Water tap valve body and its process technique

A processing technology and faucet technology, applied in the field of machinery, can solve problems such as difficulty in satisfying mass production and short-time delivery, long processing cycle, high processing cost, etc., and achieve the effect of simple structure, high processing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

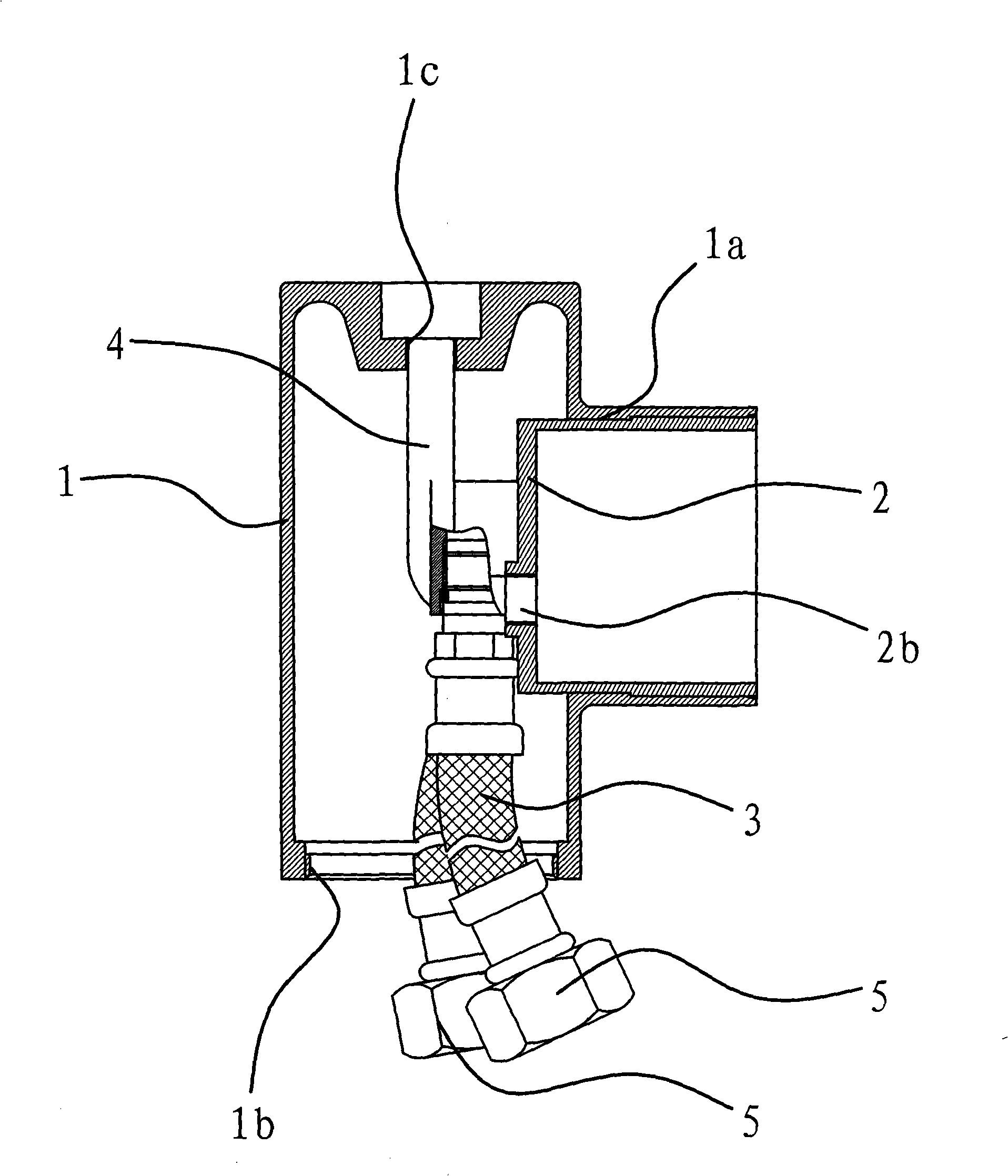

[0052] Such as figure 1 As shown, the valve body of this faucet is made up of valve housing 1, valve core seat 2 and connecting pipe. The interior of the valve casing 1 is a cavity, and the valve casing 1 has a connection hole 1a communicating with the cavity. The inside of the valve core seat 2 is a cavity, and the bottom of the valve core seat 2 has a water inlet hole 2a and a water outlet hole 2b communicating with the cavity. In this embodiment, there are two water inlet holes 2a, which can pass through hot water and cold water respectively, and the number of water outlet holes 2b is one.

