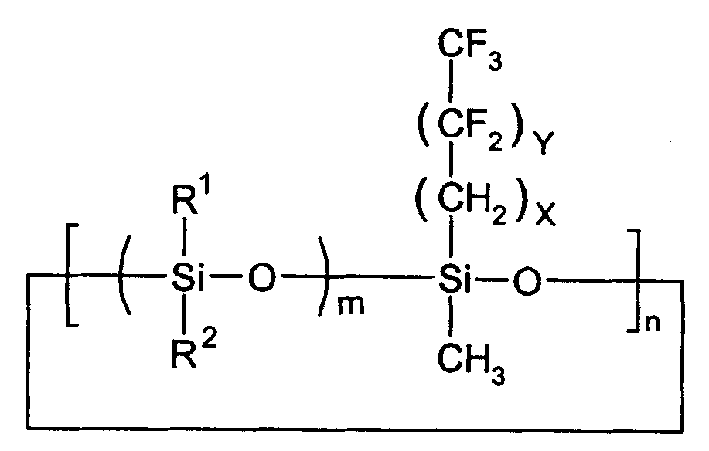

Mixed fluorinated cyclosiloxane, preparing method and use thereof

A technology of siloxane and mixed rings, applied in the direction of silicon organic compounds, etc., can solve the problems of poor stability and achieve the effect of excellent performance, good heat resistance and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The three-neck reaction flask is equipped with electromagnetic stirring, reflux condenser, thermometer and addition funnel. Add 0.35mol of calcium oxide and 150ml of ethyl acetate into the reaction flask and stir to form a suspension. Add dropwise 0.15mol of the pre-mixed solution under cooling in a water bath at 20°C. f 3 C(CF 2 ) Y (CH 2 ) x Si(CH 3 ) Cl 2 (X=2; Y=0) and 0.2mol dimethyldichlorosilane mixture; after adding the dichlorosilane mixture, continue to react for 1h; filter out the insoluble calcium salt, wash the filtrate with water 100ml×2 times, and then wash 100ml with distilled water × 2 times; dried with anhydrous sodium sulfate, filtered, distilled off ethyl acetate to obtain 28.5 g of fluorine-containing mixed cyclosiloxane, and the yield (based on the total amount of dichlorosilane) was 79.4%. product 19 F NMR (δ) - 70.57 ppm, 21.18% fluorine content.

Embodiment 2

[0023] The three-neck reaction flask is equipped with electromagnetic stirring, reflux condenser, thermometer and addition funnel. Add 0.35mol of magnesium oxide and 150ml of ethyl acetate into the reaction flask and stir to form a suspension, and dropwise add 0.15mol of the pre-mixed solution under cooling in a water bath at 20°C. f 3 C(CF 2 ) Y (CH 2 ) x Si(CH 3 ) Cl 2 (X=2; Y=0) and 0.2mol dimethyldichlorosilane mixture; after adding the dichlorosilane mixture, continue to react for 1h; filter off the insoluble magnesium salt, wash the filtrate with water 100ml×2 times, and then wash 100ml with distilled water × 2 times; dried with anhydrous sodium sulfate, filtered, distilled off ethyl acetate to obtain 24.5 g of fluorine-containing mixed cyclosiloxane, and the yield (based on the total amount of dichlorosilane) was 68.8%. product 19 F NMR (CDCl 3 , δ): -70.59ppm, the fluorine content is 21.21%.

Embodiment 3

[0025] The three-neck reaction flask is equipped with electromagnetic stirring, reflux condenser, thermometer and addition funnel. Add 0.6mol of zinc oxide and 250ml of ethyl acetate into the reaction flask and stir to form a suspension, then add the pre-mixed 0.1mol dropwise under cooling in a water bath at 20°C. f 3 C(CF 2) Y (CH 2 ) x Si(CH 3 ) Cl 2 (X=2; Y=10) and 0.5mol ethylmethyldichlorosilane mixture; after adding the dichlorosilane mixture, continue to react for 2h; wash the reaction solution with water 150ml×2 times, then wash 150ml×2 times with distilled water; After drying with anhydrous sodium sulfate, filter, distill off ethyl acetate to obtain 82.2 g of fluorine-containing mixed cyclosiloxane, and the yield (based on the total amount of dichlorosilane) is 71.0%. The fluorine content of the product is 34.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com