Patents

Literature

786 results about "Chemical purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical purity, n the degree to which a substance is undiluted or unmixed with extraneous material, typically expressed as a percentage (%).

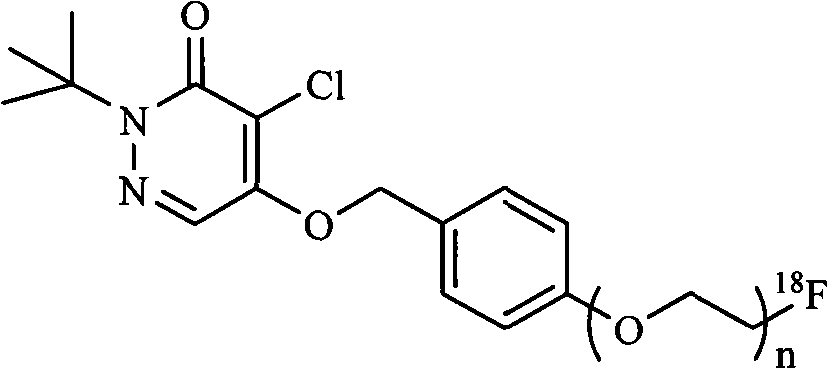

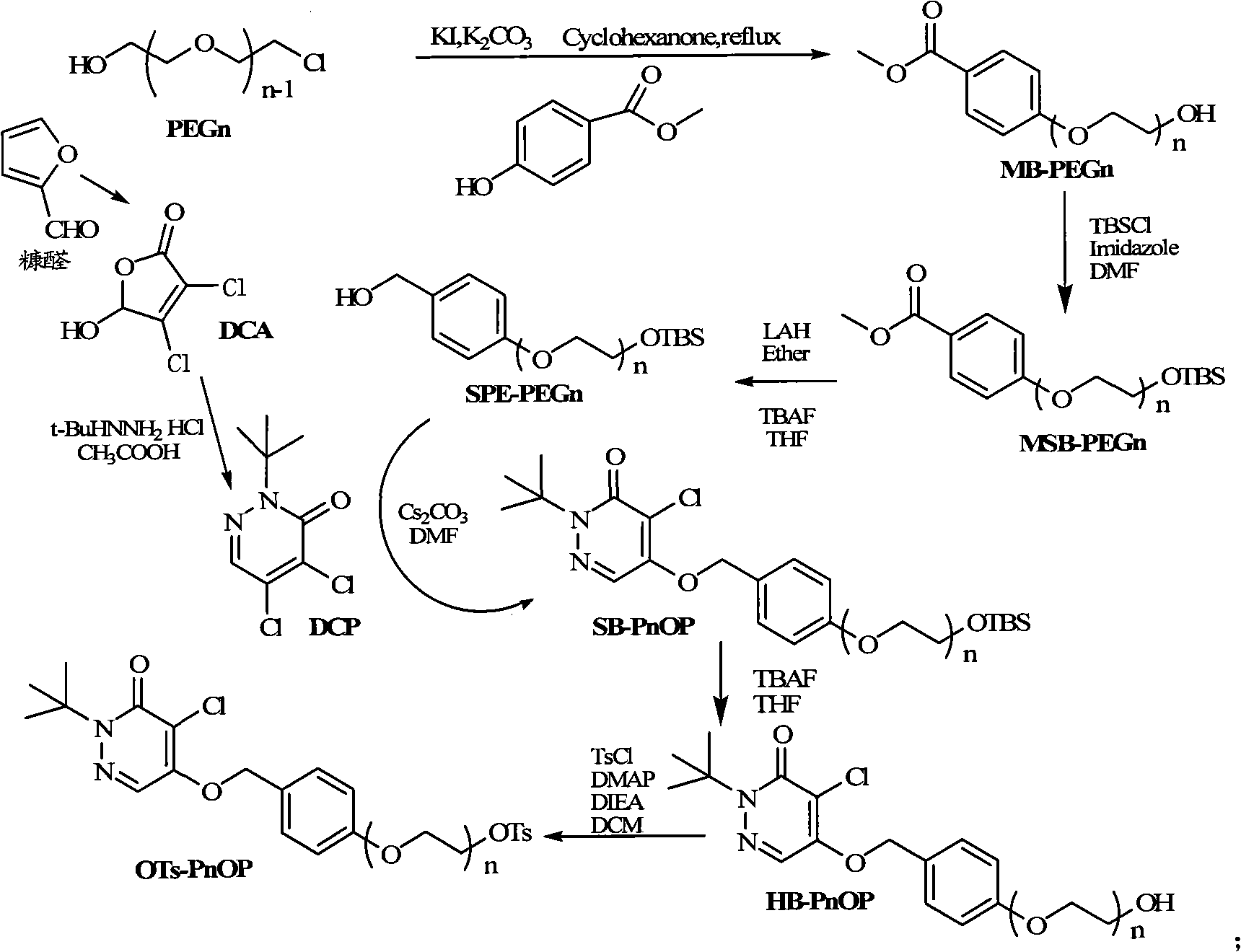

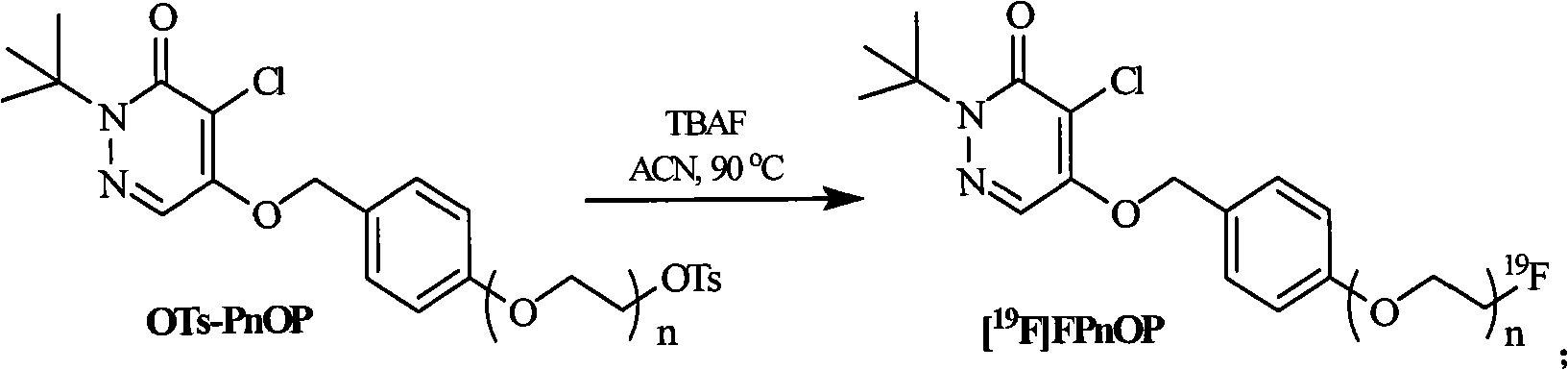

Pyridazinone compound marked by fluorine-18, preparation method and applications

InactiveCN101555232AHigh radiochemical purityGood biological propertiesOrganic chemistryRadioactive preparation carriersBiological propertyRadioactive drug

The invention discloses a pyridazinone compound marked by fluorine-18 with a molecular formula of FFPnOP and a preparation method and applications; in the formula, n is equal to 1, 2 or 3. By technical synthesis to ligand OTs-PnOP, the pyridazinone compound FFPnOP marked by radioactive fluorine-18 and stable reference compound FFPnOP are obtained by synthesis, wherein the stable reference compound is used for confirming the structure of the compound with radioactive marks; the compound has high radiochemical purity, good biological properties, high initial uptake value, simple preparation and low use cost, and is applied in the technical fields of radioactive drug chemistry and clinical nuclear medicine as a novel myocardial perfusion imaging agent marked by fluorine-18.

Owner:BEIJING NORMAL UNIVERSITY +1

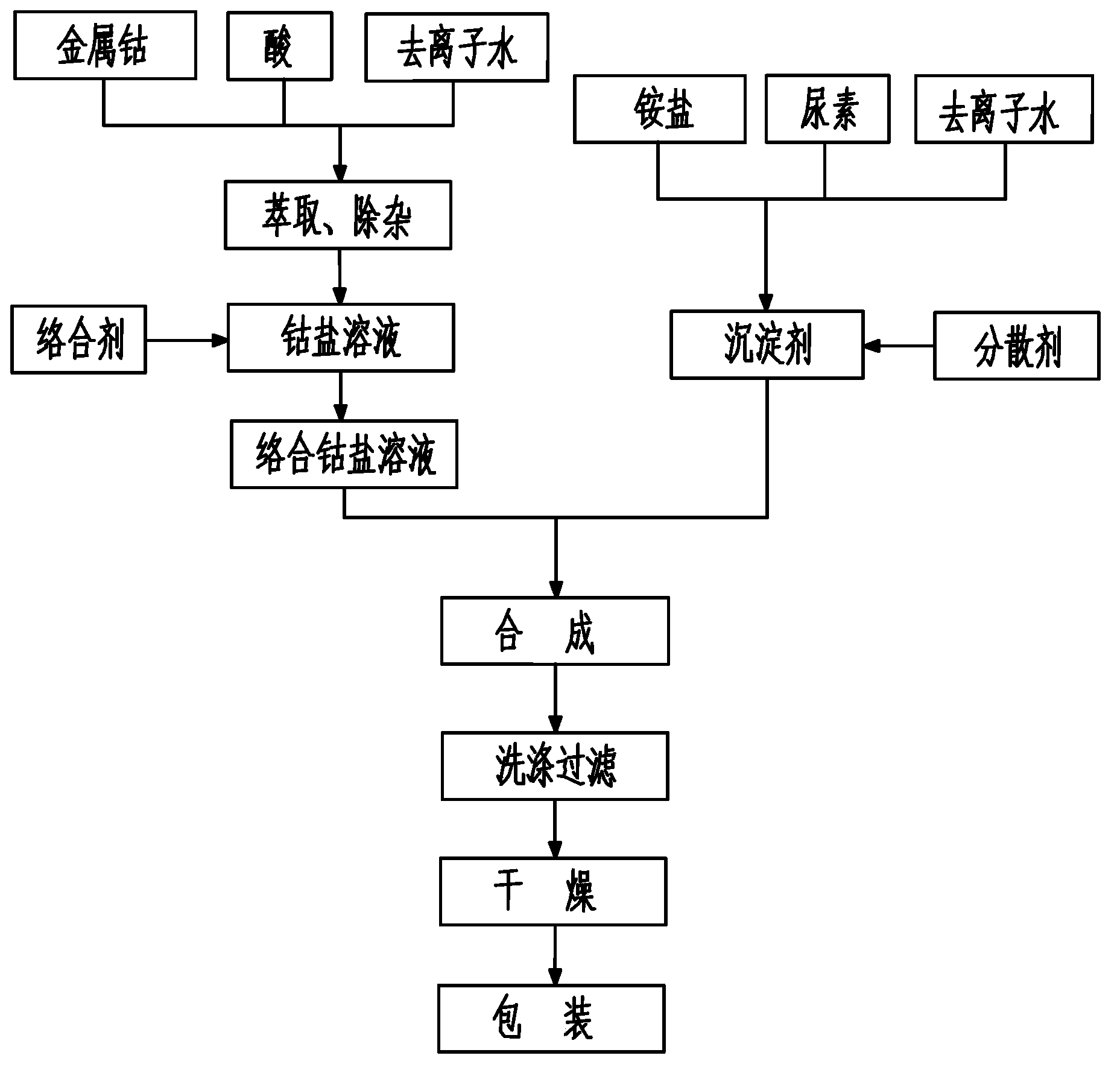

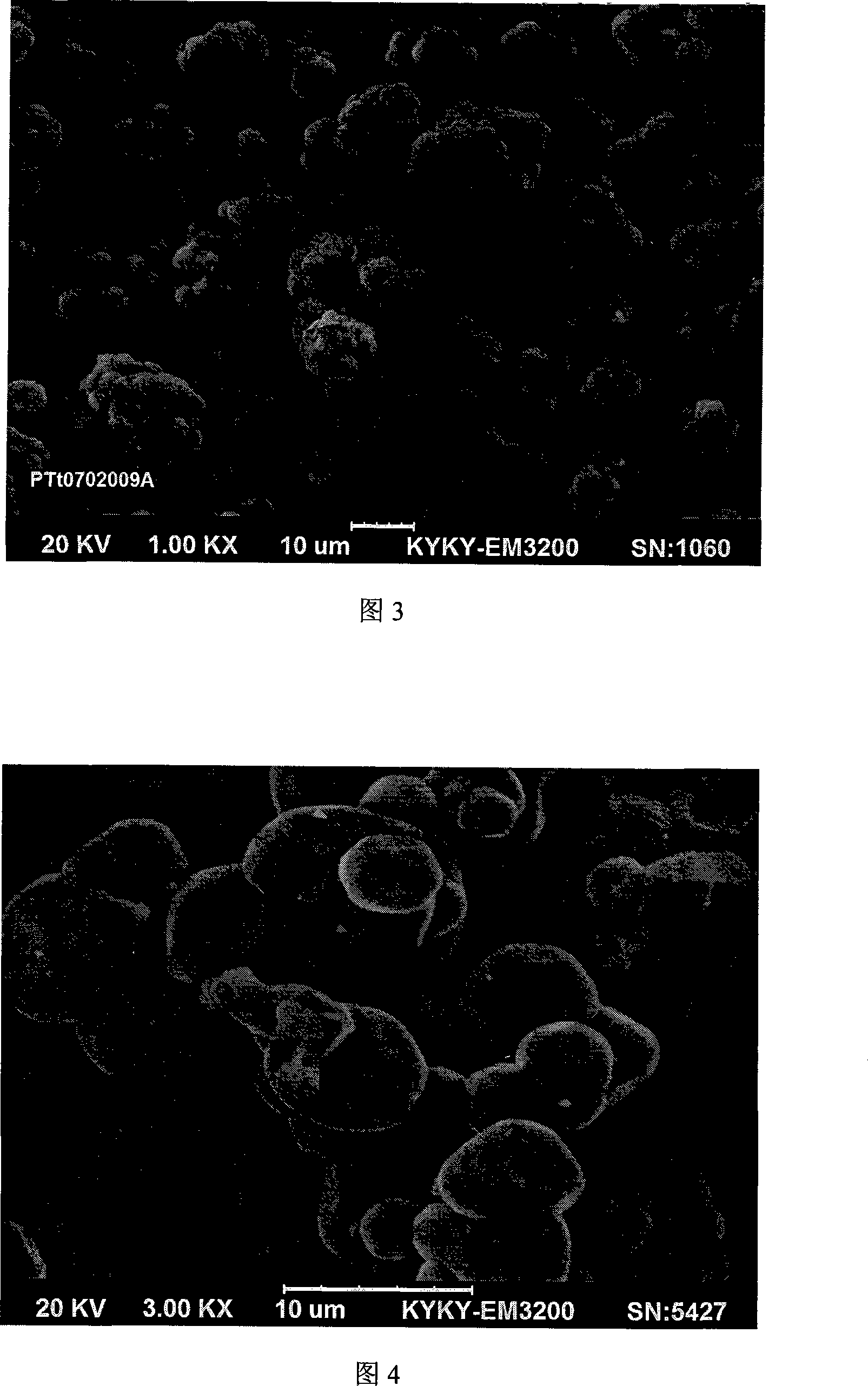

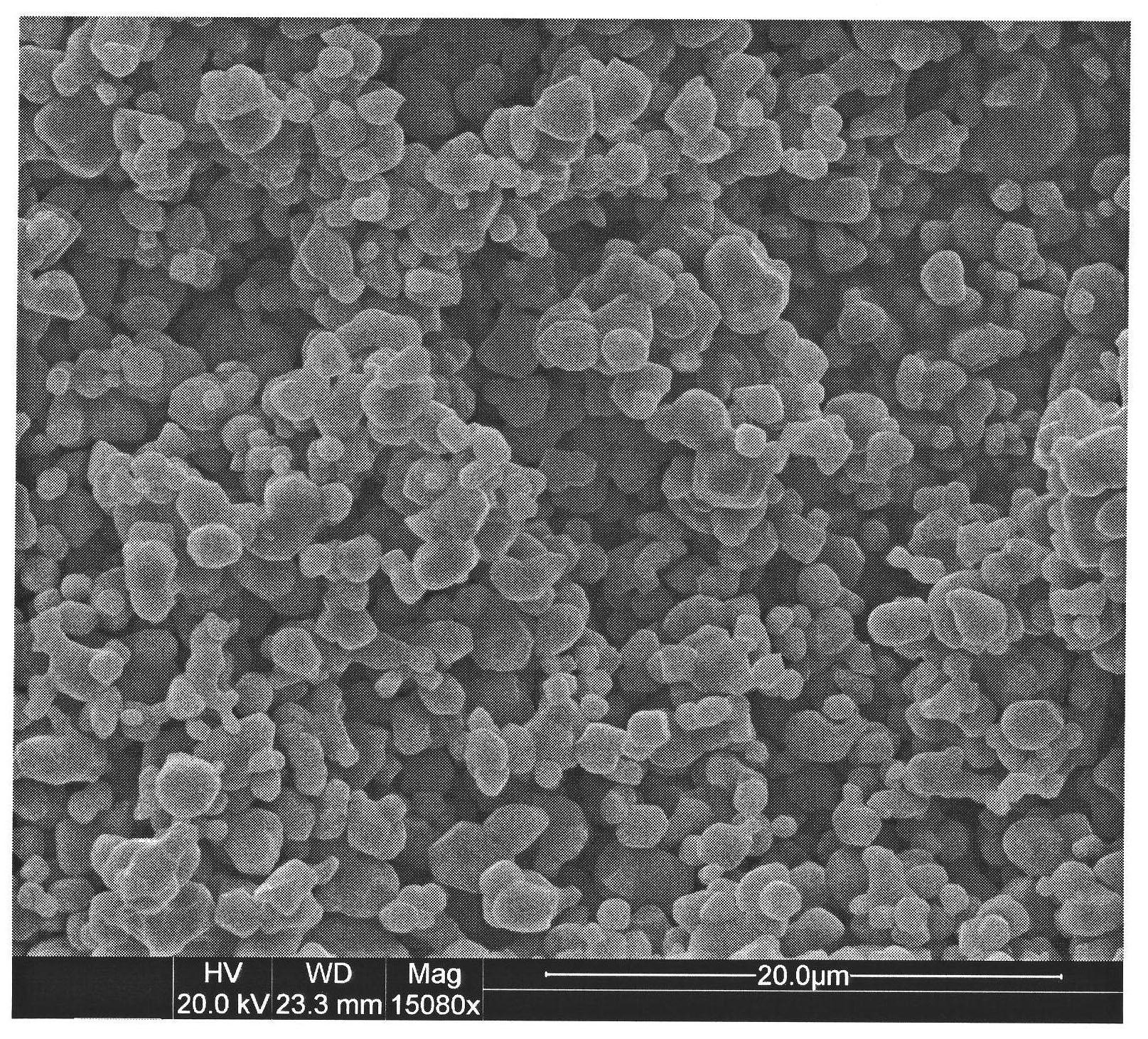

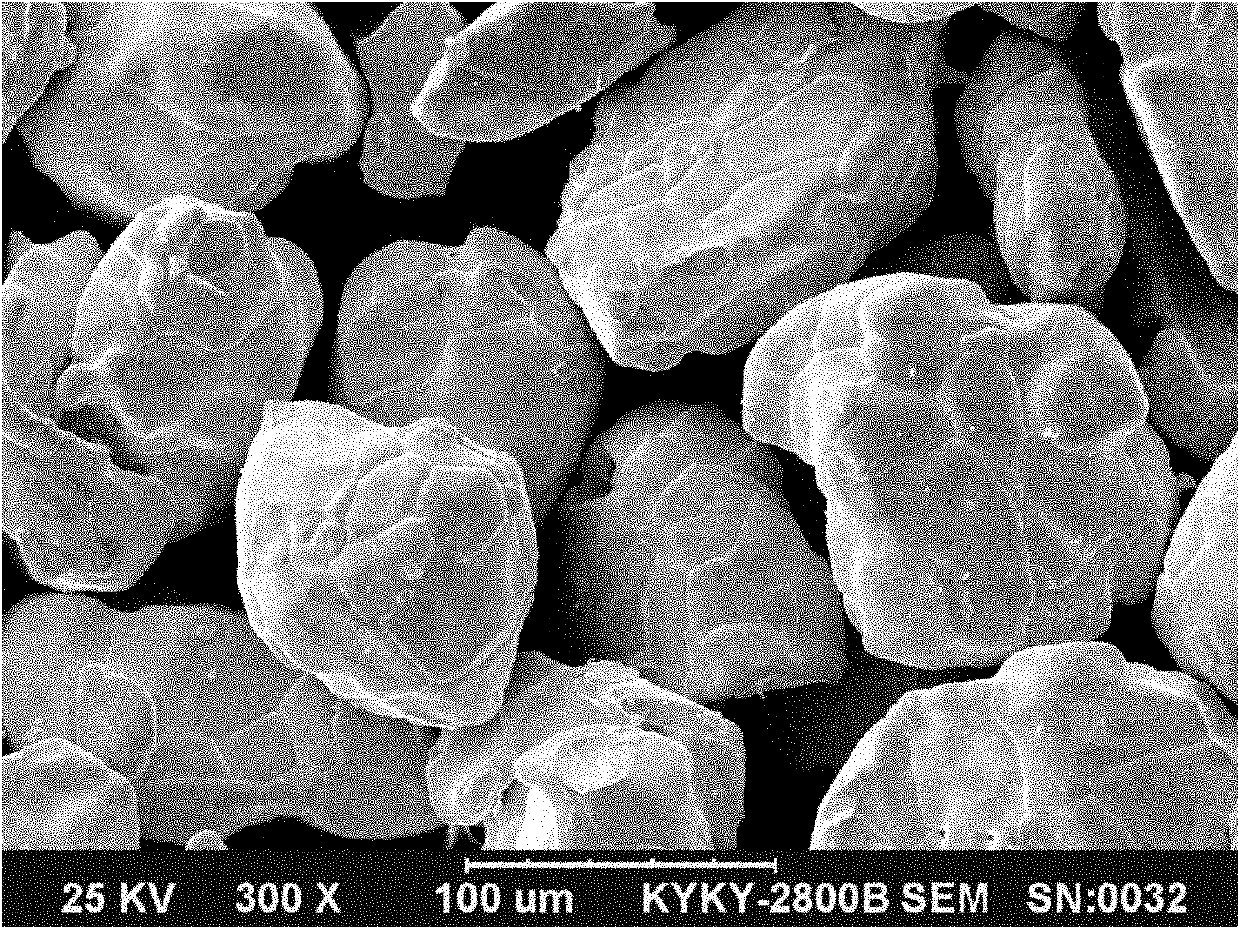

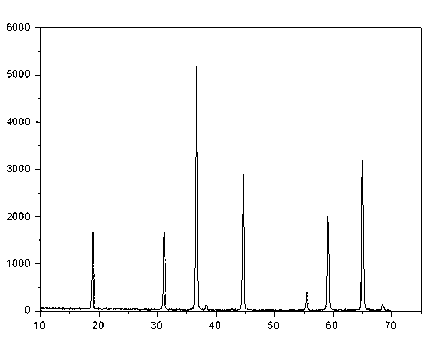

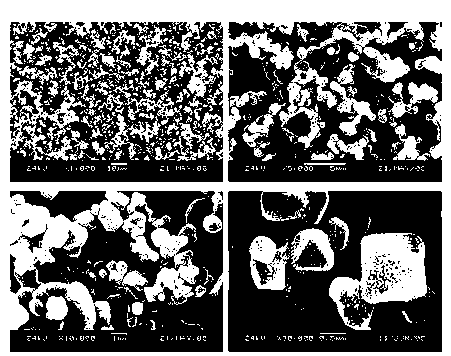

Preparation method of high-purity superfine spherical cobalt carbonate

ActiveCN103771545AQuality improvementImprove liquidityCobalt carbonatesGranularityReaction temperature

The invention discloses a preparation method of high-purity superfine spherical cobalt carbonate, and belongs to the field of preparation of metal powder materials. The preparation method is as follows: metal cobalt is used as a raw material to prepare a cobalt salt solution, a complexing agent is used for prepare a complexed cobalt salt solution from the cobalt salt solution, a mixture of an ammonium salt and urea is prepared in to a precipitant solution, a dispersant is added into the precipitant solution, the complexed cobalt salt solution and the precipitant are added agent according to a certain volume ratio by a parallel flow feeding method into a reactor for reaction, the reaction temperature is controlled at 50-80 DEG C, the pH value is controlled to 7.8-8.3, and the stirring speed is 60-200rpm, and finally the superfine spherical cobalt carbonate is obtained by washing, filtering and drying of prepared cobalt carbonate. The preparation method has the advantages of simple production process, easy control, short production cycle, high efficiency and continuous production, a prepared cobalt carbonate product has the advantages of good mobility, uniform particle size distribution, spherical microtopography, high chemical purity and good chemical properties.

