Patents

Literature

52 results about "Nickel Dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nickel base alloy surface composite plating

The invention relates to a preparation method of a composite plating layer used on the surface of nickel-based alloy, which comprises the following steps: 1) degreasing is carried out; 2) water washing is carried out; 3) acid washing is carried out; a passive film on the surface is pre-removed; activation in hydrochloric acid is carried out; the passive film on the surface of the nickel-based alloy is pre-removed; the concentration of the hydrochloric acid is 20 percent to 36 percent; and the time for activation is 1min to 10min; 4) the removal of the passive film on the surface and the pre-plating of nickel are carried out; activation in a solution containing nickel dichloride and the hydrochloric acid and the cathode electro-deposition of the nickel are carried out; time for activation is 1min to 4min; the content of the nickel dichloride is 120g / l to 480g / l; the content of the hydrochloric acid with the concentration of 20 percent to 36 percent is 60ml / l to 350ml / l; current density is 1A / dm<2> to 10A / dm<2>; and the thickness of a nickel plating layer is less than or equal to 0.1 micron; 5) water washing is carried out; and 6) nano copper-tin is prepared; an electro-deposition method is applied to prepare a nano copper-tin plating layer on the coupling surface of a nickel-based alloy oil bushing. The preparation method carries out the pre-plating of nickel on the coupling surface of the nickel-based alloy oil bushing at first and then plates a copper-tin alloy, thereby improving the anti-sticking performance of a connector of the oil bushing and meeting the requirement for completeness of the oil bushing in the aspect of screwing on and screwing off repeatedly.

Owner:BAOSHAN IRON & STEEL CO LTD

Nickel-doped metal organic framework material and preparation method thereof

InactiveCN108905975ALarge adsorption capacityImprove stabilityOther chemical processesWater/sewage treatment by sorptionN dimethylformamideSorbent

The invention discloses a nickel-doped metal organic framework material and a preparation method thereof. The nickel-doped metal organic framework material comprises MIL-53 (Fe) and the MIL-53 (Fe) isdoped with nickel ions. The preparation method comprises the following steps: mixing ferric chloride hexahydrate, terephthalic acid, nickel dichloride hexahydrate and N,N-dimethylformamide to carry out a solvothermal reaction to obtain the nickel-doped metal organic framework material. The nickel-doped metal organic framework material of the invention has larger adsorption amount, better stability and good adsorption performance, is simple to synthesize, can be widely used, can efficiently adsorb and remove pollutants in water bodies and is a novel adsorbent. The preparation method of the invention has the advantages of simple operation, convenient preparation, less kinds of raw materials, high yield, low cost and the like, is suitable for large-scale preparation and is advantageous for industrial utilization.

Owner:HUNAN UNIV

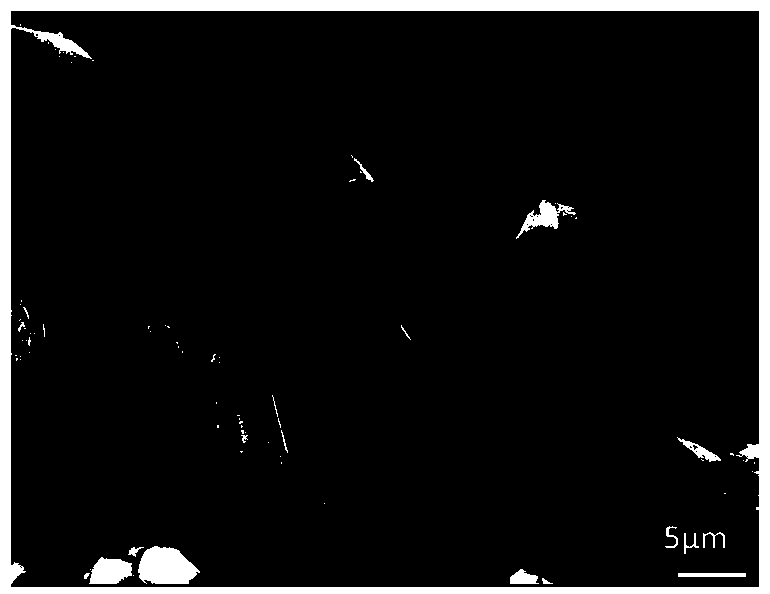

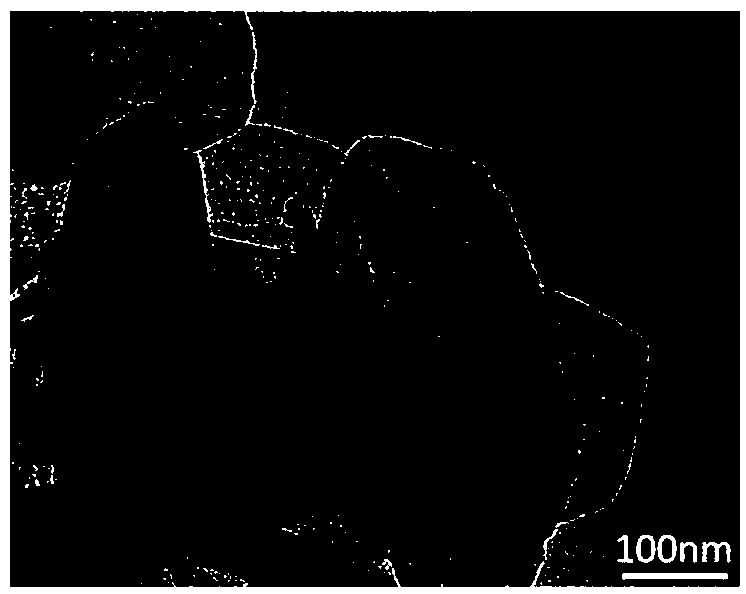

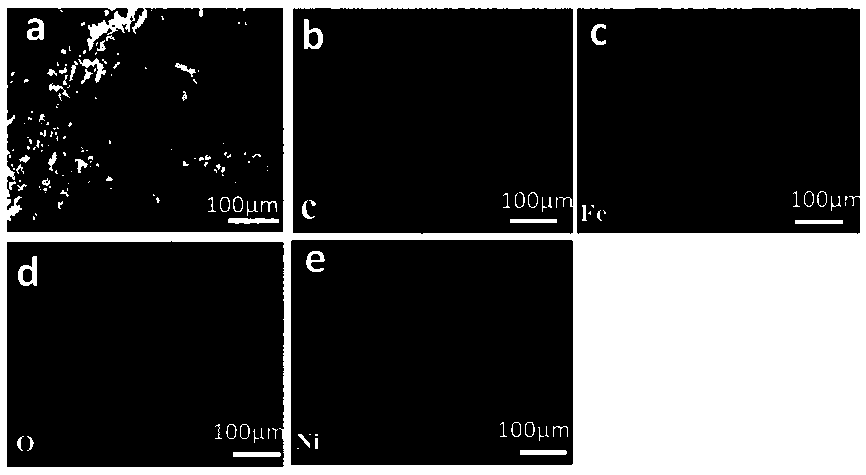

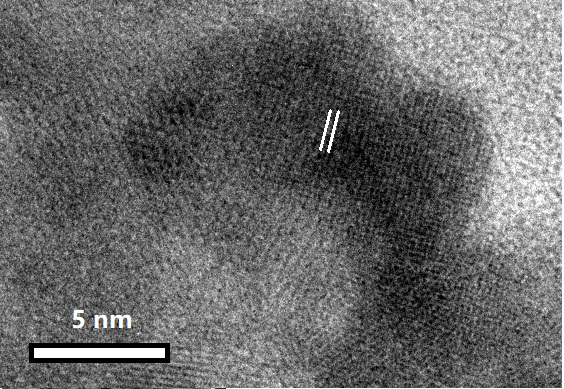

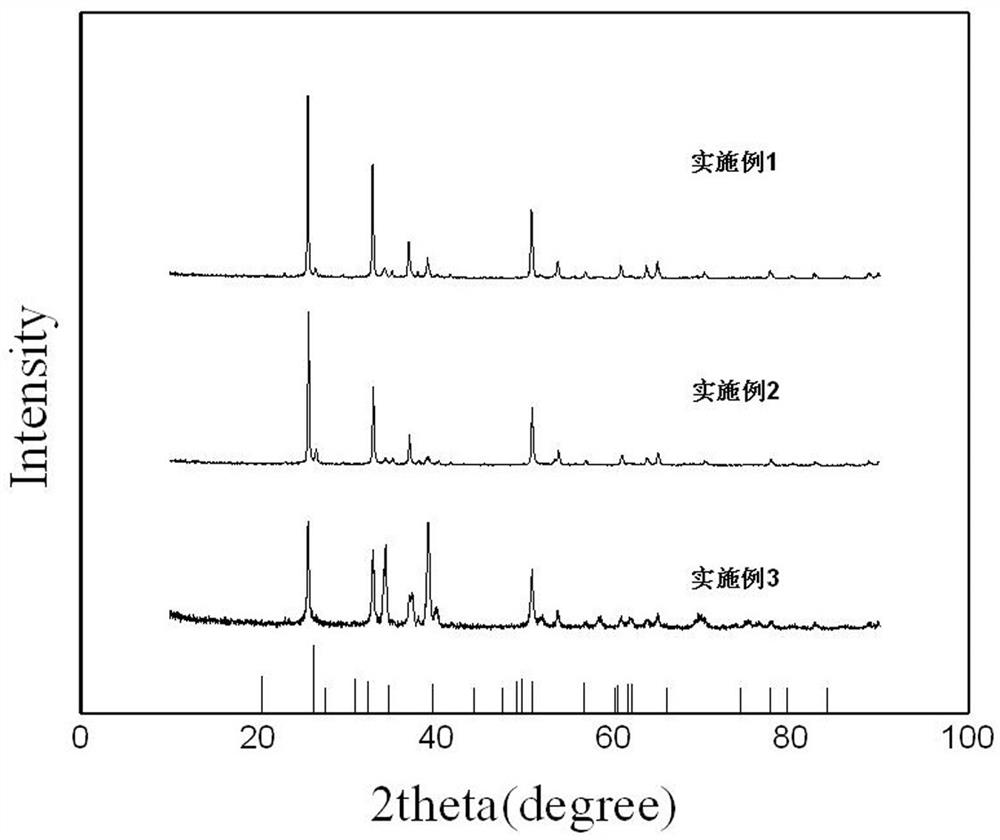

Method for controllably preparing FeNi3 micro-nano materials in various shapes

The invention discloses a method for controllably preparing FeNi3 micro-nano materials in various shapes, which relates to magnetic alloy FeNi3 micro-nano materials. The method comprises the following steps that ferric chloride hexahydrate and nickel dichloride hexahydrate are dissolved in deionized water, so as to obtain a solution with the Fe<3+> concentration of 0.005 to 0.03 mol / L and the Ni<2+> concentration of 0.015 to 0.09 mol / L, and the mole ratio of the ferric chloride hexahydrate to the nickel dichloride hexahydrate is controlled to be 1:3; then sodium hydroxide is added to full stir; then hydrazine hydrate is dropwise added to stir; the mixture is moved to a reaction kettle to be sealed, and reaction is performed at 120 to 200 DEG C for 0.5 to 24 hours; and a magnet is used for separating products, and the products are respectively washed with deionized water and absolute ethyl alcohol and then dried. According to the method, any template or external magnetic field is not used for assistance, the products in various shapes can be optionally synthesized with one step, and the method has the advantages of economy, environmental friendliness, rich product structure and shape, high selectivity and good repetitiveness.

