Patents

Literature

297results about How to "The process is easy to implement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

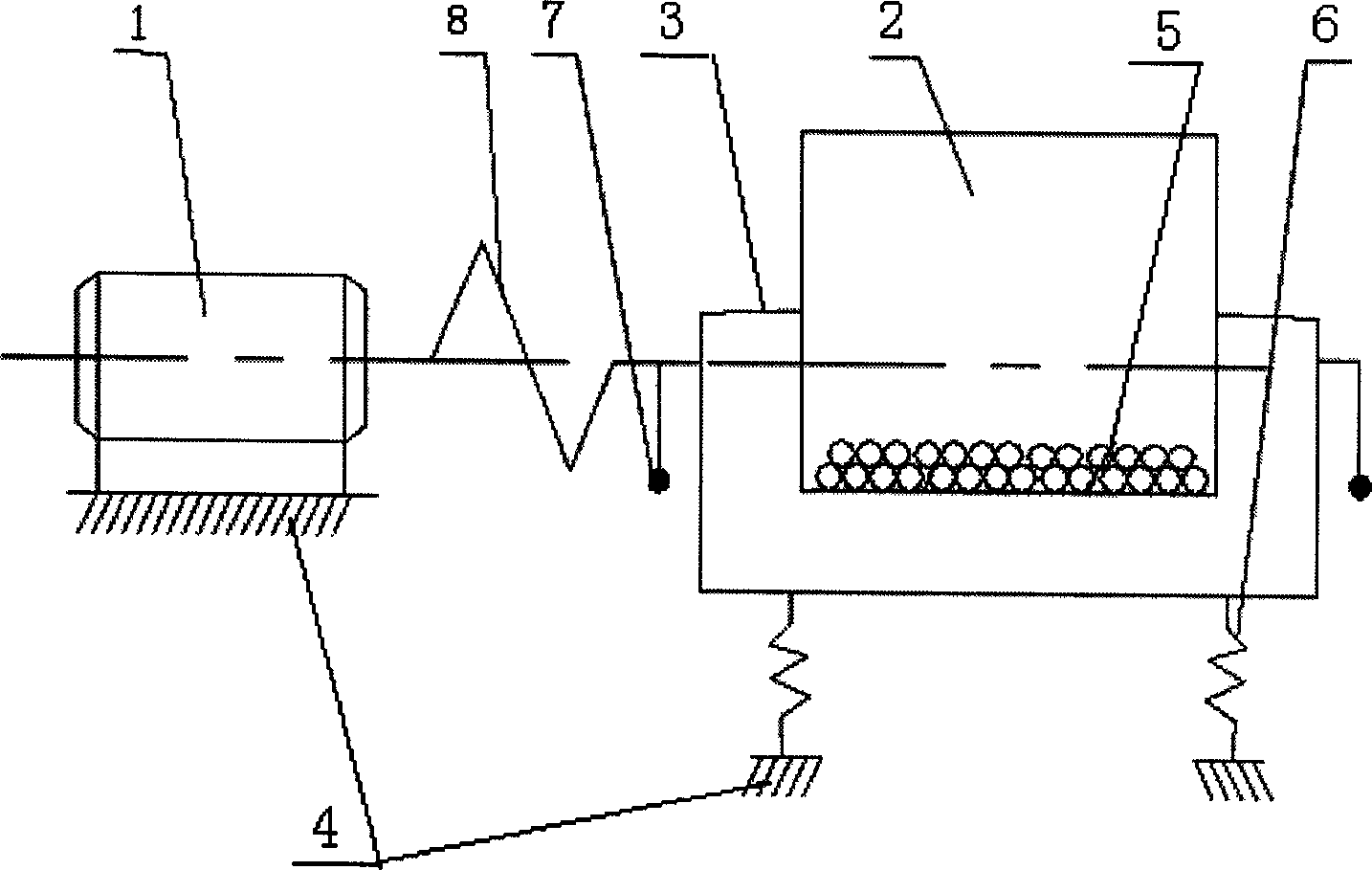

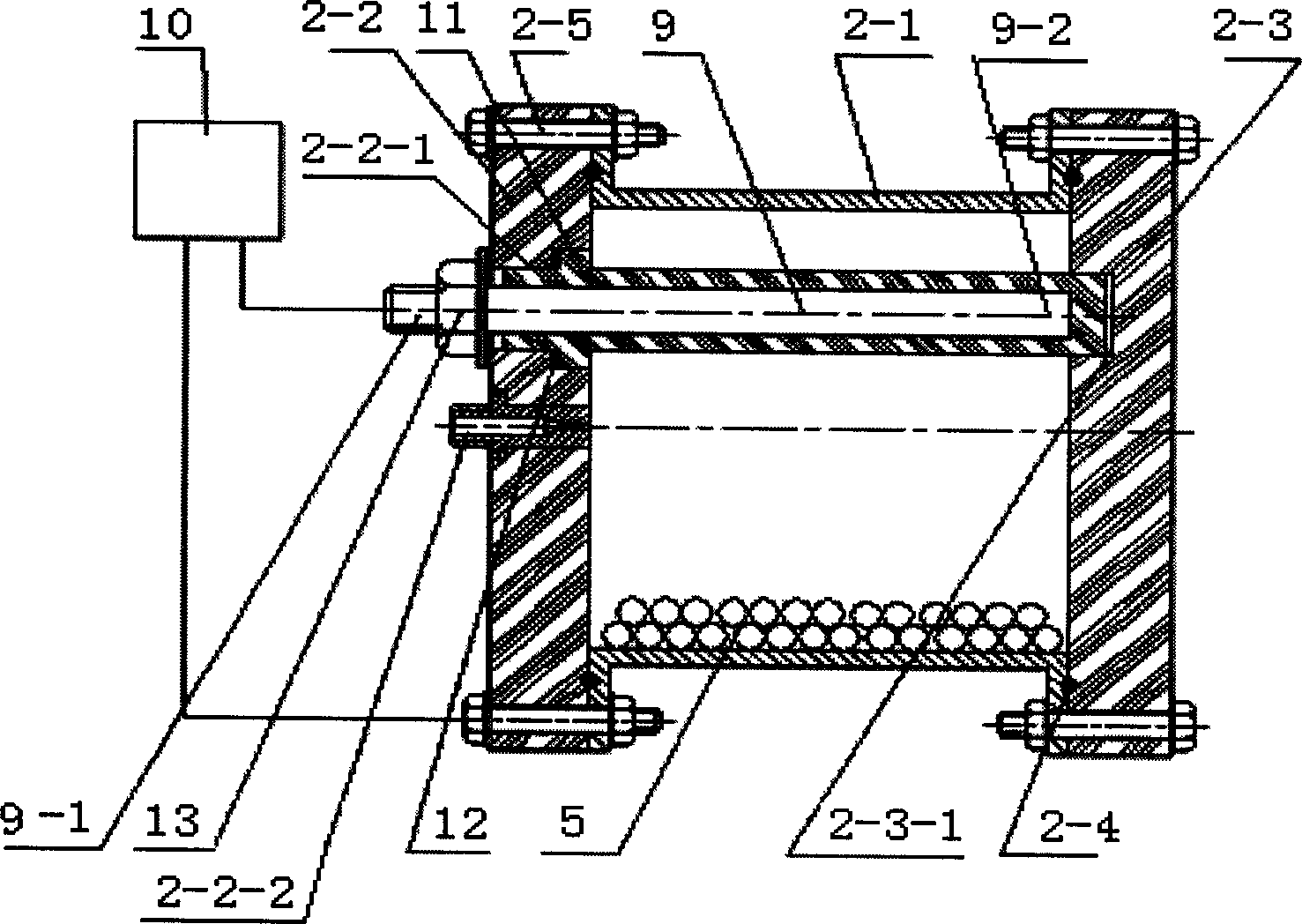

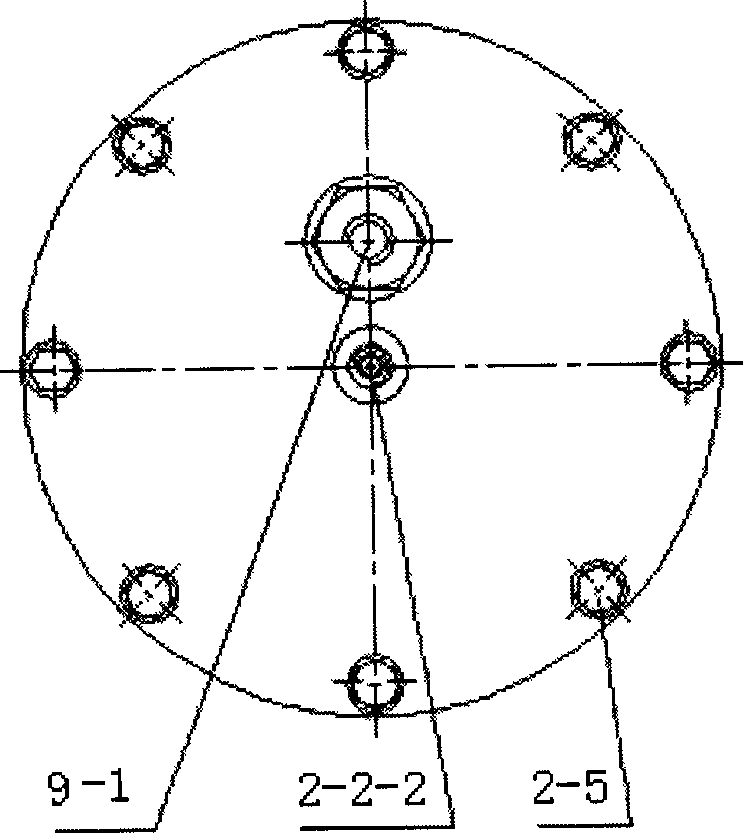

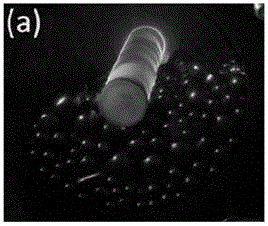

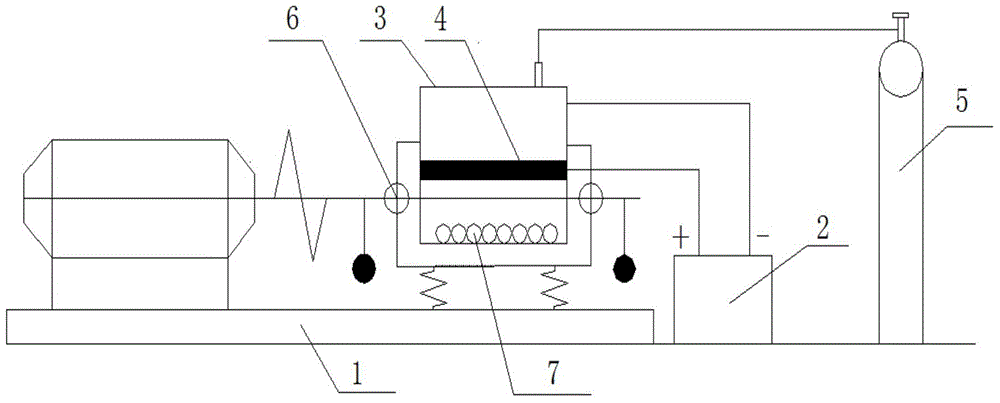

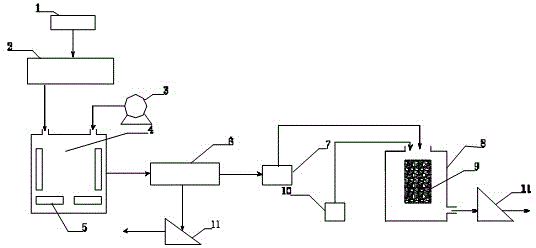

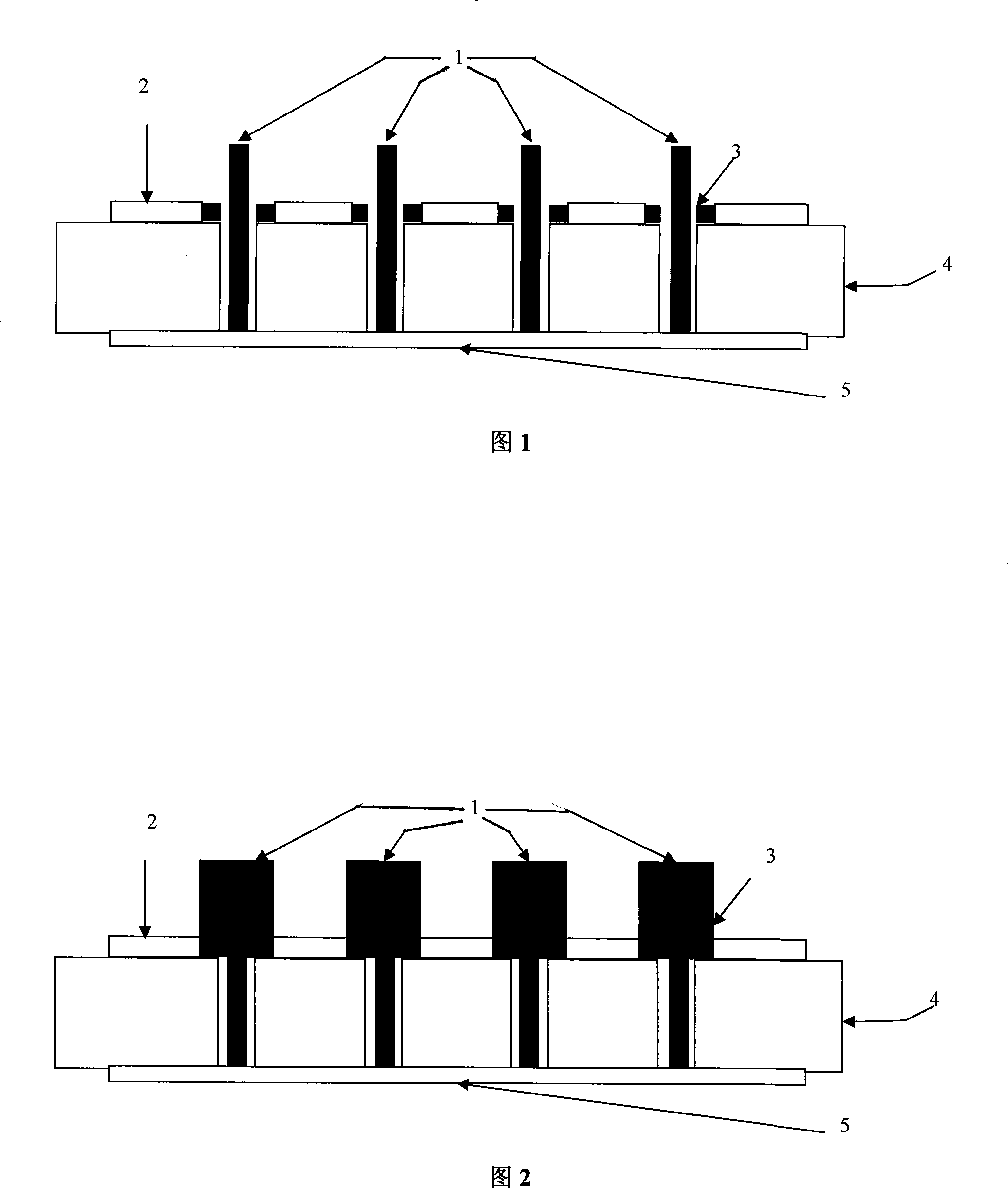

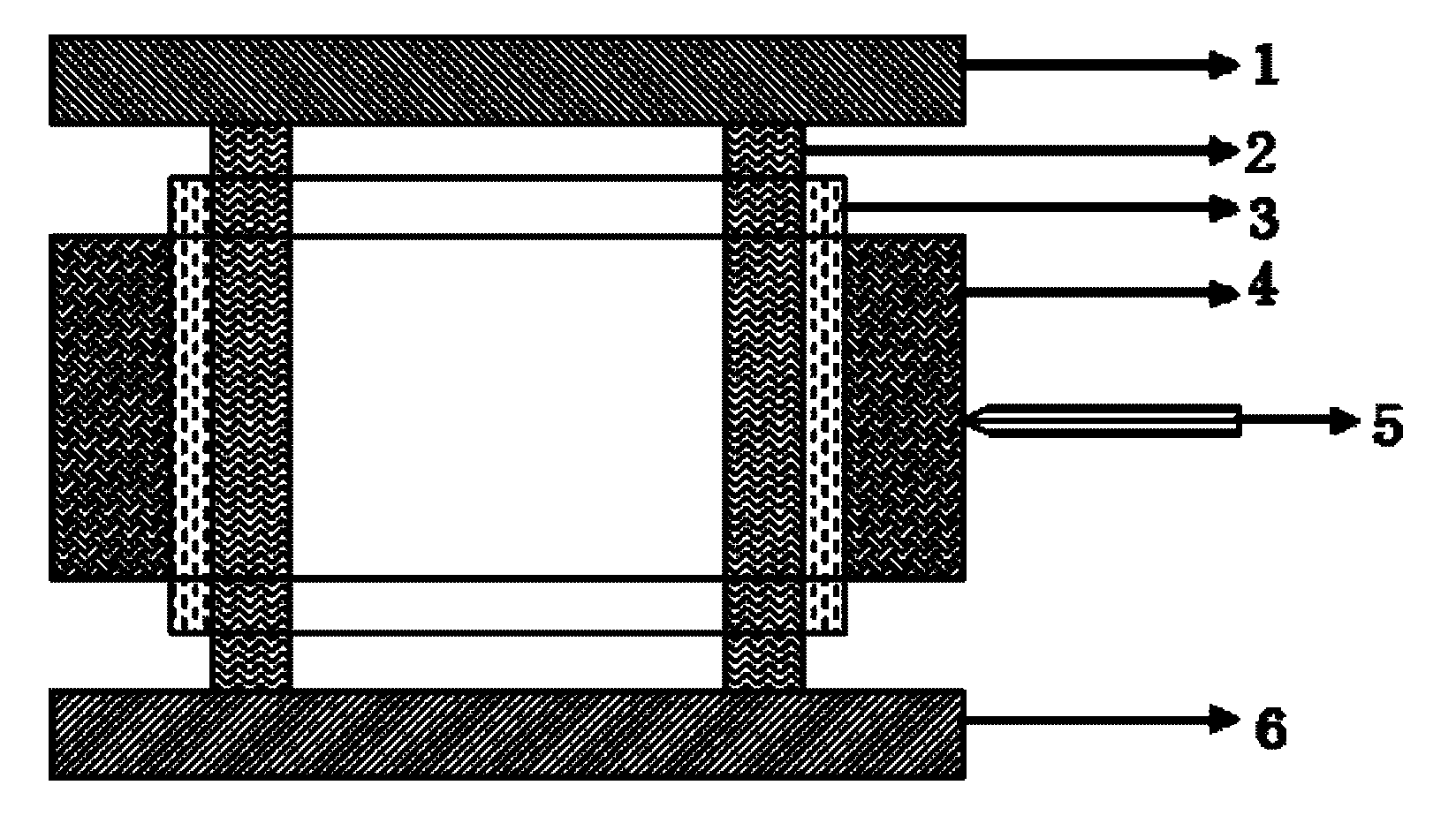

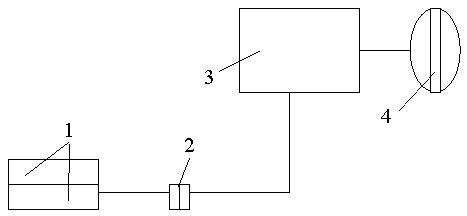

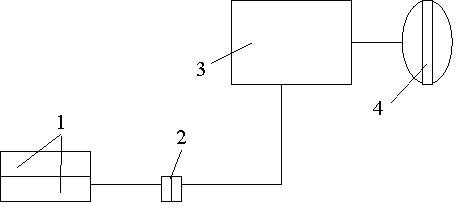

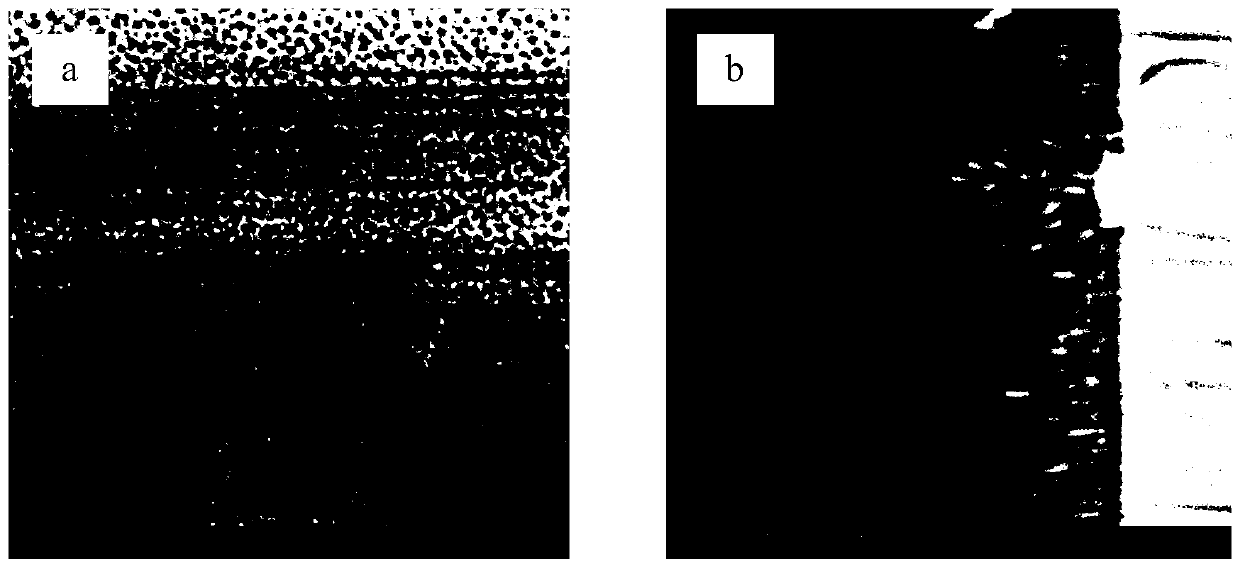

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

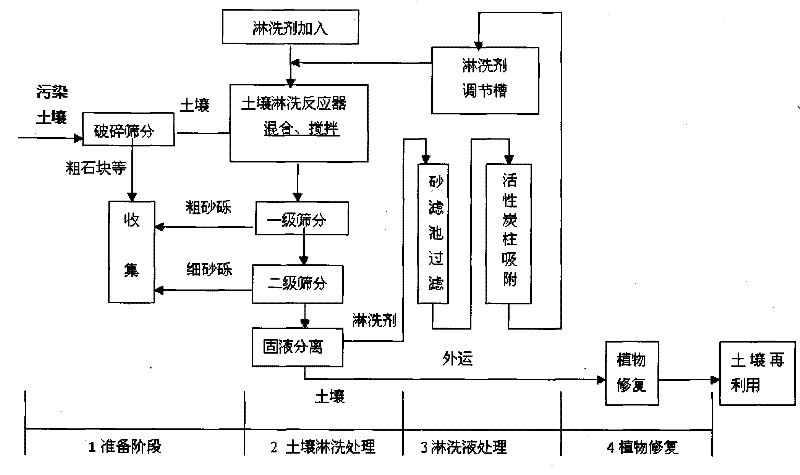

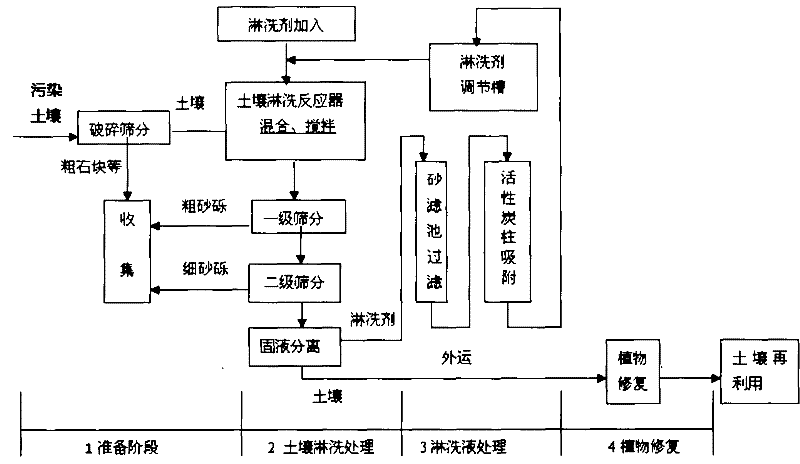

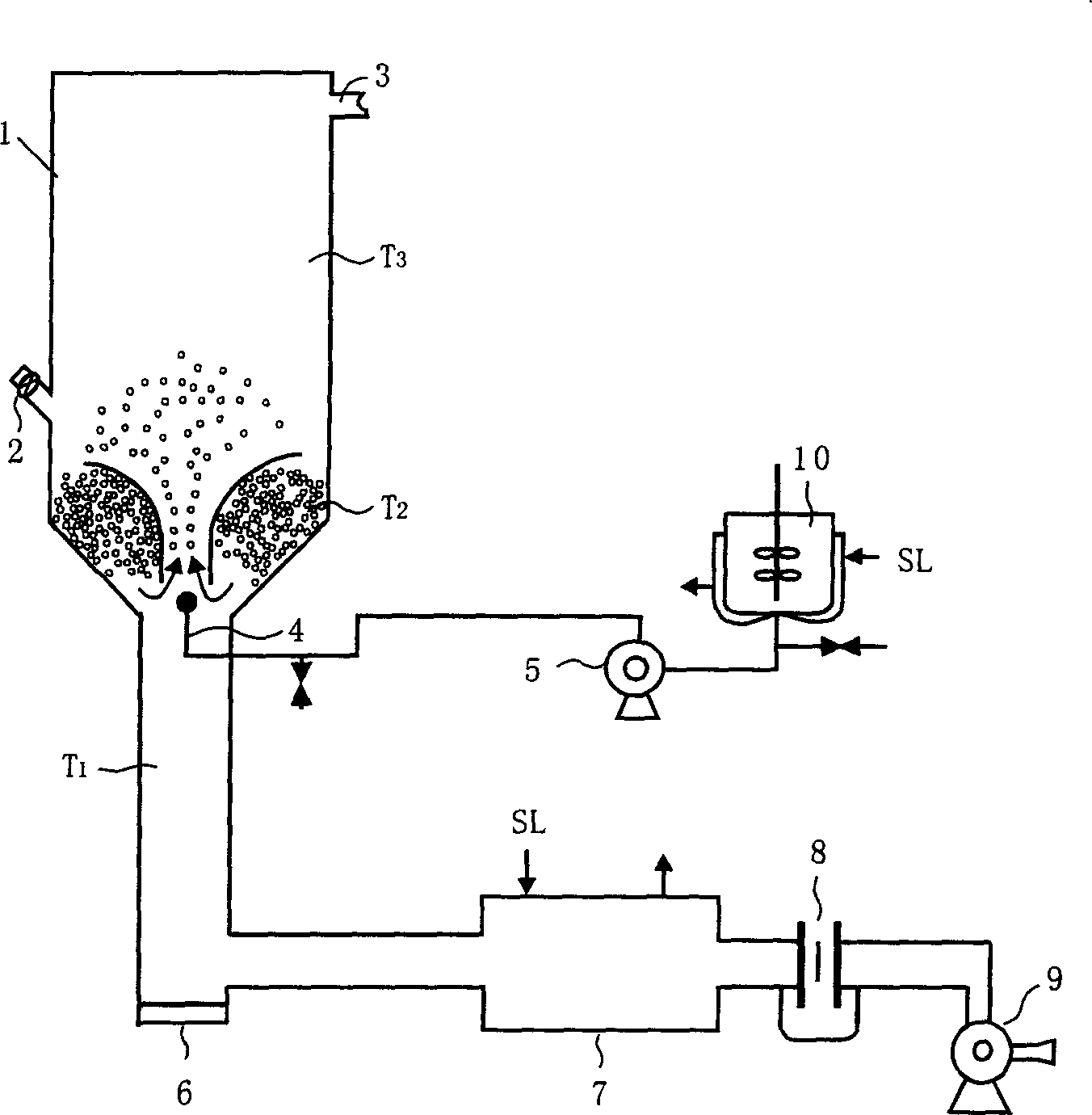

Ex-situ washing remediation method for nitrochlorobenzene-contaminated soil

InactiveCN102172614AThe process is easy to implementReduce labor inputContaminated soil reclamationEngineeringSlurry

The invention discloses an ex-situ washing remediation method for nitrochlorobenzene-contaminated soil, which comprises the following steps: crushing soil and sieving to remove stones and gravels; filling the soil into a washing reactor to fully mix the soil with a proper amount of washing solution, wherein the washing agent is ethanol; subjecting the washed mixture of slurry to two stages of sieving and filtering, wherein soil particles with large particle sizes are stopped by a screen; pumping the slurry mixture to soil-liquid separation equipment, recovering, filtering and purifying separated washing solution to regenerate the washing solution, regulating the concentration of the washing solution, and leaving the washing solution for washing at next time of washing. A sand filter column is used for filtering, active carbon is used for absorbing molecules of organic contaminants such as nitrochlorobenzene in the washing solution instead of molecules of ethanol serving as the washing agent, and thus, the washing solution is purified and can be recovered and recycling of resources is realized. The organic contaminant content of the washed soil reaches related standards. The soil particles which are sieved and