Optical grade polymethyl methacrylate continuous solution polymerization process and equipment used

A technology of polymethyl methacrylate and polymerization process, which is applied in the field of polymer compound preparation, can solve problems such as poor devolatilization process, fast reaction rate, and large heater, so as to reduce rapid reaction heat release and improve performance and color, the effect of reducing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

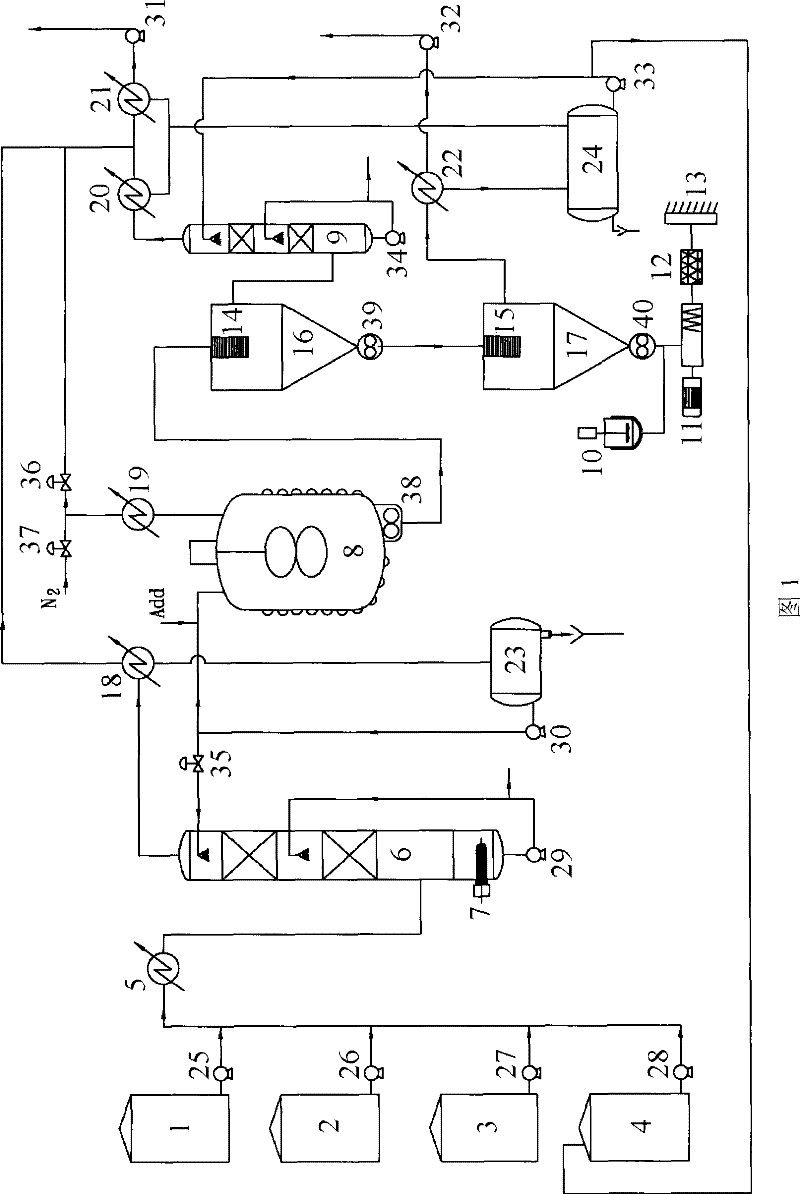

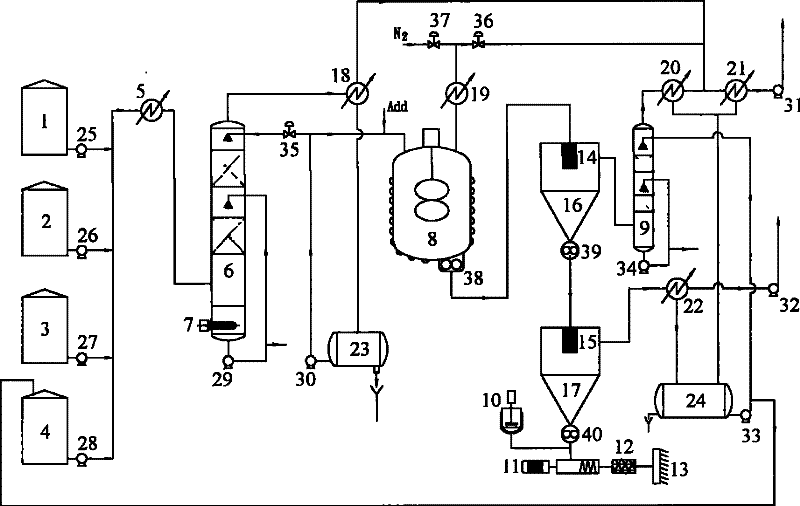

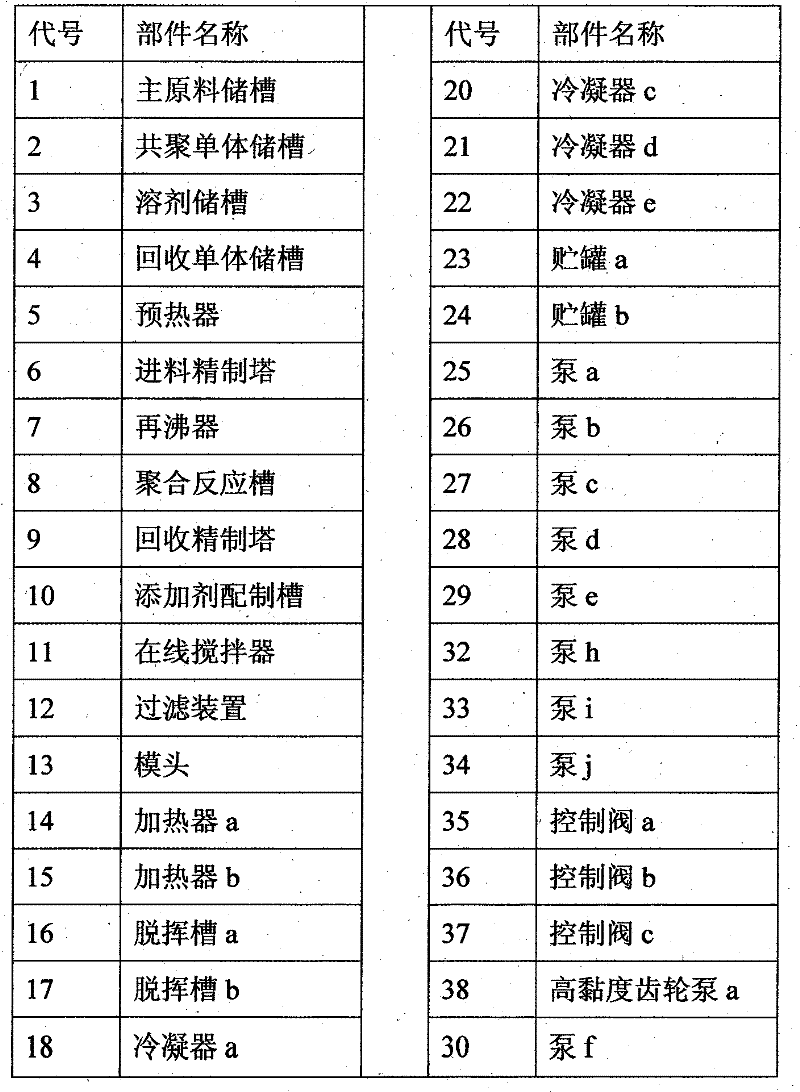

[0052] Such as figure 1 As shown, a kind of equipment used in the continuous solution polymerization process of optical grade polymethyl methacrylate is composed of a refining distillation device, a polymerization reaction device, a two-stage devolatilization device and a wire drawing granulation device in series, including: the main raw material storage Tank 1, comonomer storage tank 2, solvent storage tank 3, recovered monomer storage tank 4, preheater 5, feed refining tower 6, reboiler 7, polymerization reaction tank 8, recovery refining tower 9, additive preparation Tank 10, online stirrer 11, filter device 12, die head 13, heater a14, heater b15, devolatilization tank a16, devolatilization tank b17, condenser a18~condenser e22, storage tank a23, b24, pump a25 ~ pump j34, control valve a35 ~ control valve c37 and high viscosity gear pump a38 ~ high viscosity gear pump c40;

[0053] Among them, the main raw material storage tank 1, the comonomer storage tank 2, the solvent...

Embodiment 2

[0071] Optical grade polymethyl methacrylate continuous type solution polymerization equipment used is the same as embodiment 1, when implementing optical grade polymethyl methacrylate continuous type solution polymerization technology, except the following conditions:

[0072] 1. During the refining distillation of the first step: the solvent accounts for 5% of the total weight of the reactants; the preheater 5 is heated to 60°C; 3 Pa;

[0073] 2. During the polymerization reaction in the second step: the temperature of the polymerization reaction is controlled at 130°C;

[0074] 3. During step ③ flashing devolatilization: heater a14 is heated to 220°C; the air pressure in devolatilization tank a16 is 4×10 3 Pa; the temperature at the top of recovery refining tower 9 is at 30°C, and the air pressure in the tower is at 4×10 3 Pa; the heater b15 is heated to 220°C;

[0075] Other conditions are all the same as in Example 1.

Embodiment 3

[0077] Optical grade polymethyl methacrylate continuous type solution polymerization equipment used is the same as embodiment 1, when implementing optical grade polymethyl methacrylate continuous type solution polymerization technology, except the following conditions:

[0078] 1. During the refining distillation of the ① step: the solvent accounts for 17% of the total weight of the reactant; the preheater 5 is heated to 95° C.; 4 Pa;

[0079] 2. During the polymerization reaction in the second step: the temperature of the polymerization reaction is controlled at 145°C;

[0080] 3. In step ③ flash devolatilization: Heater a14 is heated to 270°C; the air pressure in the devolatilization tank a16 is 2.5×10 4 Pa; the temperature at the top of recovery refining tower 9 is at 55°C, and the air pressure in the tower is at 2.5×10 4 Pa; the heater b15 is heated to 255°C;

[0081] Other conditions are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com