Owner:ZHONGBEI UNIV

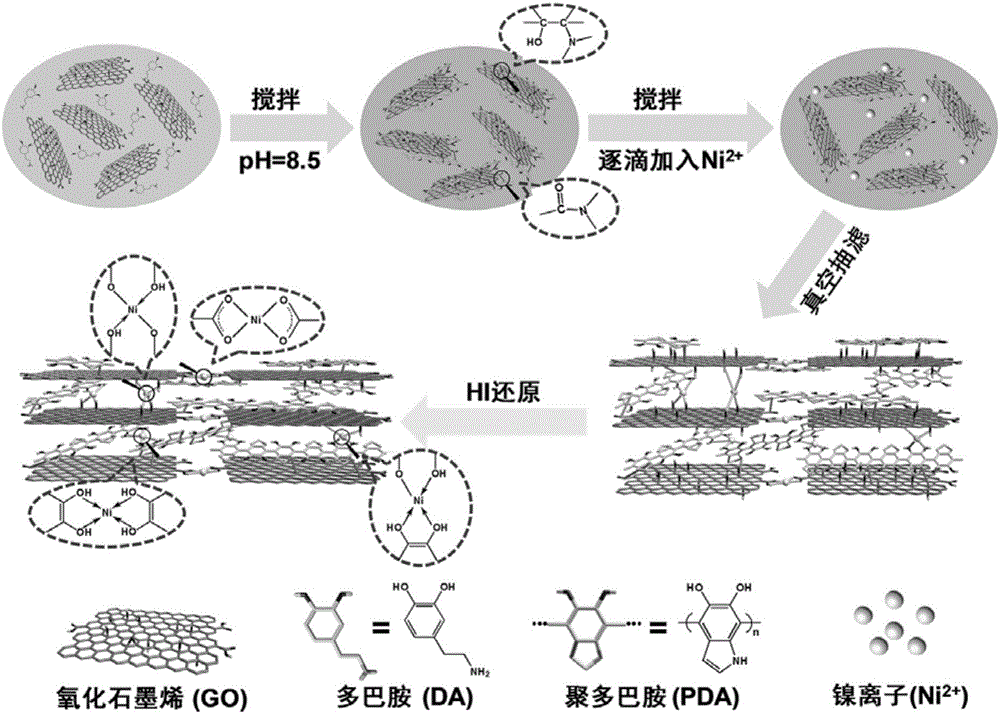

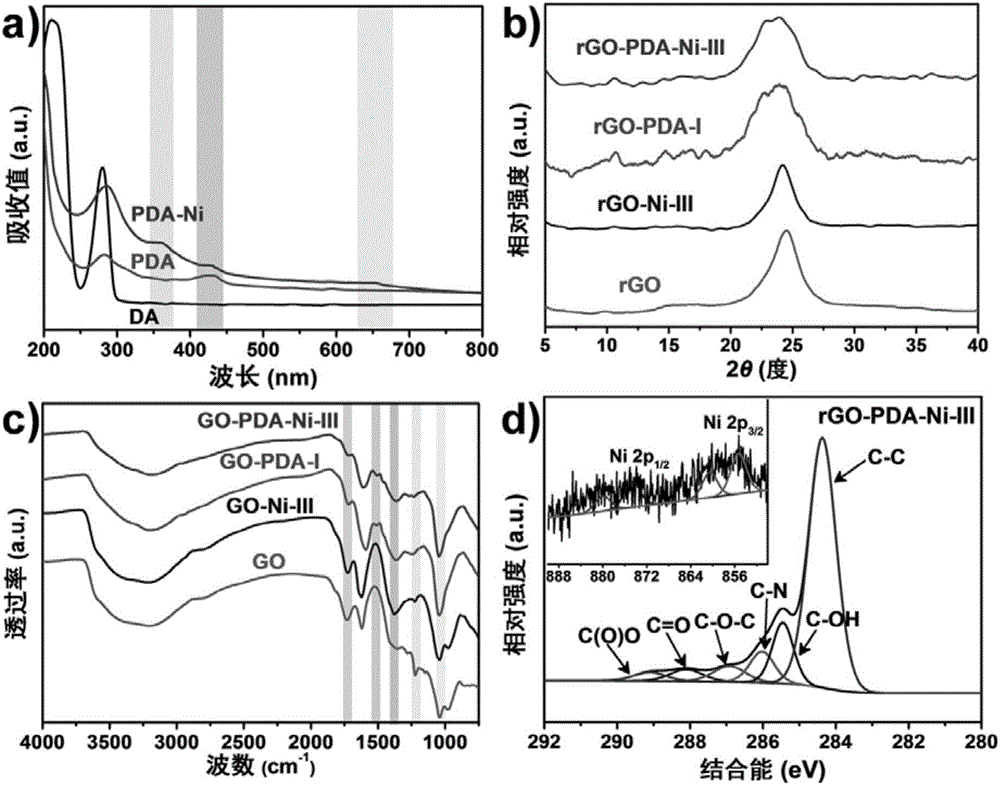

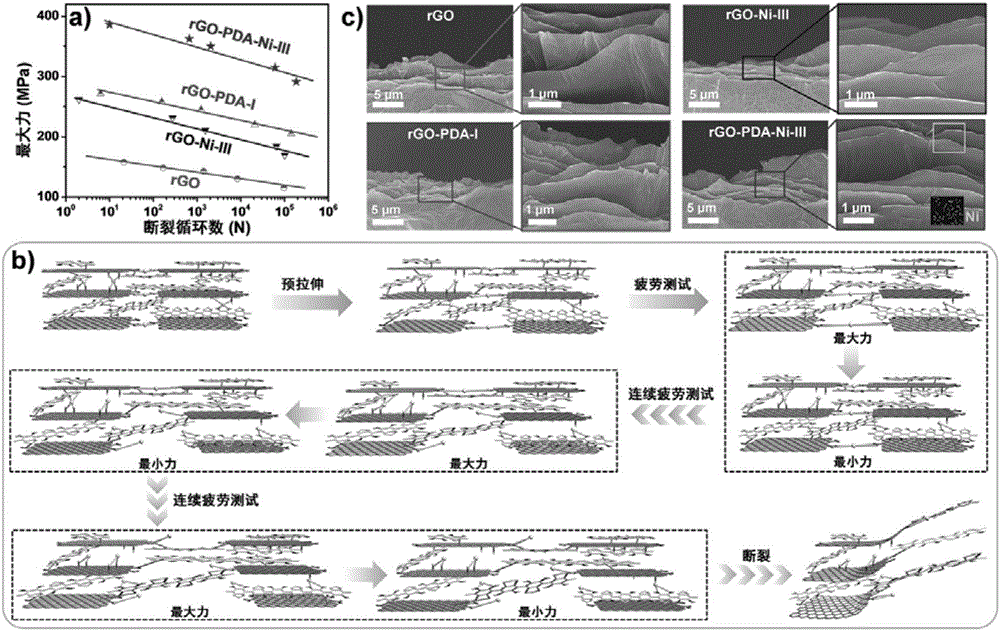

Method for preparing ultra-fatigue-resisting bionic graphene nano composite material

ActiveCN106832273AImprove mechanical propertiesImprove electrical performanceNano compositesDopamine

The invention relates to a method for preparing an ultra-fatigue-resisting bionic graphene nano composite material. The method comprises the following steps: firstly, taking inorganic graphene oxide and dopamine (DA) to react and constructing a graphene oxide-polydopamine (GO-PDA) heterogeneous elementary material; secondly, adding a nickel dichloride (NiCl2) solution and forming a chelating structure through the nickel dichloride solution and polydopamine; filtering a uniformly mixed solution, which is finally obtained, in vacuum to prepare a graphene oxide-polydopamine-Ni<2+> (GO-PDA-Ni) nano composite material; finally, chemically reducing to prepare a reduced graphene oxide-polydopamine-nickel ion (rGO-PDA-Ni) bionic graphene nano composite material. The obtained bionic graphene nano composite material not only has an ultrahigh fatigue-resisting property, but also has an excellent conducting performance. Under the tension of 290MPa, the electrical conductivity can still teach 144.5S / cm after 1.0*10<5> times of periodic extension tests. Furthermore, the maximum strength is 2.1 times as much as that of natural abalone shells and the maximum toughness is 7.5 times as much as that of the natural abalone shells.

Owner:BEIHANG UNIV

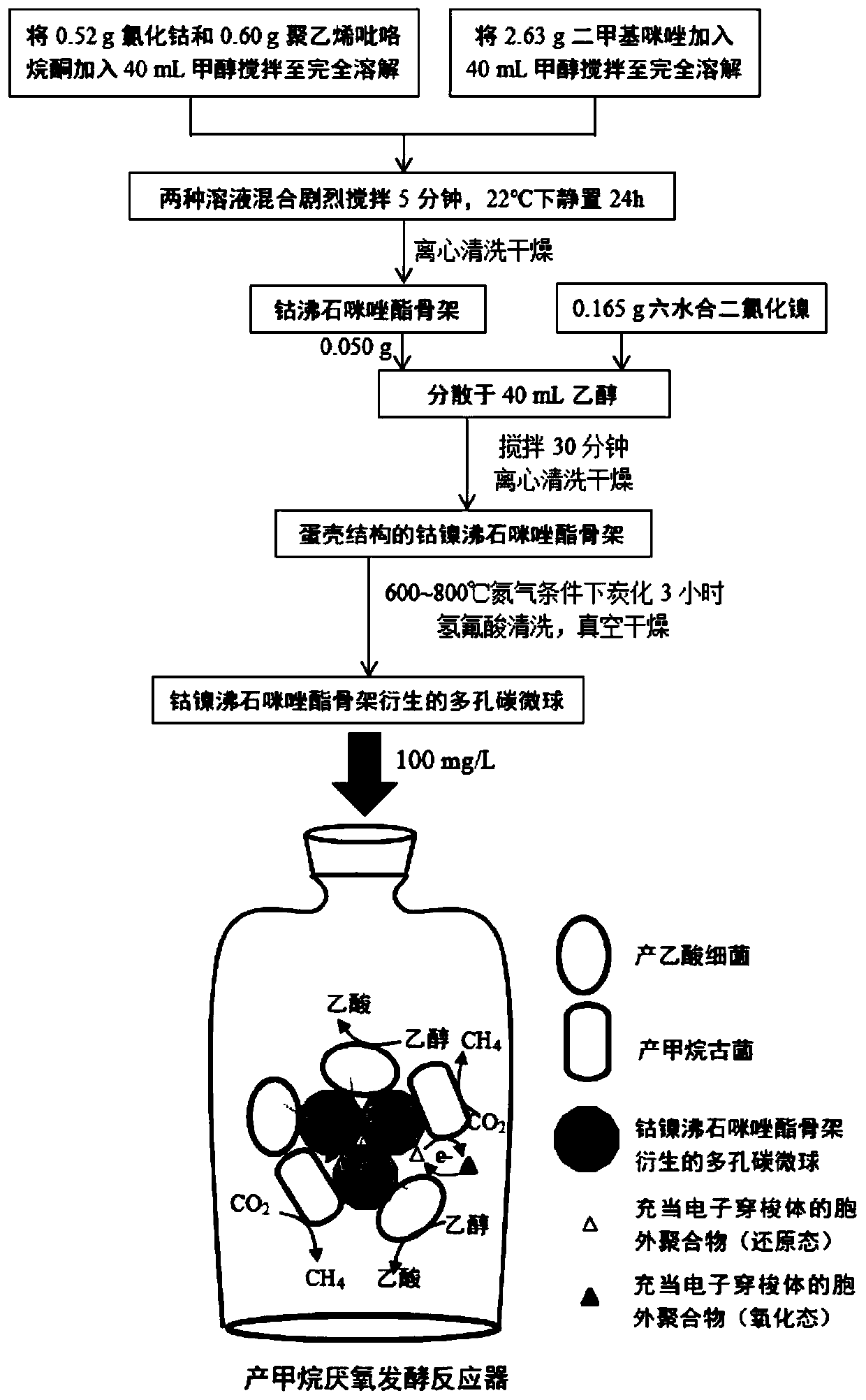

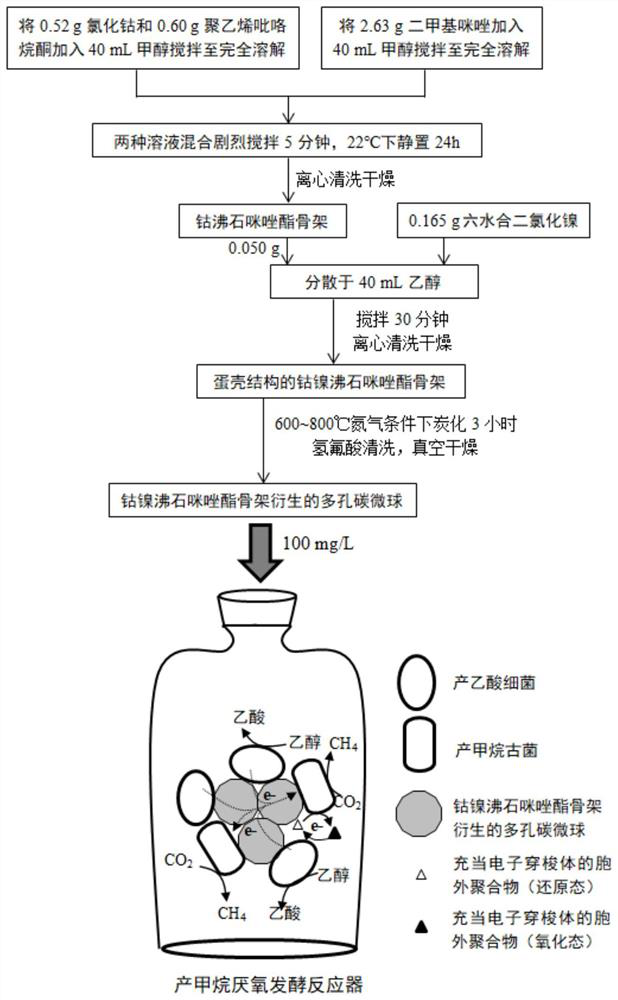

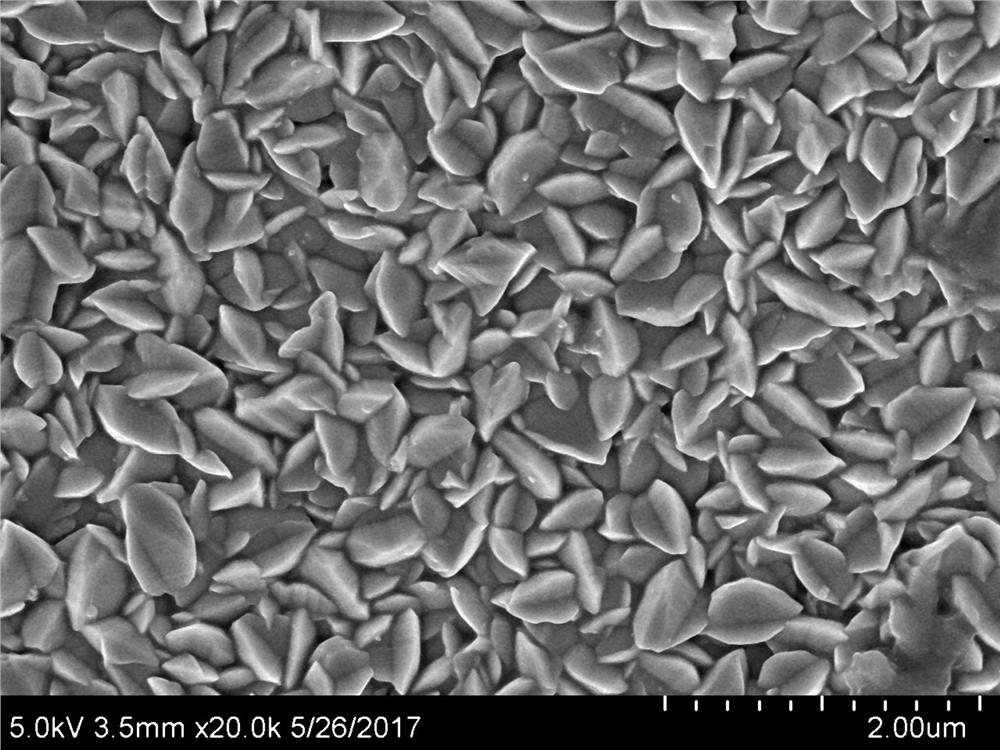

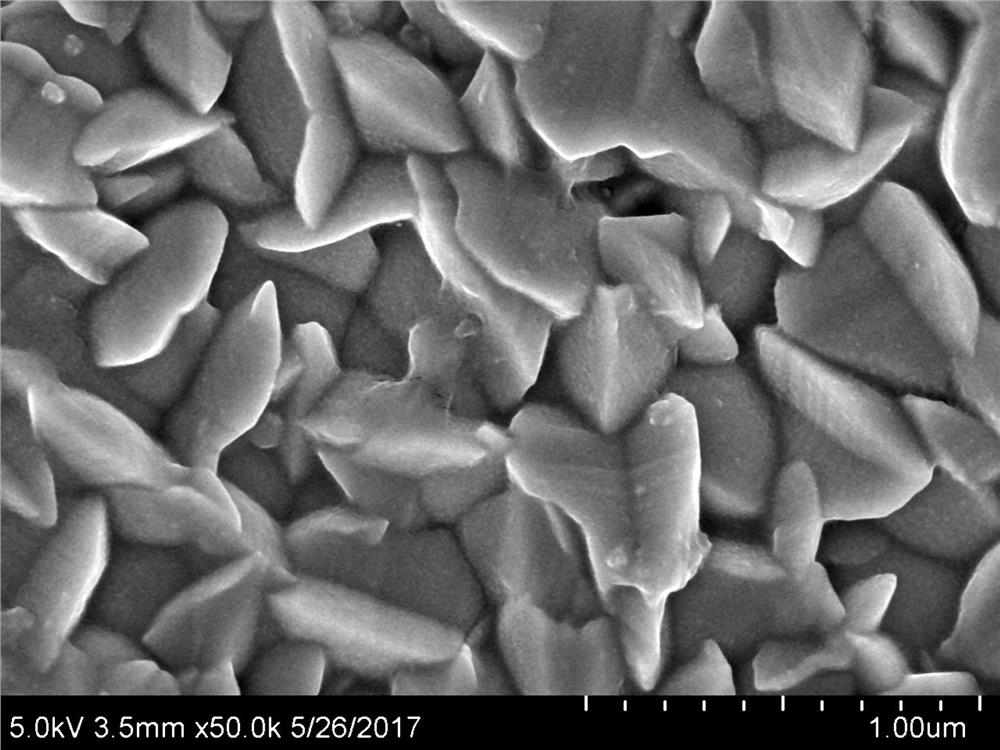

Method for promoting preparation of biomethane by cobalt-nickel zeolite imidazate framework derived porous carbon

ActiveCN111041022AHigh yieldEnhance the activity of key enzymesMicroorganism based processesWaste based fuelMicrospherePorous carbon

The invention relates to a biomass energy utilization technology, and aims to provide a method for promoting preparation of biomethane by cobalt-nickel zeolite imidazate framework derived porous carbon. The method comprises the following steps: mixing cobalt chloride, polyvinylpyrrolidone and a methanol solution of dimethylimidazole, violently stirring, and aging to obtain a cobalt zeolite imidazate framework; washing, drying in vacuum, and grinding to obtain cobalt zeolite imidazate framework powder; dispersing in ethanol, adding nickel dichloride hexahydrate, and stirring to form a cobalt-nickel zeolite imidazate framework with an eggshell structure; drying in vacuum, and carbonizing in a tube furnace under a nitrogen condition to obtain porous carbon microspheres containing cobalt-nickel nanoparticles; and washing with hydrofluoric acid, drying in vacuum, and grinding into powder to obtain the cobalt-nickel zeolite imidazate framework derived porous carbon. According to the method,the biomethane production performance of a fermentation system can be effectively improved, the electron transfer performance of the system is optimized, the content of electroactive extracellular polymeric substances in the system is increased, and electron shuttle mediated interspecific electron transfer is enhanced.

