Nickel-boron-antimony co-doped tin dioxide electrocatalytic anode and preparation method and application

A tin dioxide, electrocatalysis technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of short service life, expensive electrocatalytic anodes, etc. problems, to achieve the effect of long service life, good market prospects and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of nickel-boron-antimony co-doped tin dioxide electrocatalytic anode, the preparation steps are as follows:

[0037] Step 1. Boil the porous titanium sheet with concentrated hydrochloric acid (mass concentration: 37%) and water with a volume ratio of 1:2 for 10-20 minutes. After taking it out, transfer it to distilled water for ultrasonic cleaning for 5-10 minutes to obtain acid treatment. Porous titanium plate, spare;

[0038] Step 2. Take citric acid, ethyl Glycol, tin tetrachloride, antimony trichloride, nickel dichloride and boric acid are fully mixed, heated and dissolved at a temperature of 60~70°C until a molten gel is obtained, and set aside;

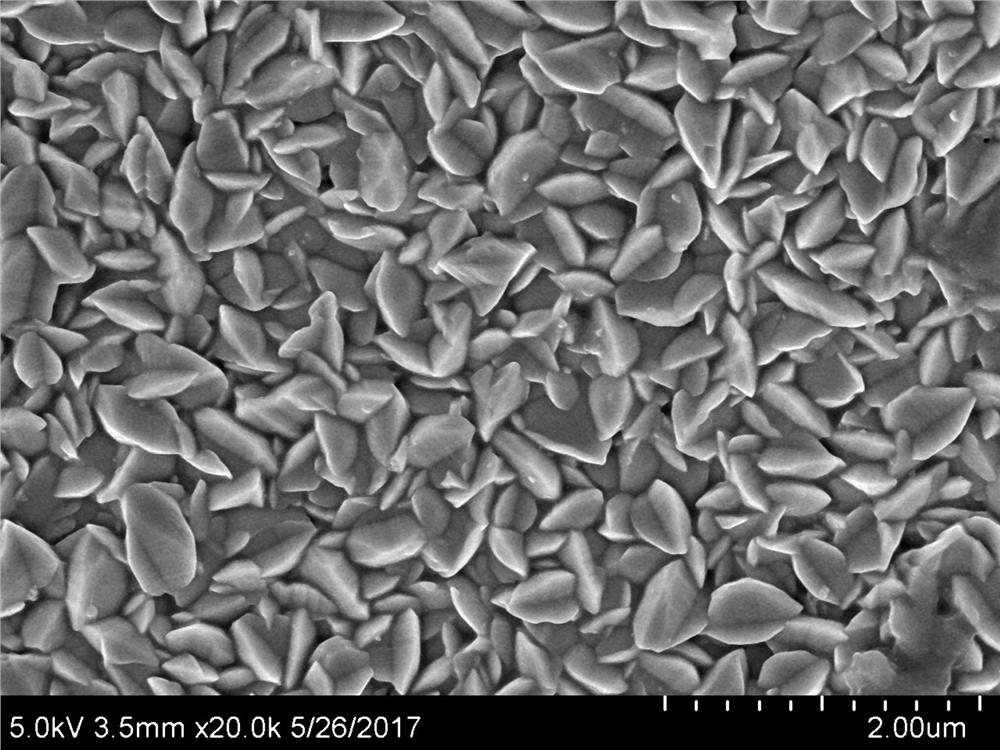

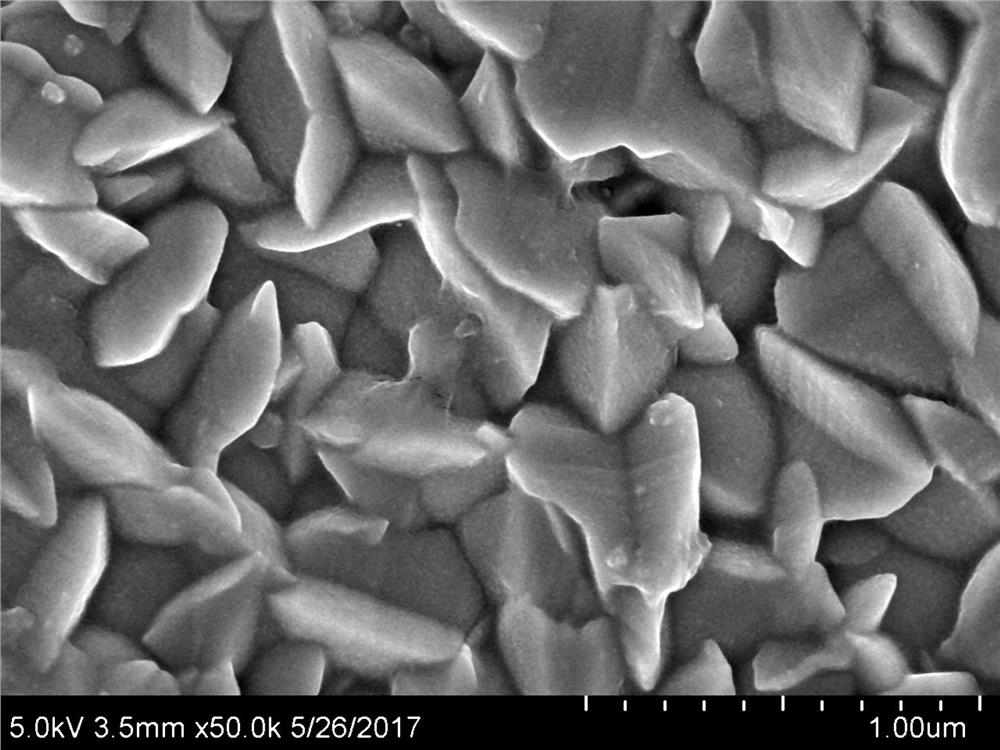

[0039] Step 3, using the impregnation method to load the molten gel prepared in step 3 on the acid-treated porous titanium plate prepared in step 2 to obtain a gel-loaded porous titanium plate, and then place the obtained gel-loaded porous titanium plate on Carry out calcining treatment in t...

