Patents

Literature

43 results about "Germanium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Germanium chloride can refer to Germanium dichloride, germanium chloride, GeCl₂ Germanium tetrachloride, germanium chloride, GeCl₄

Preparation process of 68Ge line source used for PET attenuation correction

ActiveCN101777399AIncrease profitImprove radiation resistanceRadioactive sourcesMicrosphereGlass wool

The invention discloses a preparation process of a 68Ge line source used for PET attenuation correction, which aims to provide a preparation process of a 68Ge line source which has high utilization rate, uniform activity distribution and low cost and is used for PET attenuation correction. The process comprises the following steps: (1) putting a ceramic microsphere into a mixed solution of nitric acid and germanium chloride [68Ge], carrying out an oscillating reaction, taking out after the 68Ge is absorbed on the ceramic microsphere, washing and then airing; and (2) evenly filling the dried ceramic microsphere adsorbed with the 68Ge into a stainless steel tube one end of which is sealed, sealing the other end of the stainless steel tube by using glass wool, then sleeving the stainless steel tube into a stainless steel sleeve and finally, connecting the stainless steel sleeve with a magnetic tungsten steel base, wherein the concentration of the nitric acid in the mixed solution in the step (1) is 12 to 15mol / L, the concentration of Ge ions is not greater than 5mg / ml, and the adsorption time is 10 to 20min.

Owner:HTA CO LTD

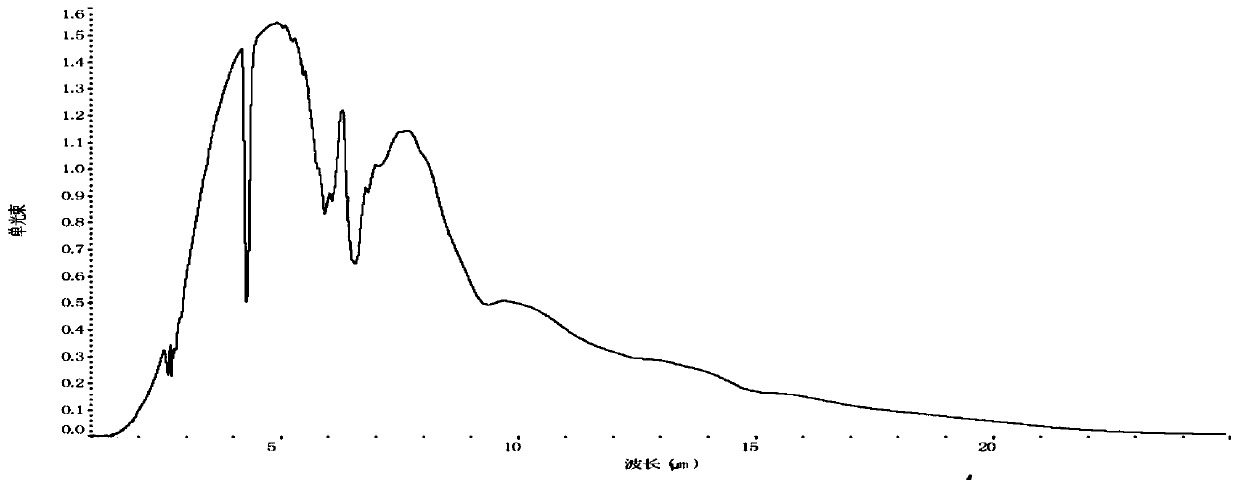

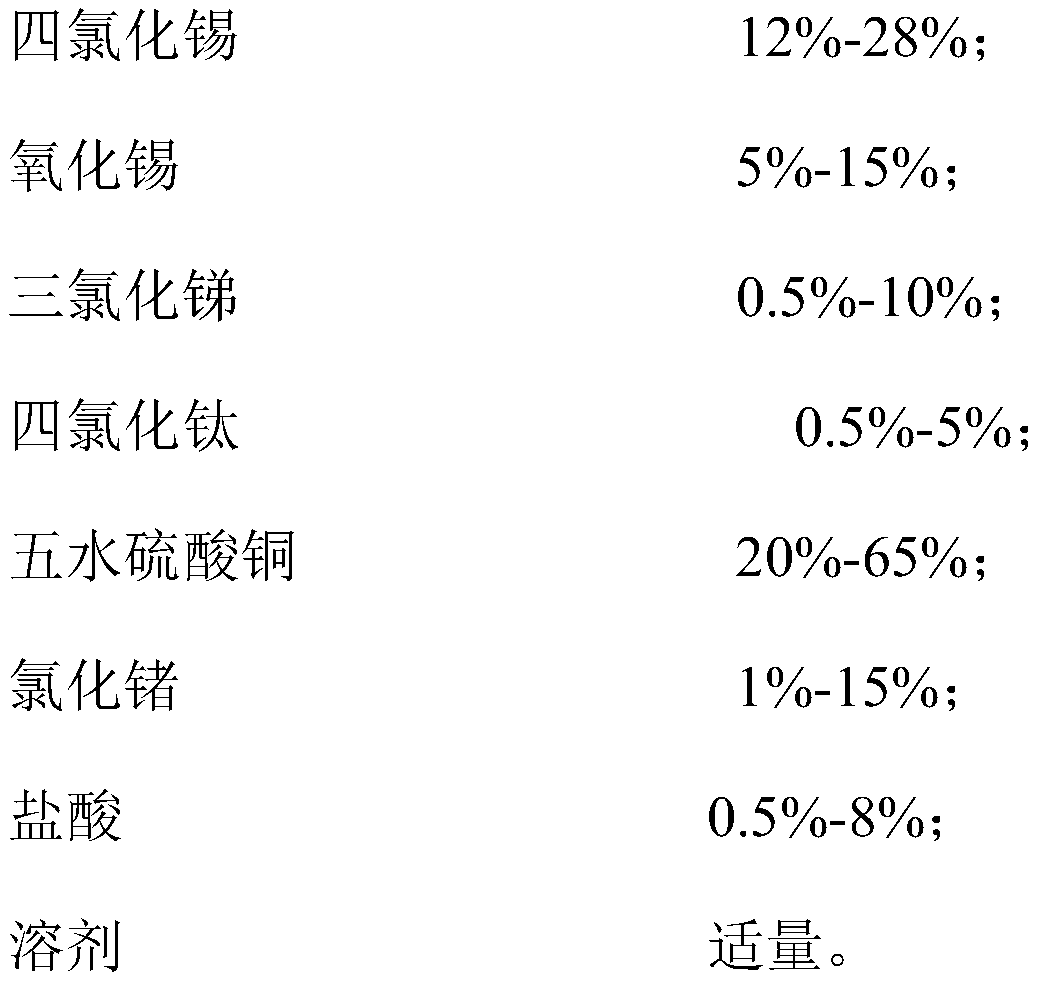

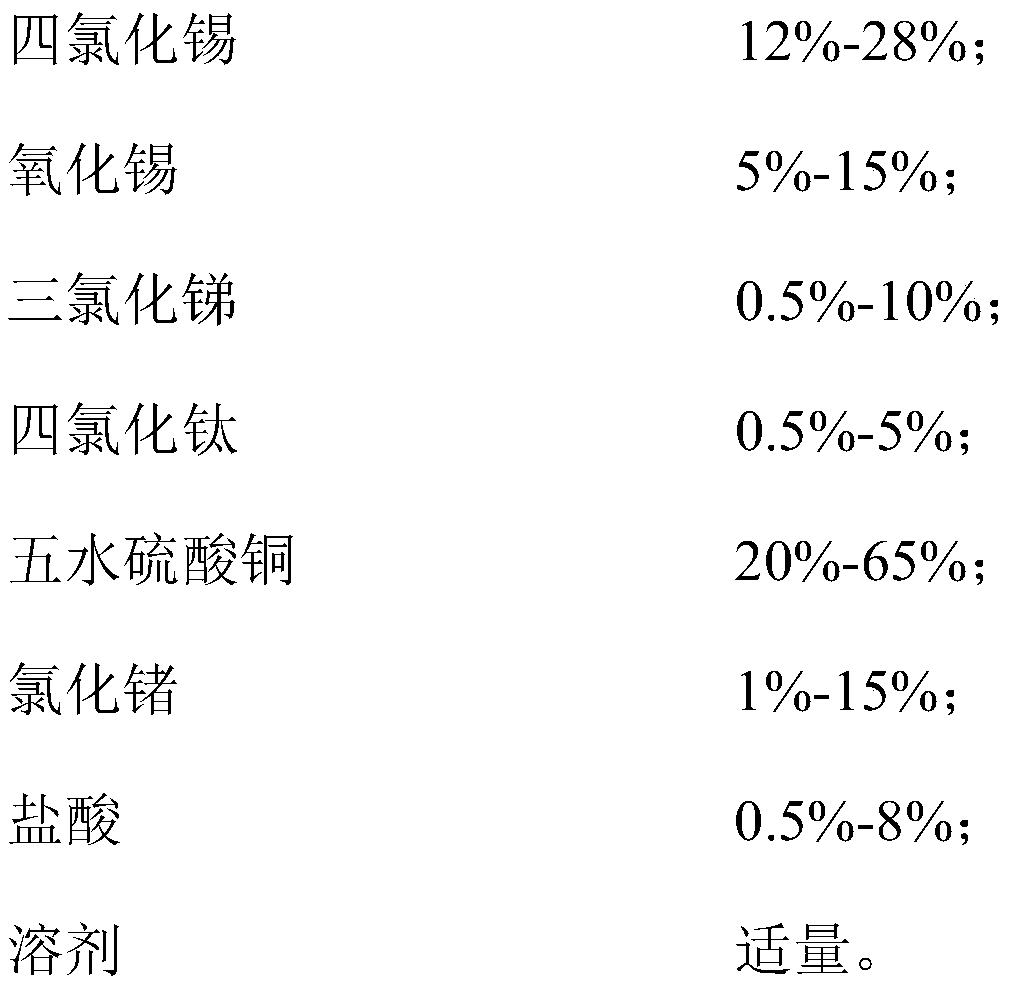

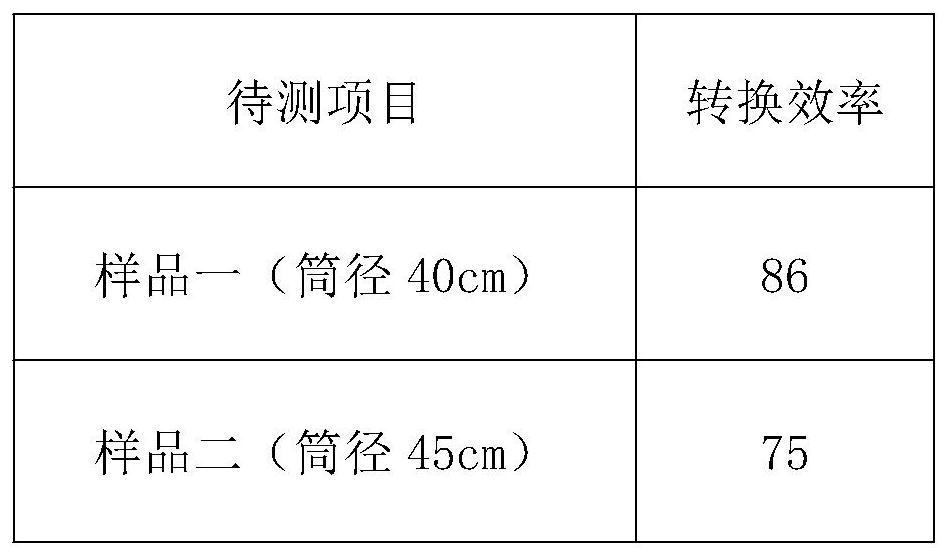

Far-infrared heating material, preparation method of far-infrared heating body and far-infrared heating body

The invention relates to a far-infrared heating material, a preparation method of a far-infrared heating body and the far-infrared heating body. The far-infrared heating material comprises tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate, germanium chloride, hydrochloric acid and a solvent. Metal elements in tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate and germanium chloride have proper energy bands, and cooperate with the conductive film layer for use; after electrification, the outer-layer electrons of the metal elements obtain an energy band, the energy of which is transited to a relatively high energy level and then returns to the energy band with the low energy level, i.e., returning a stable state and generating far-infrared radiation. According to the invention, tin tetrachloride, tin oxide, antimony trichloride, titanium tetrachloride, copper sulfate pentahydrate and germanium chloride cooperate with each other, and energy band matching is generated among molecules of all the components; the interactive transition and mutual promotion are generated among electrons on the outermost layer of metal elements, the conversion efficiency of electric energy-heat energy is improved, energy consumption is reduced, and the heating effect is good.