Owner:ZHEJIANG UNIV

Anti-aging coating for automobile body and preparation method thereof

InactiveCN109880452AImprove corrosion resistanceAccelerated corrosionAntifouling/underwater paintsPaints with biocidesEpoxyMicrosphere

The invention relates to the technical field of coating preparation, in particular to an anti-aging coating for an automobile body and a preparation method of the anti-aging coating. The coating is composed of the following raw material components: polytetrafluoroethylene emulsion, epoxy resin, dicyclohexylmethane diisocyanate, 2,4-dihydroxybenzophenone, triethylenediamine nickel dichloride, ethylacetate, diatomaceous earth, a silane coupling agent KH-550, nano silicon dioxide, hollow glass microspheres, mixed powder, pigment, a dispersing agent, a coalescing agent, a flatting agent, a defoaming agent and deionized water. According to the invention, the mixed powder is connected with epoxy resin through a bridge, namely, the silane coupling agent KH-550, thus the epoxy resin which originally has very good corrosion resistance has very good ultraviolet resistance, and the aging rate of a coating film due to irradiation of sunlight can be remarkably reduced, and the service life of thecoating is effectively prolonged; and under the combined action of the polytetrafluoroethylene emulsion and the modified epoxy resin, the aging resistance of the coating is obviously improved.

Owner:GUANGZHOU JIAJIE MACHINERY EQUIP

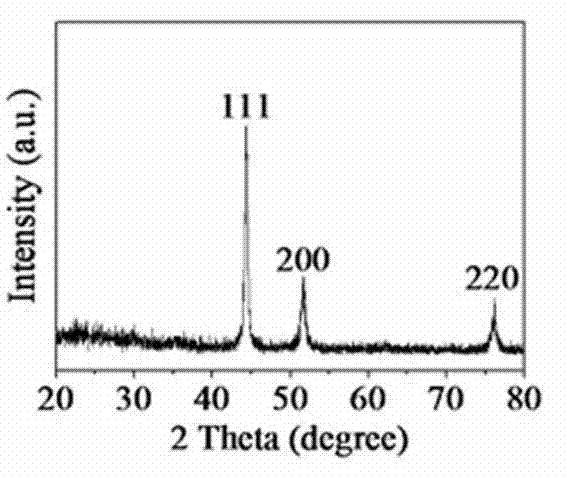

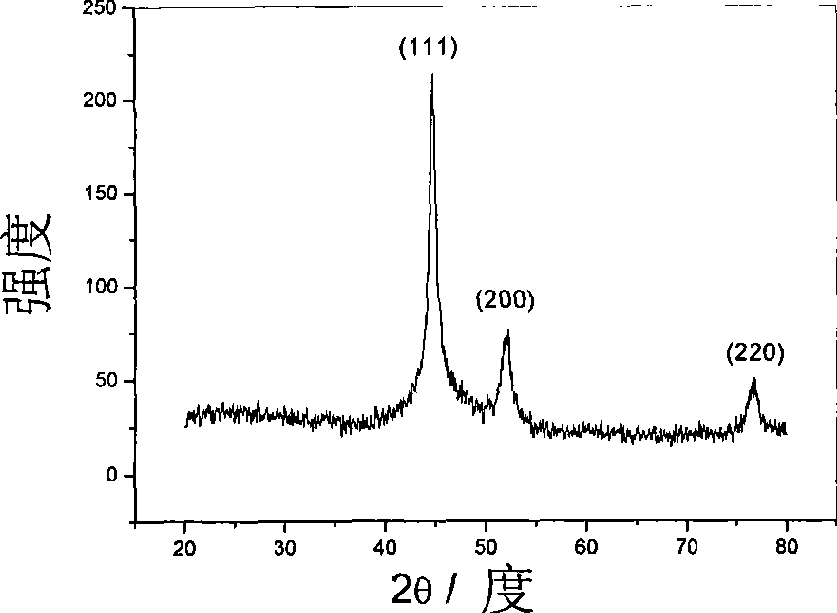

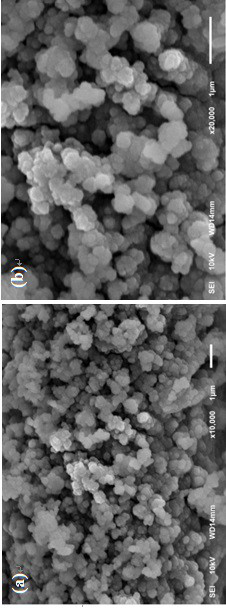

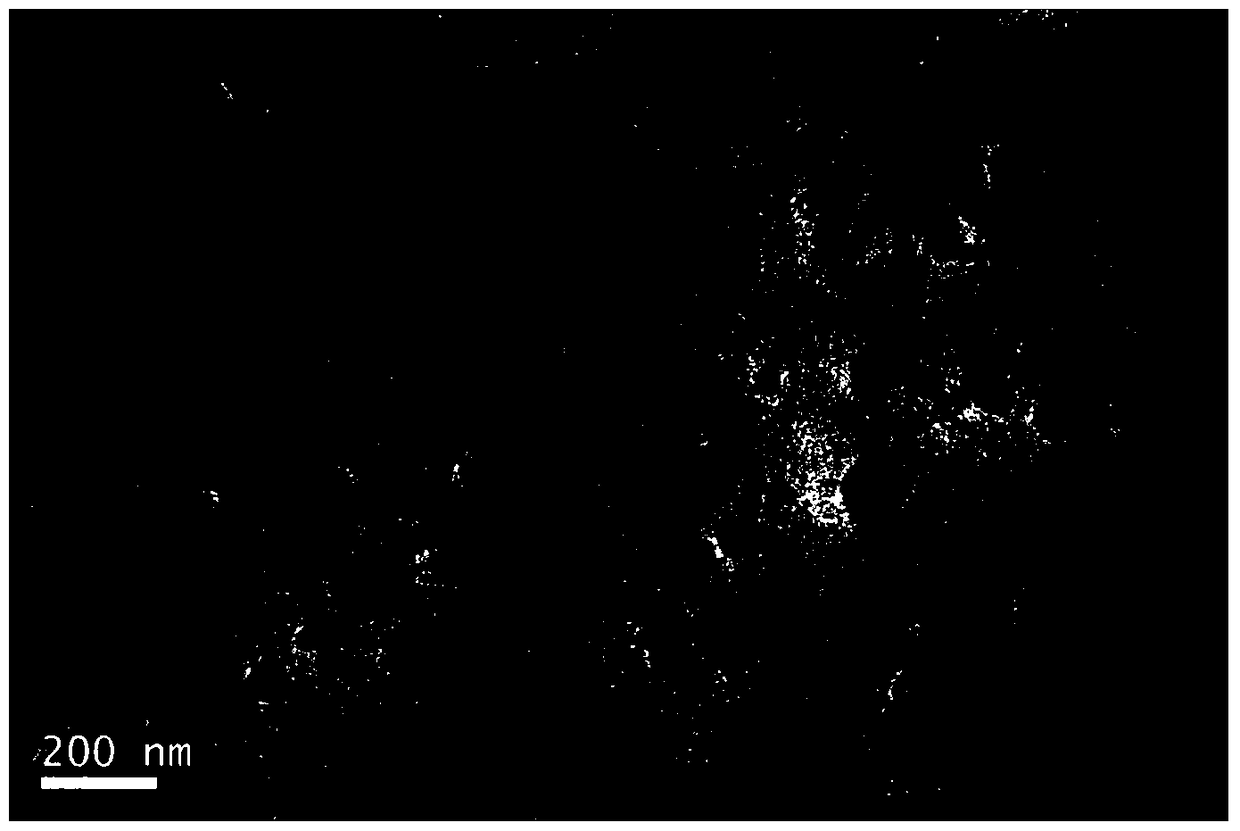

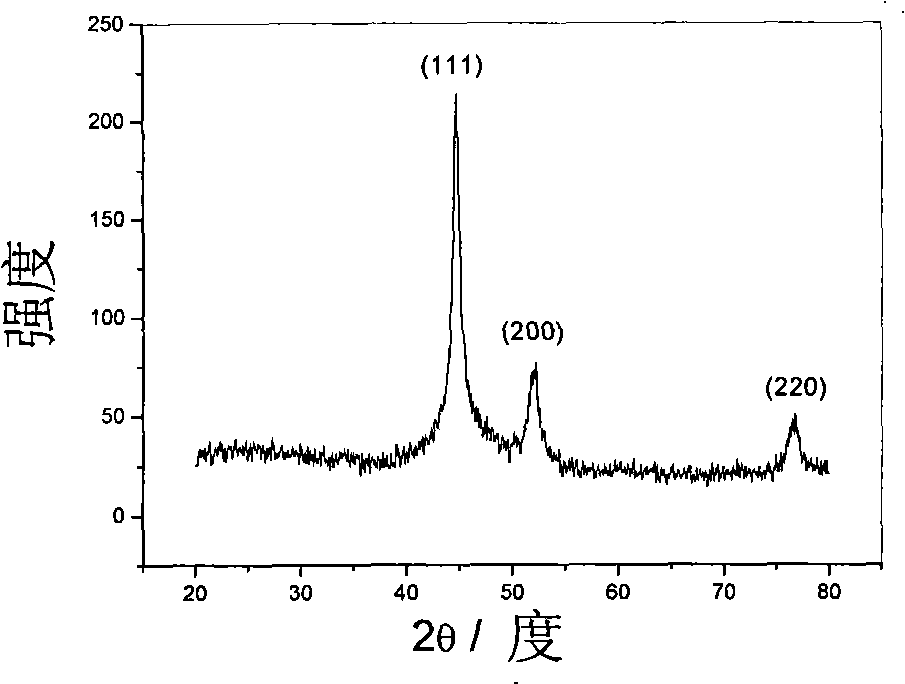

Method for producing nano nickle sphere

The invention relates to a method for preparing a nanometer nickel pellet with magnetic property. Nickel dichloride, polyvinylpyrrolidone, potassium hydroxide and sodium hypophosphite are dissolved in water respectively; a nickel dichloride solution and a potassium hydroxide solution are mixed, are introduced with nitrogen gas, then added with a sodium hypophosphite solution and continuously kept in a nitrogen introducing state for 10 minutes; the mixed solution is transferred to an inner tank of a hydrothermal kettle with cubage of 15 ml and is continuously introduced with nitrogen gas for protection; the hydrothermal kettle is sealed; the mixed solution reacts for 40 to 60 minutes at a temperature of between 130 and 150 DEG C; and an obtained product is washed by water and ethanol respectively, subjected to magnetic separation and is dried to obtain the nanometer nickel pellet with the magnetic property. The nanometer nickel pellet is subjected to characteristic representation through x ray diffraction (XRD), a transmission electron microscope (TEM) and a scanning electron microscope (SEM); the result shows that the particle diameters of a series of prepared nanometer nickel pellets are between 100 and 500 nanometers; and the particle diameter is relevant to reaction temperature, PH value, dosage of a reducer, reaction time and an added surfactant.

Owner:NANJING UNIV

Electrode and preparation method of electrode material

InactiveCN105789550AImproved pore size distributionIncrease surface areaElectrode thermal treatmentFiberCellulose acetate

The invention discloses an electrode and a preparation method of an electrode material. The preparation method of the electrode material includes the steps: putting a dried filter tip into solution of one of vanadium dichloride, lead dichloride, tungsten dichloride and nickel dichloride or solution of at least two of the vanadium dichloride, lead dichloride, tungsten dichloride and nickel dichloride mixed according to an arbitrary proportion, and soaking the dried filter tip in the solution under the circumstance of ultrasonic oscillation for 60-120 minutes; taking out the filter tip from the solution, subjecting the filter tip to drying prior to high temperature carbonization to enable cellulose acetate fibers to form a porous layered carbon material of a micropore structure, respectively generating metallic fine particles and corresponding metallic oxide fine particles, evenly distributing the metallic fine particles and the metallic oxide fine particles in surface micropores of the porous layered carbon material or between folds among layers of the layered carbon material to obtain the carbonized material for making the electrode. The electrode material has excellent electrochemical performance, and is low in cost and beneficial to energy conservation and environmental protection.

