Method for preparing magnesia-alumina spinel powder through low-temperature solid reaction process

A technology of magnesium-aluminum spinel powder and solid-phase reaction method is applied in the field of preparing magnesium-aluminum spinel powder by low-temperature solid-phase reaction method, and can solve the problems of long production cycle, coarse and uneven particles, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

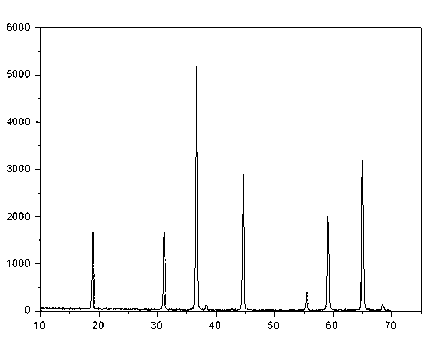

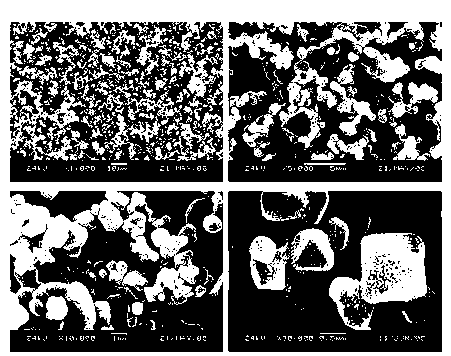

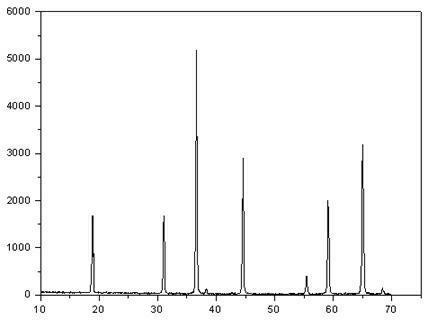

[0031] Example 1, a method for preparing magnesia-aluminum spinel powder by a low-temperature solid-state reaction method is to weigh 21.15 grams of gibbsite (AlOOH), 5 grams of magnesium oxide (MgO), and add 1 gram of AlF 3 . 3.5H 2 O was ground in a ceramic mortar to obtain a loose powder, and kept in a high-temperature furnace at 900°C to 1200°C for 3 hours to obtain a pure-phase magnesium-aluminum spinel whose primary particles were (nearly) regular octahedral crystals Stone powder, high temperature solid phase reaction:

[0032]

[0033]

[0034]

Embodiment 2

[0035] Example 2, a method for preparing magnesia-aluminum spinel powder by a low-temperature solid-state reaction method is to weigh 12.8 grams of γ-alumina (Al 2 o 3 ), 5 grams of MgO, plus 1 gram of AlF 3 . 3.5H 2 O and 15mL ethanol in a ceramic mortar, grind to obtain a loose powder, or fully mix, disperse, dry and then grind, and keep it in a high-temperature furnace at 900 ° C ~ 1200 ° C for 3 hours to obtain part of the primary The particles are pure-phase magnesium-aluminum spinel powders with regular octahedral crystals. The high-temperature solid-state reaction is as follows:

[0036]

Embodiment 3

[0037] Example 3, a method for preparing magnesia-aluminum spinel powder by a low-temperature solid-state reaction method is to weigh aluminum sulfate Al that can generate 12.8 grams of alumina 2 (SO 4 ) 3 or its hydrate, add 1 g NH 4 F and an appropriate amount of water to dissolve it completely, and add an appropriate amount of ammonia or urea aqueous solution under constant stirring until all aluminum ions completely form AlOOH or Al(OH) 3 Or its mixture, evaporate or dry at a temperature lower than 60°C, add 5 grams of MgO and grind together to obtain a loose powder, keep it in a high-temperature furnace at 900°C to 1200°C for 3 hours, and obtain some primary particles. The pure-phase magnesia-aluminum spinel powder of regular octahedral crystals, the chemical reactions that occur during the hydrolysis precipitation process are as follows, and the high-temperature solid-phase reactions are as in Example 1:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com