Supersonic liquid phase reduction process for preparing monodisperse nano germanium crystal

A monodisperse and nanocrystalline technology, which is applied in the field of ultrasonic liquid phase reduction to prepare monodisperse germanium nanocrystals, can solve the problems of uneven particle size distribution, high cost, and harsh conditions for nanocrystalline materials, and achieve low cost and high conditions. Effects that are not harsh and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

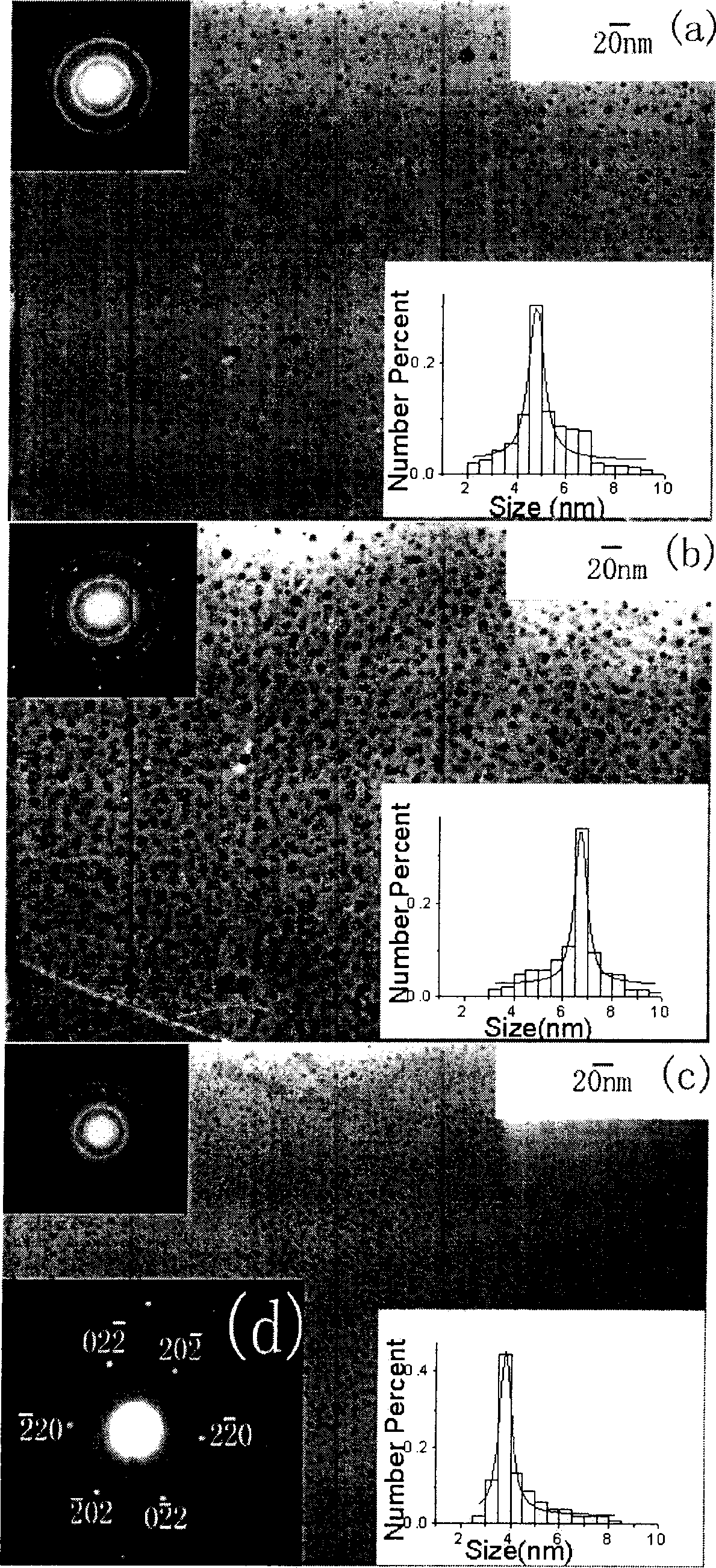

[0032] According to the preparation process, the specific GeCl 4 Amount of 10ml 0.01mol / l THF solution, such as figure 1 The reducing agent shown in (a) is NaBH 4 10ml of 0.06mol / l ethanol solution; figure 1 The reducing agent shown in (b) is LiAlH 4 The consumption is the THF solution of 10ml 0.06mol / l; figure 1 (c) The reducing agent is 85% N 2 h 4 h 2 O solution 1ml. All the reactions were performed under the action of ultrasonic waves with an ultrasonic frequency of 40KHz for 30 minutes.