Owner:YUCHEN ADVANCED ENERGY MATERIALS & TECH WUXI

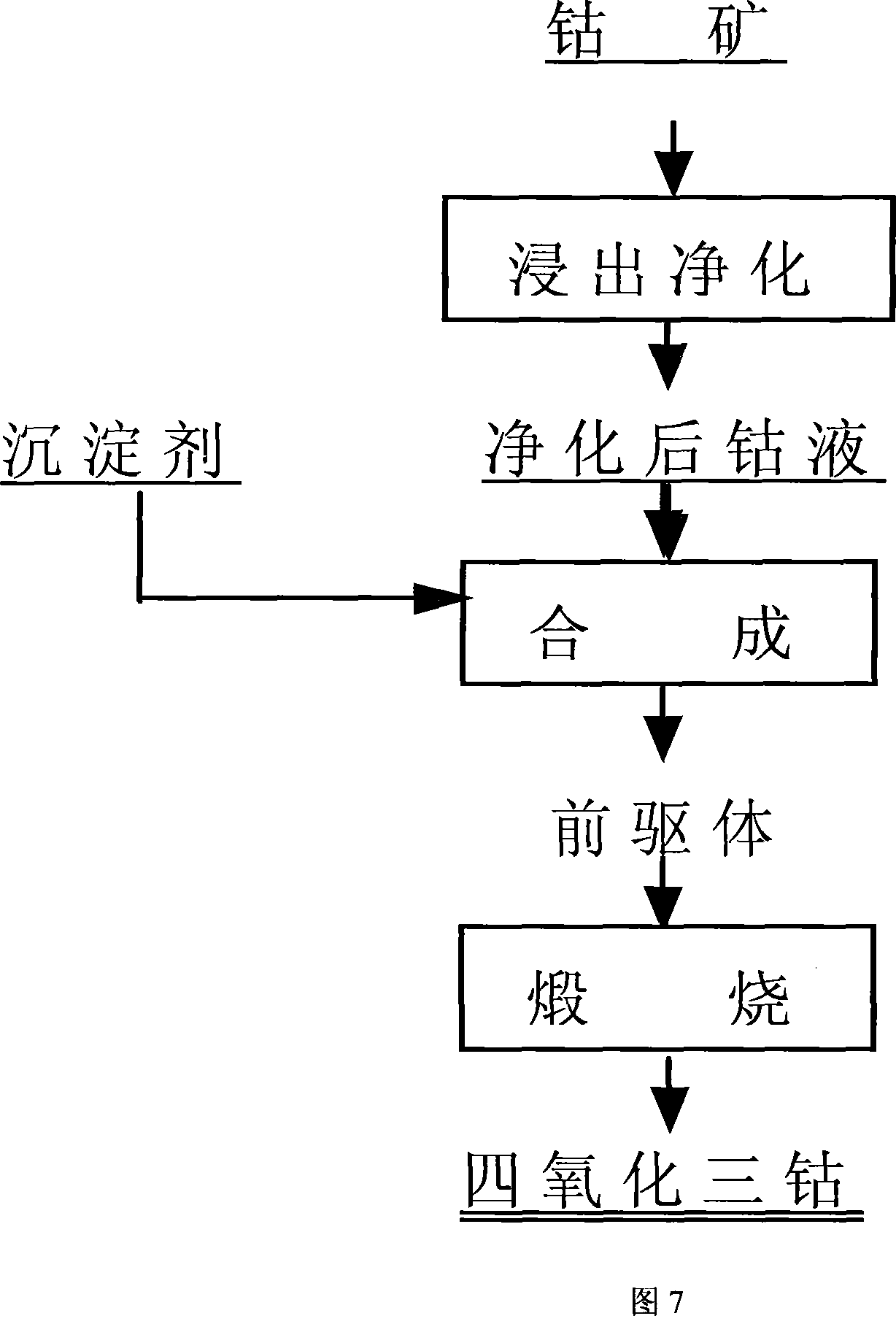

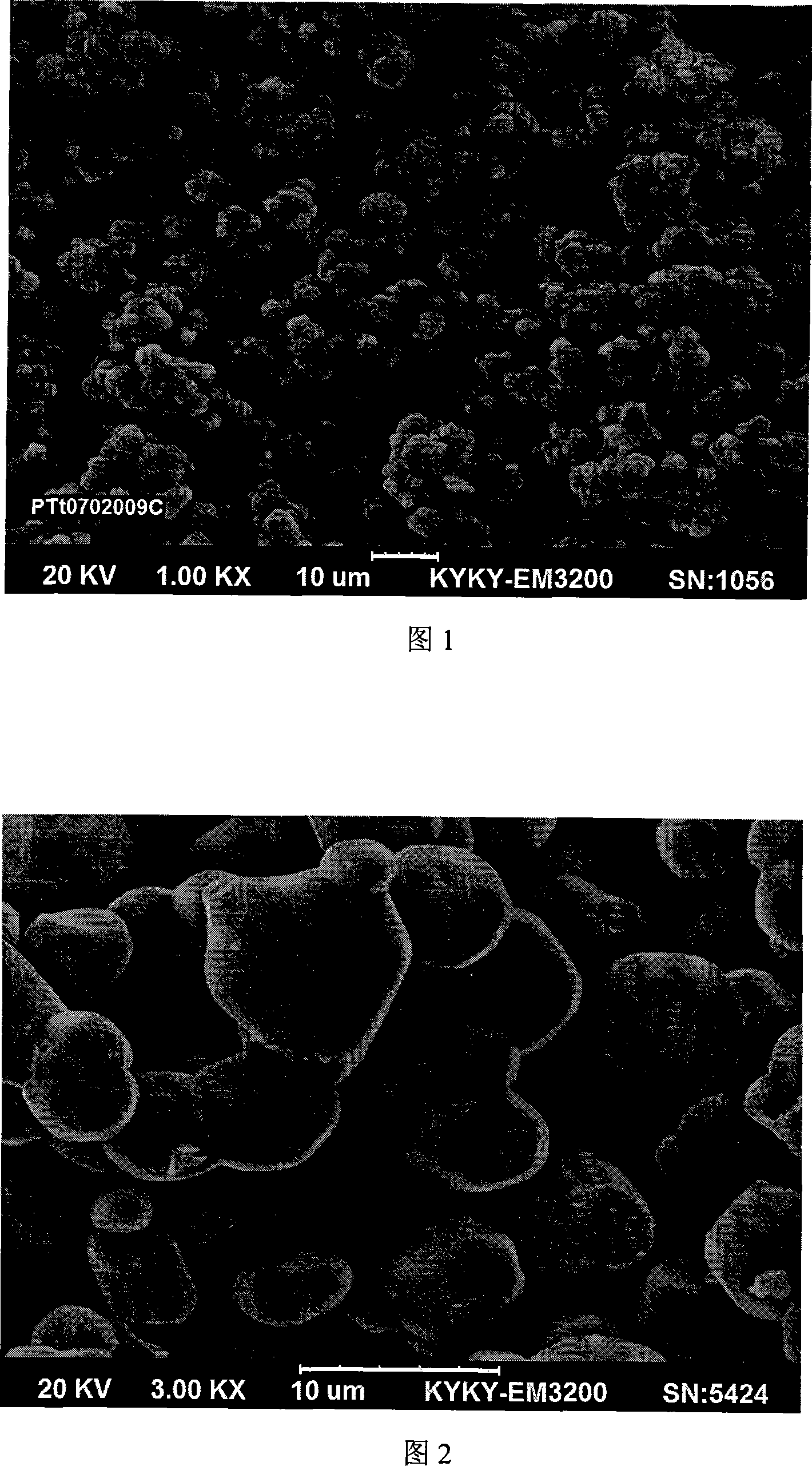

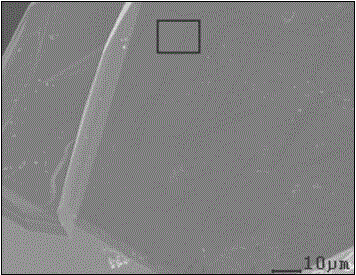

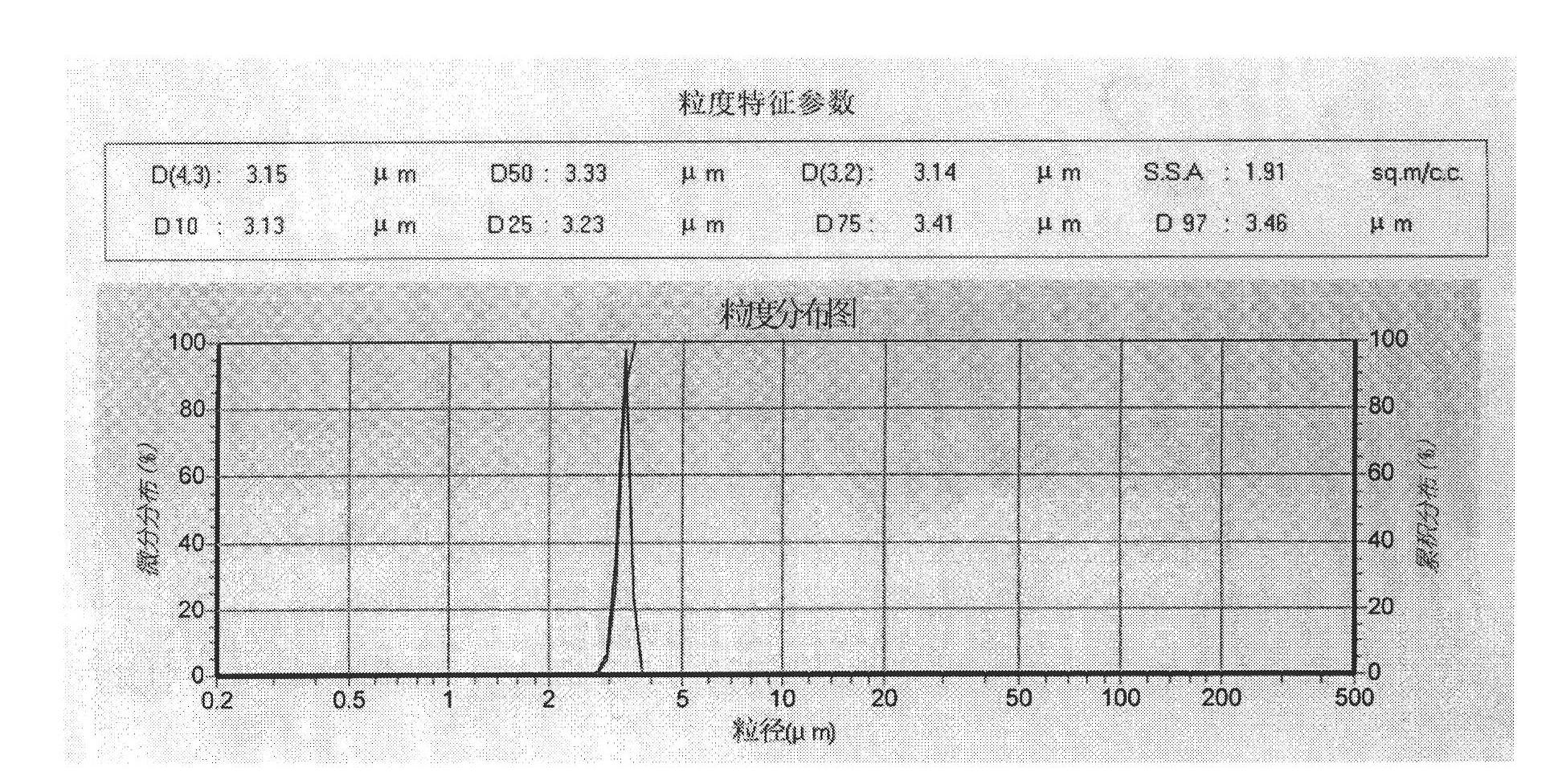

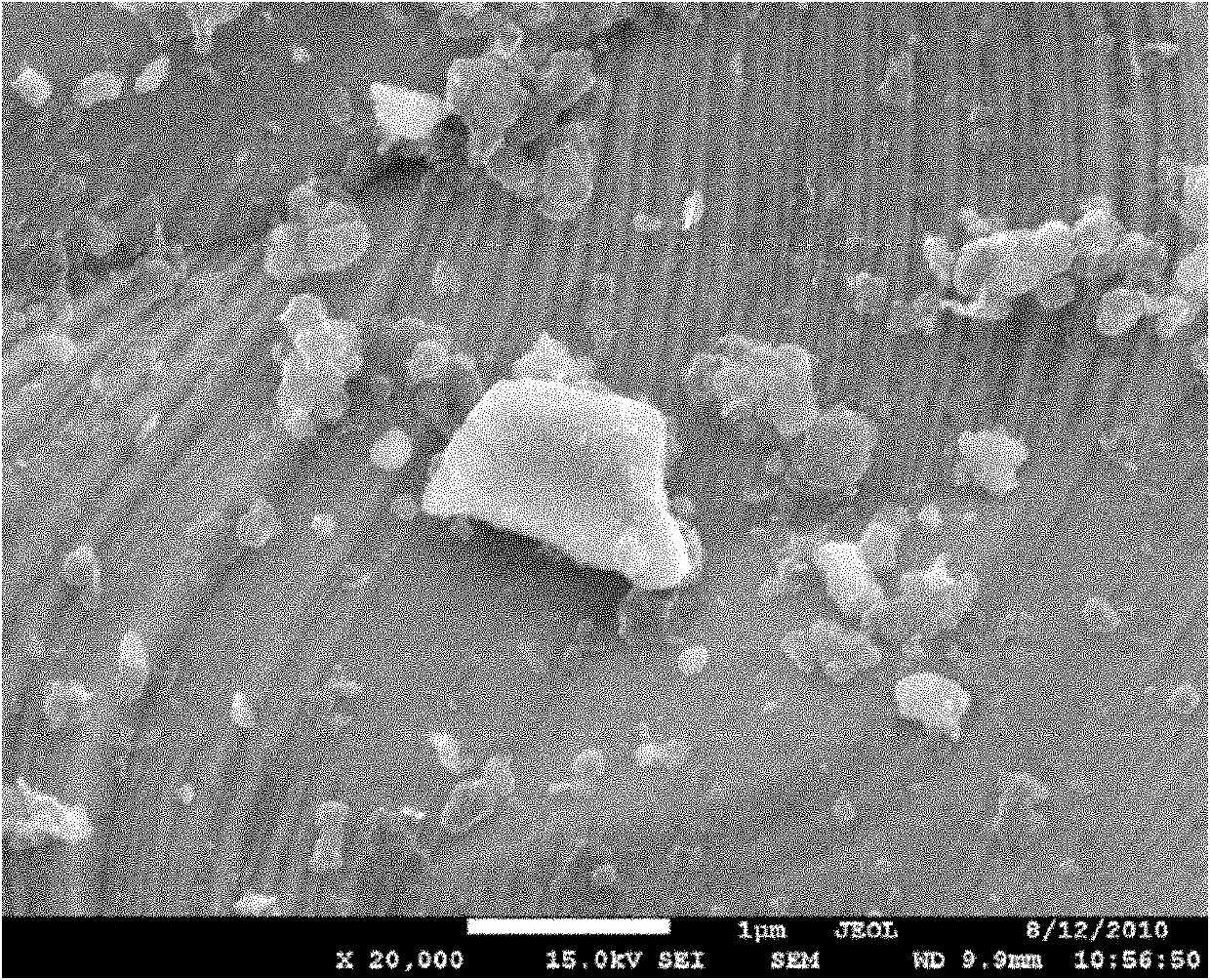

Preparation method of cobaltosic oxide for electric battery

ActiveCN101200308AImprove liquidityUniform particle sizeCobalt oxides/hydroxidesGranularityCobalt(II,III) oxide

The invention discloses a preparation method of Co3O4 for batteries, Co mineral is used as Co raw material, after purified the Co liquid is obtained, complexing-homogeneous sedimentation method is adopted to prepare precursor, i.e the Co liquid is prepared into the complexing Co salt solution, and then added with precipitator solution, the synthesis of the precursor is controlled to obtain single-dispersion sedimentation precursor so as to make the production and growth of the nucleation be separated, and then sintered under high temperature, the precursor is thermally decomposed to obtain the Co3O4 for batteries finally. The prepared Co3O4 powder has good flow property, even granularity and can utilize DCS system to adjust process parameters accurately to realize the control (D50=3um-6um,6um-9um,9um-12um), the tap density can reach 2.5g per cubic centimeter to 3.5g per cubic centimeter, microcosmic shape is single-crystal or like spherical, moreover the invention has the advantages of high chemical purity, good electrochemical performance, and no environmental pollution. The invention has simple process, stable product quality, low cost, and can adapt for the requirements of material performance and cost of various lithium cobalt oxide manufacturing factory.

Owner:ZHEJIANG HUAYOU COBALT

Quaternary sulfide semiconductor material, and preparation method and application thereof

InactiveCN104862782ALow costEasy to operatePolycrystalline material growthFrom normal temperature solutionsCooking & bakingSemiconductor materials

The invention discloses a quaternary sulfide semiconductor material, and a preparation method and application thereof. An alkali metal compound, metallic copper, binary solid solution solid solution and elemental sulfur are used as raw materials, hydrazine hydrate and polyethylene glycol are used as solvents, and a reaction is carried out in a baking oven with a temperature of 120 to 190 DEG C for 4 to 9 d so as to prepare the quaternary sulfide semiconductor material. The chemical composition of the quaternary sulfide semiconductor material is A<x>Cu<y>Sb<z>S<x+y+3z> / 2, wherein A is alkali metal atoms of a balanced anion skeleton, x represents the molar weight of the alkali metal atoms, y is the molar weight of transition metal atoms composing the skeleton and z is the molar weight of atoms composing the skeleton. The preparation method has the advantages of simple operation process, low cost of raw materials, mild reaction conditions, low synthesis temperatures, etc. Quaternary sulfide prepared by using the method has yield of 60 to 90%, a crystal grain size of 150 to 300 [mu]m and high chemical purity and can be used for preparing optical semiconductor devices.