filtered out can be used as building and road construction materials; and the soil particles obtained by solid-liquid separation can be used as raw materials for making concrete and fire bricks and also can be reclaimed. Thus, the whole soil remediation process is accomplished. In the invention, the process is easy to implement, small-scale industrial application can be realized, and an effective means is provided for scientific researchers for researching soil remediation.

Owner:南京市生态环境保护科学研究院

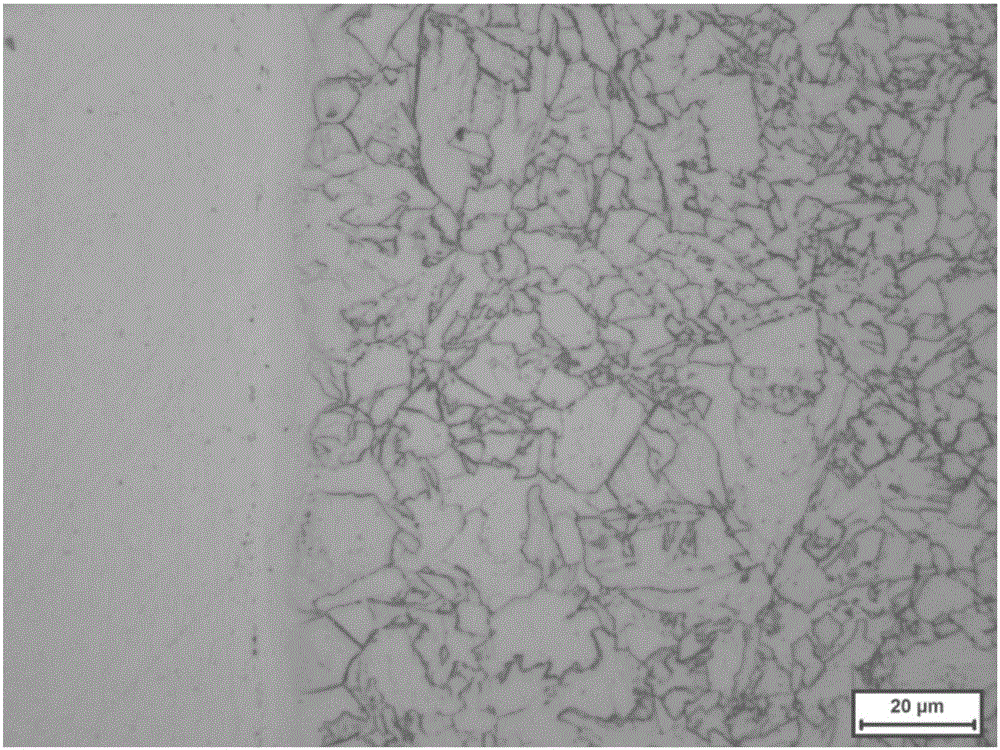

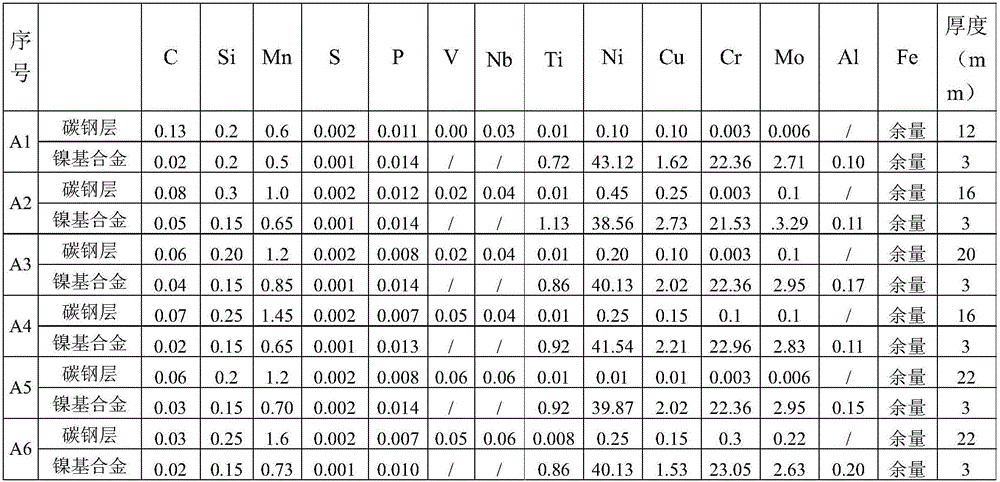

Nickel base alloy clad steel plates for pipeline and manufacturing method thereof

InactiveCN105671424AImprove bindingImprove mechanical propertiesMetal rolling arrangementsRoom temperatureAlloy

The invention discloses nickel base alloy clad steel plates for a pipeline. Each nickel base alloy clad steel plate comprises a nickel base alloy layer and a carbon steel layer. Each carbon steel layer comprises, by mass percentage, 0.01-0.20% of C, 0.10-0.5% of Si, 0.5-2.0% of Mn, at least one of less than or equal to 0.10% of V, less than or equal to 0.10% of Nb, less than or equal to 0.02% of Ti, less than or equal to 0.50% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.50% of Cr and less than or equal to 0.3% of Mo, and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the nickel base alloy clad steel plates for the pipeline. The method comprises the steps that 1, a carbon steel blank and a nickel base alloy blank are obtained; 2, the blanks are assembled through a symmetrical splitting method; 3, composite rolling is conducted, and two sets of double-layer clad steel plates are obtained; and 4, air cooling or water cooling is conducted after rolling till the room temperature is reached, or solid solution treatment is conducted.

Owner:BAOSHAN IRON & STEEL CO LTD

Release control urea and its preparing process

InactiveCN1666972AHydrolysis controlControl supplyAgriculture gas emission reductionFertilizer mixturesAcrylic resinNitrification inhibitors

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Ultrahigh strength steel with 960MPa of yield strength and production method thereof