Owner:熊菊莲

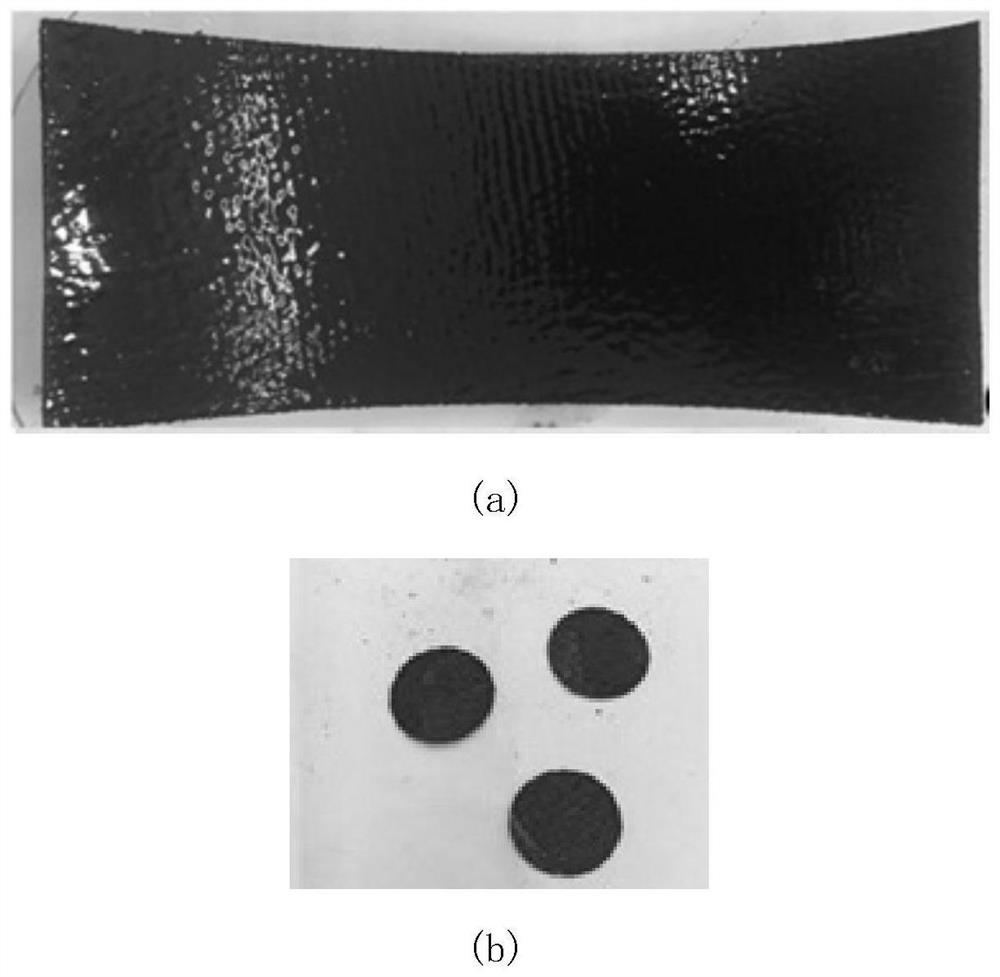

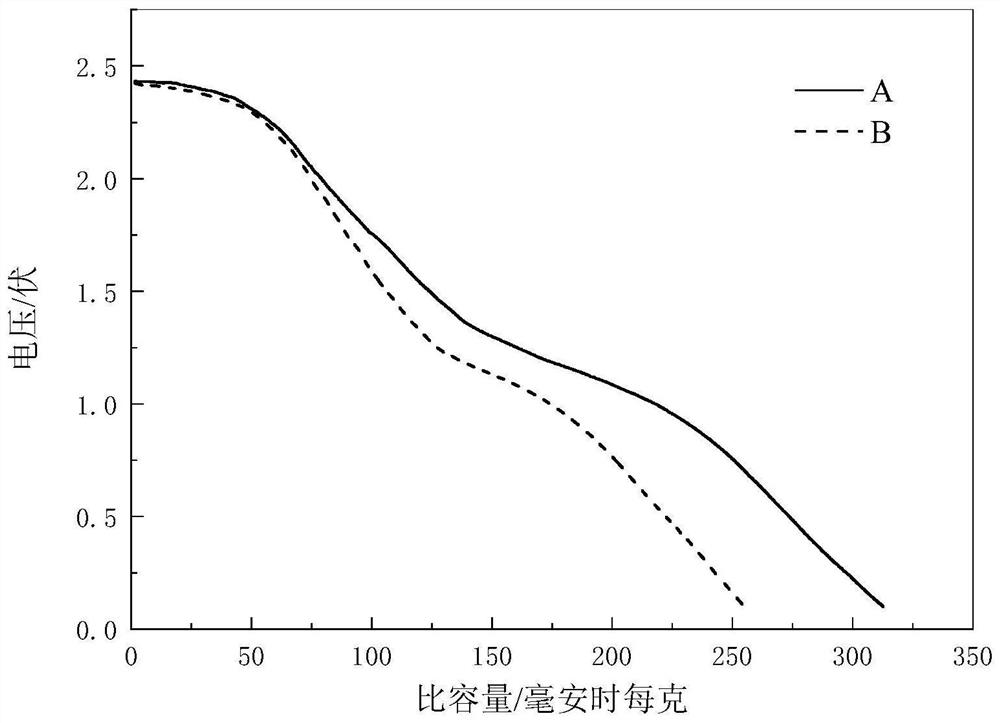

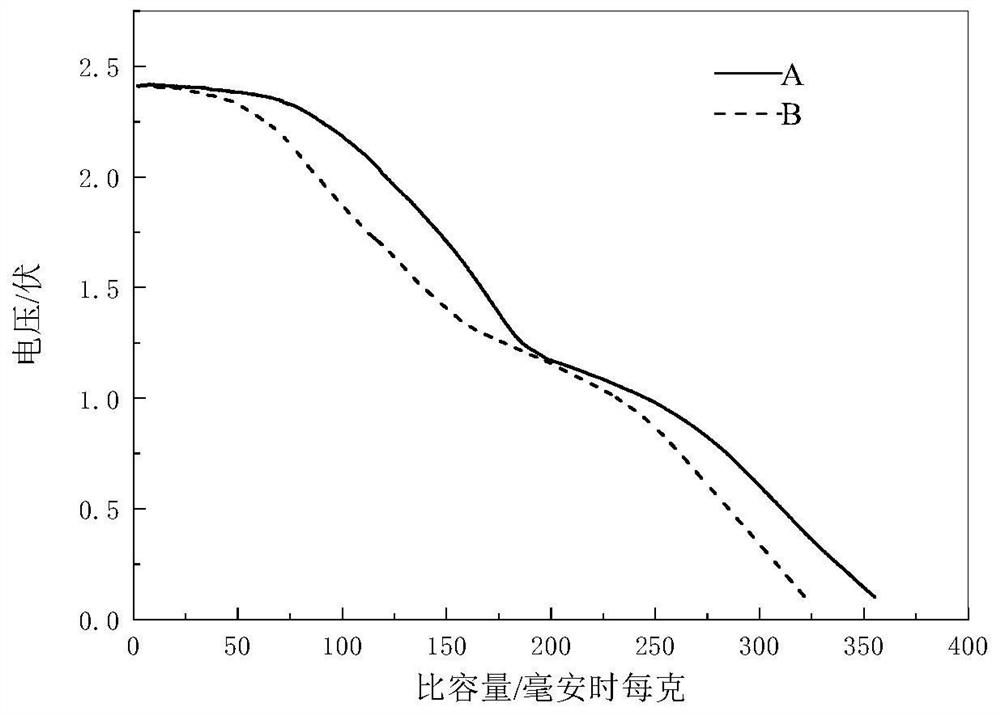

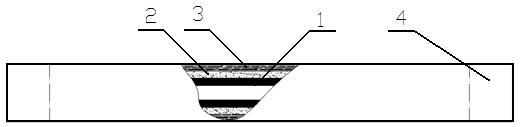

Thermal battery nickel dichloride positive electrode film material and preparation method thereof

InactiveCN112234162AReduce thicknessEasy to shapeDeferred-action cellsPrimary cell electrodesScreen printingElectrical battery

The invention provides a thermal battery nickel dichloride positive electrode film material and a preparation method thereof, which belong to the technical field of thermal battery film electrodes. The preparation method comprises the following steps: uniformly mixing nickel dichloride, an electrolyte, a conductive agent and a binder according to a certain mass ratio, adding a certain amount of absolute ethyl alcohol, and adjusting the viscosity of the mixture to obtain paste with certain viscosity; and uniformly adsorbing the paste mixture to the surface of a matrix by silk-screen printing, and putting the matrix covered with the active substance into a vacuum drying oven for vacuum drying to obtain the thermal battery film positive electrode. The thermal battery film positive electrode provided by the invention overcomes a plurality of defects caused by an existing powder tabletting preparation process of a thermal battery electrode, easily realizes preparation of a large-area or irregular-shaped electrode slice, simplifies the electrode preparation process, improves productivity, reduces cost, improves stability and discharge performance of a battery, has relatively high industrial application value, and has good application prospects.

Owner:SHENYANG LIGONG UNIV

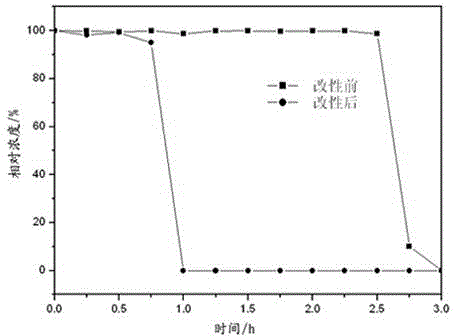

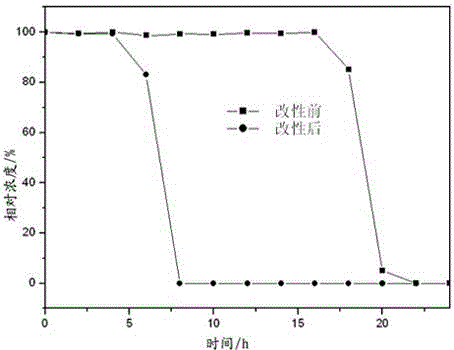

Modified nanometer titanium dioxide photocatalyst, and preparation method and application thereof

InactiveCN104128208AAvoid pollutionGood effectWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsHigh concentrationDiethyl ether

The invention provides a modified nanometer titanium dioxide photocatalyst and a preparation method and application thereof. The preparation method comprises the following steps: 1) adding nanometer TiO2 powder in a reactor filled with CCl4, adding a CCl4 solution of PCl3 at 80 DEG C, carrying out a reaction at 90 DEG C for 2 to 4 h and removing CCl4 to obtain powder I; 2) preparing 4-sodium sulfonate-phenylalkyl sodium sulfonate; 3) preparing 4-sodium sulfonate-phenyl-brominated alkyl sodium sulfonate; and 4) pouring treated metallic magnesium into a reactor filled with anhydrous ether, adding the product obtained in the step 3 until magnesium is fully reacted, adding bis(1,3-dibenzylphosphine)propyl nickel dichloride and the product obtained in the step 1), carrying out reflux for 15 to 20 h and carrying out treatment so as to obtain a finished product. The modified nanometer titanium dioxide photocatalyst is separated and recovered after degradation of high-concentration benzene-series pollutants, and the photocatalyst still has high catalytic activity after usage a plurality of times; after the photocatalyst is used 7 times, the degradation efficiency of the photocatalyst to high-concentration and hardly degradable benzene series reaches 100% in 8.0 h.

Owner:XUZHOU UNIV OF TECH

Electrode and preparation method of electrode material

InactiveCN105762344AImproved pore size distributionIncrease surface areaCell electrodesFiberWrinkle skin

The invention discloses an electrode and a preparation method of an electrode material.The preparation method of the electrode material includes the steps that cellulose acetate fibers are put into a solution of one of vanadium dichloride, lead dichloride, tungsten dichloride and nickel dichloride or a solution obtained by mixing any two of vanadium dichloride, lead dichloride, tungsten dichloride and nickel dichloride according to any proportion, and are soaked in the solution for 60-120 min in an ultrasonic oscillation environment; the cellulose acetate fibers are taken out of the solution, dried and then subjected to high-temperature carbonization treatment to form a porous layered carbon material with a micropore structure, fine metal particles and corresponding fine metal oxide particles are generated and uniformly distributed in surface micropores of the porous layered carbon material or between wrinkles between layers of the layered carbon material, and the carbonized composite material for manufacturing the electrode is obtained.The electrode material has good electrochemical performance and is low in cost.

Owner:熊菊莲

Aluminum profile surface pretreatment process

The invention discloses an aluminum profile surface pretreatment process. The aluminum profile surface pretreatment process comprises the following steps: (S01) degreasing, namely placing a to-be-treated aluminum profile in circularly-flowing degreasing liquid, wherein the temperature of the degreasing liquid is 35 to 40 DEG C and the degreasing time is 0.5 min to 3 min in a treatment process; (S02) performing alkaline soaking, namely soaking the aluminum profile in pre-treating liquid for 1 s to 2 s, wherein the pre-treating liquid consists of the following components: 15 wt% to 20 wt% of sodium hydroxide, 5 wt% to 10 wt% of sodium nitrate, 5 wt% to 10 wt% of sodium phosphate, 2 wt% to 3 wt% of anhydrous nickel dichloride and the balance of water, and the temperature of the pre-treating liquid is 90 to 95 DEG C; (S03) performing primary corrosive washing, namely stewing the aluminum profile which is subjected to the primary corrosive washing in primary corrosive washing liquid; and (S04) performing secondary corrosive washing, namely placing the degreased aluminum profile in circularly-flowing secondary corrosive washing liquid. The aluminum profile surface corrosive washing process provided by the invention is simple, feasible, low in cost and capable of being stably used for a long time; moreover produced waste water and waste liquid can be treated quietly easily, and the influences on the environment are small. The aluminum profile surface pretreatment process disclosed by the invention is especially applicable to an aluminum profile of which the surface pollution is relatively serious and an oxidation film is larger than 0.2 mm in thickness.

Owner:FOSHAN CITY GAOMING GAOSHENG ALUMINUM CO LTD

Norbornene, octafluorocyclopentene and tetrafluoroethylene ternary polymerized catalyst and ternary polymerization method

The invention relates to a norbornene, octafluorocyclopentene and tetrafluoroethylene ternary polymerized catalyst and a ternary polymerization method. The norbornene, octafluorocyclopentene and tetrafluoroethylene ternary polymerized catalyst is characterized in that a preparation method of the catalyst comprises steps as follows: bis(triphenylphosphine)nickel dichloride, alkoxy aluminum and a ligand compound are dissolved in a first solvent in a dry glass bottle with an inert gas atmosphere, the glass bottle is sealed and placed at a constant temperature of 20-50 DEG C for 15-40 min, and a nickel-aluminum complex catalyst is obtained, wherein the mole ratio of bis(triphenylphosphine)nickel dichloride to the ligand compound is (1:8)-(8:1), the mole ratio of bis(triphenylphosphine)nickel dichloride to alkoxy aluminum is (1:20)-(20:1), alkoxy aluminum is selected from aluminum Isopropoxide and aluminum tert-butoxide. The raw materials of the catalyst are low in cost and easy to obtain, the catalyst can generate catalytic activity at a low temperature and catalyze norbornene, octafluorocyclopentene and tetrafluoroethylene ternary polymerization, the reaction temperature is low, the catalytic efficiency is high, a product is very easy to wash and separate, and the yield of a copolymer is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

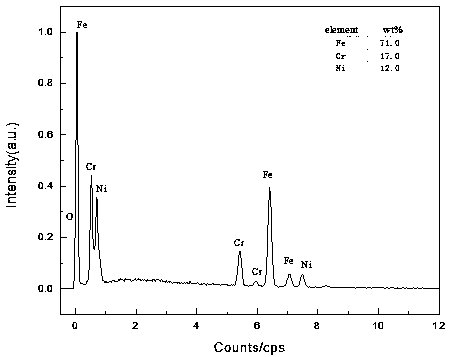

Electrodeposition preparation method of stainless steel coating by means of deep-eutectic solvent

The invention relates to an electrodeposition preparation method of a stainless steel coating by means of a deep-eutectic solvent and belongs to the technical field of surface engineering and surfacetreatment. The method comprises the steps that firstly, under an inert gas environment, quaternary ammonium salt and polyhydric alcohol are uniformly mixed to form the deep-eutectic solvent, then nickel dichloride hexahydrate, chromium trichloride hexahydrate and ferrous dichloride tetrahydrate are added into the deep-eutectic solvent, and deep-eutectic solvent electrolyte is obtained through preparation; and secondly, a chromium sheet or an inert electrode serves as an anode, a pretreated substrate serves as a cathode, under the conditions that the temperature of the deep-eutectic solvent electrolyte is controlled to be 50-80 DEG C, the bath voltage is controlled to be 0.6-1.2 V, and the distance between the anode and the cathode is controlled to be 1 cm, the anode and the cathode are subjected to electrodeposition for 30-90 min in the prepared deep-eutectic solvent electrolyte, the cathode substrate subjected to electrodeposition is flushed through acetone and distilled water and then dried, and then the coating containing the component of 304 or 316 stainless steel is obtained on the cathode substrate. The method aims at solving the problems that the existing stainless steel electroplating industry is low in current efficiency, and clean production is difficult to achieve.

Owner:KUNMING UNIV OF SCI & TECH

Lithium-lanthanum oxide coated lithium ion battery ternary positive material and preparation method thereof

InactiveCN110504433AGood electric cycle performanceHigh specific capacityCell electrodesSecondary cellsCharge dischargeLanthanum

The invention relates to the technical field of lithium ion battery ternary positive materials, and discloses a lithium-lanthanum oxide coated lithium ion battery ternary positive material and a preparation method thereof. The ternary positive material comprises the following formula raw materials: manganese chloride tetrahydrate, cobalt nitrate hexahydrate, nickel dichloride hexahydrate, ammoniawater, anhydrous lithium nitrate, anhydrous lithium carbonate and lanthanum chloride hexahydrate. According to the lithium-lanthanum oxide coated lithium ion battery ternary positive material and thepreparation method thereof, in LiMn0.35-55Co0.30-0.45Ni0.15-0.25O2 oxides, the LiCo oxide has good electrical cycling performance, the LiNi oxide has very high specific capacity, the LiMn oxide has high chemical stability, and the ternary oxide is small in NiLi mixing degree and high in electrochemical stability, so that the conductivity of the positive material is improved generally, and the charge-discharge cycle performance of a battery is improved; and a chemically inert lithium-lanthanum oxide coating layer suppresses an interface reaction between the positive material and electrolyte, avoids the loss of an LiMn0.35-55Co0.30-0.45Ni0.15-0.25O2 structure, and enhances the electrochemical stability of the positive material.

