Patents

Literature

273 results about "Antimony trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony trichloride is the chemical compound with the formula SbCl₃. The soft colorless solid with a pungent odor was known to the alchemists as butter of antimony.

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

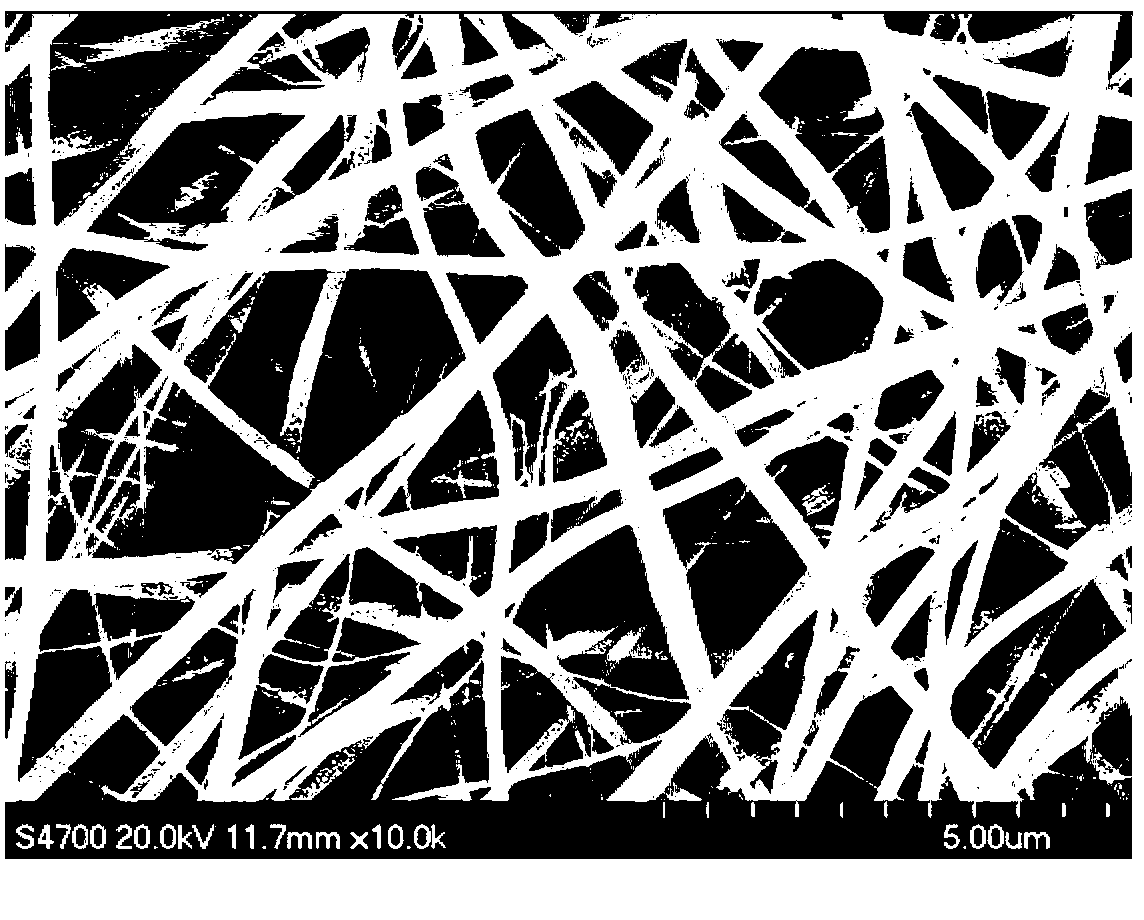

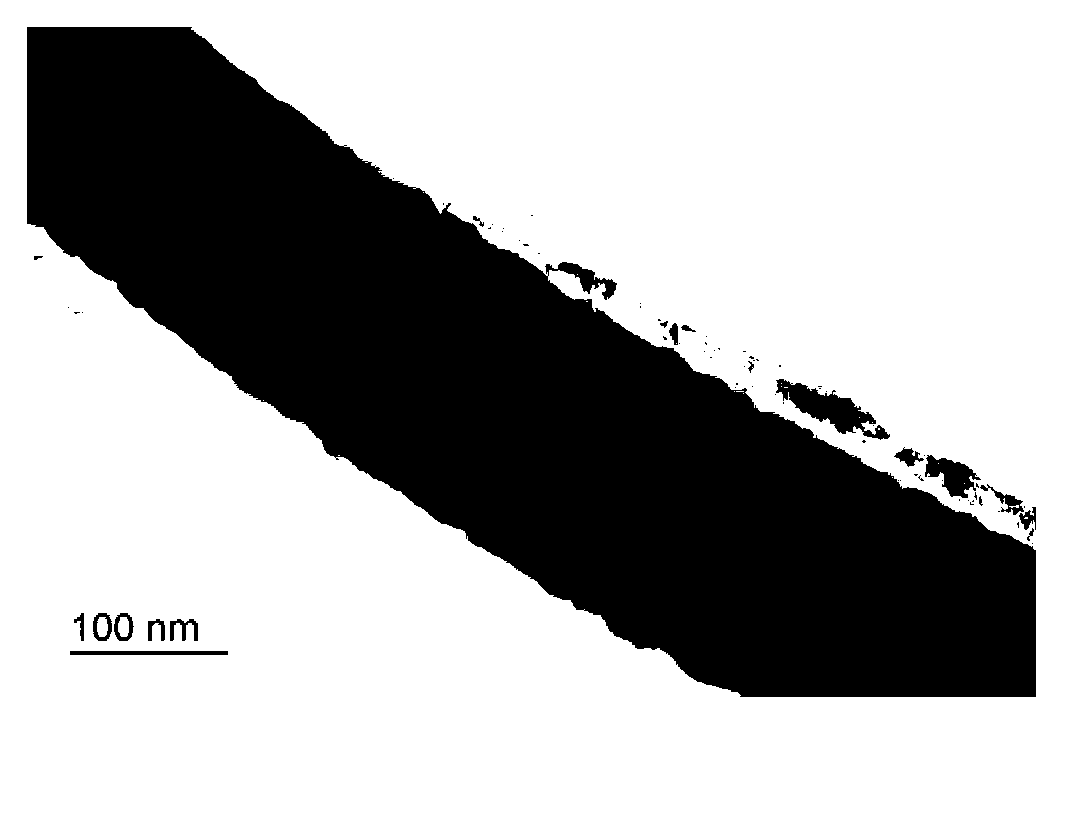

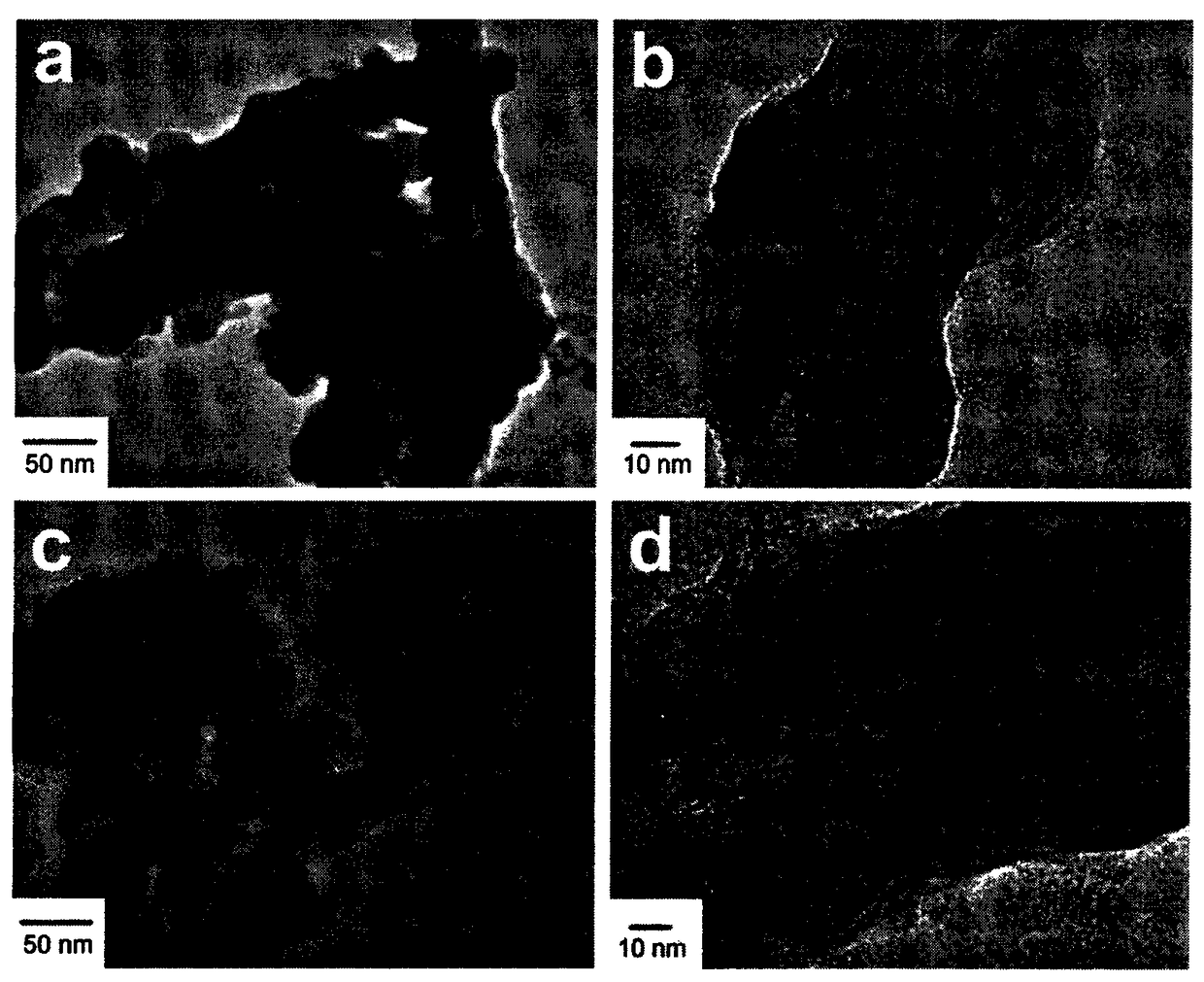

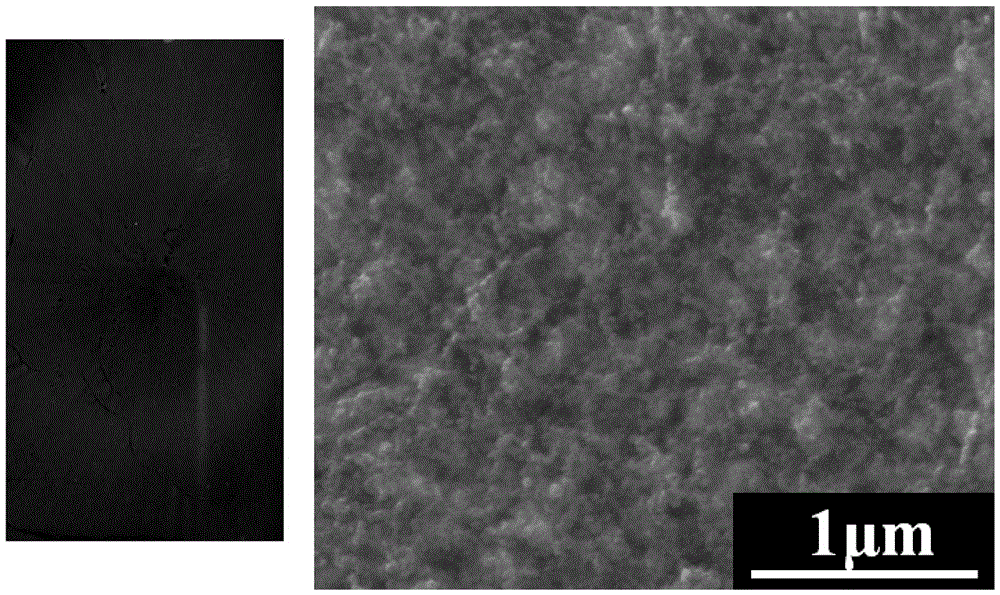

Core-shell structure TiO2/ATO nano-fiber and preparation method thereof

ActiveCN103290525ALow costSmall diameterFilament/thread formingConjugated artificial filamentsOrganic solventElectrospinning

The invention discloses a core-shell structure TiO2 / ATO nano-fiber and a preparation method thereof, and belongs to the technical field of nano-fibers. The core layer of the nano-fiber is TiO2 and the shell layer of the nano-fiber is ATO, wherein the TiO2 is 10wt%-90wt%. The preparation method of the core-shell structure TiO2 / ATO nano-fiber comprises the following the steps of: dissolving tetrabutyl titanate and polyvinylpyrrolidone in an organic solvent, stirring to obtain a uniform core-layer spinning solution; dissolving tetrachlorostannane pentahydrate, antimony trichloride and polyvinylpyrrolidone in the organic solvent, stirring to obtain a uniform shell-layer spinning solution; placing the spinning solution in an electrostatic spinning device, coaxially spinning in an electrostatic manner to obtain a non-woven fabric type fiber felt; roasting to obtain the core-shell structure TiO2 / ATO nano-fiber. The core-shell structure TiO2 / ATO nano-fiber disclosed by the invention is kept with good morphology, is a continuous fiber structure, and is better in single dispersion and small in fiber diameter.