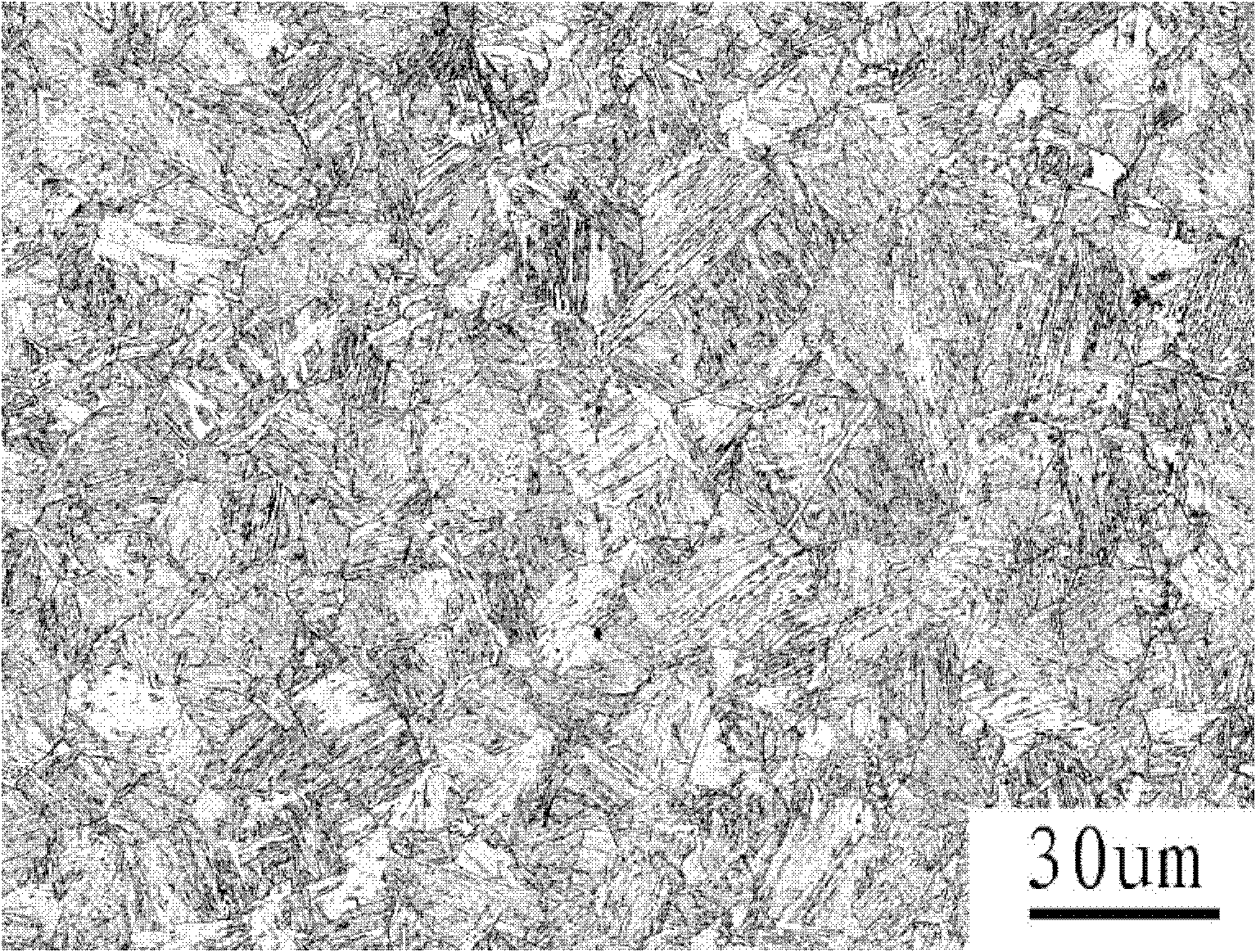

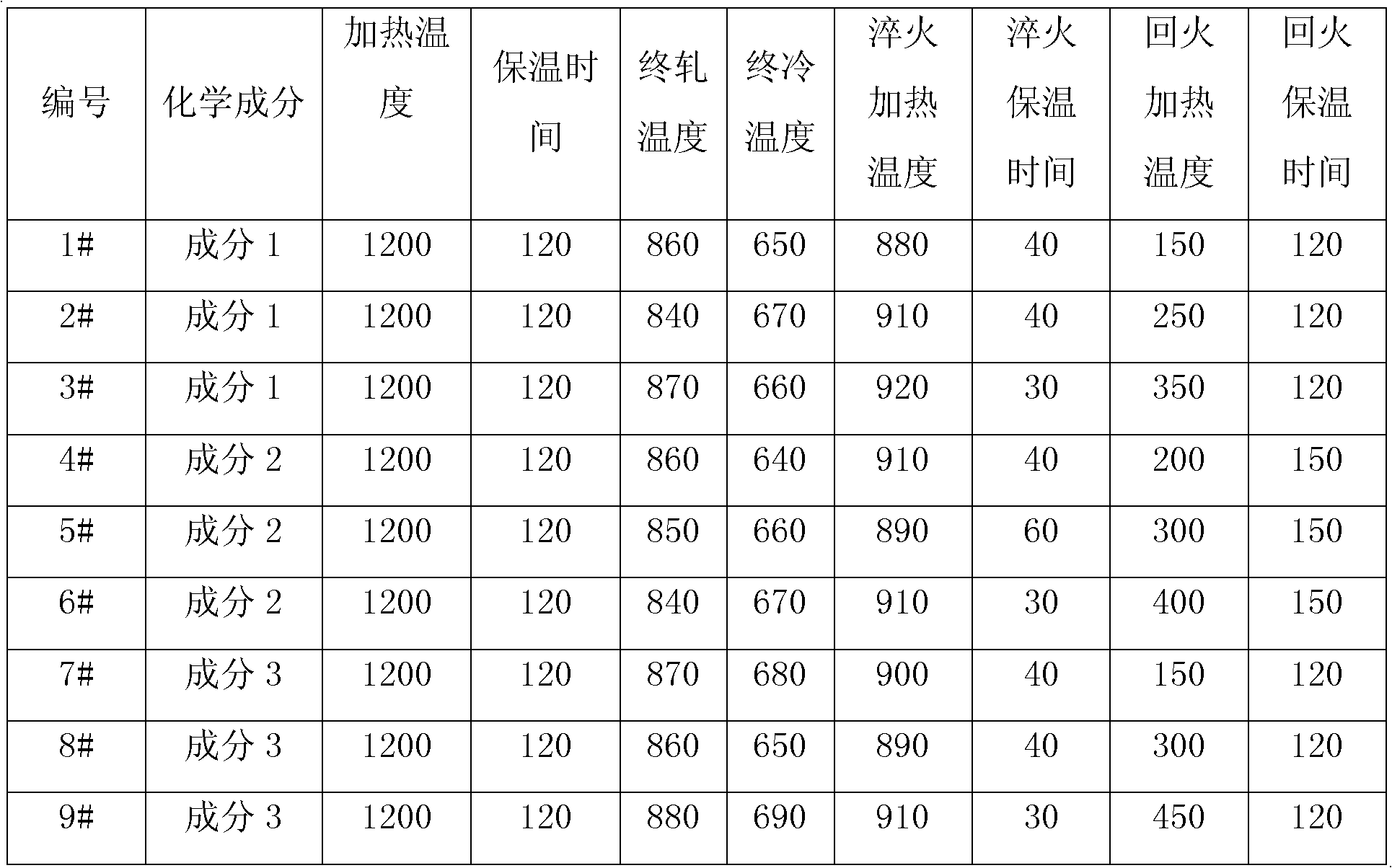

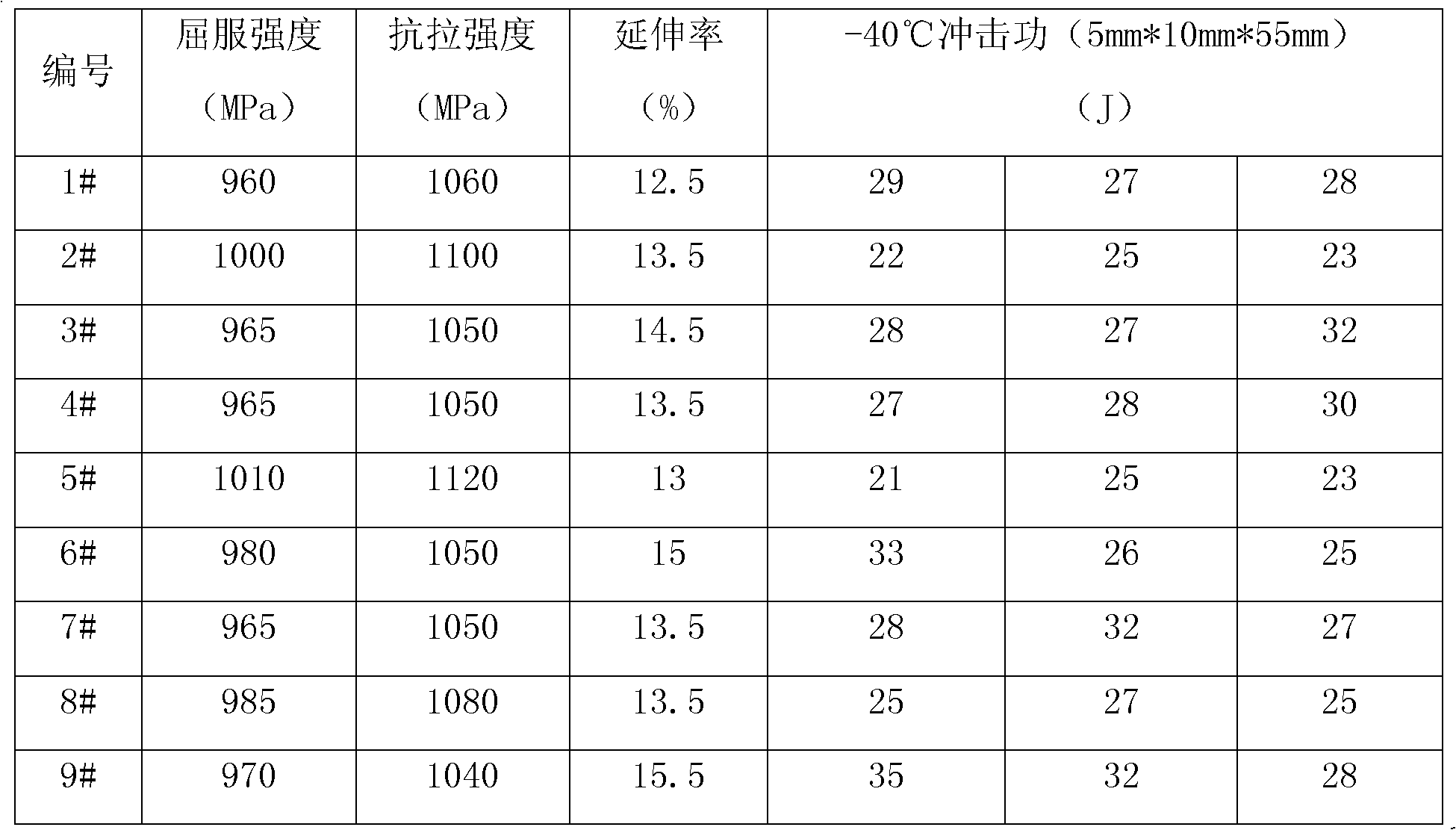

The invention provides ultrahigh strength steel with 960MPa of yield strength and a production method thereof. The steel comprises the following chemical components by weight percent: 0.07-0.09% of C, 0.15-0.25% of Si, 1.00-1.20% of Mn, 1.05-1.15% of Cr, 0.15-0.20% of Mo, 0.01-0.06% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.008% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and casting are performed to obtain a casting blank, and the casting blank is heated to 1150-1250 DEG C; the finish rolling temperature is 840-900 DEG C; the finish cooling temperature is 640-700 DEG C; and quenching and tempering are performed, the quenching heating temperature is 880-920 DEG C, the heating preservation time is 20-60 minutes, the tempering heating temperature is 150-450 DEG C, and the heating preservation time is 90-180 minutes. The obtained material meets the performance requirement of the 960MPa grade ultrahigh strength steel and has good elongation rate and impact toughness.

Owner:SHOUGANG CORPORATION

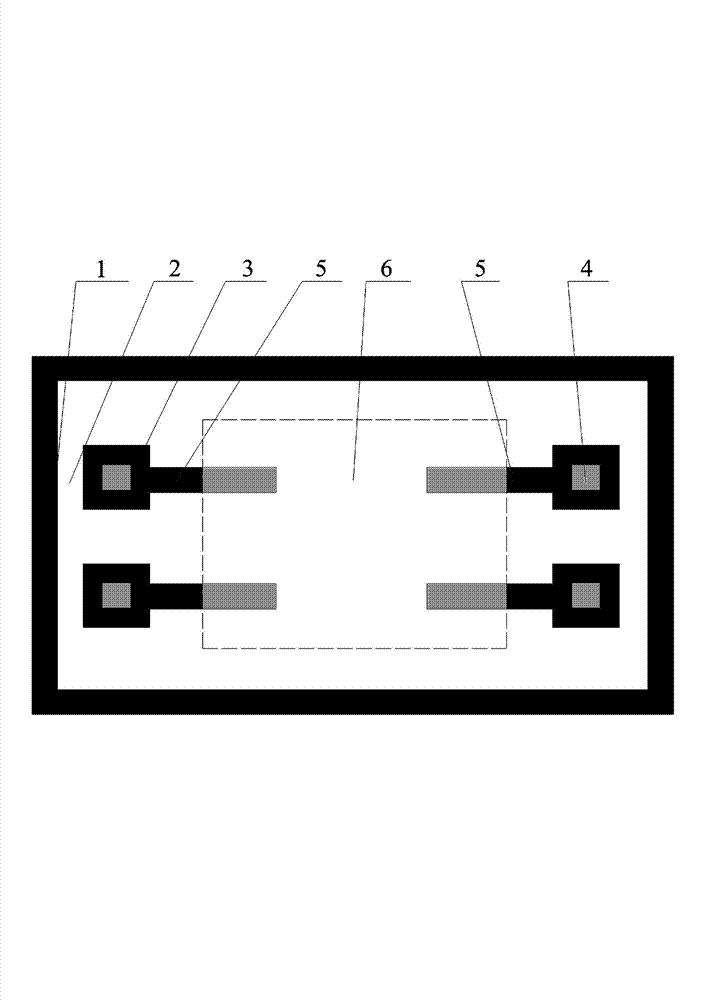

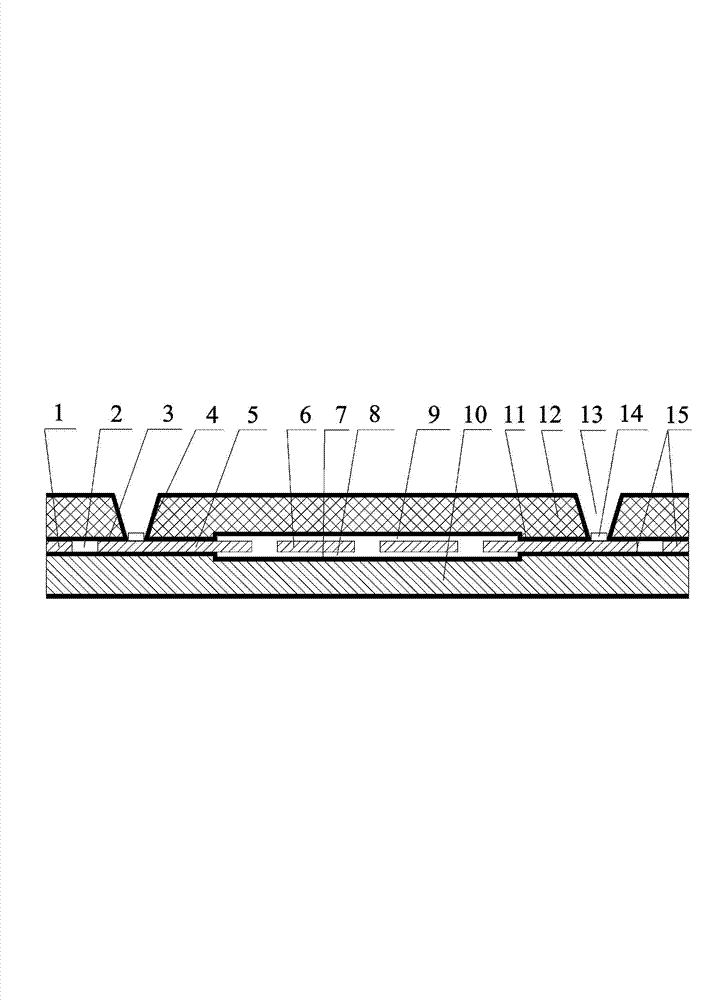

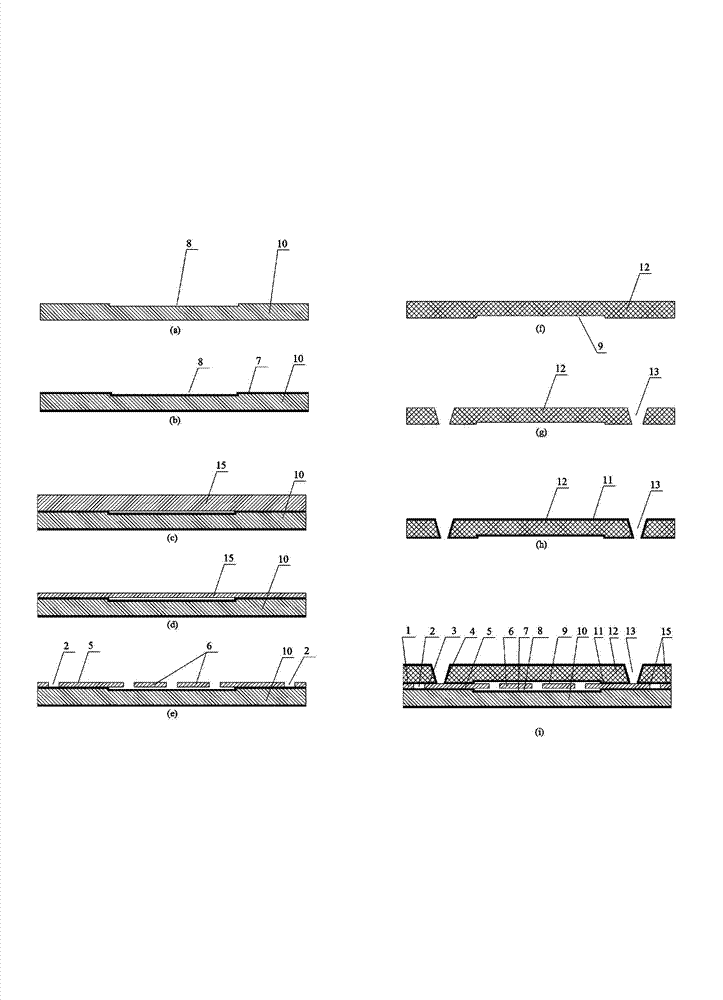

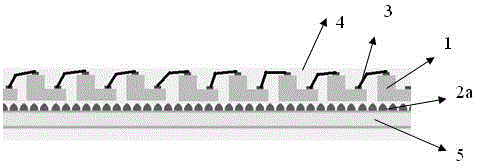

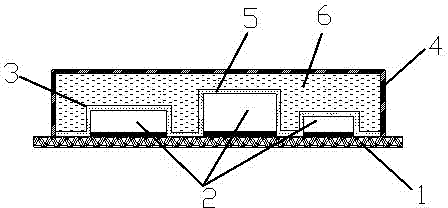

MEMS (micro-electromechanical systems) device and vacuum encapsulation method of wafer level thereof

ActiveCN102862947AGood air tightnessImprove work performancePrecision positioning equipmentSolid-state devicesAluminum electrodeWork performance

The invention relates to an MEMS (micro-electromechanical systems) device and a vacuum encapsulation method of the wafer level thereof. The device is characterized in that wafer level vacuum encapsulation is realized by adopting a silicon-silicon direct bonding technology, a low-resistance silicon wafer is adopted in a silicon structure layer (15) bonded to a silicon substrate, and is directly etched on the silicon layer to form an electrical interconnection lead wire (5); and aluminum electrode (14) is sputtered on an electrical interconnection lead wire bonding area (4) in a lead wire through hole (13) of a silicon nut cap (12). The device has the advantages that a total silicon structure is adopted, and no residual stress exits after bonding, so that the working performance of the device can be greatly improved; low-resistance silicon is utilized as an electrode lead wire, so that damage of high temperature to a metal electrode in the silicon-silicon direct bonding process can be avoided; and the silicon-silicon direct bonding air tightness is extremely good, so that the encapsulation cost is greatly reduced. The method is high in accordance and reliability, and the process is easily implemented.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