Embodiment 2

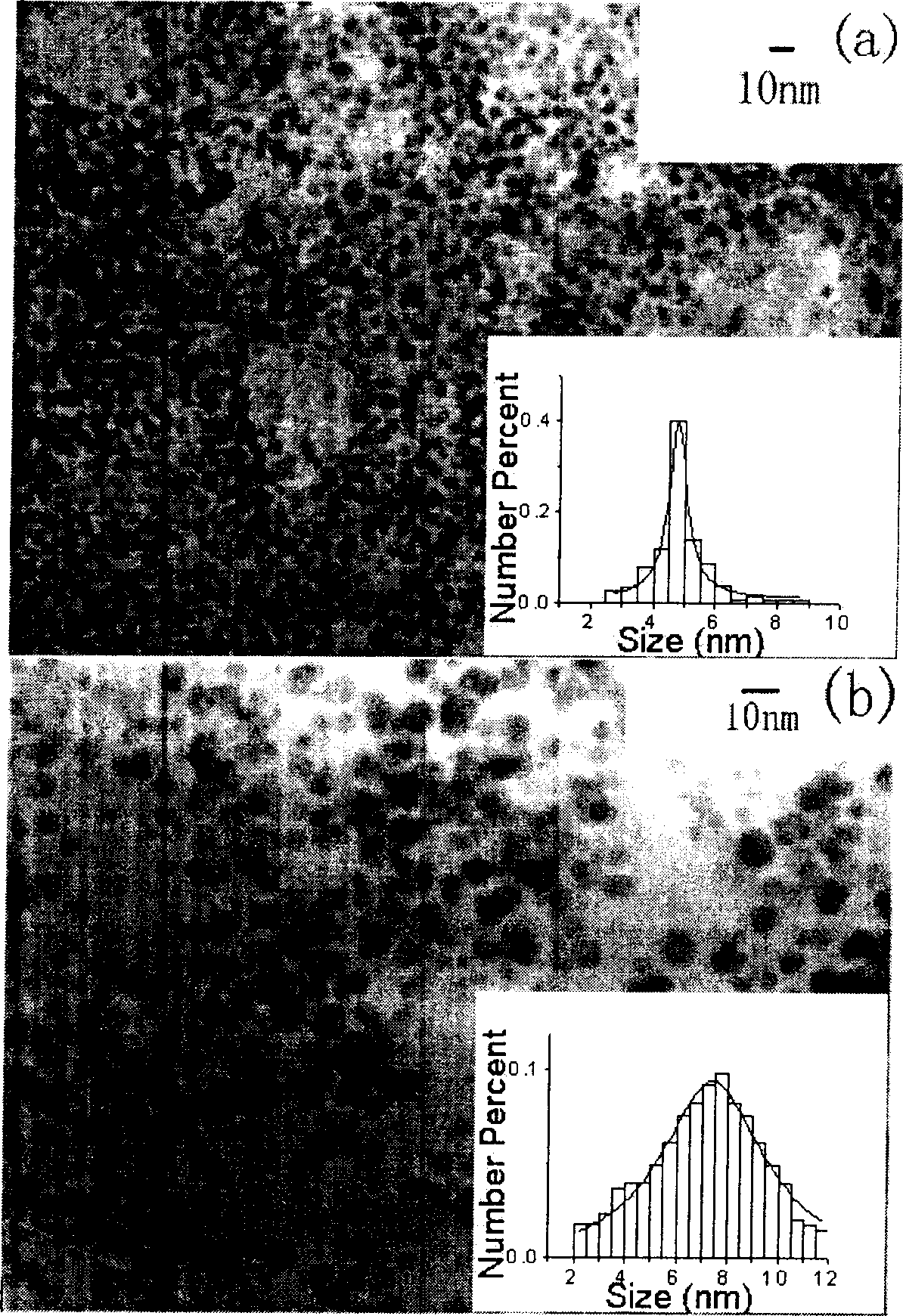

[0034] figure 2 (a) The sample is carried out according to the preparation process, using specific GeCl 4 The amount is 10ml of 0.01mol / l THF solution, using reducing agent NaBH 4 The dosage is 10ml of 0.06mol / l ethanol solution. The reaction was performed under the action of ultrasonic waves with an ultrasonic frequency of 50KHz for 30 minutes. figure 2 The reaction of (b) sample is carried out in the process of magnetic stirring at a stirring rate of 300r / min, using specific GeCl 4 The amount is 10ml of 0.01mol / l THF solution, and the reducing agent is NaBH 4 The specific dosage is 10 ml of 0.06 mol / l ethanol solution, and the reaction time is 30 minutes.