Owner:BEIJING UNIV OF CHEM TECH

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

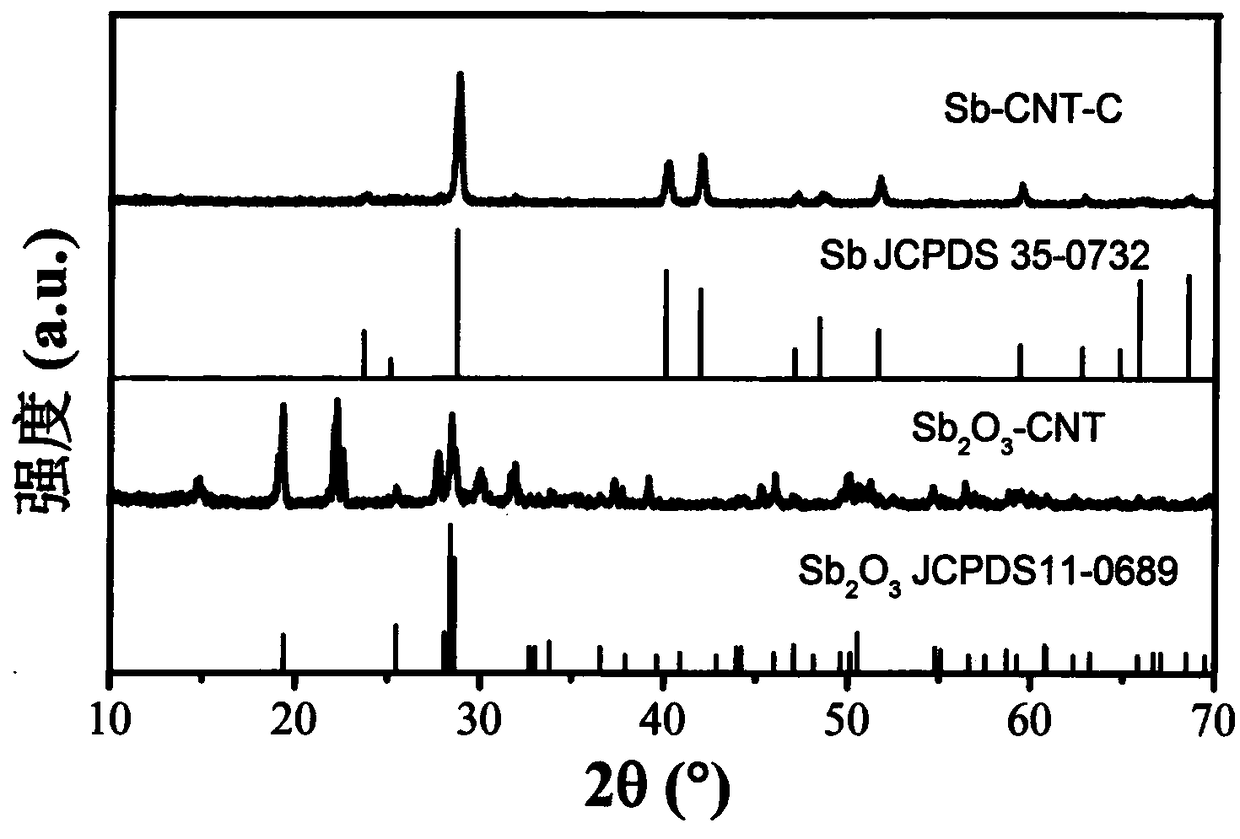

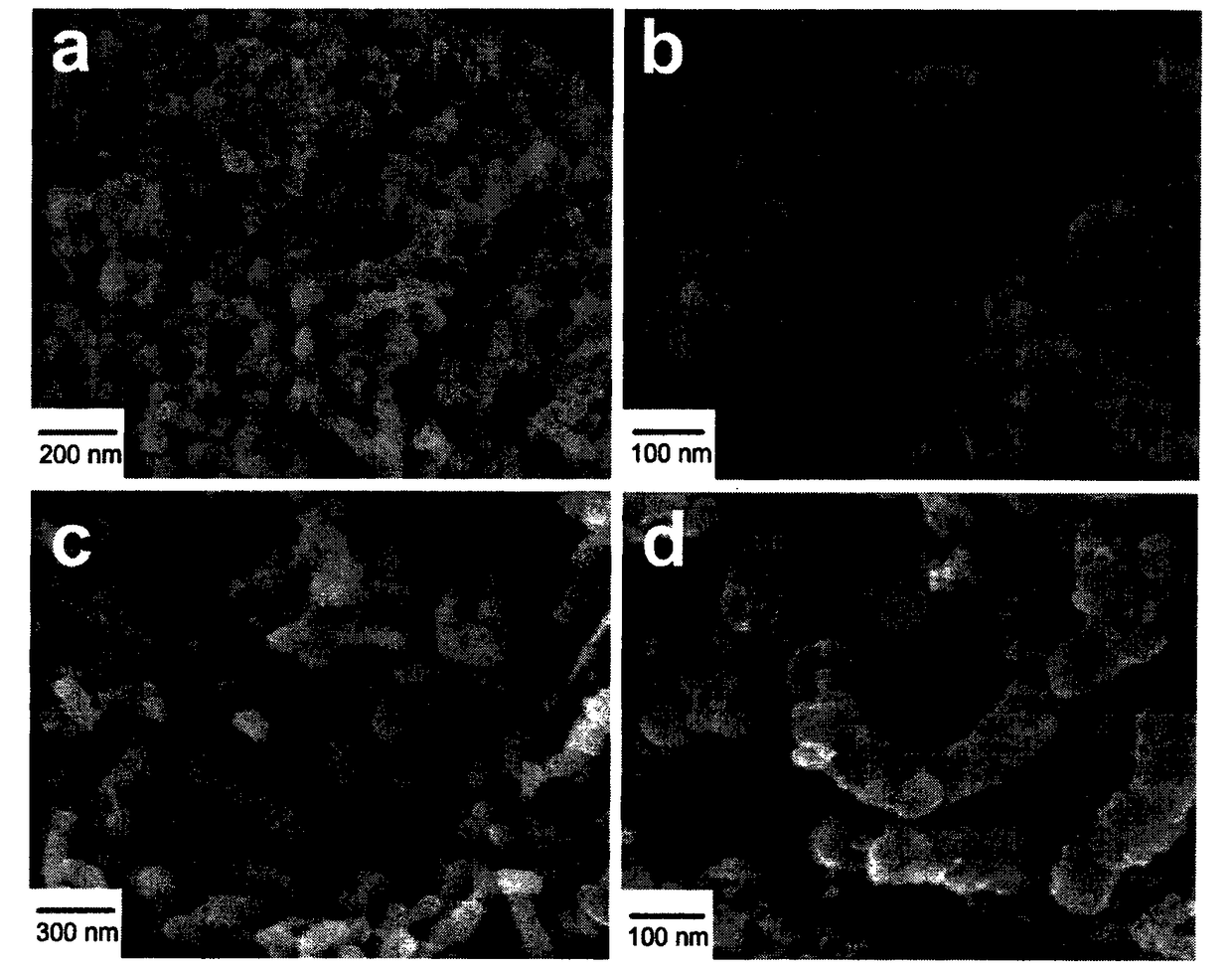

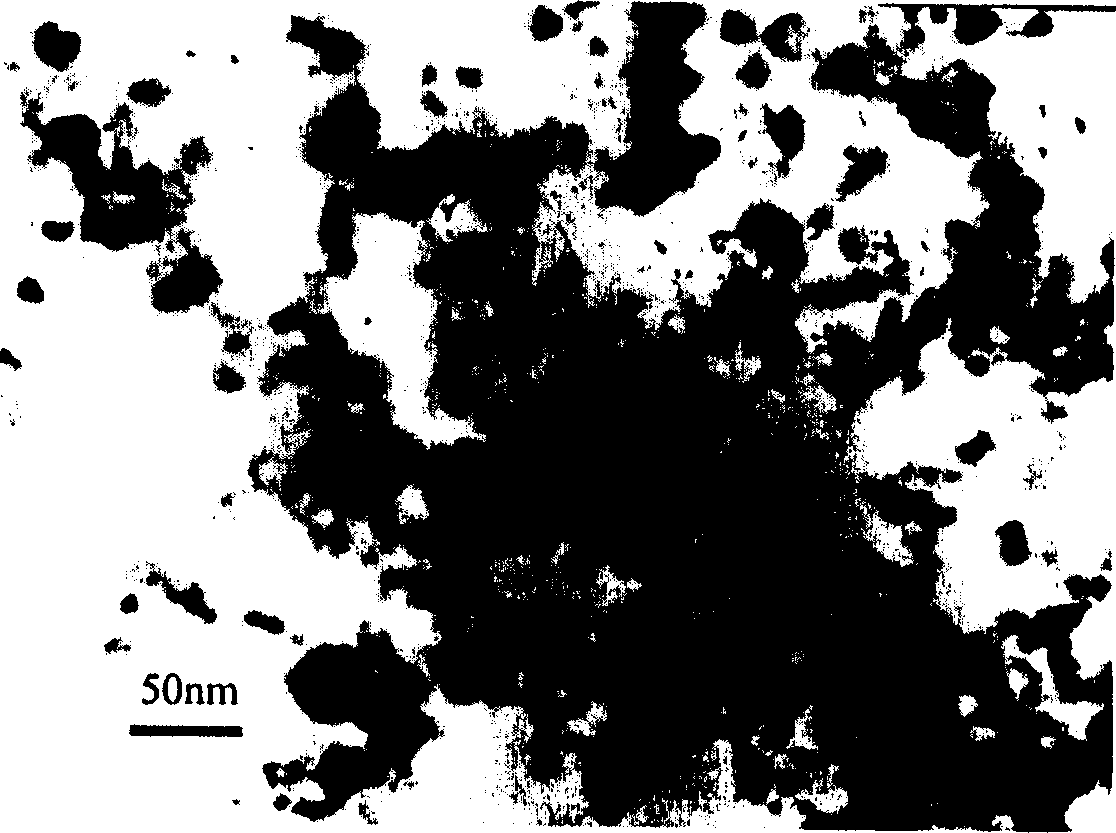

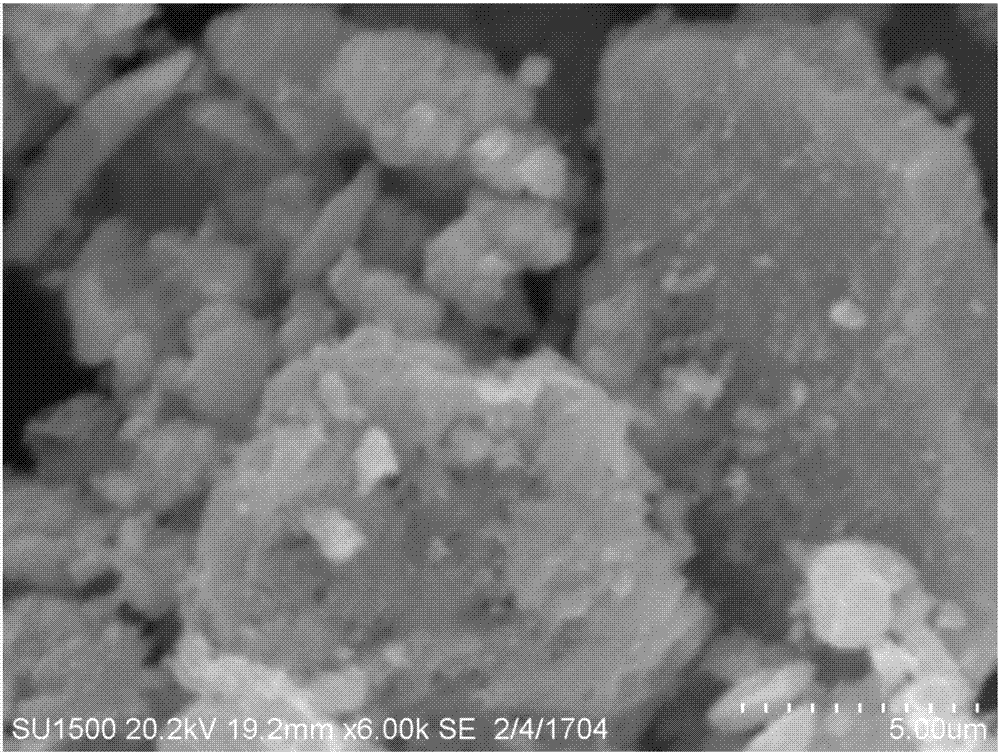

Antimony-carbon nano-tube-carbon composite material, as well as preparation method and application thereof

ActiveCN108899504AWell mixedRich sourcesMaterial nanotechnologyCell electrodesCarbon compositesHigh rate

The invention discloses an antimony-carbon nano-tube-carbon composite material, a preparation method of the composite material and application of the composite material in the cathode material of a lithium ion or sodium ion battery. The composite material has a nanorod shape, wherein antimony particles are uniformly distributed in a carbon-based layer generated by in-situ synthesis. The preparation method comprises the following steps: treating an original multi-wall carbon nano-tube with a mixed solution of sulfuric acid and nitric acid to obtain an acidified carbon nano-tube; dissolving theacidified carbon nano-tube and polyethylene glycol with lauryl sodium sulfate, adding antimony trichloride, and dropwise adding a sodium hydroxide solution into the mixed solution, heating and insulating; cooling, washing and drying to obtain an antimony trichloride / carbon nano-tube precursor; uniformly mixing the precursor with an organic high-molecular polymer, sufficiently grinding, and calcining in an inert gas atmosphere to obtain the antimony / carbon nano-tube / carbon composite material. The preparation process is simple and has easily controlled synthesizing conditions; and the product has a relatively high specific capacity, excellent charging and discharging efficiency, cycling efficiency and high rate performance.