Owner:ZHEJIANG UNIV

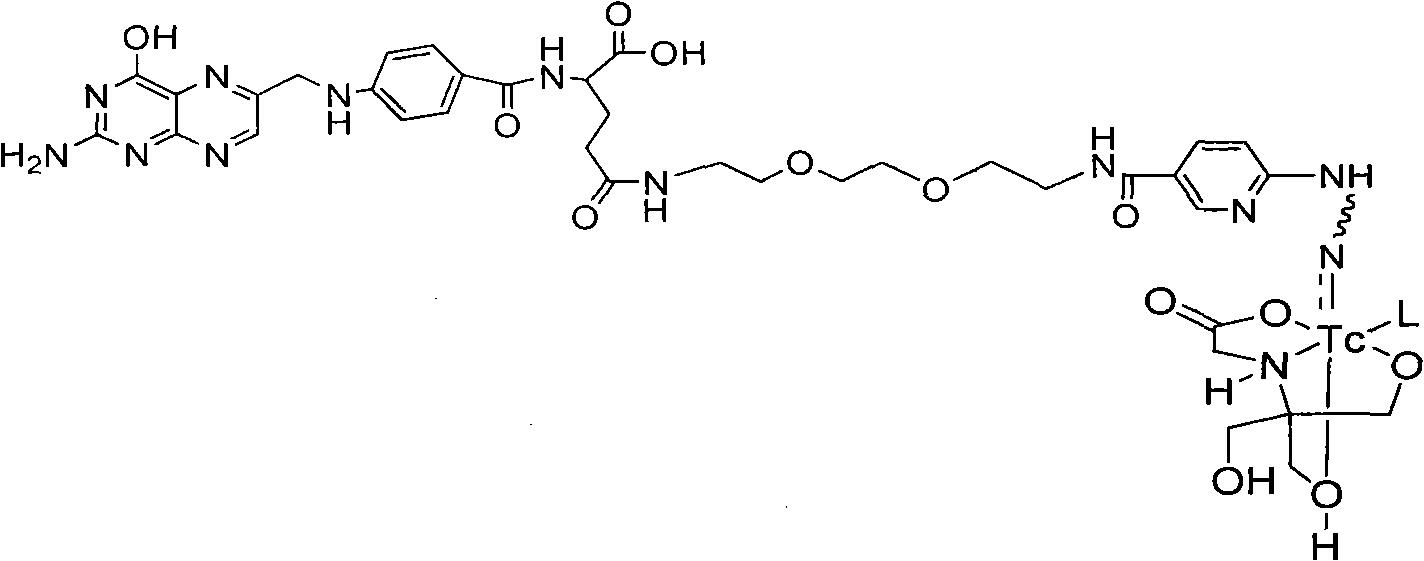

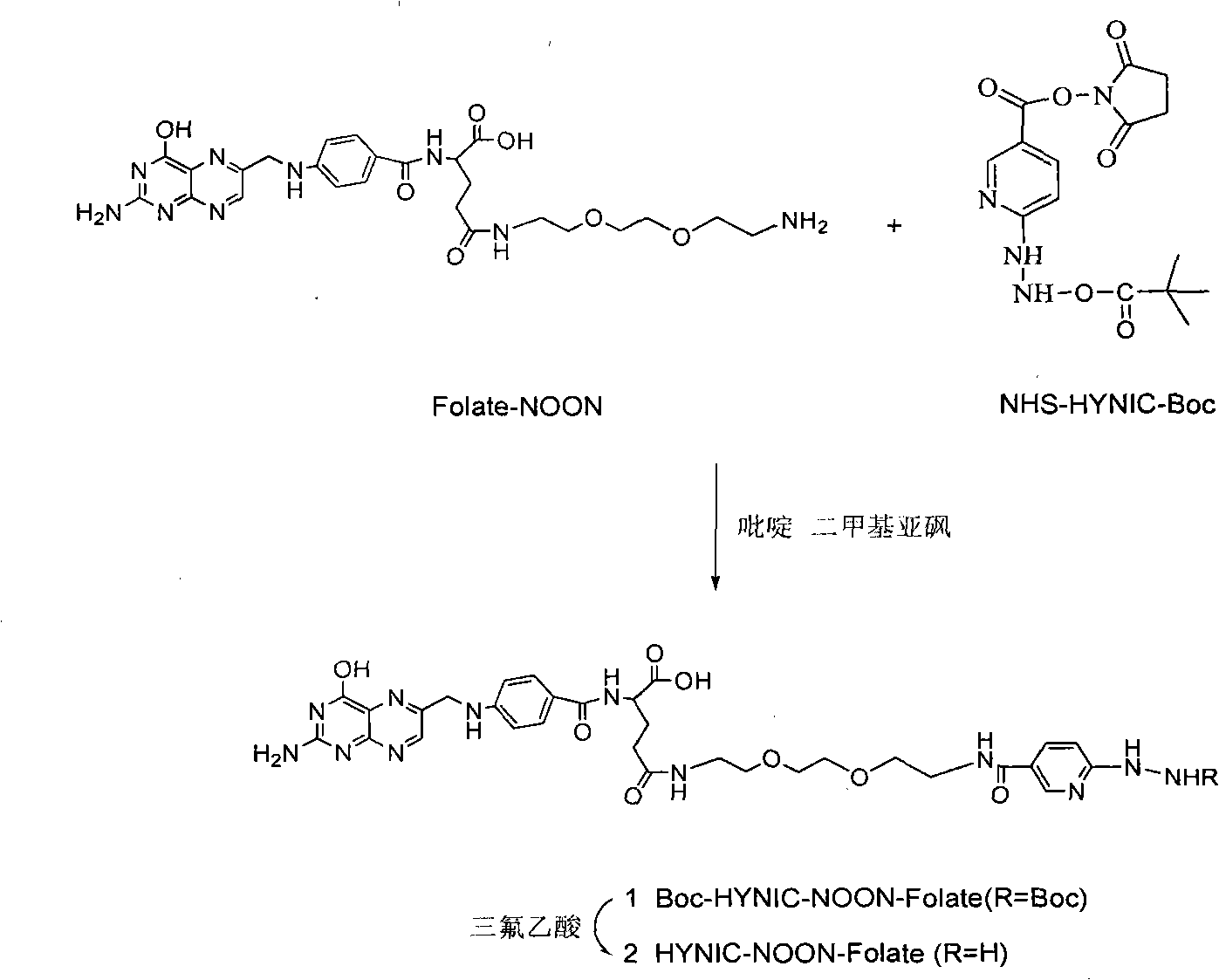

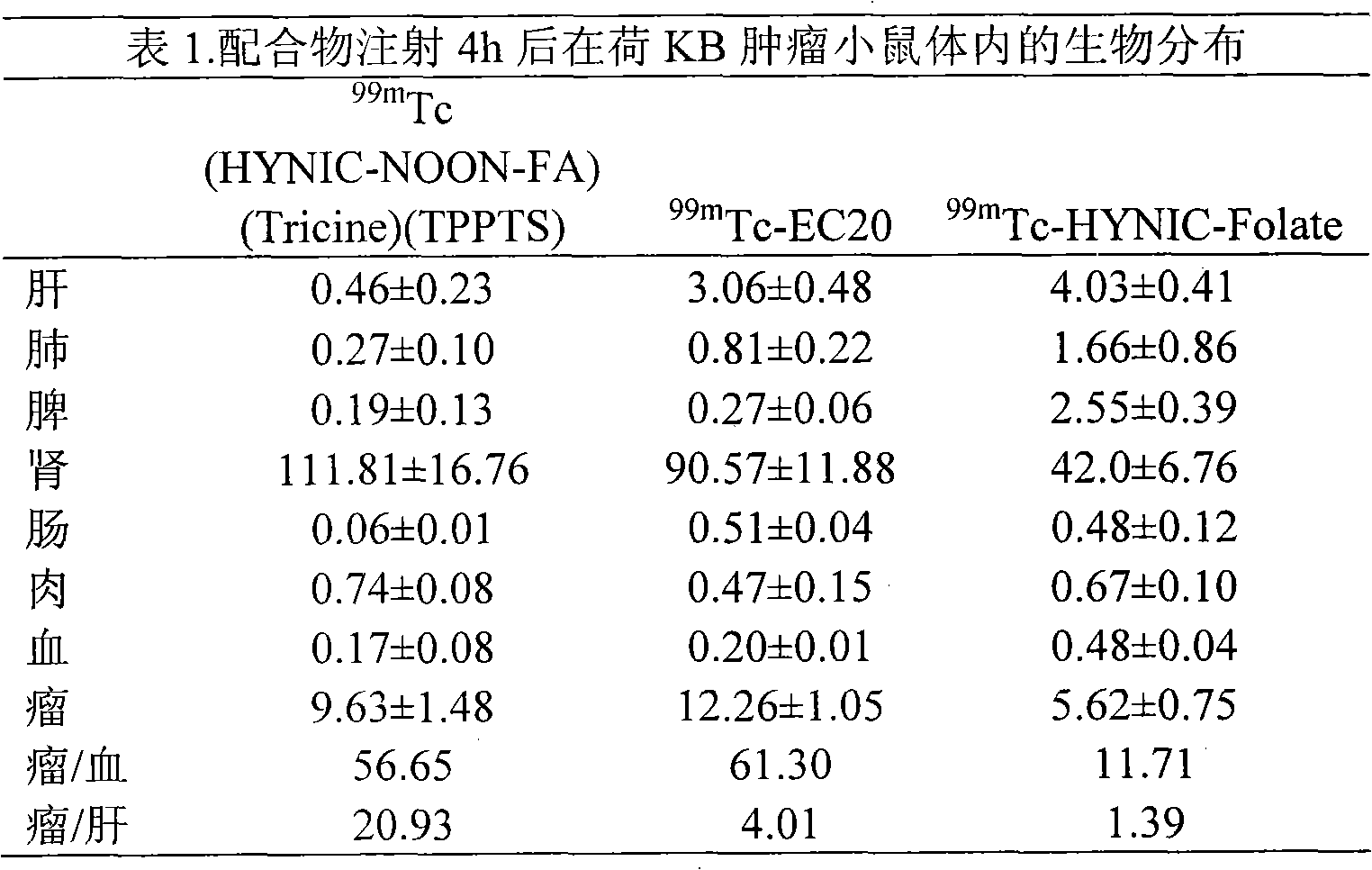

Labeled 99mTc hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound and preparation method

InactiveCN101863924AImprove performanceRadioactive preparation carriersGroup 7/17 element organic compoundsSodium phosphatesNiacin

The invention discloses a labeled 99mTc hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound with a general formula of 99mTc(HYNIC-NOON-FA)(Tricine)(L). In the structural formula, L is triphenyl sodium phosphate or triphenyl sodium photrisulfonic acid, wherein 1,8-diamido-3,6-octane dioxide is used as a connecting chain for generating a hydrazino-nicotinamide-3,6-dioxodecoyl-folic acid coupler respectively with folic acid and hydrazino-niacin through amido bonds and coordinating with oxygen atoms and phosphorus atoms in a co-ligand Tricine and an L molecule and 99mTc, and the 99mTc(HYNIC-NOON-FA)(Tricine)(L) coordination compound is obtained through two steps of: (a) synthesizing the hydrazino-nicotinamide-3,6-dioxodecoyl-folic acid coupler used as a ligand; and (b) labeling the 99mTc-hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound. The coordination compound has the advantages of high radiochemical purity, good stability, high tumor intake, good retention, low non-target organ background and clear tumor SPECT (Single Photon Emission Computed Tomography) development and can be prepared into a novel 99mTc labeled folic acid receptor tumor developer widely applied to the technical field of radioactive pharmaceutical chemistry and nuclear medicine.

Owner:BEIJING NORMAL UNIVERSITY +1

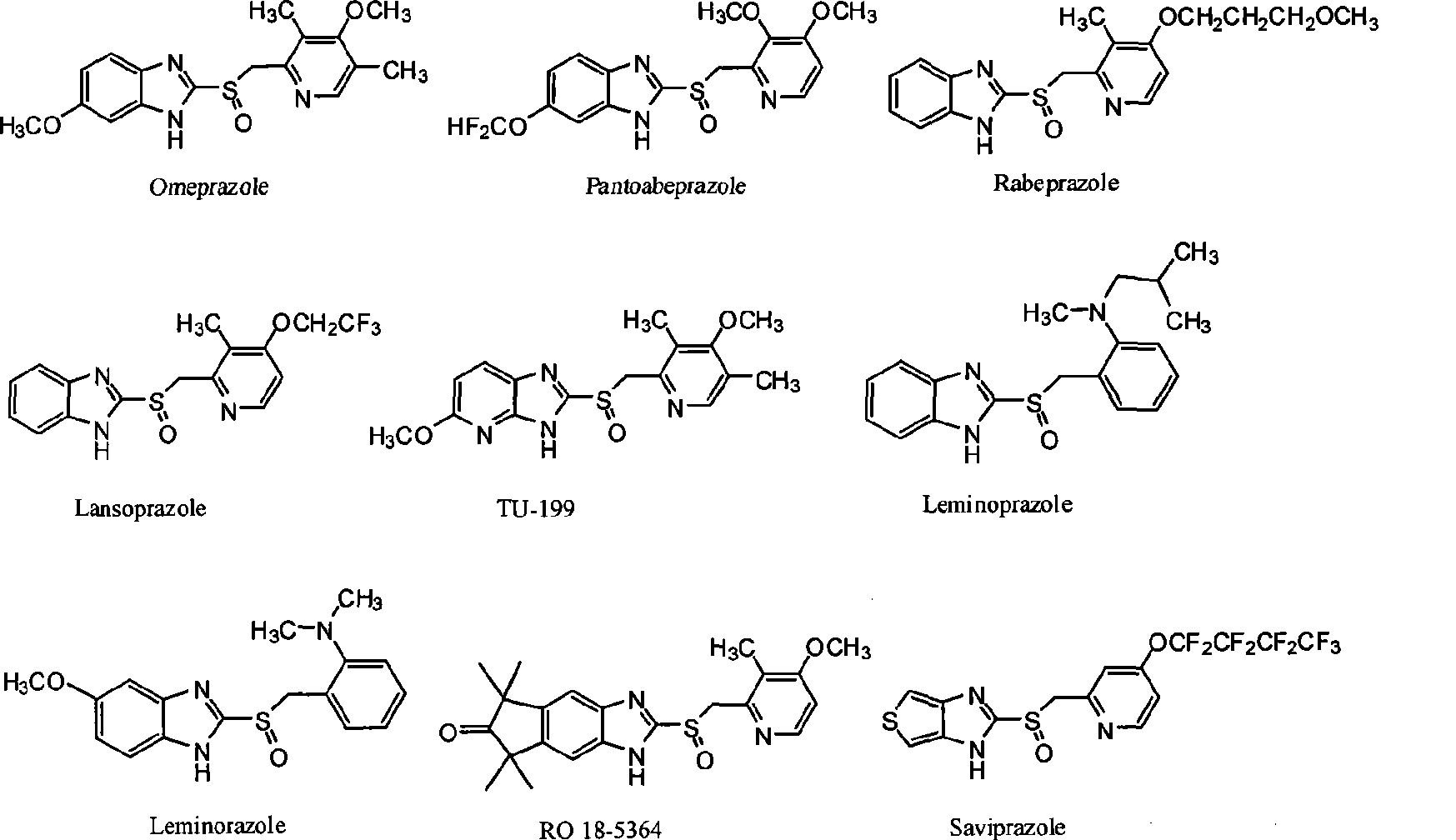

Novel method for producing chiral sulfoxide derivant

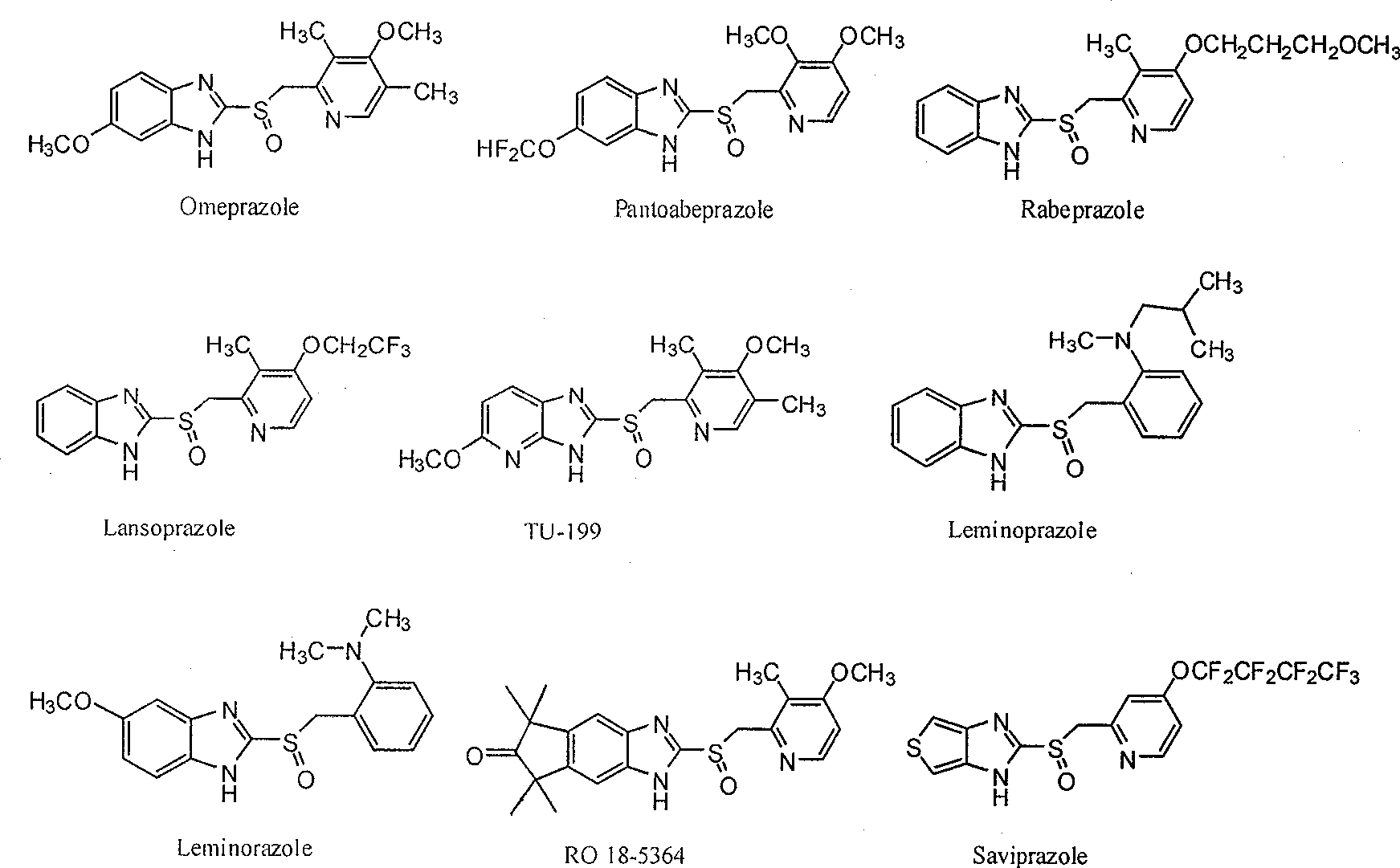

InactiveCN101429192AReduce generationMild responseOrganic chemistryDigestive systemTitaniumOxidizing agent

The invention discloses a novel method for producing a chiral sulphoxide derivative. The method comprises the following steps: an oxidant is utilized to selectively oxidize a corresponding prochiral thioether compound in the presence of a chiral titanium complex. The method has high yield and few byproducts, and the obtained product has higher optical purity and chemical purity.

