Product made of clay embedded with block copolymer

A technology of block copolymer and clay, which is applied in the treatment of dyed polymer organic compounds, silicon compounds, aluminum compounds, etc., can solve the problems of loss of mechanical strength and achieve the effect of improving modulus and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

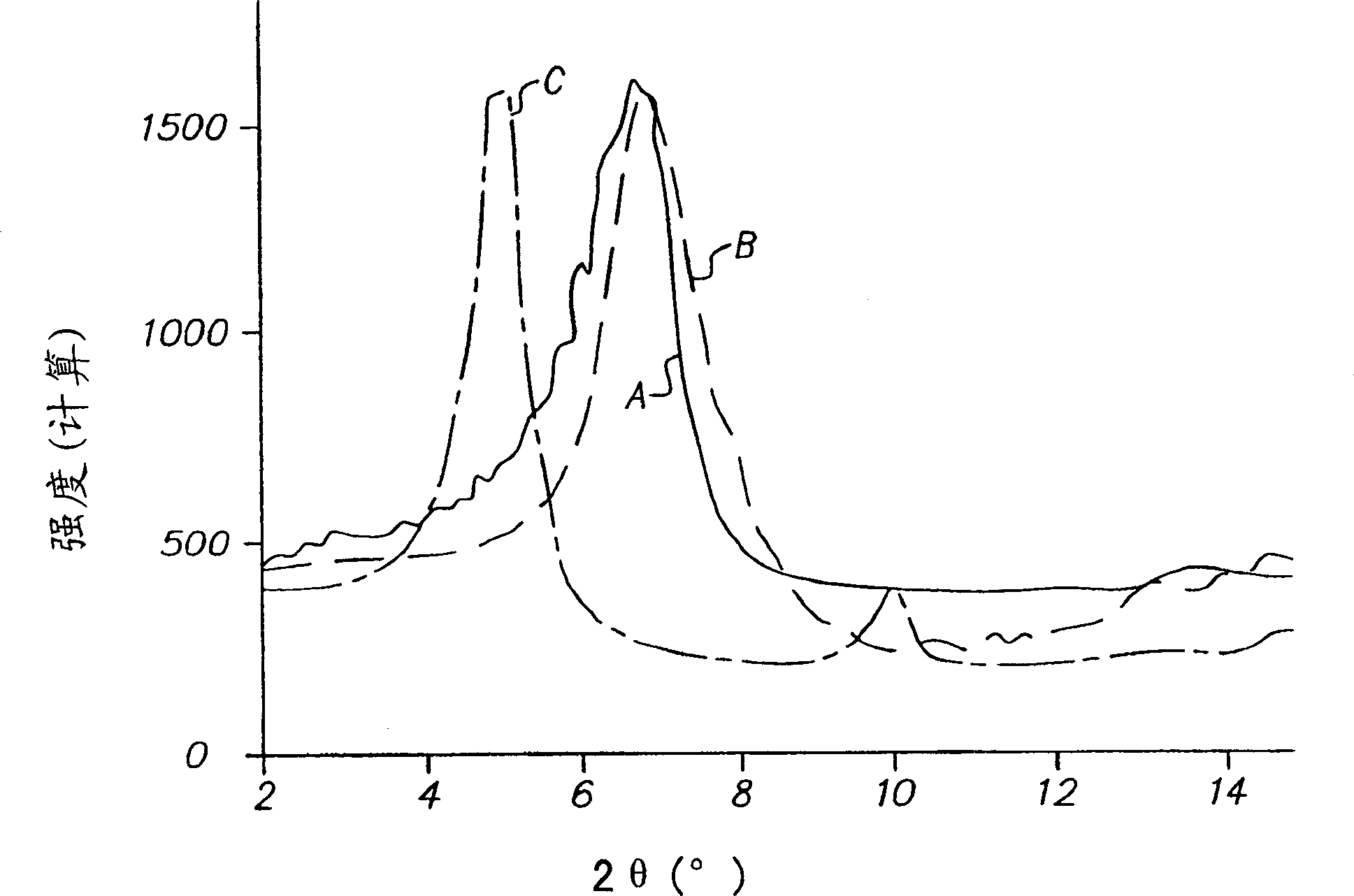

[0079] Samples of Examples 1 to 3 were prepared by weighing predetermined amounts of Na Cloisite clay and PEO-b-PCL in glass containers. The mixture was heated in the oven at 70°C, mixed with a spatula, heated on a hot plate, then mixed with the spatula again and cooled to ambient temperature (21°C). An aliquot of Examples 1 to 3 in the solid state was placed between two polytetrafluoroethylene or polyimide sheets and then pressed using a Carver press while the heating plate was maintained at 175°C. The (001) basal-planar spacing of the film samples obtained was analyzed by means of XRD. The XRD results for Examples 1 to 3 and Na Cloisite clay are summarized in Table 1. These data indicate that PEO-PCL is embedded in Na Cloisite clay, as reflected by the (001) basal plane spacing.

[0080] sample

[0081] Samples for Examples 4 to 6 were prepared by weighing predetermined amounts of Na Cloisite or Cloisite 25A clay and PEO-b-PCL into separate glass containers. Hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com