Preparation method for radioactive 68Ge solution

A radioactive and solution-based technology, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high technical difficulty of Ni alloy target, weak copper target support, easy to generate aerosol, etc. The method is convenient and fast , The target is firm and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

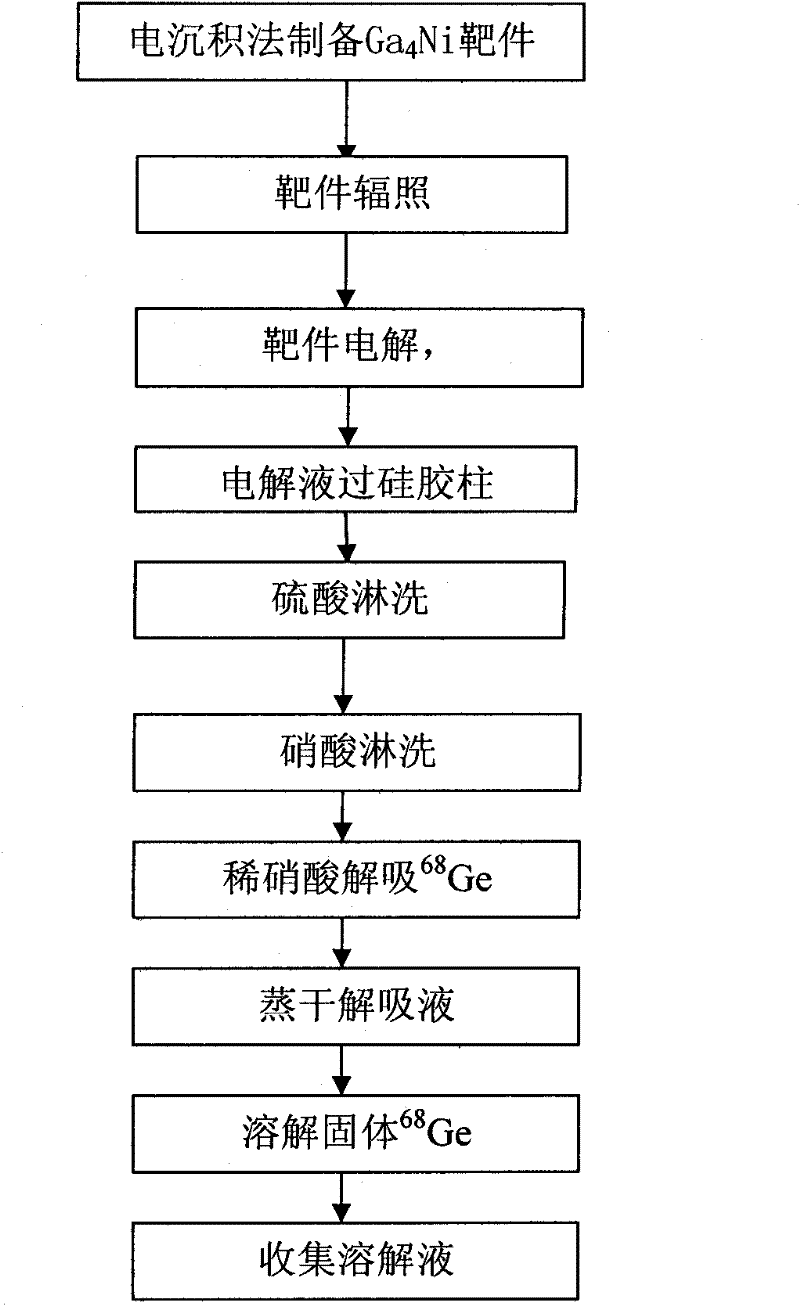

[0033] Radioactive 68 The preparation method of Ge solution is: dissolving gallium salt and nickel salt in hydrochloric acid solution, using the principle of electrodeposition, co-depositing two metals of gallium and nickel on the copper target holder to prepare gallium and nickel alloy targets; alloy targets After being irradiated by CYCLONE30, 68 Ge alloy target, place the target after cooling and irradiated, electrolyze the irradiated target, and separate, purify, desorb the electrolyte on a silica gel column, evaporate the desorbed liquid, dissolve the solid after evaporation, collect and dissolve Liquid, prepared for preparation 68 Ge- 68 Radioactivity of Ga generator 68 Ge solution, it contains the following steps:

[0034] 1) Prepare Ga by electrodeposition 4 Ni alloy target

[0035] Preparation of Ga by Electrodeposition 4 The electroplating tank of the Ni alloy target is a constant temperature water bath vertical plating tank with stirring function, the anode and cathode s...

Embodiment 1

[0051] Radioactive 68 The preparation method of Ge solution is: dissolving gallium salt and nickel salt in hydrochloric acid solution, using the principle of electrodeposition, co-depositing two metals of gallium and nickel on the copper target holder to prepare gallium and nickel alloy targets; alloy targets After being irradiated by CYCLONE30, 68 The Ge alloy target is left to cool the target for one month, and then the target is electrolyzed. Electrolysis is the reverse process of electroplating; then the electrolyte is separated, purified, and desorbed on a silica gel column, and the desorbed solution is evaporated to dissolve the remaining Solid matter, realize the conversion of desorption liquid medium, and prepare it for preparation 68 Ge- 68 Radioactivity of Ga generator 68 Ge solution, it contains the following steps:

[0052] 1) Prepare Ga by electrodeposition 4 Ni alloy target

[0053] Dissolve 1.0mol / L gallium trichloride and 0.25mol / L nickel dichloride in 0.1mol / L hydr...

Embodiment 2

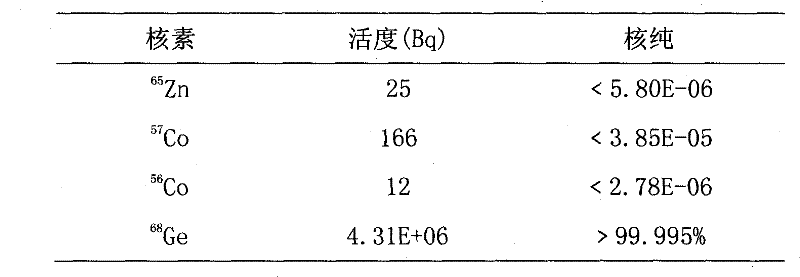

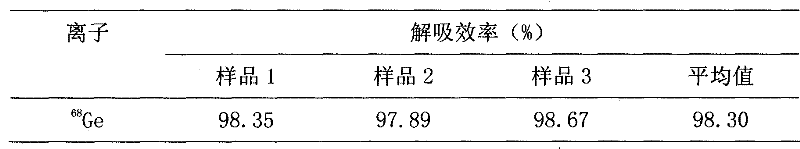

[0068] Radioactive prepared according to the preparation method and operation steps described in Example 1 of the present invention 68 The technical indicators of Ge solution are as follows: nuclear purity is greater than 99.995%, chemical purity is greater than 98%, and sulfate ion concentration is less than 14.9×10 -4 moL / L (as shown in Table 1, 2, 3, 4).

[0069] Table 1 68 Nuclear purity of Ge solution

[0070]

[0071] Table 2 68 The desorption efficiency of Ge solution,

[0072]

[0073] table 3 68 Chemical purity of Ge solution

[0074]

[0075] Table 4 68 Concentration of sulfate in Ge solution

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com