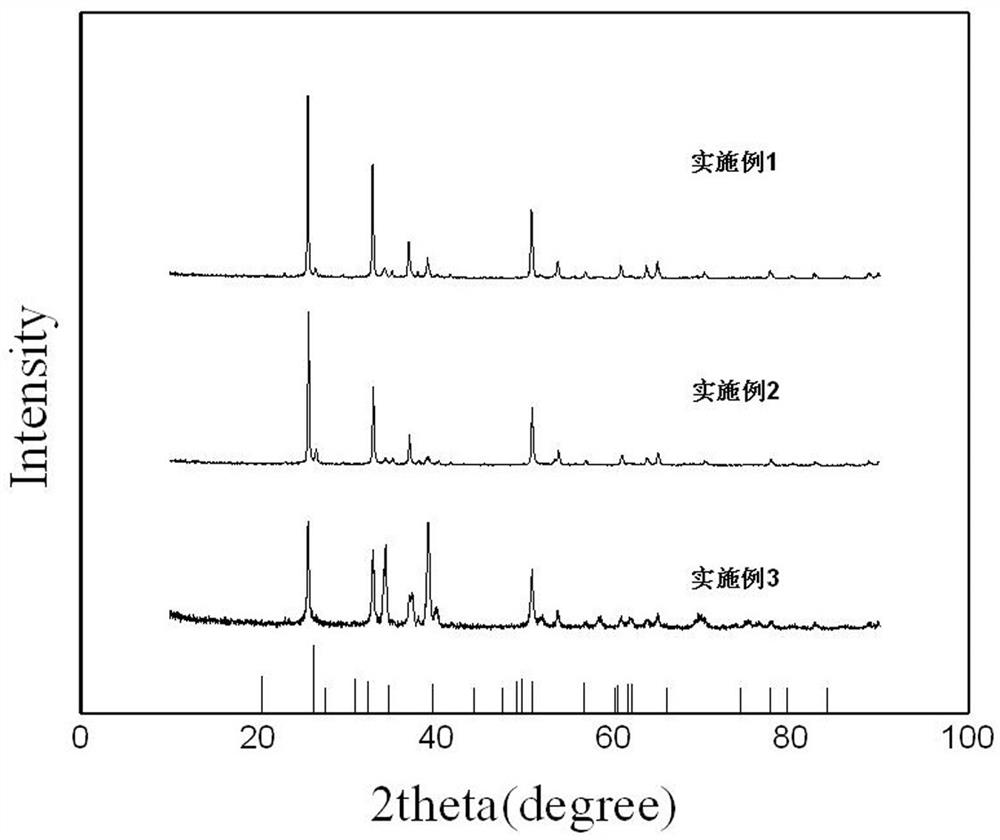

Embodiment 1

[0044] A nickel-boron-antimony co-doped tin dioxide electrocatalytic anode is made by impregnating the anode coating on a porous titanium plate and then calcining. The molar ratio of the components in the anode coating is: citric acid: Ethylene glycol: tin tetrachloride: antimony trichloride: nickel dichloride: boric acid=650:100:100:5:0.5:2.

[0045] Concrete preparation steps are as follows:

[0046] Step 1. Boil the porous titanium sheet with concentrated hydrochloric acid and water with a volume ratio of 1:2 for 10 minutes, take out the porous titanium sheet, and ultrasonically clean it in distilled water for 5 minutes to obtain an acid-treated porous titanium sheet, which is set aside;

[0047] Step 2. Take each component according to the molar ratio. The molar ratio of citric acid: ethylene glycol: tin tetrachloride: antimony trichloride: nickel dichloride: boric acid is 650:100:100:5:0.5:2;

[0048] Step 3. Mix the raw materials weighed in step 2 and heat to dissolve a...

Embodiment 2

[0052] A nickel-boron-antimony co-doped tin dioxide electrocatalytic anode is made by impregnating the anode coating on a porous titanium plate and then calcining. The molar ratio of the components in the anode coating is: citric acid: Ethylene glycol: tin tetrachloride: antimony trichloride: nickel dichloride: boric acid=600:150:120:6.5:1:3.

[0053] Concrete preparation steps are as follows:

[0054] Step 1. Boil the porous titanium sheet with concentrated hydrochloric acid and water with a volume ratio of 1:2 for 15 minutes, take out the porous titanium sheet, and ultrasonically clean it in distilled water for 7 minutes to obtain an acid-treated porous titanium sheet, which is set aside;

[0055] Step 2. Take each component according to the molar ratio, citric acid: ethylene glycol: tin tetrachloride: antimony trichloride: nickel dichloride: boric acid mole is 600:150:120:6.5:1:3;

[0056] Step 3. Mix the raw materials weighed in step 2 and heat to dissolve at 65°C. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com