Nickel base alloy clad steel plates for pipeline and manufacturing method thereof

A technology of nickel-based alloy and clad steel plate, applied in the direction of metal rolling, etc., can solve the problems of increased production difficulty and large difference in processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

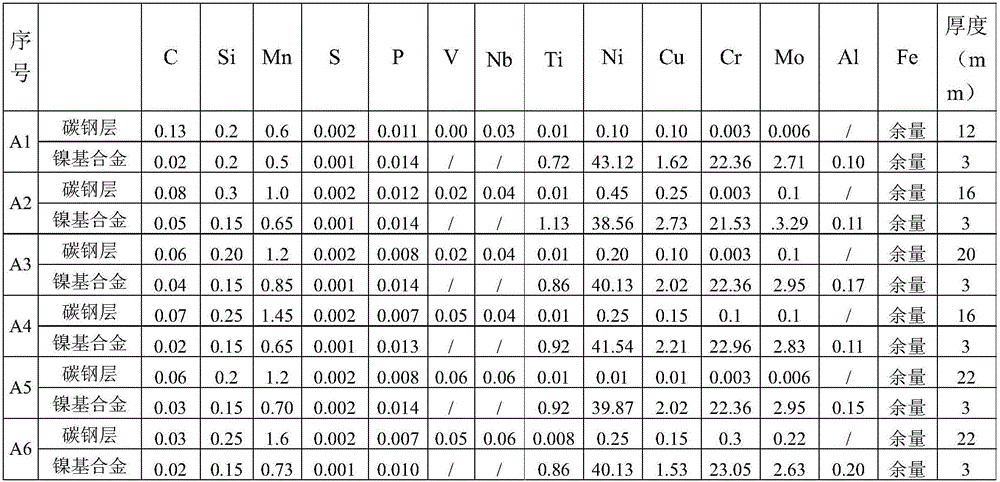

Embodiment A1-A6

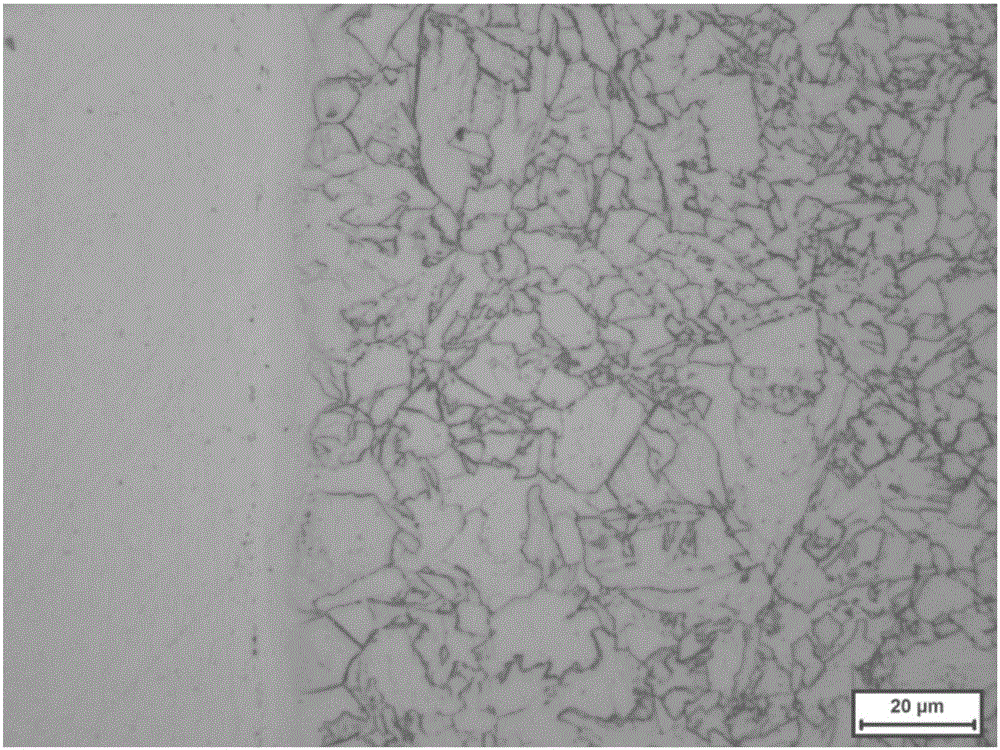

[0069] The nickel-based alloy clad steel plate for pipelines in the above-mentioned embodiments is prepared by the following steps:

[0070] (1) obtain carbon steel billet and nickel base alloy billet, each chemical element in carbon steel billet and nickel base alloy billet is as shown in table 1;

[0071] (2) Using symmetrical separation method to assemble billets: set carbon steel blanks, nickel-based alloy blanks, nickel-based alloy blanks and carbon steel blanks in sequence from top to bottom, and carry out vacuum assembly of one carbon steel blank corresponding to one nickel-based alloy blank, To form two sets of vacuum group billets independent of each other; a separating agent is arranged between the two nickel-based alloy billets of the two groups of vacuum group billets, and then the two groups of vacuum group billets are formed into billets to be rolled;

[0072] (3) Composite rolling: the heating temperature is 1050-1250°C, and the rolling temperature is 750-1250°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com