A flowable chemical vapor deposition method for silicon oxide films

A flow chemistry and vapor deposition technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as high proportion, inability to meet actual needs, and reduction of H-Si bond density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

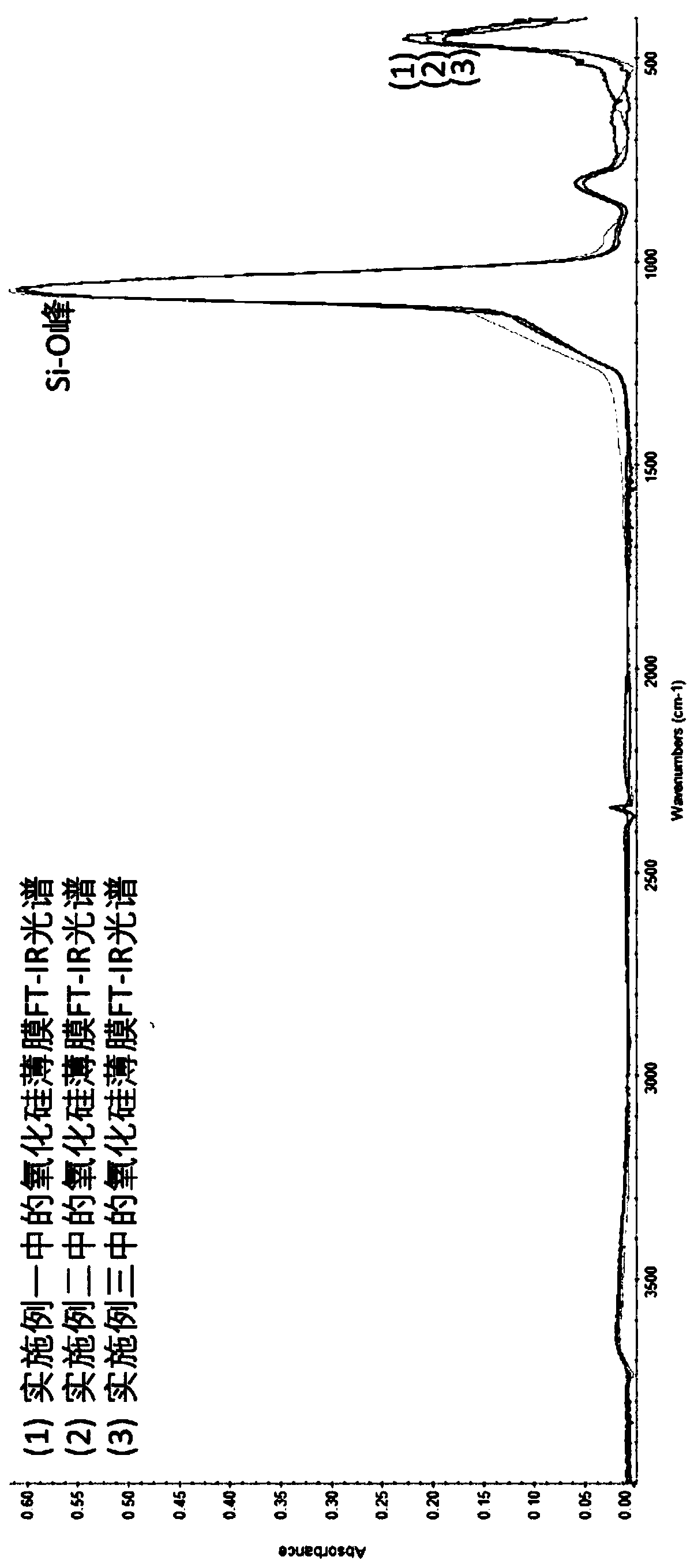

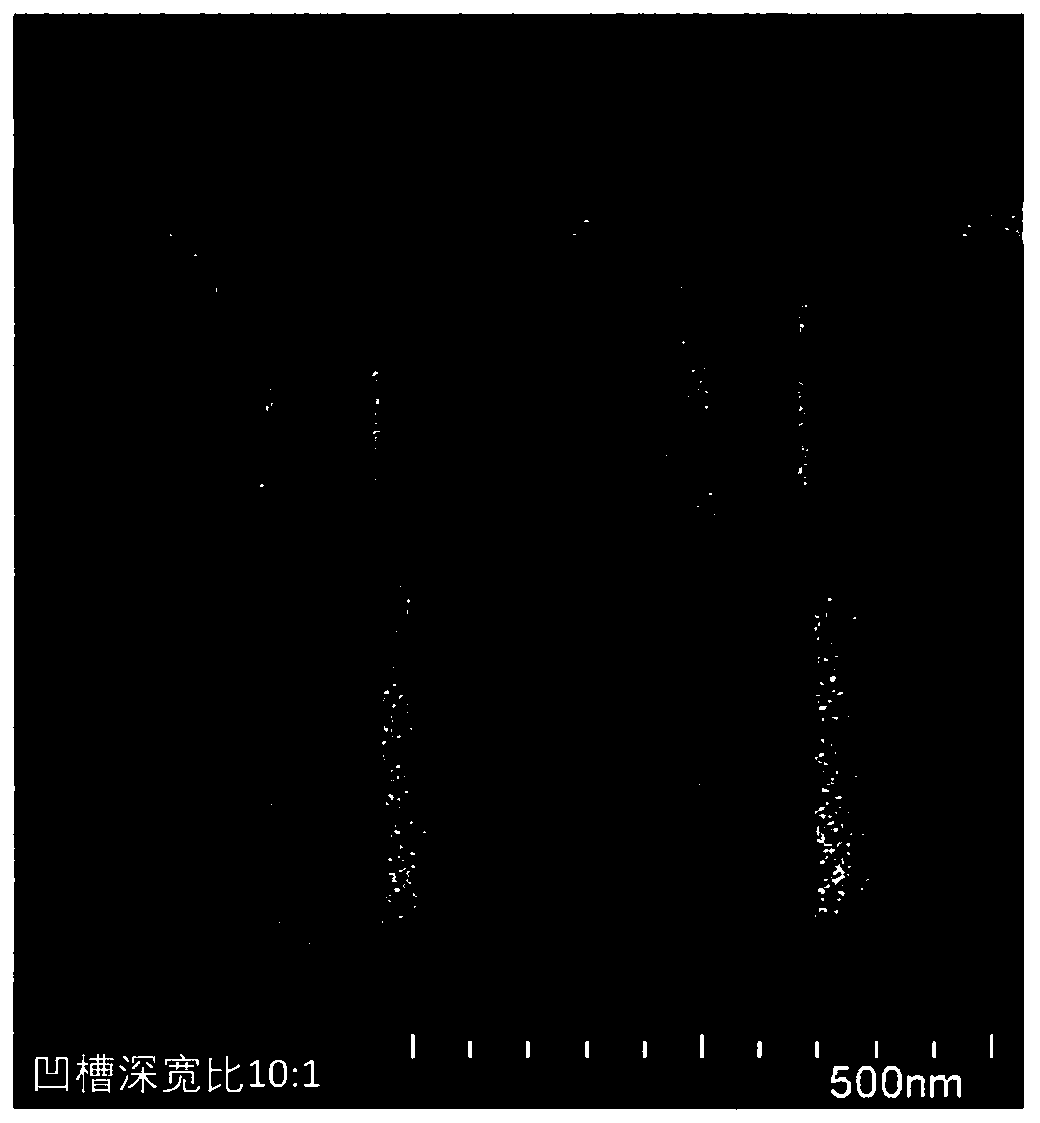

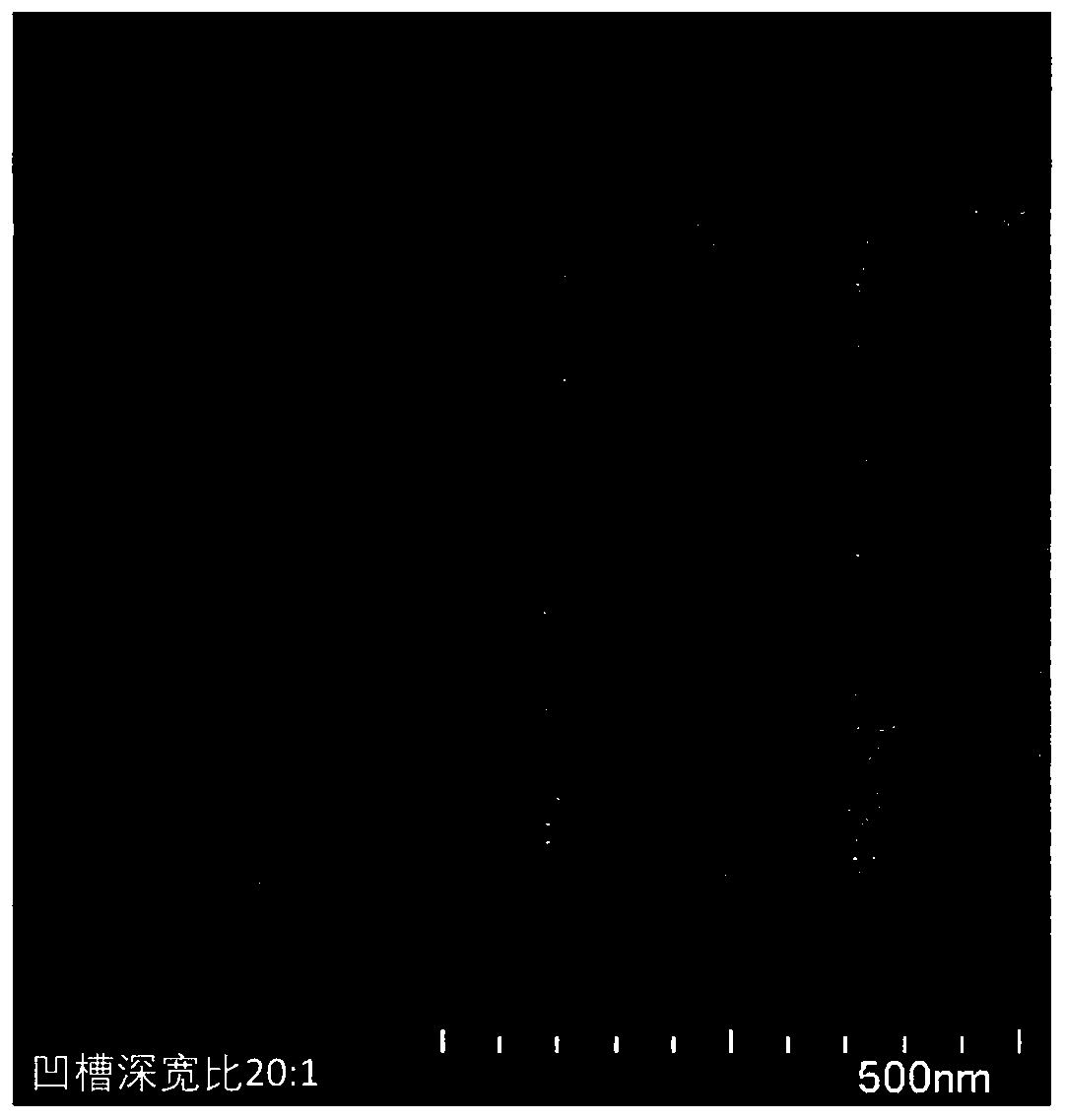

[0060] At a temperature of 20°C, react cyclosilane with a nitrogen-containing compound and deposit it on a single crystal silicon wafer substrate with a medium resistivity (that is, a resistivity of 8-12Ω·cm, such as 8Ω·cm, 10Ω·cm, 12Ω·cm) On the bottom and the silicon pattern wafer, a flowable silicon-nitrogen film is formed; then the flowable silicon-nitrogen film is in O 3 Medium oxidation for 10 minutes, annealing at 700°C for 3 hours after oxidation, and finally a dense silicon oxide film is obtained.