Owner:YANGTZE RIVER PHARM GRP CO LTD

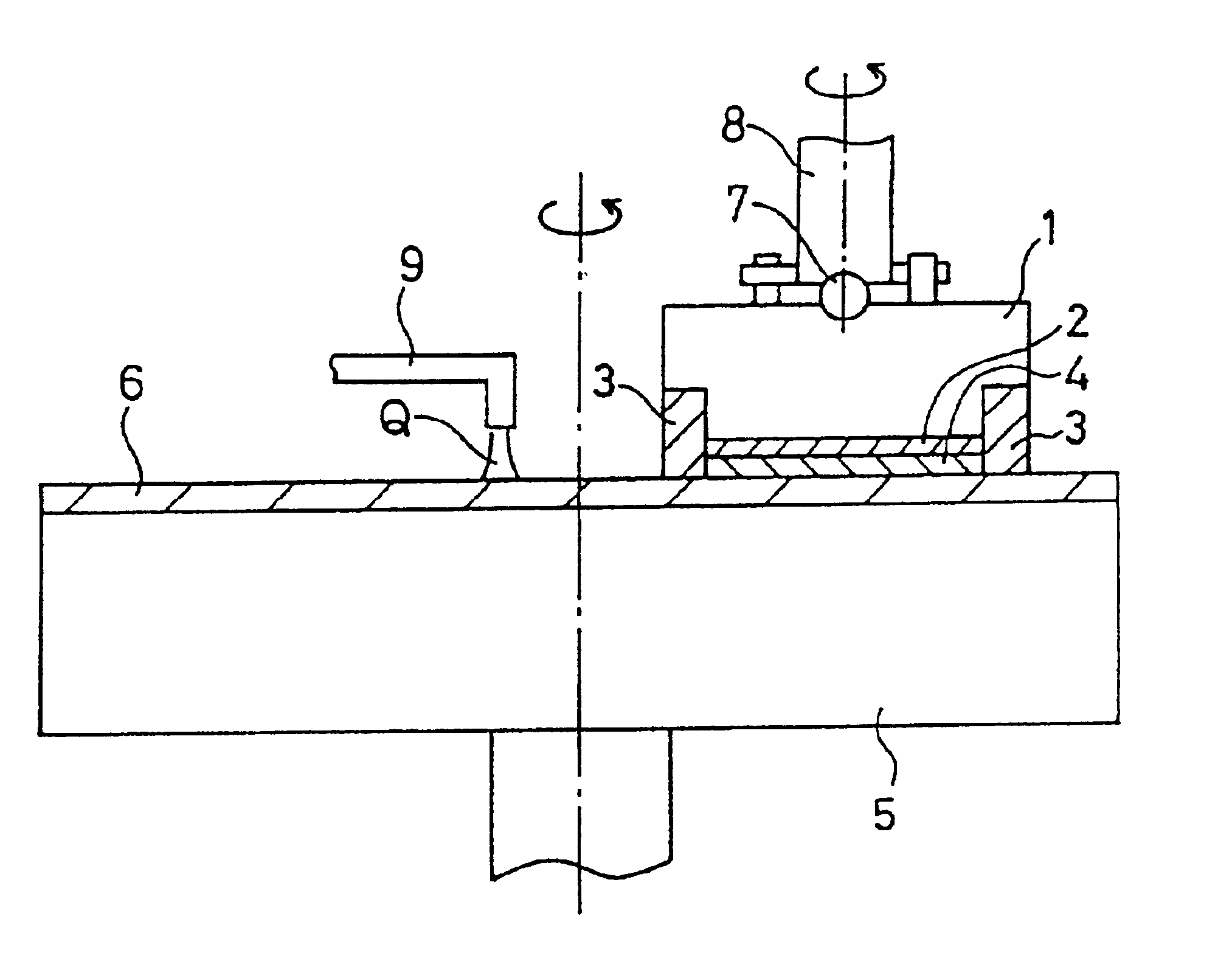

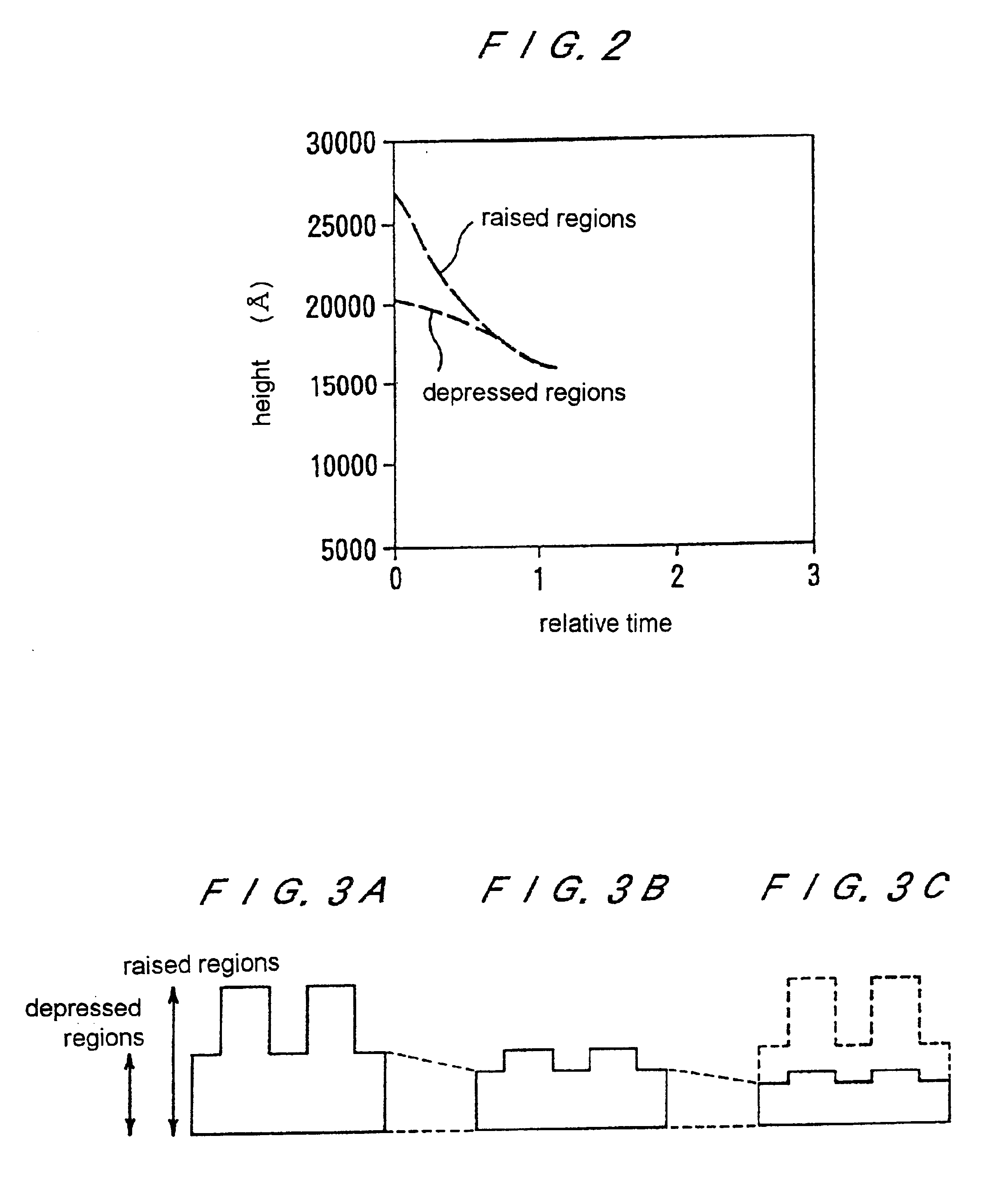

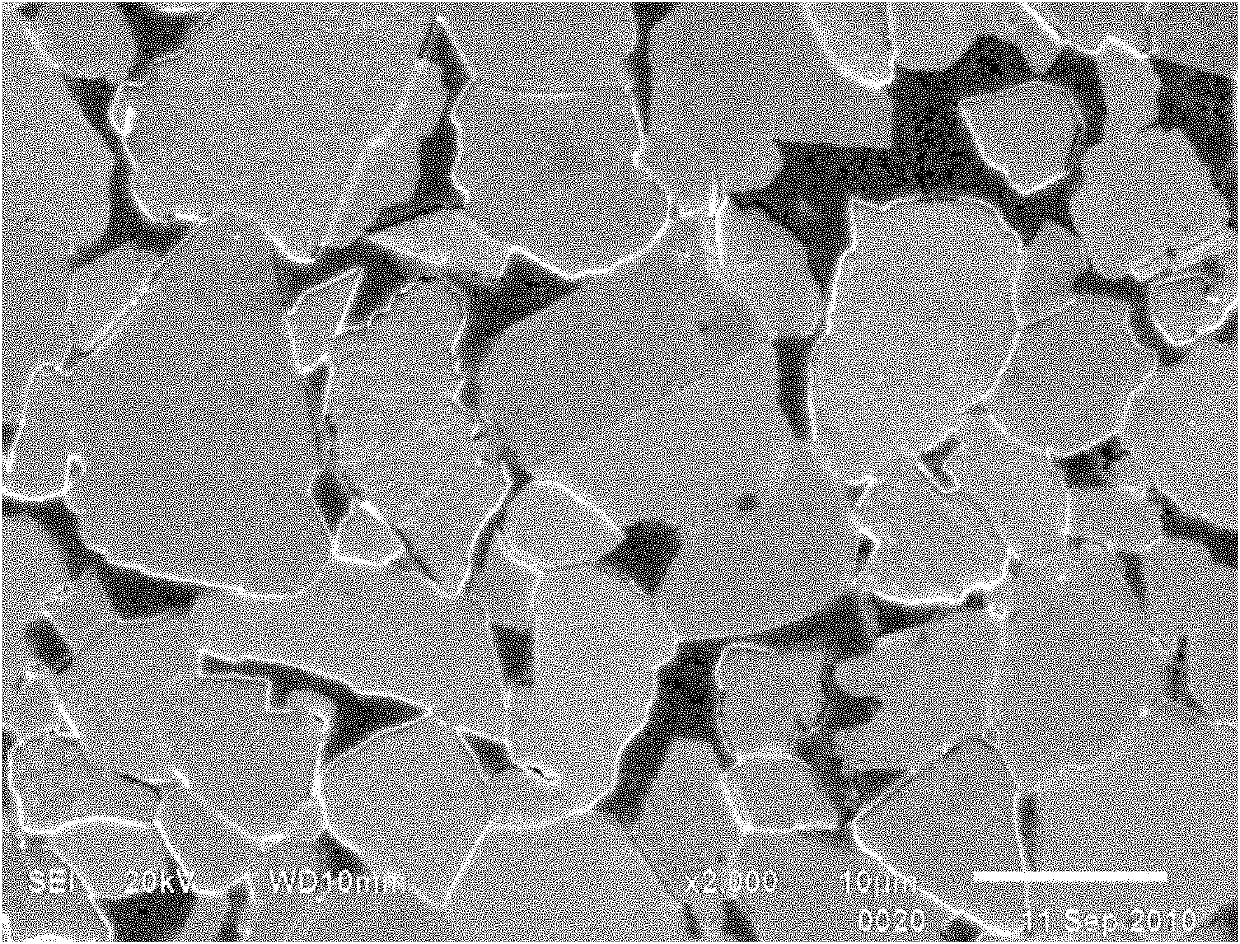

Polishing method using an abrading plate

InactiveUS6942548B2Stabilized polishing rateLow polishing ratePolishing machinesRevolution surface grinding machinesPorosityMicrometer

An abrading plate has a self-stopping capability such that when an object, such as a semiconductor wafer having a device structure that includes raised regions and depressed regions fabricated on the surface, is being polished, the raised regions are removed and polishing stops automatically. The abrading plate, to produce a flat and mirror polished surface on the an object, has abrasive particles having a chemical purity of not less than 90% and a particle size of not more than two micrometers, a binder material, and a given volume of porosity. A ratio of the abrasive particles and the binder material is not less than 1:0.5 by volume, and proportions of abrasive particles, a binder material and porosity are, respectively, not less than 10%, not more than 60% and 10-40% by volume. A surface is polished for a given duration with a liquid not containing abrasive particles so as to eliminate the raised regions and to obtain a flat surface. Additional surface removal is performed by supplying abrasive particles to the polishing interface to remove surface material uniformly from the entire surface.

Owner:EBARA CORP

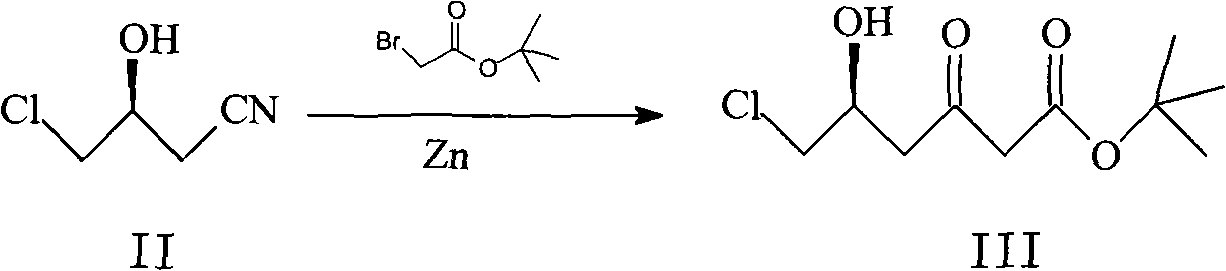

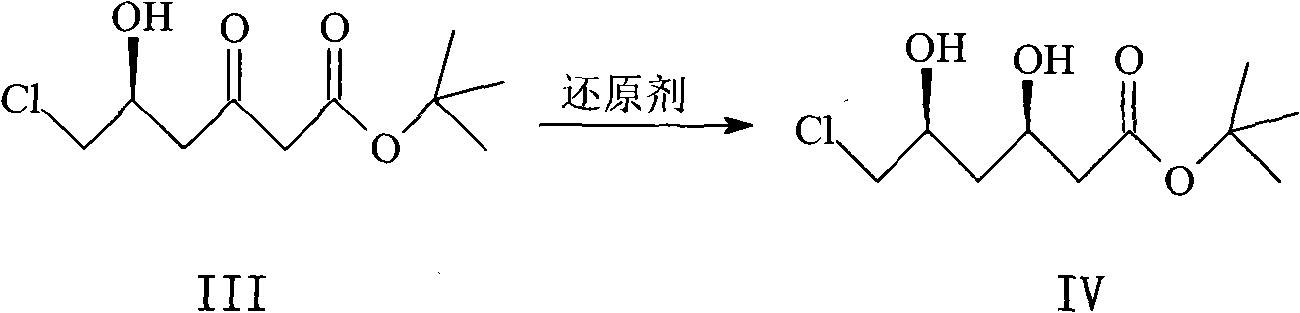

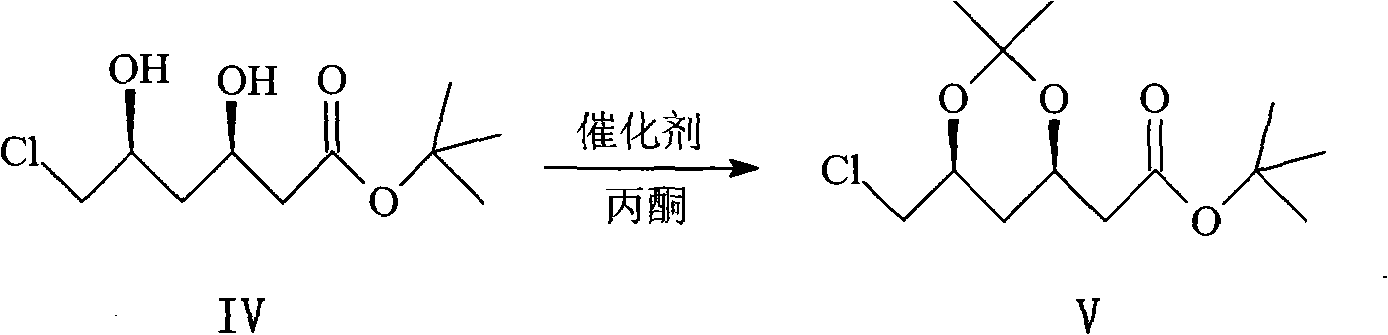

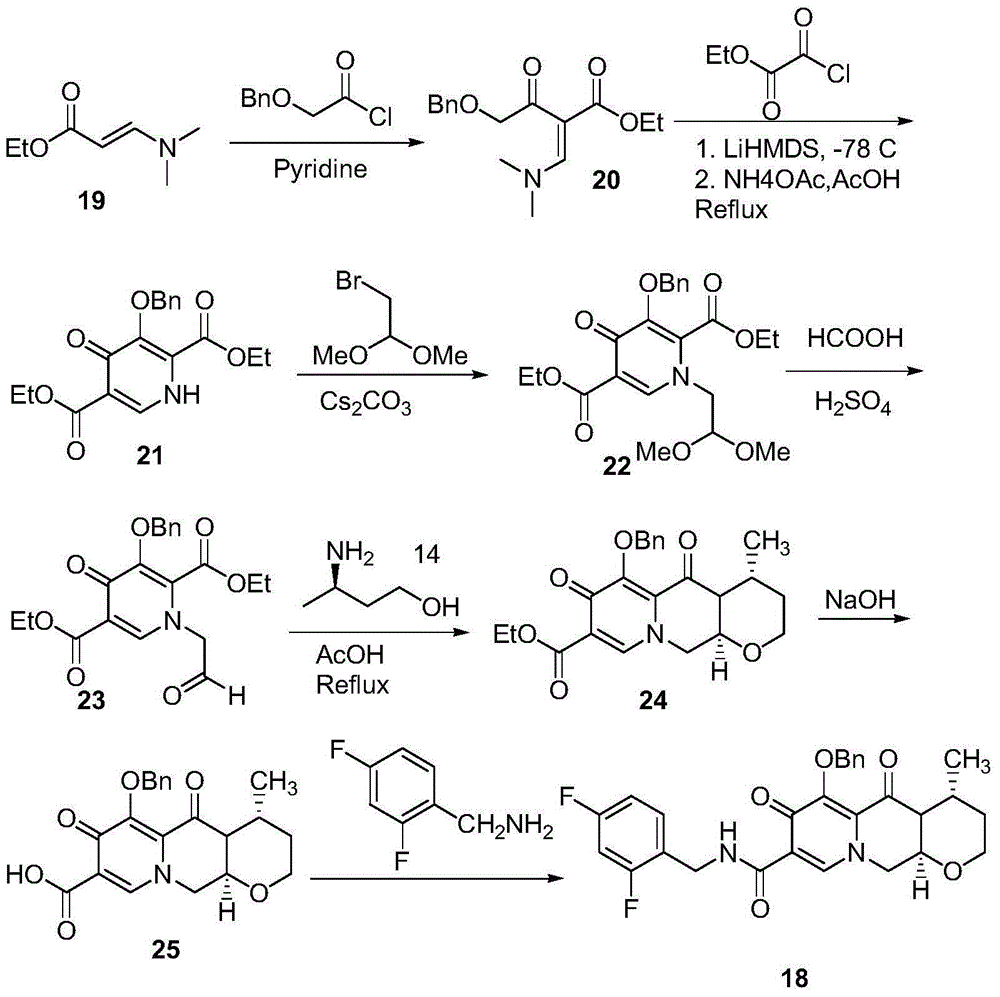

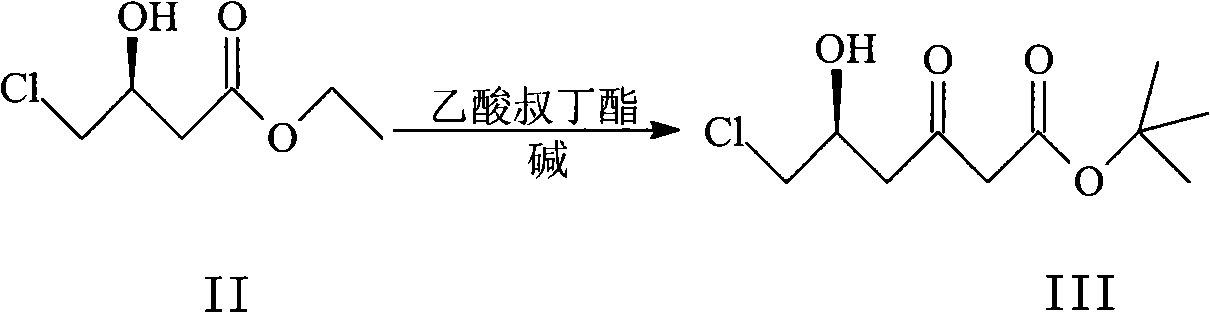

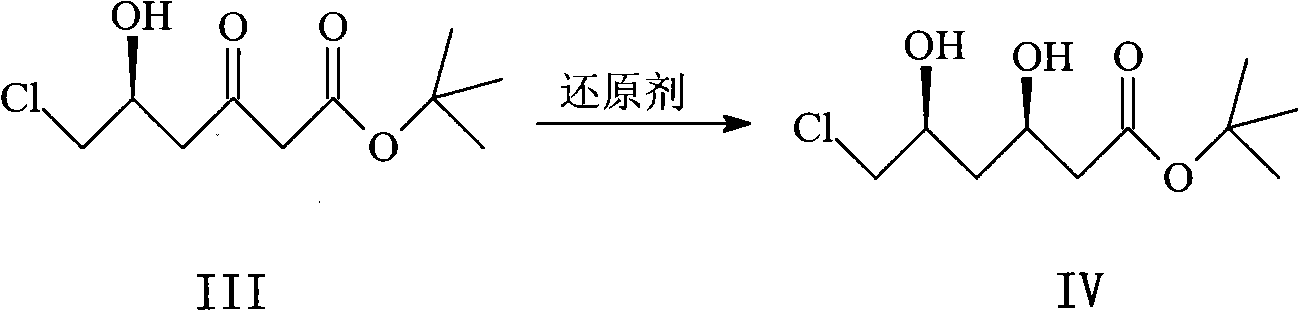

Synthetic method of key intermediate of rosuvastatin calcium side chain

ActiveCN101613341AEase of industrial productionSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationSide chainRosuvastatin Calcium

The invention discloses a preparation method of a key intermediate of rosuvastatin calcium side chains. (S)-3-hydroxy-4-chlorine-butyronitrile is taken as a starting material and subject to four steps condensation, reduction, hydroxyl protection and condensation reactions to obtain the intermediate. The method has simple operation during the reaction, products in the steps are easily separated and purified, no silica gel column is needed for purification and separation, the yield is above 80%, an intermediate with high chemical purity and optical purity can be obtained, and conclusion of GC determination is that the chemical purity is not less than 99.4%, and the optical purity is not less than 99.3%ee.