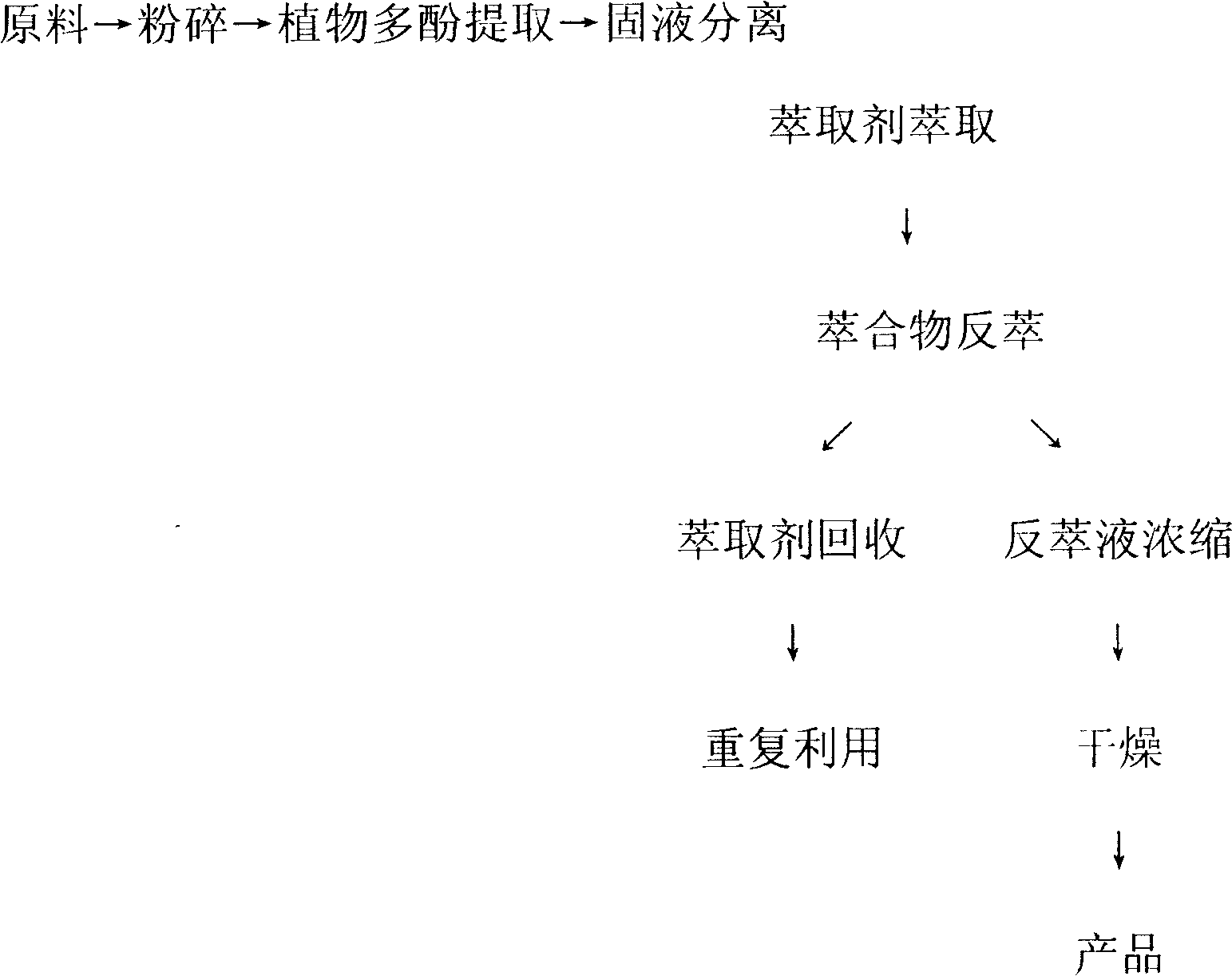

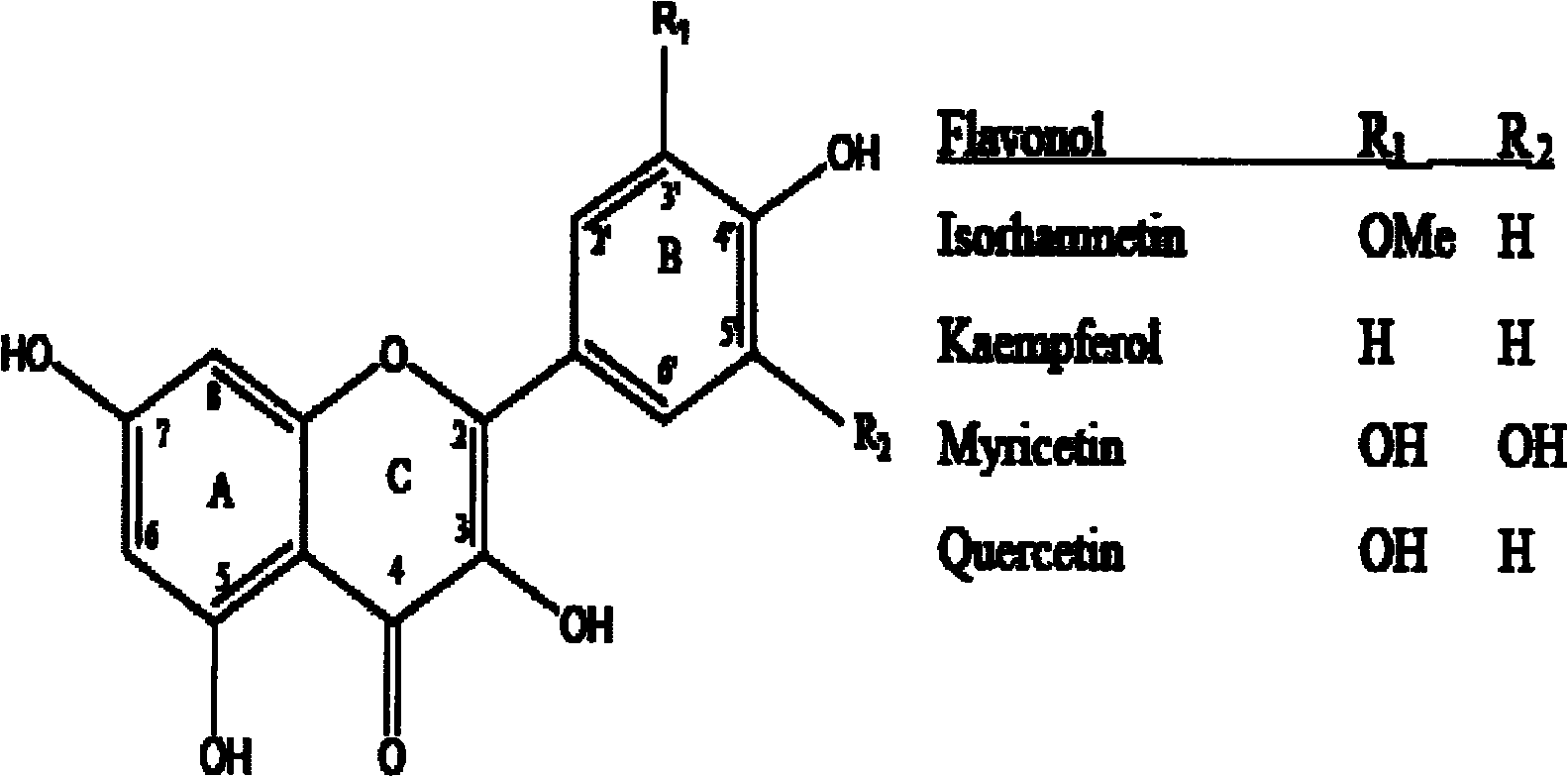

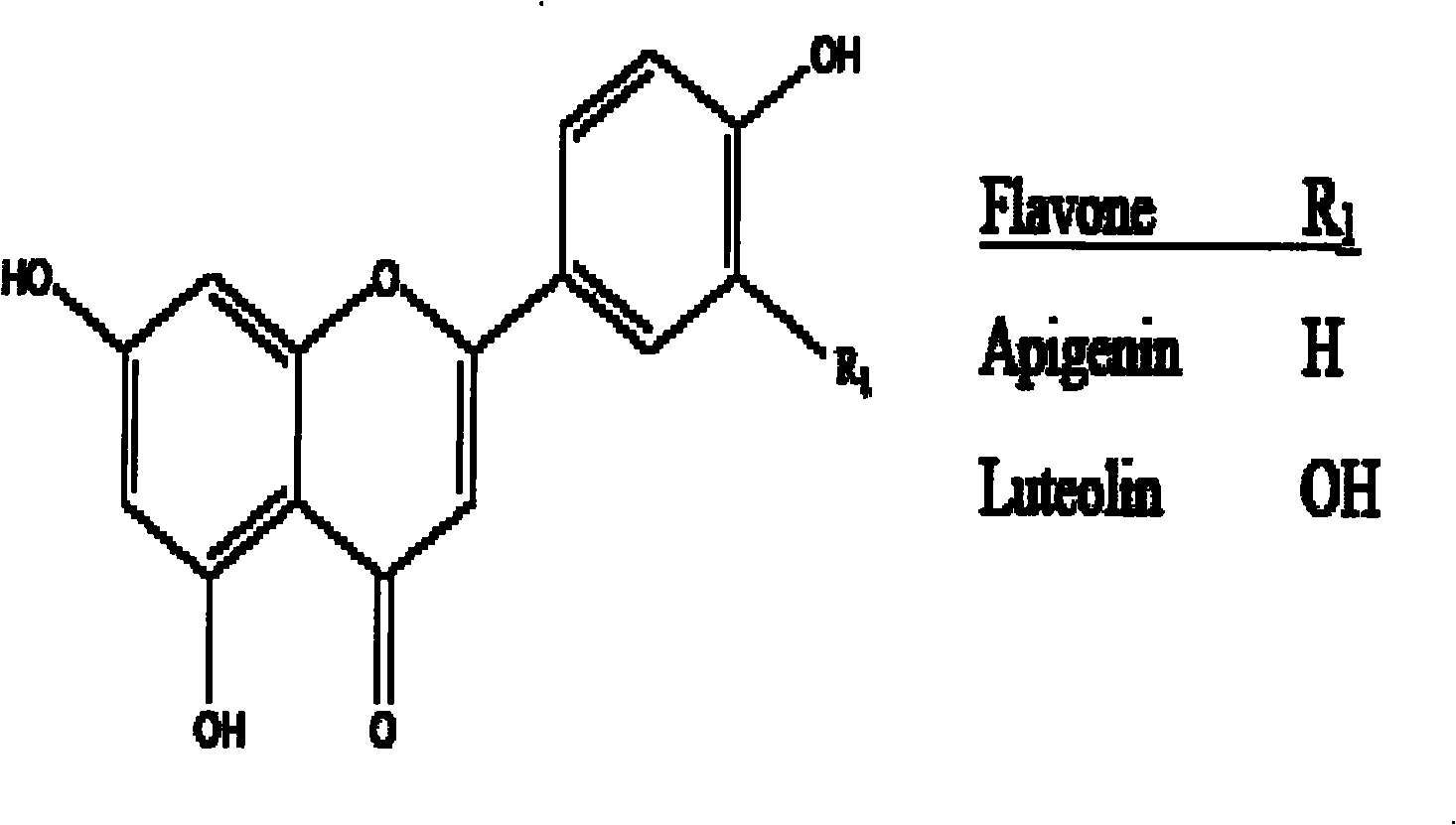

Complexation extraction method of plant polyphenols substances

InactiveCN101284022AImprove separation efficiencyHigh selectivityOrganic chemistryAntinoxious agentsPolyphenolEnergy consumption

The invention relates to a method for complexing and extracting plant polyphenol compounds to realizes the extraction of the plant polyphenol compound based on reversible complex reaction. Compared with the conventional physical extraction method, the method has the advantages of high separation efficiency and high purity of plant polyphenols, simple process, easy operation, and low energy consumption.

Owner:INST OF COMPREHENSIVE AGRI PROD UTILIZATION SHANXI PROV ACAD OF AGRI

Tobacco humectant and preparing method thereof

The invention discloses tobacco humectant and a preparing method thereof. The tobacco humectant is composed of, by weight, 1-5 parts of water soluble plant oil, 50-80 parts of polyhydric alcohol, 2-5 parts of polyethylene glycol, 2-5 parts of polydextrose, 2-5 parts of maltose, 3-7 parts of inositol and 5-25 parts of absolute ethyl alcohol. The tobacco humectant comprises the hydrophilic humectant polyhydric alcohol and the water soluble plant oil, the hydrophilic humectant absorbs moisture from damp air, the water soluble plant oil forms a protection membrane on the surface of cut tobacco, and the speed of the moisture loss is reduced. The hydrophilic humectant polyhydric alcohol and the water soluble plant oil form an even and stable system under a certain condition and fully play the roles of all components, and a good tobacco leaf moistening effect is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Restoration method of soil polluted by radionuclide Cs-137

ActiveCN104690083AThe process is easy to implementEasy to implementContaminated soil reclamationFiltrationRestoration method

The invention discloses a restoration method of soil polluted by radionuclide Cs-137, and belongs to the field of environmental protection. The method comprises following steps: 1, soil extraction, crushing, and sieving; 2, physical leaching; 3, multi-stage separation and filtration; 4, chemical leaching; and 5, soil particle recovery, dehydration, pH adjustment and soil backfilling. A deionized water and ultrasonic wave combination technology is adopted in the physical leaching stage, so the decontamination percentage reaches 66%. The decontamination percentage of chemical leaching reaches 80%, and the total decontamination percentage reaches 93%, and is greatly higher than the decontamination efficiency of traditional methods. The method disclosed in the invention has the advantages of easy realization, clean process, simple device, good safety and low running cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

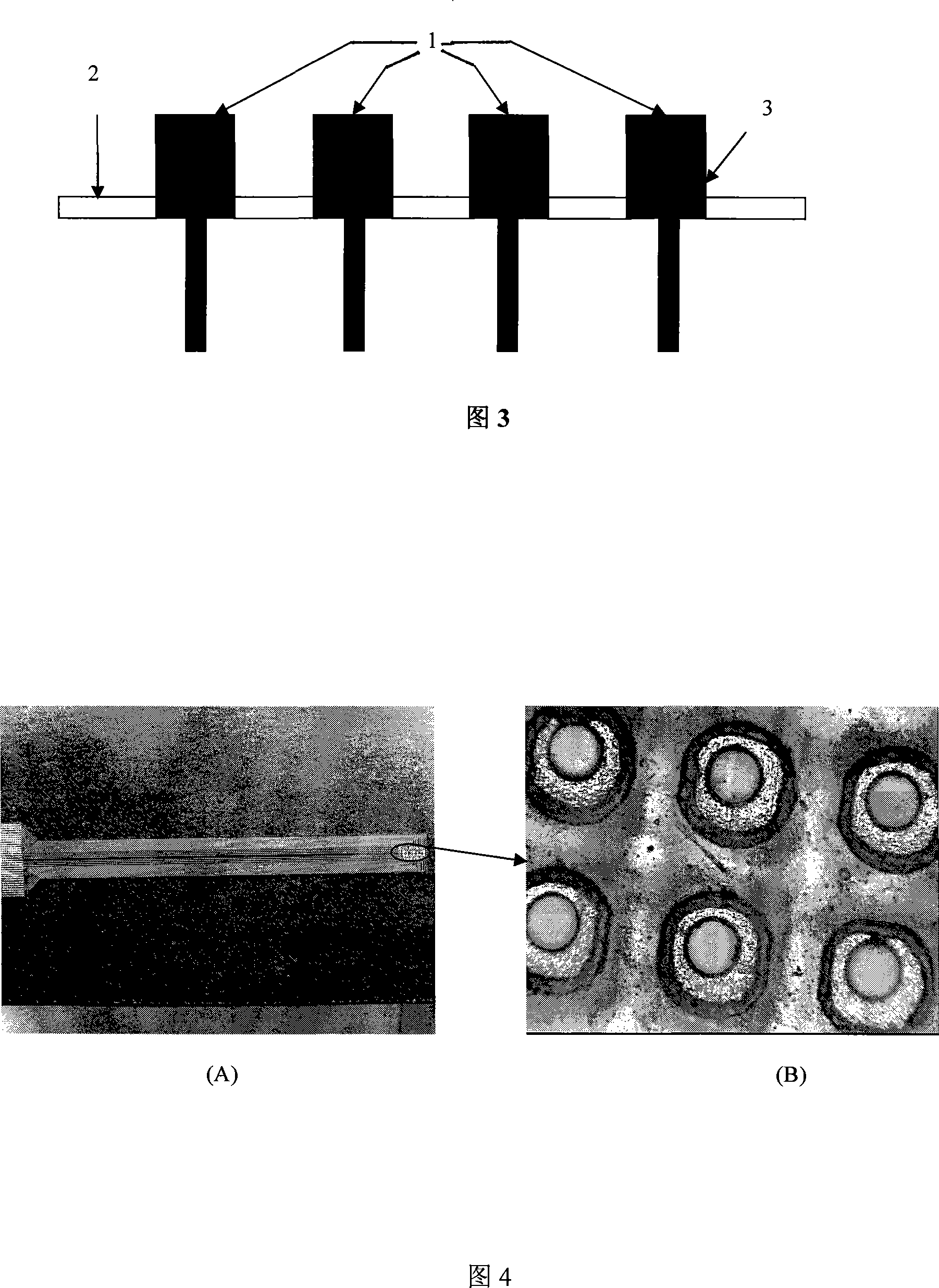

Plating self-welding method for three-dimensional micro-electrode array

InactiveCN101240435AThe process is easy to implementImprove welding effectMicroelectrodeElectrode array

The invention relates to a method for electroplating self-welding a three-dimensional microelectrode, belonging to the field of microelectrode preparation technology. The steps comprises: putting the microelectrode through a metal micropore, and fixing on a slot; and electroplating the metal micropore to lessen the metal micropore, until the metal micropore and the microelectrode being combined together, so that self-welding of metal micropore and the microelectrode is realized. The welding method can easily realize three-dimensional welding of metal microelectrode array and metal micropore, the effect is good, the method is easy and has low cost.