Owner:杭州语茵科技有限公司

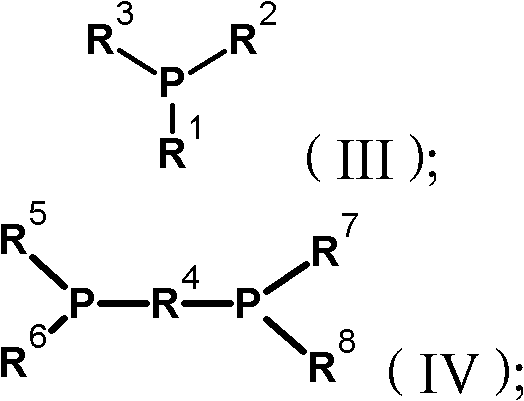

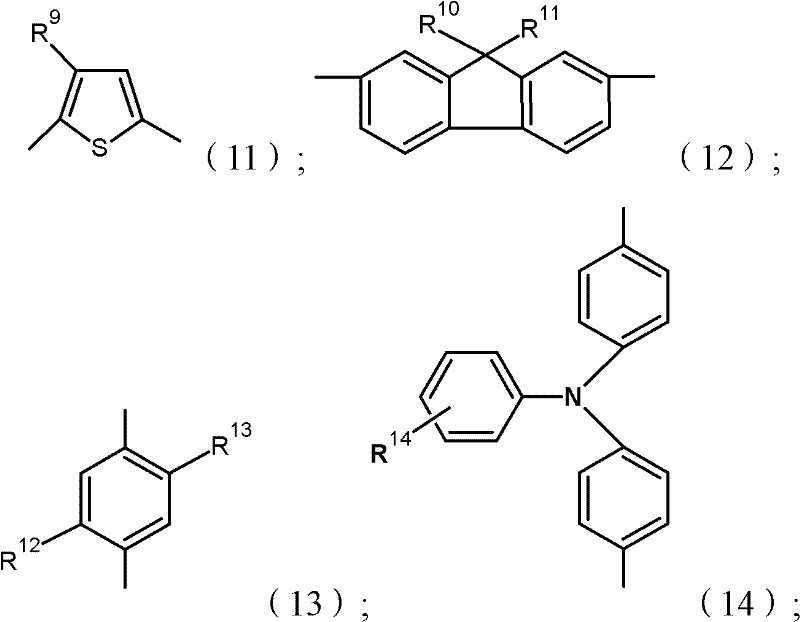

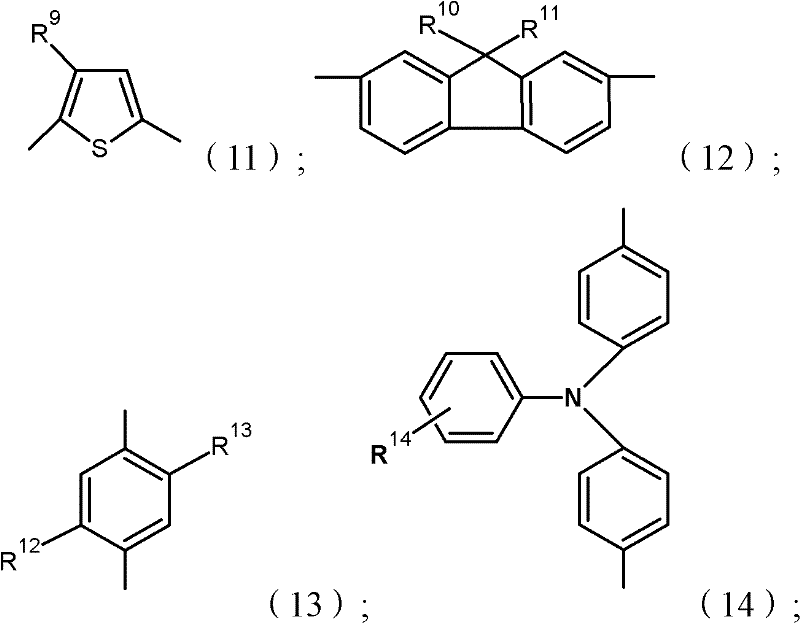

Preparation method of aromatic conjugated polymer

The invention provides a preparation method of an aromatic conjugated polymer, comprising the following steps of subjecting a first halogenated aromatic Grignard reagent monomer to polycondensation reaction under the catalysis of a catalyst to obtain the aromatic conjugated polymer. The catalyst comprises a nickelous compound and an organic phosphine ligand which are at the molar ratio of 1: (0.5-3), wherein the nickelous compound is nickel dichloride, nckel bromide, nickel acetylacetonate, nickel acetate or nickelous perchlorate. The first halogenated aromatic Grignard reagent monomer has the following structural formula (I): X1-Q1-MgX2 (I), wherein the X1 and the X2 are independently selected from halogen, and the Q1 is the aromatic base or substituted aromatic base. The catalyst provided by the invention is easy to prepare and can be well dissolved a solvent to lead to the polymerase chain reaction at the same time to obtain the aromatic conjugated homopolymer or aromatic conjugated block copolymer with controllable molecular weight and narrow molecular weight distribution.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

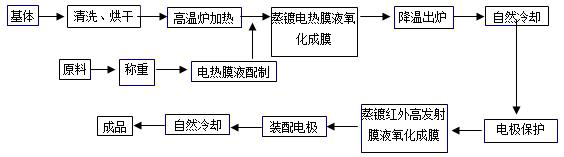

Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

InactiveCN102036433BReasonable ratioSimple preparation processHeater elementsHeating element shapesInfraredEvaporation

The invention discloses an infrared electric heating film heating device with a double-film layer structure, which structurally comprises an electric heating film substrate and electrodes arranged on the two ends of the electric heating film substrate, wherein an electric conduction film layer and an infrared high emission film layer are sequentially evaporated on the surface of the electric heating film substrate. A preparation method of the infrared electric heating film heating device comprises the steps of: sequentially evaporating the electric conduction film layer and the infrared high emission film layer to the electric heating film substrate by using a high-temperature evaporation furnace, wherein an electric heating film solution comprises the components in parts by weight: 45-58parts of stannic chloride, 0.3-2.0 parts of antimony butter, 0.4-1.2 parts of nickel trichloride, 0.3-1.0 part of indium chloride, 5-15 parts of ethanol / glycerol, 6-17 parts of inorganic acid, and 20-30 parts of deionized water, and an infrared high emission film solution comprises the components in parts by weight: 35-45 parts of manganous chloride, 15-20 parts of nickel dichloride, 5-10 parts of chromium trichloride, 5-15 parts of ethanol / glycerol and 20-30 parts of deionized water; and finally assembling the electrodes to obtain the infrared electric heating film heating device. In the invention, the double-film layer structure is adopted for the infrared electric heating film heating device, which can greatly enhance radiative heat transfer, reduce convection heat transfer, improve energy efficiency and save energy sources.

Owner:吕一诺

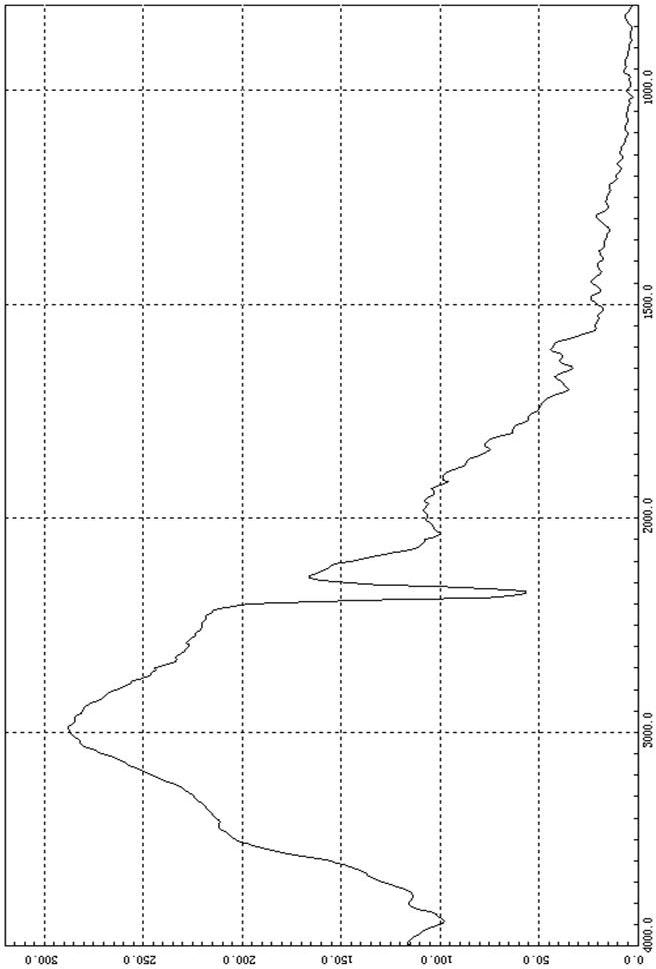

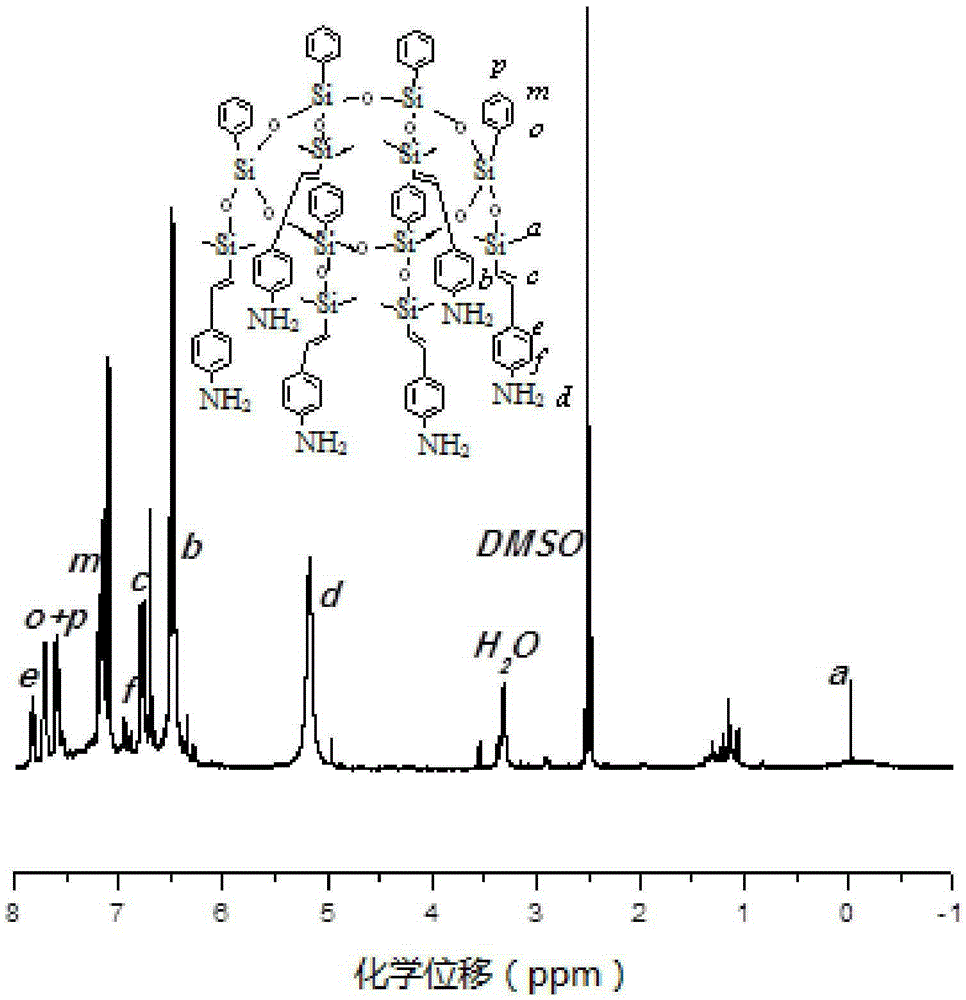

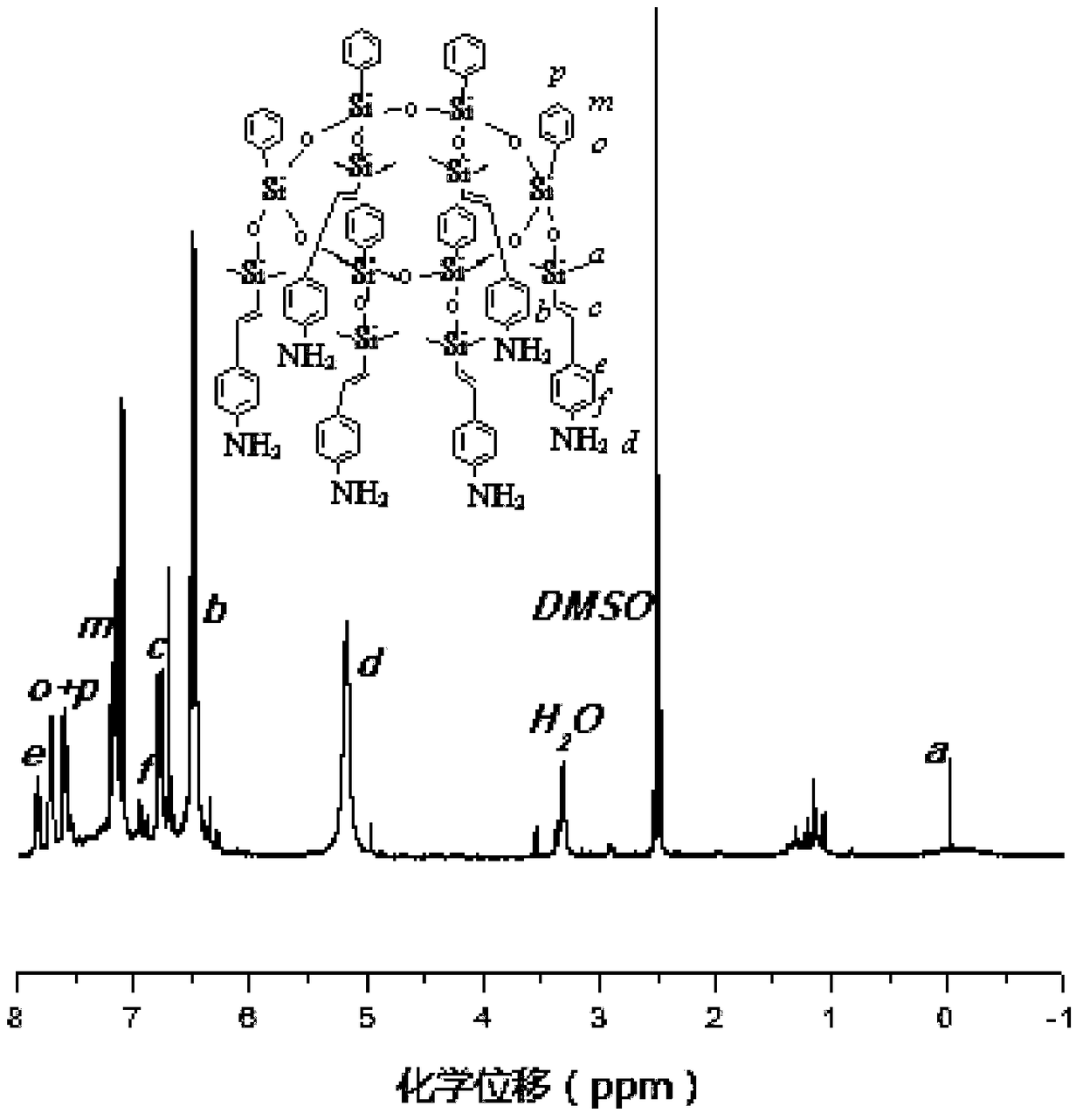

Synthetic method of hexamine phenyl large ring oligomerization silsesquioxane

ActiveCN105294750ALow dryness requirementImprove performanceGroup 4/14 element organic compoundsSilanesSilsesquioxane

The invention relates to a synthetic method of hexamine phenyl large ring oligomerization silsesquioxane. The method comprises the steps that silane, sodium hydroxide and hexamine nickel dichloride serve as raw materials for generating hex-nickel sodium silanolate through a reaction, then alkenyl-terminated large ring oligomerization silsesquioxane is generated through a reaction of hex-nickel sodium silanolate and alkenyl-terminated chlorosilane, then a coupling reaction is conducted through alkenyl-terminated large ring oligomerization silsesquioxane and bromo-arylamine compounds under the action of catalysts and coordination compounds, and the hexamine phenyl large ring oligomerization silsesquioxane is obtained. Compared with the prior art, The synthetic method is simple in synthesis step, mild in condition, good in controllability, short in cycle and high in yield, the obtained hexamine phenyl large ring oligomerization silsesquioxane can be used for modification of thermosetting resin or thermoplastic resin, and good application prospect is achieved.

