Patents

Literature

54results about How to "Conditions are not harsh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silver nano-wire in large batch

ActiveCN101310899AUniform sizeReduce manufacturing costPolycrystalline material growthSingle crystal growth detailsReducerSolvent

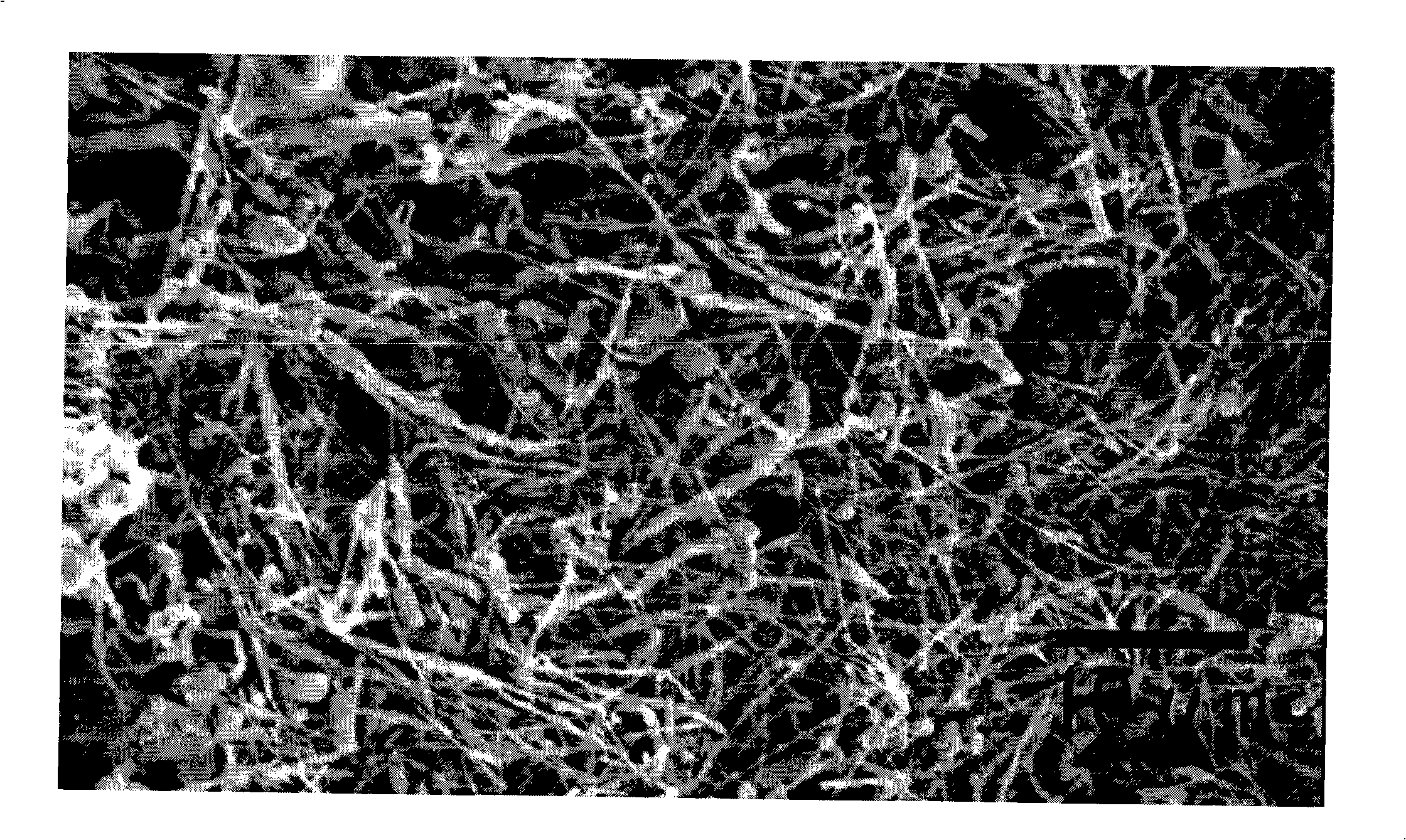

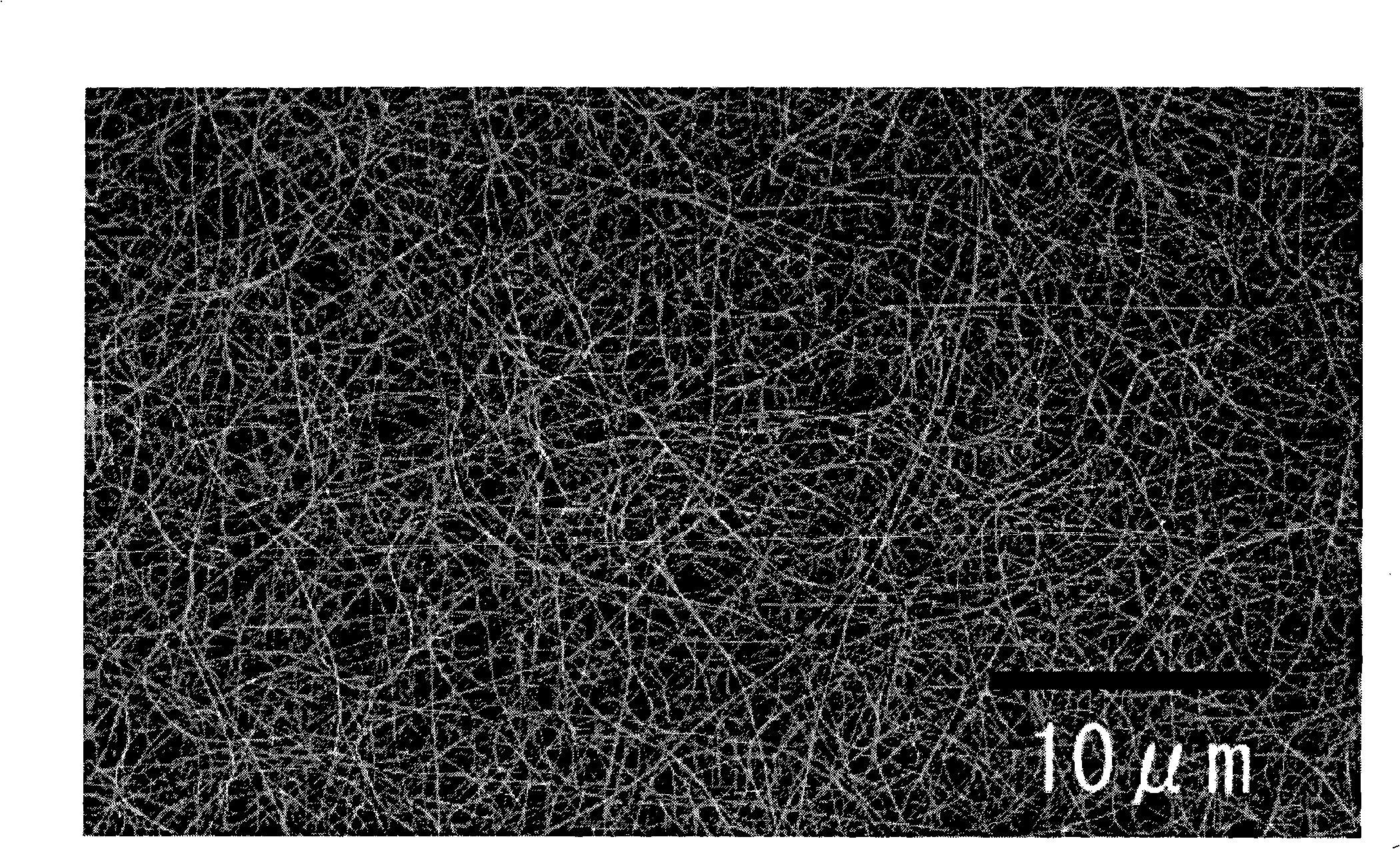

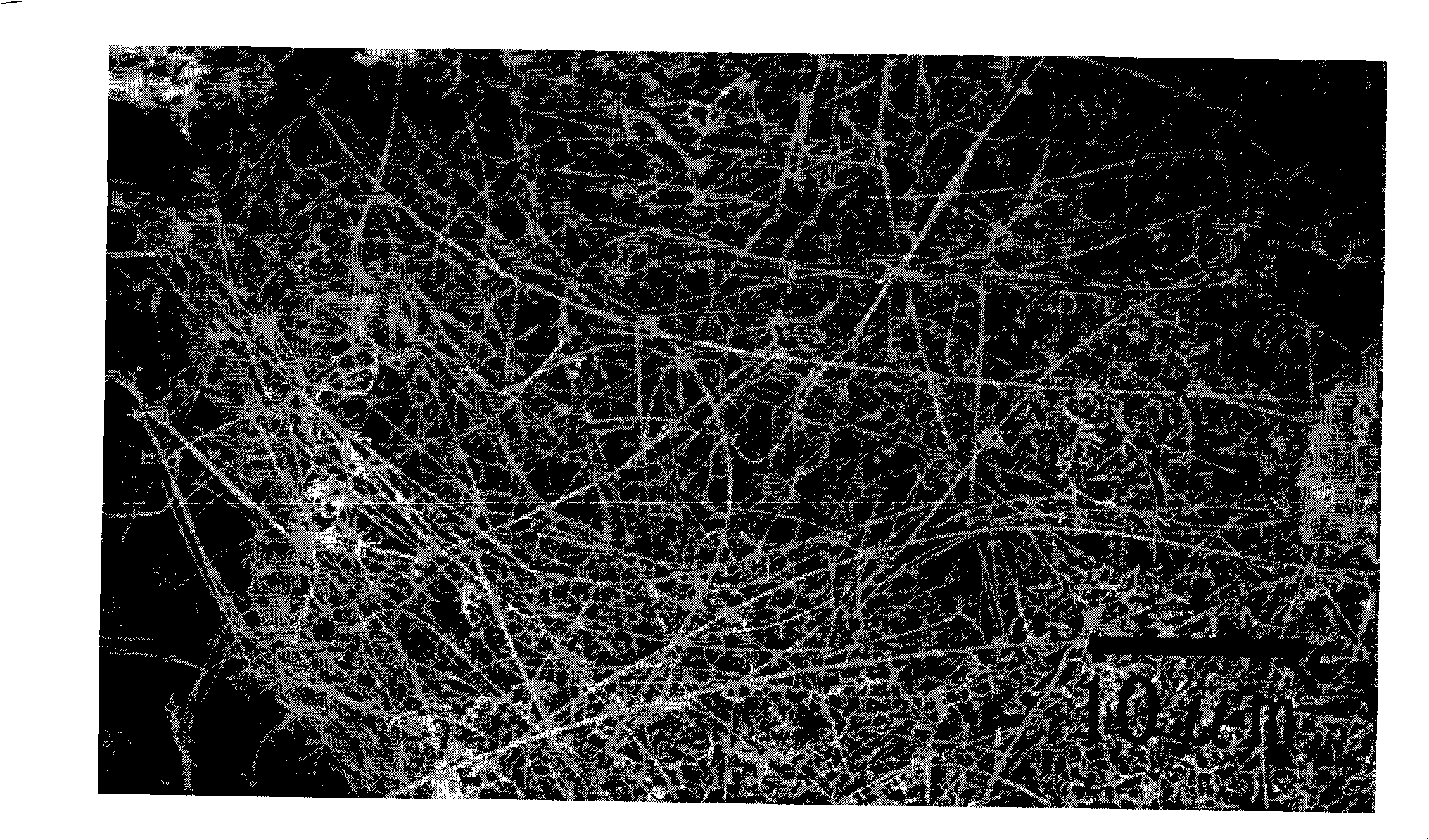

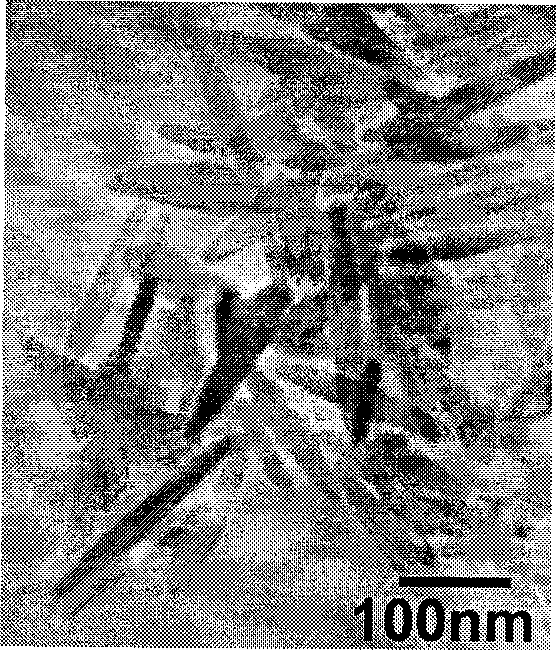

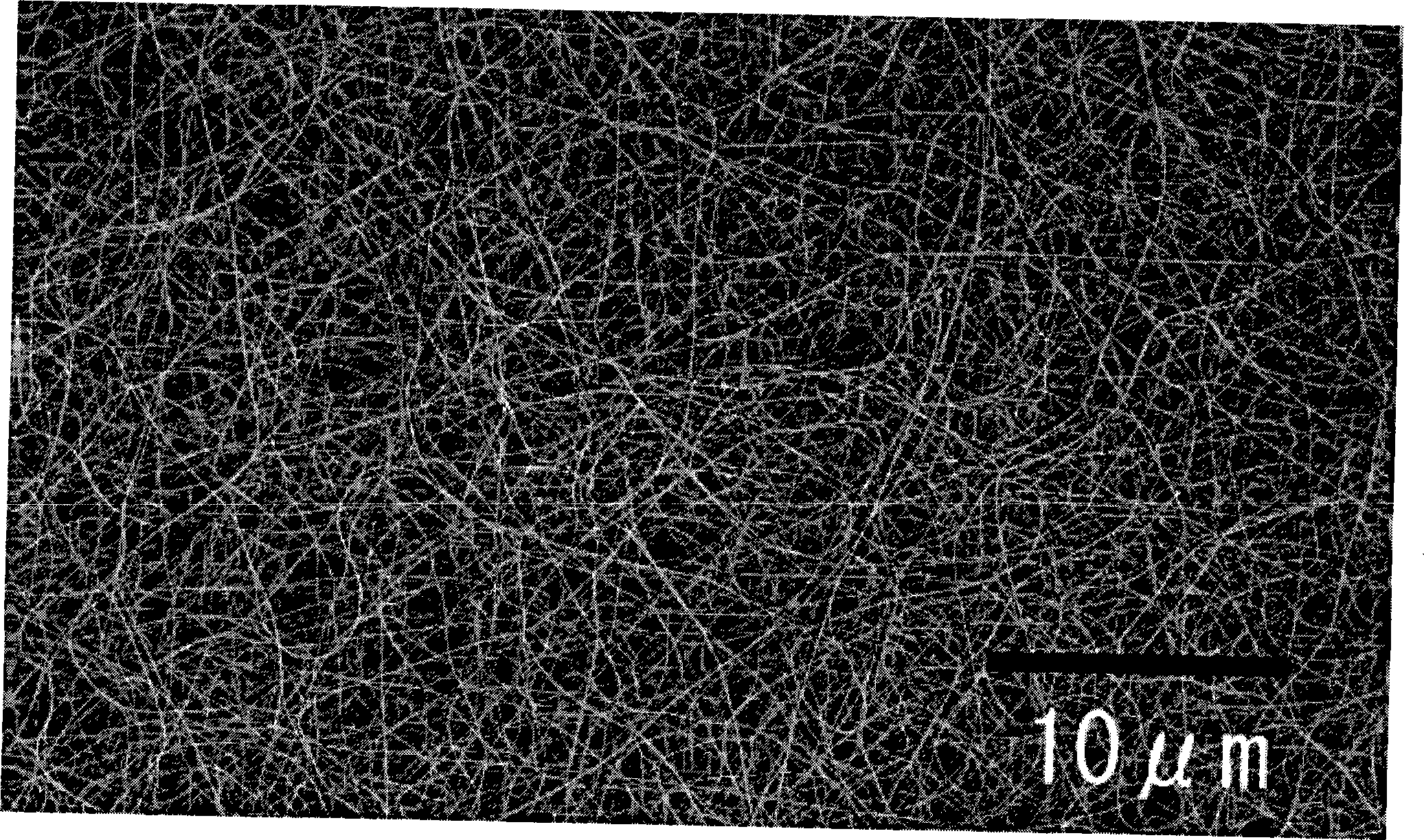