Owner:东莞市中科智恒新材料有限公司

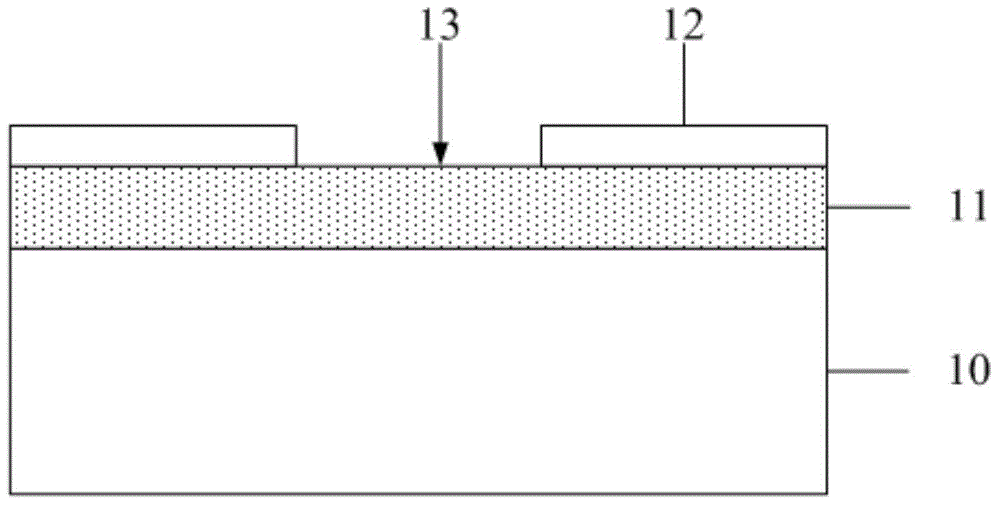

Germanium etching method

ActiveCN104465369AGood lookingImprove performanceSemiconductor/solid-state device manufacturingOxygenPhotoresist

A germanium etching method comprises the steps that a semiconductor substrate is provided; a germanium layer is formed on the semiconductor substrate; part of the germanium layer is removed through a dry etching process, and gas in dry etching contains chlorine; after dry etching is performed, the etched germanium layer is washed with cleaning gas in situ, and the cleaning gas is oxygen. The germanium etching method can remove germanium chloride polymer adhering to the surface of photoresist in the etching process, the appearance of the etched germanium layer is improved, and the yield of formed semiconductor devices is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for producing germanium tetrachloride for optical fibre

InactiveCN101234780AGood removal effectSimple processGermanium halidesPhysical chemistryNitrogen gas

The invention discloses a method for producing germanium tetrachloride for optical fibers, which includes the steps: hydrochloric acid and germanium tetrachloride with a volume ratio of 0.25-2.0: 1 are added into a distiller to be distilled; or while separately distilling the germanium tetrachloride, HCI gas is pumped in until the distilling is finished with the distilling temperature of 76-80 DEG C; after the distilled solution is separated by a hydrochloric separator, the germanium tetrachloride solution is stored in a storage tank to be discharged to an empty tower distiller for 36-72 hours of standing; temperature of the germanium tetrachloride solution is raised to 70-75 DEG C; while continuous pumping nitrogen for 12-36 hours, an ultraviolet lamp is adopted for lighting; finally, distillation operation is carried out at 76-80 DEG C and the product is transferred. The method for producing the germanium tetrachloride for optical fibers has the advantages of simple process course and convenient operation which can remove the impurity containing hydrogen in the germanium tetrachloride with high value for industrial use.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