Owner:SHANGHAI JIAO TONG UNIV

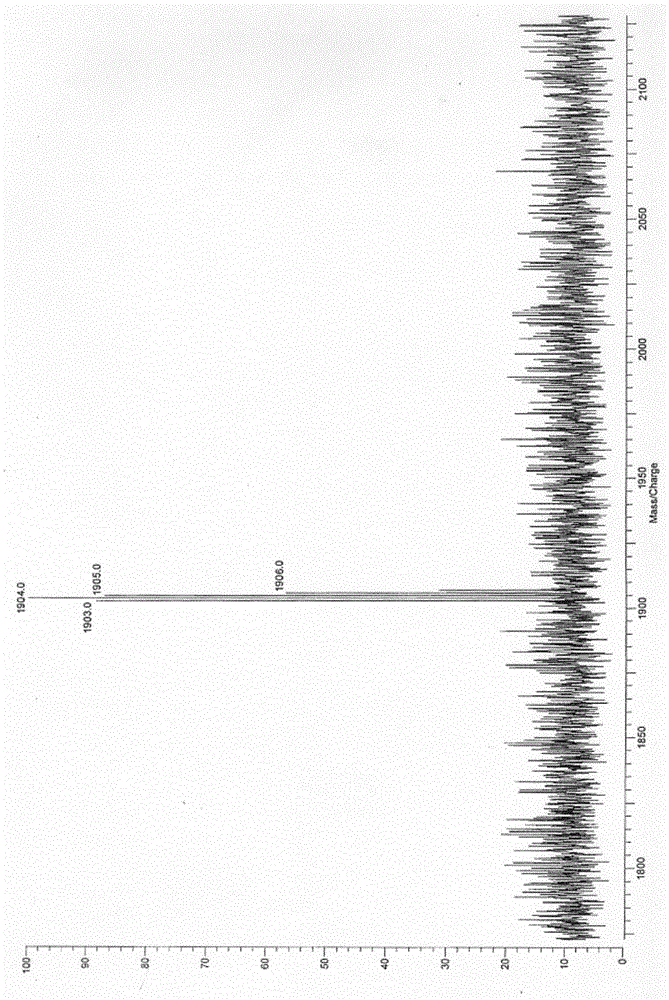

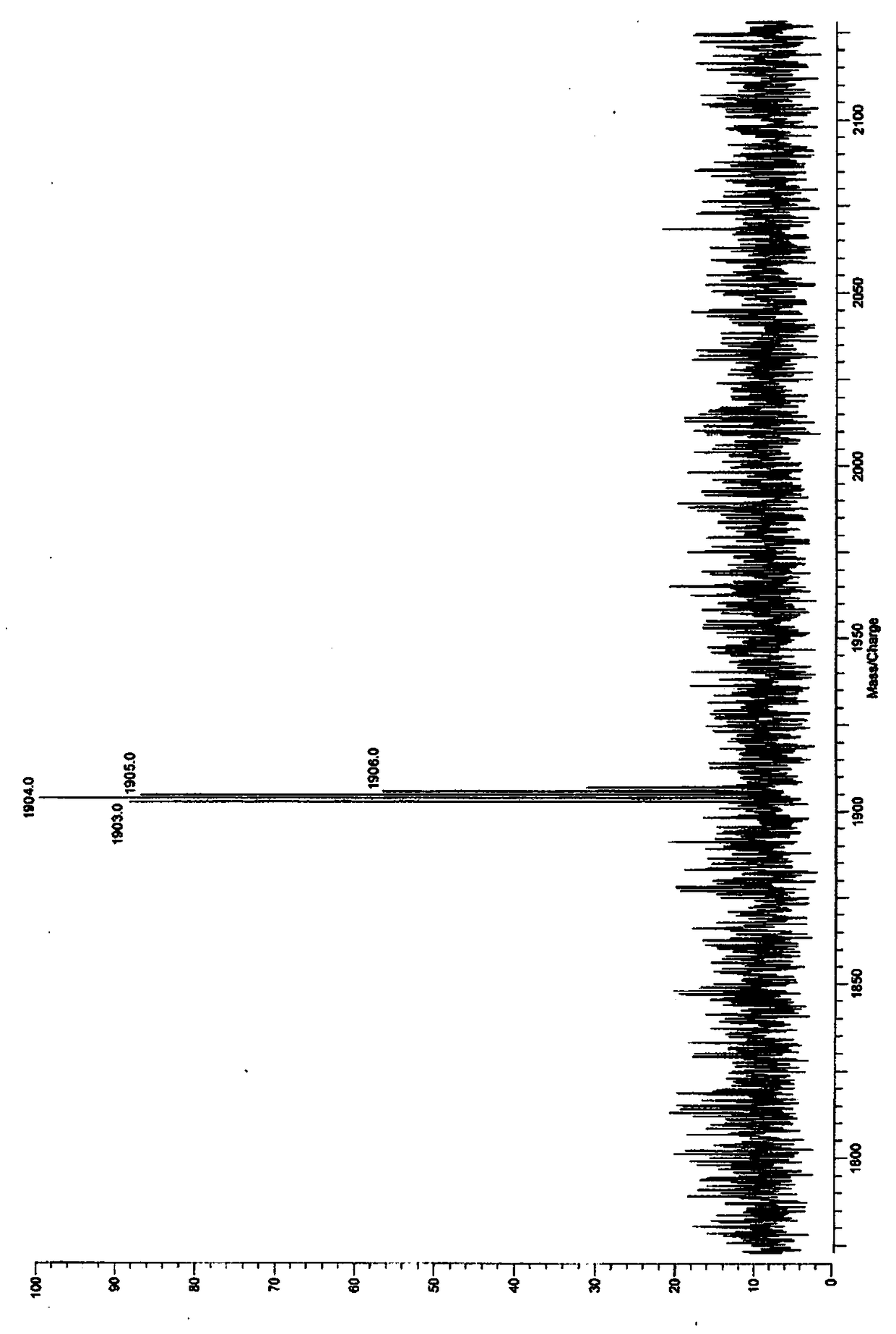

Organic metal borate of ferroelectric material and preparation method and application thereof

The invention discloses organic metal borate of a ferroelectric material and a preparation method and applications thereof. The molecular formula of borate is C8H34B10N6NiO20, the space group is C2(No.5), and the unit cell parameter is indicated as follows: alpha=gamma=90.00 degrees, belta=96.875 (10) degrees, Z=2 and unit cell volume V=1445.6(4) angstroms<3>; the ferroelectric material is prepared under the hydrothermal condition by in situ synthesis; reagents of nickel dichloride (NiCl2), boracic acid (H3BO3) and diethylenetriamine (C4H13N3) serve as raw materials, and water and pyridine are used as solvents; the ferroelectric material is applied to a pagination unit for storing and recovering information, transmitting optical information, displaying image and holography and is applied to storing holography of a ferroelectric light valve array.