Embodiment 3

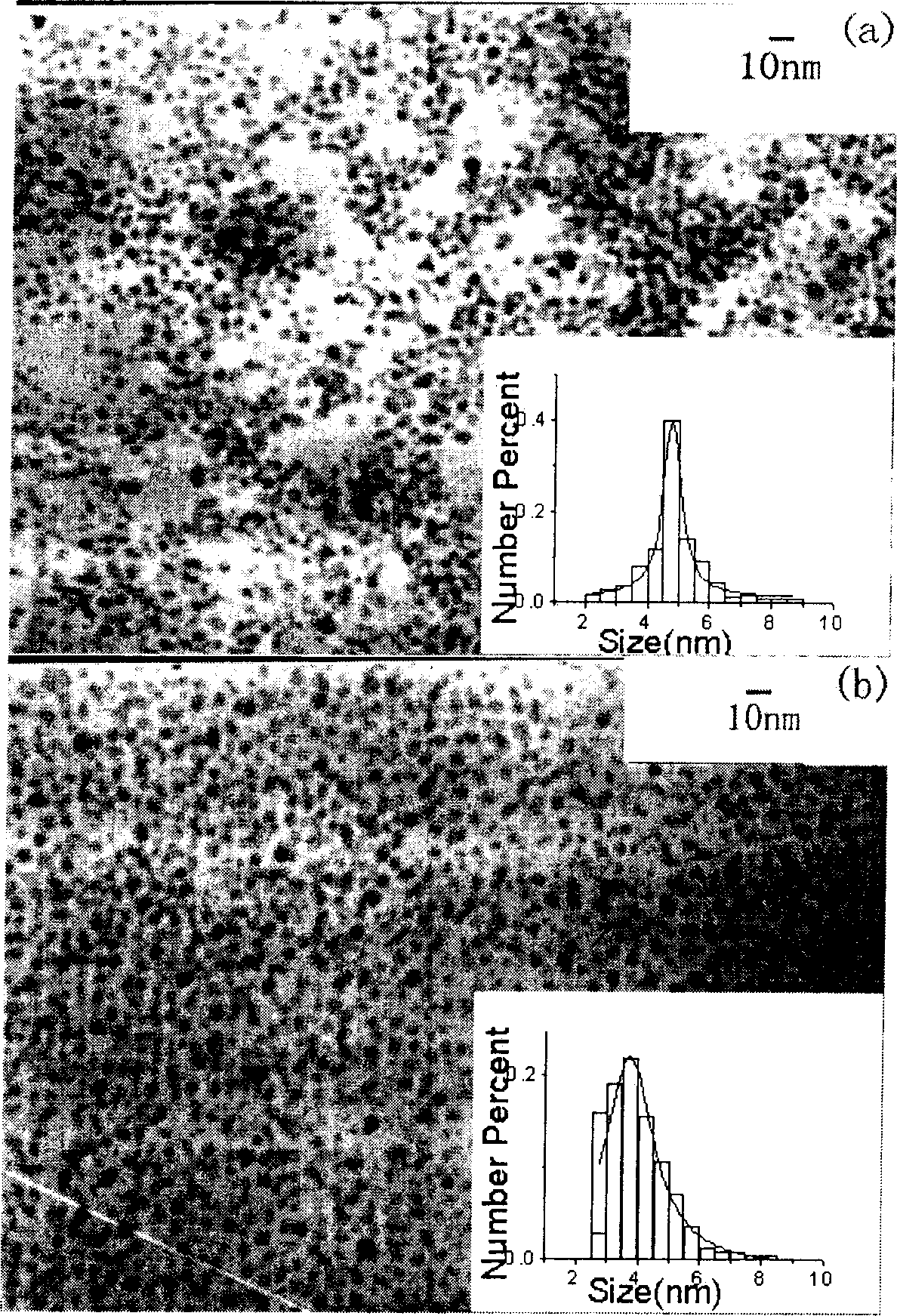

[0036] image 3 (a) The sample is carried out according to the preparation process, using specific GeCl 4 Amount of 10ml 0.01mol / l THF solution, reducing agent NaBH 4 The specific dosage is 10ml of 0.06mol / l ethanol solution. image 3 (b) using specific GeCl 4 The amount is 10ml of 0.1mol / l THF solution, and the reducing agent is NaBH 4 The specific dosage is 10ml of 0.6mol / l ethanol solution. All reactions were performed under ultrasound for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com