Owner:FUDAN UNIV

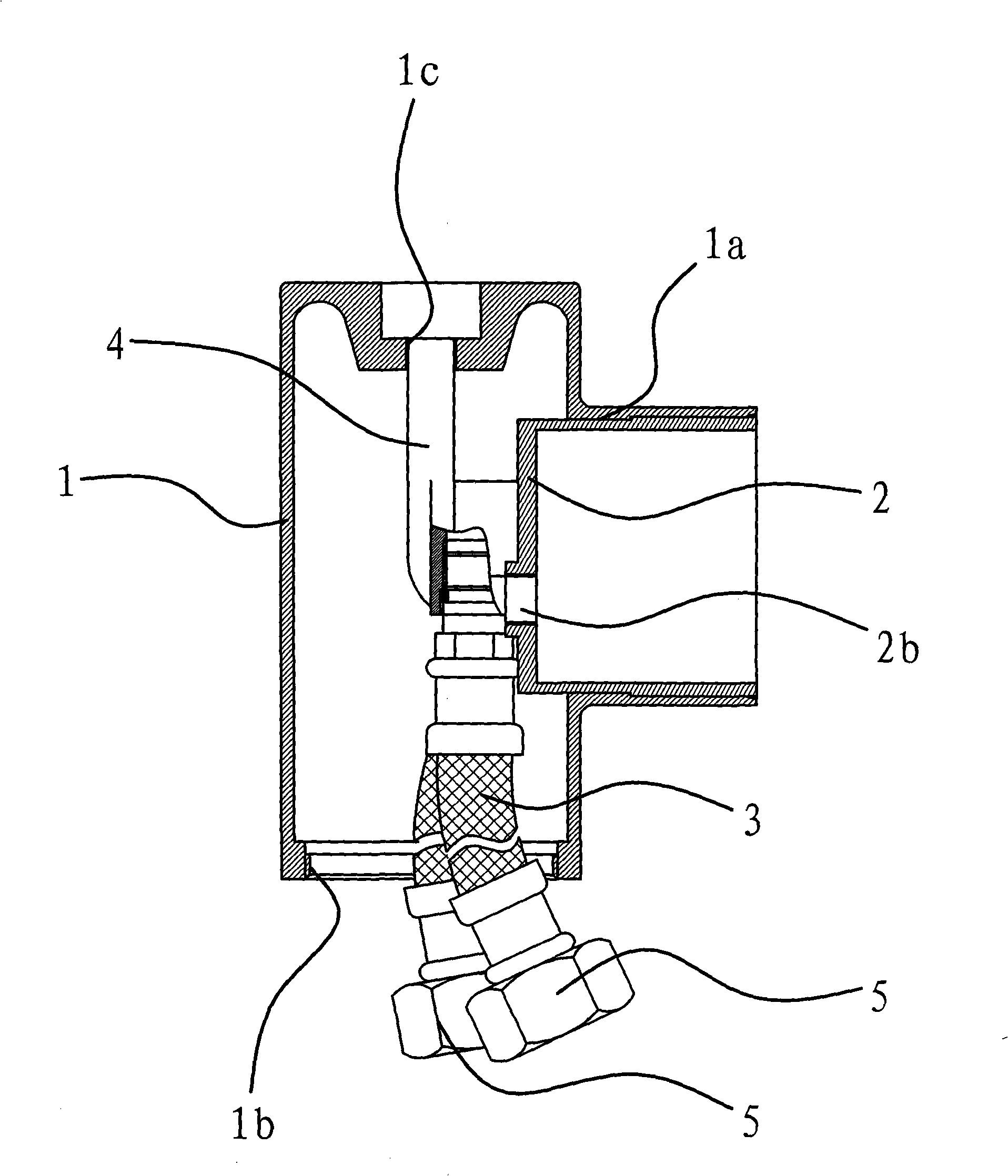

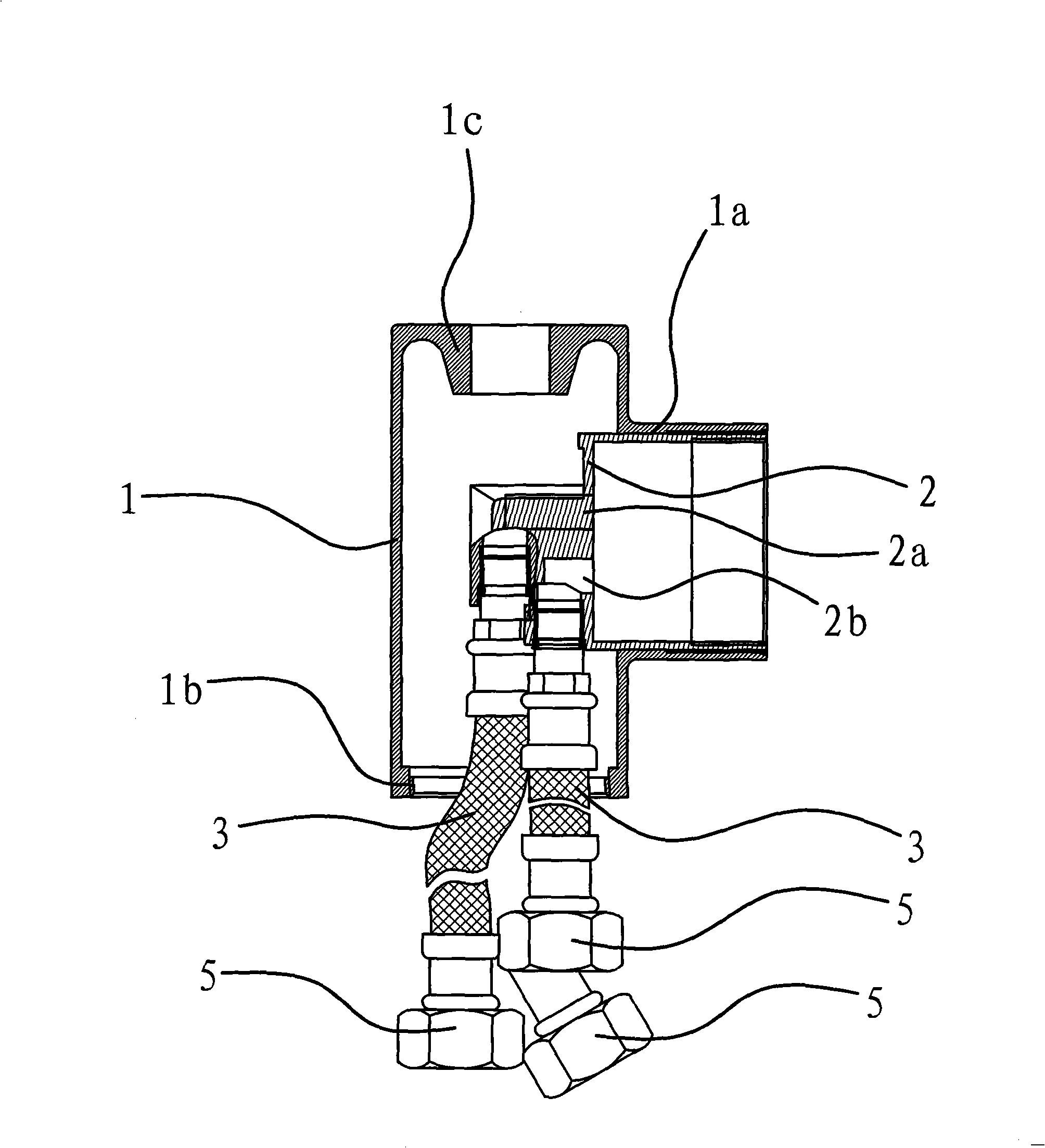

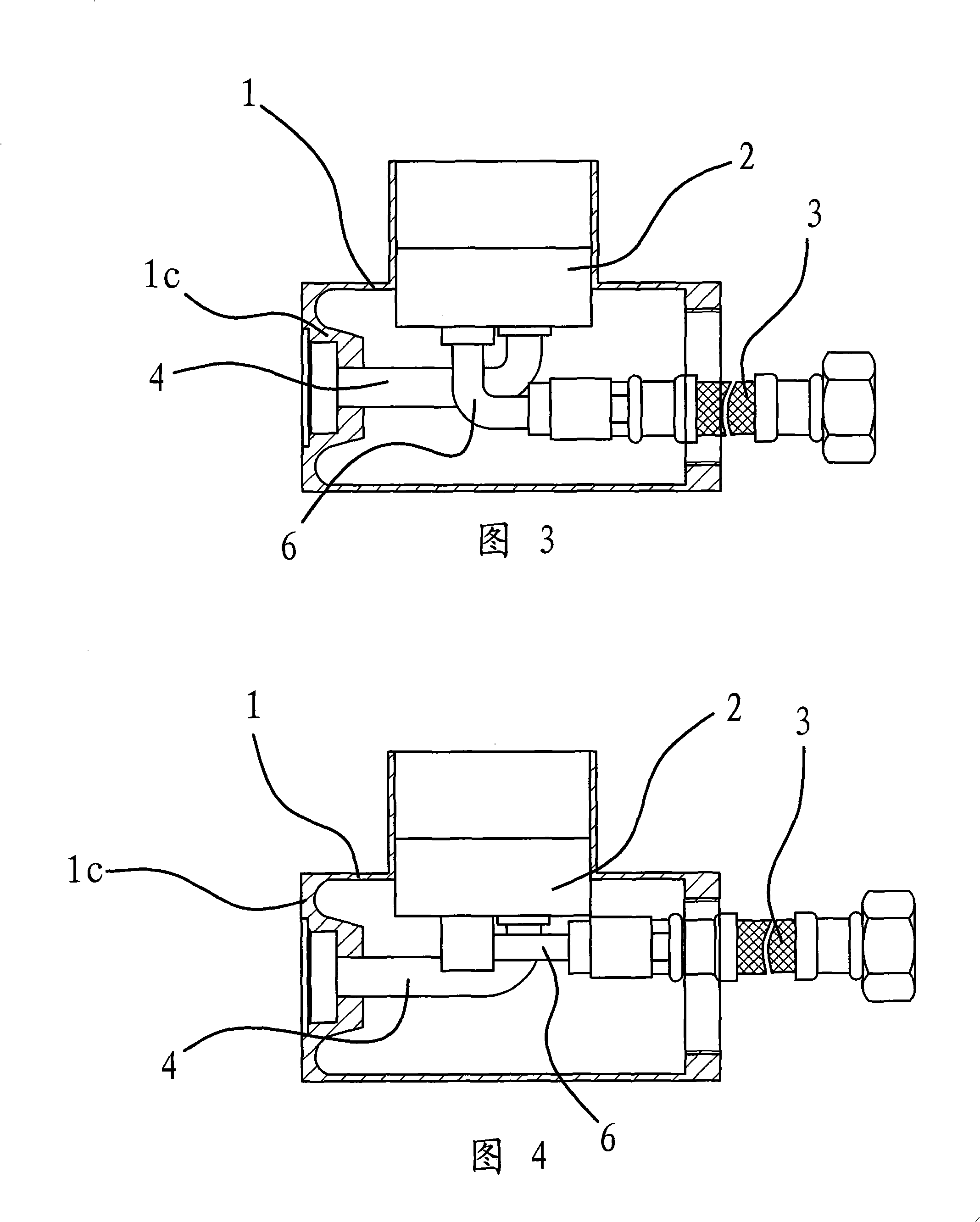

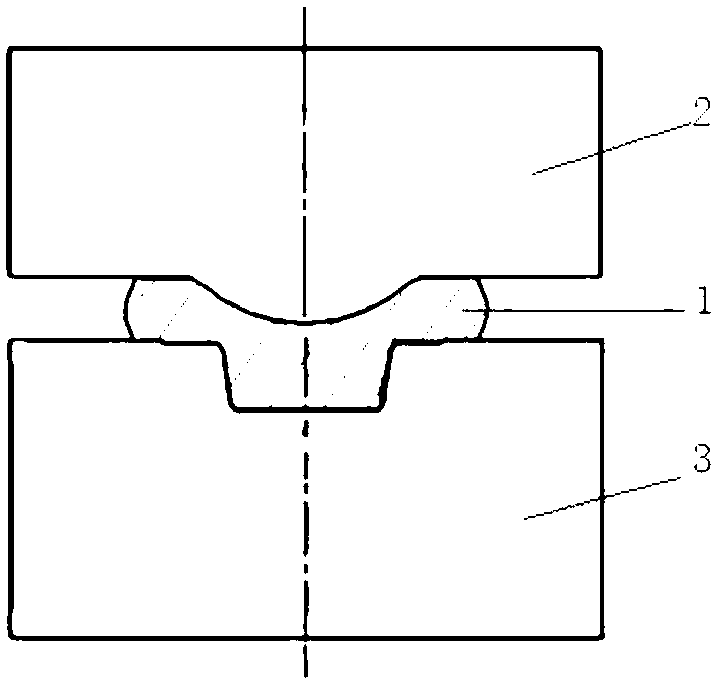

Water tap valve body and its process technique

The invention provides a water faucet valve body and a processing technology thereof which belong to the mechanical technical field and solve the problems that the existing water faucet valve body has high manufacturing cost, tedious manufacturing method and long processing cycle. The water faucet valve body comprises a valve shell, the inner part of which has a cavity, and a valve core seat; the valve shell has a connection hole which is communicated with the cavity; the valve core seat is fixedly connected with the connection hole and has a water inlet and a water outlet which are communicated with the valve shell; the valve shell has a connection pipe; the water inlet and the water outlet are both connected with the connection pipe, the other end of which is positioned in the valve shell or partially protrudes out of the valve shell. The processing technology of the water faucet valve body is realized by the following steps: a. part processing; b. welding; c. fine finishing; and d. pipe connection. The water faucet valve body has the advantages of simple structure, lower cost, higher stability, simple process implementation, and higher processing efficiency.

Owner:李仁波

Preparation technology of traditional Chinese medicine detoxification smoke-quit perfuming annex solution for cigarette

InactiveCN101623126AHarm reductionSatisfy hobbiesNervous disorderTobacco treatmentMedicinal herbsGanoderma lucidum

The invention relates to a preparation technology of a traditional Chinese medicine detoxification smoke-quit perfuming annex solution for cigarette, which comprises the following steps: (1) mixing and pulverizing 17 Chinese medicinal herbs such as 60g of Ganoderma lucidum, and the like, dipping in 1000mL cold water for 40 min, decocting for 25 min on slow fire, purifying with a Chinese herb extractor for 8 hours to obtain extract, staying the extract in a container for over 8 hours and finally processing with a centrifuge to obtain a purified traditional Chinese medicine liquid which is sealed in the container for stand-by; (2) mixing natural extractive with antioxygenic substances and 20g organic lecithin and sealing in a container for use later; (3) sealing 15g of edible natural essence in a container for use later; (4) mixing solutions obtained in the step (1), (2) and (3), staying for 12h, filtering, and finally processing with the centrifuge to obtain the annex solution. The scientifically-processed traditional Chinese medicine detoxification smoke-quit perfuming annex solution for cigarette has easy processing procedure and strong practicality.

Owner:曾华林

Hot forging method for transmission shaft yoke with horizontal yoke part

ActiveCN103121075AReduce consumptionReduce manufacturing costForging/hammering/pressing machinesMaterials scienceExtrusion

The invention provides a hot forging method for a transmission shaft yoke with a horizontal yoke part, and belongs to the technical field of forging forming. Preform bodies are sequentially conducted flat-die flatten, preforging bending and finishing forging forming. The flat-die flatten is that the preform bodies which are horizontally arranged in a flat-die are flattened to form strip shapes, the preforging bending is that the strip-shaped preform bodies are arranged in a bending die with a specific shape, and the strip-shaped preform bodies are bended and flattened to form preforging parts. Compared with horizontal open type die forging, axial blind holes are directly forged on the transmission shaft yoke prepared by the hot forging method for the transmission shaft yoke with the horizontal yoke part, follow-up machining working procedures are omitted, trimming metal consumption is small, and material utilization is more than 85%. Compared with vertical type hot extrusion forming, the process of the hot forging method for the transmission shaft yoke with the horizontal yoke part is convenient to implement, and stable in process. Dies are relatively simple and low in manufacturing cost.

Owner:SHANGHAI JIAO TONG UNIV +1

Manufacturing method for ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric

The invention discloses a manufacturing method for an ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric. The high-level tooling fabric adopts yarn formed by blending ultra-high molecular weight polyethylene staple fiber and viscose as raw materials and manufactured through a weaving production method. The method comprises the specific steps that warp and weft form piled yarn through plying and doubling of the ultra-high molecular weight polyethylene staple fiber yarn and viscose blended yarn, a warp beam is manufactured through sectional warping, the ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric is produced on a gripper loom, and a finished product is obtained through dyeing treatment after off-machine finishing. According to the method, the technological process is simple, the production efficiency is high, the product quality is stable, the warp tensile strength of the fabric reaches more than 1500 N, the weft tensile strength reaches more than 1000 N, the warp and weft tearing strength is larger than 60 N, the air permeability reaches more than 80 mm / s, the moisture permeability reaches 180 g / m<2>.h, and various color fastnesses reach more than 4 grades.

Owner:IANGSU COLLEGE OF ENG & TECH

Production technology of cool high-grade simulated down poplin bedding fabric

InactiveCN105155096AFlat surfaceWith wear resistanceWarping machinesDyeing processAir-jet loomEngineering

The invention discloses a production technology of cool high-grade simulated down poplin bedding fabric. Yarn formed by ultra-high molecular weight polyethylene staple fibers and viscose staple fibers in a blending mode serves as a raw material of the cool high-grade simulated down poplin bedding fabric. The cool high-grade simulated down poplin bedding fabric is prepared through a weaving production method. Specifically, warp yarn and weft yarn are made from blended yarn of the ultra-high molecular weight polyethylene staple fibers and the viscose fibers, beam warping is performed in batches, a warp beam is manufactured through slashing, the cool high-grade simulated down poplin bedding fabric formed by blending the ultra-high molecular weight polyethylene staple fibers and the viscose staple fibers is produced on an air jet loom, and after sorting of fabric which is taken off from the machine, the finished product is obtained through dyeing or printing after desizing. The cloth cover of the cool high-grade simulated down poplin bedding fabric is smooth, cool, pliable and tough, ultra high in abrasion resistance, capable of absorbing moisture and breathable, the fabric can give full play to the unique excellent performance of the ultra-high molecular weight polyethylene fibers, because ultra-high molecular weight polyethylene fiber products have certain anti-pricking and anti-cutting performance, the fabric can also be used for manufacturing anti-pricking and anti-cutting cases, and therefore the application range and the application field of the fabric can be widened.

Owner:IANGSU COLLEGE OF ENG & TECH

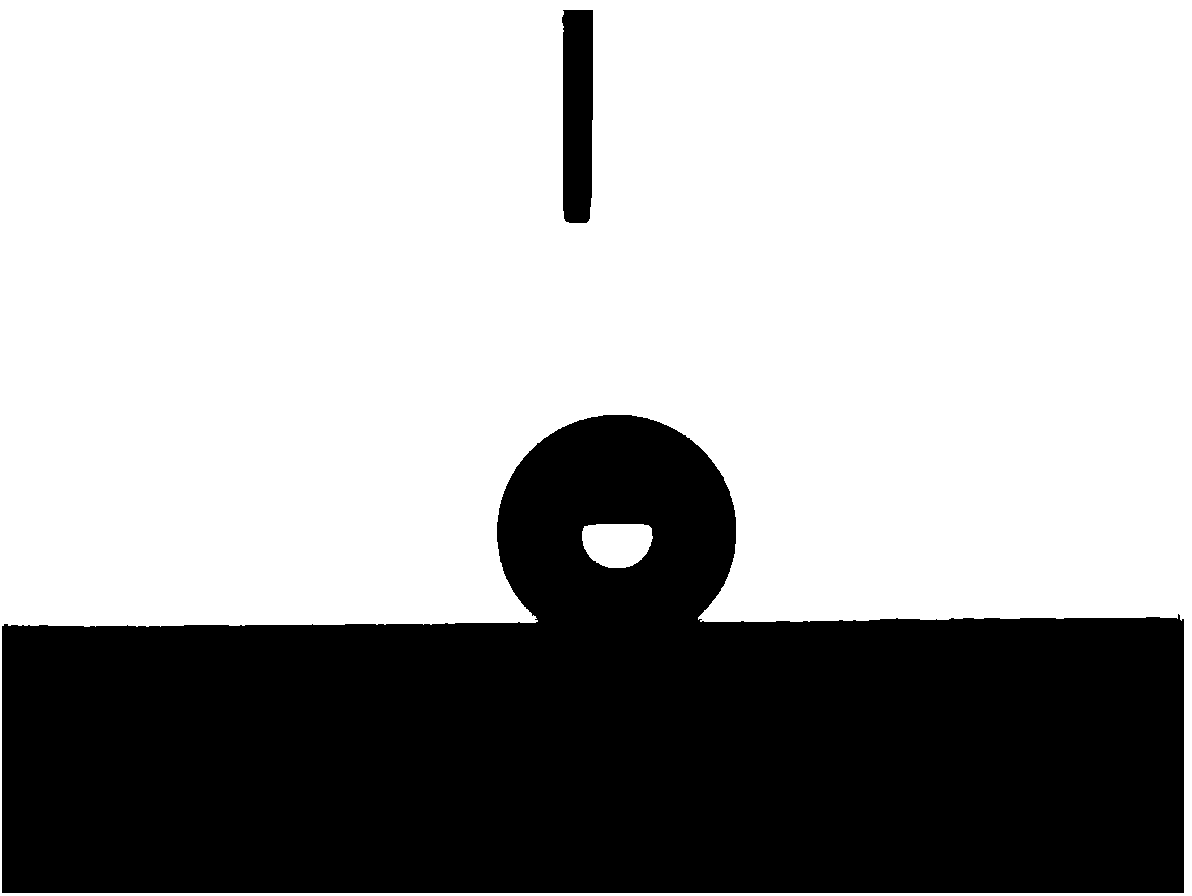

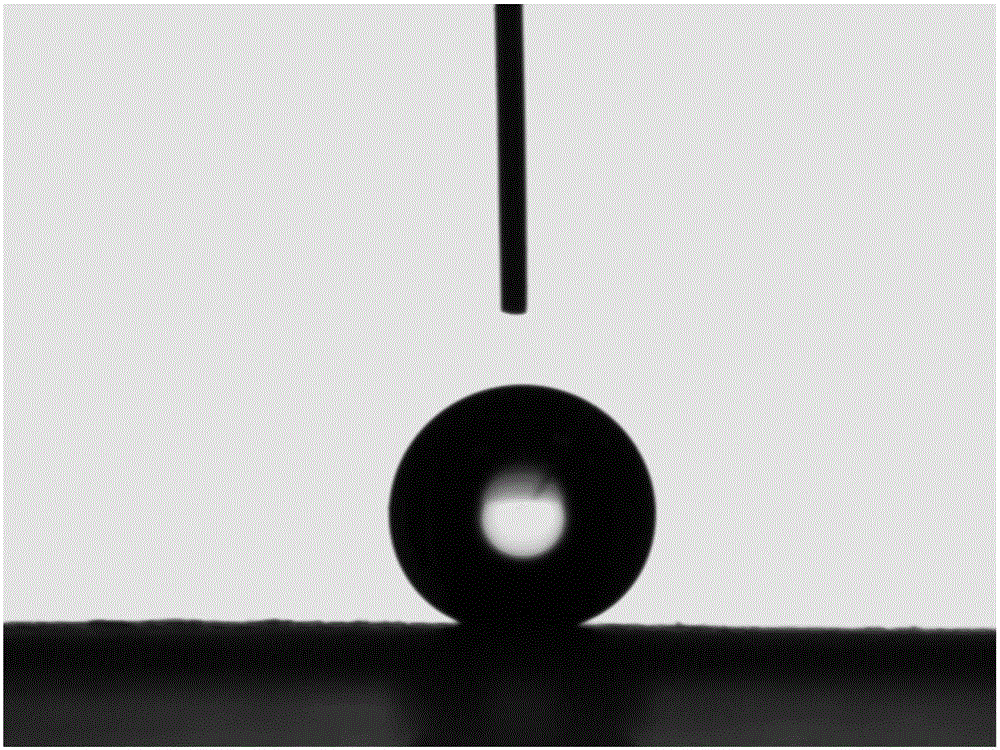

Method for preparing super-hydrophobic membrane layer on surface of magnesium alloy through one-step method as well as alloy and application of uper-hydrophobic membrane layer

The invention belongs to the technical field of surface treatment and modification of magnesium alloys and discloses a method for preparing a super-hydrophobic membrane layer on a surface of a magnesium alloy through a one-step method as well as an alloy and an application of the super-hydrophobic membrane layer. The method comprises the following steps and process conditions: by taking a pretreated magnesium alloy as a negative pole and taking a platinum plate as a positive pole, carrying out electric deposition in electroplate liquid to prepare the super-hydrophobic membrane layer on the surface of the magnesium alloy, wherein the electroplate liquid is a mixed solution of Ce(NO3).6H2O. The method is capable of synchronously preparing coarse structures and low-surface-energy materials needed for a super-hydrophobic structure on the surface of the magnesium alloy in one step to prepare the magnesium alloy with the super-hydrophobic membrane layer. The method for preparing the super-hydrophobic membrane layer on the surface of the magnesium alloy through the one-step method is simple; the treatment process is easy to implement; the solution is environmental friendly in formula and is non-toxic and green; the super-hydrophobic membrane layer can be prepared on the surface of the magnesium alloy in one minute at the soonest; an efficient method is capable of implementing the industrial application of the surface treatment of the magnesium alloy and can be widely applied to the surface treatment of the alloy.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing single polymer composite material by using two-component composite fiber

ActiveCN102400398AEasy to recycleEasy to reuseFilament/thread formingWoven fabricsFiberPolymer composites

The present invention relates to a method for preparing a single polymer composite material by using two-component composite fiber. The method comprises the following steps: (1) adopting a composite spinning technology to prepare two homogeneous polymers into two-component composite fiber, wherein the two homogeneous polymers comprise a matrix polymer and a reinforcement phase polymer, the arrangement of the two-component composite fiber is a parallel type arrangement or a core-sheath type arrangement, when the arrangement of the two-component composite fiber is the core-sheath type arrangement, the core material is the reinforcement phase polymer, and the surface material is the matrix polymer; (2) weaving the two-component composite fiber from the step (1) to form composite fiber fabric; (3) carrying out hot pressing for the composite fiber fabric from the step (2) at the temperature between the melting point of the reinforcement phase polymer and the melting point of the matrix polymer, such that the matrix polymer is molten, and compounded to form the single polymer composite material. Compared to the prior art, the method of the present invention has advantages of simple process, large-scale production, environmental protection and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