[0053] The valve core seat 2 is fixedly connected to the connection hole 1a of the valve casing 1 by welding, and the water inlet hole 2a and the water outlet hole 2b of the valve core seat 2 are both communicated with the inner cavity of the valve casing 1 .

[0054] The connecting pipes are located in the valve casing 1, and there are three connecting pipes, two of which are hoses 3...

Embodiment 2

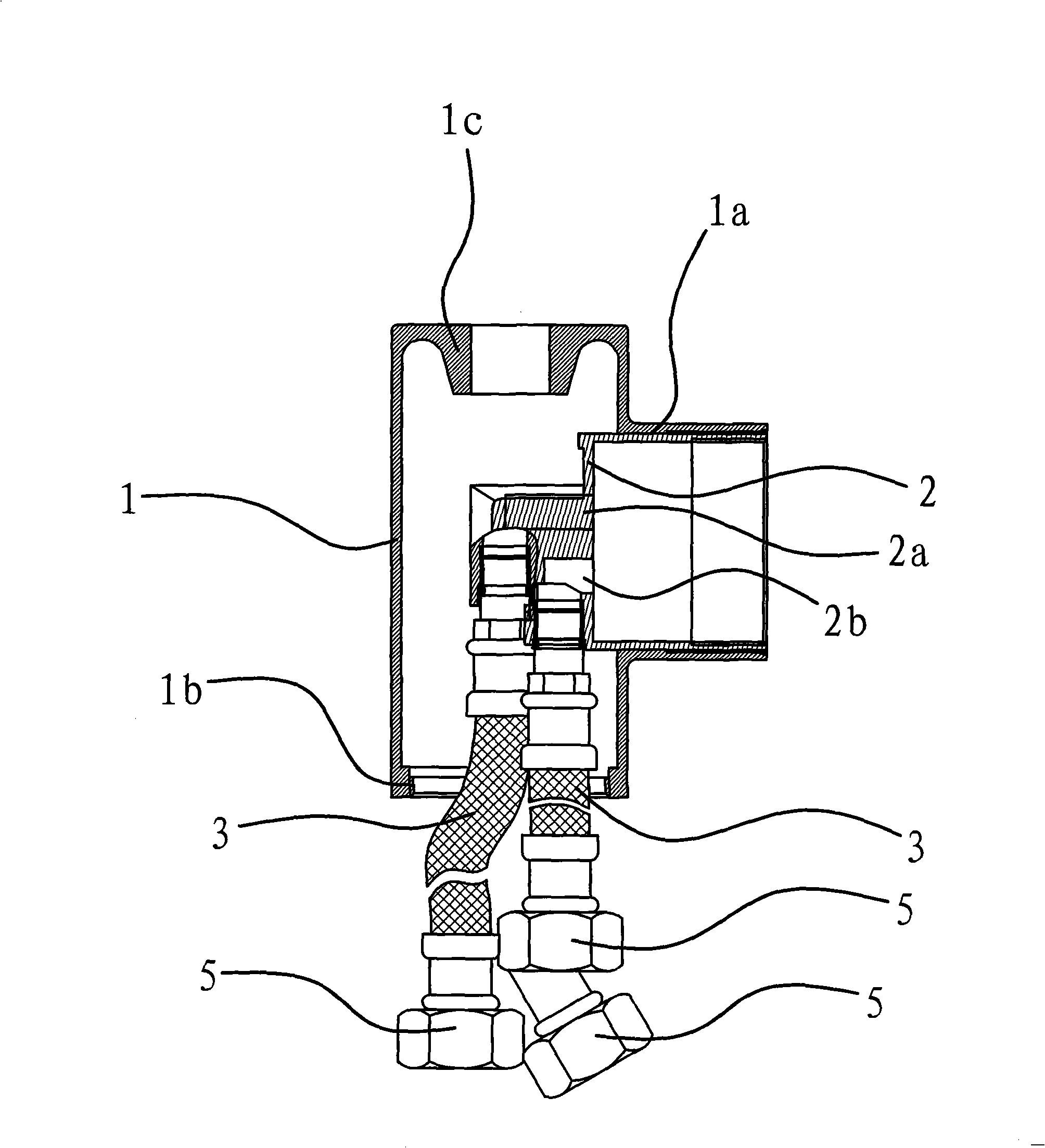

[0070] This embodiment is basically the same as Embodiment 1, the difference is that there are three connecting pipes, and these three are all flexible pipes 3, and the two ends of each flexible pipe 3 all have joints 5, see figure 2 shown.