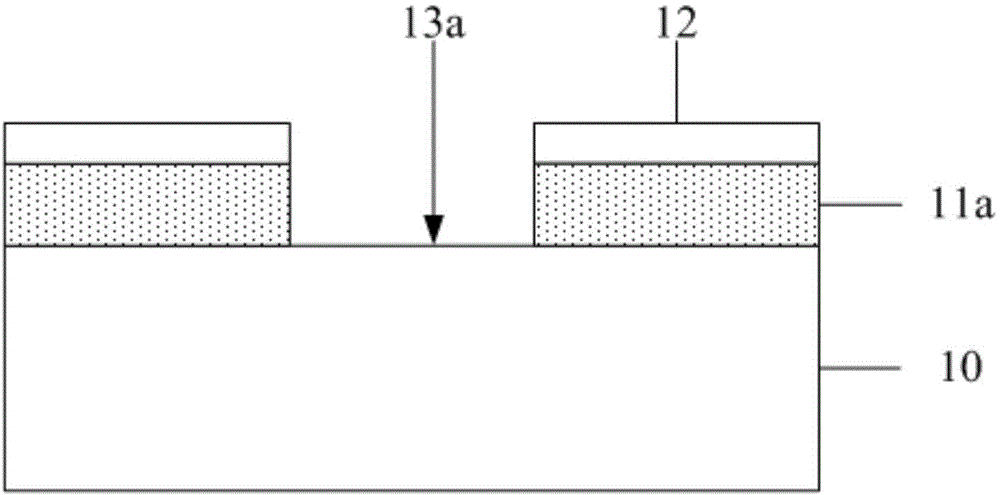

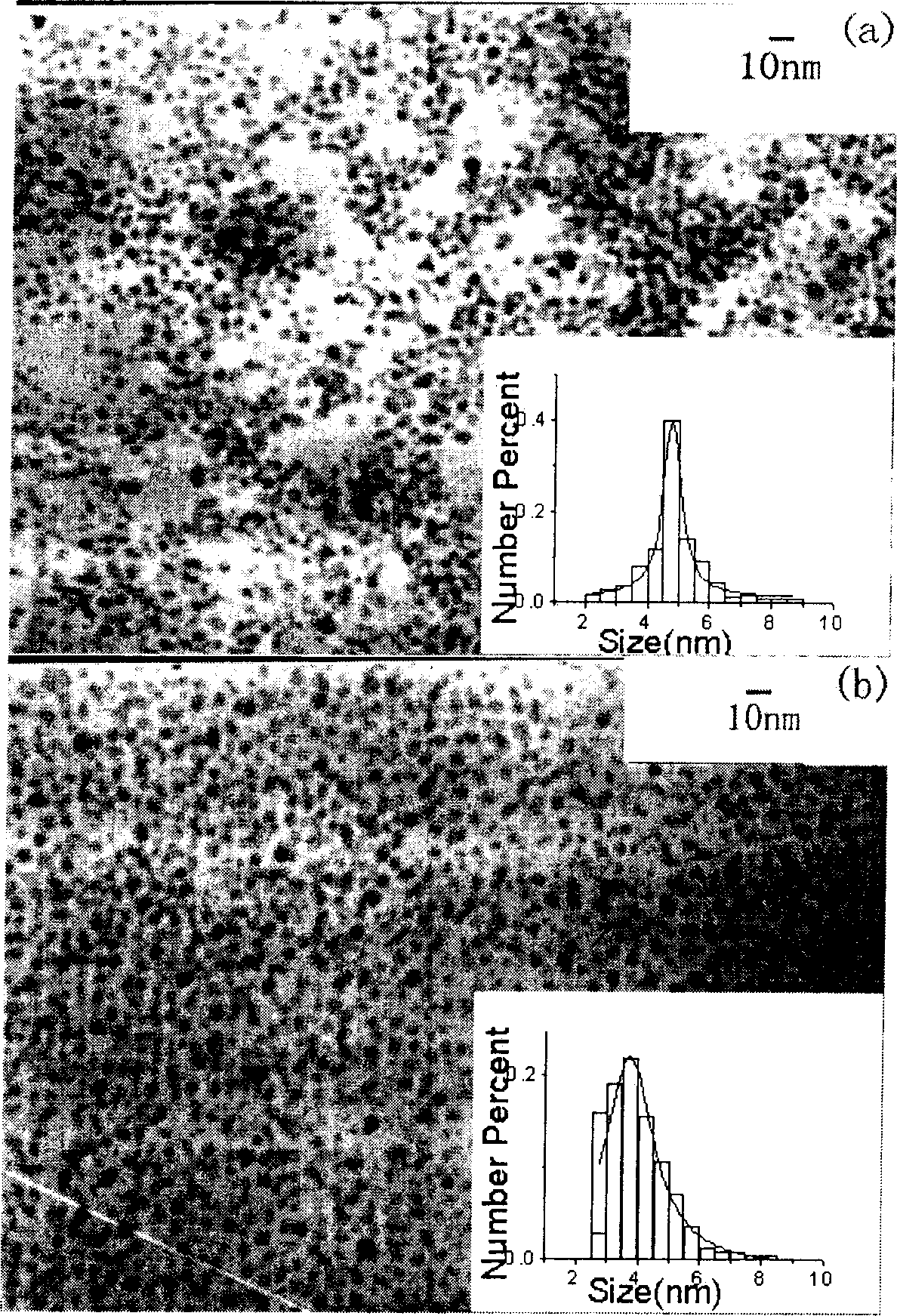

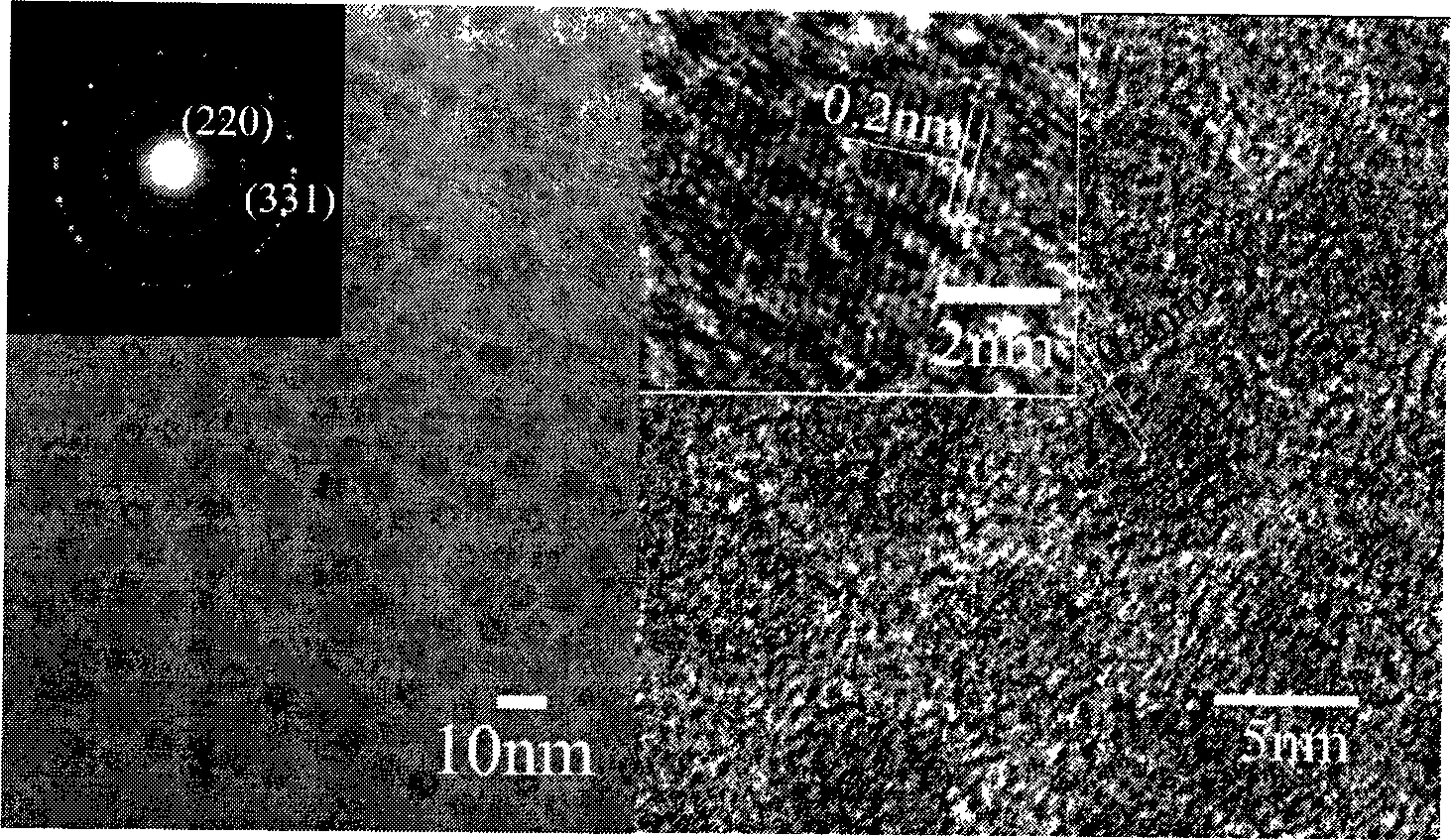

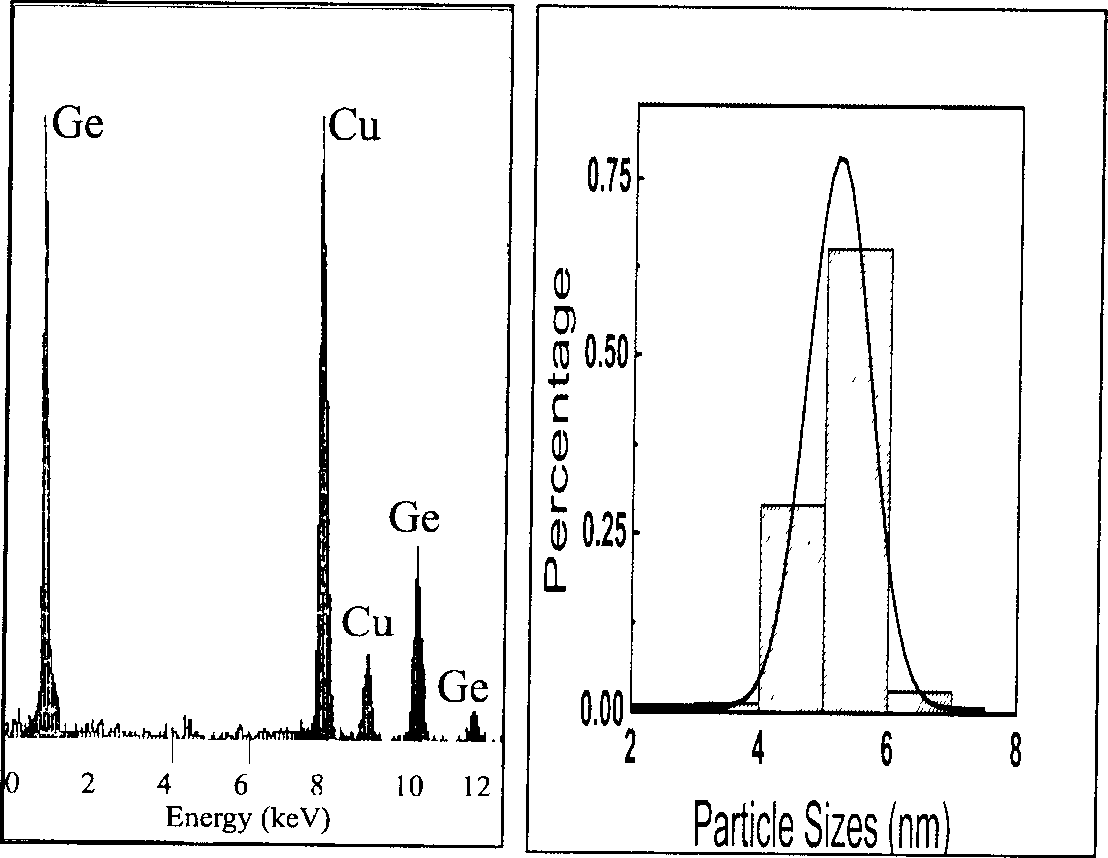

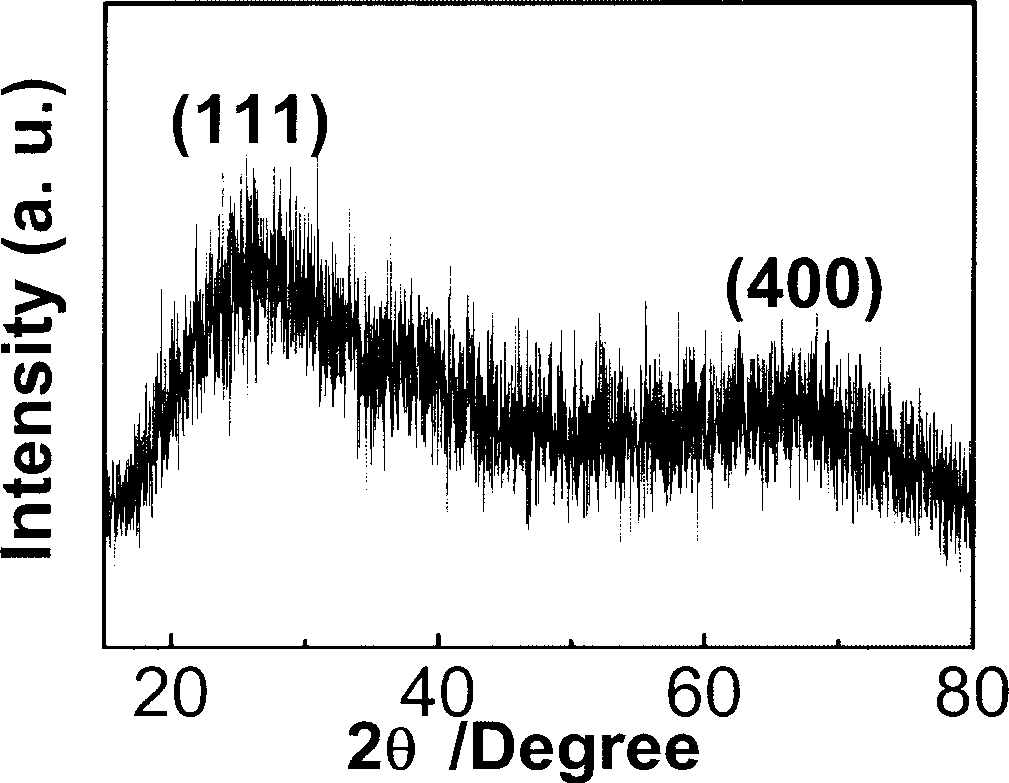

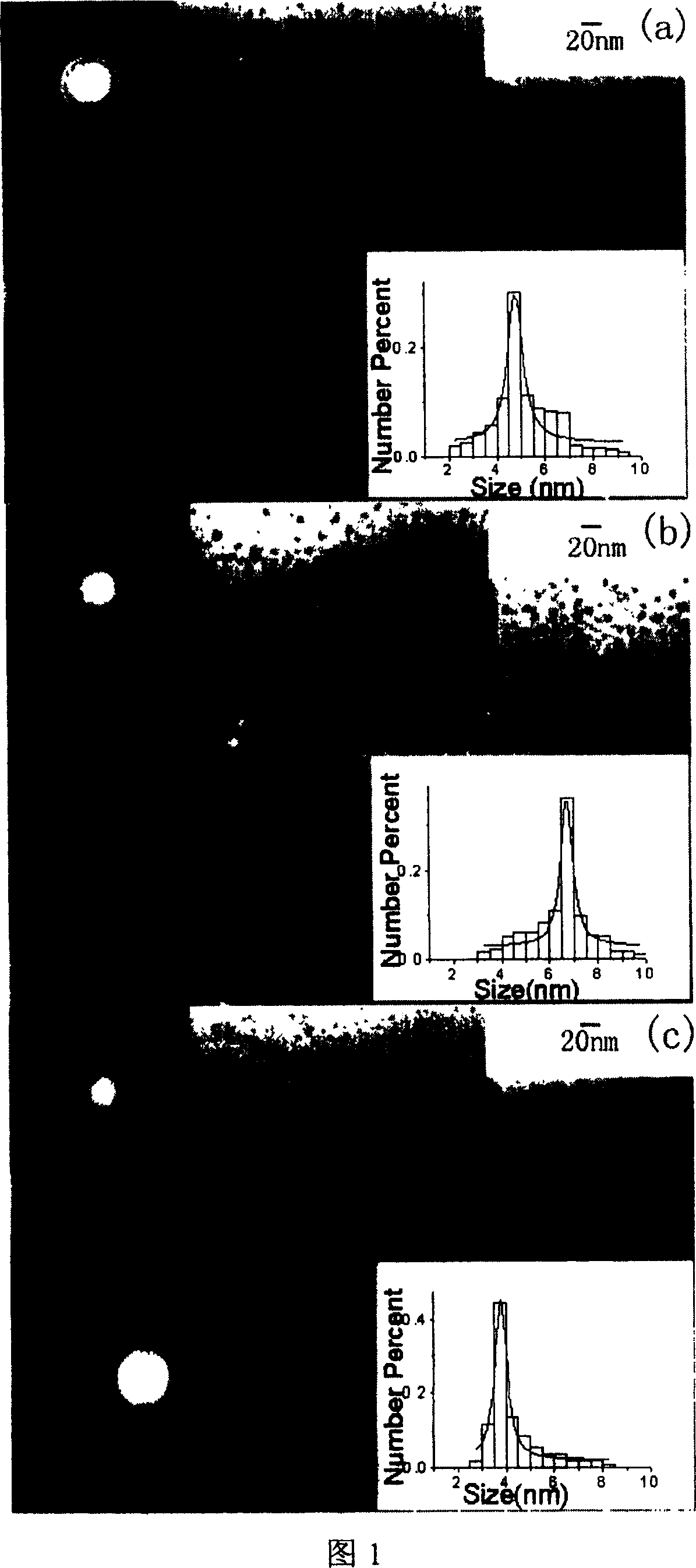

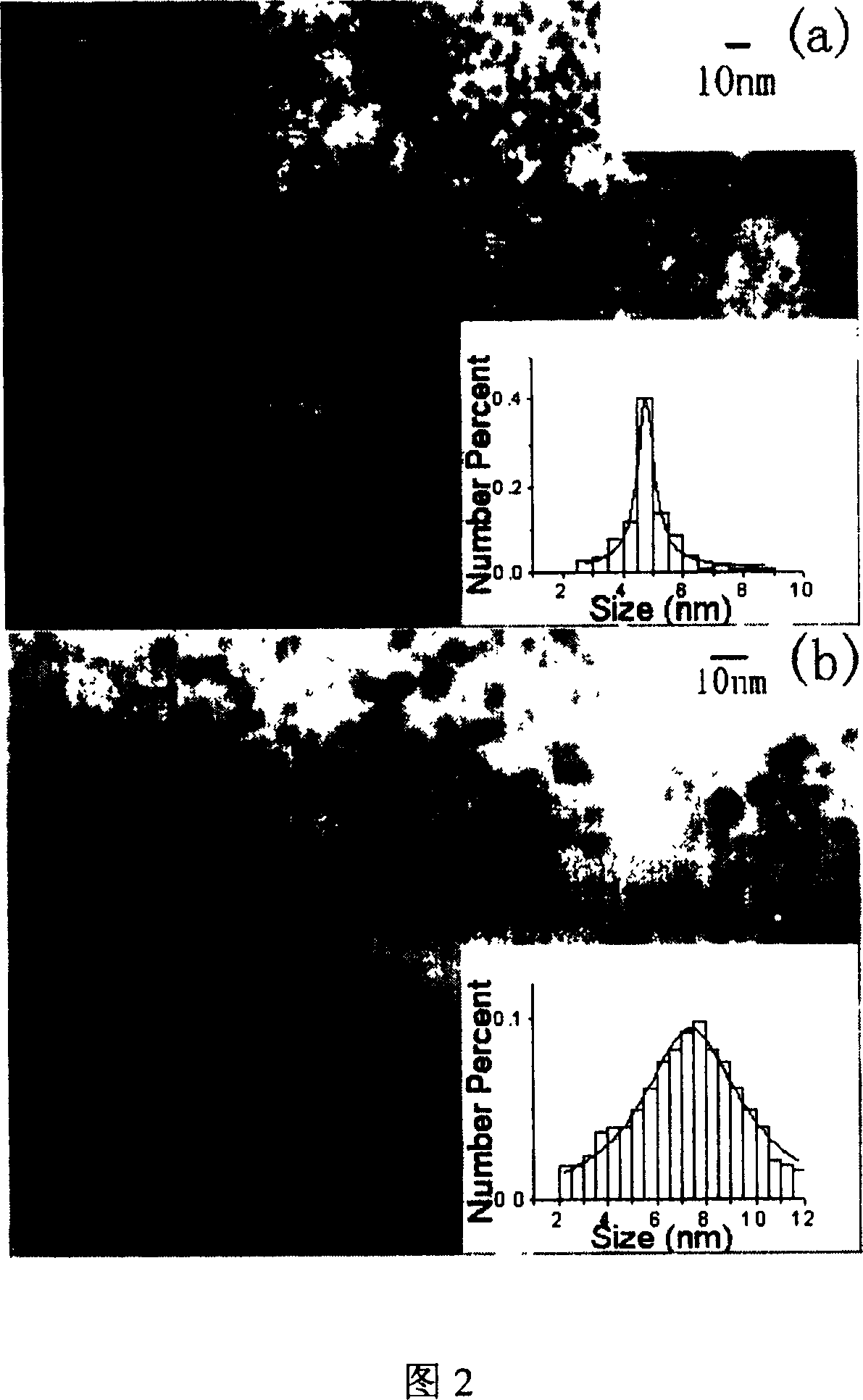

Supersonic liquid phase reduction process for preparing monodisperse nano germanium crystal

The present invention is the process of utilizing metal hydride to reduce germanium chloride to prepare near monodisperse nanometer germanium crystal under supersonic reaction condition. The present invention has high energy supersonic water bath to replace high temperature reaction environment to promote the formation of nanometer crystal and the dispersion in the solution, and adopts strongly reductive metal hydride as reductant for preparing near monodisperse nanometer germanium crystal under room temperature condition. Through experiments, the nanometer germanium crystal preparing conditions are optimized. Preparing monodisperse nanometer germanium crystal is significant in research of the relationship between the performance and the size of nanometer material and is valuable in the design and manufacture of semiconductor devices.

Owner:ZHEJIANG UNIV

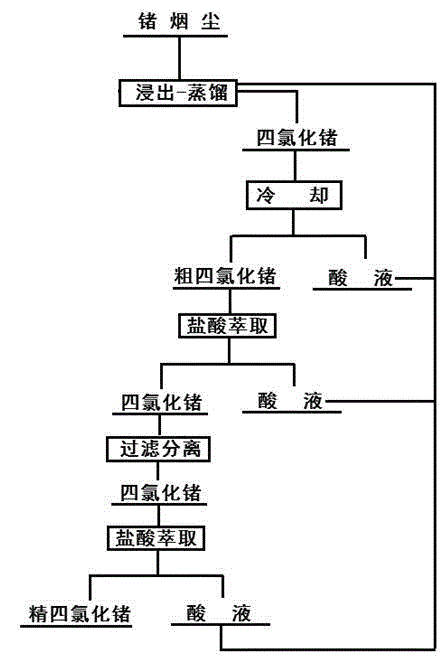

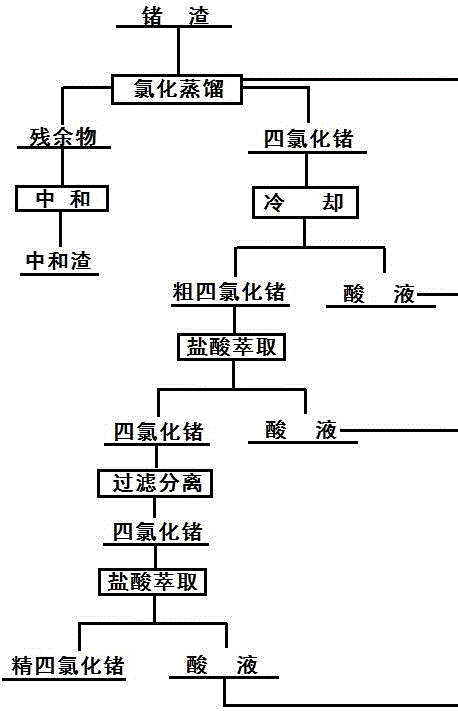

Method for extracting germanium from germanium-containing smoke dust

ActiveCN104789785AStable recoveryHigh purityProcess efficiency improvementRefining (metallurgy)Distillation

The invention relates to a method for extracting germanium from germanium-containing smoke dust, and belongs to the technical field of chemical metallurgy. The method adopts the germanium-containing smoke dust, which is obtained by dry distillation of lignite and has the germanium content of 8.0-30.0wt%, as a raw material to perform extraction, and comprises the following steps: performing leaching distillation on the germanium-containing smoke dust; cooling the obtained gas containing germanium tetrachloride to obtain a crude germanium tetrachloride solution; performing first-time extraction on the crude germanium tetrachloride solution; filtering the germanium tetrachloride solution obtained by the first-time extraction by using a separating column; performing second-time filtration on the obtained germanium tetrachloride solution to obtain a refined germanium tetrachloride solution; and hydrolyzing the obtained refined germanium tetrachloride solution into germanium dioxide, and reducing the germanium dioxide to obtain germanium. According to the method provided by the invention, the technological process is easy to control and strong in operability, the germanium recovery rate is stable, the cost is significantly reduced relative to that of a continuous distillation or continuous extraction process, the purity of germanium can reach more than 99.999%, and the resistivity of germanium is more than 15 ohm cm.