Owner:LUNAN PHARMA GROUP CORPORATION

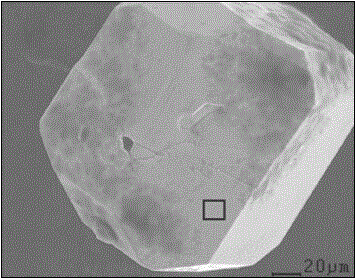

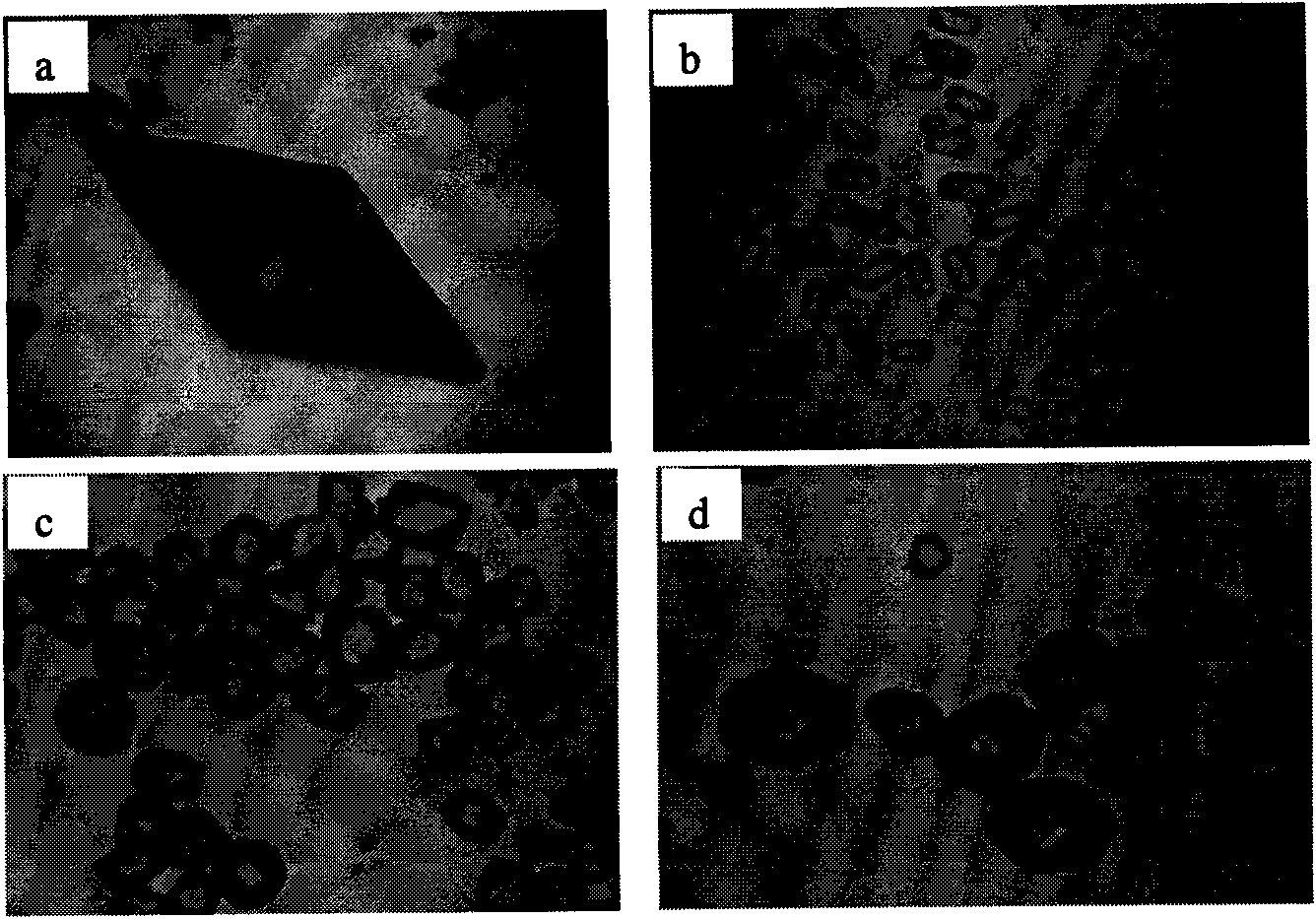

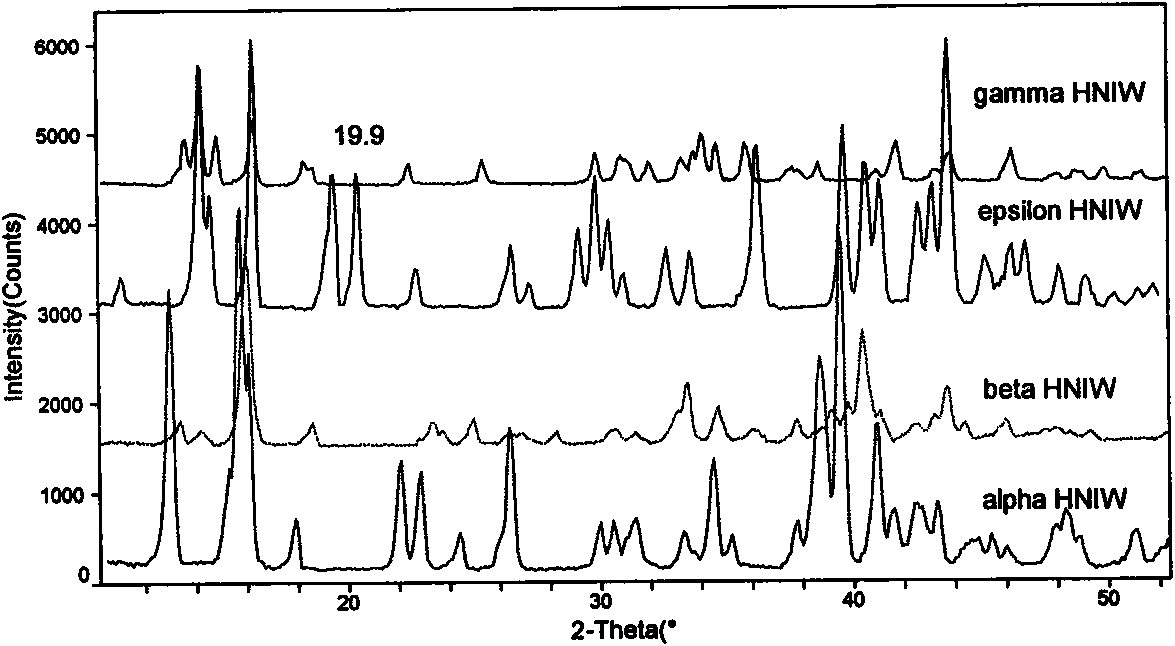

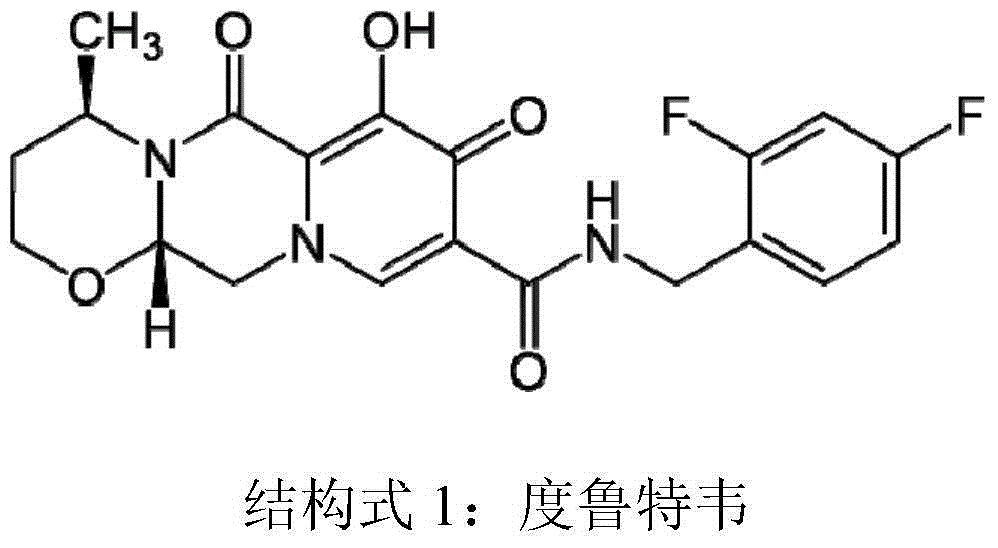

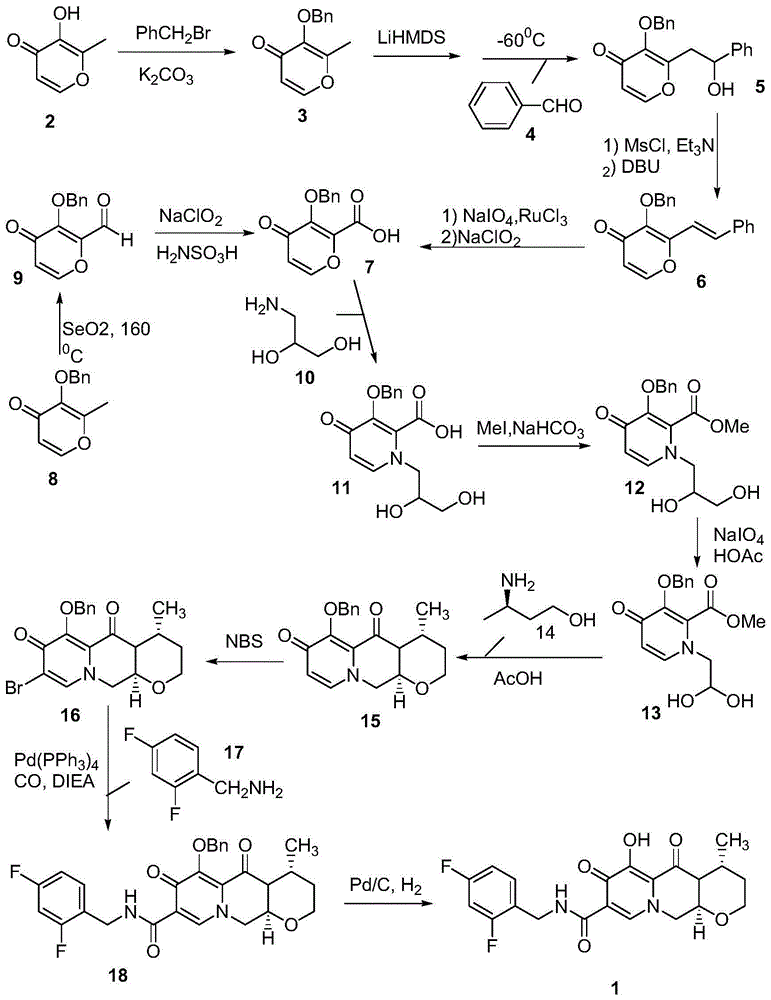

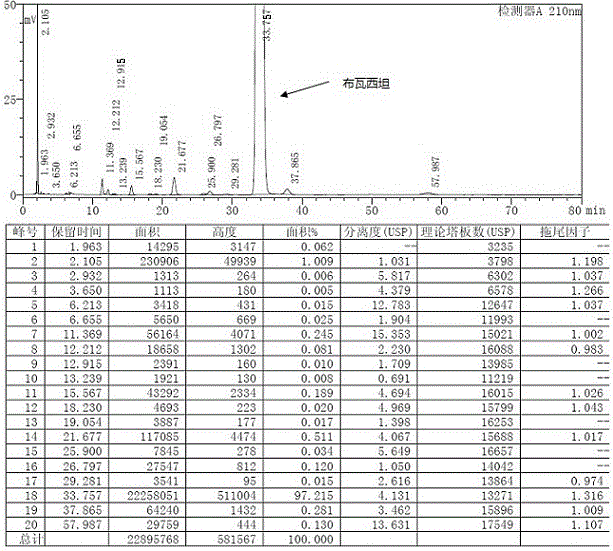

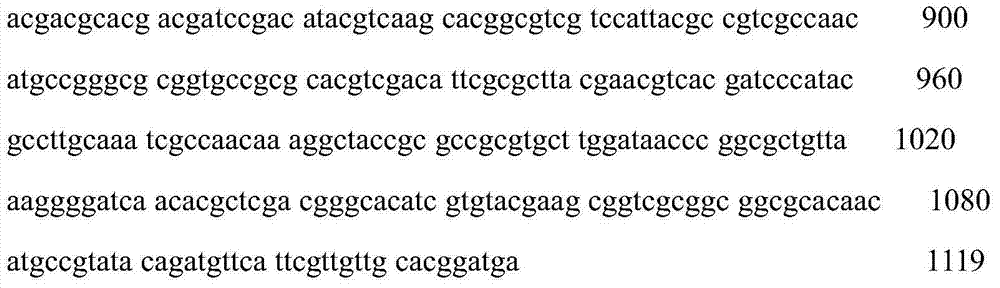

Sphericized hexanitrohexaazaisowurtzitane (HNIW) crystal and preparation method thereof

The invention provides a sphericized epsilon type hexanitrohexaazaisowurtzitane (HNIW) crystal and a preparation method thereof. The preparation method of the sphericized epsilon type hexanitrohexaazaisowurtzitane (HNIW) crystal comprises the following steps: a) dissolving alpha-HNIW, beta-HNIW and gamma-HNIW or mixture of the alpha-HNIW, the beta-HNIW and the gamma-HNIW into a solvent to form a saturated solution of the alpha-HNIW, the beta-HNIW and the gamma-HNIW or the mixture of the alpha-HNIW, the beta-HNIW and the gamma-HNIW; b) adding a crystal growth control agent to the saturated solution and adding an anti-solvent to form a supersaturated solution; and c) adding epsilon-HNIW seed crystals to the supersaturated solution and continuously adding the anti-solvent until all HNIW in the supersaturated solution is released to grow a sphericized epsilon-HNIW crystal. The sphericized epsilon-HNIW crystal does not have sharp edges and corners but has a multi-faceted spherical shape, particle size of 20 to 500 um, chemical purity of 98 to 99.9 percent determined by high performance liquid chromatography, porosity of 0.01 percent to 0.40 percent and 5kg drop hammer impact sensitivity H50 of 26 to 52 centimeters.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid

ActiveCN104370755ANon-hazardousImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationSolventHydrolysis

The present invention discloses a preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid. The optical activity active 3-amino butanol preparation method comprises: in a solvent, under effects of a hydroboration reduction agent and a Lewis acid, carrying out a reduction reaction on a compound represented by a formlu 65 to produce a compound represented by a formlu 14. The optical activity active 3-amino butyric acid preparation method comprises: carrying out a hydrolysis reaction on a compound represented by a formlu 64 to produce a compound represented by a formlu 65. According to the present invention, the preparation method has characteristics of cheap and easily-available raw materials, simple operation, short process route, no hazard of raw materials, high yield, little waste production, environment protection, high raw material conversion rate, high product chemical purity and high product optical purity, and the industrialization is easily achieved. The formulas 64, 65 and 14 are defined in the instruction.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

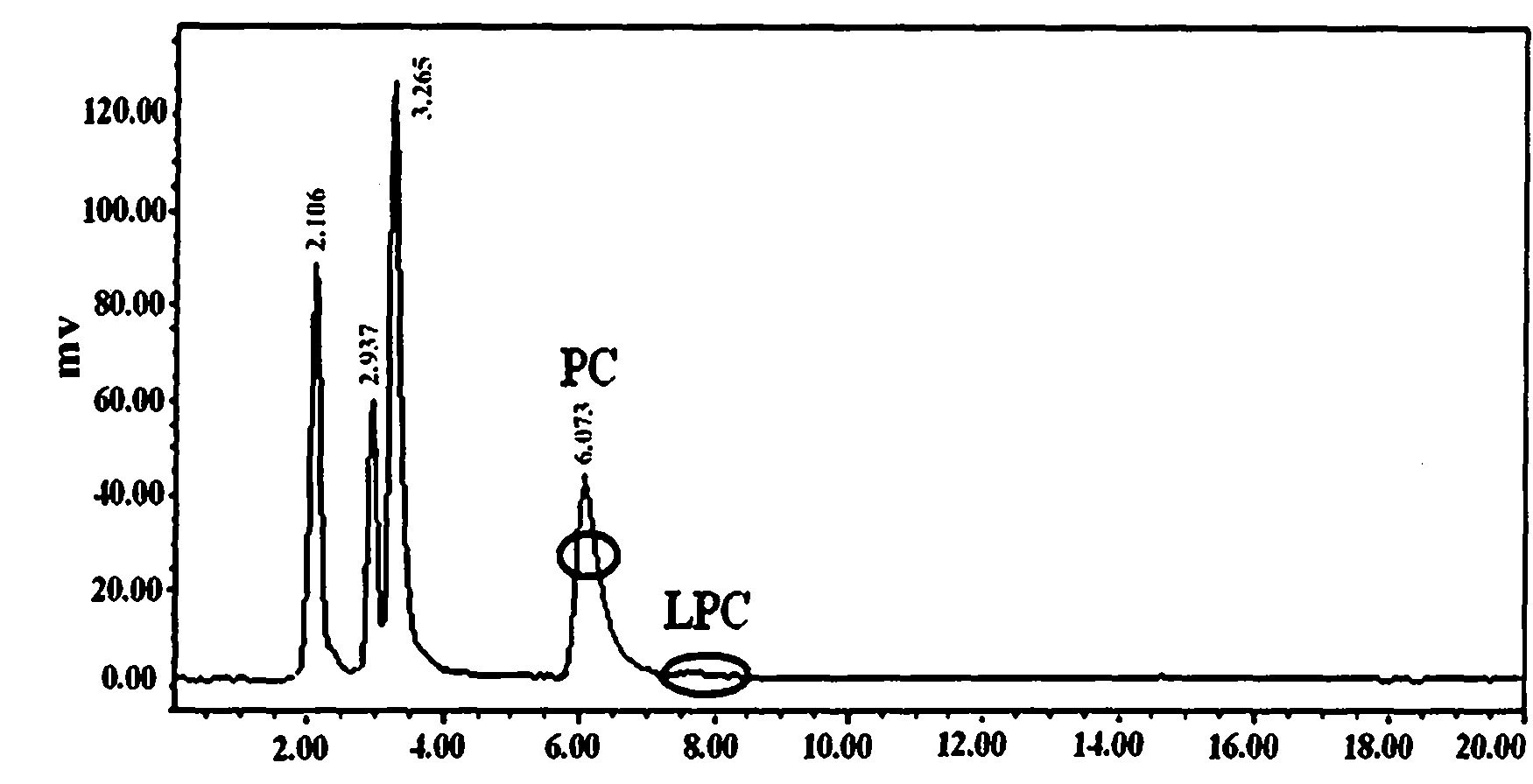

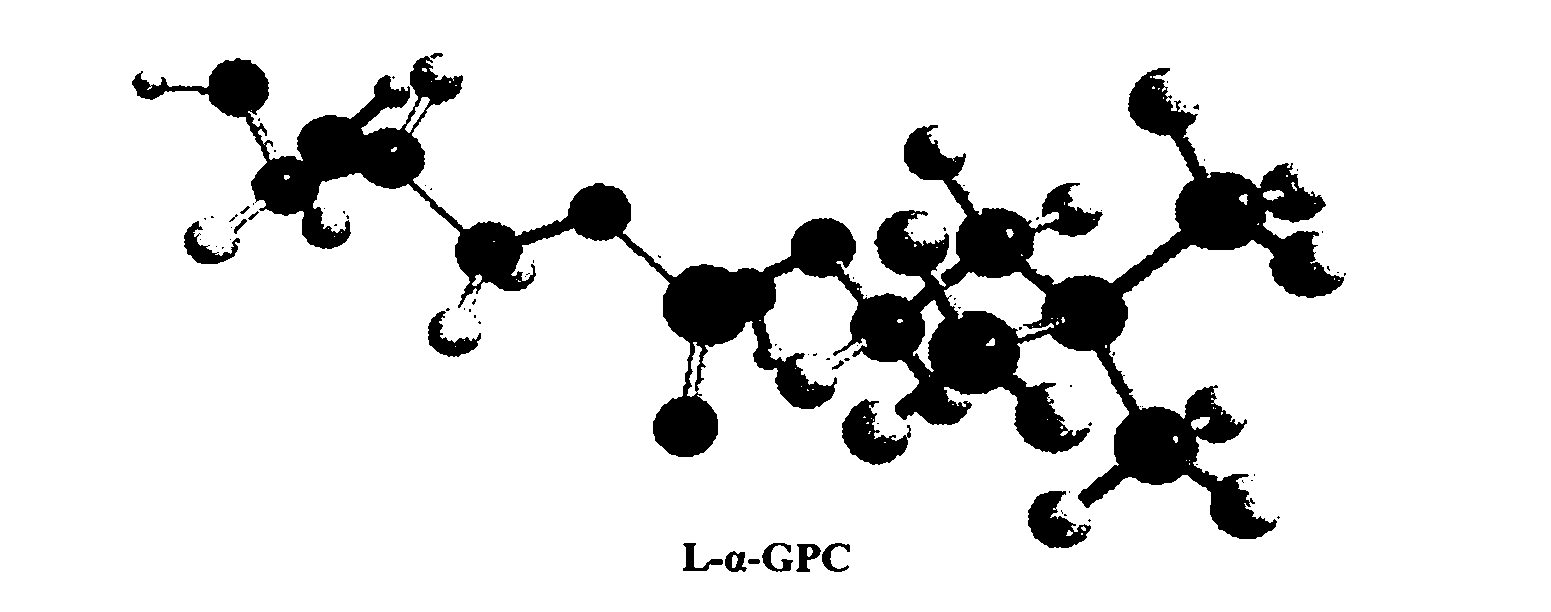

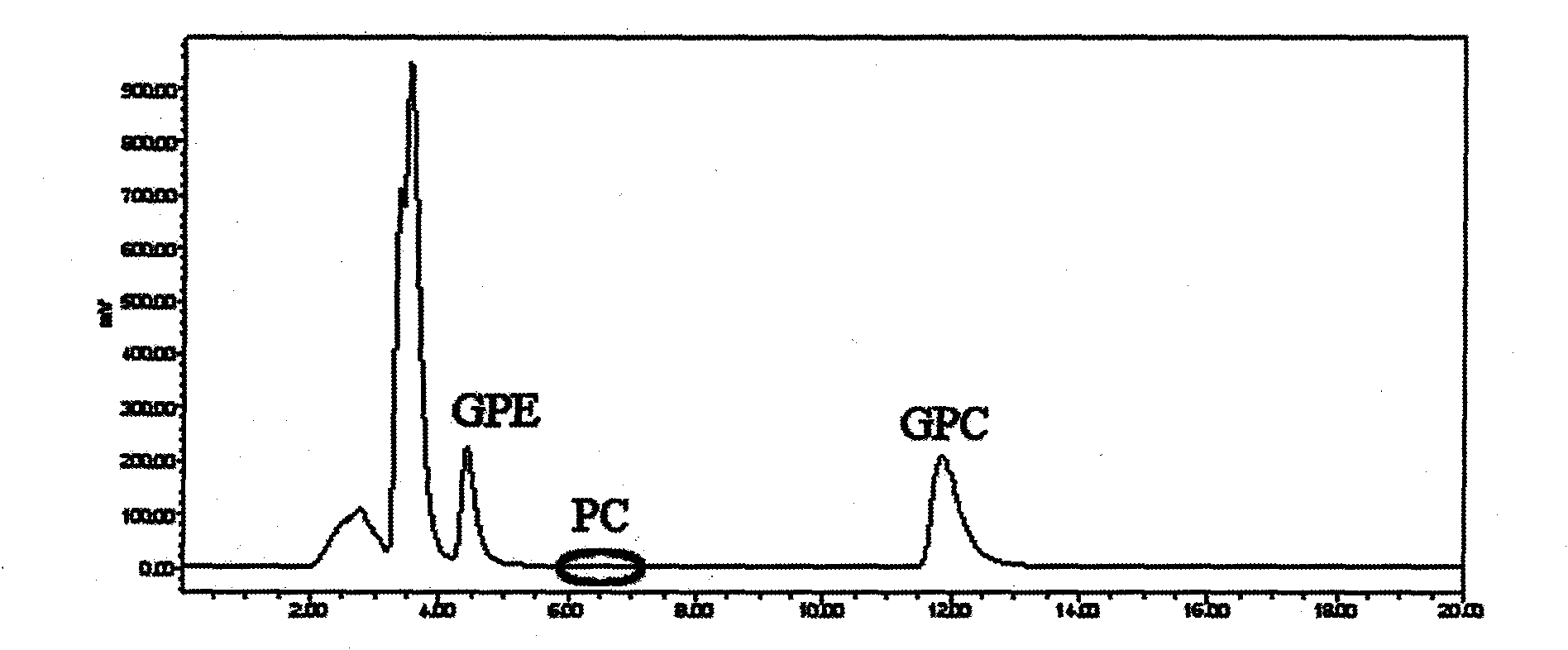

Method for separating and purifying L-alpha-glycerophosphorylcholine (L-alpha-GPC) by silica gel column chromatography

ActiveCN102093410ALow costGuaranteed optical activityFermentationPhosphorus organic compoundsChromatographic separationPurification methods

The invention discloses a method for separating and purifying L-alpha-GPC by silica gel column chromatography, which belongs to the technical field of lipid development and application and comprises the following steps: removing Ca<2+> and Cl<-> from enzymatic hydrolysis reaction solution serving as a raw material by using ion exchange resin, converting a water phase into an alcohol phase, separating L-alpha-GPC from glycerol polyglycidyl ether (GPE), lysophosphatidylcholine (LPC) and other byproducts, decolorizing by active carbon, and dewatering through vacuum concentration to obtain a colorless and transparent product; directly passing alcoholysis reaction solution serving as a raw material through a silica gel column for separation, removing Na<+> by cation exchange resin, decolorizing by active carbon, and dewatering through vacuum concentration to obtain a product. According to the test of the indexes of the product, the chemical purity is 99.6 percent, the optical purity ee is 99 percent, and the melting point (mp) is 142 to 143 DEG C (wherein C is equal to 2.6, the H2O content is 16 percent, and the pH value is 5.8). The invention provides a new way of thought and a new method for separating and purifying L-alpha-GPC, and realizes the application of the silica gel column chromatographic separation and purification method in lipid science.

