Far-infrared heating material, preparation method of far-infrared heating body and far-infrared heating body

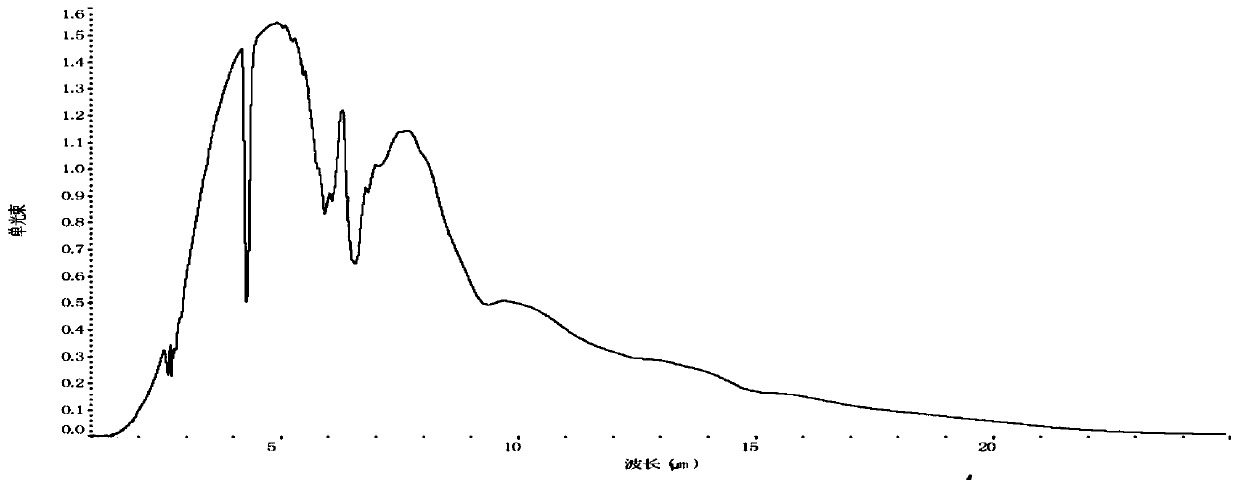

A technology of far-infrared heating and infrared heating elements, applied in the direction of heating element materials, etc., can solve the problems of low far-infrared radiation efficiency, large energy consumption, and unsatisfactory heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing a far-infrared heating element, using the above-mentioned far-infrared heating material, the preparation method comprising the following steps:

[0030] S100: Add hydrochloric acid and solvent into the reaction vessel, mix evenly, add antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate, germanium chloride, tin tetrachloride and tin oxide, stir until each component is completely dissolved, and obtain mixture.

[0031] S200: adding an activator to the mixed solution, mixing evenly, then adding a film-forming resin, stirring and mixing evenly, and standing still to obtain an initial material.

[0032] In one embodiment, the activator is anilinomethyltrimethoxysilane and bisbenzylamino ether, and anilinomethyltrimethoxysilane reacts with the film-forming resin, and forms a film-forming resin with the inorganic component of the far-infrared heating material- The bonding layer of anilinomethyltr...

Embodiment 1

[0045] The preparation method of the far-infrared heating element of the present embodiment comprises the following steps:

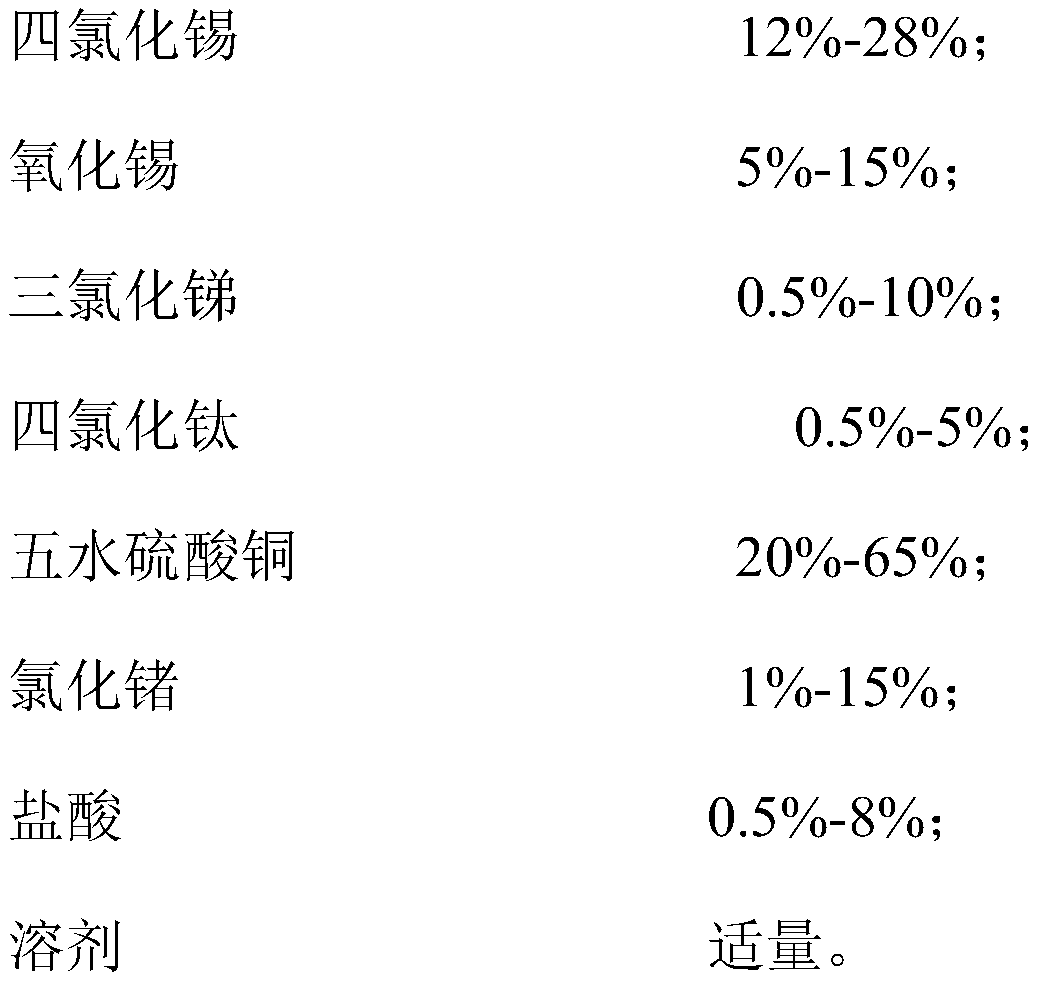

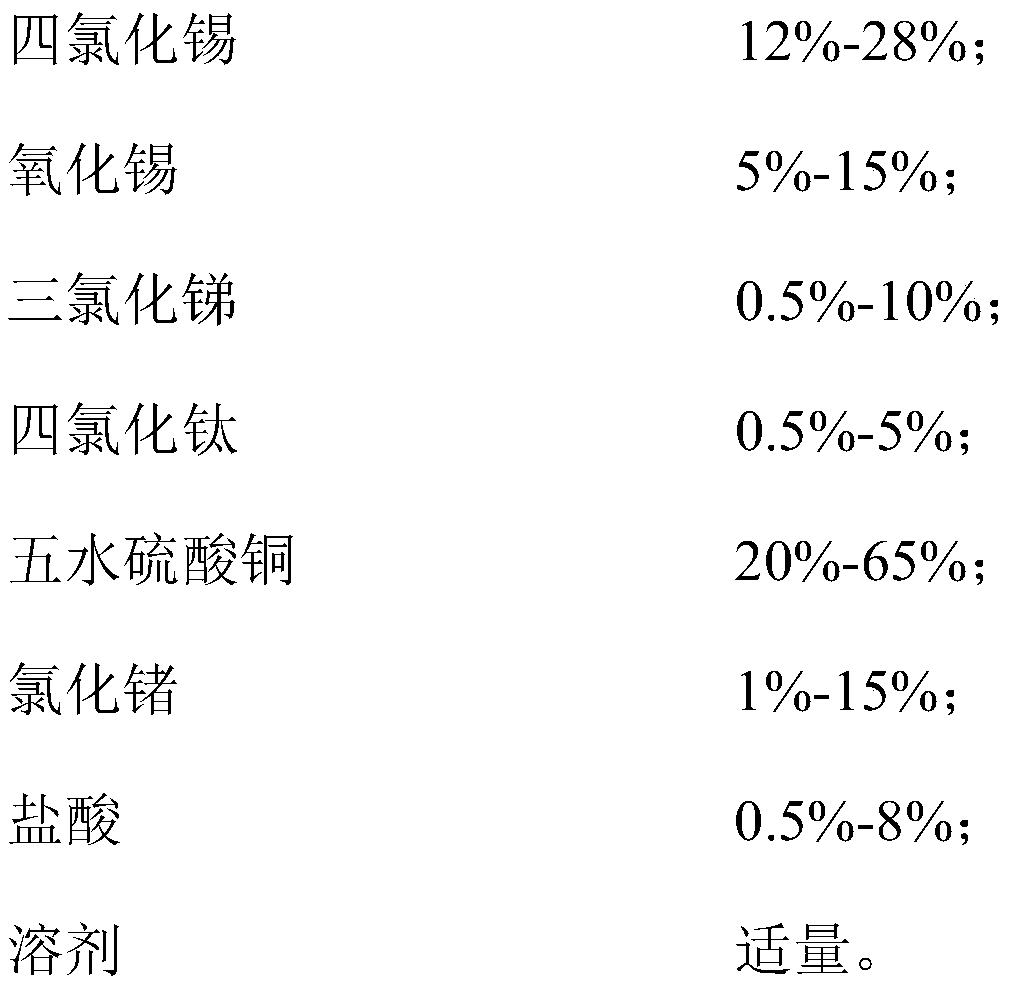

[0046] S050: Weigh the components of the far-infrared heating material according to the following weight percentages: 13% of tin tetrachloride, 15% of tin oxide, 8% of antimony trichloride, 3.5% of titanium tetrachloride, 44% of copper sulfate pentahydrate %, germanium chloride 7%, hydrochloric acid 2% and ethanol 7.5%.

[0047] S100: Add hydrochloric acid and ethanol to the reaction vessel, mix evenly, add antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate, germanium chloride, tin tetrachloride and tin oxide, stir until each component is completely dissolved, and obtain mixture.

[0048]S200: Add an activator to the mixed solution, mix evenly, then add a film-forming resin polystyrene resin, stir and mix evenly, and let stand for 50 minutes to obtain an initial material.

[0049] The activator is anilinomethyltrimethoxysilane an...

Embodiment 2

[0057] The preparation method of the far-infrared heating element of the present embodiment comprises the following steps:

[0058] S050: Weigh the components of the far-infrared heating material according to the following weight percentages: 22% tin tetrachloride, 5% tin oxide, 10% antimony trichloride, 5% titanium tetrachloride, 37% copper sulfate pentahydrate %, germanium chloride 1.5%, hydrochloric acid 5% and ethanol 14.5%.

[0059] S100: Add hydrochloric acid and ethanol to the reaction vessel, mix evenly, add antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate, germanium chloride, tin tetrachloride and tin oxide, stir until each component is completely dissolved, and obtain mixture.

[0060] S200: Add an activator to the mixed solution, mix evenly, then add a film-forming resin, stir and mix evenly, and let stand for 45 minutes to obtain an initial material.

[0061] The activator is anilinomethyltrimethoxysilane and bisbenzylamino ether, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com