Embodiment 3

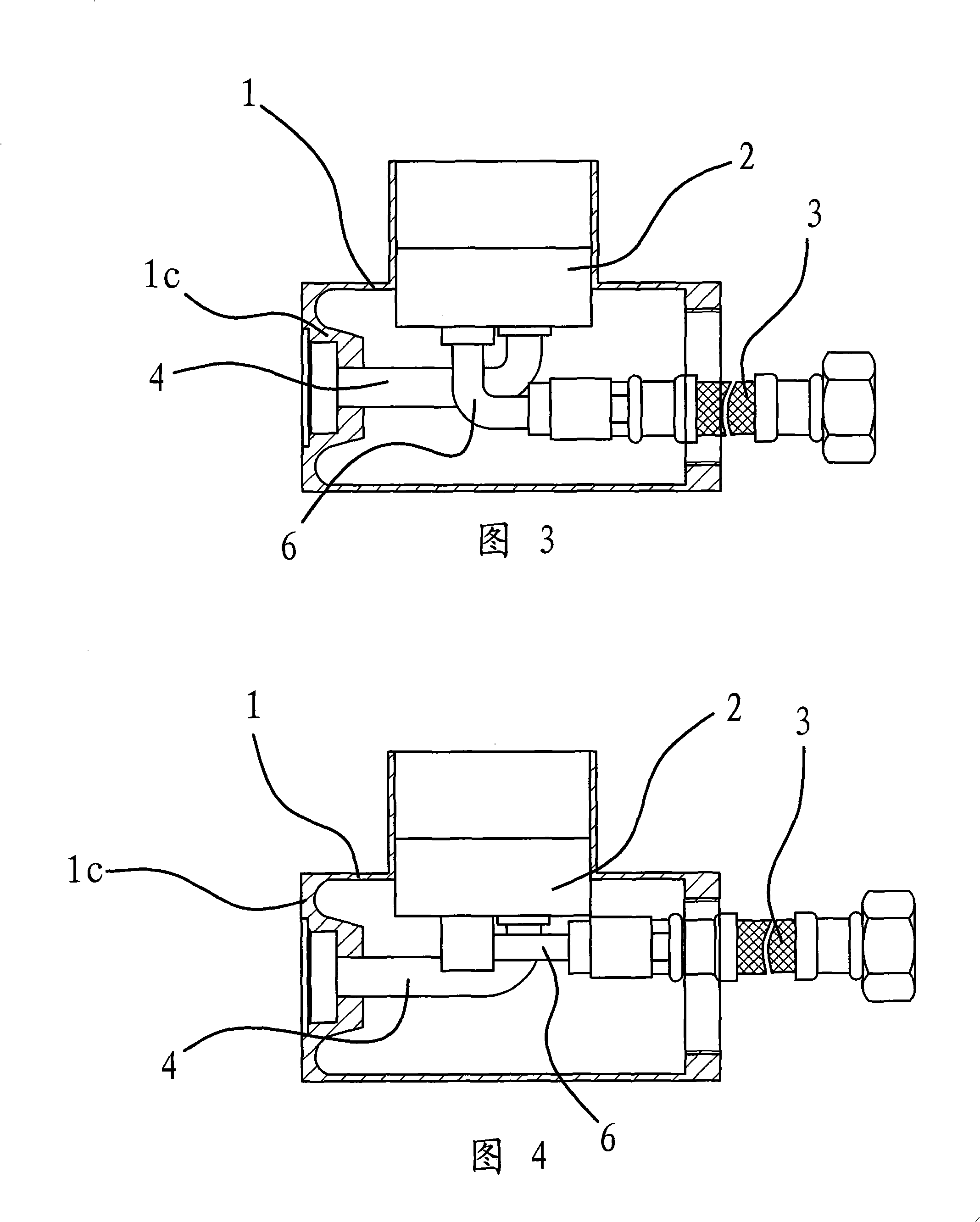

[0072] This embodiment is basically the same as Embodiment 1, the difference is that there is also a connecting copper pipe 6 between the water inlet hole 2a of the valve core seat 2 and the hose 3, and one end of the connecting copper pipe 6 is welded on the valve core seat 2 The other end of the copper pipe 6 is connected to the hose 3 at the water inlet hole 2a, as shown in Fig. 3 and Fig. 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com