Owner:JIANGNAN UNIV +1

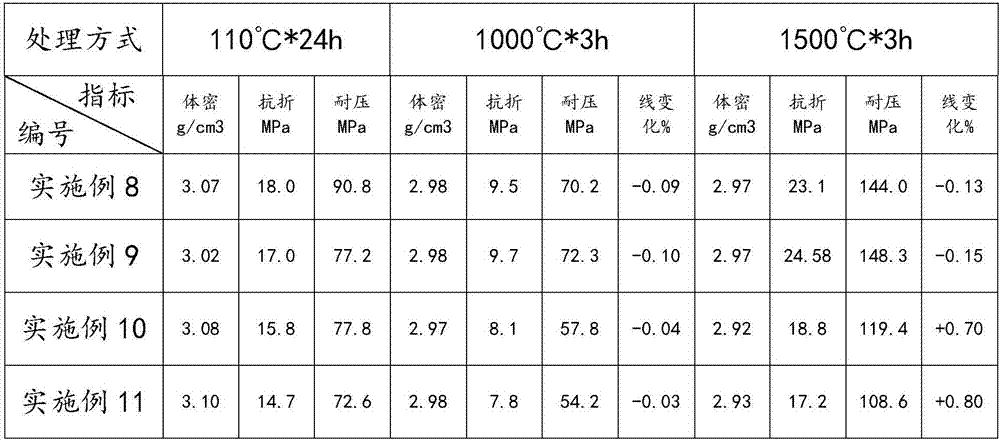

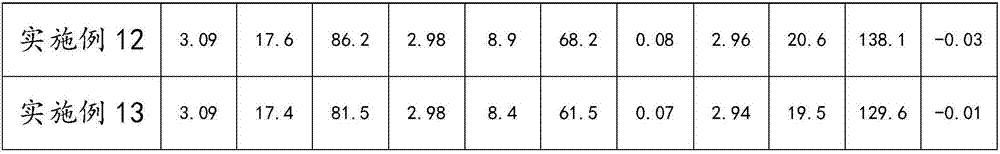

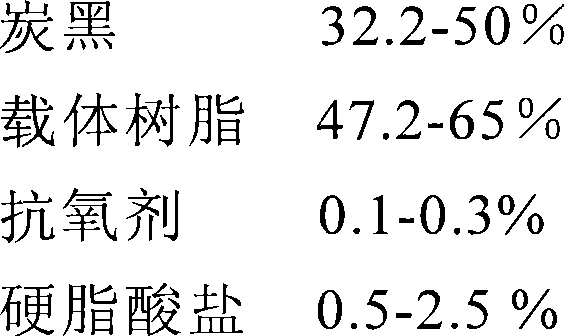

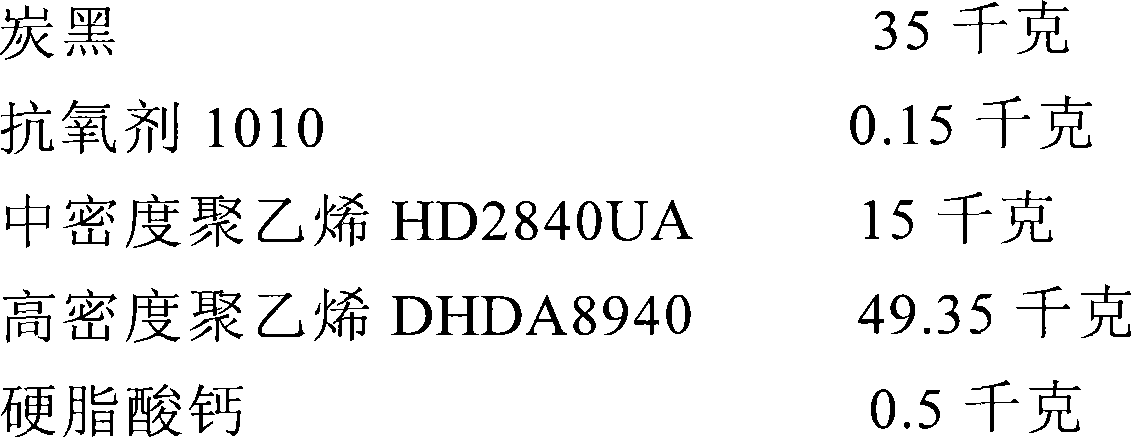

Black master batch of polythene pipes mixing special material for feeding water and preparation method thereof

The invention discloses black master batch special for the mixing of the water polyethylene pipe material. The formula is 32.7 to 45.4 percent of carbon black, 54 to 66 percent of carrier resin, 0.1 to 0.3 percent of antioxidant, and 0.5 to 0.1 percent of stearic acid salt. The preparation method is: the automatic weighing and feeding system is used; a plurality of materials strictly are matched according to the process with a plurality of weightless and continuous weighing electronic balance; the dual-rotor continuous densely refining and extruding machine group is directly added into; after mixing well, cutting, dispersing, extruding and palletizing, the black master batch can be made. The black master batch produced in the invention is characterized in the high concentration, the easiness of dispersion and the small amount of the addition; after the addition, the performance indicators, such as the dispersion degree of the carbon black, the chemical purity, the pressure resistance, the anti-aging performance, the process of mixed materials, and so on, suit and meet the requirements of the special mixing material of the water polyethylene pipe material.

Owner:SUZHOU GUOJIA POLYMER TECH

Preparation method of high purity aluminium oxide powder

InactiveCN1903728AHigh chemical purityReduce sodiumAluminium oxide/hydroxide preparationWater bathsAluminium hydroxide

The present invention relates to a preparation method of high-purity aluminium oxide powder body. It is characterized by that it adopts aluminium sheet whose purity is 99.9999% and organic alkal; and makes them be mutually reacted in hot water bath to obtain the precipitate of aluminium hydroxide, then the precipitate is calcined at 1100-1200deg.C and ground so as to obtain high-purity ultrafine aluminium oxide powder body. The described organic alkal; includes any one of choline, hexamethohydrotetramine and dopamine.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of key intermediate of rosuvastatin calcium side chain

ActiveCN101624390AEase of industrial productionSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationSide chainRosuvastatin Calcium

The invention provides a preparation method of a key intermediate of a rosuvastatin calcium side chain, comprising the following steps: using (S)-4-chlorine-3-hydroxybutanoate as an initial raw material; and preparing the key intermediate through four-step reactions of condensation, reduction, hydroxy group protection and condensation. The reaction process is simple to operate, the products in each step are easy to separate and purify, the purification and separation step is carried out without a silicagel column, and the yield is more than 80 percent, therefore, the intermediate with higher chemical purity and optical purity can be obtained. The GC determination shows that the chemical purity is more than or equal to 99.5 percent and the optical purity is more than or equal to 99.2 percent ee.

Owner:LUNAN PHARMA GROUP CORPORATION

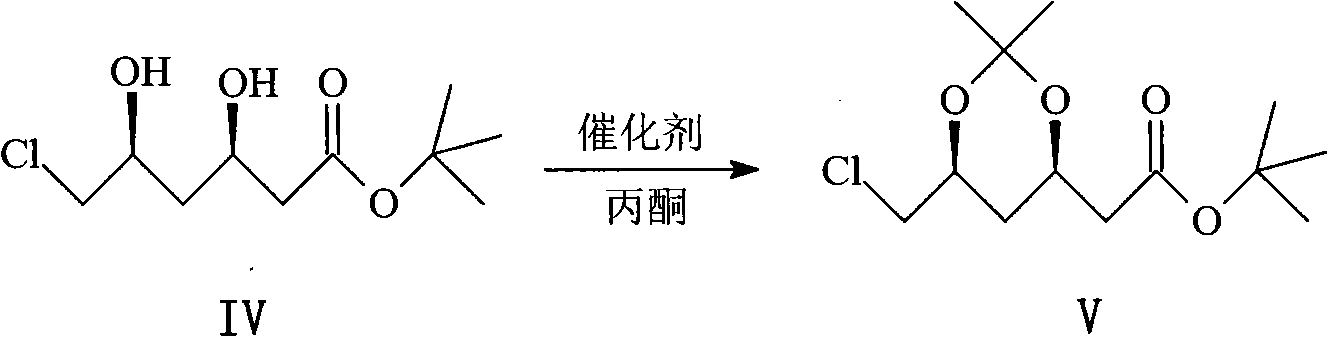

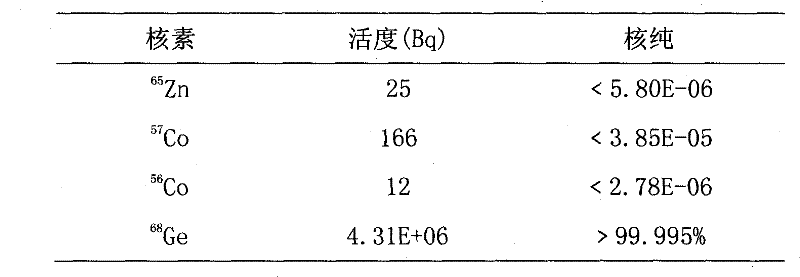

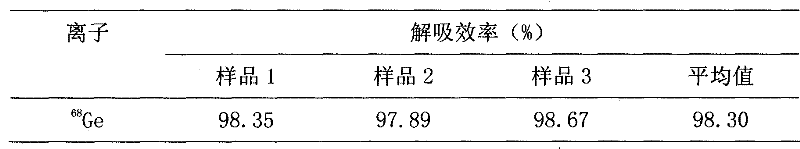

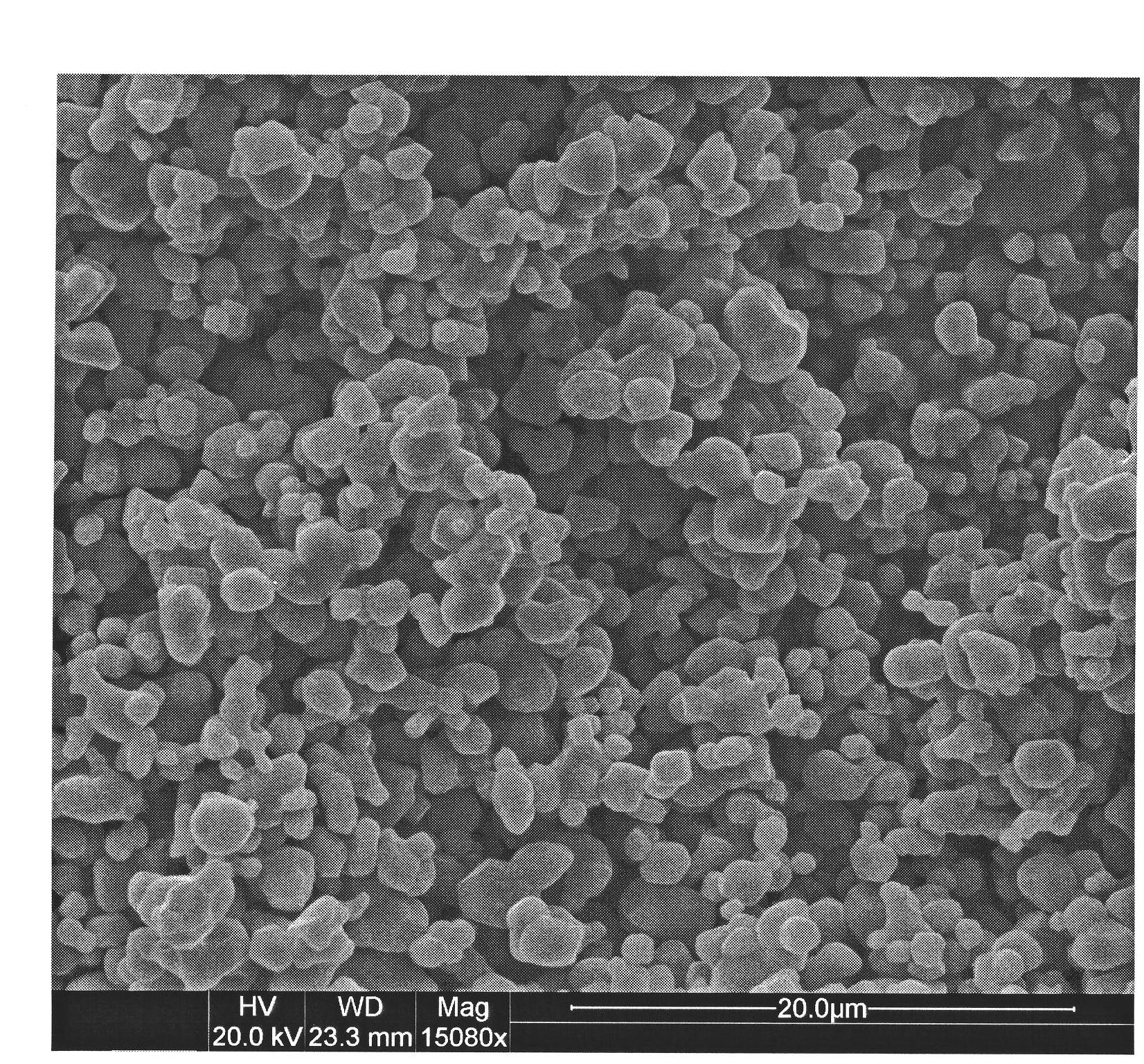

Preparation method for radioactive 68Ge solution

ActiveCN102382994AOvercome the disadvantages of aerosol pollution and cumbersome operationSimple methodPhotography auxillary processesProcess efficiency improvementCycloneDesorption

The invention belongs to the field of preparation of radioactive nuclide, and discloses a preparation method for a radioactive 68Ge solution. The preparation method comprises the following steps of: preparing a solid Ga4Ni alloy target containing gallium and nickel by using an electro-deposition method; performing CYCLONE 30 irradiation on the alloy target to prepare an alloy target containing radioactive 68Ge; cooling; electrolyzing the target; separating and purifying electrolyte on a silica gel column; desorbing 68Ge by using a nitric acid solution; evaporating a desorption solution to dryness; and dissolving solid-state 68Ge to prepare the radioactive 68Ge solution for a 68Ge-68Ga generator. The method has the advantages of simple equipment for preparing the Ga4Ni alloy target, quickness in method, high repeatability, stable process, firm target, high quality and easiness in target shooting. The 68Ge has the advantages of stable purification process, completeness in separation from impurity ions, nuclear purity of more than 99.995 percent, chemical purity of more than 98 percent, desorption efficiency of more than 98 percent, easiness in operation, no pollution and contribution to conventional and large-scale production.

Owner:HTA CO LTD

Battery-grade cobaltosic oxide preparation method

InactiveCN101913659AHigh densityHigh chemical purityCobalt oxides/hydroxidesReaction temperatureSpherical shaped

The invention relates to a battery-grade cobaltosic oxide preparation method, which comprises the following steps of: preparing solution of cobalt and solution of precipitator from a cobalt raw material and a precipitator by using de-ionized water respectively; preparing a precursor by using a homogeneous crystallization precipitation method, wherein the precipitate precursor is synthesized by adding the prepared solution of cobalt at a certain concentration and the solution of precipitator at a certain concentration into a reactor according to a certain molar ratio by using a cocurrent-flow feeding method, and effectively controlling chemical impurities, crystallinity of crystals, granularity, density and the like of the precursor by controlling parameters such as reaction temperature, feeding speed, pH value and stirring speed; directly filling a water-containing filter cake into a pot after washing and dewatering, and controlling grain size and crystal shape by using low-temperature dehydration phase-change calcination and high-temperature nodulizing sintering; crushing by using a machine and performing classified activation treatment; and finally, removing magnetic metal foreign bodies to obtain the battery-grade cobaltosic oxide similar to spheres. The battery-grade cobaltosic oxide has high density and high chemical purity, the grain size is easy to control, grain composition is uniform and narrow in distribution, and the magnetic metal foreign body content is low.

Owner:JIANGSU DONGXIN ENERGY TECH

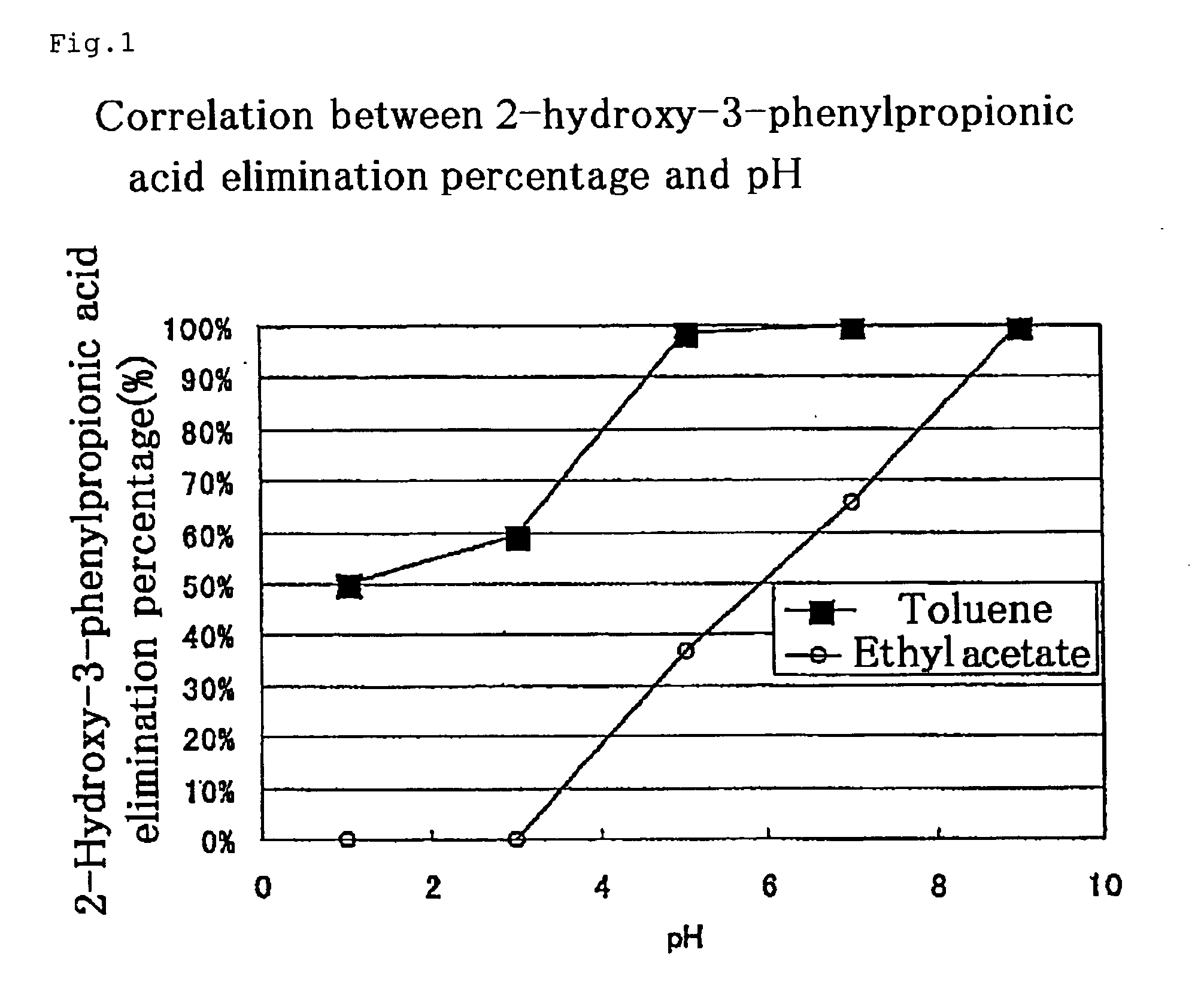

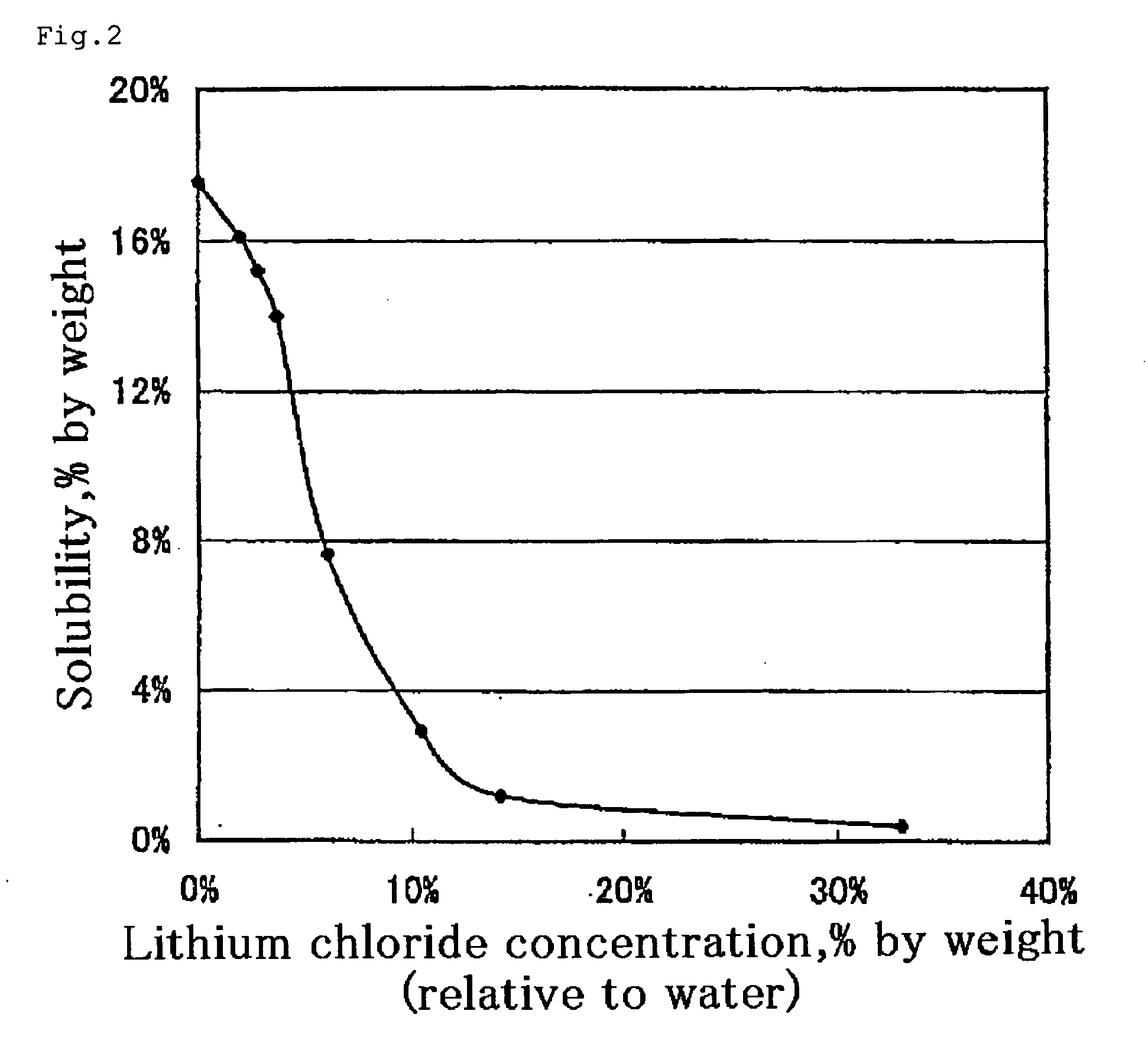

Process for producing optically active 2-substituted carboxylic acid

InactiveUS20050245764A1High optical purityHigh chemical purityOrganic compound preparationOrganic chemistry methodsMedicinal chemistrySubstituted carboxylic acid