Owner:HEBEI UNIV OF ENG

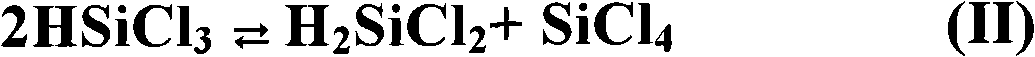

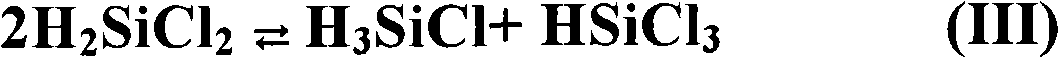

Process and device for preparing compounds or high purity compounds with general formula R<4-m-n>Cl<m>H<n>, especially silicone hydride

InactiveCN101284843ASimple processEasy to operateTin organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilanesFractionating column

The invention relates to a method for making compound or high-purity compound with the general formula equal to R4-m-nAClmHn (A is equal to Si, Ge, Ti or Sn) and a device suitable to carry out the method. Particularly, the invention relates to a device and a method for making silicane with the general formula equal to HnSiCl4-n (n is equal to 1, 2, 3 or 4) through disproportionating highly chloridized silicane under the action of catalyst, wherein the device used in the method is an integrated body based on at least one distillation tower and at least one bypass reactor, i.e. an outer reactor. In one respect, the invention relates to the catalyst of alkylamino trialkoxy silane with the general formula equal to (CxH2x+1O)3Si(CH2)zN(CyH2y+1)2. In addition, the invention also relates to a method for making trichlorosilane (HSiCl3) through the catalytic hydrogenation and dehalogenation of tetrachloro silicane (SiCl4) under a hydric condition. In another respect, the invention relates to a method for making alkyl hydrochlorosilane with the general formula equal to Ia(R4-m-n SiClmHn), wherein m is equal to 1 or 2, while n is equal to 1 or 2; moreover, m plus n is not equal to 3, and R represents alkyl with one to five carbon atoms. Moreover, the invention also discloses a method and a device used in the treatment of silicon tetrachloride, germanium tetrachloride, titanium tetrachloride or stannum tetrachloride mixed with at least one sort of hydrogen containing compound which is difficult to separate through distillation. In addition, the invention also discloses a continuous method, equipment and a reactor used to make high-purity silicon tetrachloride, germanium tetrachloride, titanium tetrachloride or stannum tetrachloride.

Owner:GOLDSCHMIDT CHEM CORP

Electrothermal film, coating process and device

InactiveCN101610610AImprove adhesionUniform resistanceChemical vapor deposition coatingHeating element materialsUltrasound attenuationElectrical resistance and conductance

The invention provides an electrothermal film, which is prepared from tin tetrachloride, antimony chloride, chromium trichloride, gallium chloride and germanium chloride. The invention also provides a coating process and a vapor deposition device. The electrothermal film solves the technical problems that an electrothermal film layer has non-uniform resistance, uneven heat in the process of heating, lower electro-thermal conversion efficiency and short service life of the electrothermal film in the prior art, and simultaneously the technical problem that the unity of the resistance is difficult to control by the conventional electrothermal film production process. Compared with the electrothermal film in the prior art, the electrothermal film of the invention can ensure that the resistance is uniform, the resistance value can be controlled, and insusceptibility to burning and long service life can be achieved; and the adhesiveness of the electrothermal film is greatly improved, no shedding and attenuation, and long service life are ensured, so the electrical property is greatly improved and application range of the electrothermal film is greatly widen.

Owner:谭沉浮

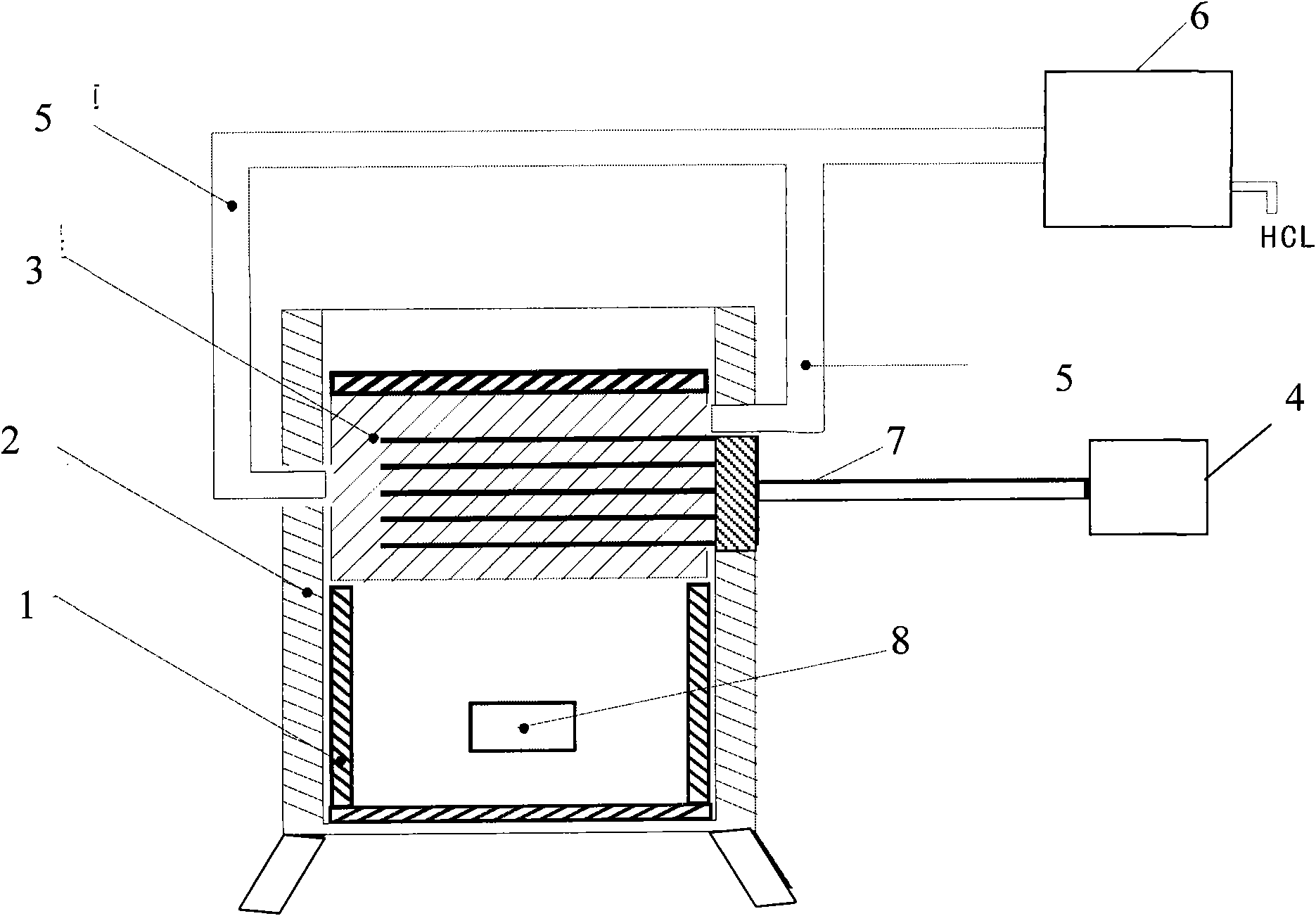

Technique for recovering germanium from electric furnace germanium slag

InactiveCN104818396AHigh purityEasy to controlProcess efficiency improvementRefining (metallurgy)Tetrachloride

The invention relates to a technique for recovering germanium from electric furnace germanium slag, belonging to the technical field of chemical metallurgy. The technique for recovering germanium from electric furnace germanium slag comprises the following steps: carrying out chlorination distillation on the electric furnace germanium slag, cooling germanium-tetrachloride-containing gas obtained by chlorination distillation to obtain a crude germanium tetrachloride liquid, carrying out primary extraction on the crude germanium tetrachloride liquid by using hydrochloric acid containing saturated chlorine, filtering the germanium tetrachloride liquid obtained by primary extraction through a solid-filled separating column, and carrying out secondary extraction on the filtered germanium tetrachloride liquid by using hydrochloric acid containing saturated chlorine, thereby obtaining refined germanium tetrachloride. The technique has the advantages of controllable process, high operability, high and stable germanium recovery rate and high purity of the recovered germanium, and obviously lowers the cost as compared with the continuous distillation or continuous extraction technique.

Owner:HEBEI UNIV OF ENG

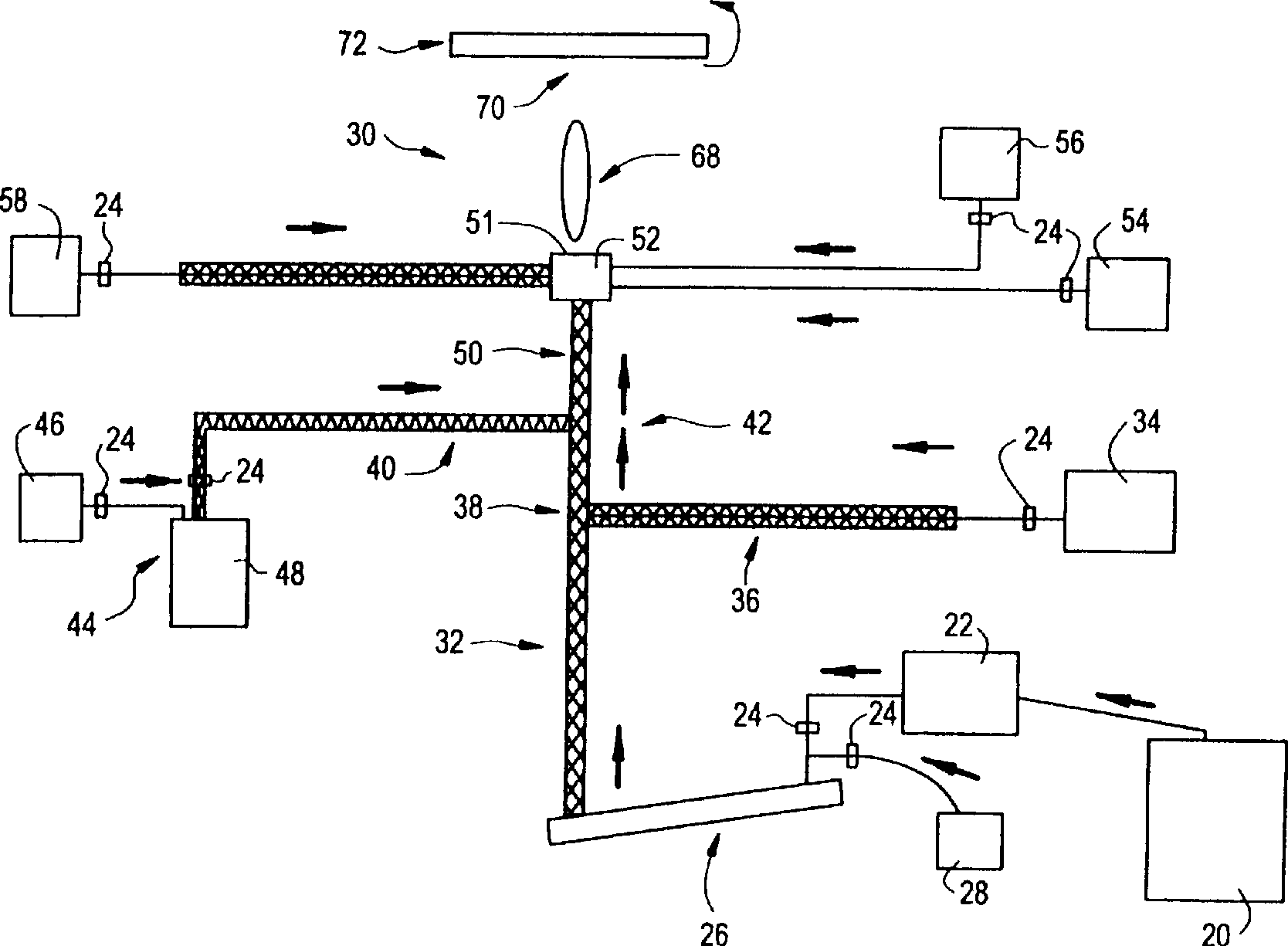

Germanium chloride and siloxane feedstock for forming silica glass and method

Disclosed is a method of making optical waveguide preforms and optical waveguides which may be drawn to a fiber. A silica forming feedstock which includes a mixture of siloxane and germanium chloride and an optical waveguide preform manufacturing apparatus is also disclosed. Further disclosure includes the mixing prior to deposition and use of high purity siloxane with high purity germanium chloride to produce germanium doped silica. The delivery lines for the feedstock to the deposition side may be heated to 175 DEG C-200 DEG C.

Owner:CORNING INC

Optical fiber preform and preparation method thereof

PendingCN111320374AReduce lossAchieving Uniform DistributionGlass deposition burnersSilicon oxideSilicon dioxide

The invention provides a preparation method of an optical fiber preform. A vapor deposition process is adopted, deposition is carried out in sequence through a first blowtorch, a second blowtorch anda third blowtorch; fluoride, silicon tetrachloride, combustible gas, inert gas and oxygen are introduced into the first blowtorch to form a silicon dioxide loose body containing a fluorine element; oxygen, combustible gas, silicon tetrachloride, germanium tetrachloride and inert gas are introduced into the second blowtorch to form a core layer loose body; and oxygen, combustible gas, silicon tetrachloride and inert gas are introduced into the third blowtorch to form a silicon dioxide inner cladding to obtain a core rod; the core rod is subjected to de-hydroxylation and vitrification sintering;a trench layer and a middle cladding are prepared by adopting a fluorine doping process; and an outer cladding is prepared by adopting a vapor deposition process or a sleeve process so as to obtain the optical fiber preform. The concave depth of the core layer is controlled through the bias design of the raw material opening of the first blowtorch, the loss of the prepared product is reduced, anda large effective area is realized.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

