Max phase-boron nitride composite ceramic side seal plate for thin-strip casting and manufacturing method of Max phase-boron nitride composite ceramic side seal plate

A technology of composite ceramics and boron nitride, which is applied in the field of ceramic composite materials, can solve the problems of restricting the industrialization process of thin strip continuous casting, failing to meet the requirements of industrial production, poor service life and wear resistance, and achieve high density, The effect of improving the service life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

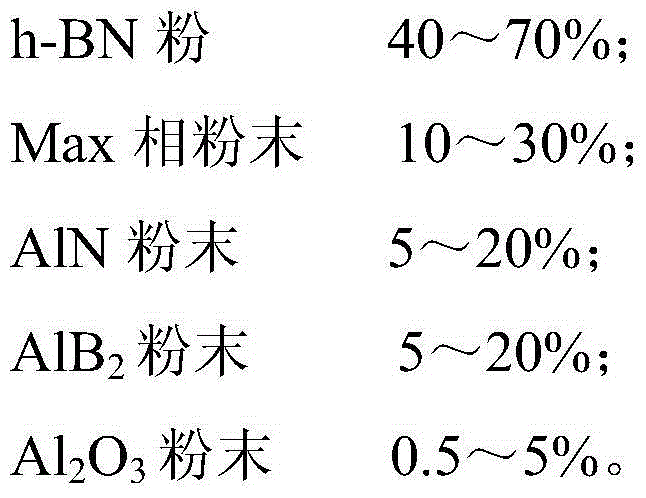

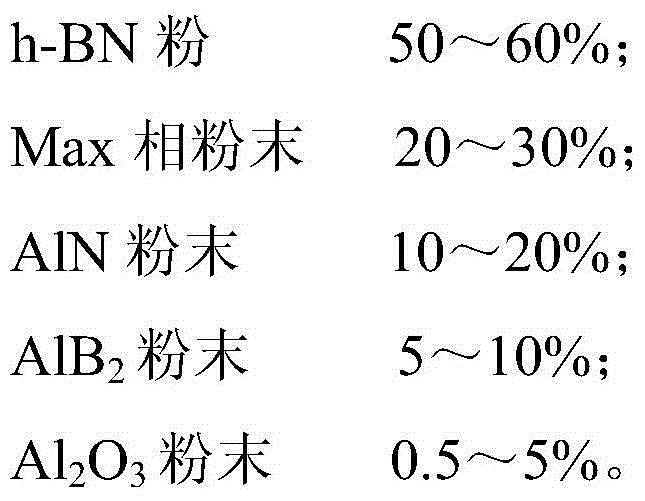

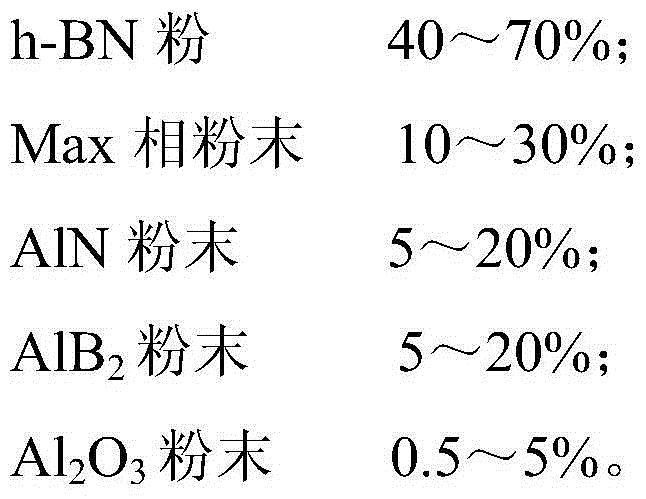

Method used

Image

Examples

Embodiment 1

[0030] A Max phase-boron nitride composite ceramic side sealing plate for thin strip continuous casting and a preparation method thereof, comprising the following steps:

[0031]1) The preparation of Max phase (ternary compound) powder, its preparation process comprises following three steps:

[0032] ① Raw material selection: select Ti powder with a chemical purity and a particle size of 20 μm; Al powder with a chemical purity and a particle size of 10 μm; activated carbon powder with a chemical purity and a particle size of 10 μm;

[0033] ②Max phase sintered body preparation: first according to Ti 2 AlC(M 2 AX phase) stoichiometry (ie: by Ti 2 In the chemical formula of AlC, the molar ratio of Ti:Al:C is 2:1:1) Select Ti powder, Al powder and activated carbon powder for batching, and then use planetary ball mill to mix the batch materials, and the mixed solvent is absolute ethanol or acetone, the mixing time is 5 hours, and then the mixture is dried in a blast drying ove...

Embodiment 2

[0042] A Max phase-boron nitride composite ceramic side sealing plate for thin strip continuous casting and a preparation method thereof, comprising the following steps:

[0043] 1) The preparation of Max phase (ternary compound) powder, its preparation process comprises following three steps:

[0044] ① Raw material selection: select Ti powder with chemical purity and particle size of 30 μm; Al powder with chemical purity and particle size of 20 μm; activated carbon powder with chemical purity and particle size of 5 μm.

[0045] ②Max phase sintered body preparation: first according to Ti 3 AlC 2 (M 3 AX 2 The stoichiometry of phase) selects Ti powder, Al powder and active carbon powder to carry out batching, utilizes planetary ball mill to mix batch material then, mixed solvent is absolute ethanol or acetone, and mixing time is 7h, utilizes blast type drying oven to mix again. The mixture is dried, and finally the dried powder is sintered by hot-pressing sintering method....

Embodiment 3

[0054] A Max phase-boron nitride composite ceramic side sealing plate for thin strip continuous casting and a preparation method thereof, comprising the following steps:

[0055] 1) The preparation of Max phase (ternary compound) powder, its preparation process comprises following three steps:

[0056] ① Raw material selection: select Ti powder with a chemical purity and a particle size of 25 μm; Al powder with a chemical purity and a particle size of 30 μm; activated carbon powder with a chemical purity and a particle size of 15 μm; silicon carbide (SiC) powder , the purity is chemically pure, and the particle size is about 35 μm;

[0057] ②Max phase sintered body preparation: first according to Ti 3 SiC 2 (M 3 AX 2 Phase) stoichiometry Select Ti powder, Al powder, activated carbon powder and SiC powder for batching, and then use planetary ball mill to mix the batch materials, the mixing medium is absolute ethanol, and the mixing time is 10h, and then use the blast drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com