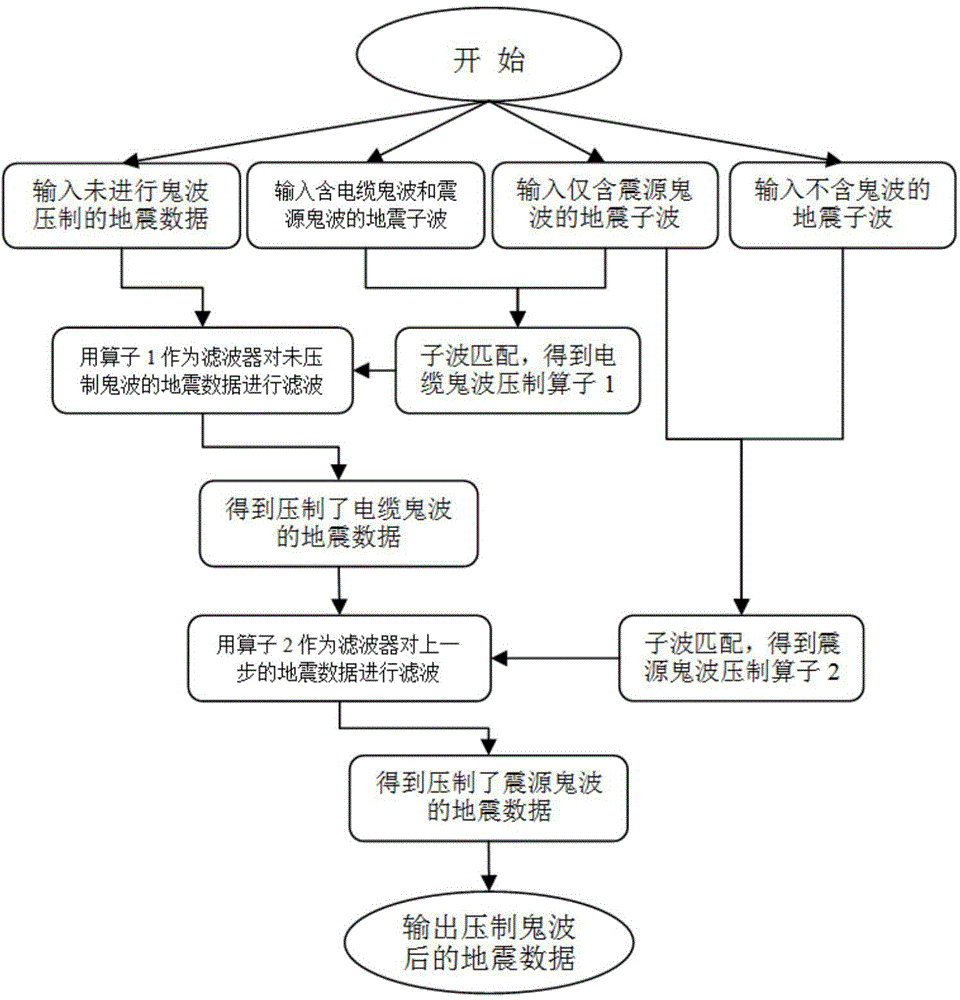

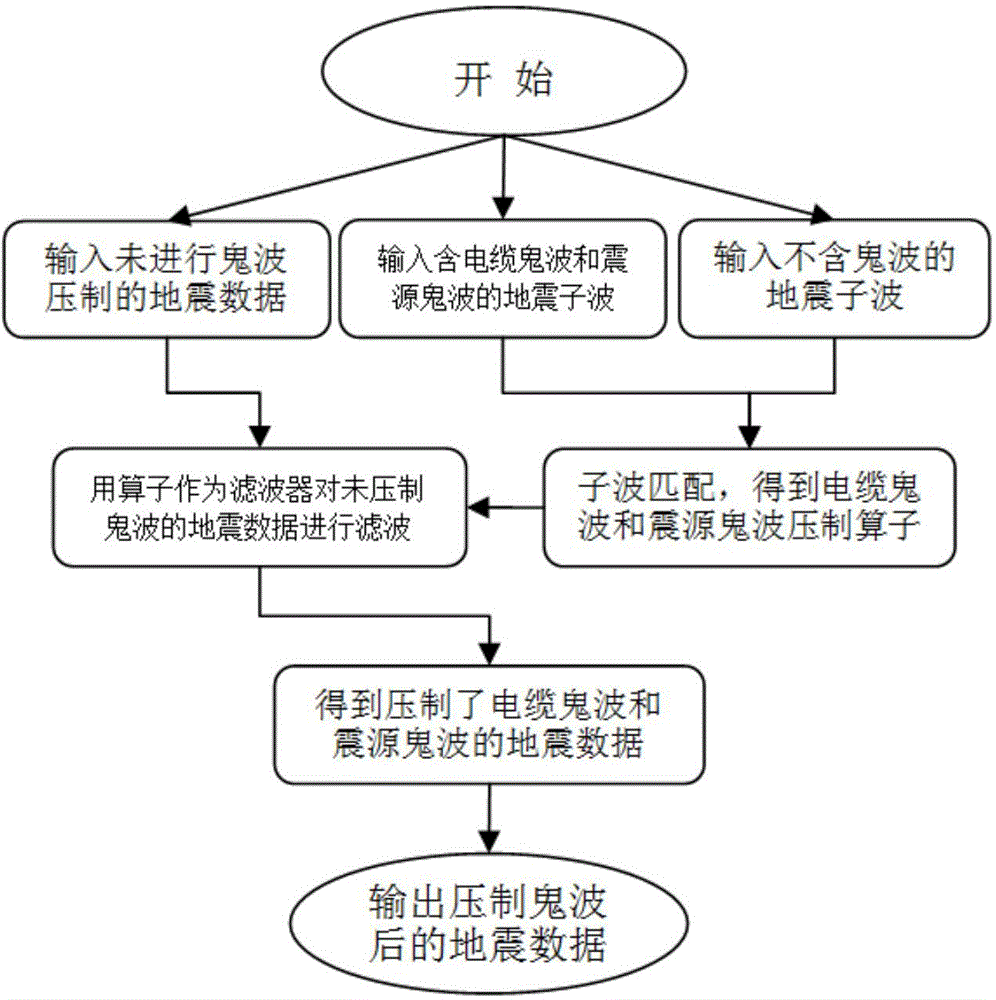

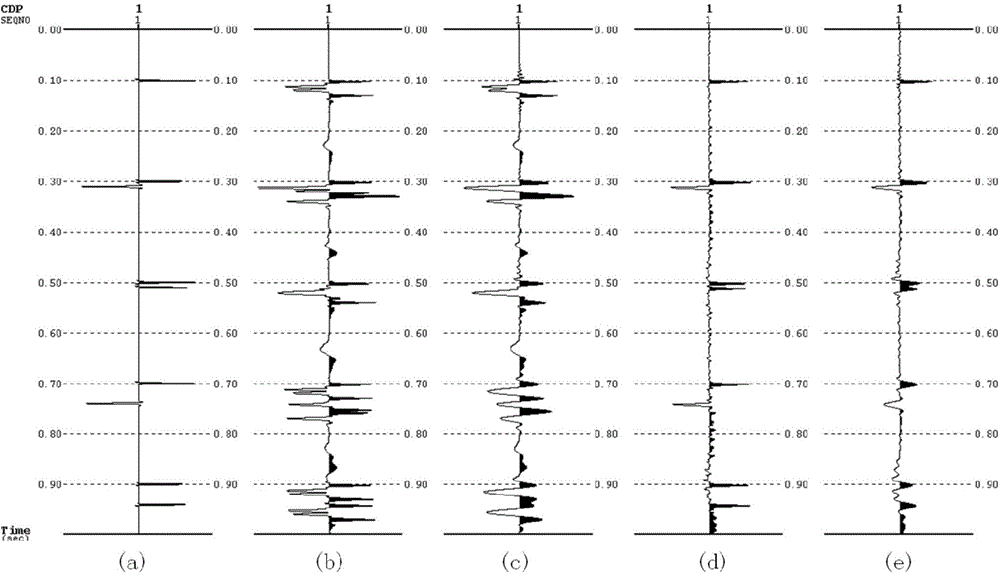

Ghost wave compression method based on wavelet processing

InactiveCN104536045ASuppression achievedLow costSeismic signal processingData informationCompression method

The invention relates to a ghost wave compression method based on wavelet processing. The method comprises the steps that (1) offshore seismic data information are input, wherein the seismic data information comprises three kinds of seismic wavelets and seismic data comprising uncompressed ghost waves, and the three kinds of seismic wavelets comprise the seismic wavelet comprising cable ghost waves and seismic source ghost waves, the seismic wavelet comprising the seismic source ghost waves only and the seismic wavelet comprising no ghost waves; (2) ghost wave compression is carried out on seismic data with uncompressed ghost waves through the seismic wavelets; (3) seismic data which compress the cable ghost waves and the seismic source ghost waves at the same time are output. According to the ghost wave compression method, the wavelet matching algorithm is adopted for compressing the ghost waves, and the ghost waves are compressed starting from seismic data processing instead of collection, so that the processing process is easy to implement, and the cost is saved; the ghost wave compression method can compress the seismic source ghost waves and the cable ghost waves in the offshore seismic data, and can be widely applied in the offshore seismic exploration process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of ultra-strong flame-retardant special protective garment fabric

The invention discloses a preparation method of an ultra-strong flame-retardant special protective garment fabric. The ultra-strong flame-retardant special protective garment fabric is prepared from yarns, which are formed by blending ultra-high molecular weight polyethylene short fibers and flame-retardant polyester fibers and is taken as a raw material, by virtue of a weaving production method. The preparation method comprises the following steps: combining wefts and warps, which adopt blended yarns of ultra-high molecular weight polyethylene short fibers and flame-retardant polyester fibers, into strands and twisting the strands into plied yarns; then performing sectional warping to obtain a live axle so as to produce an ultra-strong flame-retardant special protective garment fabric blank on a gripper loom; discharging and performing fabric finishing; and then performing dyeing treatment, thereby obtaining a finished product. The prepared ultra-strong flame-retardant special protective garment fabric is capable of giving full play to the unique excellent performance of the ultra-high molecular weight polyethylene fibers; if the stab-resistant anti-cutting performance of the ultra-strong flame-retardant special protective garment fabric is required to be enhanced, the use amount of the ultra-high molecular weight polyethylene short fibers in the blended yarns can be increased.

Owner:黑龙江省锟龙泽医药有限公司

Quick carbon deposition method of carbon/carbon material member

ActiveCN101798078ASolve the problem that the movement needs to punch holes in the productIntegrity guaranteedFiberCarbon fibers

The invention provides a quick carbon deposition method of a carbon / carbon material member, which comprises the following steps: (1) putting a carbon fiber preform into a high-temperature graphitizing furnace for high-temperature pretreatment; (2) fixedly connecting the carbon fiber preform with a heating unit, and isolating the carbon fiber preform from the heating unit by an isolator; (3) putting the carbon fiber preform and the heating unit assembly into a deposition chamber, putting a thermocouple on the external surface of the carbon fiber preform, vacuumizing for eliminating atmosphere firstly, and then, introducing reaction gas; and (4) heating the heating unit, and carrying out vapor deposition of carbon for 20-200h to prepare the carbon / carbon material member once. In the method of the invention for preparing the carbon / carbon member, the thermocouple only needs to be put on the external surface of the member, thus the member does not need to be perforated in the process of preparation, and the integrity of the member can be kept. The method of the invention has short production cycle and low process cost, can realize the purpose of quick densification, and is suitable for large-scale production in batches.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

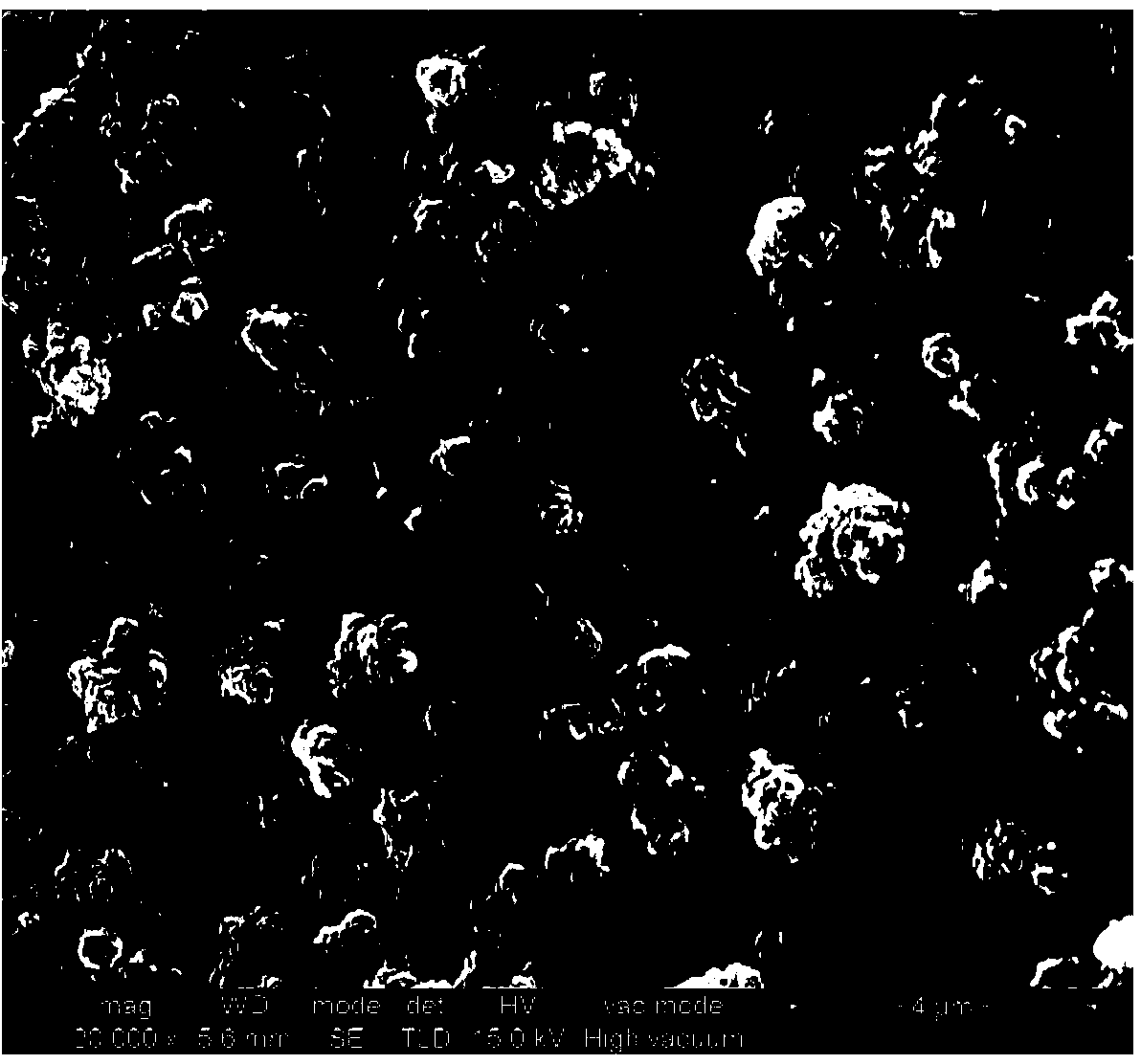

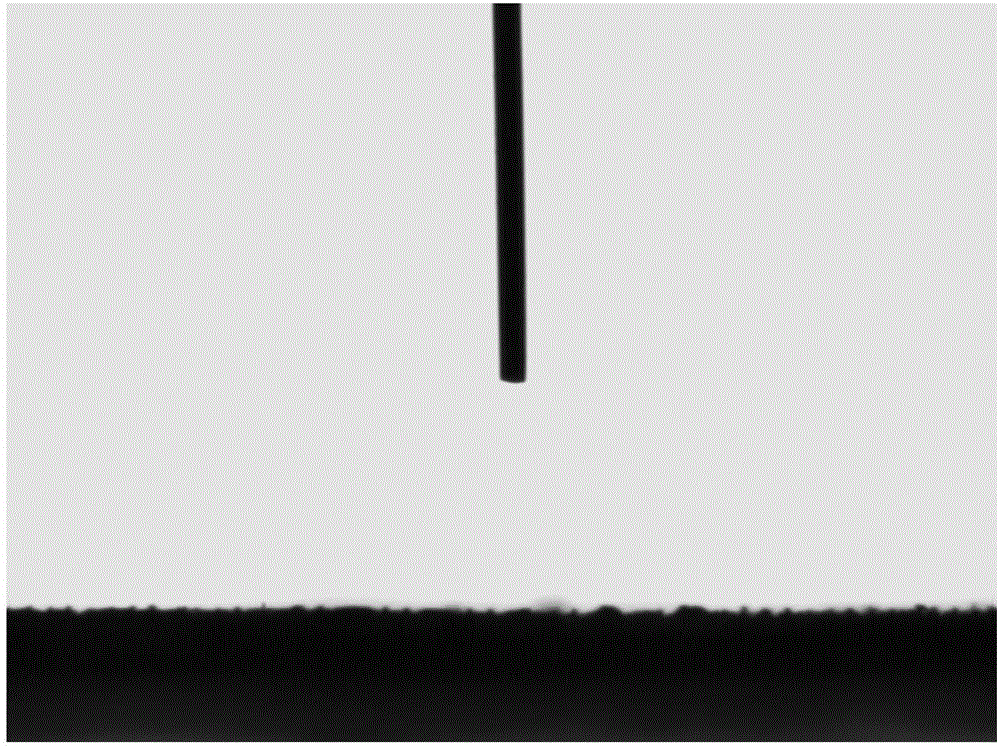

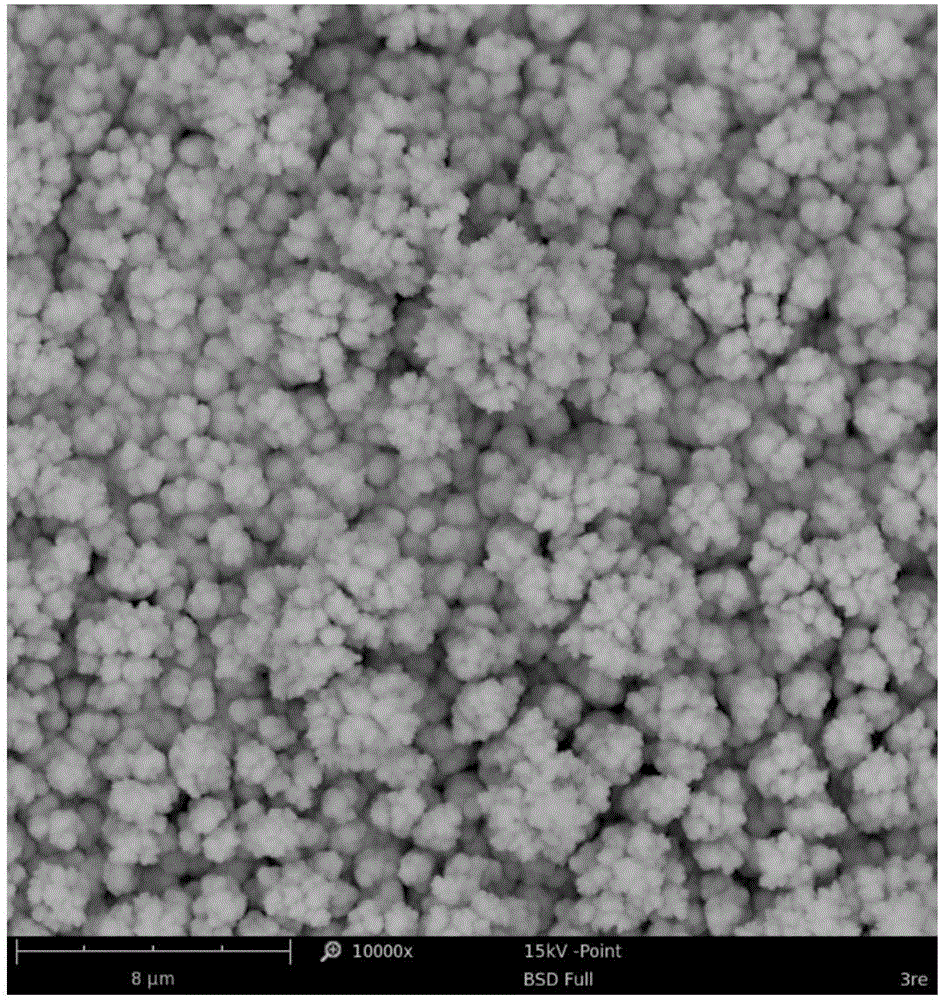

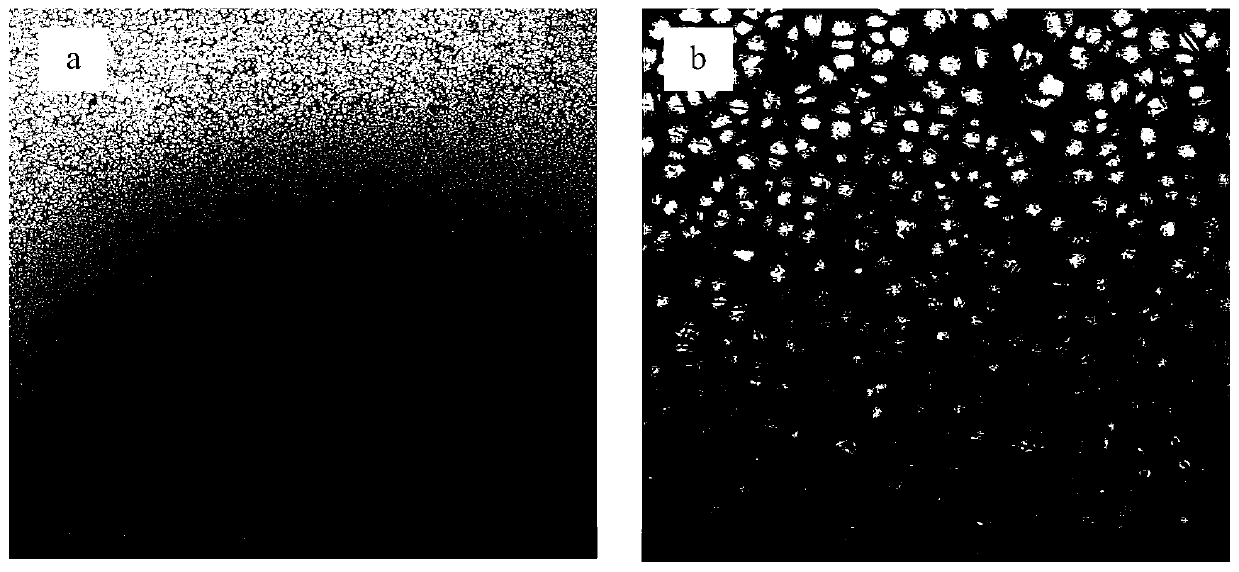

Super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and preparation method thereof

ActiveCN106823469AFast etchThe process is easy to implementNon-miscible liquid separationCopper wireMetallic materials

The invention belongs to the technical field of metal material surface treatment and discloses a super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and a preparation method thereof. The preparation method comprises the steps of cleaning and drying the copper wire meshes, and taking two pieces of copper wire meshes as two electrodes of AC separately; carrying out electrodeposition in a deionized water electroplate liquid containing thioacetamide, ethylenediamine tetraacetic acid disodium and copper sulfate pentahydrate; and cleaning the copper meshes subjected to electrodeposition and then carrying out high-temperature drying at 80-200 DEG C to obtain the super-hydrophobic and super-oleophilic copper wire mesh. The two electrodes of the AC can be quickly etched at the same time, and the super-hydrophobic and super-oleophilic copper wire mesh is suitable for large-area production, special equipment does not need to be used, and the treatment process is easy to implement; and the related solution formula does not contain a toxic fluorine-containing or carbon-containing low surface energy material, is free of harm to the environment and a human body, and has good economical and environmental benefits.