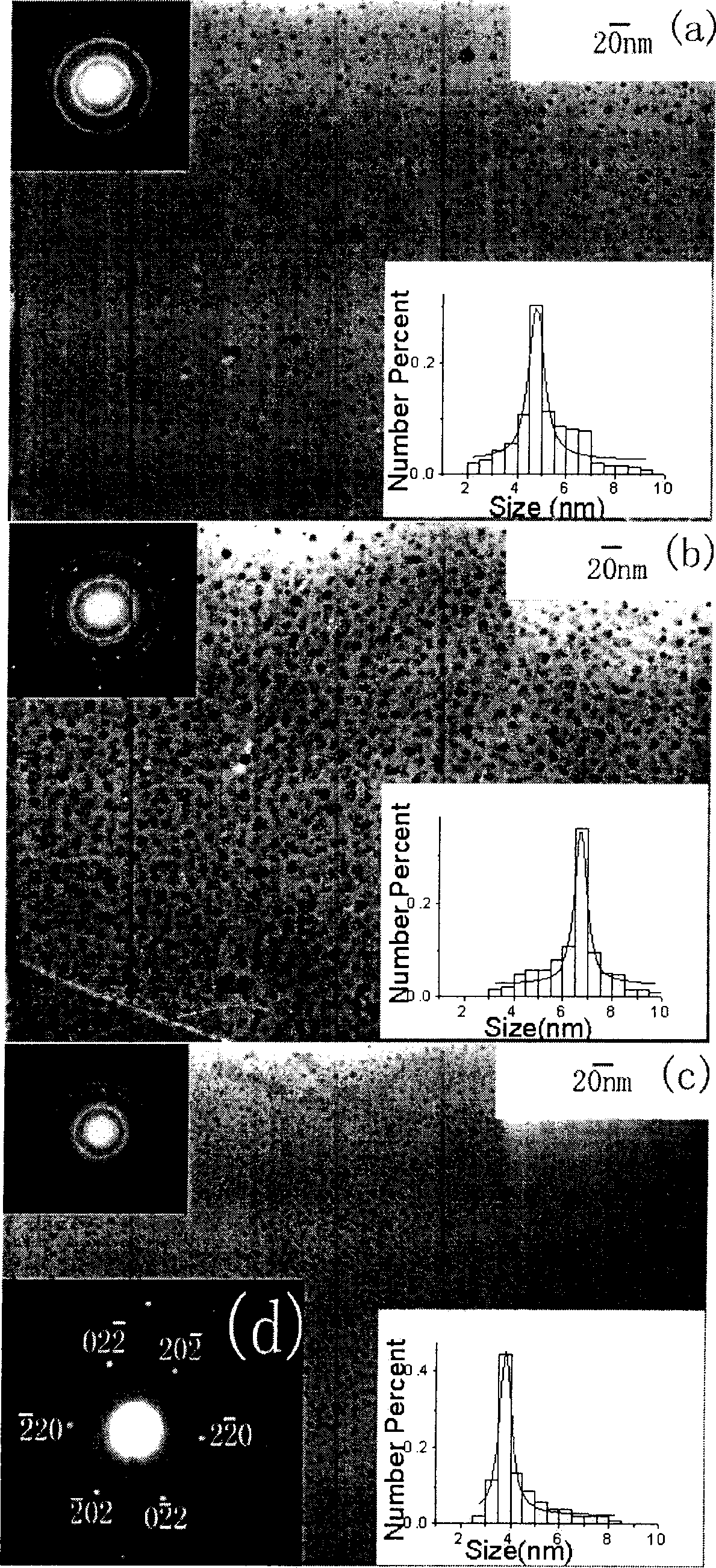

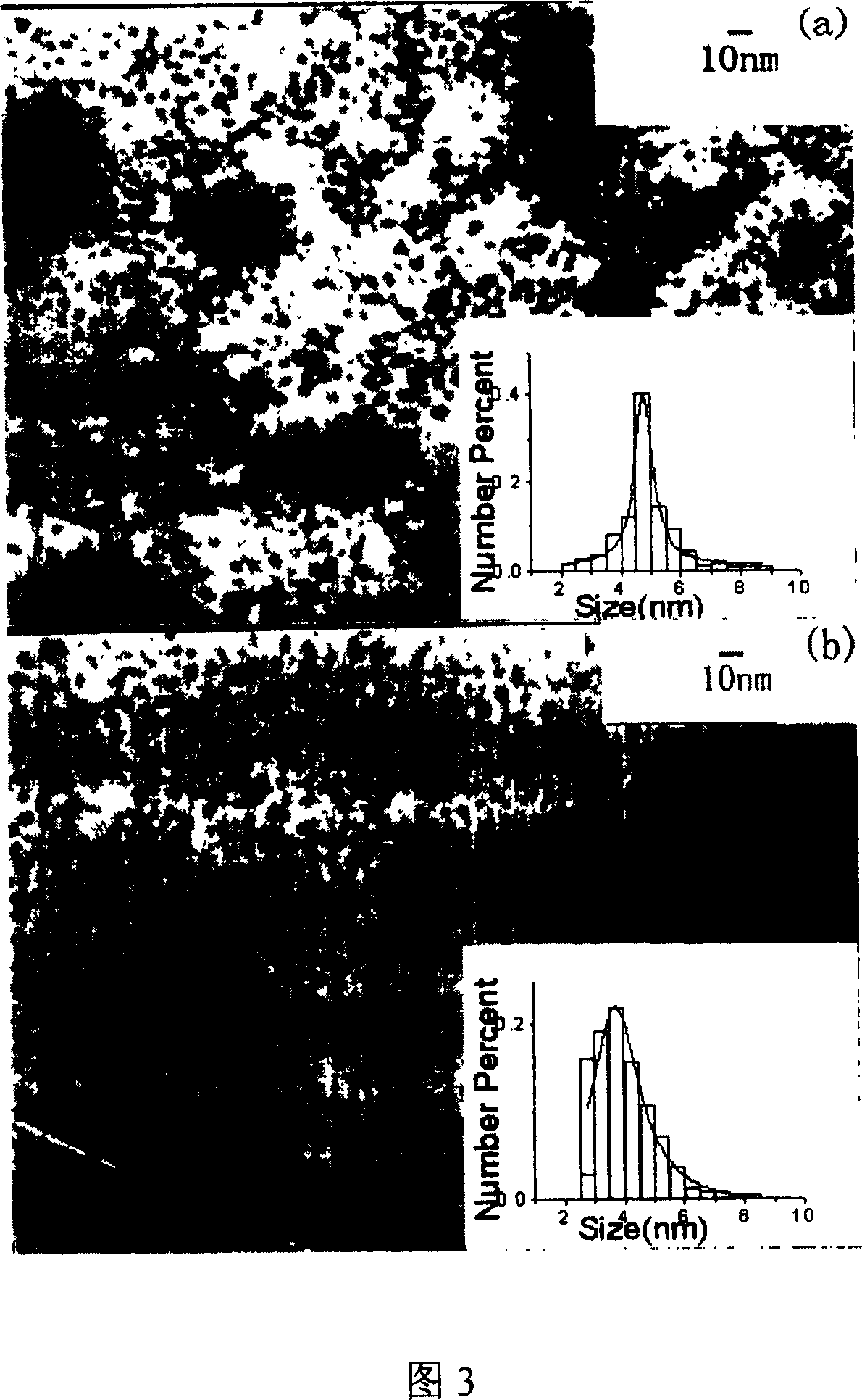

Method for preparing monodisperse germanium nanocrystal by thermolysis

InactiveCN1827863ALow costSimple methodPolycrystalline material growthSingle crystal growth detailsSurface-active agentsComputational chemistry

The invention discloses the method for preparing monodisperse germanium nanocrystalline with thermal decomposition. The method comprises the following steps: germanium chloride and oil amine carrying out addition reaction, getting the oil amine germanium, at 290Deg.C, inverse flow for 7 hours, and getting Ge nanocrystalline particle enwrapped by surface active agent. According to experiment, find the optimum method for preparing nanocrystalline particle. The method has the advantages of low cost, simple technology, important meaning and high practical value in optical device design and manufacture.

Owner:ZHEJIANG UNIV

Production method of health care food with characteristics of rich multiple nutrients and diabetes rehabilitation

InactiveCN103461992AOvercome absorbencyOvercome the disadvantages of side effects caused by direct administrationFood preparationLithium chloridePotassium iodine

The present invention relates to a production method of a health care food with characteristics of rich multiple nutrients, diabetes rehabilitation and complication reduction. The production method comprises: filling grains into a square container, and weighing chromium chloride, zinc chloride, nickel chloride, sodium selenite, sodium metavanadate, germanium tetrachloride, copper sulfate, manganese chloride, iron chloride, lithium chloride, sodium tetraborate, potassium iodide, sodium tungstate, sodium molybdate and cobalt chloride according to a certain mass ratio; mixing the salts, and adding water to dilute to obtain a mixed salt solution until the salt solution is completely absorbed by the grains; and drying and crushing the obtained grains to obtain the health care food. The health care food is rich in multiple trace elements required by human body, wherein the trace elements and amino acids are combined to form multiple amino acid salts, and the amino acid salts are easily absorbed by human bodies so as to maintain balance of multiple trace elements in the human body, prevent and correct metabolic disorders of inorganic salts and trace elements, recover diabetes, reduce complications, and provide good prevention and health care effects for diabetes.

Owner:买世禄 +1

Method used for preparing compounds or high-purity compounds having general formula of R(4-m-n)AClmHn, especially silane, and apparatus thereof

InactiveCN103272637AGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTitanium chloridePtru catalyst

The invention relates to a method used for preparing compounds or high-purity compounds having a general formula of R(4-m-n)AClmHn, and an apparatus suitable for implementing the method, and especially relates to an apparatus for preparing silane having a general formula of HnSiCl4-n through disproportionating highly-chlorinated silane in the presence of a catalyst, and a method thereof, wherein A is Si, Ge, Ti or Sn; n is 1, 2, 3 or 4; and the apparatus used for the method is an assembly composed of at least one distillation tower and at least one bypass reactor which is an external reactor. The invention also relates to a catalyst comprising alkylaminotrialkoxy silane having a general formula of (CxH2x+1O)3Si(CH2)zN(CyH2y+1)2, and a method for preparing trichlorosilane (HSiCl3) through catalytic hydrogenation dehalogenation of tetrachlorosilicane (SiCl4) in the presence of hydrogen. The invention further relates to a method for preparing alkylhydrochlorosilane having a general formula of Ia(R(4-m-n)SiClmHn), wherein m is 1 or 2, n is 1 or 2, the m+n value is not equal to 3, and R represents a C1-5 alkyl group. The invention discloses a method for processing silicon tetrachloride, germanium tetrachloride, titanium tetrachloride or tin tetrachloride containing at least one hydrogen-containing compound which cannot be separated through distillation, and an apparatus thereof. The invention also discloses a continuous method for preparing high-purity silicon tetrachloride, germanium tetrachloride, titanium tetrachloride or tin tetrachloride, and an apparatus and a reactor thereof.

Owner:EVONIK DEGUSSA GMBH

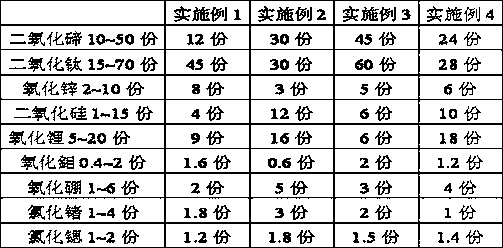

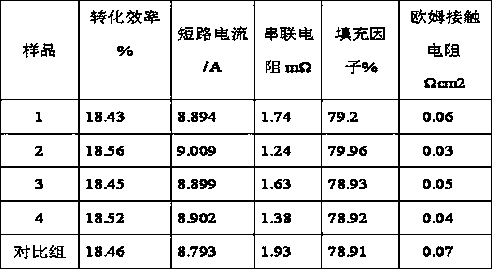

Conductive silver paste used for solar cells

InactiveCN108666002AImprove conversion efficiencySpeed up the flowNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFine lineStrontium chloride

The invention discloses conductive silver paste used for solar cells. The conductive paste consists of the following components, by weight: 75-92 parts of silver powder, 5-12 parts of an organic solvent, 2-3 parts of an organic carrier, 0.5-1 part of alkyl phenol polyoxyethylene ether, and 0.8-5.3 parts of metal microcrystalline glass powder. The particle size D50 of the metal microcrystalline glass powder is 0.3-2 mu m. The metal microcrystalline glass powder consists of the following components: 10-50 parts of tellurium dioxide, 15-70 parts of titanium diboride, 2-10 parts of zinc oxide, 1-15 parts of silicon dioxide, 5-20 parts of lithium oxide, 0.4-2 parts of molybdenum oxide, 1-6 parts of boron oxide, 1-4 parts of germanium chloride, and 1-2 parts of strontium chloride. The conductivepaste effectively improves the conversion efficiency of cells, and has the characteristics of high temperature viscosity and large surface tension. Molten glass cannot not flow easily during a pastesintering process, thereby maintaining a fine line shape.

Owner:SUZHOU ISILVER MATERIALS

Method for green production of germanium tetrachloride from germanium mud

The invention discloses a method for green production of germanium tetrachloride from germanium mud, and relates to the technical field of chemical production. The method comprises the following steps: S1, pretreating germanium mud; S2, slurrying and heating the germanium mud; S3, dropwise adding a 35% hydrogen peroxide solution for oxidation; S4, conducting filter pressing and drying; and S5, adding hydrochloric acid for distillation. Germanium tetrachloride is produced by adopting a hydrogen peroxide oxidation and hydrochloric acid chlorination distillation method, a hydrogen peroxide solution is used as an oxidizing agent in the process, distillation raffinate does not contain solid waste residues, a production pipeline is not blocked, the production process is assisted by ultrasonic oscillation and microwave heating, and the reaction process is completed in an oxidation kettle and a distillation kettle. The direct recovery rate of germanium tetrachloride produced from germanium mudis increased through accurate control, and the problems that a large amount of acid-containing ferrous chloride waste residues are easily generated in an existing ferric trichloride oxidation and hydrochloric acid chlorination distillation process, a large amount of crystals are separated out to block a pipeline after distillation raffinate is cooled, and the direct recovery rate is not high aresolved.

