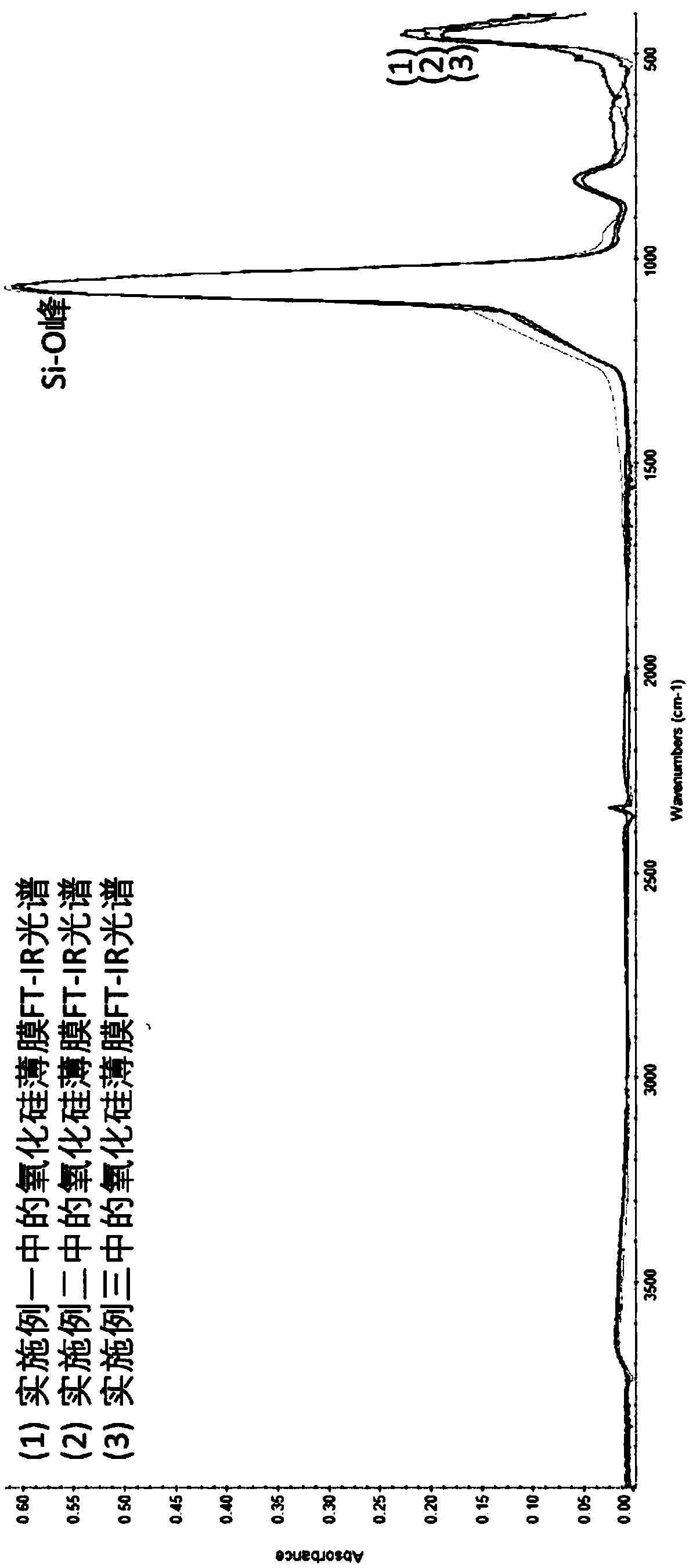

Embodiment 1

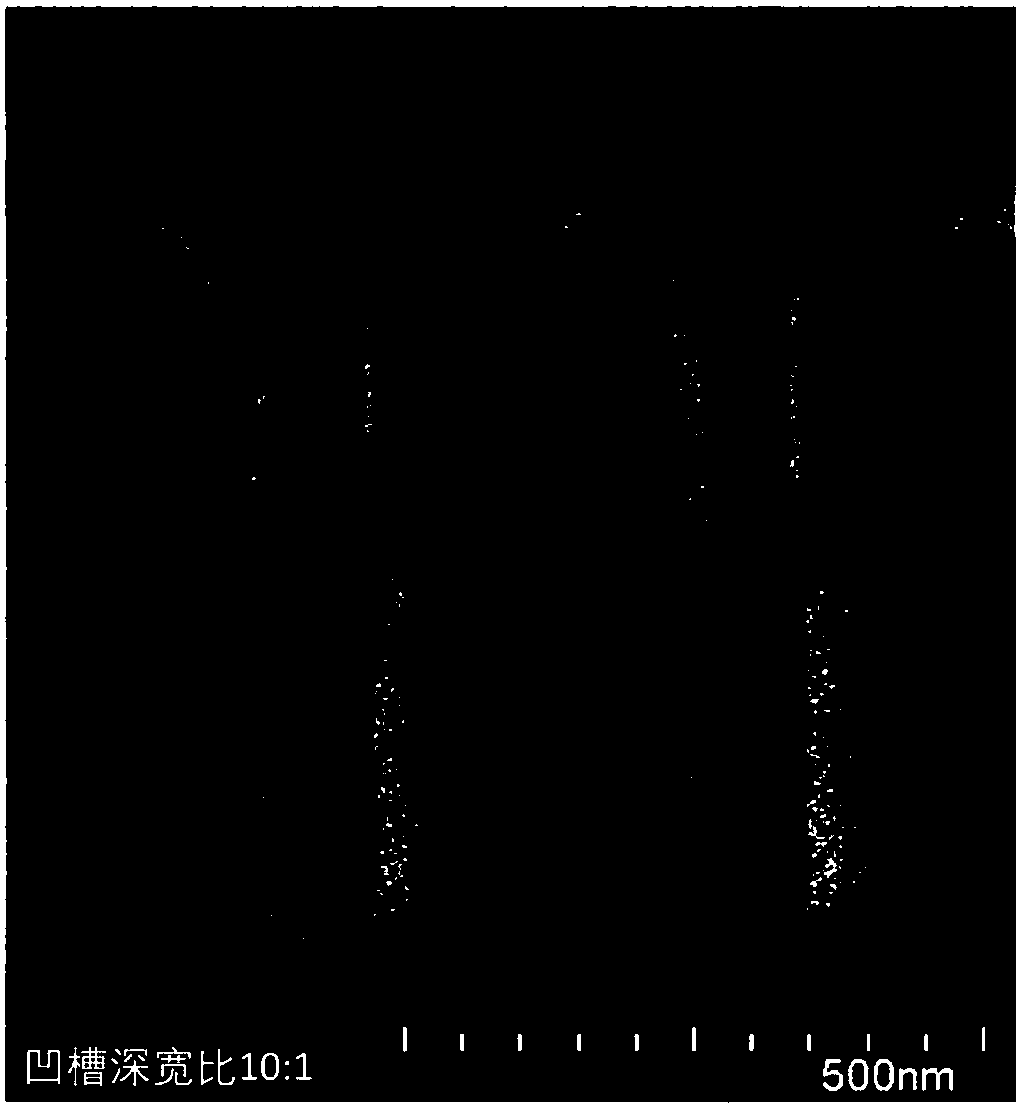

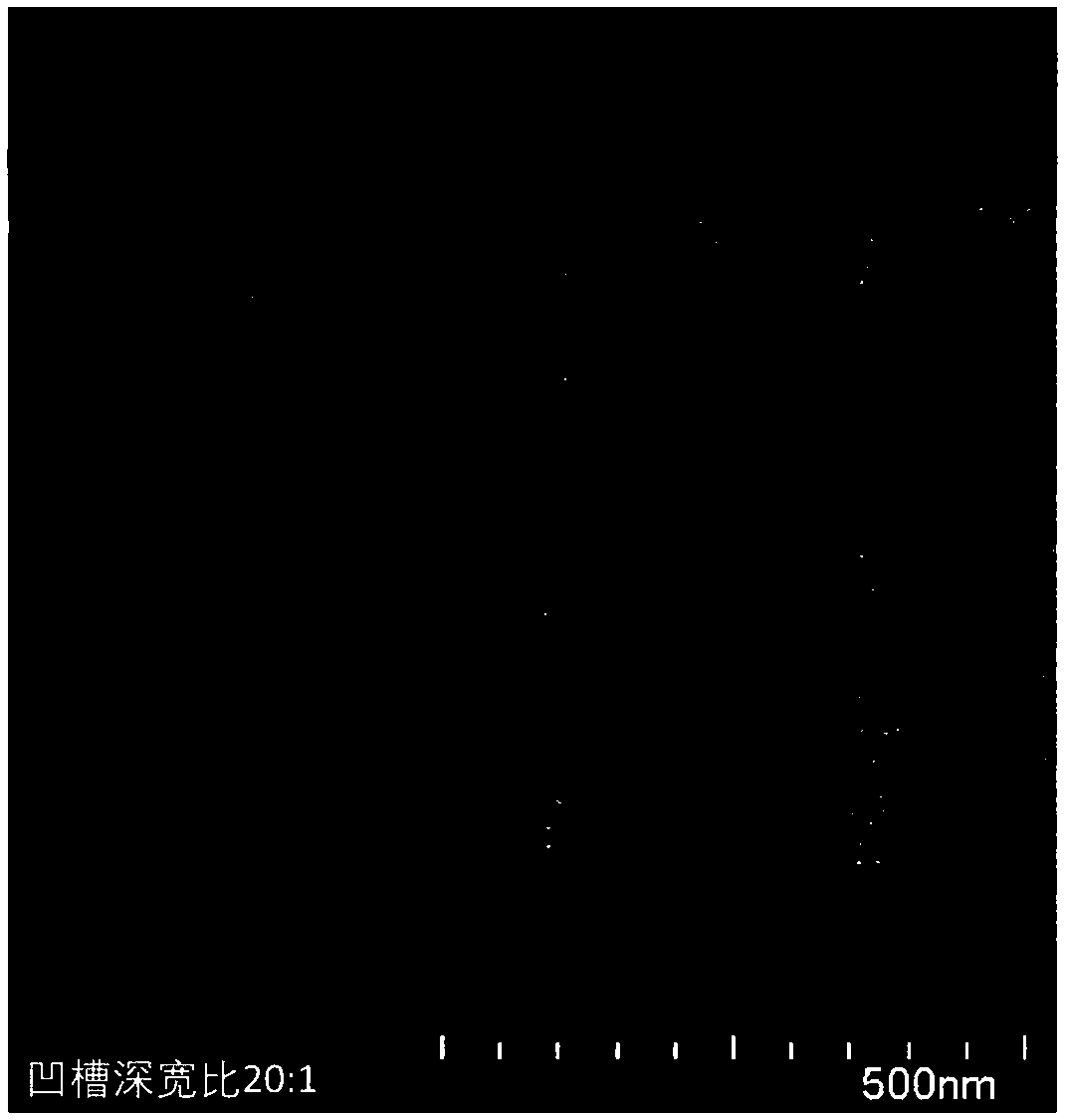

[0060] At a temperature of 20°C, react cyclosilane with a nitrogen-containing compound and deposit it on a single crystal silicon wafer substrate with a medium resistivity (that is, a resistivity of 8-12Ω·cm, such as 8Ω·cm, 10Ω·cm, 12Ω·cm) On the bottom and the silicon pattern wafer, a flowable silicon-nitrogen film is formed; then the flowable silicon-nitrogen film is in O 3 Medium oxidation for 10 minutes, annealing at 700°C for 3 hours after oxidation, and finally a dense silicon oxide film is obtained.

[0061] The cyclosilane is cyclopentasilane, cyclohexasilane or cyclooctylsilane. The nitrogen-containing compound is ammonia, nitrogen / hydrogen