Owner:DONGHUA UNIV

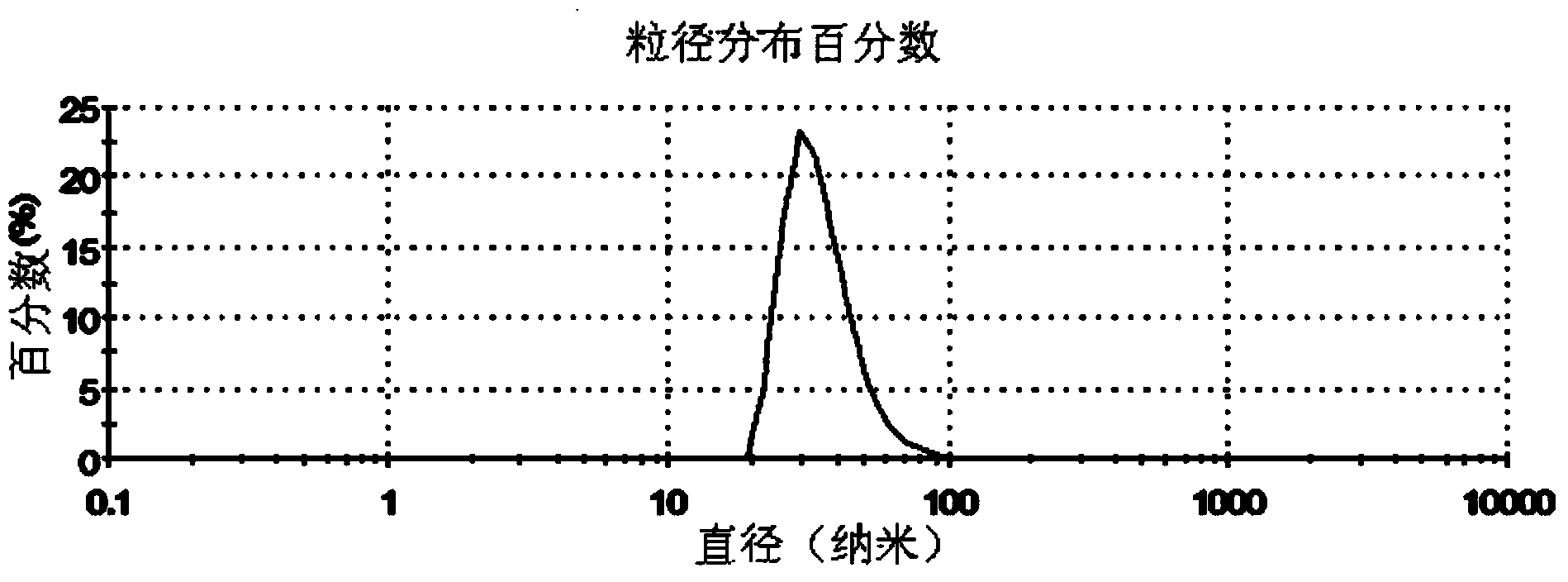

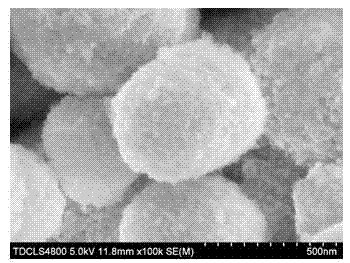

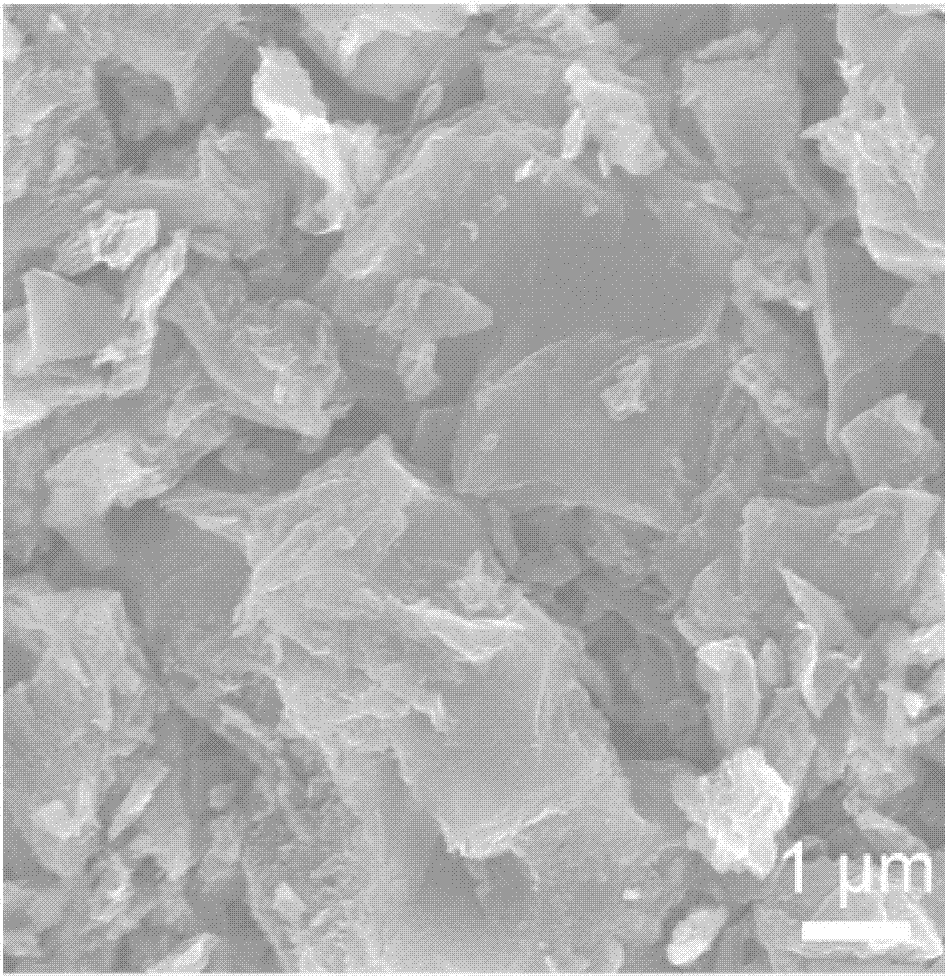

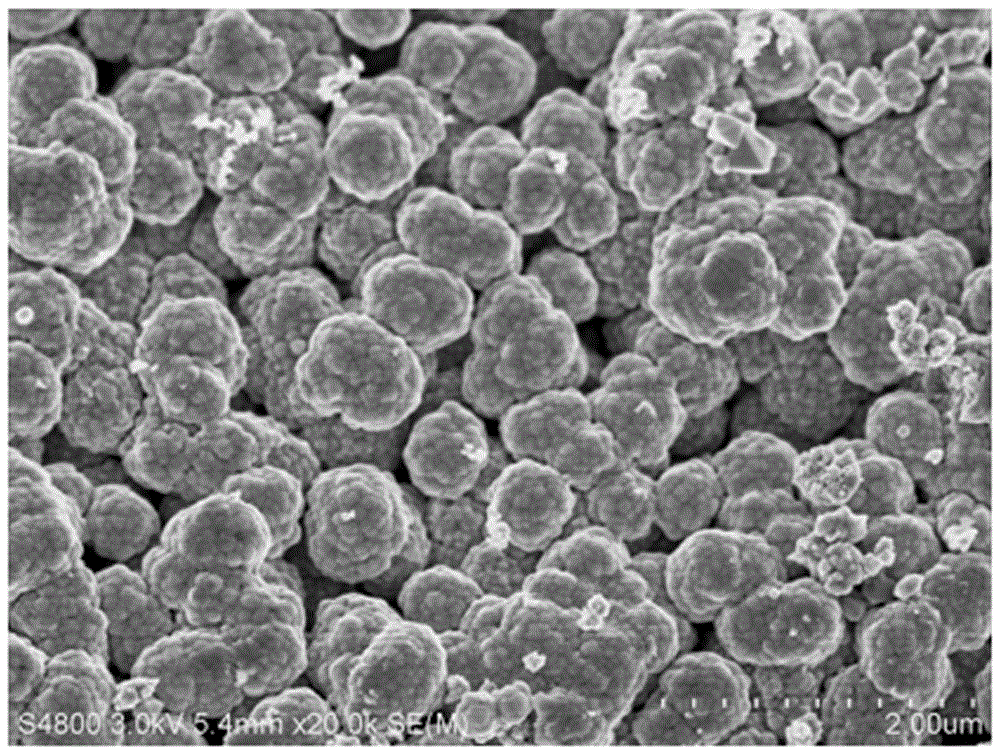

Preparation method for antimony-doped tin oxide powder

InactiveCN103553120AControl release speedEvenly dopedPolyurea/polyurethane coatingsTin oxidesFiltrationReaction temperature

The invention relates to a preparation method for antimony-doped tin oxide powder. The preparation method comprises the following steps of mixing antimony trichloride, tin tetrachloride pentahydrate and a compounding ingredient, adding into a hydrochloric acid solution, and uniformly stirring a mixed solution to obtain transparent liquid; uniformly mixing a dispersing agent, tin tetrachloride pentahydrate, water and ethanol to obtain a base solution; dropwise adding the transparent liquid and an ammonium hydroxide precipitating agent into the base solution within 30 to 80 minutes in a double titration way, controlling reaction temperature to be 50 to 60 DEG C while stirring, and controlling final reaction pH to be 5 to 6; stopping stirring after titration, and performing curing to obtain precursor suspension; performing filtration, water washing, alcohol washing, azeotropic distillation, drying, grinding and calcination on obtained precursor precipitates. According to the method, tin and antimony are synchronously hydrolyzed and precipitated, and antimony is uniformly doped; the powder prepared by the method has the advantages of small particle size, loose structure, low agglomeration rate, high dispersibility and the like.

Owner:SOUTH CHINA UNIV OF TECH

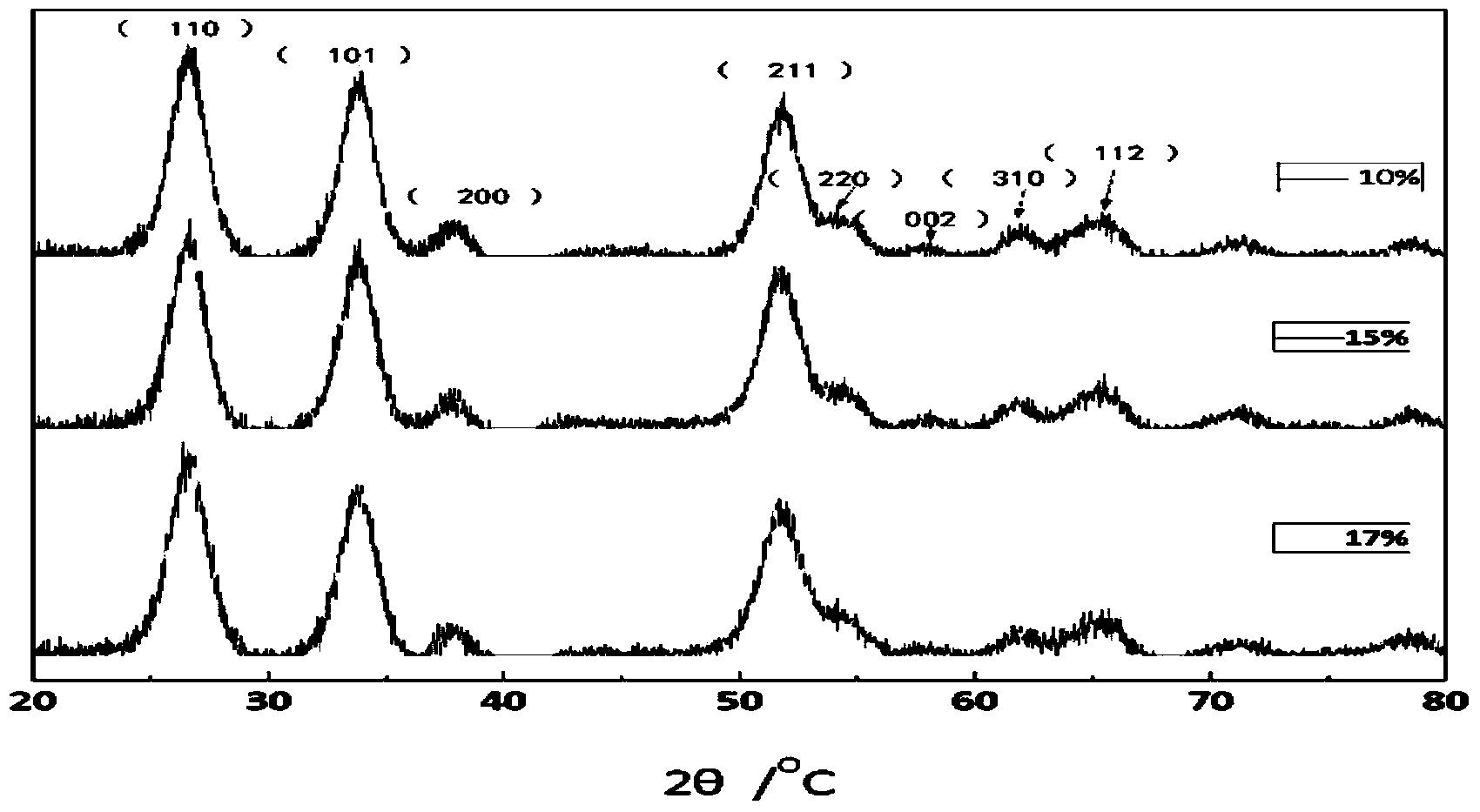

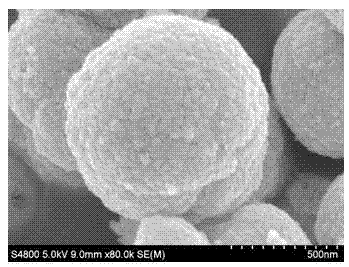

Preparation method of ATO (Antimony doped Tin Oxide) nanopowder

ActiveCN103318951ASolve the serious problem of reunionImprove conductivityMaterial nanotechnologyTin oxidesSlurryAntimony trichloride

The invention discloses a preparation method of ATO (Antimony doped Tin Oxide) nanopowder. The ATO nanopowder is prepared by the following steps of: mixing the ethanol solution of a complexing agent and a hydrochloric acid solution of stannic chloride and antimony trichloride to prepare a tin antimony mixed solution; taking hydrochloric acid solution of stannic chloride and antimony trichloride to perform hydrolysis reaction and dispersing to form seed crystal suspension; simultaneously dropwise adding the tin antimony mixed solution and ammonia water solution into the seed crystal suspension to perform hydrolysis reaction so as to form precursor slurry; performing centrifugal washing, spray drying and baking. The prepared ATO nanopowder has the advantages of high conductivity, easiness in dispersion, short time consumption, less energy consumption, high efficiency, simple process, stable quality, low production cost, safety, environment friendliness and easiness in industrial production.

Owner:烟台同立高科新材料股份有限公司

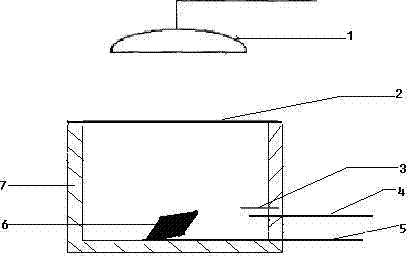

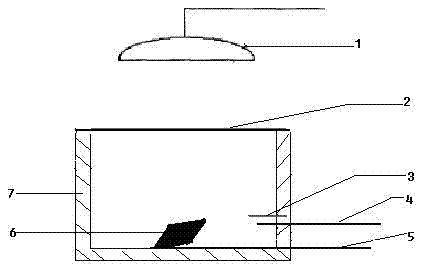

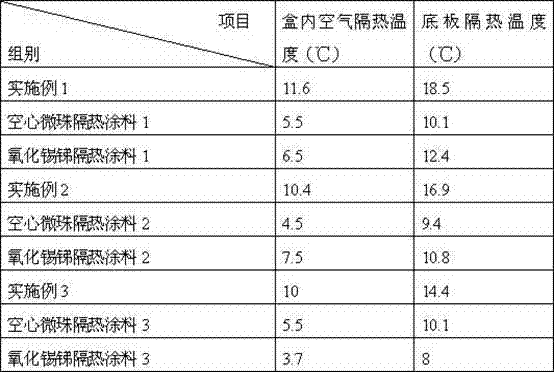

Heat-insulating coating and preparation method thereof

InactiveCN102408760AGood heat insulationLow costAntimony compoundsReflecting/signal paintsTetrachlorideWeather resistance

The invention relates to the technical field of a heat-insulating material, and specifically relates to a heat-insulating coating which contains 1-25wt% of composite tin antimony oxide heat-insulating material, wherein the composite tin antimony oxide heat-insulating material is prepared from hollow beads, tin tetrachloride and antimony trichloride according to a ratio of 0.5-5g:0.015-0.06mol:0.00125-0.00378mol. The preparation method comprises the following steps: preparing a crystal seed; preparing a composite tin antimony oxide precursor; calcining the composite tin antimony oxide precursor to obtain the composite tin antimony oxide heat-insulating material; and preparing heat-insulating paint, and applying to obtain the heat-insulating coating. The composite tin antimony oxide heat-insulating material has the advantages of good heat insulation effect, simple and easily-acquired raw materials and low cost, reduces the transmission of heat, lowers the temperature and saves the cooling cost. By adding ammonia water used as precipitant, tin antimony oxide can be firmly attached to the surfaces of the hollow beads, thereby ensuring that the composite tin antimony oxide heat-insulating material has long service life and good heat insulation effect; and the heat-insulating coating has good weatherability, high adhesive capacity and fine heat insulation effect.