The present invention relates to a process for efficiently producing an optically active 2-bromocarboylic acid and an optically active 2-sulfonyloxycarboxylic acid, which are important in the production of medicinal compounds and so forth. An optically active 2-sulfonyloxycarboxylic acid ester is subjected to deprotection under acid conditions to obtain an optically active 2-sulfonyloxycarboxylic acid. A metal bromide is caused to act on the acid to brominate it with configuration inversion at position 2 to thereby produce an optically active 2-bromocarboxylic acid. The resultant optically active 2-bromocarboxylic acid is isolated / purified by subjecting it to a step in which the acid is crystallized and separated as a salt with a base. Thus, an optically active 2-bromocarboxylic acid having a high chemical purity and high optical purity can be produced.

Owner:KANEKA CORP

High-purity diamond micropowder and its purification

A high-purity superfine diamond powder used for grinding and polishing the monocrystal wafer, IC board, or hard disc is prepared from the superfine diamond powder prepared by static pressure synthesis or explosion through wet-type chemical treating by nitric acid, perchloric acid, and hydrofluoric acid, washing with purified water, and drying.

Owner:HENAN UNION ABRASIVES

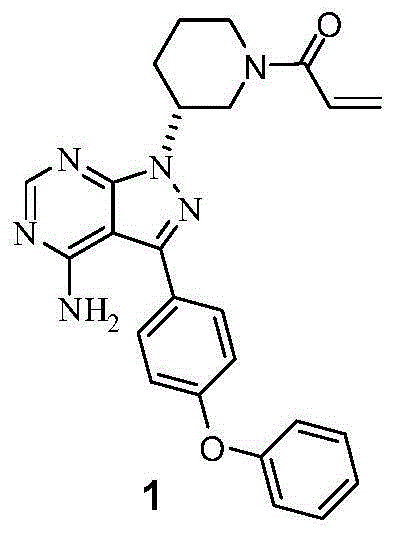

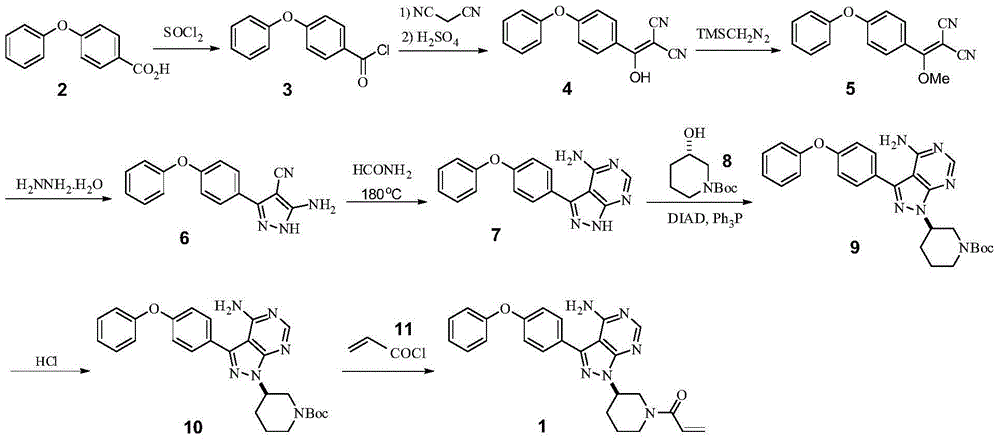

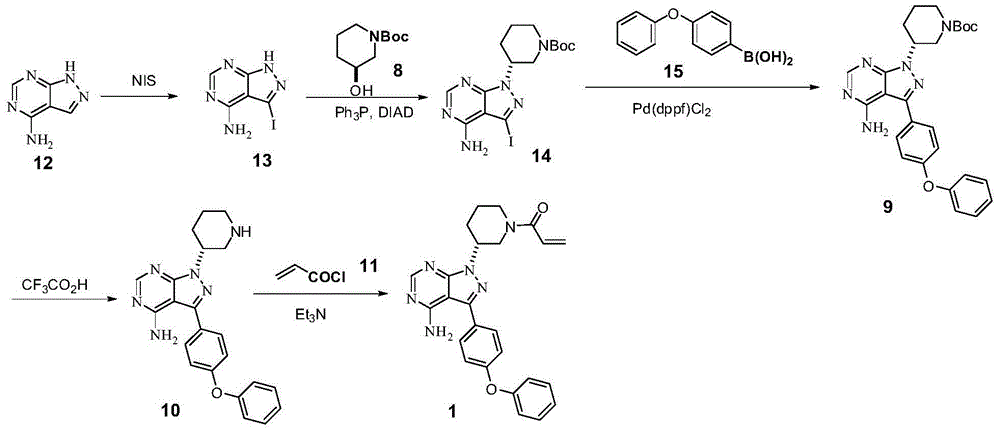

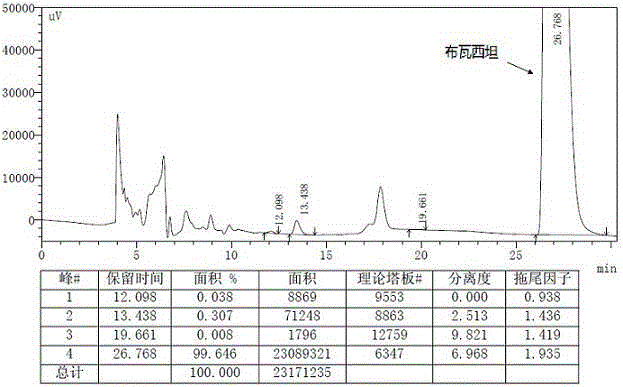

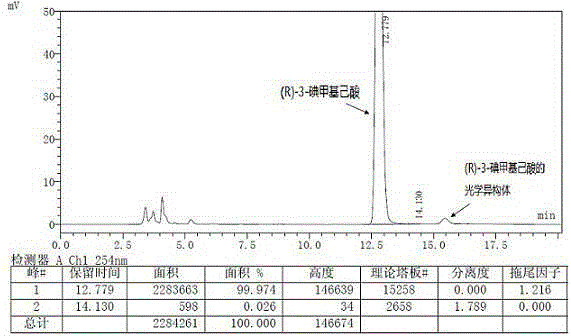

Synthesis method of ibrutinib

The invention discloses a synthesis method of ibrutinib. The method uses Suzuki coupling reaction and Kumada coupling reaction, does not need to separate the intermediate, obtains the intermediate (9) at high yield by a one-pot process, and uses mixed anhydrides instead of acryloyl chloride. The technique utilizes cheap 4-halodianisole as the initial raw material, adopts Suzuki coupling reaction and Kumada coupling reaction, and uses the one-pot process. The whole route is disclosed in the specification. The method can obtain the intermediate (9) (the chemical purity and optical purity are greater than or equal to 99%) at high yield without separating and purifying the intermediate, and avoids microwave, high temperature / high pressure and other specific reaction conditions; and the acrylic acid and mixed anhydrides generated by acyl chloride and sulfonyl chloride are used instead of the acryloyl chloride in the last step to avoid the amidation reaction of the intermediate (10) in multiple sites and reduce the generation of the byproduct, thereby obtaining the high-purity ibrutinib at high yield. The method has the advantages of short process route and lower cost, and is beneficial to the environment and suitable for industrialized scale-up production.

Owner:ARROMAX PHARMATECH

Preparation method of brivaracetam and intermediate thereof

The invention relates to a preparation method of brivaracetam and an intermediate thereof, wherein the brivaracetam is prepared with high-optical-purity (R)-4-n-propyl-dihydrofuran-2-one as a raw material. The preparation method is low in requirement on production equipment and can be used for preparing a brivaracetam crude product at higher chemical and optical purities and higher yield. The method greatly reduces the cost of large-scale industrial production of the brivaracetam.

Owner:CHENGDU GUOHONG PHARMA

Preparation method of high-stability high-purity extra-coarse tungsten carbide powder

InactiveCN102557028ANarrow particle size distributionImprove stabilityTungsten/molybdenum carbideGranularityCarbonization

A preparation method of a high-stability high-purity extra-coarse tungsten carbide powder contains the following steps of: (1) grinding a high-purity extra-coarse tungsten carbide powdered raw material with its chemical purity being greater than or equal to 99.98 wt%, and carrying out size grading to obtain the required average granularity and a high-purity extra-coarse tungsten powder according to the particle size distribution; (2) carrying out carbon addition by the use of carbon black according to the total carbon content of the obtained tungsten carbide powder being 6.13+ / -0.05%, followed by ball milling and mixing to obtain a ball-milling mixture; (3) filling the obtained ball-milling mixture into a graphite boat and a carbide furnace, and carrying out high-temperature carbonization at 1600-2500 DEGC for the carbonization time of 1-10 hours; and (4) carrying out coarse crushing on the obtained carbonized material, followed by grinding and crushing, and carrying out size grading to obtain the high-purity extra-coarse tungsten carbide powder. The method provided by the invention can be adopted to produce the high-purity extra-coarse tungsten carbide powder with good crush resistance, morphology and structure and excellent thermal stability. The high-purity extra-coarse tungsten carbide powder is used to prepare an extra-coarse crystal cemented carbide product with high performance.

Owner:江西耀升钨业股份有限公司 +1

Compact calcium hexaluminate cast material and preparation method thereof

The invention relates to a compact calcium hexaluminate cast material, which is prepared from the following raw materials in percentage by weight: 15 to 45 percent of calcium hexaluminate raw materials with the particle diameters being 3 to 5mm, 10 to 30 percent of calcium hexaluminate raw materials with the particle diameters being 3 to 5mm, 0 to 20 percent of calcium hexaluminate raw materials with the particle diameters being 0.088 to 1mm, 0 to 20 percent of corundum raw materials with the particle diameters being 0.088 to 1mm, 0 to 30 percent of calcium hexaluminate raw materials with the particle diameters being smaller than 88 mum, 0 to 30 percent of sintered corundum powder with the being smaller than 88 mum, 0 to 10 percent of alpha-Al2O3 micro powder, 5 to 15 percent of pure aluminate cement and 0 to 20 percent of spinelle. The compact calcium hexaluminate cast material provided by the invention has the advantages that the chemical purity is high; mineral facies generated through reaction at high temperature are all high-melting-point facies; the intensity and the fire-resistant degree are high; the anti-erosion and anti-peeling performance is good; the purification effect is achieved on molten steel.

Owner:WUHAN WINNING TECH +1

Carbon black master batch, preparation method and application thereof

InactiveCN103012929APrevent photo-oxidative degradationQuality improvementDispersityHigh concentration

The invention relates to a carbon black master batch in mixing ingredients for preparing a polyethylene (PE) tube, preparation method and application of the carbon black master batch. The carbon black master batch comprises the following components by weight: 32.2-50% of carbon black, 47.2-65% of carrier resin, 0.1-0.3% of antioxidant, and 0.5-2.5% of stearate. The carbon black pigment can be used for dyeing and ultraviolet light stabilizer to effectively prevent the PE tube from photo-oxidative degradation due to sunshine irradiation, thereby improving the quality and the service life of the PE material product. The carbon black master batch has the advantages of accurate measurement, good dispersibility, high concentration, low adding amount and the like. After the carbon black master batch is added, the requirements on the PE tube mixing ingredients for water supply can be met at the aspects of carbon black dispersity, chemical purity degree, pressure resistance, anti-aging and processing performance of the mixing ingredients, so that the PE tube for water supply can achieve the 50-year service life under the pressure resistant state.

Owner:SUZHOU GUOJIA POLYMER TECH

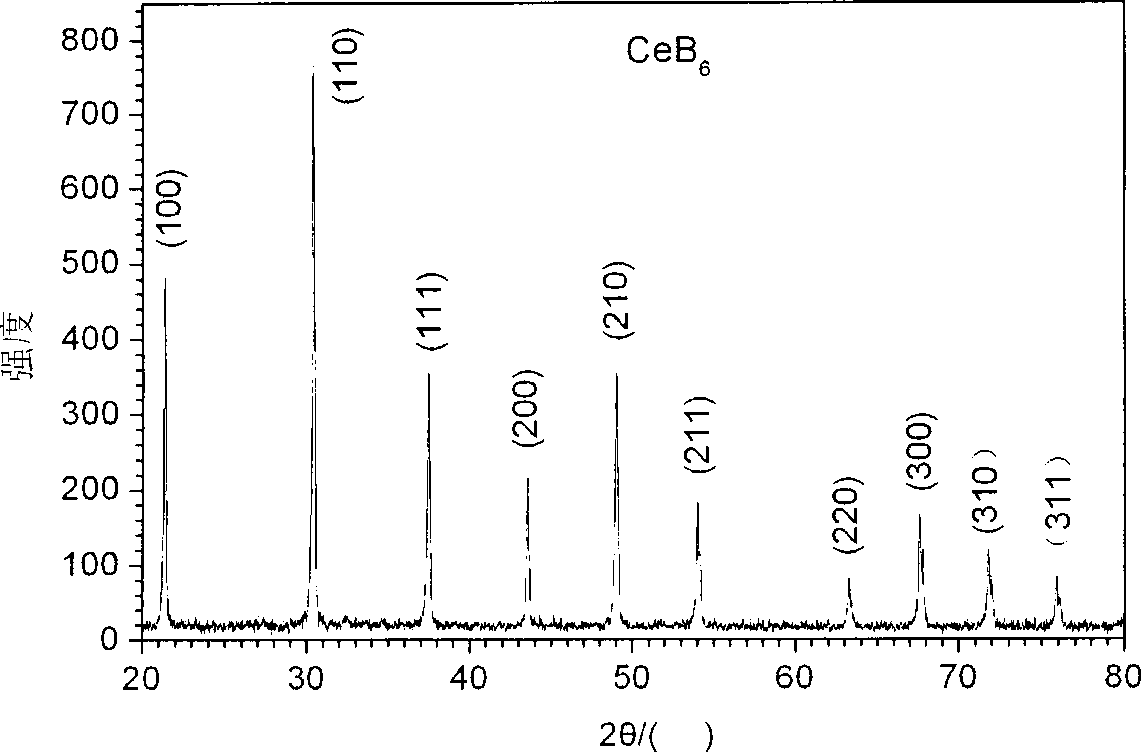

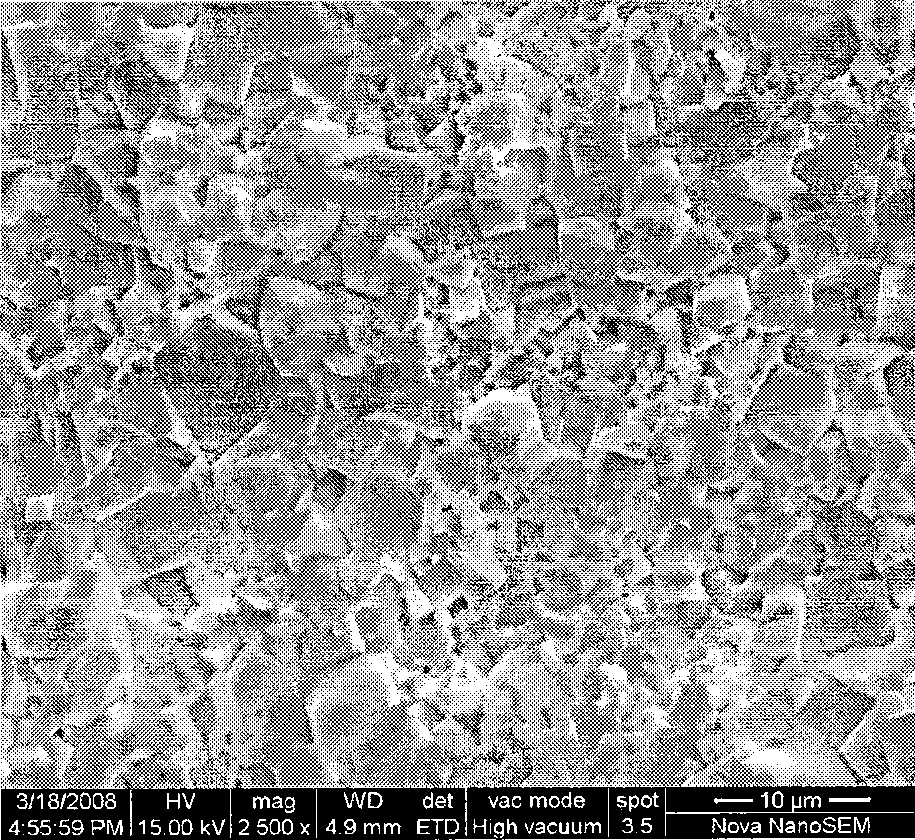

Preparation of high purity high dense polycrystal CeB6 block cathode material

A method for preparing a high-purity and high-density polycrystalline CeB6 cathode material pertains to the technical field of rare earth boride cathode materials. The existing preparation process of the CeB6 is complicated, and the obtained sample has low purity and poor density. The method comprises the following steps: cerium hydride nano-powder is prepared by a DC arc evaporation condensation process, then the cerium hydride nano-powder and boron powder are mixed by grinding in a hypoxia environment, and sintered in vacuum or a high-purity argon atmosphere by a discharge plasma sintering technology to obtain the polycrystalline CeB6 cathode material. The method has the advantages of simple process and low sintering temperature, and that the prepared cathode material has high purity, good density, high chemical purity and excellent emission performance.

Owner:BEIJING UNIV OF TECH

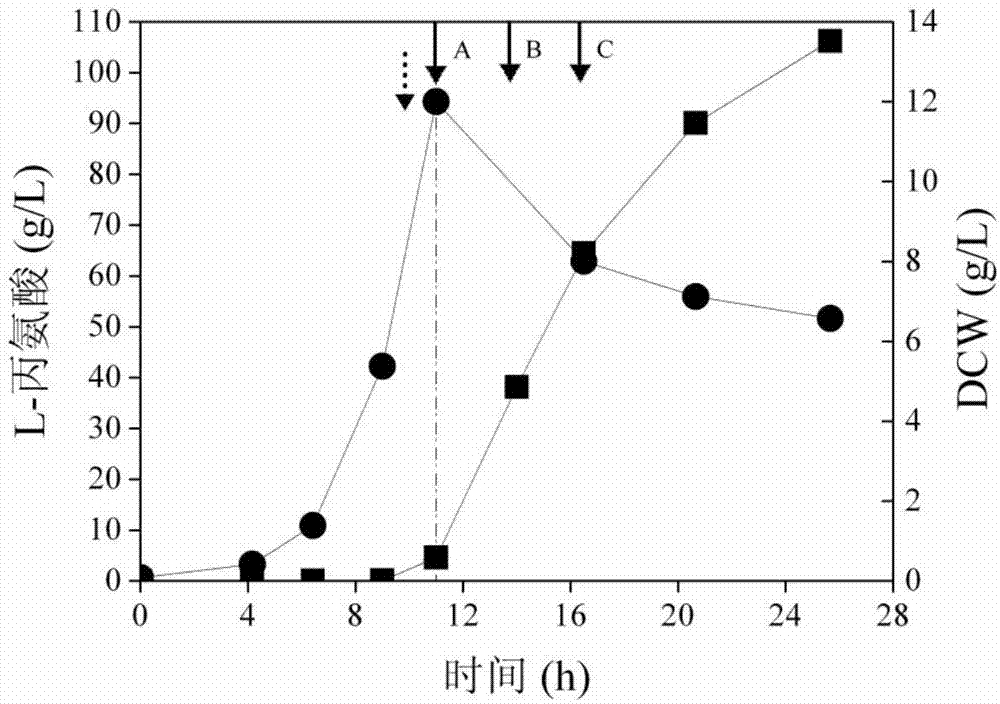

Escherichia coli for efficiently producing L-alanine by fermentation

ActiveCN104774790AAbility to produce high L-alanineHigh chemical purityBacteriaMicroorganism based processesEscherichia coliSuccinic acid

The invention discloses escherichia coli for efficiently producing L-alanine by fermentation, and belongs to the technical field of microbial metabolic engineering. Coding genes for a synthesis route for byproducts acetic acid, formic acid, alcohol, succinic acid and lactic acid on a chromosome of escherichia coli CGMCC No.10628 provided by the invention are deleted, and the chromosome dadX gene is replaced as an alanine dehydrogenase gene, wherein the coding genes comprise ackA-pta, pflB, adhE, frdA and idhA. The recombinant bacterium is fermented for 26 hours to produce 106g / L or more than 106g / L L-alanine with high optical purity and high chemical purity at 28-45 DEG C; and in the whole fermentation process, the production strength reaches 4.27g / L.h or more.

