Germanium etching method

A dry etching and germanium layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor morphology and affect the performance of semiconductor devices, and achieve the effect of improving morphology and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

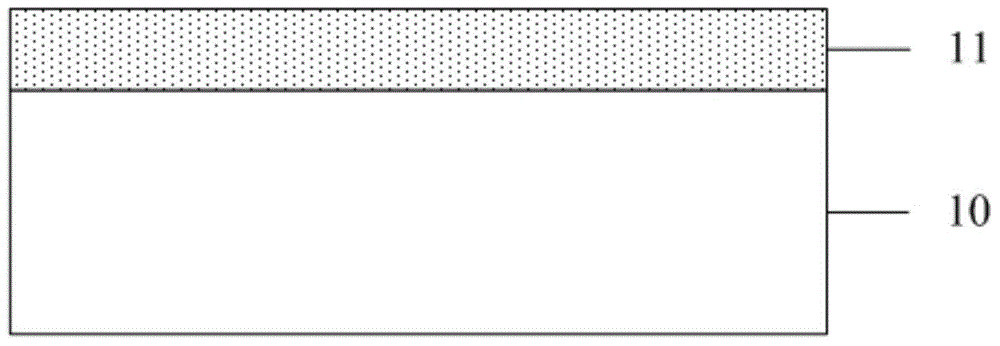

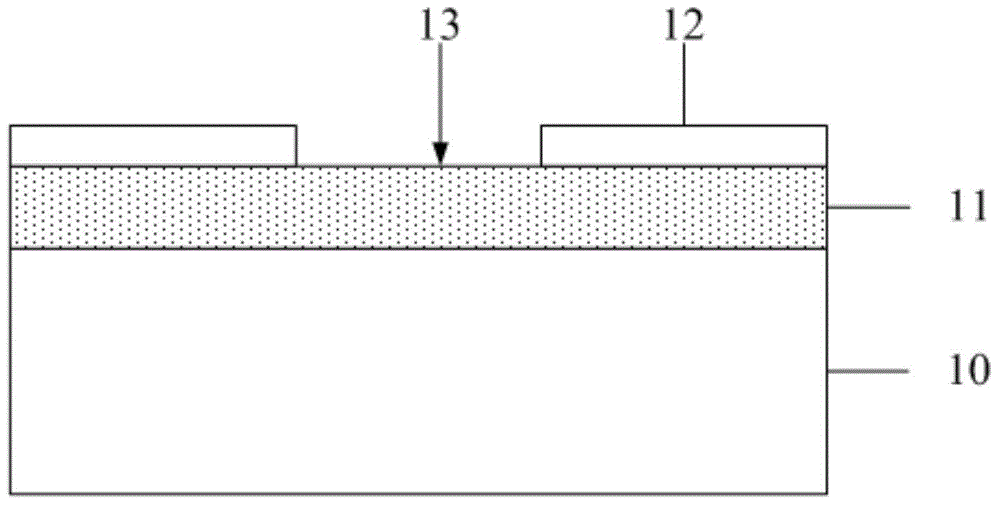

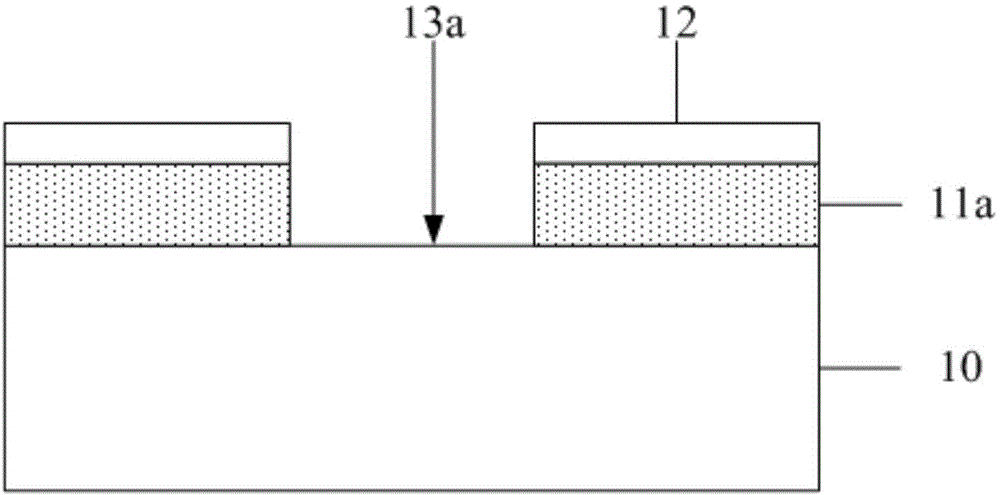

[0028] It can be seen from the background technology that the morphology of the germanium layer formed by the existing germanium etching process is relatively poor. The reason is analyzed: the etching gas used in dry etching includes: chlorine gas (Cl 2 ), boron chloride (BCl 2 ), argon (Ar), nitrogen (N 2 ). Among them, chlorine gas is used as the main etching gas to react with the germanium layer to form germanium chloride (GeCl x ), the gas flow in the etched reaction chamber is taken out of the reaction chamber. However, when germanium is dry-etched, the germanium chloride generated by etching is easy to redeposit and adheres to the top or sidewall of the photoresist. The attached germanium chloride is difficult to remove by traditional etching methods. Moreover, the attached germanium chloride will affect the removal process of the photoresist, and the resulting germanium chloride is prone to redeposition, forming a germanium chloride polymer attached to the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com