Owner:GUANGDONG UNIV OF TECH

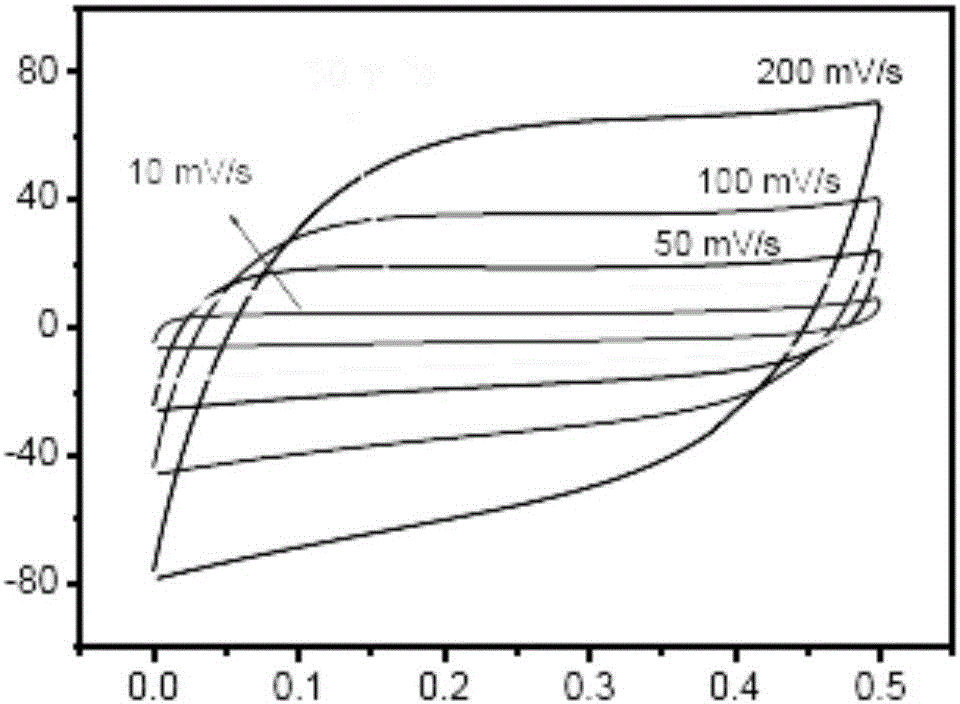

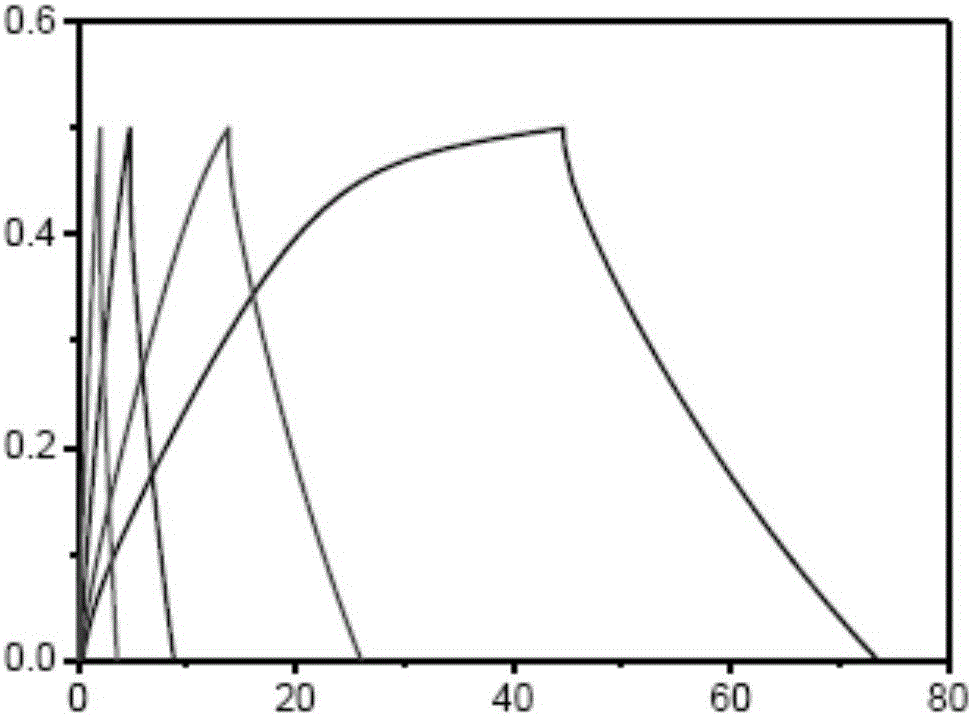

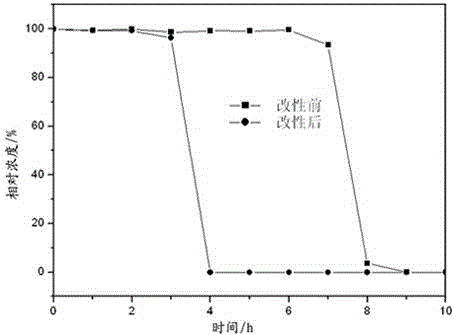

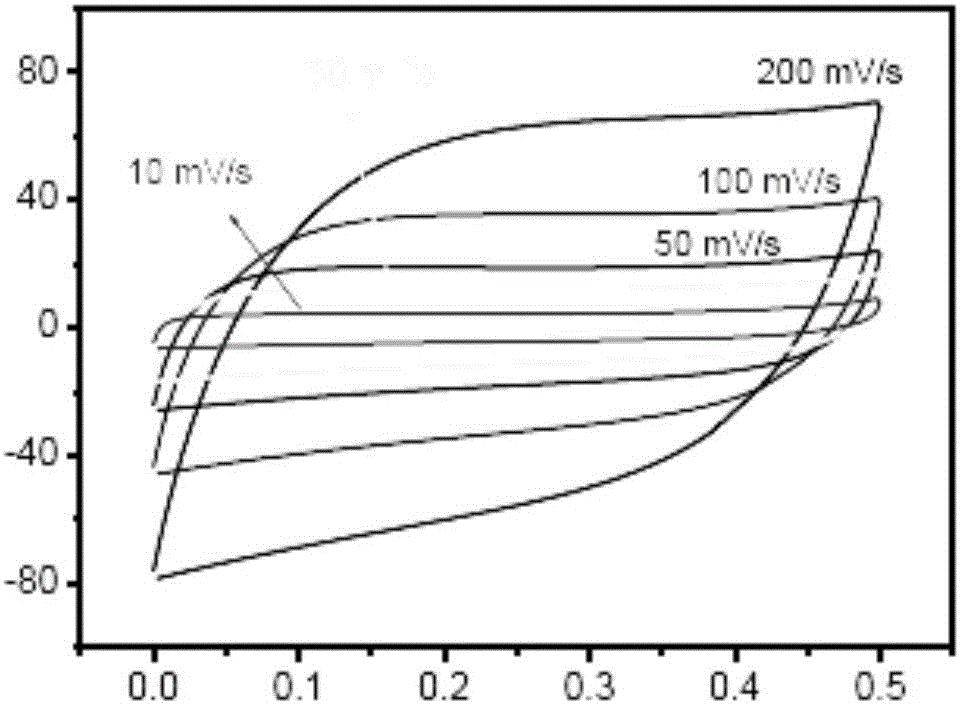

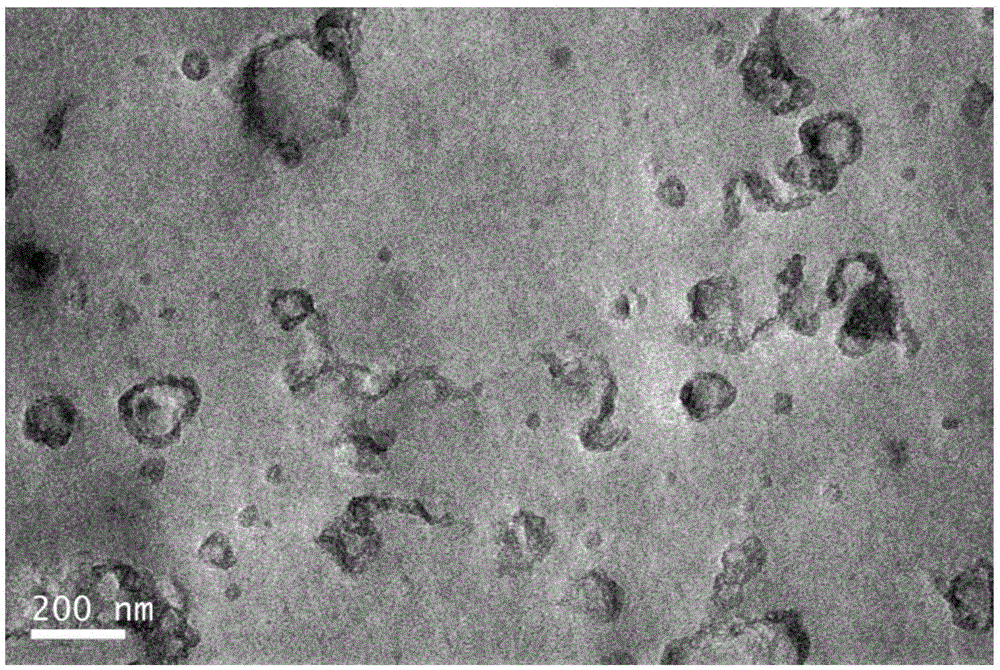

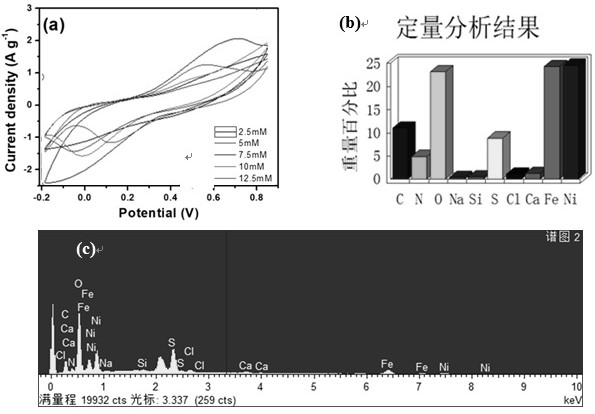

Method for preparing nickel-iron sulfide nano-composite electrode through one-step electrodeposition

PendingCN113793760AImprove cycle stabilityImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufactureCyclic voltametryCarbon fibers

The invention discloses a preparation method of a one-step electrodeposition nickel-iron sulfide nano-composite electrode. The preparation method comprises the following steps: pretreatment of carbon fiber cloth: cutting the carbon fiber cloth into patterns with uniform sizes, performing ultrasonic treatment in a mixed solution of acetone and ethanol for a period of time, washing and then immersing the cloth into a potassium permanganate solution for oil bath, and finally, washing and drying; preparation of electro-deposition liquid: co-depositing Ni-Fe-S electrochemically on the flexible carbon cloth with the woven carbon fiber structure, wherein the electro-deposition solution contains ferric trichloride hexahydrate, nickel dichloride hexahydrate with different concentrations and thiourea, and obtaining five compounds with different concentrations; electrochemical deposition: taking carbon cloth as a working electrode, taking Pt as a counter electrode, taking Hg / HgCl as a reference electrode, adopting a cyclic voltammetry method to carry out electrodynamic deposition in a three-electrode system, and carrying out cyclic voltammetry tests for many times at a certain scanning rate under a certain voltage range condition; washing the carbon cloth subjected to electro-deposition with a large amount of deionized water, drying the carbon cloth, and determining the mass load of Ni-Fe-S on the carbon cloth according to the mass difference of an electronic balance before and after electro-deposition.

Owner:IANGSU COLLEGE OF ENG & TECH

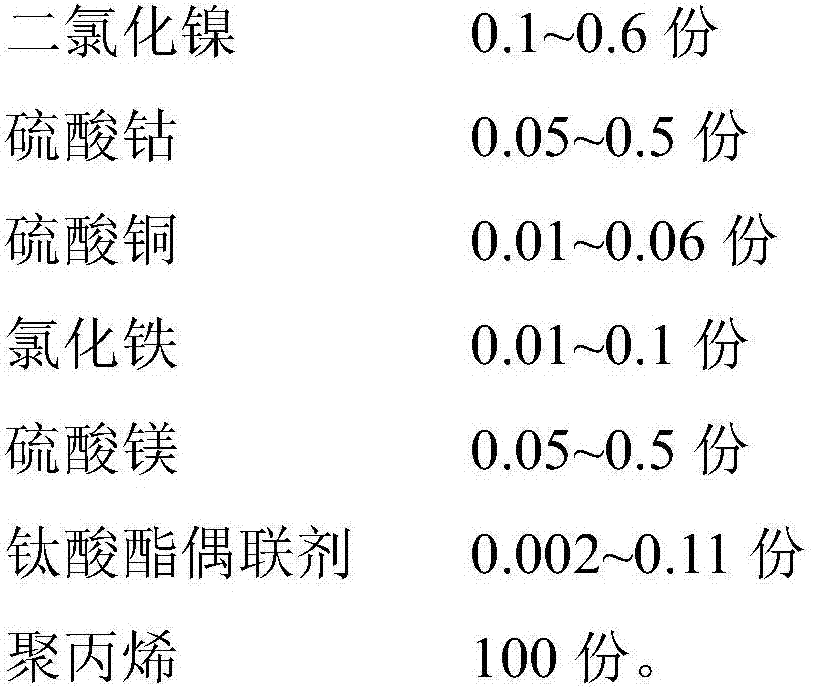

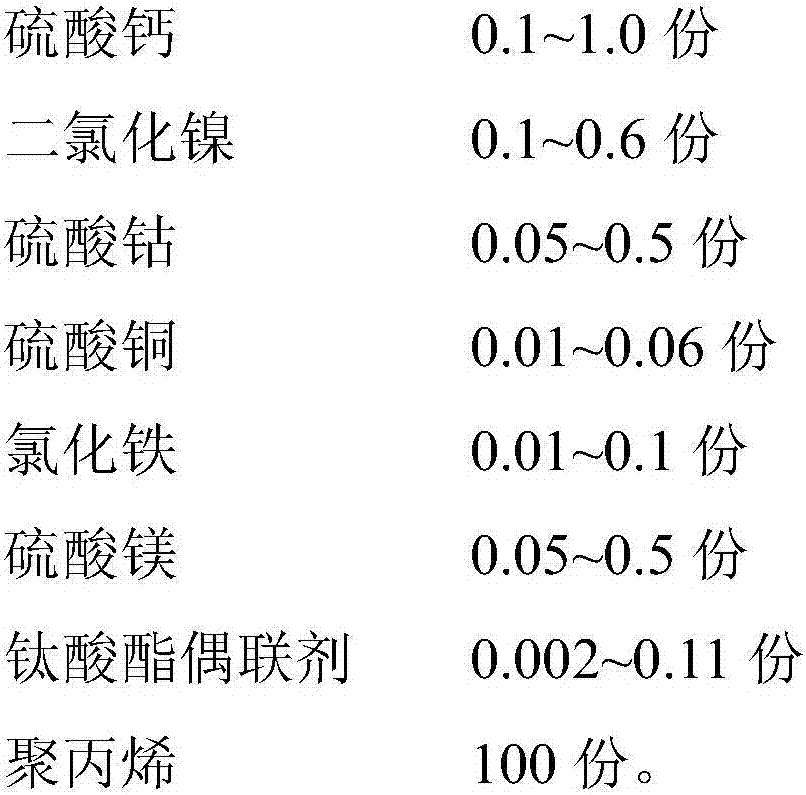

Compound biological filler and preparation method thereof

InactiveCN107162171AHang film fastHigh tensile strengthSustainable biological treatmentBiological water/sewage treatmentWater treatment systemChloride

The application relates to a compound biological filler and a preparation method thereof. The compound biological filler and the preparation method thereof comprises the following components in parts by weight: 0.1 to 1.0 part of calcium sulfate, 0.1 to 0.6 parts of nickel dichloride, 0.05 to 0.5 parts of cobalt sulfate, 0.01 to 0.06 parts of copper sulfate, 0.01 to 0.1 parts of ferric chloride, 0.05 to 0.5 parts of magnesium sulfate, 0.002 to 0.11 parts of titanate coupling agent and 100 parts of polypropylene. Biofilm formation on the compound biological filler is faster, so that the debugging of a sewage treatment system can be more quickly finished, and thereby the sewage treatment system can be more quickly put into operation. Moreover, both the tensile strength and impact strength of the compound biological filler are greatly increased in comparison with the tensile strength and impact strength of conventional biological fillers.