Owner:SHANDONG UNIV OF SCI & TECH +1

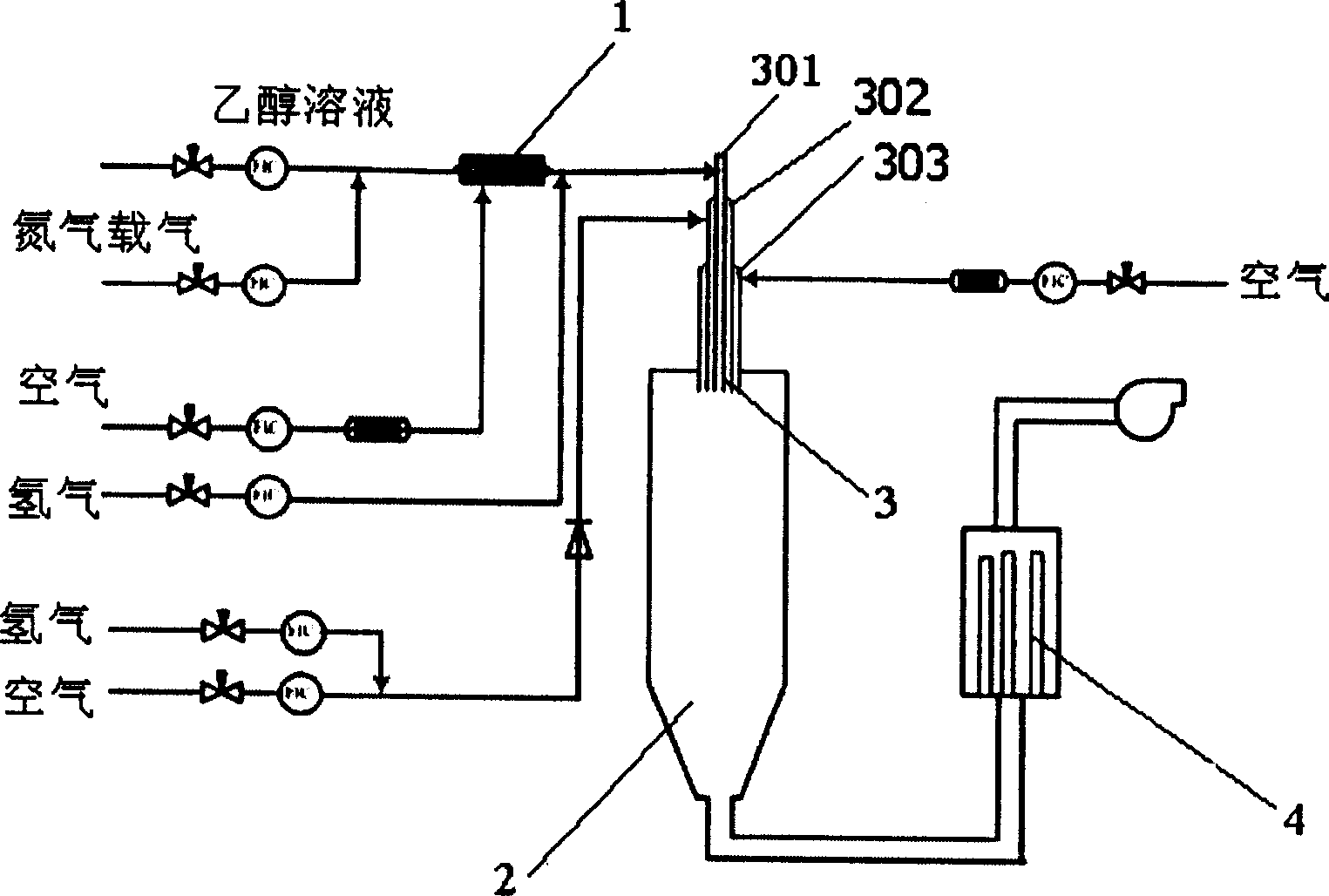

Method for preparing antimony doped stannic oxide nanometer electricity-conductive powder

The invention discloses a method for preparing nanometer conductive powder mixed with stannic oxide, comprising following steps: evaporating mixed solution of tin tetrachloride, antimony trichloride and alcohol in evaporator loaded by nitrogen; mixing with hydrogen and air, entering into combustor through central tube of three-channel nozzle installed on top of combustor, proceeding hydrolytic reaction; collecting produced ATO conductive powder with bag filter, discharging exhaust gas after passing hydrogen chloride absorbing tower; adding hydrogen and air into combustor through three-channel nozzle at the same time; and adding air through three-race pipe of three-channel nozzle. The invention is characterized by simple device and high controllable degree. ATO nanometer conductive powder of small size, large specific surface area and good dispersibility can be prepared.

Owner:EAST CHINA UNIV OF SCI & TECH

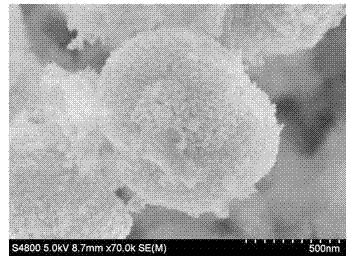

Antimony-doped tin dioxide coated porous manganese dioxide composite electrode material and preparation

InactiveCN103811190AImprove conductivityIncrease profitHybrid capacitor electrodesTin dioxideManganese

The invention discloses an antimony-doped tin dioxide coated porous manganese dioxide composite electrode material and a preparation method. The composite material is of a core-shell structure, the average particle size of the composite material is 400-600nm, an antimony-doped tin dioxide coated layer is arranged on an outer layer, a core is a porous manganese dioxide spherical particle, the molar ratio of manganese to tin in the composite material is 100: (5-20), and the molar ratio of the tin to antimony is 100: (2-6). The preparation method includes the steps: reacting sodium carbonate and manganese sulfate to obtain manganese carbonate; dissolving tin tetrachloride and antimony trichloride in ethanol water solution to prepare sol; adding the manganese carbonate into the sol; preparing an antimony-doped tin dioxide coated manganese carbonate composite material; calcining the obtained composite material to prepare the antimony-doped tin dioxide coated porous manganese dioxide composite electrode material. The preparation method is simple, and the obtained electrode material is high in specific capacity and fine in cycling stability and can serve as a novel super-capacitor electrode material.

Owner:TIANJIN UNIV

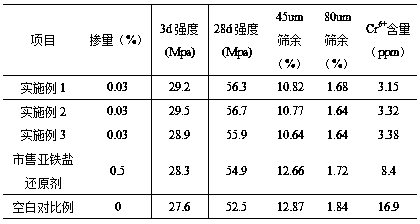

Low-dosage cement chromium-removing grinding aid and preparation method thereof

The invention discloses a low-dosage cement chromium removal grinding aid and a preparation method thereof, and belongs to the technical field of cement admixtures. The cement chromium removal grinding aid is prepared from the following raw materials in parts by weight: 20-40 parts of alcohol amine substances, 20-40 parts of alcohol substances, 25-40 parts of antimony trichloride and 5-15 parts ofethanol. The antimony trichloride is used as a hexavalent chromium reducing agent and can be well compatible with main raw materials, namely the alcohol amine and alcohol substances, of the grindingaid, and the grinding aid and the hexavalent chromium reducing agent are compounded for use. According to the invention, the antimony trichloride and the alcohol amine substances are ingeniously utilized to form an acid-base complex; according to the present invention, the reduction effect of Sb < 3 + > on Cr < 6 + > is retained, and the formed acid-base complex has good stability compared to theantimony trichloride, and the low-dosage cement chromium removal grinding aid has characteristics of low doping amount, low production cost, convenient use, chromium removing effect and grinding aid effect, and has good promotion and application value.

Owner:安徽海螺材料科技股份有限公司 +1

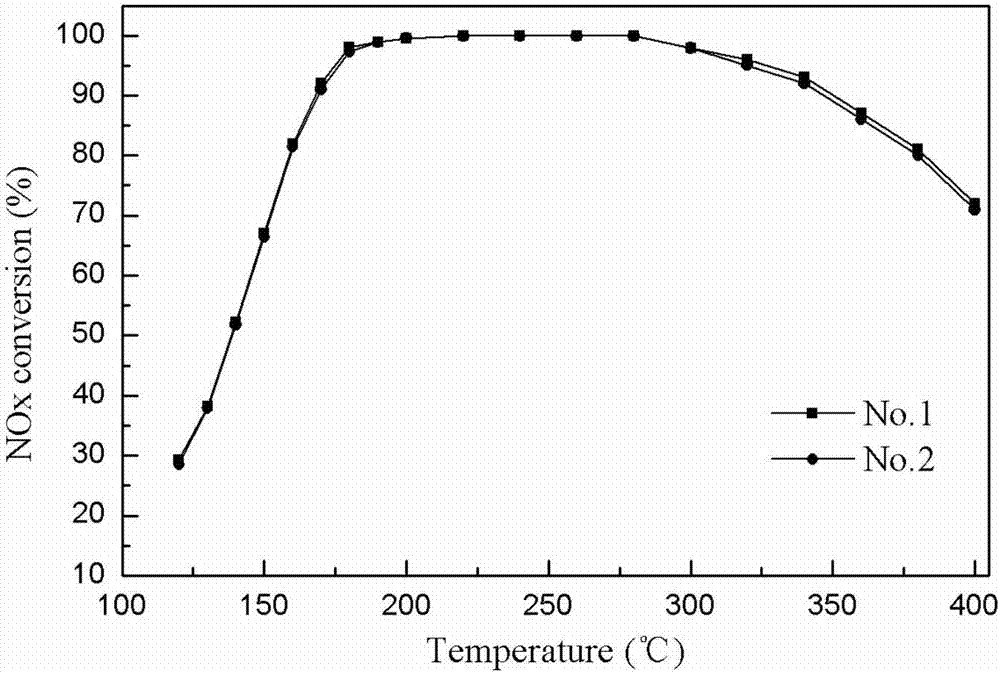

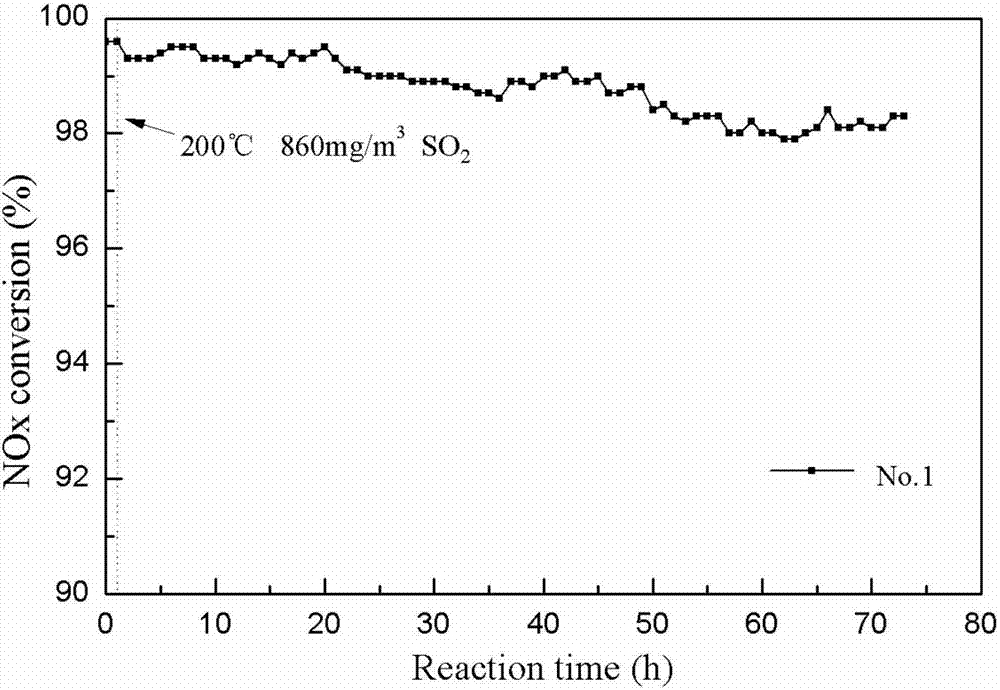

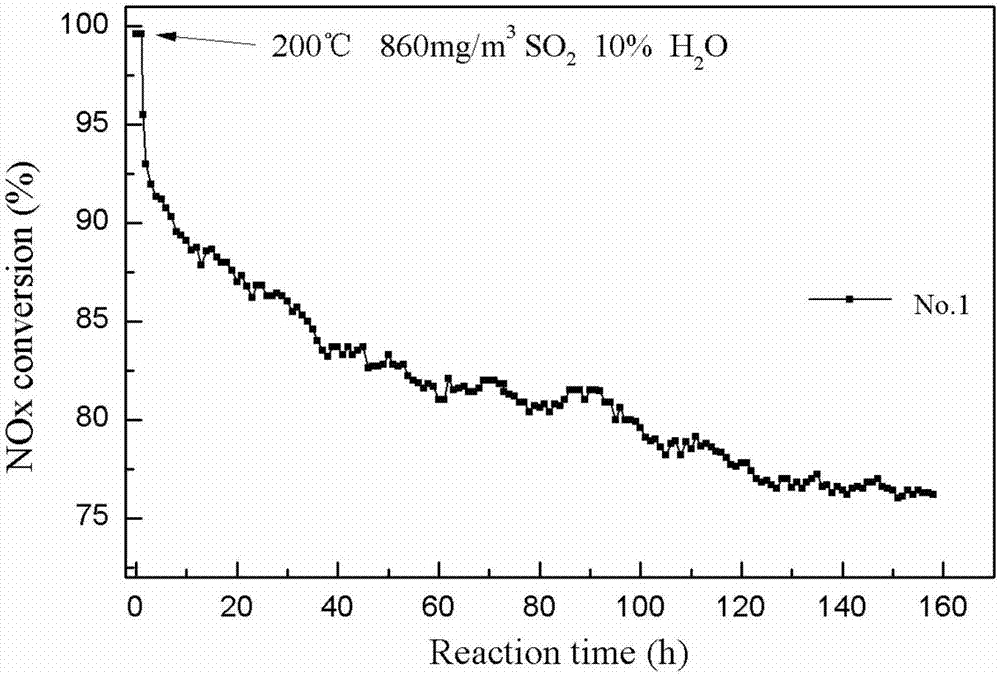

Preparation method of low-temperature sulfur-resistant and water-resistant denitration catalyst

InactiveCN106881077ALow starting temperatureGood processing effectGas treatmentHeterogenous catalyst chemical elementsSulfurAmmonium metavanadate

The invention discloses a preparation method of a low-temperature sulfur-resistant and water-resistant denitration catalyst, and belongs to the field of low-temperature denitration catalysts. The low-temperature sulfur-resistant and water-resistant denitration catalyst is prepared by an impregnation method by loading the surface of anatase-type titanium dioxide as a carrier with vanadium pentoxide and antimony trioxide, wherein TiO2 accounts for 60-90wt%, V2O5 accounts for 1-10wt% and Sb2O3 accounts for 5-30wt%. Precursors of the chemical components are as follows respectively: the precursor of V2O5 is ammonium metavanadate and the precursor of Sb2O3 is antimony trichloride. On the basis of an original vanadium titanium catalyst, through loading of the Sb2O3, the low-temperature sulfur-resistant and water-resistant denitration catalyst can not only maintain the efficiency being 90% or higher at 170-300 DEG C, but also has certain sulfur resistance and water resistance. By the preparation method, deactivation of the low-temperature sulfur-resistant and water-resistant denitration catalyst can be delayed; the preparation method is simple and high in reproducibility, and is suitable for industrial production.