mixed gas, hydrazine or nitrogen trifluoride. o 3As an oxidizing gas, the oxidizing gas can also be oxygen, water vapor, nitrous oxide, oxygen plasma or nitrous oxide plasma. A pre-deposition treatment is performed on the above-mentioned single crystal silicon wafer substrate in advance, and the specific pre-deposition treatment...

Embodiment 2

[0064] The difference from Example 1 is that the flowable SiN film is in O 3 Medium oxidation for 15 minutes, followed by annealing at 900°C for 1 hour to obtain a dense silicon oxide film. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 5000 mg / min, the flow rate of nitrogen-containing compound is 1000 sccm, and the in-situ plasma power density is 3.5 W / cm 2 , the pressure is 12Torr.

Embodiment 3

[0066] The difference from Example 1 is that the flowable SiN film contains O 3 The atmosphere is treated with ultraviolet light for 12 minutes, and after oxidation, it is cured by bombardment with oxygen-containing ion beams at 400°C. Repeat the above steps until a dense silicon oxide film with a certain thickness is obtained. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 2000mg / min, the flow rate of nitrogen-containing compound is 600sccm, and the in-situ plasma power density is 0.3W / cm 2 , the pressure is 5Torr.

[0067] The resulting dense silicon oxide film was immersed in a 100:1 hydrofluoric acid solution to measure the wet etching rate, and the wet etching rate was 2.2 times that of the silicon oxide film prepared by traditional thermal deposition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com