Owner:SOUTH CHINA UNIV OF TECH

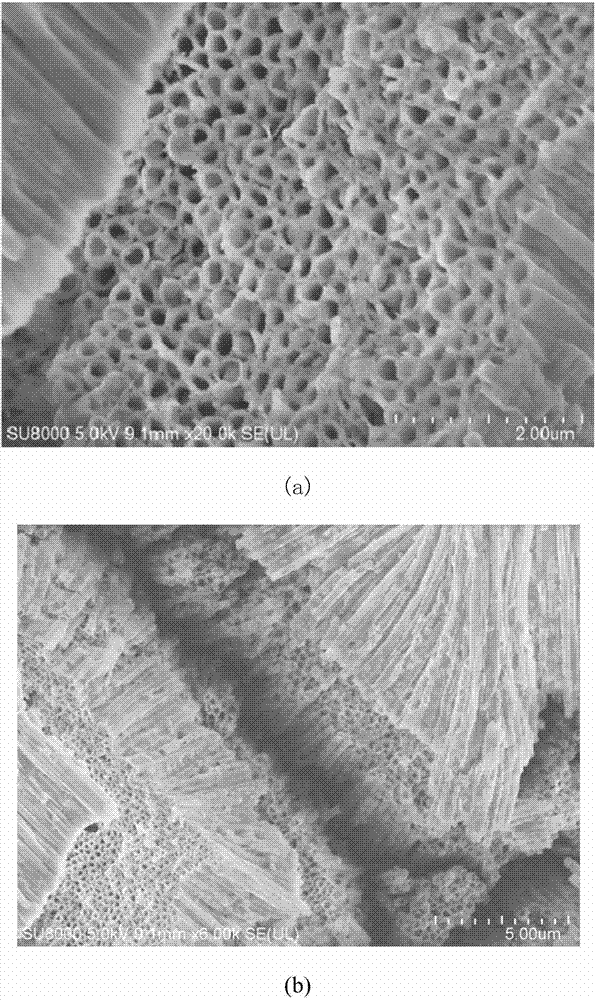

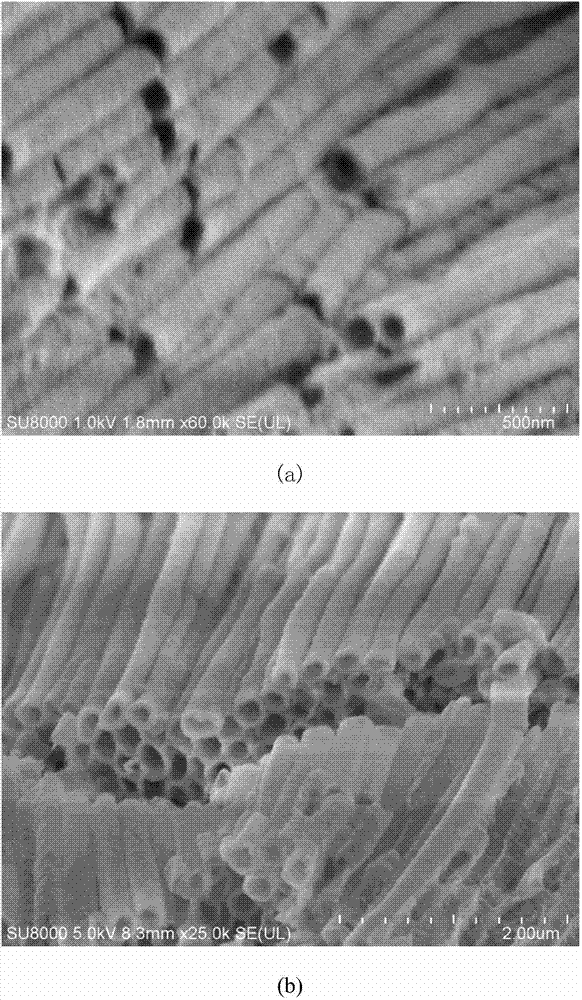

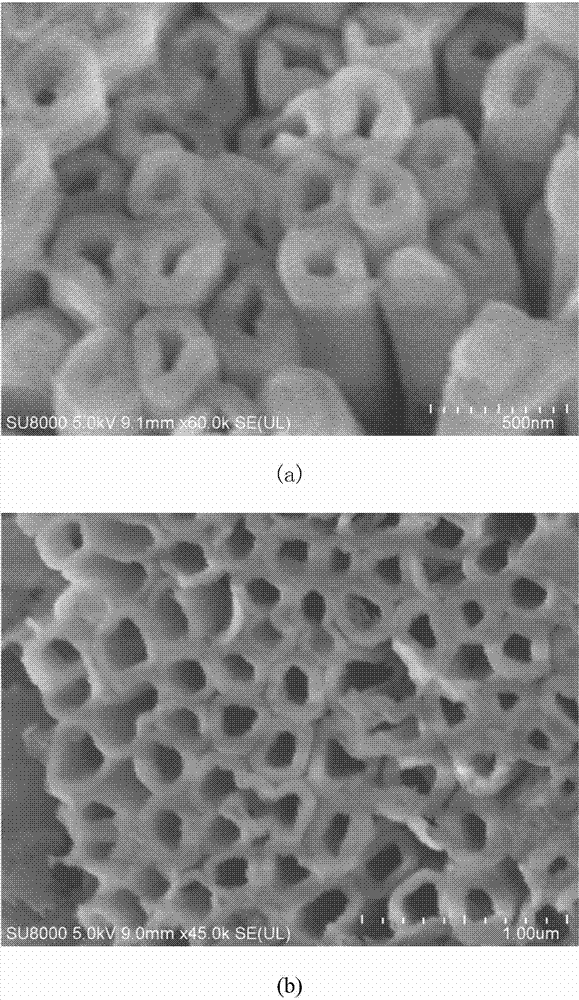

Electrochemical synthesis method of nickel-phosphorus alloy nanotube array

InactiveCN103806040ARaw materials are readily availableThe experimental equipment is simpleNanotechnologySynthesis methodsElectrolyte

The invention relates to an electrochemical preparation method of a nickel-phosphorus alloy nanotube array. The preparation method comprises the steps of cleaning and airing an anodic aluminum oxide template, sputtering one gold film layer on the back surface of the anodic aluminum oxide template, preparing an aqueous solution containing nickel sulfate, boric acid and sodium hypophosphite as an electrolyte solution, connecting the gold-spraying surface of the anodic aluminum oxide template with a negative electrode of a power supply to serve as the cathode for electrochemical deposition reaction; connecting a graphite electrode with a positive electrode of the power supply to serve as the anode for electrochemical deposition reaction; and immersing the anodic aluminum oxide template and the graphite electrode into the prepared aqueous solution, and preparing a nickel-phosphorus nanotube in a constant-voltage deposition mode and in a constant-current deposition mode respectively. The used raw materials are easily available, the experiment equipment is simple, the process is easy to realize, and the nickel-phosphorus alloy nanotube array with outer diameter of 200 nanometers and length of 50-60 micrometers can be synthesized.

Owner:XI AN JIAOTONG UNIV

Technology for reprocessing waste silk in polyester staple fiber production process

InactiveCN102691139AImprove qualityGood mechanical propertiesNew-spun product collectionArtificial filament washing/dryingPolyesterWater baths

The invention relates to a technology for reprocessing waste silk in the polyester staple fiber production process. The technology comprises the following steps of: a) feeding head and tail silk and abnormal silk into a silk guide device; b) feeding generated silk into an oil immersion tank; c) feeding the silk subjected to oil immersion into a first drafting machine, a water bath and a second drafting machine; d) feeding the processed silk into a steam heating box to be heated and then feeding the heated silk into a tension-setting machine; e) feeding the processed silk into a third drafting machine, a silk folding machine, three rollers and a tension roller in sequence; f) feeding the processed silk into a crimping and heating box and a crimping machine; g) feeding the processed silk into a relaxation heat setting machine; and h) finally carrying out cutting off and packing. The technology has the following advantages that the waste silk generated in the production process can be effectively recycled, thus saving the production cost and improving the product competitiveness; and the technology is simple to implement and is considerable in benefits.

Owner:FUJIAN JINLUN FIBER SHAREHOLDING CO LTD

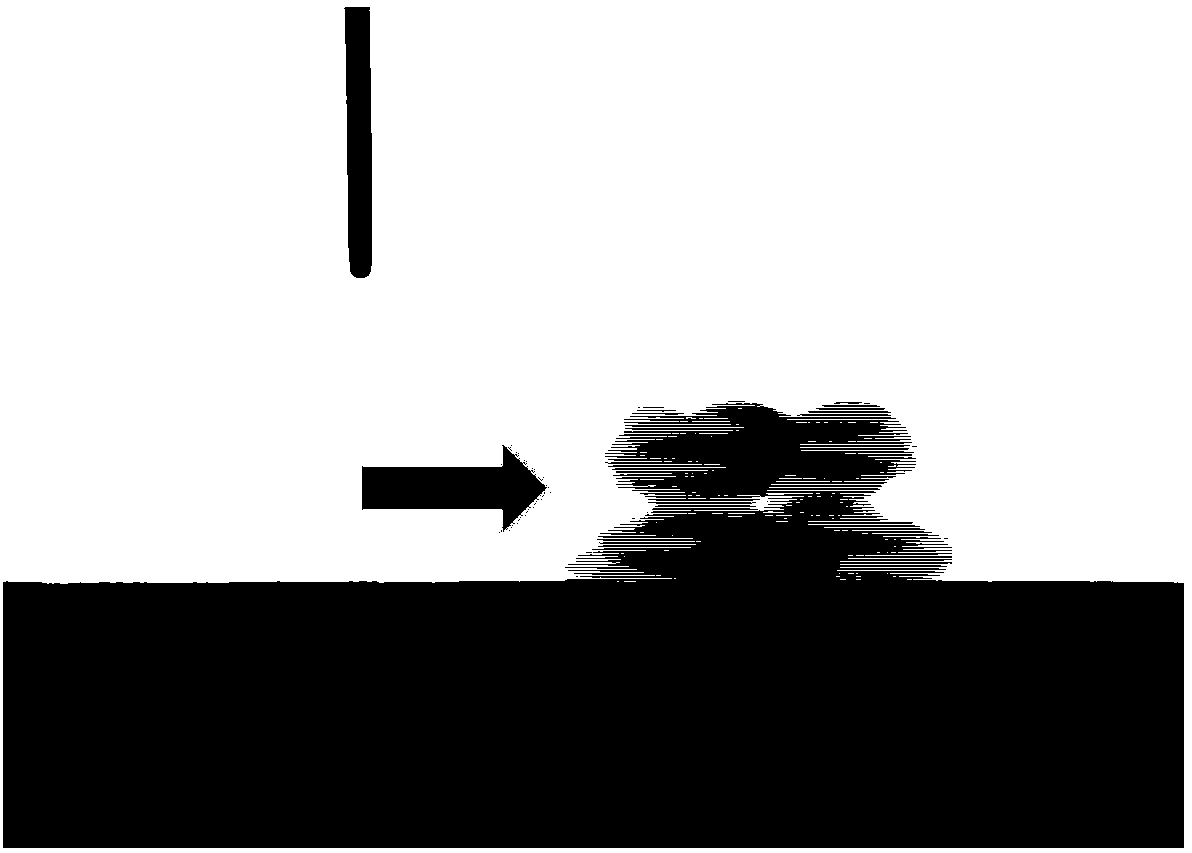

Method for preparing corrosion-resistant super hydrophobic membrane layer on surface of aluminum alloy

The invention discloses a method for preparing a corrosion-resistant super hydrophobic membrane layer on a surface of an aluminum alloy. In the method, firstly, a pre milled aluminum alloy matrix is cleaned in turn by deionized water and ethanol in an ultrasonic cleaning instrument; the aluminum alloy matrix is electropolished, anodized and pore-enlarging; the matrix is placed in electrochemical nickel plating liquid to obtain a convex texture on the surface of the matrix, and then the matrix is placed in the electrochemical cobalt plating device to conduct the electrochemical cobalt plating treatment, through the treatment of the above steps, the petal-shaped micro nano rough structure is constructed on the surface of the matrix mainly through the combination of anodizing and electrochemical deposition. Finally, the surface free energy of the treated matrix was reduced by immersion modification in fluorosilane ethanol solution, so that the surface of aluminum alloy obtains the corrosion-resistant super hydrophobic membrane layer, and the corrosion resistance of the aluminum alloy is effectively improved.

Owner:JIANGSU UNIV OF SCI & TECH

LED bulb lamp and method for manufacturing same

InactiveCN103822114AIncrease contactReduce difficultyPoint-like light sourceElectric circuit arrangementsEngineeringMechanical engineering

The invention relates to an LED bulb lamp and a method for manufacturing the same, and belongs to the field of LED illuminating lamp application technologies. The LED bulb lamp comprises an LED light source, a support, a lampshade, a lamp holder and a power source. The LED light source is arranged on the support, is placed in the lampshade and is connected with the power source by a power line, and the power source is fixed into the lamp holder. The LED bulb lamp and the method have the advantages that the cost can be saved, and a process for manufacturing the LED bulb lamp can be simplified.

Owner:亚浦耳照明股份有限公司 +2

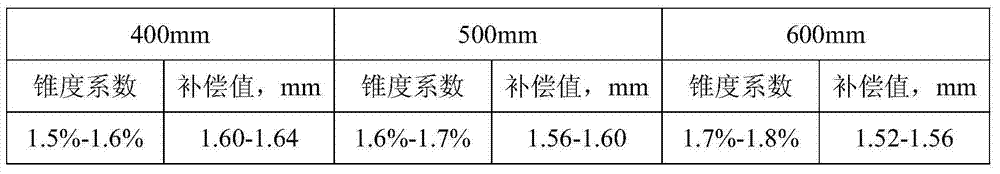

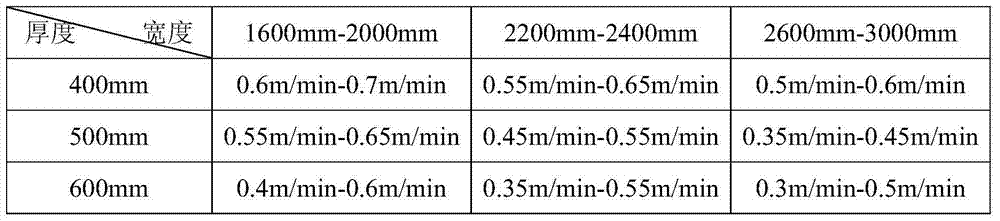

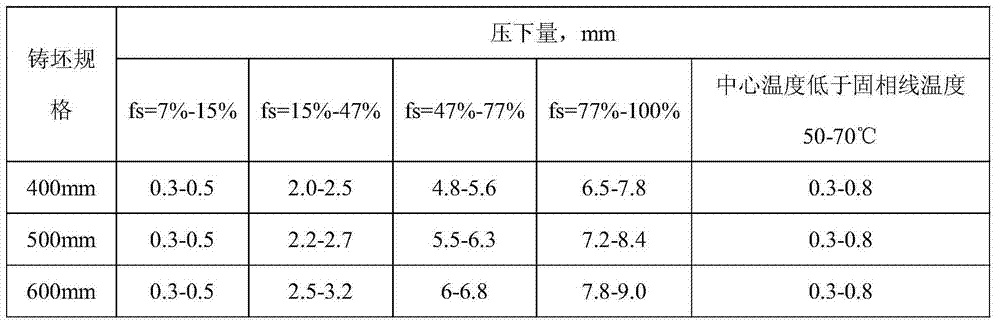

Continuous casting manufacturing process of ultra-thick slabs for hydropower station pressure vessel steel

ActiveCN103611903AThe process is easy to implementThe continuous casting production process is smoothPenstockSteelmaking continuous casting

The invention discloses a continuous casting manufacturing process of ultra-thick slabs for hydropower station pressure vessel steel, and belongs to the technical field of steelmaking-continuous casting. The process includes the steps that casting powder special for peritectic steel of which the carbon content ranges from 0.08% to 0.14% is designed according to continuous casting characteristics of the peritectic steel; taper values of hydropower station steel penstock casting blanks with different thicknesses are set according to steel type conditions. The defects of surface transverse cracks of the casting blanks and corner transverse cracks of the casting blanks are overcome by setting an ultra-thick slab continuous casting secondary cooling mode. Different pulling rates are set according to the thickness and the width of the slabs, and the problem of center segregation of the ultra-thick slabs is solved through low-pulling-rate casting. The process has the advantages that the process is simple and high in generalization performance, the applicable thickness specification range of the continuous casting slabs is from 400mm to 600mm, and the width specification range is from 1600mm to 3000mm. By utilizing the ultra-thick slabs to manufacture hydropower station steel penstocks through the process, surface indentations, surface transverse cracks and the center segregation level of the casting blanks all can be well controlled.

Owner:SHOUGANG CORPORATION

Packaging structure for integrated circuit chip

InactiveCN102347313AReduce electromagnetic wave hazardsReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon

The invention discloses a packaging structure for an integrated circuit chip. The packaging structure for the integrated circuit chip mainly comprises a circuit board, a chip set, a packaging body and a metal shell. The packaging structure is characterized in that: the chip set is electrically connected with the circuit board and packaged by sealing glue; the packaging body is divided to an internal layer and an external layer; two layers are formed by the different packaging processes and materials; the internal-layer packaging body is adhered to the chip group and formed by a thermally spraying process; the external-layer package body is attached outside the internal-layer package body and made of mixed silicon gel material; and the metal shell is attached outside the package body and electrically connected with the circuit board. In the invention, the packaging structure for the integrated circuit chip is disclosed; the special material and the structure of the packaging body of the packaging structure be used for effectively shielding electromagnetic waves produced by the internal chip and reducing the harm of the electromagnetic waves; and therefore, the common metal shell with a high performance in the market is replaced, the packaging cost is reduced, the process is simply and conveniently implemented and the market prospect is wide.

Owner:常熟市广大电器有限公司

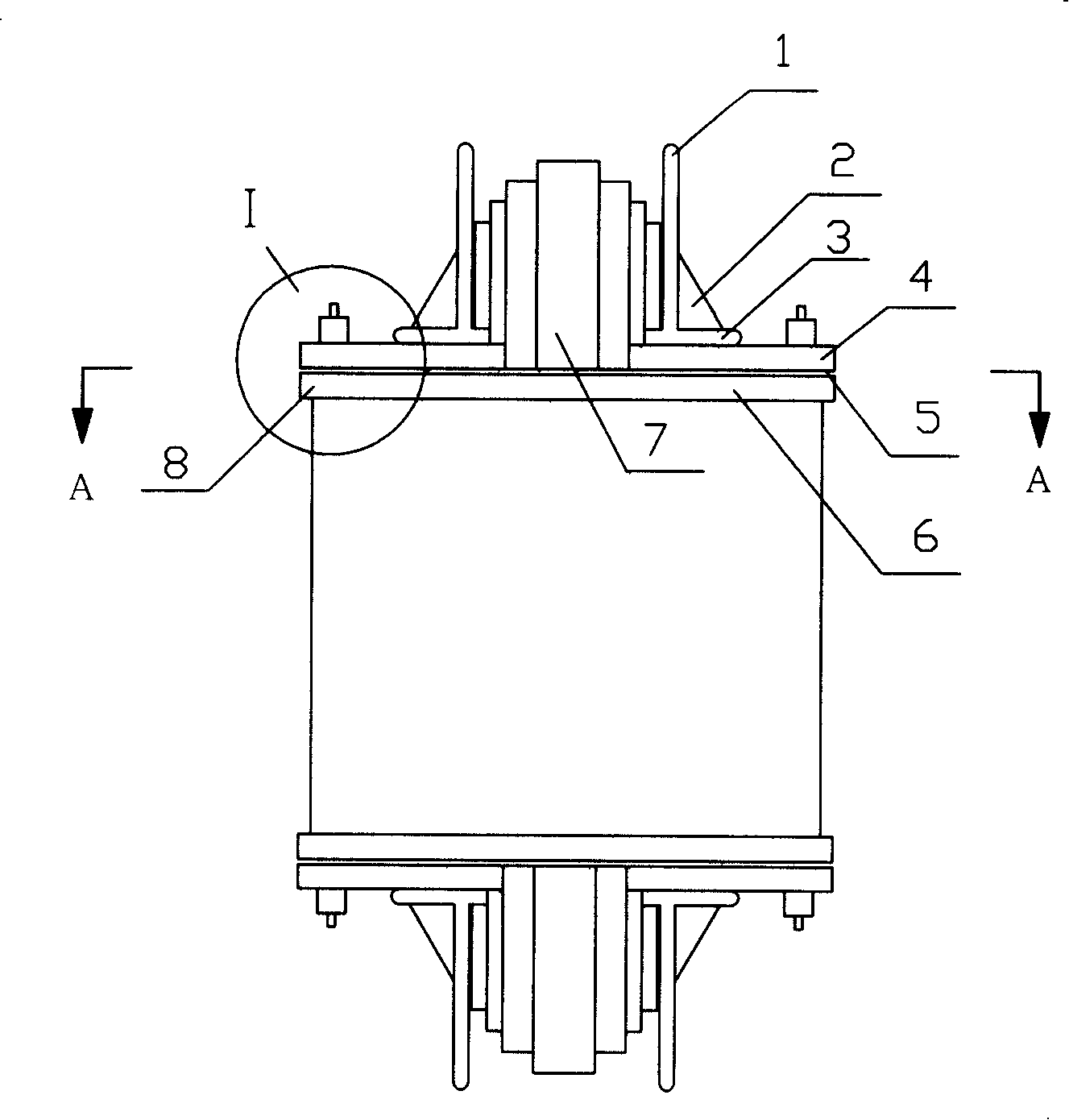

Compacting process of flexible pipe on transformer

ActiveCN101178975AEven by forceAccurately control the size of the pressing forceInductances/transformers/magnets manufactureEngineeringMechanical engineering

The technique of the invention relates to a compaction technology for a transformer body. The technology arranges a support board and a force substrate respectively on clamping parts at two ends of the transformer body and levels up an iron core step with a pressure plate of an insulating layer, thus ensuring that the pressure plate of the insulating layer and an inner surface of an iron yoke are on a same plane. A pressure plate on the upper body has a hose groove into which a hose is led. One end of the hose is sealed, and the other end is communicated with a hydraulic system. The surface of the pressure plate on the upper body has a protective layer. The hydraulic system is started up to fill oil and increase pressure in the hose and then keeps the pressure after a stated pressure is reached. A stay plate which is dried in advance is pushed into the hose, and the hose discharges oil and pressure and then exits from the hose groove. The dried stay plate is pushed into the hose groove to finish the compaction for the transformer body. The invention solves the technical problems in the background technique such as poor reliability during compaction which leads to decreased performance of short circuit withstanding of the transformer. The invention can ensure even stress on a winding group of the transformer and can present simple realization technology and low cost.