Owner:BEIJING UNIV OF TECH

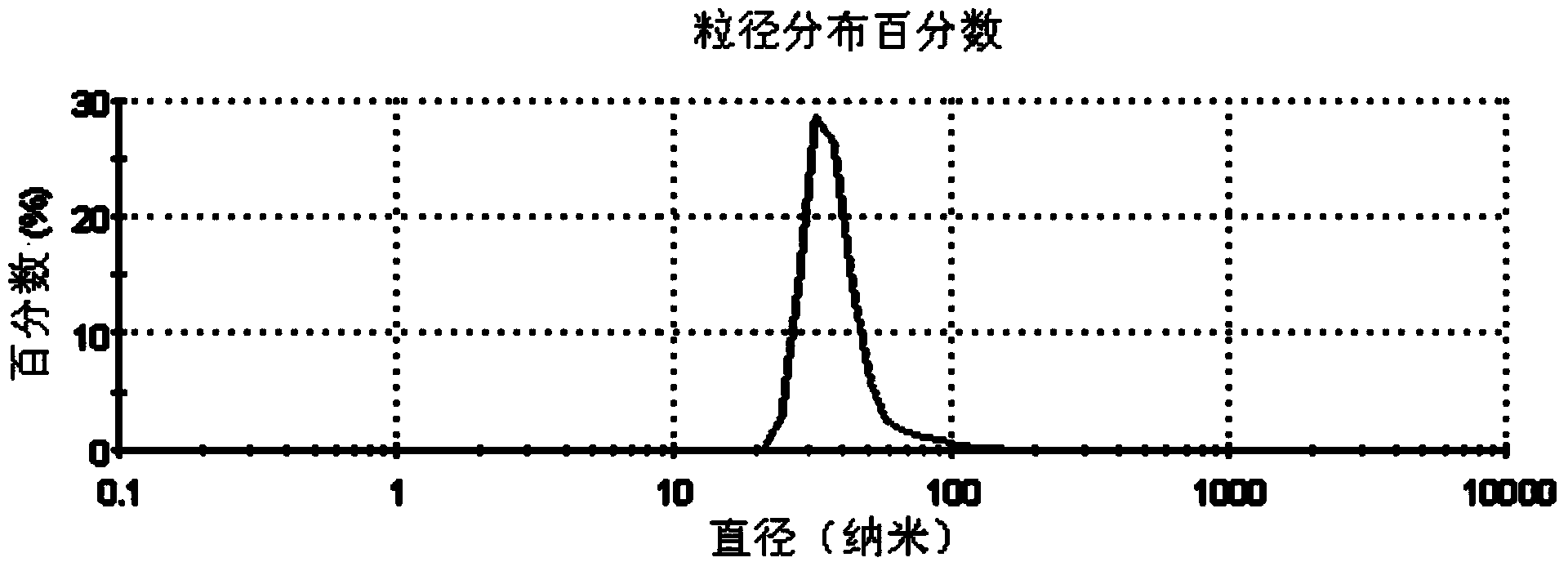

Stable nano antimony-doped tin dioxide hydrosol and preparation method thereof

InactiveCN104925853AOvercoming the problem of poor stabilitySimple preparation processTin oxidesTin dioxideQuaternary ammonium cation

The invention discloses stable nano antimony-doped tin dioxide (ATO) hydrosol which is composed of 3-5 percent of nano ATO particles with the average particle size of 10-20 nm, 0.2-2 percent of salicylic acid, 0.005-0.1 percent of long-chain quaternary ammonium salt and deionized water. A preparation process comprises the following steps: carrying out alkali hydrolysis on a tin tetrachloride and antimony trichloride aqueous solution to generate hydration SnO2 / Sb2O3 precipitates, dispersing in deionized water, removing mixed chloridion ions through strong-basicity ion exchange resin, peptizing the precipitates by salicylic acid at 60-70 DEG C, carrying out hydrothermal treatment to form the antimony-doped tin dioxide hydrosol, crystallizing for separating free salicylic acid, and adding a long-chain quaternary ammonium salt stabilizer to enable the long-chain quaternary ammonium salt stabilizer to react with salicylic acid in the hydrosol, so as to enable the hydrosol to be viscosified and stabilized.

Owner:TIANJIN VOCATIONAL INST

Antimony/nitrogen-doped carbon compound by taking 1-ethyl-3-methylimidazole dicyanamide as carbon source, and preparation method and application thereof

ActiveCN107248569AImprove electrochemical performanceSimple processCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention provides a preparation method of an antimony / nitrogen-doped carbon compound by taking 1-ethyl-3-methylimidazole dicyanamide as a carbon source. The preparation method comprises the steps of dissolving antimony trichloride and 1-ethyl-3-methylimidazole dicyanamide into methyl alcohol separately, mixing under strong stirring to enable the two kinds of solutions to be fully mixed and then standing, next, performing centrifuging and collecting gel-shaped white solid body, and performing centrifuging and washing by methyl alcohol; and performing carbonization on the obtained product in H<2> / Ar atmosphere to obtain the antimony / nitrogen-doped carbon compound. The invention also provides the antimony / nitrogen-doped carbon compound prepared by the method and an application of the compound as a negative electrode material of a sodium ion battery. Antimony trichloride, ionic liquid and 1-ethyl-3-methylimidazole dicyanamide ionic liquid are taken as the raw materials, and simple process, green and environment friendly raw materials, and batch production are realized favorably; and the prepared antimony / nitrogen-doped carbon compound has excellent electrochemical performance, and can be used as the ideal negative electrode material of the sodium ion battery to replace hard carbon with low reversible capacity to be applied to the sodium ion battery.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of brominated polystyrene

The invention relates to a preparation method of brominated polystyrene, comprising three steps of catalyzing and brominating, neutralizing washing, and solidifying and separating. The step of catalyzing and brominating comprises the following steps: dissolving polystyrene into dichloroethane solvent, adding antimony trichloride catalyst into the solution, dropwise adding bromine chloride into the solution which is added with antimony trichloride catalyst, wherein the mole ratio of bromine chloride to polystyrene monomer is 3.8:1-3.5:1, keeping the temperature at 10-25 DEG C and reacting for 3-4 hours; the step of neutralizing washing comprises the following steps: adding 5wt% of sodium sulfite or sodium bisulfite aqueous solution into the polystyrene reaction liquid after catalyzing and brominating to terminate the reaction, then adding 5wt% of sodium hydroxide solution to be in neutrality, and then washing with water; and the step of solidifying and separating comprises the following steps: adding the brominated polystyrene solution after neutralizing washing into a high-speed stirring device with high shearing force at a speed of 5mL / min-20mL / min, wherein the high-speed stirring device is filled with alcohol separating agent; regulating the rotating speed to be in a range of 2000-3000 r.p.m.; scattering the brominated polystyrene product in the alcohol to cure into small particles; separating solid products, washing with alcohol, then filtering and drying to obtain brominated polystyrene products.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Preparation method of composite core-shell-structure nano powder

ActiveCN107162044AGood dispersionThe experimental equipment is simpleSilicaCoatingsWater bathsTin dioxide

The invention discloses a preparation method of a composite core-shell-structure nano powder. The preparation method includes the steps of: 1) dissolving tin chloride pentahydrate and antimony trichloride in a hydrochloric acid solution, and adding ammonia water to obtain a first solution; 2) performing a reaction to the first solution in constant-temperature water bath to form a first precipitate, and calcining the first precipitate to prepare an antimony-doped tin dioxide nano-powder; 3) dispersing the antimony-doped tin dioxide nano-powder in anhydrous ethanol, and adding ammonia water to obtain a second solution; 4) adding tetraethyl orthosilicate to the second solution and performing a reaction to form a second precipitate, and calcining the second precipitate to prepare an intermediate powder; 5) dissolving tin chloride pentahydrate and antimony trichloride in anhydrous ethanol containing acetylacetone, stirring the mixture and performing a reaction to obtain a third solution, dropwise adding distilled water with stirring and aging the solution to prepare antimony-doped tin hydroxide sol; and 6) adding the intermediate powder to the antimony-doped tin hydroxide sol with dispersion, sealing the mixture, allowing the mixture to stand to obtain a third precipitate, and calcining the third precipitate to obtain the composite core-shell-structure nano powder.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

Preparation method of titanium-based lead dioxide anode

ActiveCN108914122AExtended service lifeGrain refinementWater treatment parameter controlElectrolytic inorganic material coatingLead dioxideCerium

A preparation method of a titanium-based lead dioxide anode comprises the following steps that a titanium-based matrix is pre-treated; tin tetrachloride and antimony trichloride are dissolved into isopropyl alcohol containing hydrochloric acid, the surface of a titanium plate matrix is coated with the mixture, and an electrode with an antimony-tin oxide bottom layer is obtained after drying and roasting; the electrode with the antimony-tin oxide bottom layer serves as the anode, a titanium plate serves as a cathode, and alpha-PbO2 intermediate layer is subjected to electro-deposition in a sodium hydroxide plating solution where PbO is dissolved; the titanium plate serves as the anode, another titanium plate serves as the cathode, modified beta-PbO2 active layer containing cerium dioxide, erbium and fluorine is prepared through electro-deposition, and the titanium-based lead dioxide anode is obtained. The surface of a polar plate prepared through the preparation method is uniform and compact, the service life is long, the electrochemical oxidation performance is high, and the treatment cost is low.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

Precursor solution for preparing semiconductor electro-thermal film, electro-thermal film and preparation method of electro-thermal film

ActiveCN105228273AImprove impact performanceIncrease stressHeating element materialsTin dioxidePotassium

The invention discloses a precursor solution for preparing a semiconductor electro-thermal film, the electro-thermal film and a preparation method of the electro-thermal film. The preparation method comprises the following steps: firstly, providing a precursor solution for preparing the semiconductor electro-thermal film formed by mixing tin tetrachloride, nanometer tin dioxide, antimony trichloride, hydrofluoric acid, boric acid, potassium chloride, triethanolamine and relevant solvents; and secondly, providing a film forming process combining a spray film forming process and a dipping process assisted by a gradient heat treatment process in order to obtain the semiconductor electro-thermal film which has high film forming quality and is suitable for large-size production. Binding force between the electro-thermal film and a substrate is enhanced, and the electro-thermal film with a high thermal shock resistance is obtained. The uniformity and film-making efficiency of large-area film formation are improved. The electro-thermal film with a large square resistance adjustable range is obtained in order to meet different industry demands.

Owner:深圳市热客派尔热力科技有限公司

Composition for preparing semiconductor electrothermal film, electrothermal film and preparation method

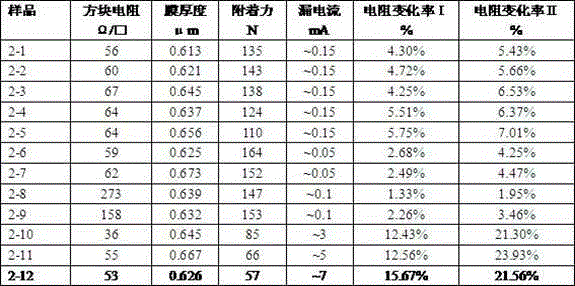

InactiveCN105722257AReduce leakage currentStable electrothermal conversion performanceHeating element materialsAntimony trichlorideFluoboric acid

The invention relates to a composition for preparing a semiconductor electrothermal film. The composition is prepared from the following components in parts by weight: 15-20 parts of stannic chloride, 6-10 parts of nickel tetrachloride, 10-30 parts of graphite, 3-6 parts of antimony trichloride, 0.2-0.4 part of titanium tetrachloride, 0.2-0.6 part of antimonous oxide, 0.1-0.8 part of fullerene, 0.1-1.5 parts of boric acid, 0.1-1.5 part of fluoboric acid, 0.3-0.5 part of sodium chloride, 3-6 parts of water, 2-4 parts of methylbenzene and 30-50 parts of ethanol. The adhesive force of the semiconductor electrothermal film prepared according to the method on a substrate is 180-200N; the leakage current is smaller than 0.10mA; the electrothermal conversion efficiency is greater than or equal to 99%; the square resistance is 20-500ohm / square; and the lifetime is over 5,000 hours.

Owner:顾伟

Formula of film liquid of nano electrothermal film, preparation method and preparation method of electrical heating tube

InactiveCN107172727AStable powerReasonable ratioOhmic-resistance electrodesHeating element shapesAntimony trichlorideCobalt chloride

The invention provides a formula of film liquid of a nano electrothermal film, a preparation method and a preparation method of an electrical heating tube. The preparation method of the nano electrothermal film comprises steps of using the material formulas of tin tetrachloride, antimony trichloride, graphite, absolute ethyl alcohol and cobalt chloride and carrying out sufficient mixing, stirring and dissolving in the constant-temperature bath environment proportionally to prepare nano electrothermal film liquid; through a low-pressure high-atomization spray gun system, spraying the nano electrothermal film liquid to the inner surface of a workpiece carrier tube body in a 500-550 DEG C high-temperature furnace so as to plate a layer of nano semiconductor electrothermal film with the nano-level thickness; coating the surface of the electrothermal film on the inner surface of the tube body with two or three high temperature resisting silver paste electrode rings; and through 550-650 DEG C high temperature sintering, preparing high temperature-resisting silver-electrode electrode rings, thereby forming a nano electrothermal film finished product. According to the invention, the thermal conversion of the prepared electrothermal film is high; the thermal efficiency reaches 98% or more, thereby facilitating saving of electric energy from the source; the service lifetime reaches 20000 hours or more; and using quantity and maintenance cost of the electrical heating tube are reduced.

Owner:广西泰亿诺新能源有限公司

Process for producing zinc antimonide powder at low temperature

The process of composing ZnSb powder includes the following steps: dissolving zinc sulfate in water to compound solution and electrolysis to produce metal zinc grain dissolving antimony chloride in water to compound solution and reducing with sodium borohydride to obtain metal antimony grain, compounding metal zinc grain and metal antimony grain in the atom ratio of 1 to 1 to form reactant, and heat treating the reactant in an electric furnace at 150-200 deg.c under the protection of nitrogen to produce ZnSb. The process produces ZnSb powder at relatively low temperature, and Compared with available technology, the present invention has the advantages of simple materials, simple apparatus, simple process and low cost.