[0061] The cyclosilane is cyclopentasilane, cyclohexasilane or cyclooctylsilane. The nitrogen-containing compound is ammonia, nitrogen / hydrogen mixed gas, hydrazine or nitrogen trifluoride. o 3As an oxidizing gas, the oxidizing gas can also be oxygen, water vapor, nitrous oxide, oxygen plasma or nitrous oxide plasma. A pre-deposition treatment is performed on the above-mentioned single crystal silicon wafer substrate in advance, and the specific pre-deposition treatment...

Embodiment 2

[0064] The difference from Example 1 is that the flowable SiN film is in O 3 Medium oxidation for 15 minutes, followed by annealing at 900°C for 1 hour to obtain a dense silicon oxide film. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 5000 mg / min, the flow rate of nitrogen-containing compound is 1000 sccm, and the in-situ plasma power density is 3.5 W / cm 2 , the pressure is 12Torr.

Embodiment 3

[0066] The difference from Example 1 is that the flowable SiN film contains O 3 The atmosphere is treated with ultraviolet light for 12 minutes, and after oxidation, it is cured by bombardment with oxygen-containing ion beams at 400°C. Repeat the above steps until a dense silicon oxide film with a certain thickness is obtained. The process parameters of the plasma flowable chemical vapor deposition are as follows: the flow rate of cyclosilane is 2000mg / min, the flow rate of nitrogen-containing compound is 600sccm, and the in-situ plasma power density is 0.3W / cm 2 , the pressure is 5Torr.

[0067] The resulting dense silicon oxide film was immersed in a 100:1 hydrofluoric acid solution to measure the wet etching rate, and the wet etching rate was 2.2 times that of the silicon oxide film prepared by traditional thermal deposition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com