Owner:JIANGNAN UNIV

Method for preparing magnesia-alumina spinel powder through low-temperature solid reaction process

The invention discloses a method for preparing magnesia-alumina spinel powder through the low-temperature solid reaction process. Raw material containing aluminum and magnesium is weighted according to the stoichiometric proportion of magnesia-alumina spinels, the weighted raw material is subject to dry-process pretreatment, wet-process pretreatment, saline hydrolysis process pretreatment or saline precipitation process pretreatment to obtain mixture powder as a precursor, the precursor is subject to the heat treatment or roasting at the temperature of 900 to 1,200 DEG C to obtain the magnesia-alumina spinel powder with better dispersibility and pure phase, and part of particles takes the shape of an octahedra. According to the invention, fluorochemicals are taken as mineralizing agents, the effective control on the solid-phase reaction of alumina (or aluminum hydroxide) and marmag (or magnesium hydroxide) at a high temperature is achieved, and the characteristics that the reaction temperature is low, the pure-phase or almost pure-phase magnesia-alumina spinel powder can be manufactured, the chemical purity of the powder can keep the same level with that of the powder before the solid-phase reaction, the granularity of the powder is micron-grade or submicron-grade, and the raw material particles of the powder take the shape of a regular octahedra sometimes are achieved.

Owner:DALIAN JIAOTONG UNIVERSITY +1

Method for producing high-purity vanadium pentoxide

ActiveCN102923776APut an end to the introductionReduce pollutionVanadium oxidesAmmonium metavanadateImpurity

The invention relates to a method for producing high-purity vanadium pentoxide by utilizing ammonium metavanadate. The method comprises the following steps of dissolving crude ammonium metavanadate in 85-98 DEG C deionized water, regulating the pH value of a sodium hydroxide regulation solution to be 8-10, adding calcium chloride for removing impurities so as to further regulate the pH value of the filter liquid to be 10-12, removing the impurities out of the filter liquid again, introducing ammonia gas in the filter liquid under increased pressure, and releasing the pressure; and carrying out ultrasonic atomization, crystallizing when the ammonium metavanadate is cooled, scrapping crystals, washing in water, and roasting the washed crystals at 500-550 DEG C to obtain the vanadium pentoxide with the purity of 99.95%. The method for producing the high-purity vanadium pentoxide disclosed by the invention combines physical purification and chemical purification which supplements each other, has the advantages of novel and advanced process, low medical agent consumption, low production cost and can be industrialized favorably.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

Finegrained aluminium-chromium composite fireproof materials

The invention relates to a novel fire-resistant raw material for preparing periclasite magnesium aluminate spinel fireproof material and high grade fusion-cast AZS fireproof material whose formulation is, desiliconisation zirconium 30-73%, commercial alumina 27%-70%, magnesite 0-10%, wherein the content of zirconium dioxide in desiliconisation zirconium is 85-92%, the content of magnesium oxide in magnesite is 97%, the total content of magnesium oxide in the formulation is 0.2-10%, the total content of silicon oxide is 0.5-1.5%, the total content of zirconium oxide is 30-60%, the total content of alumina is 30-65%. The raw material can be used to prepare periclasite-magnesium aluminate spinel material with substantial improvement on heat and shock resistance, thermal conductivity.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

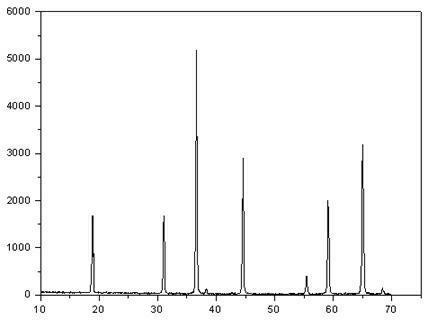

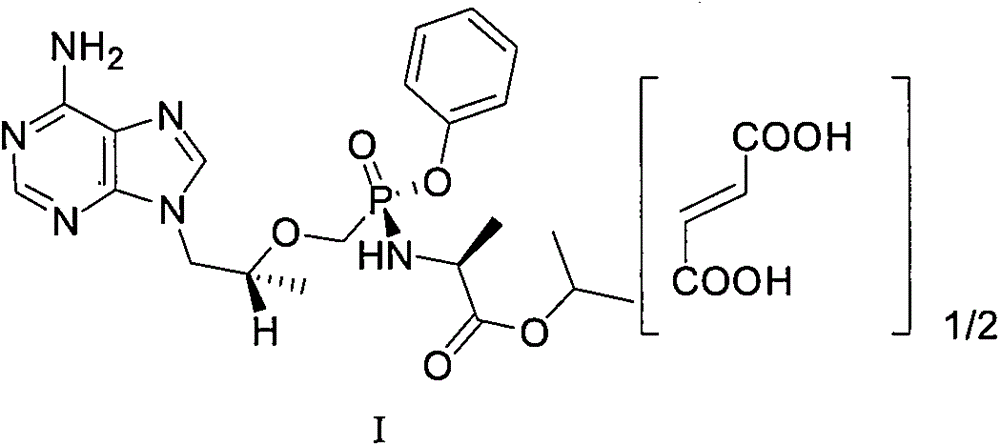

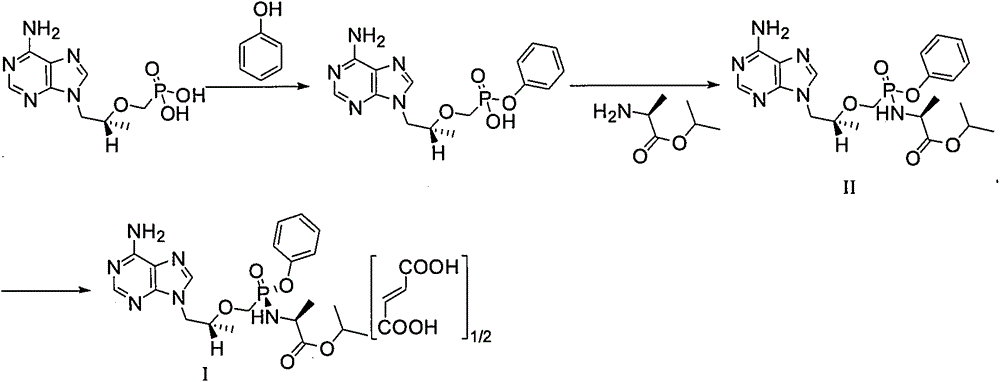

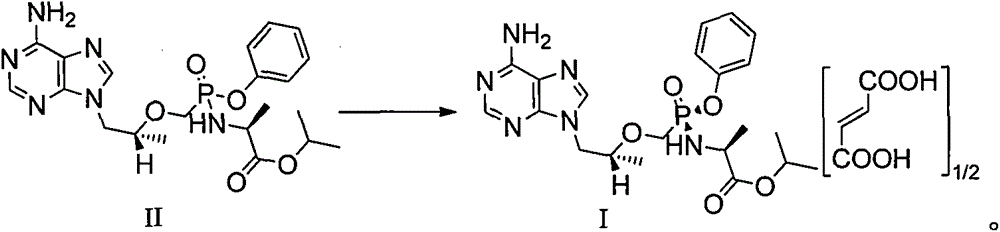

Preparation method and application for high-purity tenofovir alafenamide fumarate intermediate

ActiveCN106478725ASimple and safe operationHigh yieldGroup 5/15 element organic compoundsOrganic chemistry methodsTenofovir alafenamideSolvent

The invention discloses a preparation method and an application for a high-purity tenofovir alafenamide fumarate intermediate. The preparation method for the tenofovir alafenamide fumarate intermediate namely tenofovir alafenamide II provided by the invention comprises the following steps: subjecting crude tenofovir alafenamide fumarate intermediate namely tenofovir alafenamide II to recrystallization in a mixed solvent of a nitrile solvent and water or a mixed solvent of the nitrile solvent and an aromatic hydrocarbon solvent so as to obtain the high-purity tenofovir alafenamide fumarate intermediate namely tenofovir alafenamide II. The high-purity tenofovir alafenamide II has an optical purity larger than 99.50% and a chemical purity larger than 99.60%; and the crude tenofovir alafenamide fumarate intermediate namely tenofovir alafenamide II has the optical purity in a range of 60.00% to 99.00% and the chemical purity in a range of 60.00% to 99.00%. The preparation method provided by the invention has the advantages of simple and safe operation, high yield, high product purity, low production cost, and applicability to industrial production.

Owner:SHANGHAI BOCIMED PHARMA CO LTD

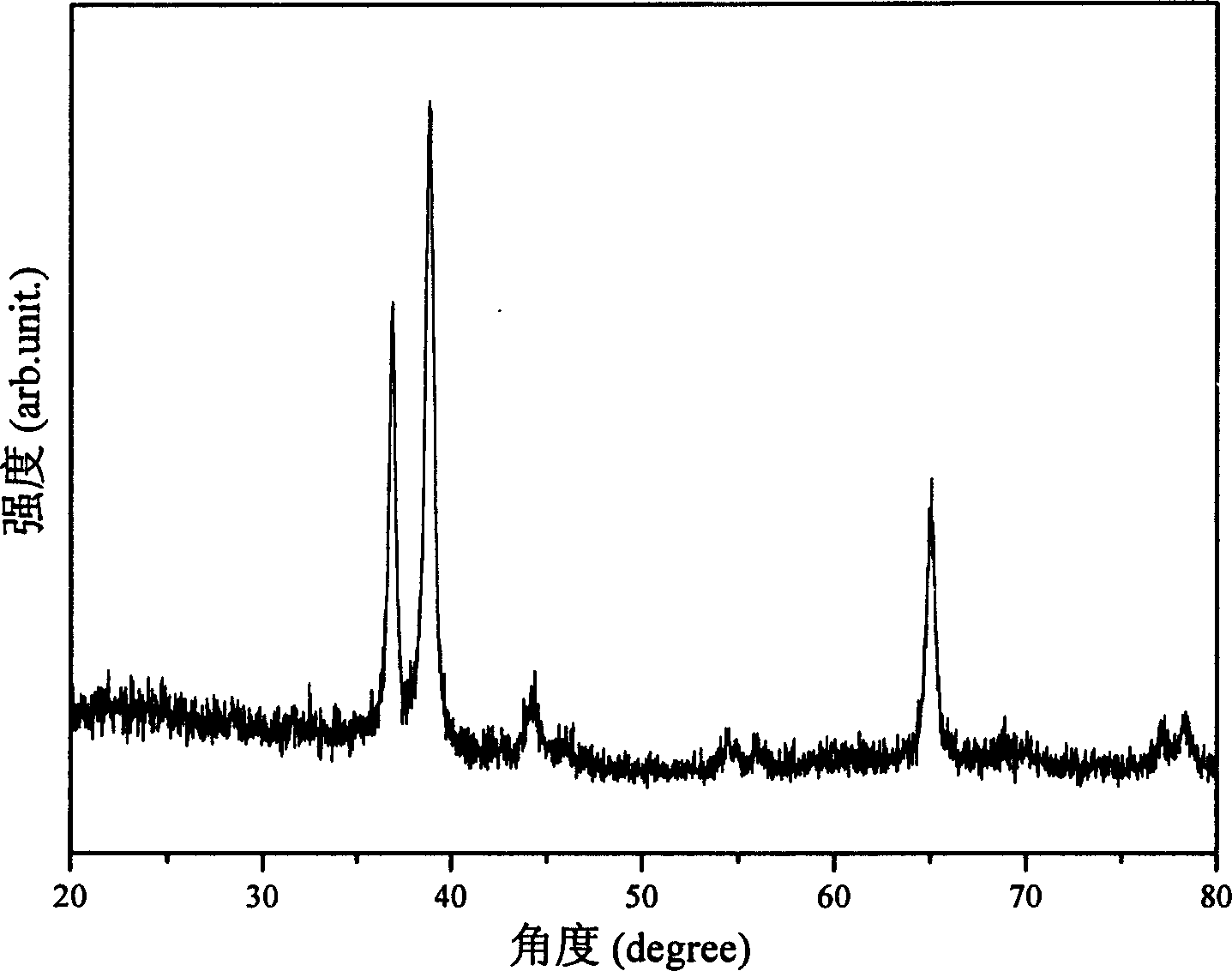

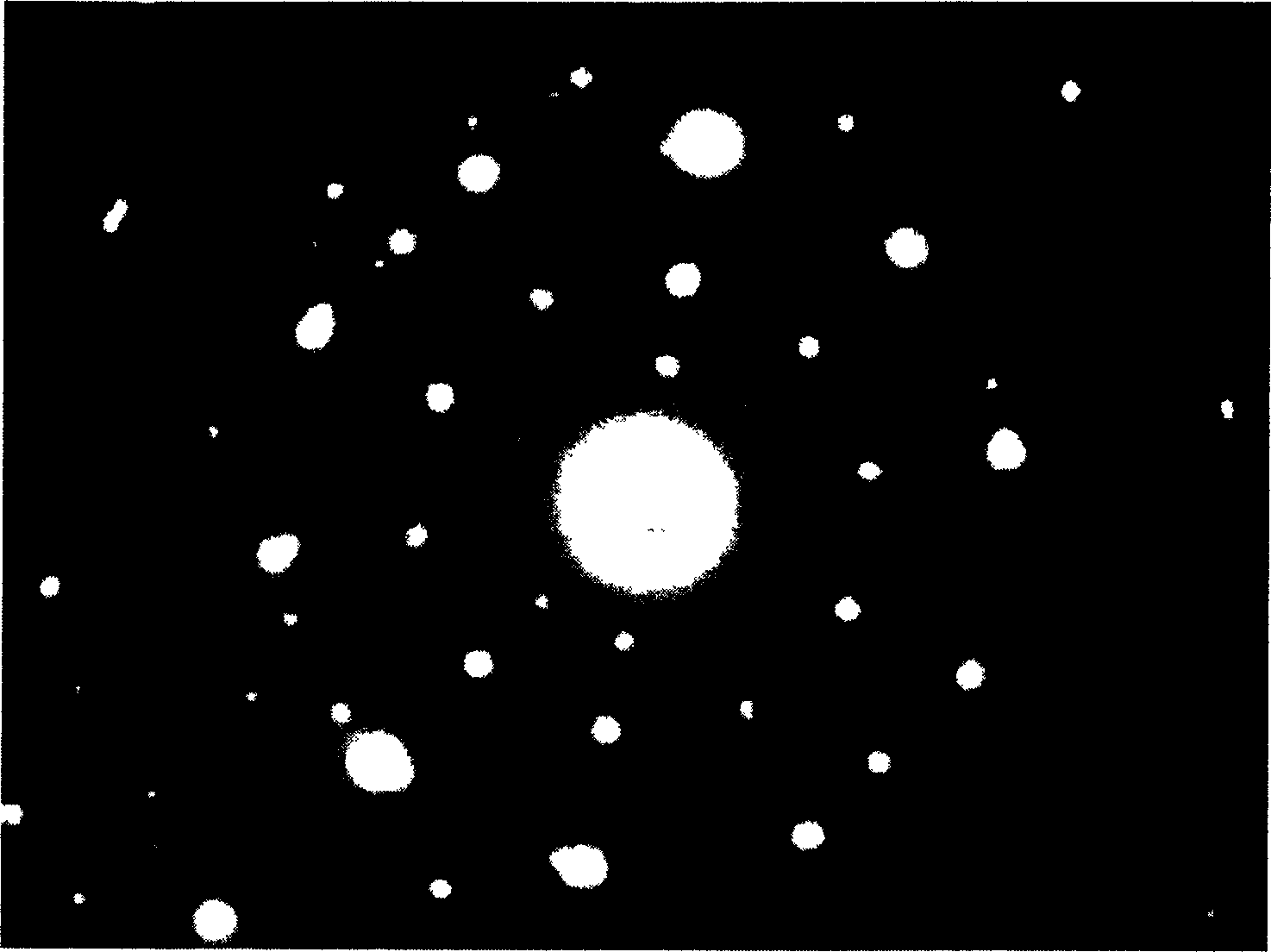

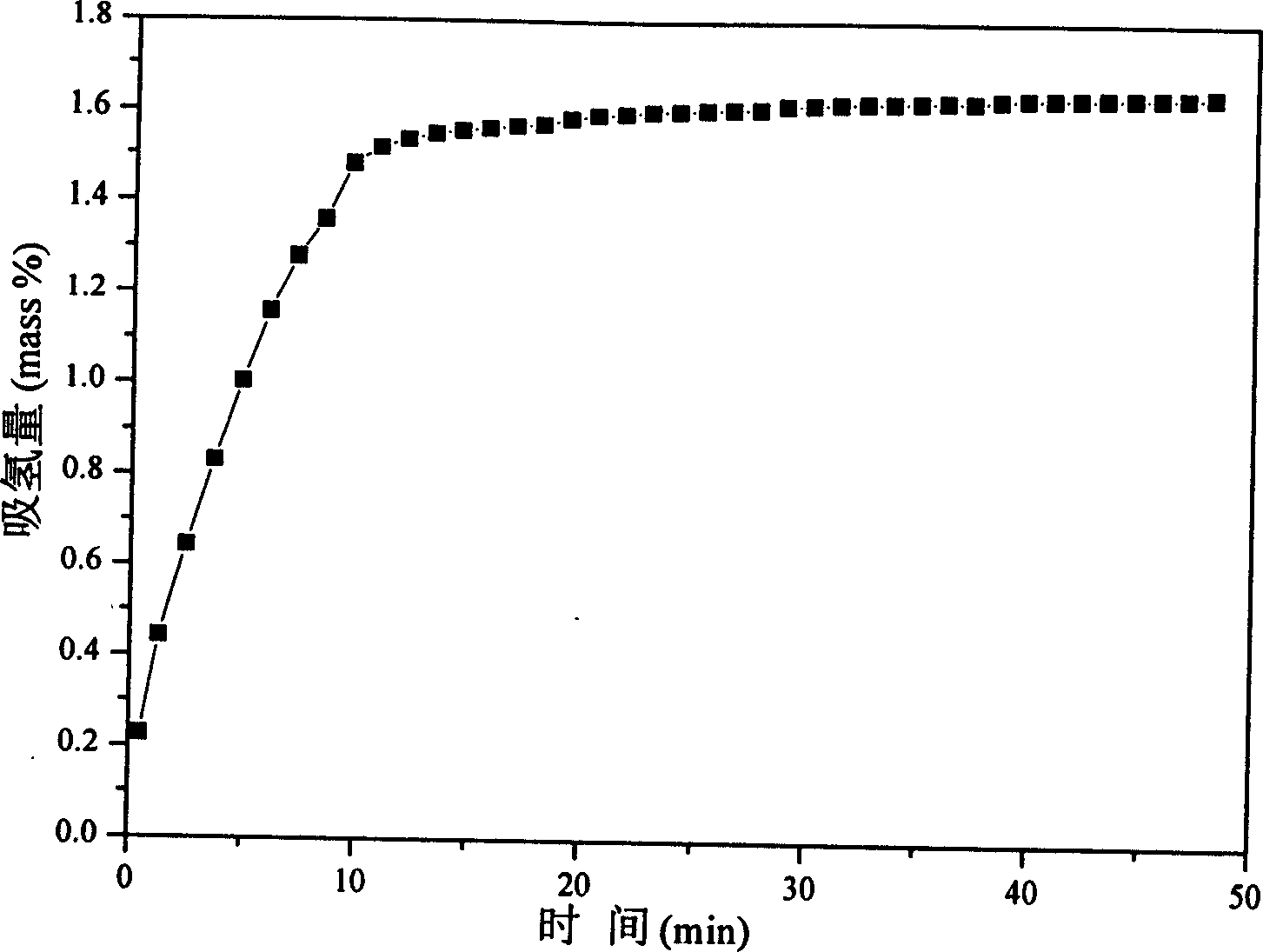

Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

InactiveCN1709564AStrong ability to form quasicrystalsEasy to operateOther chemical processesHigh energyTitanium

The invention provides a kind of single icosahedron quasicrystal material with hydrogen storing function. Its component is Ti100-x-y-zZrxNiyCuz, thereinto, 10 < x < 45, 5 < y < 20, 1 < z < 10. the forming ability of the alloy quasicrystal is strong, and the formed quasicrystal material is single icosahedron structure. It is thermodynamics is stable, and has good hydrogen storing function. It can be applied in gaseous state hydrogen storing material and battery cathode material; meantime, it provides a kind of producing method of the material: according to the count of the component formula of the quasicrystal material, choose powders of Ti, Zr, Ni, and Cu of 100 holes per cm2 chemical purity, encase them in the ball milling pot of the high energy ball mill, the ball material rate is 20 : 1, ball mill for 100 - 200 hours under the protection of argon, seal the ball milled alloy powders in the quartz tube, have heat processing at 1 í‡ 10-3 Pa, the heat processing temperature is 480 - 650 Deg. C, the time is 0.5 - 6 hours. Its craft is simple, the operational ability is strong, and it is easy to be industrialized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com