Owner:深圳市绿洲生态科技有限公司

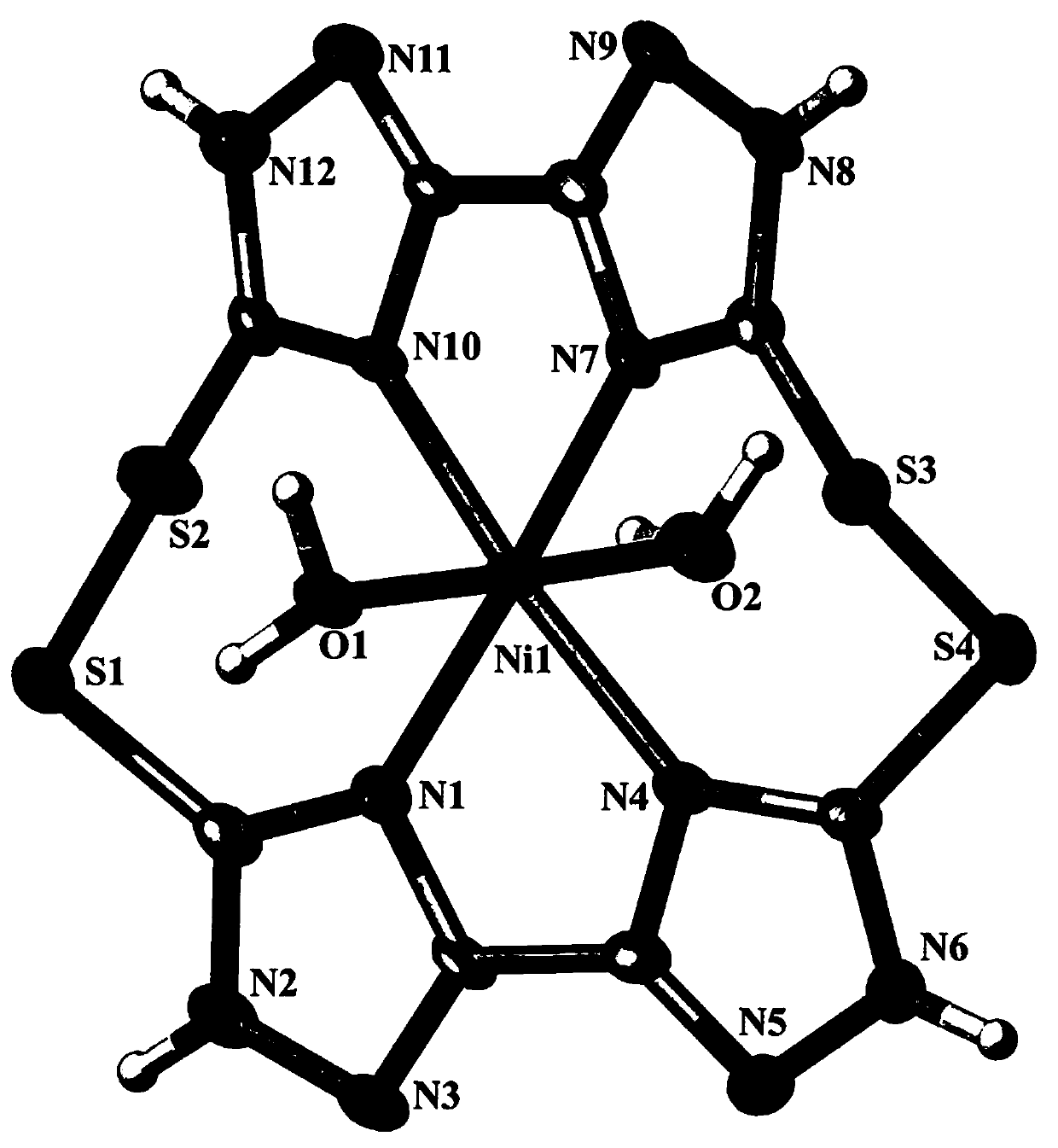

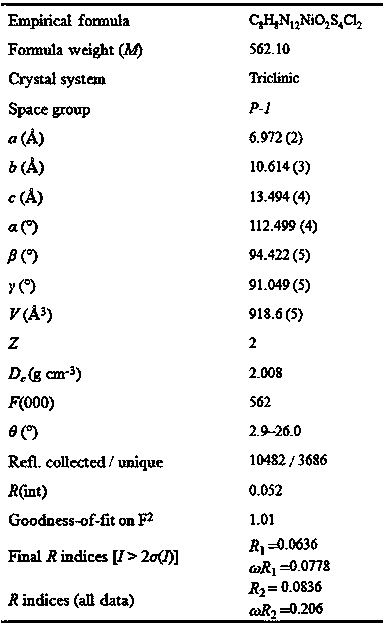

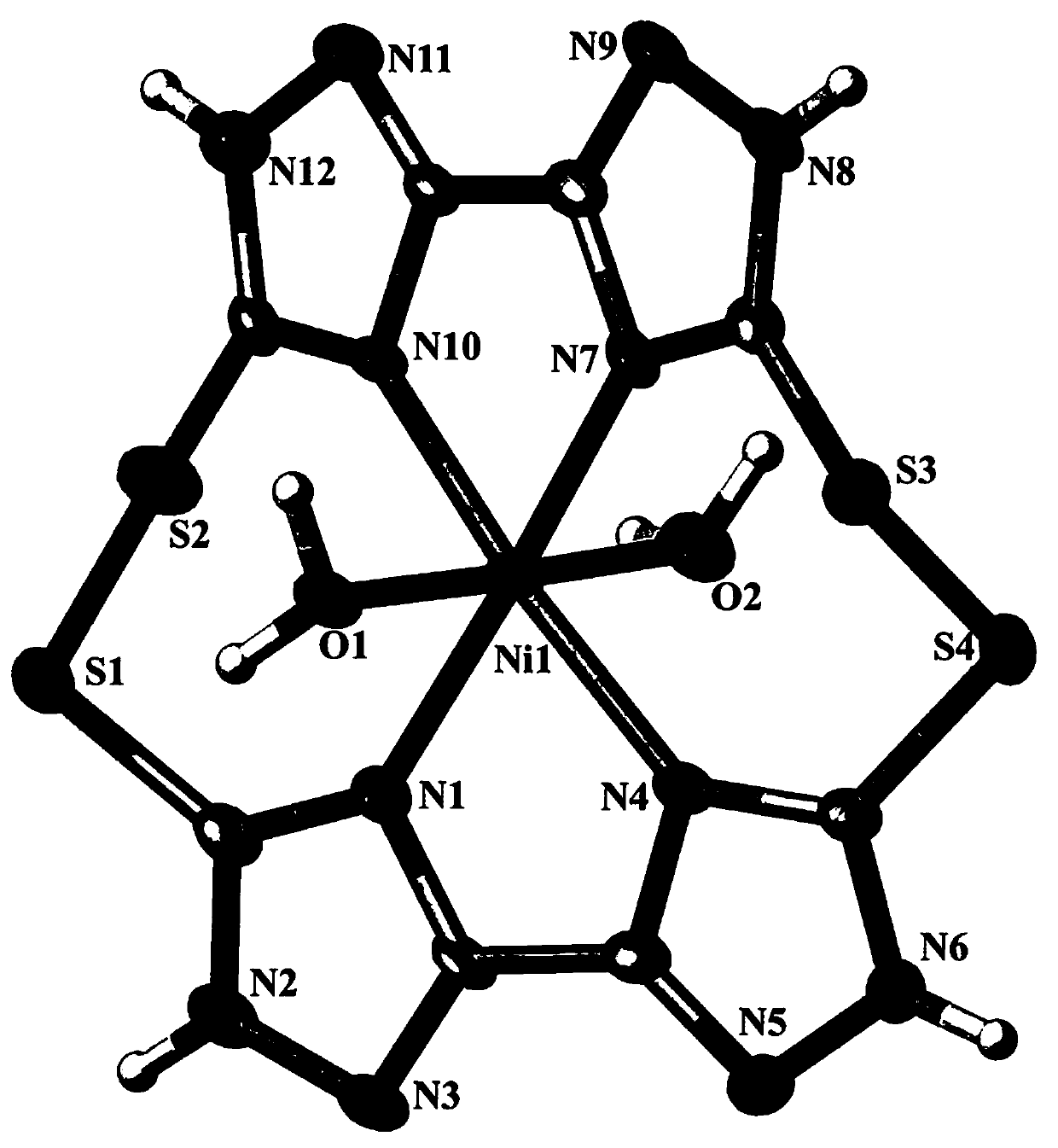

Sulfur-sulfur bond containing dipolymacrocyclic nickel (II) complex and in-situ synthesis method thereof

The invention discloses a sulfur-sulfur bond containing dipolymacrocyclic nickel (II) complex and an in-situ synthesis method thereof. The nickel complex has a chemical formula [Ni(H4L1)(H2O)2]*2Cl, in the formula, H4L1 is a macrocyclic ligand formed by two 3,3'-di(5-sulfydryl-1,2,4-triazole) through sulfur-sulfur bonds. The in-situ synthesis method of the nickel (II) complex comprises the following steps: (1) weighing 0.04-0.05g of 3,3'-di(5-sulfydryl-1,2,4-triazole) and 0.04-0.05g of hexahydrate nickel dichloride NiCl2*6H2O, adding 3-5mL of methanol and 5-7mL of 1,4-dioxane, and stirring toenable the mixed liquid to react for 6-7 hours at the room temperature; (2) filtering the mixed liquid, putting filtrate into a flask, and naturally volatizing the filtrate at the room temperature, thereby obtaining a single crystal grade purple flaky crystal. The nickel (II) complex has potential application values in antibacterial, anti-tumor and medicine targeted release carriers, and the like,and the method has great application prospects in in-situ synthesis of sulfur-sulfur bond containing macrocyclic metallic complexes.

Owner:GUANGXI NORMAL UNIV

Pretreating method for improving brazing performance of stainless steel

InactiveCN102451941AExcellent brazeabilityHigh thermal conductivitySoldering apparatusPretreatment methodStain

The invention provides a pretreating method for improving the brazing performance of stainless steel. The method comprises the following steps of: (1) removing oil: wetting one of ethylene trichloride, acetic ether, acetone and butanone with absorbent cotton for wiping, removing oil stains, and wiping with a clean cotton fabric for 2-4 times; (2) soaking and activating: soaking and activating with 300-400 parts by weight of 98 percent sulfuric acid at the temperature of 65-85 DEG C for 1-2 minutes; and (3) activating and pre-plating: activating and pre-plating with a solution which comprises 20-200 parts by weight of hexahydrate nickel dichloride and 15-60 parts by weight of 37 percent sulfuric acid at the cathode treatment current density of 0.5-10 at the normal temperature for 2-4 minutes. Due to the adoption of the pretreating method, the brazing performance of stainless steel can be improved by plating proper metals, high-temperature oxidation is relieved, the heat conductivity and electric conductivity are increased, high adhesion is ensured, the stainless steel is more glossy, attractive and resistant to rusting and wear, and the electric conductivity, lubricating property, strength, heat resistance and weather resistance are improved.

Owner:张国斌

Preparation method of nickel-stannic oxide-zinc oxide composite thin film

InactiveCN109794254AEvenly dispersedHigh absorption strengthCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater bathsTin dioxide

The invention discloses a preparation method of a nickel-stannic oxide-zinc oxide composite thin film. The preparation method includes the steps that 1, in the presence of acid, nickel dichloride is dissolved in a n-butyl alcohol solution, so that a nickel dichloride solution is obtained, stannic oxide is dissolved in absolute ethyl alcohol, magnetic stirring is conducted fro 2-3 h under the condition of a water bath at the temperature of 60-70 DEG C, and therefore a stannic oxide solution is obtained; 2, the nickel dichloride solution and the stannic oxide solution are mixed and subjected toreflux for 2-5 h at the temperature of 70-90 DEG C, and therefore nickel-stannic oxide sol is obtained; 3, the nickel-stannic oxide sol is slowly added into zinc oxide sol, water-bath heating is conduced for 2-3 h at the temperature of 50-60 DEG C, and therefore nickel-stannic oxide-zinc oxide composite sol is obtained; 4, a cleaned carried is soaked into the nickel-stannic oxide-zinc oxide composite sol to be pulled 4-6 times, pulling speed is controlled to be 1-10 cm / min, every time pulling is ended, heat treatment is conducted for 5-10 min at the temperature of 80-100 DEG C, finally, heat treatment is conducted fro 10-60 min at the temperature of 450-600 DEG C, and accordingly the nickel-stannic oxide-zinc oxide composite thin film is obtained. The photocatalytic activity of the composite thin film is high.

Owner:范佳晨

Cobalt-nickel zeolite imidazolate framework-derived porous carbon for biomethane production

ActiveCN111041022BIncrease production capacityImprove conductivityMicroorganism based processesWaste based fuelPorous carbonMicrosphere

The invention relates to biomass energy utilization technology, and aims to provide a method for promoting the preparation of biomethane by porous carbon derived from cobalt-nickel zeolite imidazolate skeleton. Including: mixing the methanol solution of cobalt chloride, polyvinylpyrrolidone and dimethylimidazole, stirring vigorously, aging to obtain the cobalt zeolite imidazolate skeleton; washing, vacuum drying and grinding to obtain the cobalt zeolite imidazolate skeleton powder; dispersing in ethanol Then add nickel dichloride hexahydrate, and stir to form a cobalt-nickel zeolite imidazolate framework with an eggshell structure; place it in a tube furnace after vacuum drying, and carbonize it under nitrogen; obtain porous carbon microspheres containing cobalt-nickel nanoparticles; Cleaning with hydrofluoric acid, vacuum drying and grinding into powder to obtain porous carbon derived from cobalt-nickel zeolite imidazolate framework. The invention can effectively improve the biomethane production performance of the fermentation system, optimize the electron transfer performance of the system, increase the content of the electroactive extracellular polymer in the system, and strengthen the interspecies electron transfer mediated by the electron shuttle.

Owner:ZHEJIANG UNIV

Nickel-boron-antimony co-doped tin dioxide electrocatalytic anode and preparation method and application

ActiveCN107555548BImprove mechanical stabilityExtended service lifeWater contaminantsWater/sewage treatmentTin dioxidePhysical chemistry

The invention relates to a nickel-boron-antimony-co-doped stannic oxide electrical catalytic anode which is prepared by impregnating the surface of a porous titanium plate with an anode coating and calcining the same. The anode coating is prepared from the following components in parts by mole: 600-700 parts of citric acid, 100-200 parts of ethanediol, 100-150 parts of stannic chloride, 5-10 partsof antimony trichloride, 0.5-2 parts of nickel dichloride and 2-4 parts of boric acid. The anode provided by the invention aims to solve the problem that in the prior art, an electrical catalytic anode is high in price and short in service life. The nickel-boron-antimony-co-doped stannic oxide electrical catalytic anode is prepared by means of a method of impregnating a gel coat and calcining ata high temperature, and has the technical advantages of high catalytic activity and stability, low production cost and good phenol degrading effect.

Owner:HENAN UNIV OF SCI & TECH

Polycarbonate film for bags and suitcases

ActiveCN114479411AGood mechanical propertiesImprove heat resistancePolycarbonateDodecylsulfonic acid

A preparation method of the polycarbonate film comprises the following steps: 1) adding sepiolite into an aqueous solution of sodium dodecyl sulfate, then adding an aqueous solution of ferric chloride, pyrrole and ferric citrate, washing, drying, carrying out ball milling, and sieving with a 1000-mesh sieve to obtain sieved powder; 2) soaking the sieved powder in an aqueous solution of cerium trichloride and nickel dichloride, adding octadecyl trimethyl ammonium bromide, and calcining to obtain calcined powder; 3) soaking the calcined powder in an N, N-dimethylformamide solution of lipoic acid to form a mixture, and performing sealed heating, solid-liquid separation, washing and drying to obtain modified powder; and 4) carrying out melt blending on polycarbonate and the modified powder, carrying out extrusion granulation, and then carrying out injection molding and film drawing to form the polycarbonate film. The polycarbonate material prepared by the invention has good mechanical properties and certain heat resistance, the use effect of the polycarbonate body is obviously improved, the durability of the material is improved, and the use range of the film is widened.

Owner:株洲地博光电材料有限公司

Synthetic method of hexaaminephenyl macrocyclic oligomerized silsesquioxane

ActiveCN105294750BLow dryness requirementImprove performanceSilicon organic compoundsSilanesSilsesquioxane

Owner:SHANGHAI JIAOTONG UNIV

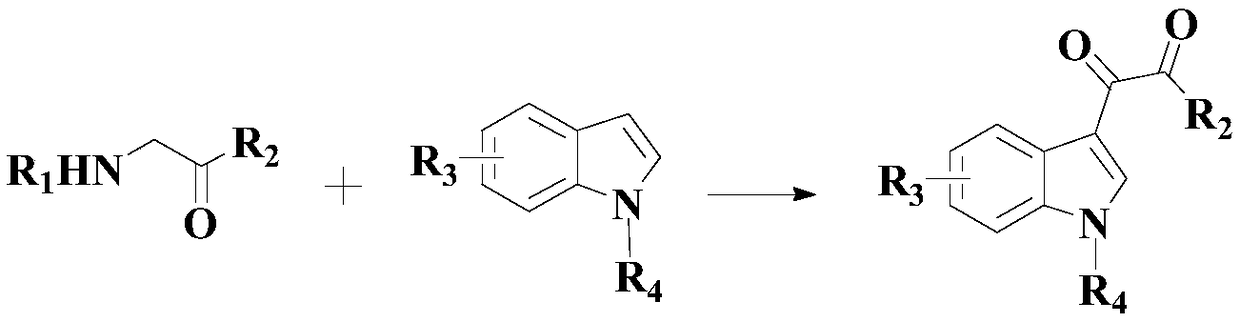

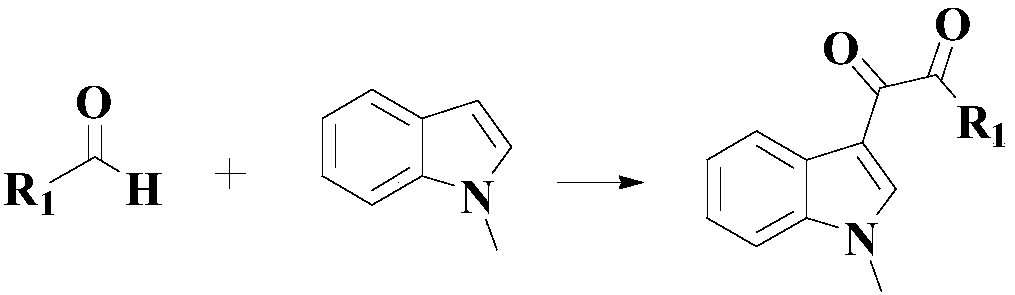

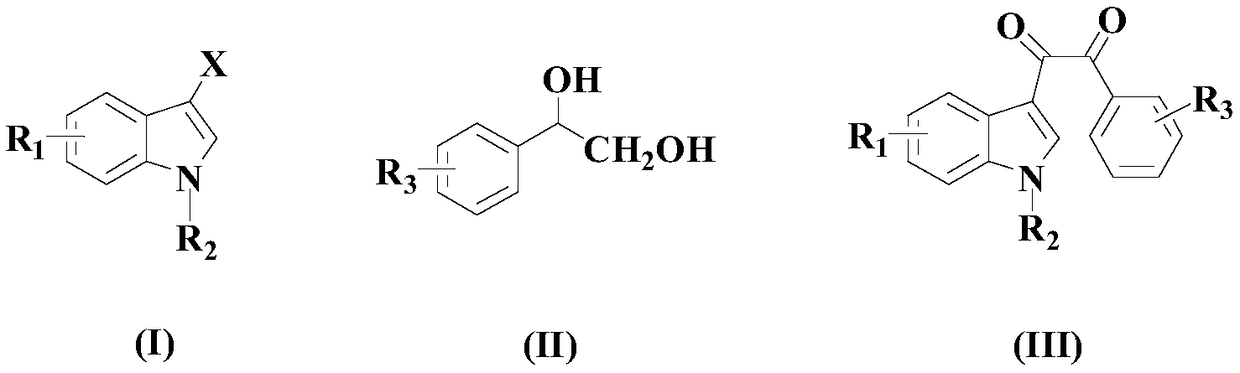

Synthetic method of diaryl-substituted dicarbonyl compound

InactiveCN108912033AHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChromatographic separationDistillation

The invention relates to a synthetic method of a diaryl-substituted dicarbonyl compound shown as the following formula (III), the equation is shown in the description, and the synthetic method specifically comprises the steps of adding 100 mmol of a compound shown as formula (I), 130 mmol of a compound shown as formula (II), 12 mmol of a catalyst (composed of 6 mmol of 1,3-bi(diphenylphosphine propane) nickel dichloride and 6 mmol of hexafluoroacetylacetone copper), 240 mmol of 2-iodoxybenzoic acid, 110 mmol of dimethylaminopyridine and 17 mmol od tetraphenylporphyrin, then stirring and heating to 90 DEG C, and stirring for reacting for 7 hours under 90 DEG C; after the reaction is finished, quenching the reaction with deionized water, filtering, washing the filter liquor sufficiently withdeionized water, extracting an organic phase for 2 to 3 times by using ethyl acetate, combining the organic phase and drying with anhydrous sodium sulfate, finally performing reduced pressure distillation to perform chromatographic separation on the obtained thick residue by a 300 to 400-mesh silicagel column, wherein an elution solvent is a mixture of acetone and chloroform with the volume ratioof 1 to 2, thus obtaining the compound of the formula (II).

Owner:方美兰

Method for producing nano nickle sphere

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com