Owner:HANGZHOU DIANZI UNIV

Saturated solution for preparing semiconductor electrothermal films

InactiveCN104486849AEnsure safetyGuaranteed to be environmentally friendlyHeating element materialsThermal energyPotassium

The invention discloses a saturated solution for preparing semiconductor electrothermal films in the technical field of semiconductor electrothermal film materials. According to percentage by weight, the composition of the saturated solution is as follows: 40 to 60 percent of tin tetrachloride, 0.5 to 2 percent of titanium tetrachloride, 2 to 8 percent of nickel tetrachloride, 1 to 3 percent of potassium chloride, 5 to 8 percent of antimony trichloride and the balance of absolute ethanol. The saturated solution is sufficiently vaporized, and permeates surface pores, deposits and is sintered on a high-insulativity, sudden change-resistant and high temperature-resistant substrate, and thereby an electrothermal film is produced. The saturated solution has the following advantages: the efficiency of electric energy-to-thermal energy conversion is high (up to 99.5 percent), naked flames do not exist, power attenuation is little, an electrothermal source does not have surge current, and operation is stable. The highest working temperature can reach 750 DEG C, the service life is long, and the electrothermal film can continuously work for more than 5000 hours. The electrothermal film can be adapted to various power supply modes, the fabrication cost is low, and application fields are extremely broad.

Owner:罗敏 +2

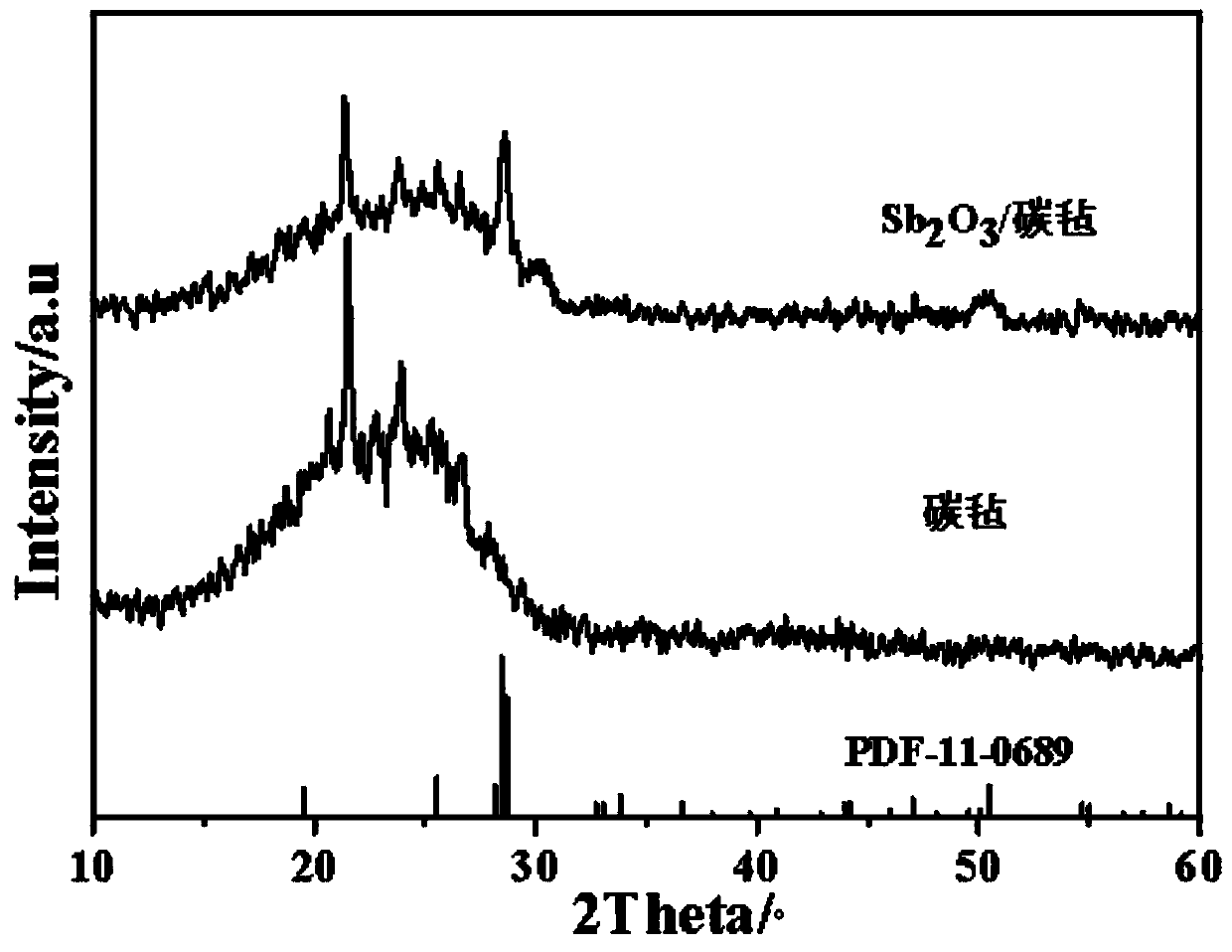

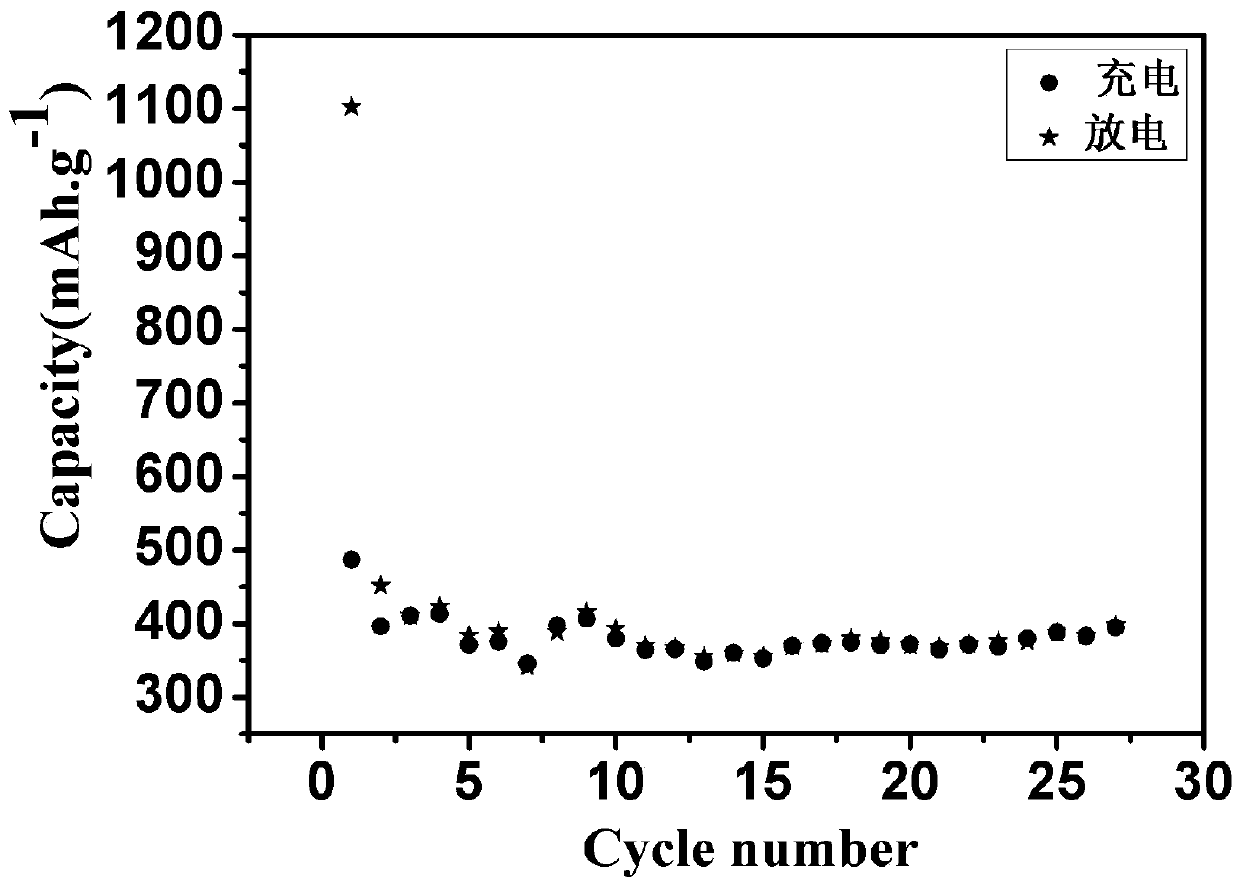

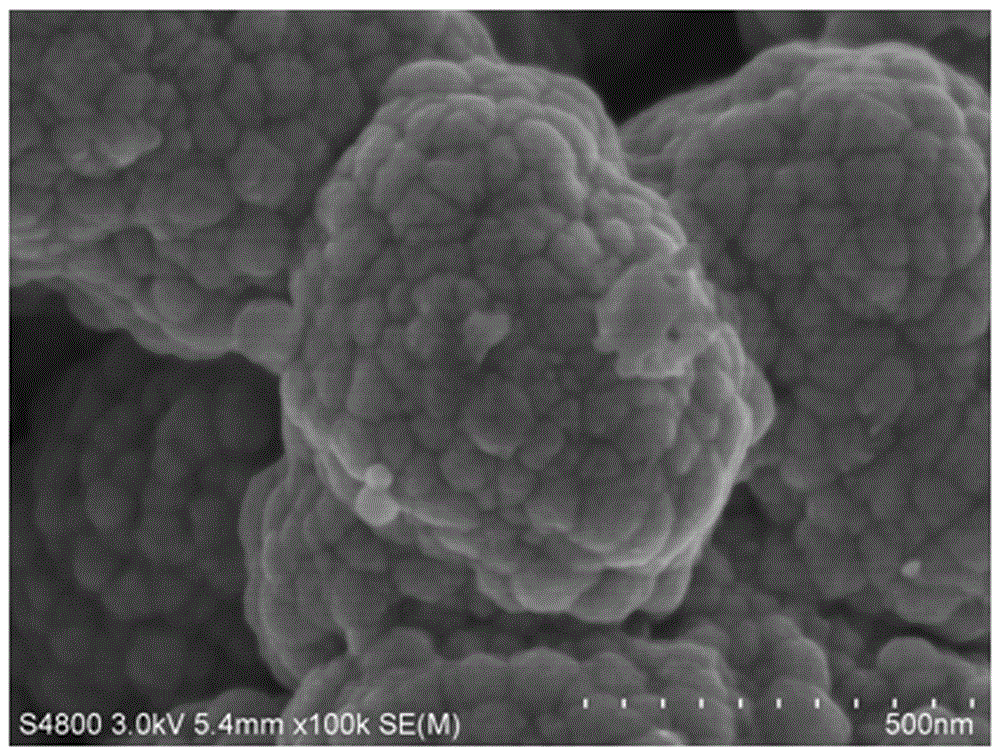

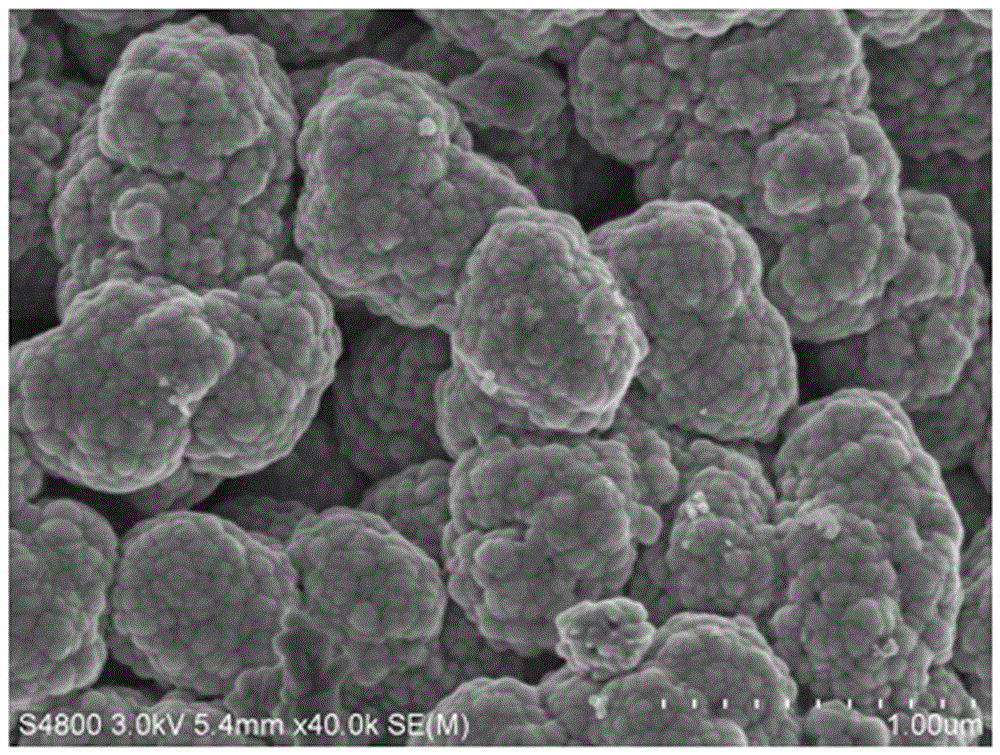

Method for preparing Sb2O3/carbon felt flexible sodium ion battery anode material

InactiveCN110190246AEasy to storeFast deliveryChemical electrode manufacturingSecondary cellsCarbon feltSodium-ion battery

The invention provides a method for preparing a Sb2O3 / carbon felt flexible sodium ion battery anode material, comprising a step 1 of immersing and purifying the carbon felt in acetone, and then anodizing and drying the carbon felt; a step 2 of adding antimony trichloride to absolute ethyl alcohol to obtain an antimony trichloride solution, and adding sodium hydroxide to deionized water to obtain asodium hydroxide solution; and a step 3 of adding the sodium hydroxide solution dropwise to the antimony trichloride solution to obtain a mixed solution, immersing the treated carbon felt in the mixed liquid, transferring the mixed solution and the carbon felt to a hydrothermal kettle for a hydrothermal reaction, naturally cooling a reaction product to room temperature, washing the reaction product with deionized water and ethanol, and then drying the reaction product to obtain the Sb2O3 / carbon felt flexible sodium ion battery anode material. By preparing the Sb2O3 / carbon felt flexible electrode material by the hydrothermal method, the Sb2O3 is uniformly grown on the carbon felt. The method of the invention is simple in process, short in period, high in repeatability, low in energy consumption, and low in cost, and has great significance to the research of the flexible sodium ion battery anode material.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of zinc oxide/antimony tin oxide composite nano-material

InactiveCN105854867AReduce craft production costControllableHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsCross-linkAntimony trichloride

The invention belongs to the technical field of preparation of functional materials, and relates to a preparation method of a zinc oxide / antimony tin oxide composite nano-material. The method comprises the following steps: slowly adding an alcohol solution of zinc acetylacetonate to a tin tetrachloride and antimony trichloride mixed DMF solution in a dropwise manner, fully stirring above solutions to realize uniform mixing, carrying out a cross-linking reaction at a certain temperature, and carrying out heat treatment in a muffle furnace to obtain the zinc oxide / antimony tin oxide composite nano-material. The preparation method is simple and easy, and the zinc oxide / antimony tin oxide composite nano-material has the advantages of high purity, low content of impurities, low preparation cost, excellent performances, and realization of industrial batch production. The zinc oxide / antimony tin oxide composite nano-material prepared in the invention has high catalysis activity as a photocatalytic material, and has wide application prospects in the field of degradation of dye wastewater and indoor harmful gases and the field of photocatalytic disinfection.