Owner:云南驰宏国际锗业有限公司

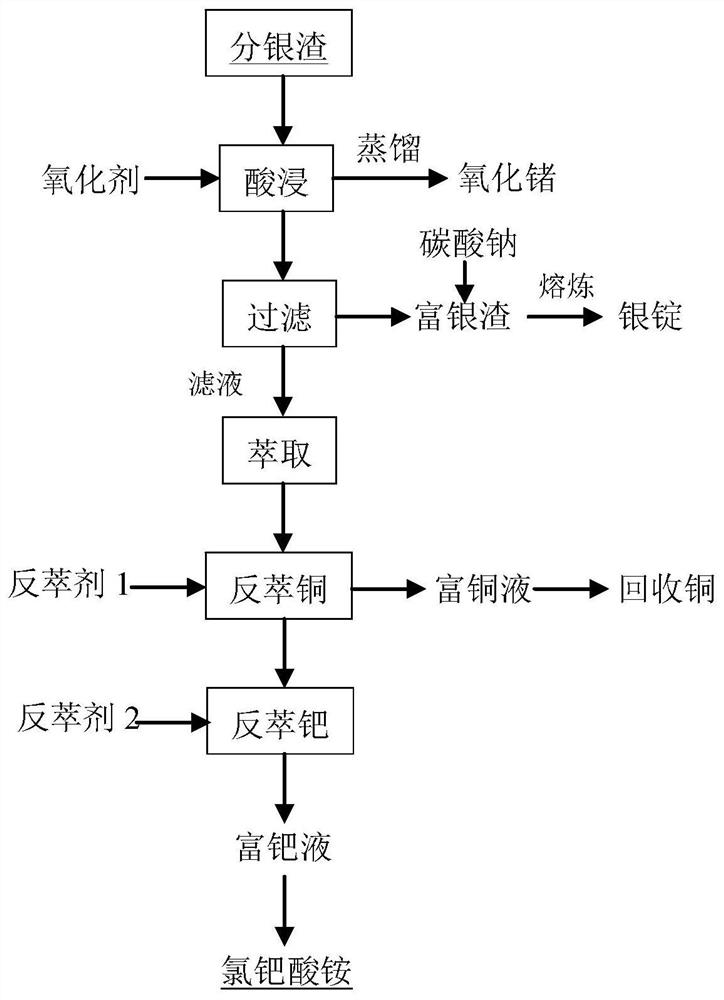

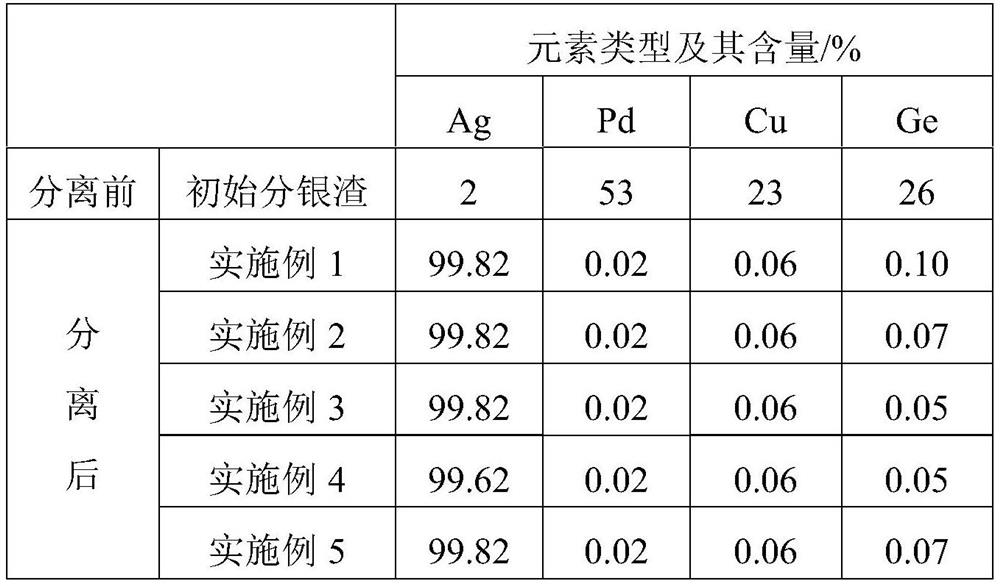

Method for separating and extracting silver, palladium, copper and germanium in silver separation residues

InactiveCN113337723AEfficient recyclingSimple processProcess efficiency improvementWater chlorinationOxidizing agent

The invention provides a method for separating and extracting silver, palladium, copper and germanium in silver separation residues. The method comprises the steps that S1, water is added into the silver separation residues for size mixing, after uniform stirring, an acid solution and a chlorine-containing oxidant are added, a system is heated and distilled, germanium chloride liquid is obtained, and the germanium chloride liquid is subjected to hydrolyzing and post-treatment to obtain germanium oxide; S2, the silver separation residues obtained after the reaction in the step S1 are filtered, leaching residues and filtrate are obtained, the leaching residues and sodium carbonate are smelted after being uniformly mixed, and metal silver is obtained; S3, organic extraction liquid is added into the filtrate obtained in the step S2, element palladium element and element copper are extracted and separated, and the organic extraction liquid comprises an extraction agent and an organic diluent; S4, a mixed liquid loaded organic phase obtained in the step S3 is subjected to reverse extraction and separation on the element palladium and the element copper, and copper reverse extraction liquid and palladium reverse extraction liquid are obtained; S5, the copper reverse extraction liquid is concentrated and crystallized to obtain copper salt, and a precipitator is added into the palladium reverse extraction liquid to prepare ammonium chloropalladate precipitate; and S6, ammonium chloropalladate is subjected to calcining and reduction to obtain metal palladium.

Owner:FIRST RARE MATERIALS CO LTD

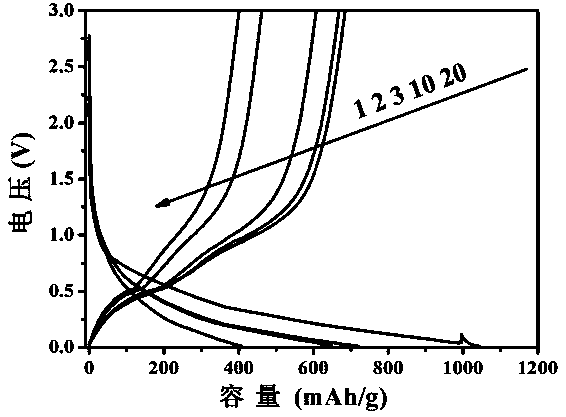

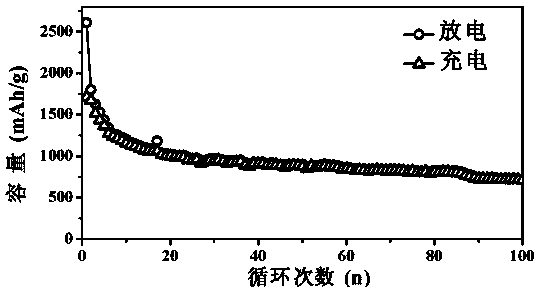

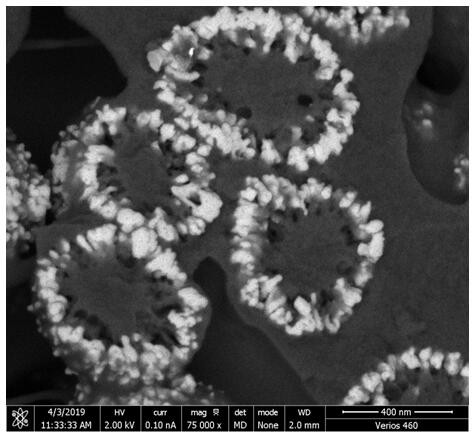

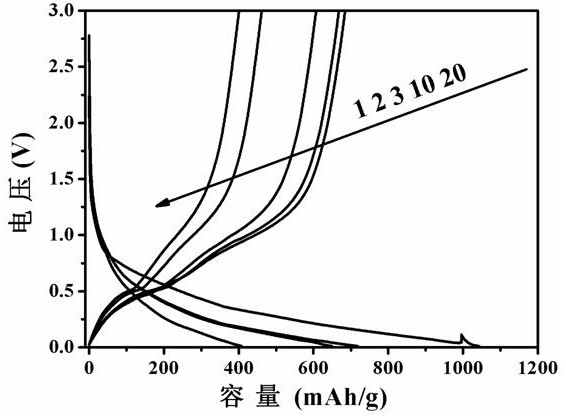

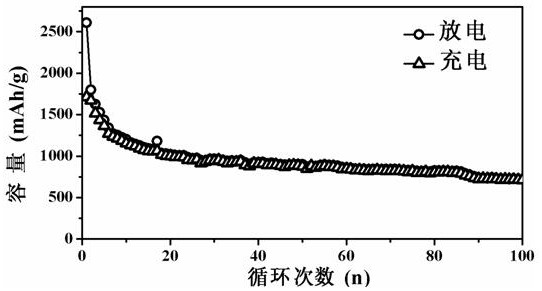

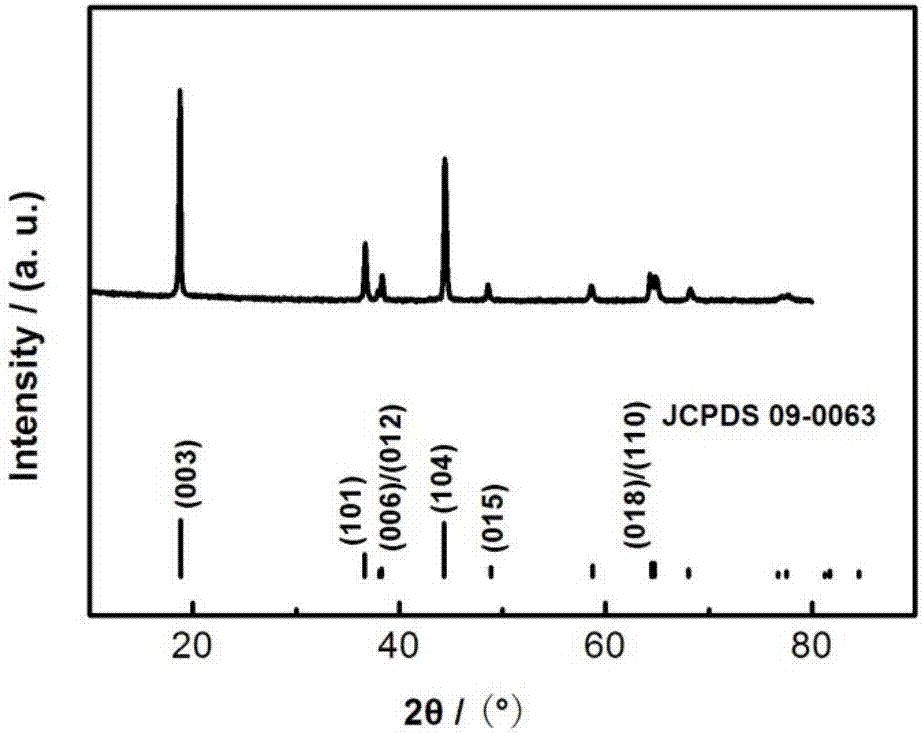

Annular nano germanium dioxide/polyion liquid composite material and preparation method and application thereof

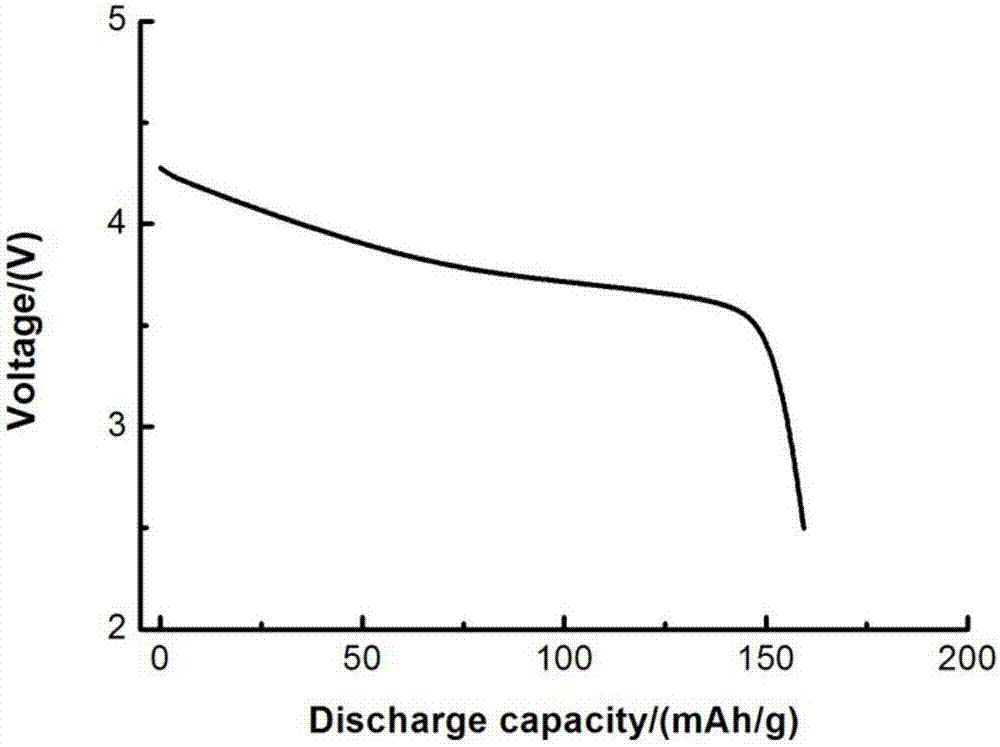

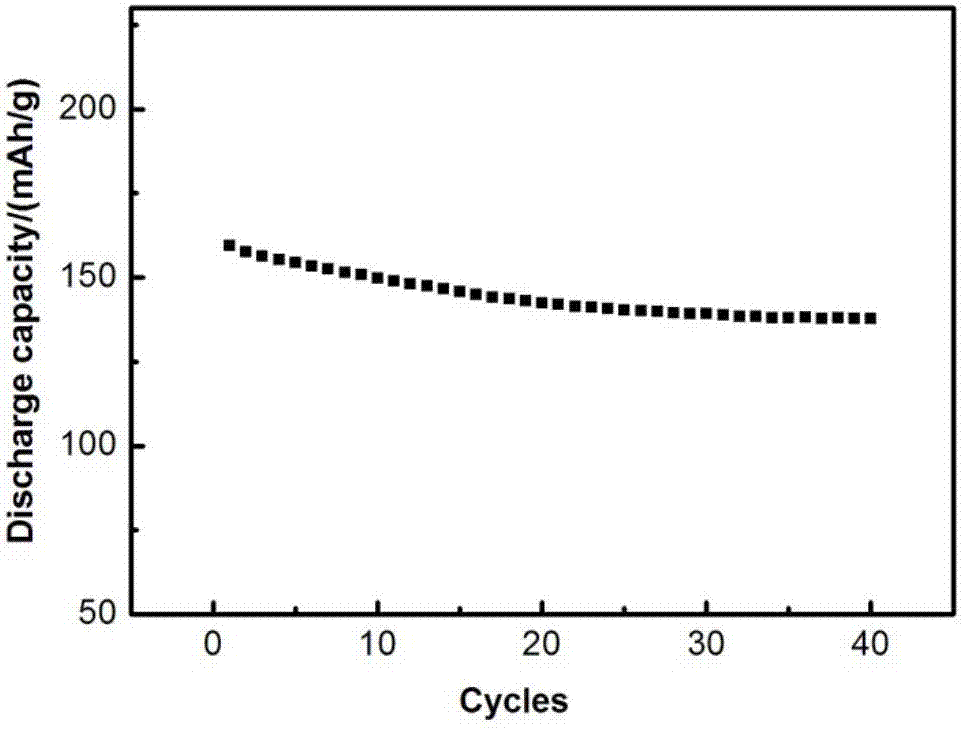

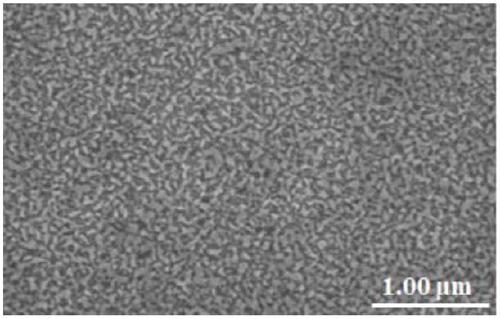

ActiveCN110729464AImprove solubilityImprove stabilityCell electrodesSecondary cellsDivinylbenzeneGermanium dioxide

The invention discloses an annular nano germanium dioxide / polyion liquid composite material and a preparation method and application thereof. The composite material is annular germanium dioxide nanoparticles dispersed in polyion liquid. In the composite material, germanium dioxide is uniformly distributed in the polyion liquid. According to the invention, an annular nano germanium dioxide composite material dispersed in a polyionic liquid carrier is prepared through a free radical initiated polymerization method by taking vinyl functionalized imidazolium ionic liquid, germanium tetrachloride,divinylbenzene and azodiisobutyronitrile as raw materials and absolute ethyl alcohol as a solvent. As a lithium ion battery negative electrode material, the annular nano germanium dioxide / polyion liquid composite material has first reversible capacity of 1711mAh / g under the current density of 200mA / g, has a capacity retention ratio of 40-55% after 100 cycles, and shows high charge-discharge capacity and good cycle performance.