Owner:XIAN XIDIAN TRANSFORMER

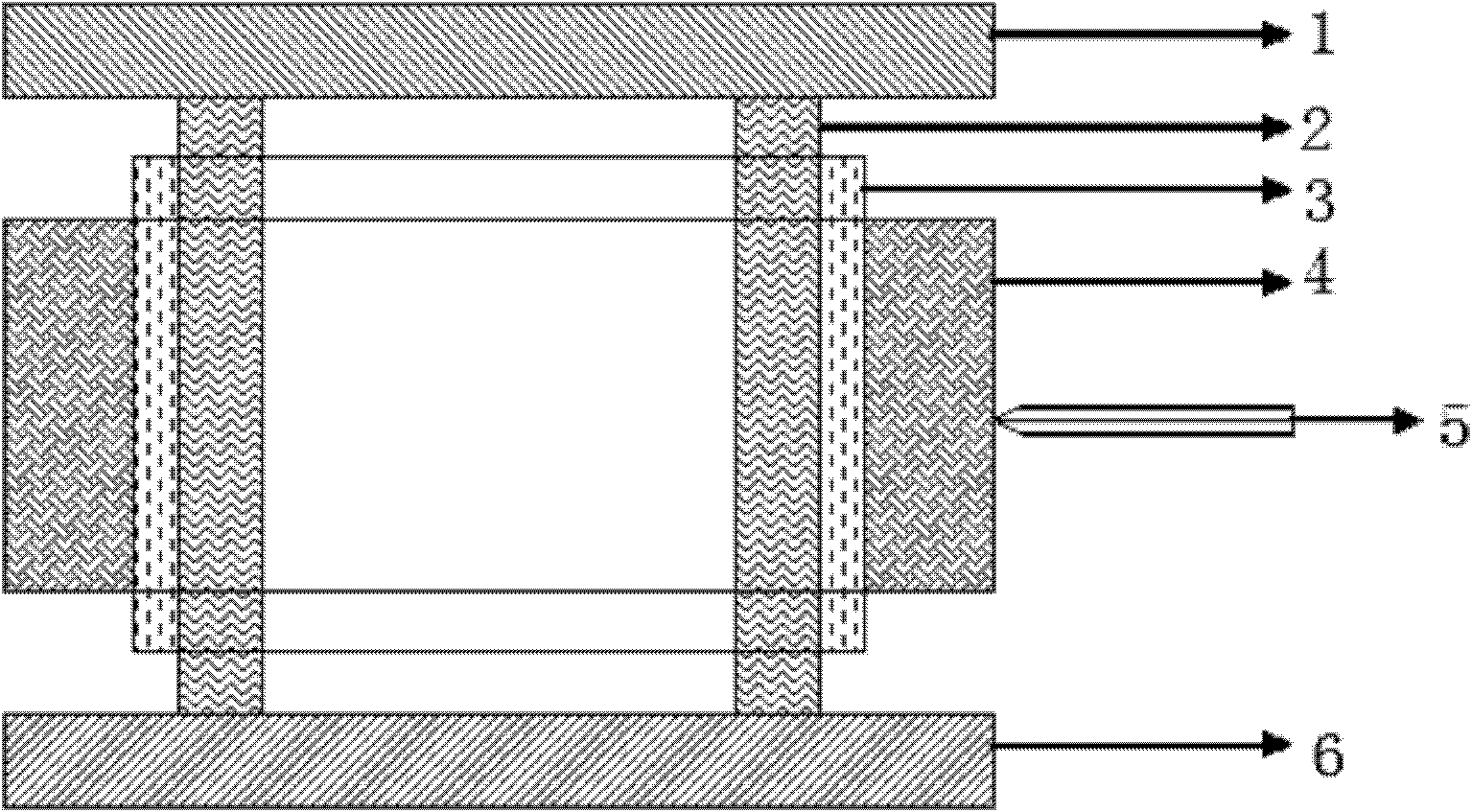

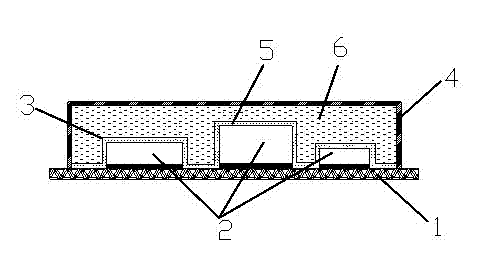

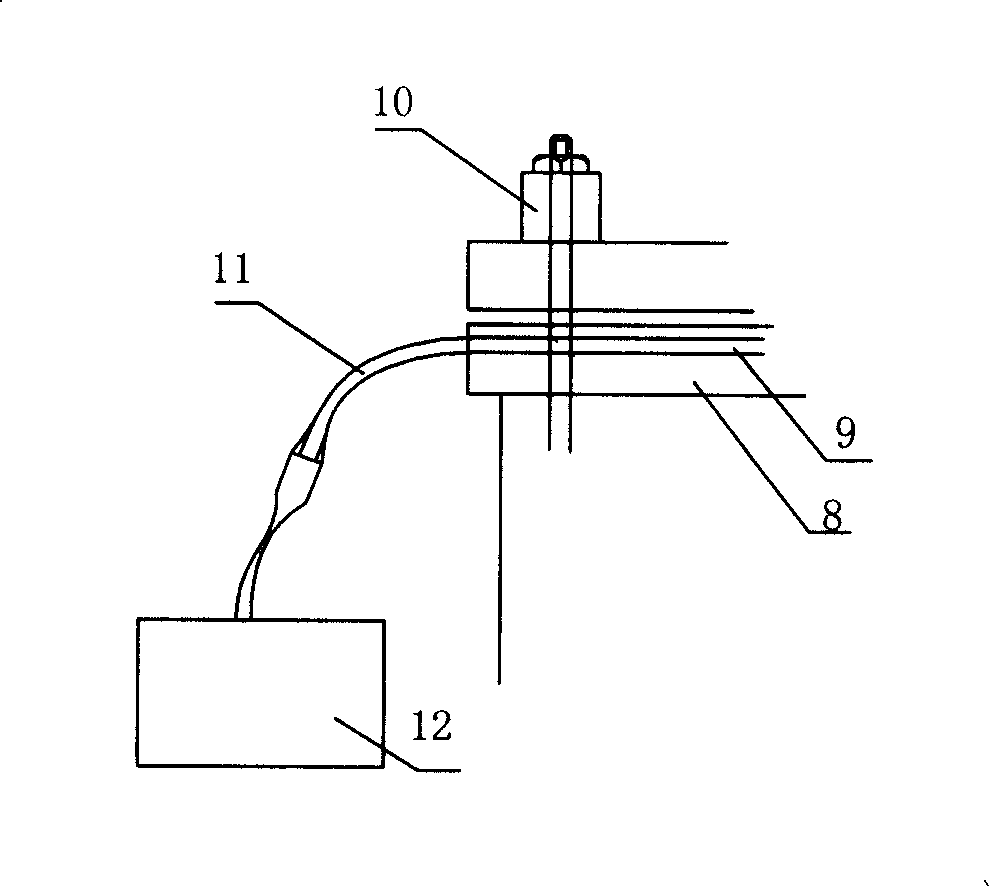

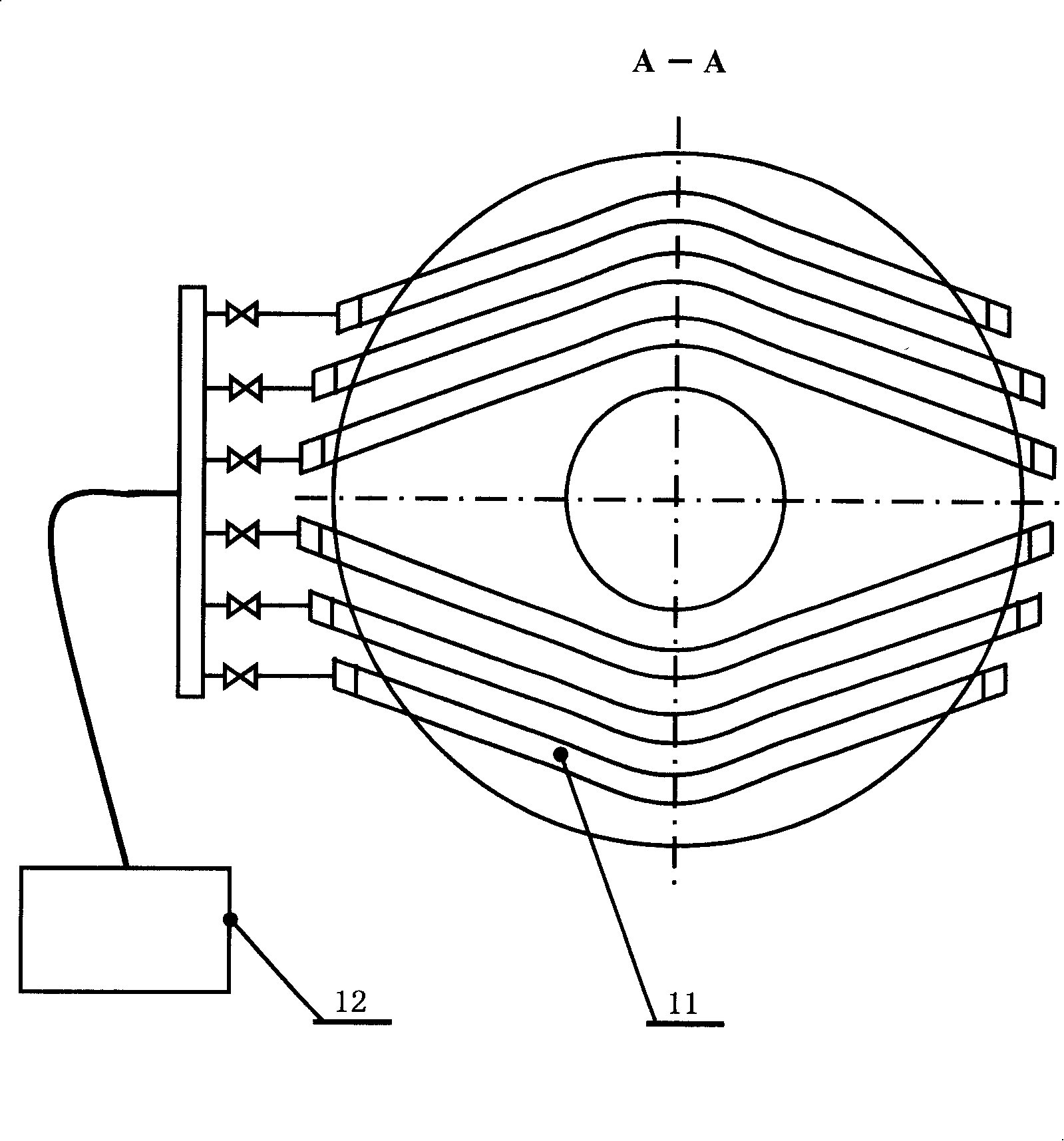

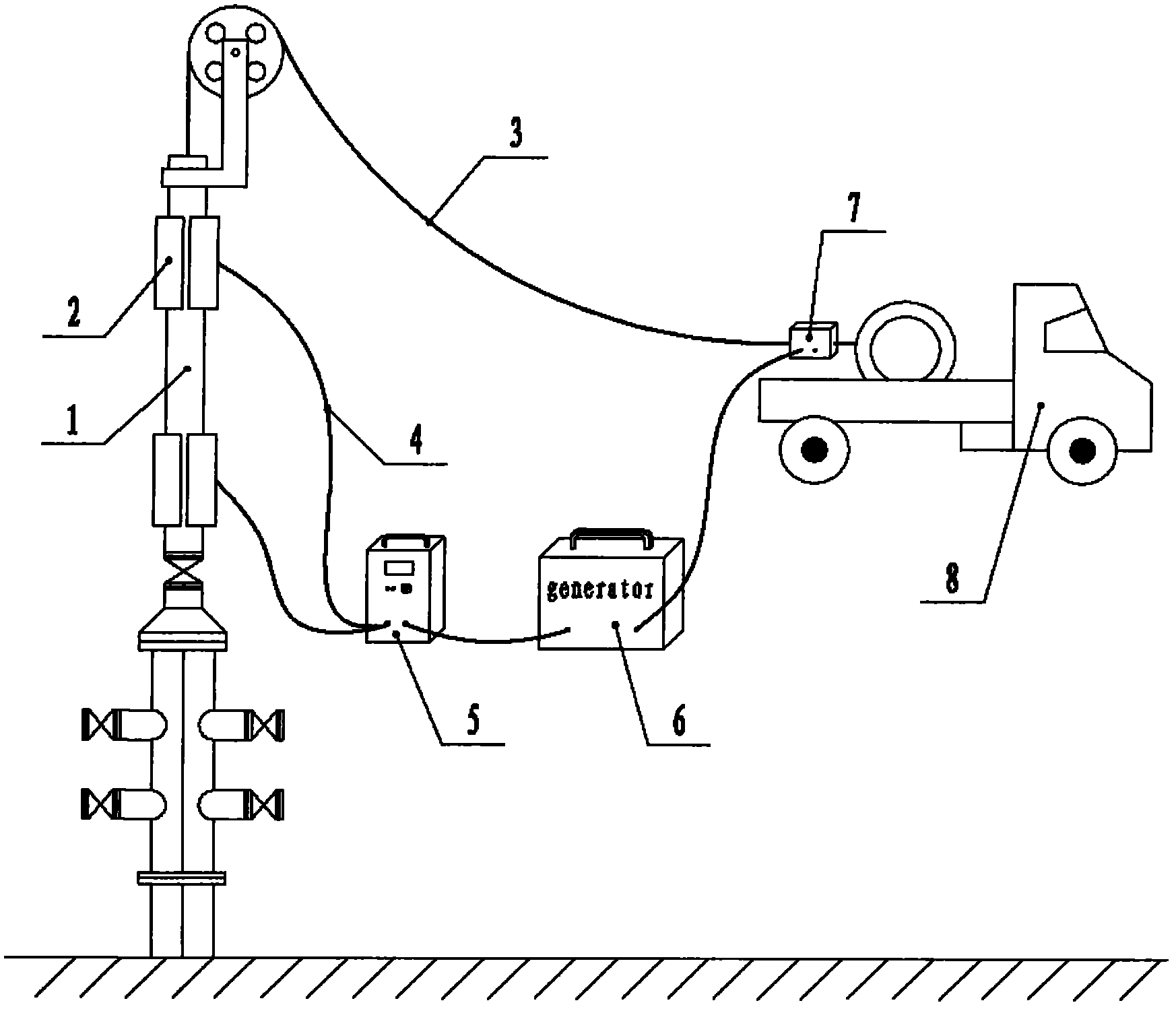

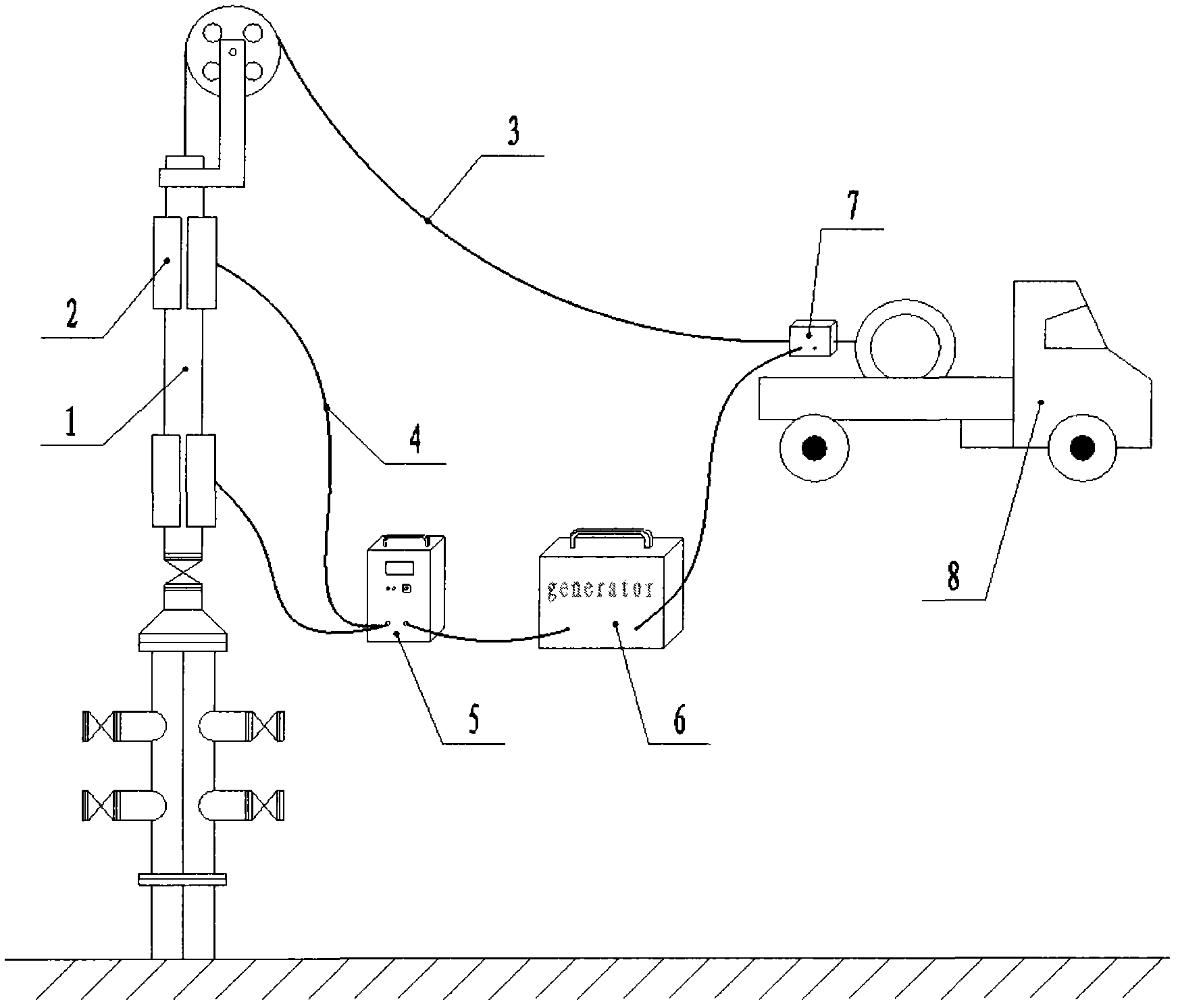

Anti-freezing process for blowout-preventing pipe and cable matched with water injection well test

The invention relates to the technical field of oil field water well operation, and in particular relates to an anti-freezing process for a blowout-preventing pipe and a cable matched with an oil field water injection well test. The anti-freezing process is designed for solving the problems of cable icing and blowout-preventing pipe freezing and blockage happening easily in an oil field water injection well during winter testing construction. The anti-freezing process mainly adopts a blowout-preventing pipe 1, an integrative coil 2, a cable 3, a multi-core wire 4, a heating power supply 5, a generator 6, a cable deicer 7 and a cable car 8, and is used for preventing freeze and defrosting of the blowout-preventing pipe 1 and the cable 3 matched with the water injection well test. The anti-freezing process is used in the oil field water well operation, and has the advantages of deicing the cable at low cost efficiently and quickly, preventing freeze and defrosting the blowout-preventing pipe and the like.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com