Owner:BOHAI UNIV

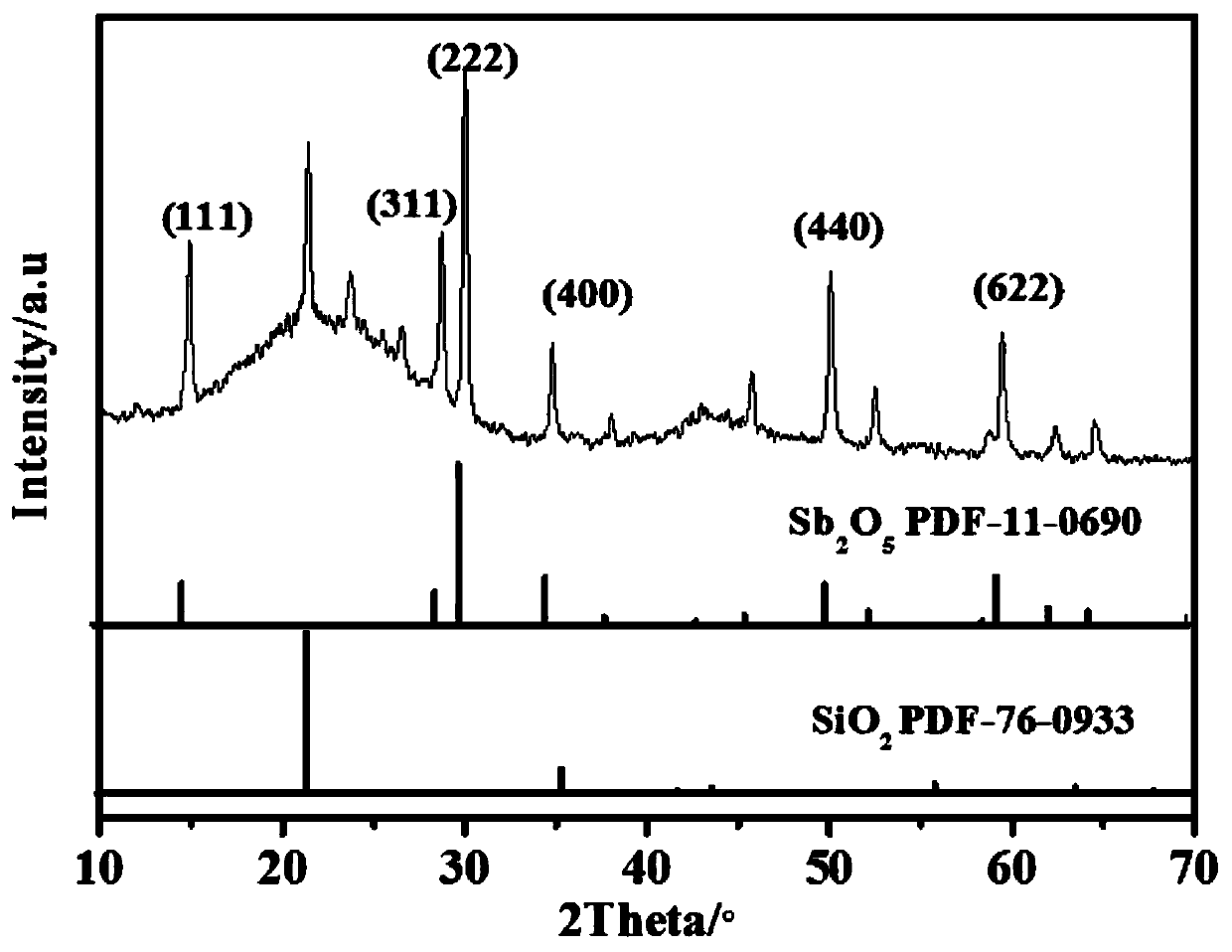

Preparation of antimony pentoxide/silicon dioxide/carbon cloth flexible material and application thereof as negative electrode of sodium-ion battery

The invention discloses preparation of an antimony pentoxide / silicon dioxide / carbon cloth flexible material and an application thereof as a negative electrode of a sodium-ion battery, which comprisesthe following steps: grinding silicon dioxide, adding the silicon dioxide into deionized water for dissolution to obtain a solution A; adding antimony trichloride into the ethanol solution for dissolution to obtain an antimony trichloride solution, and adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value of the antimony trichloride solution to obtain a solution B; adding the solution A into the solution B and stirring to obtain a solution C; impregnating the activated carbon cloth in the solution C, transferring the solution C and the carboncloth into a reaction kettle for hydrothermal reaction, cooling the carbon cloth to room temperature, moving out the carbon cloth, and cleaning and drying the carbon cloth to obtain the antimony pentoxide / silicon dioxide / carbon cloth flexible sodium ion battery negative electrode material. The method is simple to operate and low in cost, and the silicon material can be applied to the negative electrode material of the sodium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of catalyst for treating low-concentration formaldehyde wastewater

InactiveCN106622260AEasy to prepareLow costWater contaminantsHeterogenous catalyst chemical elementsNickel saltEvaporation

The invention provides a preparation method and application of a catalyst for treating low-concentration formaldehyde wastewater. A composite oxide is a nickel antimony vanadium composite oxide. The method is performed according to the following steps of using vanadium pentoxide, soluble nickel salt, antimony trichloride and hydrogen peroxide as raw materials; mixing the materials at low temperature; stirring the mixture till the dissolution; then, performing heating evaporation drying; and roasting the obtained precipitates so as to obtain the nickel antimony vanadium composite oxide powder. The prepared nickel antimony vanadium composite oxide powder is put into an aqueous alkali solution to be subjected to heating treatment; then, filtering and washing are performed until the pH value is 6.9 to 7.2; next, drying is performed; the catalyst is obtained. The catalyst provided by the invention has the characteristics that the activity is high; the hydrogen peroxide can be fast and effectively catalyzed within a short time for degrading contaminants; the wastewater treatment method can be performed at normal temperature and normal pressure without light irradiation; the technical flow process is simple; no secondary pollution is generated; in addition, the operation cost is low, and the like. In addition, the catalyst can be repeatedly used for many times; high practical application values can be realized.

Owner:HUBEI UNIV OF TECH

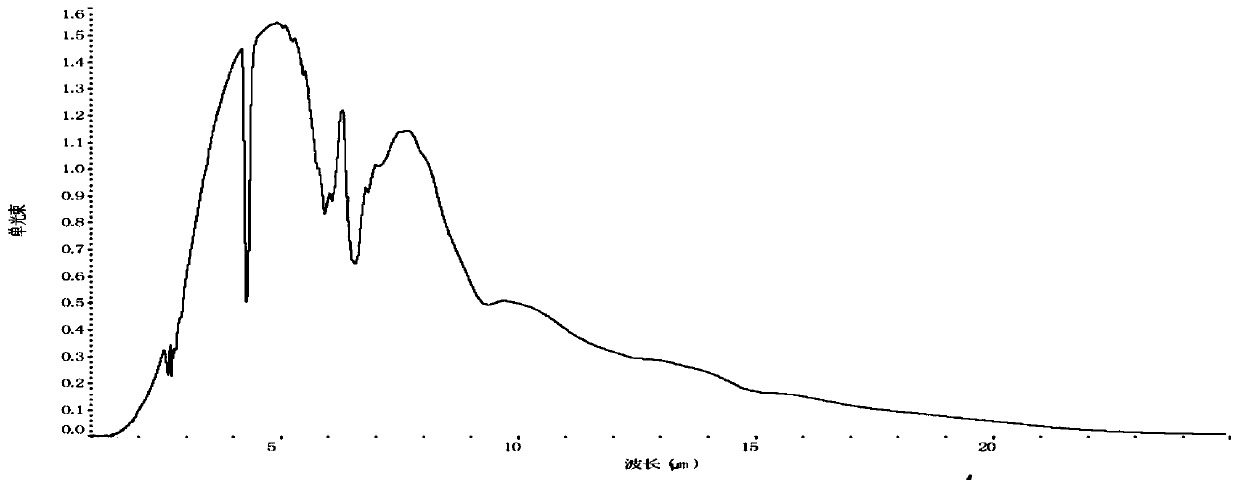

Far-infrared heating material, preparation method of far-infrared heating body and far-infrared heating body

The invention relates to a far-infrared heating material, a preparation method of a far-infrared heating body and the far-infrared heating body. The far-infrared heating material comprises tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate, germanium chloride, hydrochloric acid and a solvent. Metal elements in tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate and germanium chloride have proper energy bands, and cooperate with the conductive film layer for use; after electrification, the outer-layer electrons of the metal elements obtain an energy band, the energy of which is transited to a relatively high energy level and then returns to the energy band with the low energy level, i.e., returning a stable state and generating far-infrared radiation. According to the invention, tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate and germanium chloride cooperate with each other, and energy band matching is generated among molecules of all the components; the interactive transition and mutual promotion are generated among electrons on the outermost layer of metal elements, the conversion efficiency of electric energy-heat energy is improved, energy consumption is reduced, and the heating effect is good.

Owner:东莞市中科智恒新材料有限公司

Preparation method of C/Sb<2>S<3> composite thin-film counter electrode material

ActiveCN105489384AImprove uniformityGood repeatabilityLight-sensitive devicesPhotovoltaic energy generationComposite filmThiourea

The invention provides a preparation method of a C / Sb<2>S<3> composite thin-film counter electrode material. The method comprises the following steps: gradually adding a certain amount of antimony trichloride and thiourea to dimethyl formamide, and uniformly and lastingly stirring the mixture for a period of time to obtain an Sb-Tu precursor solution; carrying out spin-coating on the surface of a carbon nanoparticle thin-film with the solution, and putting the carbon nanoparticle thin-film into an atmosphere furnace for annealing treatment to obtain the C / Sb<2>S<3> composite thin-film; on the other hand, evaporating a solvent of the Sb-Tu precursor solution to dryness in air and carrying out annealing to obtain Sb<2>S<3> powder; and putting a certain amount of powder into a corundum boat, covering the corundum boat with the carbon nanoparticle thin-film, and carrying out constant-temperature thermal evaporation under atmosphere protection for 10 minutes to an hour, so as to obtain the C / Sb<2>S<3> composite thin-film.