Owner:SHANGQIU NORMAL UNIVERSITY

Polycrystalline silicon material and preparation method thereof

PendingCN112410872AImprovement ingredientsSimple preparation processPolycrystalline material growthDiffusion/dopingMetallurgySilicic acid

The invention provides a polycrystalline silicon material and a preparation method thereof. According to the technical scheme, the components of polycrystalline silicon are compounded based on the metal ion doping principle, a trace amount of CoCl2, Ag2CrO4, BaCl2O8 and other components are introduced, TiC and GaAs are adopted for protecting the crystal structure, and meanwhile the formula proportion is optimized. On the basis, the invention provides a preparation method of the polycrystalline silicon material, the method is based on an improved Siemens method, and germanium tetrachloride, Bi(NO3)3 and BaCl2O8 are added in the process of preparing SiHCl3 to obtain doped trichlorosilane; then condensation and impurity removal are carried out, and CoCl2, Ag2CrO4 and magnesium trisilicate arefurther doped; in the reduction process, TiC, GaAs and trichlorosilane are vaporized together and then fed into a reduction furnace, metal ions are embedded into crystal lattices along with growth ofcrystals, and then the polycrystalline silicon material is obtained. The photoelectric conversion efficiency of the polycrystalline silicon material can reach about 28% and the service life is obviously prolonged, so that the polycrystalline silicon material has outstanding technical advantages.

Owner:山东金韵能源技术有限公司

Supersonic liquid phase reduction process for preparing monodisperse nano germanium crystal

InactiveCN1315605CEasy to prepareLow costPolycrystalline material growthSingle crystal growth detailsWater bathsHigh energy

The present invention is the process of utilizing metal hydride to reduce germanium chloride to prepare near monodisperse nanometer germanium crystal under supersonic reaction condition. The present invention has high energy supersonic water bath to replace high temperature reaction environment to promote the formation of nanometer crystal and the dispersion in the solution, and adopts strongly reductive metal hydride as reductant for preparing near monodisperse nanometer germanium crystal under room temperature condition. Through experiments, the nanometer germanium crystal preparing conditions are optimized. Preparing monodisperse nanometer germanium crystal is significant in research of the relationship between the performance and the size of nanometer material and is valuable in the design and manufacture of semiconductor devices.

Owner:ZHEJIANG UNIV

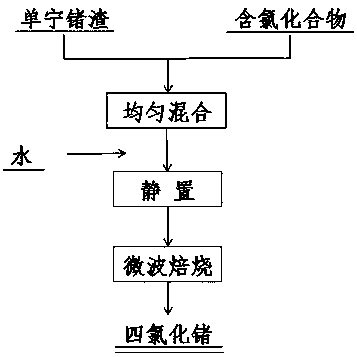

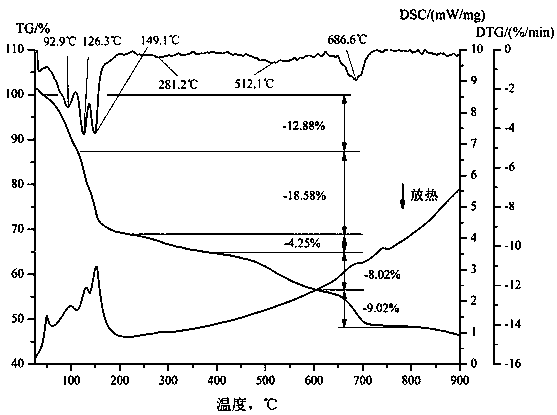

Method for preparing germanium chloride from tannin germanium slag through microwave one-step process

ActiveCN111074082AShorten the time for preparing germanium tetrachlorideSolve complex processWater chlorinationTannin

The invention relates to a method for preparing germanium chloride from tannin germanium slag through a microwave one-step process, and belongs to the technical field of metallurgy and energy. The method comprises the following steps: uniformly mixing tannin germanium slag with a chlorine-containing compound to obtain a mixture A; adding water into the mixture A to uniformly mix and stand for 5-30minutes to obtain a mixture B; performing microwave roasting on the mixture B, and condensing roasting steam to obtain germanium tetrachloride. The method can effectively shorten time of preparing germanium tetrachloride from industrial tannin germanium slag, and improves complex processes of washing, roasting, chlorinating and distilling; moreover, tannin germanium slag belongs to a macromolecular organic salt, is good in wave absorption and can remarkably reduce process energy consumption, and prepared germanium tetrachloride is lower in impurity content. The method has the advantages of being simple in process, efficient, easy to operate, high in sample purity and the like.

Owner:KUNMING UNIV OF SCI & TECH

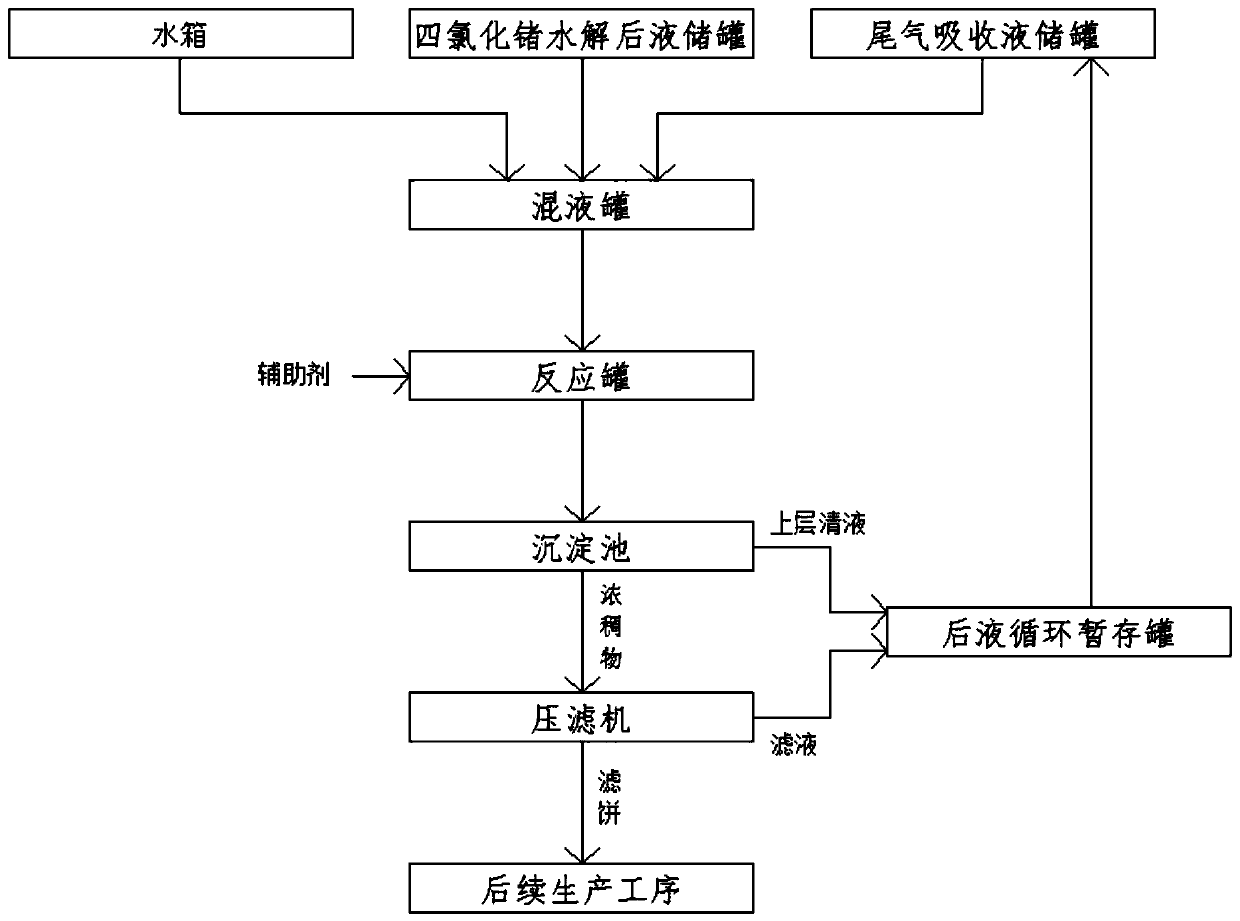

Recovery system and method for germanium-containing liquid in high-purity germanium dioxide production

InactiveCN110921905AAvoid adjustmentSludge treatment by de-watering/drying/thickeningWater contaminantsLiquid storage tankWater chlorination

The invention provides a recovery system and method for germanium-containing liquid in high-purity germanium dioxide production and relates to the technical field of germanium-containing liquid recovery. The recovery system comprises a germanium tetrachloride hydrolyzed liquid storage tank, a tail gas absorption liquid storage tank, a water tank, a liquid mixing tank, a reaction tank, a sedimentation tank and a filter press. The germanium tetrachloride post-hydrolysis liquid storage tank, the tail gas absorption liquid storage tank and the water tank are respectively communicated with the liquid mixing tank, the liquid mixing tank, the reaction tank, the sedimentation tank and the filter press are sequentially communicated to be used for treating an aqueous solution step by step, in the whole production process, only the pH needs to be tested at intervals, the system can be used after the requirement is met, the repeated adjustment of the pH value is avoided, the mixing volume of all liquid does not need to be accurate, and the effect can be achieved within a rough range.

Owner:四川高锗再生资源有限公司

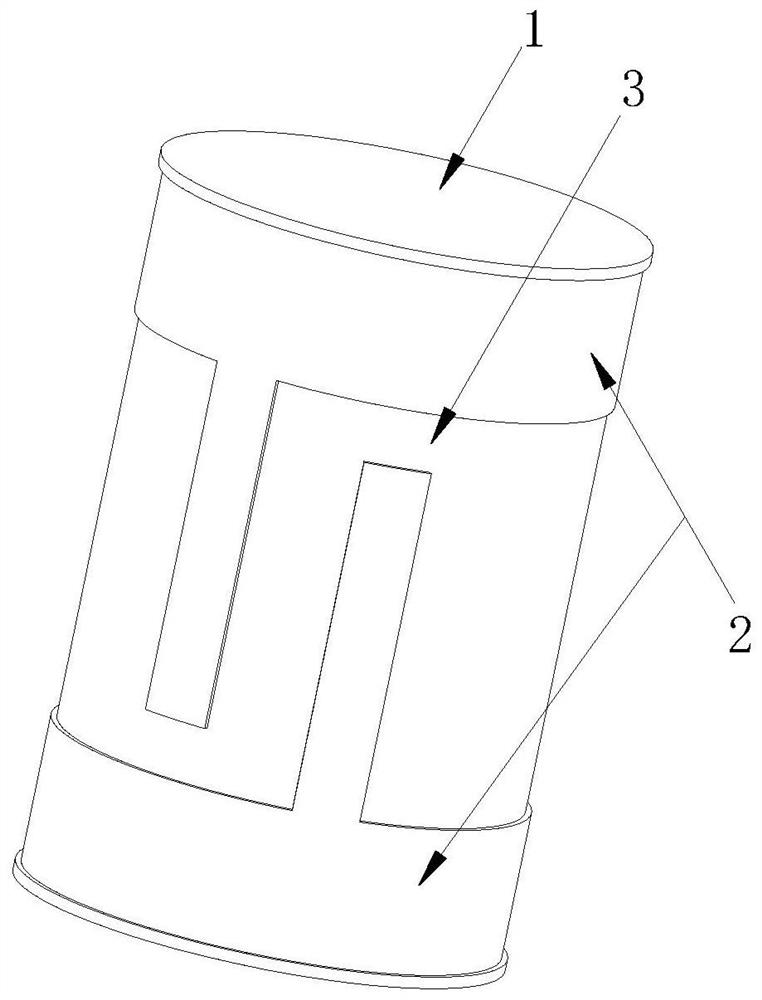

Tubular small heating component

PendingCN111867161AImprove conversion efficiencyImprove energy utilizationHeating element shapesHeating element materialsTitanium chlorideHigh energy

The invention discloses a tubular small heating component which comprises a tubular pipe fitting, the outer wall of the pipe fitting is coated with a coating, and electrode layers are arranged outsidethe coating and located at the two ends of the pipe fitting. A base material of the pipe fitting is an insulating quartz material resistant to high temperature and low temperature; and the coating isan environment-friendly nano far-infrared heating material coating. The tin tetrachloride, the tin oxide, the antimony trichloride, the titanium tetrachloride, the copper sulfate pentahydrate and thegermanium chloride are matched, energy band matching is generated among molecules of all the components, interactive transition and mutual promotion are generated among electrons on the outermost layer of metal elements, the conversion efficiency of electric energy and heat energy is improved, energy consumption is reduced, and a good heating effect is achieved; and secondly, after the far infrared heating component is electrified, the nano micromolecules are subjected to resonance friction to generate Brownian motion, and the functional film layer of the far infrared heating body is matchedwith the conductive film layer for use, so that the conversion efficiency of electric energy and heat energy is higher, the energy utilization rate is improved, the energy consumption is reduced, anda better heating effect is achieved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Preparation process of 68Ge line source used for PET attenuation correction

ActiveCN101777399BIncrease profitImprove radiation resistanceRadioactive sourcesMicrosphereGlass wool

The invention discloses a preparation process of a 68Ge line source used for PET attenuation correction, which aims to provide a preparation process of a 68Ge line source which has high utilization rate, uniform activity distribution and low cost and is used for PET attenuation correction. The process comprises the following steps: (1) putting a ceramic microsphere into a mixed solution of nitricacid and germanium chloride [68Ge], carrying out an oscillating reaction, taking out after the 68Ge is absorbed on the ceramic microsphere, washing and then airing; and (2) evenly filling the dried ceramic microsphere adsorbed with the 68Ge into a stainless steel tube one end of which is sealed, sealing the other end of the stainless steel tube by using glass wool, then sleeving the stainless steel tube into a stainless steel sleeve and finally, connecting the stainless steel sleeve with a magnetic tungsten steel base, wherein the concentration of the nitric acid in the mixed solution in the step (1) is 12 to 15mol / L, the concentration of Ge ions is not greater than 5mg / ml, and the adsorption time is 10 to 20min.