Owner:CHINA THREE GORGES UNIV

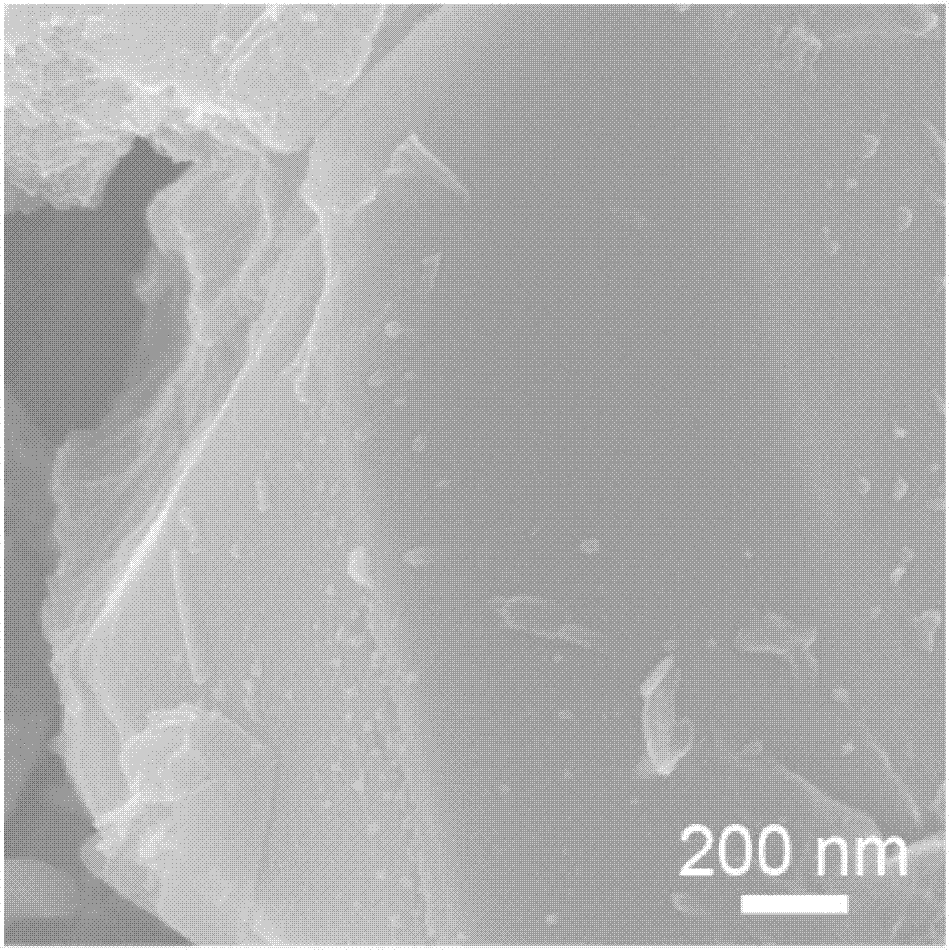

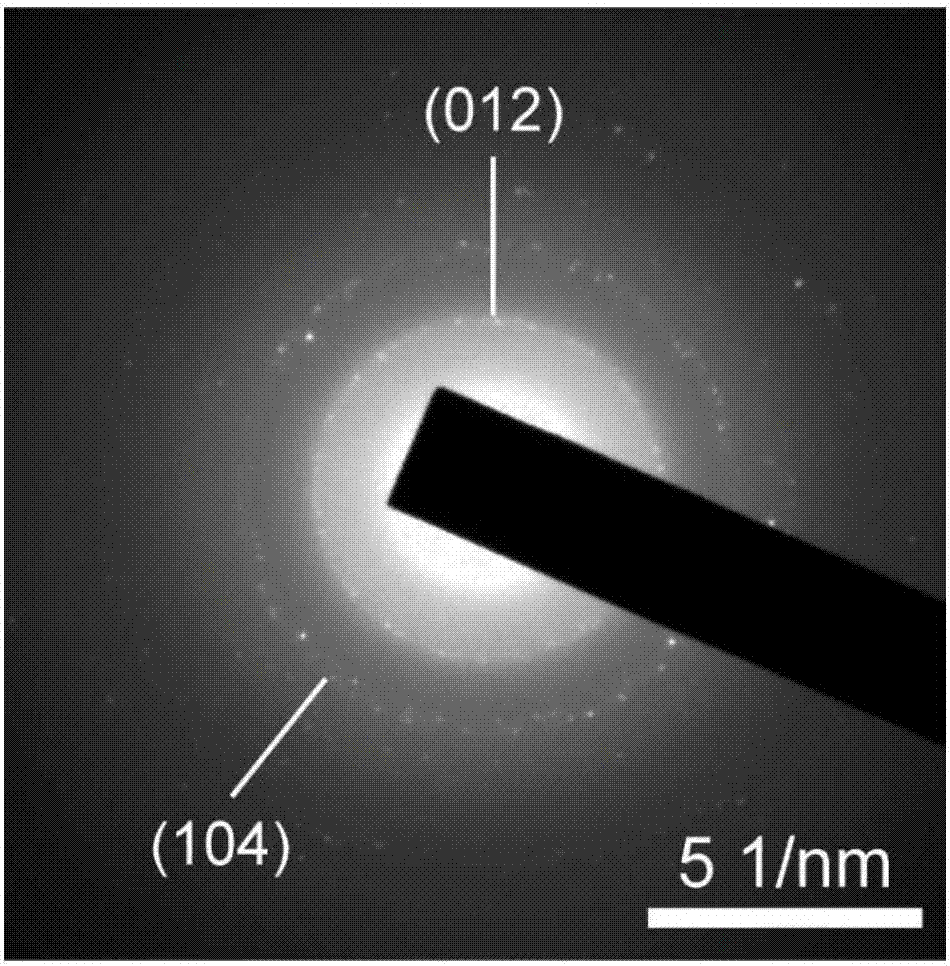

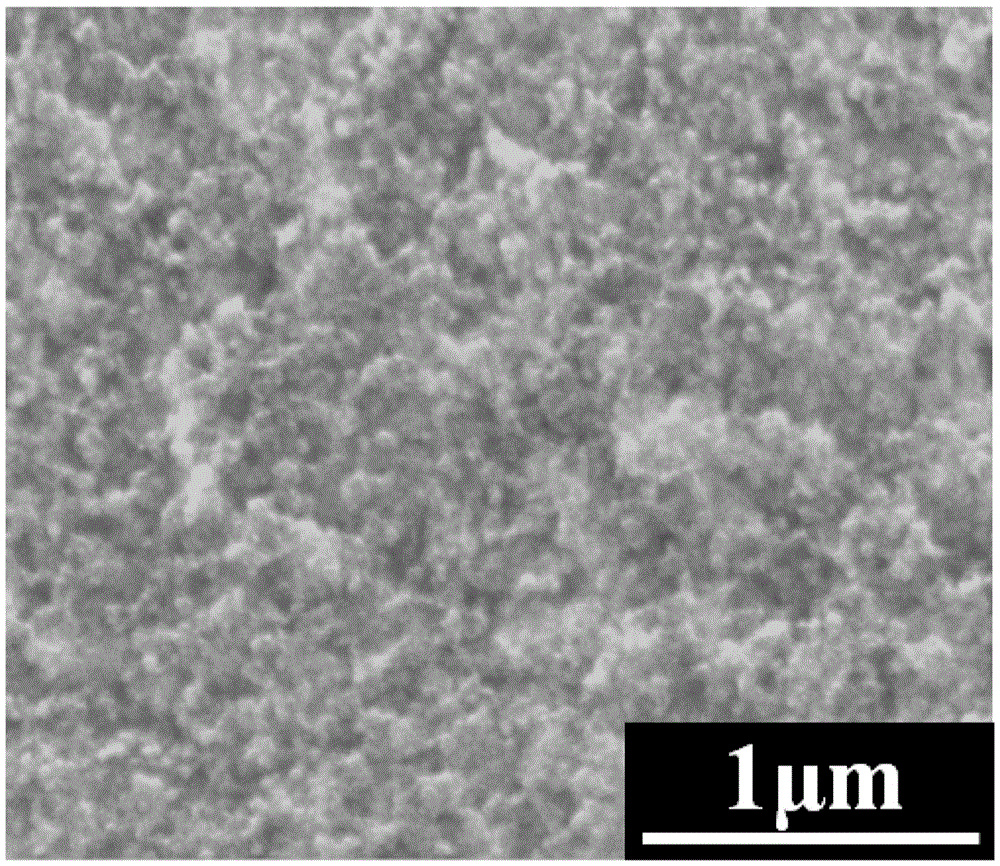

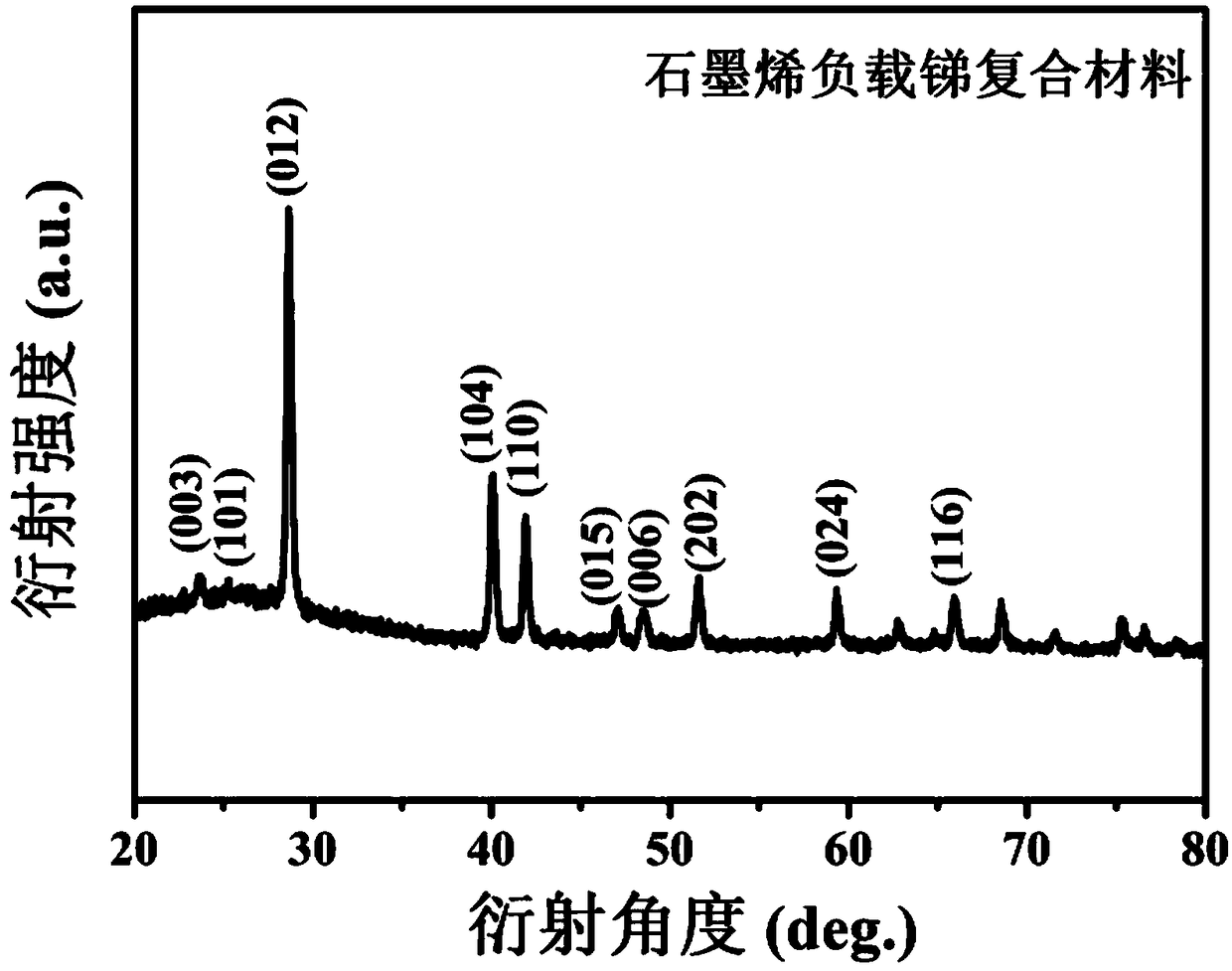

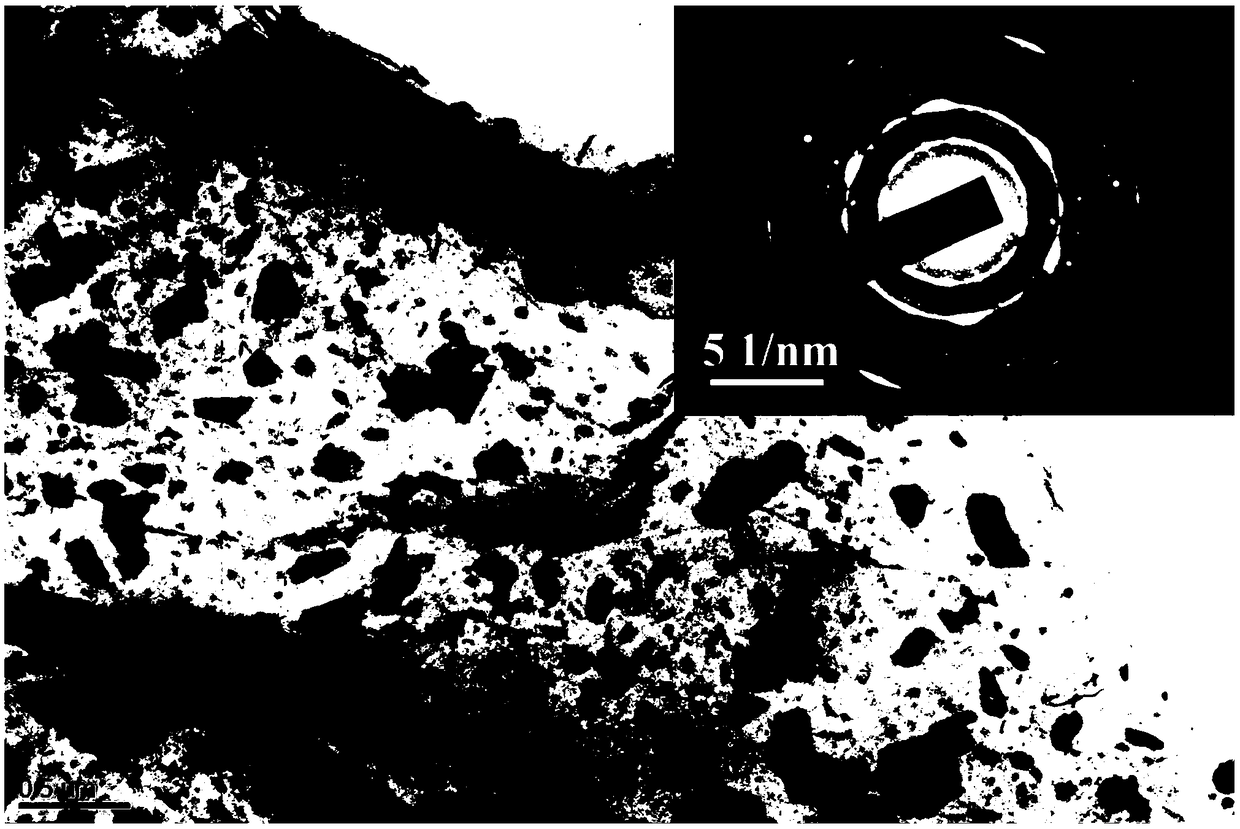

Reduced graphene oxide loaded antimony sodium-ion battery negative electrode material and preparation method thereof

ActiveCN109473663AImproved cycle rate performanceSimple methodCell electrodesHigh current densityReduction treatment

The invention discloses a reduced graphene oxide loaded antimony sodium-ion battery negative electrode material and a preparation method thereof, and relates to the technical field of electrochemicalenergy storage. Antimony trichloride, ammonia water and flake graphite are used as raw materials, graphene oxide is prepared by using a chemical oxidation method and a stripping method, antimony precursor particles are loaded on a graphene oxide sheet layer by an improved liquid-phase synthesis method, and finally thermal reduction treatment is carried out to obtain the reduced graphene oxide loaded antimony sodium-ion battery negative electrode material. The reduced graphene oxide loaded antimony sodium-ion battery negative electrode material has excellent circulation ratio performance; aftercirculation at the high current density of 2A g<-1> for 100 circles, Sb-rGO can still keep the capacity of more than 140mAh g<-1>, and the coulombic efficiency is maintained above 97%; the preparation method provided by the invention does not need to add a surfactant and a reducing agent, the method is simple, the cost is low, and the negative electrode material is suitable for large-scale preparation.

Owner:BEIHANG UNIV

Preparation method of high-purity triethyl antimony

The invention provides a preparation method of high-purity triethyl antimony. Under the protection of inert gas, the preparation method of the high-purity triethyl antimony comprises the following steps: S1, adding a monohalogenated ethane solution into a mixture of magnesium chips and an organic solvent to prepare a Grignard reagent; S2, dropwise adding an antimony trichloride solution into the Grignard reagent, and reacting to prepare a triethyl antimony solution; and S3, carrying out atmospheric distillation twice, reduced pressure distillation twice and reduced pressure rectification once on the triethyl antimony solution to obtain the high-purity triethyl antimony with the purity more than 5N. The method for synthesizing triethyl antimony by adopting a Grignard reagent process is carried out under the protection of the inert gas, the yield is high, the purity is high, the operation is safe, and the cost is low.

Owner:FIRST RARE MATERIALS CO LTD

Production method of terpene resin

The invention relates to a production method of a terpene resin, belonging to the technical field of chemical material production. The invention is an improvement on the basis of the traditional synthesis method of a terpene resin. The production method comprises steps as follows: alpha-pinene or beta-pinene is used as the main raw material, a non-benzene solvent is used as a production solvent instead of methylbenzene or dimethylbenzene, and aluminum trichloride or an aluminum trichloride / antimony trichloride compound system is used as a catalyst; and polymerization is carried out at low temperature or normal temperature, and the product is washed with water to obtain the terpene resin. The solvent is cyclohexane and homologs thereof, and the like, which are saturated alkanes with bioinertness, and the mass ratio of the solvent to the raw material is (0.2-2.0):1; the reaction time is 1-15 hours; the catalyst accounts for 3-10% of the raw material; the reaction temperature range is -10-130 DEG C; and the reaction pressure is 0-0.3MPa (gage pressure). The production technique is simple, safe and sanitary; and the terpene resin synthesized by the method can be used in the field of gum confection bodying agents, hot-melt adhesives for food packaging, sanitary products and the like more safely.

Owner:WUXI XINDA ROSIN & ESTER SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com