Owner:HTA CO LTD

Composite refraction ink glass panel used for vehicle front windscreen and manufacturing method of composite refraction ink glass panel

InactiveCN109572373AReduce iron contentHigh light transmittanceWindowsWindscreensSilicon tetrafluorideMechanical engineering

The invention discloses a composite refraction ink glass panel used for a vehicle front windscreen and a manufacturing method of the composite refraction ink glass panel. Glass body constituents of the panel are composed of silicon dioxide and potassium oxide. A high refraction layer composed of silicon tetrafluoride, cerium oxide and germanium tetrachloride is fixed to the convex face of a glassbody, and a low refraction layer composed of silicon tetrafluoride, zirconium oxide, titanium oxide and boron oxide is fixed to the concave face. An ink screen is cured inside, and the basic structureof the ink screen comprises a high-transmittance ITO film and a balanced ITO film which are cured through indium oxide and stannic oxide according to different mass ratios, transparent oily liquid containing white particles with charges and transparent particle microcapsules with opposite charges suspends between the two films, the ink screen is provided with two electrostatic systems, one electrostatic system comprises transparent front and rear electrostatic substrates composed of the two ITO films, and the other electrostatic system comprises left and right electrostatic substrates composed of metal bars on the two sides. The composite refraction ink glass panel refracts part of external light and is good in inward vision light transmission, adjustable in transparency and wide in application range.

Owner:张园园

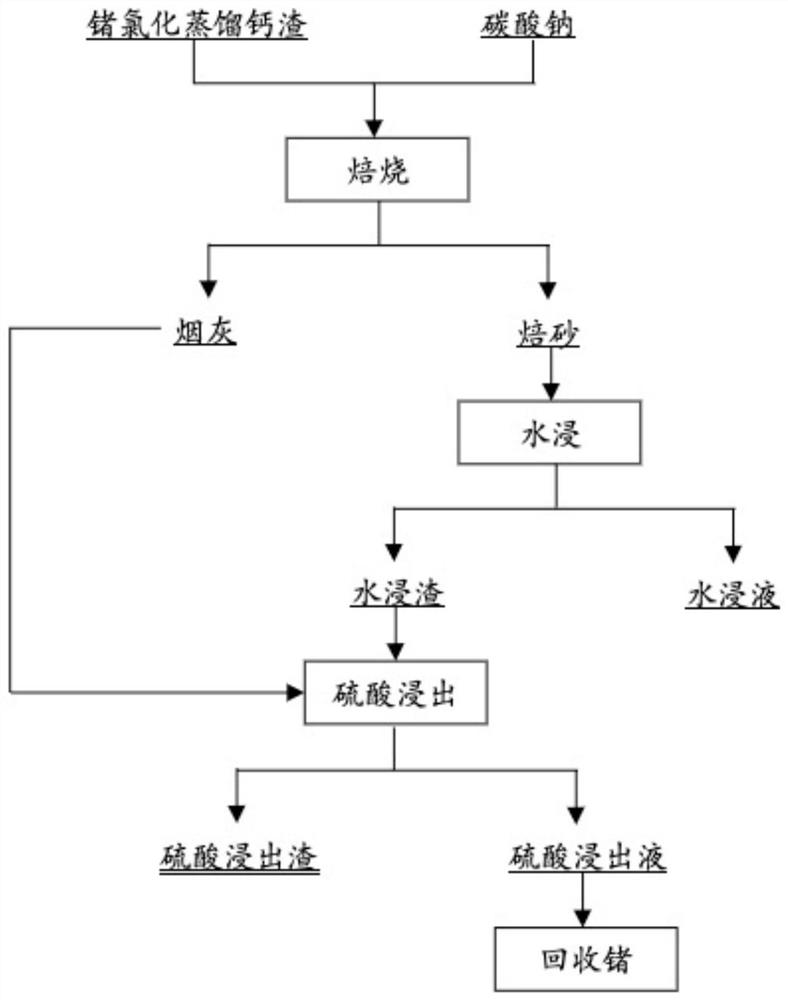

A method for leaching germanium from germanium chloride distillation calcium slag

ActiveCN109777961BPromote leachingEfficient leachingProcess efficiency improvementDistillationWater chlorination

The invention discloses a method for leaching out germanium from germanium chlorination distilled calcium slag and relates to the technical field of wet metallurgy. According to the method, at first,the germanium chlorination distilled calcium slag and sodium carbonate are mixed and then roasted at certain temperature, calcium sulfate, silicon dioxide and silicon germinate in the germanium chlorination distilled calcium slag are converted into calcium carbonate, sodium silicate and sodium germinate correspondingly; wrapping of calcium sulfate and silicon dioxide to germanium is opened, and follow-up leaching out of germanium is benefitted; secondly, water is adopted for leaching out a roasted product, sodium sulfate, sodium silicate and sodium germinate enter a water solution, and the situation that silica gel is formed in the follow-up sulfuric acid leaching out process is avoided; and finally, under the condition of low sulfuric acid concentration, efficient leaching out of germanium is achieved, efficient recovery of valuable resources can be achieved, meanwhile, consumption of sulfuric acid is reduced, and generation of silica gel in the leaching out process is avoided.

Owner:GUANGDONG INST OF RARE METALS

A ring-shaped nano-germanium dioxide/polyionic liquid composite material and its preparation method and application

ActiveCN110729464BImprove solubilityImprove stabilityCell electrodesSecondary cellsDivinylbenzeneGermanium dioxide

The invention discloses an annular nano germanium dioxide / polyion liquid composite material and a preparation method and application thereof. The composite material is annular germanium dioxide nanoparticles dispersed in polyion liquid. In the composite material, germanium dioxide is uniformly distributed in the polyion liquid. According to the invention, an annular nano germanium dioxide composite material dispersed in a polyionic liquid carrier is prepared through a free radical initiated polymerization method by taking vinyl functionalized imidazolium ionic liquid, germanium tetrachloride,divinylbenzene and azodiisobutyronitrile as raw materials and absolute ethyl alcohol as a solvent. As a lithium ion battery negative electrode material, the annular nano germanium dioxide / polyion liquid composite material has first reversible capacity of 1711mAh / g under the current density of 200mA / g, has a capacity retention ratio of 40-55% after 100 cycles, and shows high charge-discharge capacity and good cycle performance.

Owner:SHANGQIU NORMAL UNIVERSITY

Preparation method of quadrivalent cation-doped nickel-cobalt-manganese ternary material

ActiveCN107579243ALow costWide variety of sourcesCell electrodesSecondary cellsManganeseLithium compound

The invention relates to a preparation method of a quadrivalent cation-doped nickel-cobalt-manganese ternary material. The preparation method is characterized in that a tetravalent ion-doped compoundis zirconium tetrachloride, zirconium oxychloride, zirconium dioxide, zirconium carbonate, basic zirconium chloride, zirconium acetate, ammonium zirconium carbonate, zirconium nitrate phosphite, Ge(OH)2, Ge(OH)4, germanium oxide, germanium chloride or germanium nitrate. Nickel, cobalt, manganese and the tetravalent ion-doped compound are mixed, and a dry precursor is prepared through wet grinding,ammonia water adding, lithium compound adding, aging, drying and other steps and then is placed in oxygen-enriched air or a pure oxygen atmosphere, and the quadrivalent cation-doped nickel-cobalt-manganese ternary cathode material is prepared by adopting a programmed heating method or a gradual heating zone heating method.

Owner:FUJIAN NORMAL UNIV

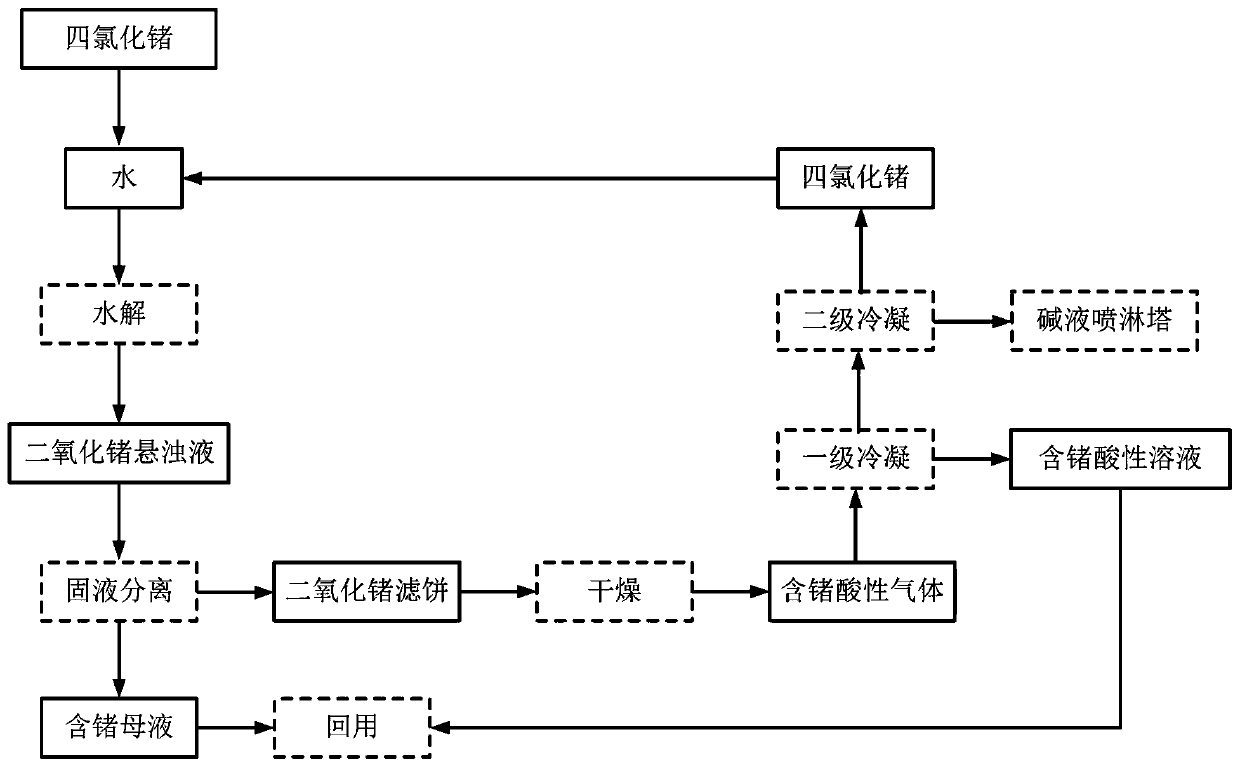

Preparation method of germanium dioxide powder

PendingCN111484069ALess quantitySave washing waterGermanium dioxideProcess efficiency improvementPhysical chemistryDistilled water

The invention discloses a preparation method of germanium dioxide powder, and relates to the technical field of semiconductor oxide preparation. The preparation method specifically comprises the following steps: uniformly adding germanium tetrachloride liquid into high-purity water or secondary distilled water with the temperature of 0-10 DEG C, stirring for hydrolysis reaction to form turbid liquid, performing solid-liquid separation to obtain a germanium dioxide filter cake and germanium-containing mother liquor, and drying and crushing the germanium dioxide filter cake to obtain the germanium dioxide powder, wherein germanium-containing acid gas generated in the drying process of germanium dioxide is subjected to secondary condensation recovery, acid germanium-containing waste liquid returns to germanium extraction production, and the germanium tetrachloride returns to hydrolysis production of the germanium dioxide. According to the method, the traditional germanium tetrachloride hydrolysis, repeated washing and drying processes are abandoned, so that the washing water of the germanium dioxide filter cake is greatly reduced, and the amount of the germanium-containing mother liquor is reduced; and the generated germanium-containing acid gas is subjected to fractional condensation recovery, so that the germanium loss caused by volatilization of the germanium tetrachloride in the process of producing the germanium dioxide by hydrolysis, washing and drying is reduced.

Owner:湖北联合贵稀资源再生科技有限公司

Ge (II) precursor as well as preparation method and application thereof

InactiveCN111333546AImprove thermal stabilityVolatileHydrazine preparationChemical vapor deposition coatingPhysical chemistryCombinatorial chemistry

The invention relates to a Ge (II) precursor as well as a preparation method and application thereof. The Ge (II) precursor is a coordination compound formed by coordination of a ligand shown in a formula (A), a formula (B) or a formula (C) and dichloride of germanium, wherein the dichloride of germanium comprises germanium dichloride, a germanium dichloride hydrate or a germanium dichloride complex. The preparation method comprises the following steps: under the protection of a protective gas, reacting the ligand with lithium alkyl to obtain a lithium salt; and reacting the lithium salt withthe dichloride of germanium to obtain the Ge (II) precursor. The preparation method is simple in preparation process, mild in condition, low in raw material cost, low in energy consumption, economicaland environmentally friendly, and the prepared Ge (II) precursor has excellent thermal stability, volatility and film-forming property.

Owner:紫石能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com