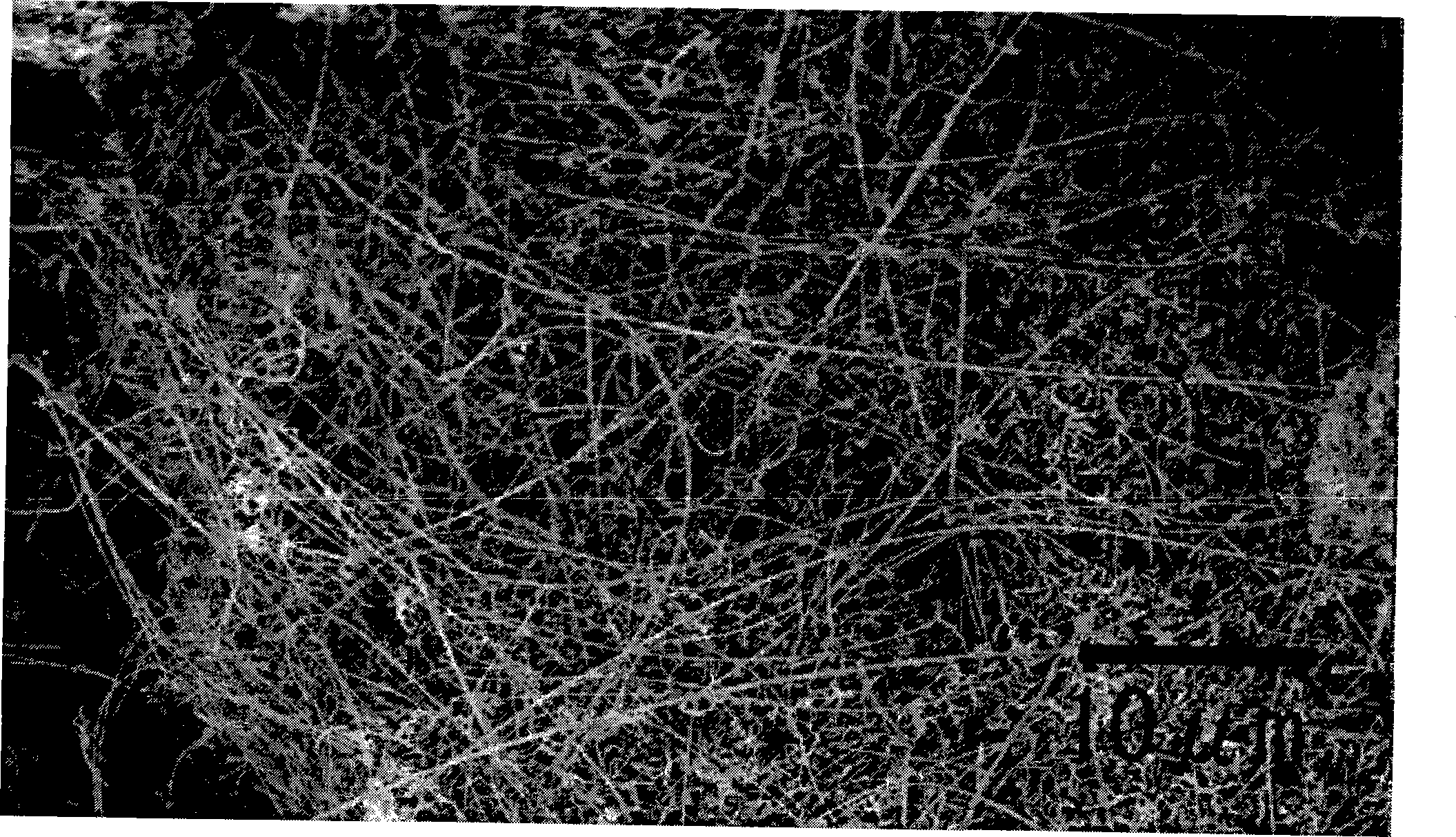

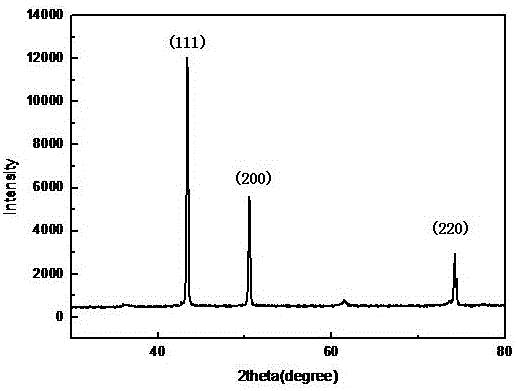

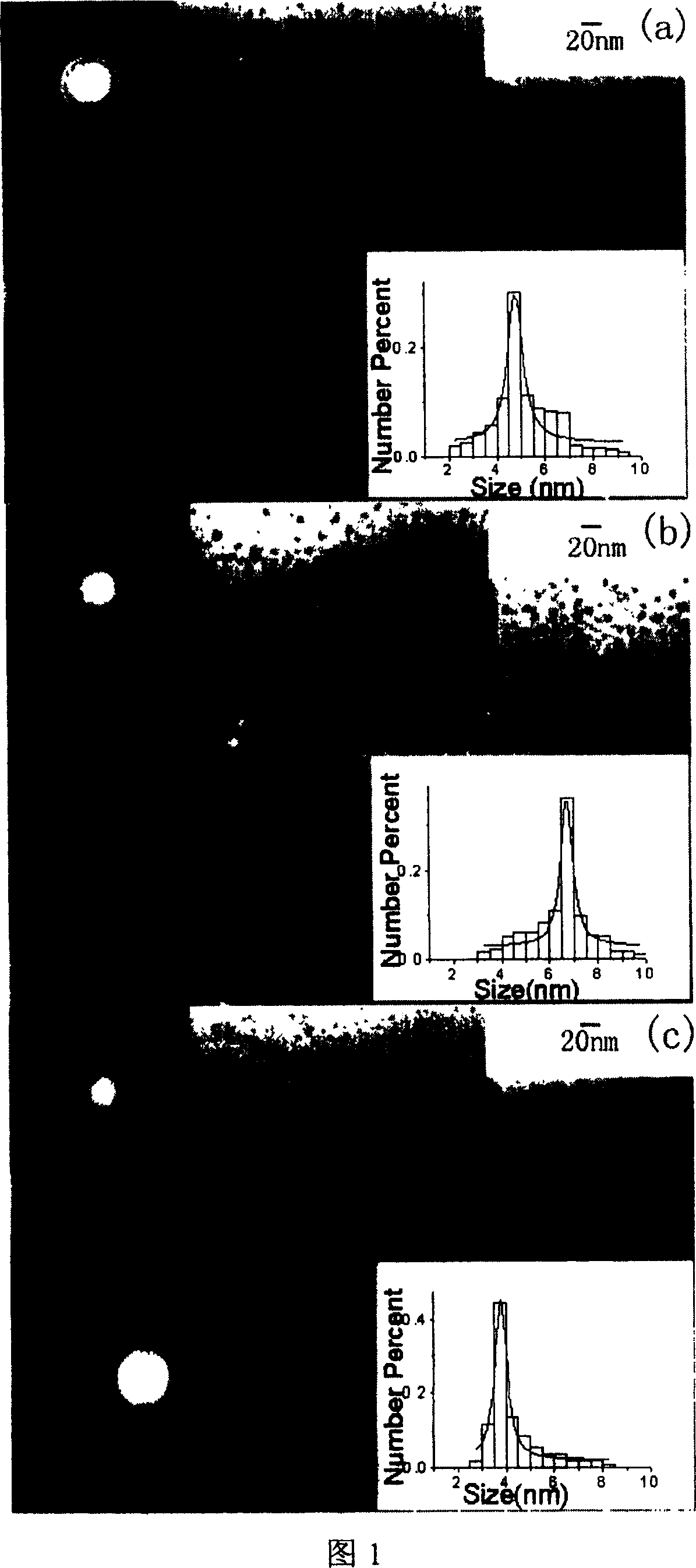

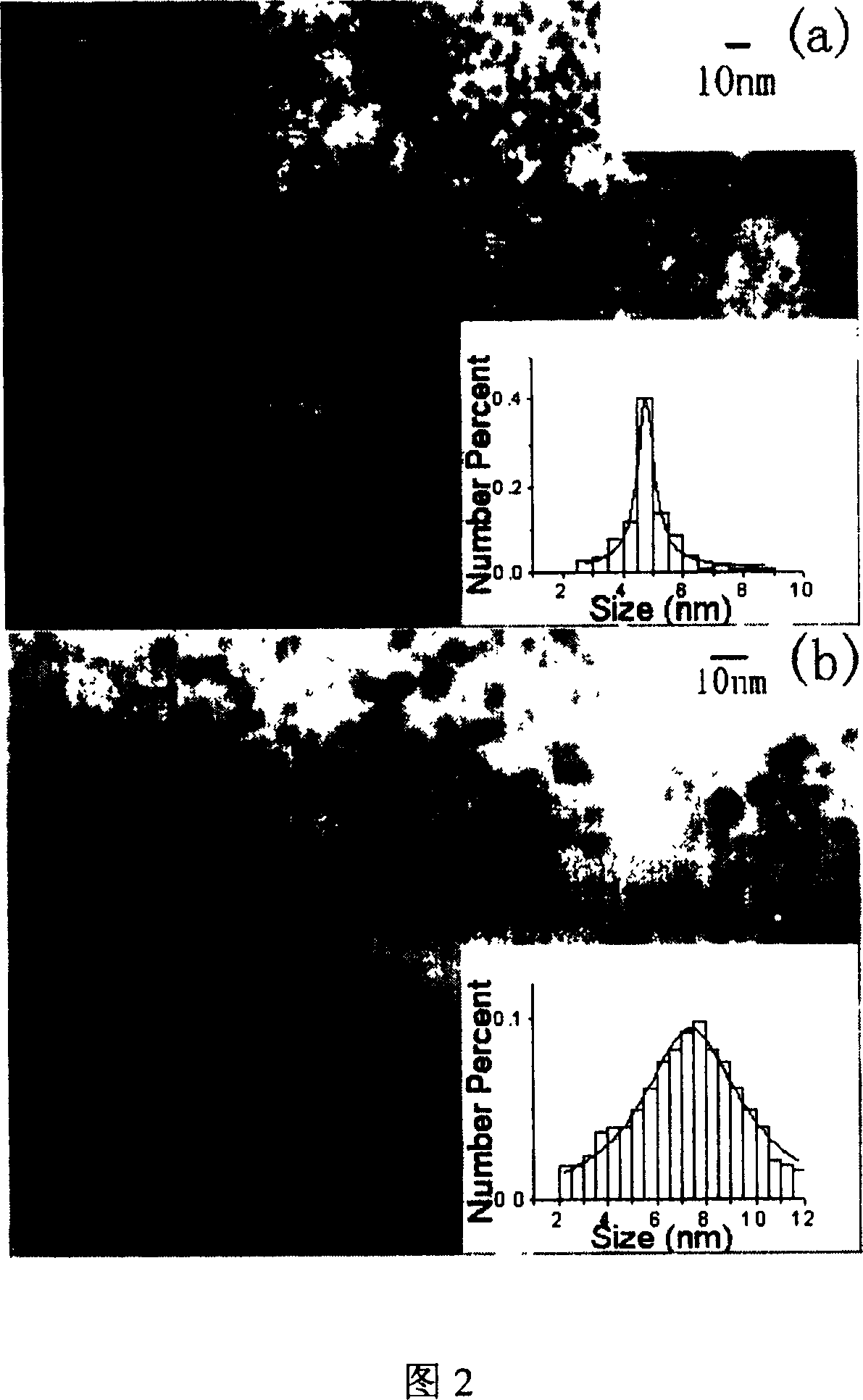

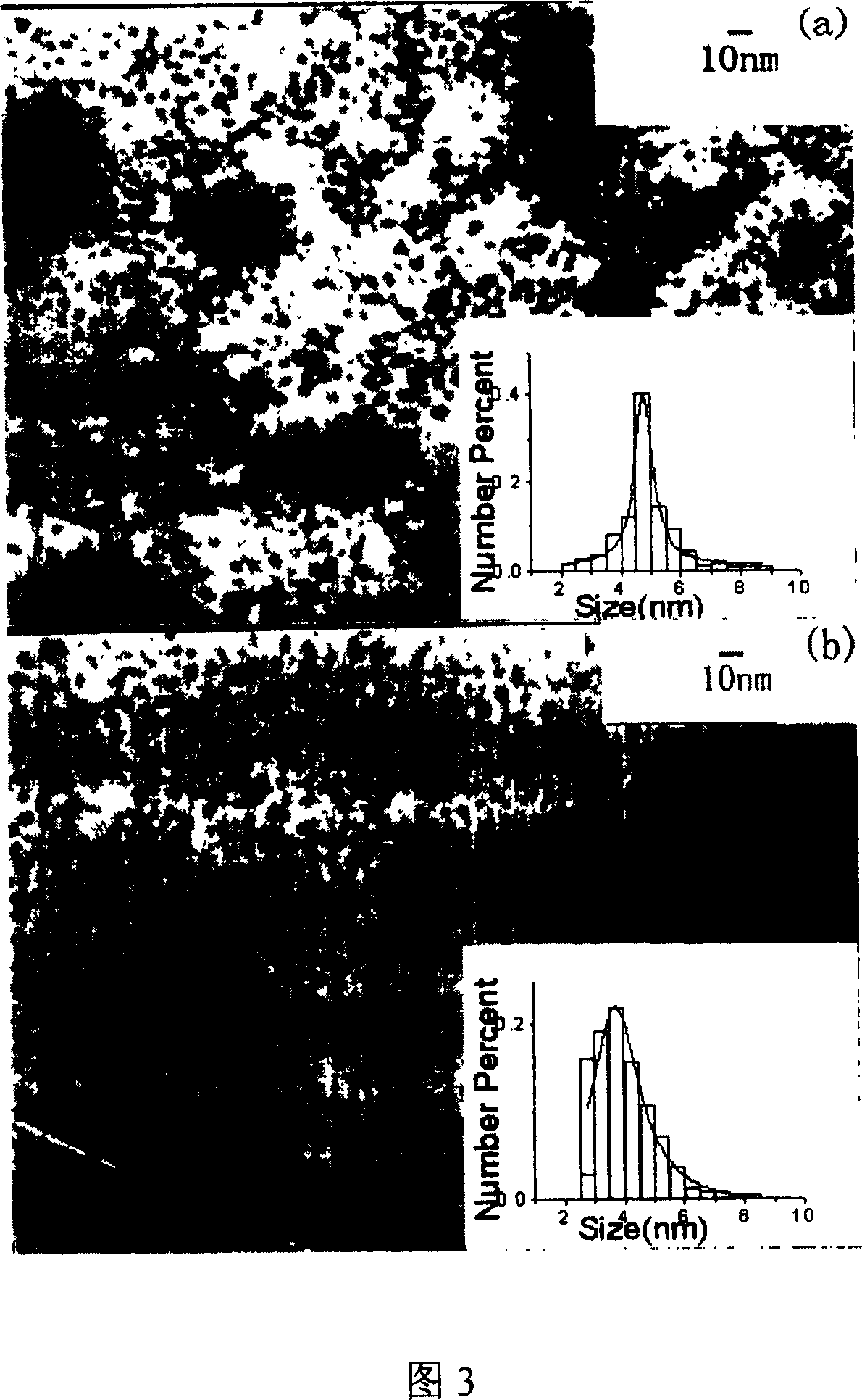

The invention discloses a method for preparing nanometer silver lines in large batch. anhydrous silver nitrate AgNO3 with the concentration of 99.9percent, anhydrous glycol (C2H6O2) of 99.8percent and polyvinylpyrrolidone (PVP, with the molecular weight of 55,000) of 98percent are selected as the raw materials; in a microwave-assisting environment, the method of adopting the glycol to reduce the silver nitrate is adopted to prepare nanometer silver lines in large batch. By replacing the original solvent heating method with the high-heat environment created by microwave, the method not only greatly saves the reaction time but also reduces the preparing costs for the nanometer silver lines. The glycol, a moderate reducer, can slow the reaction, thus providing the time for the growth of nanometer silver lines. The method of the invention is the optimal method for preparing the nanometer silver line according to testing results by comparing the influence of micro strength, precursor concentration and microwave processing time on the appearance and size of the prepared nanometer lines. The method of the invention has low cost, is simple method and easily controlled and has high practical value in the application to the industrial production developing nanometer silver lines.

Owner:溧阳常大技术转移中心有限公司

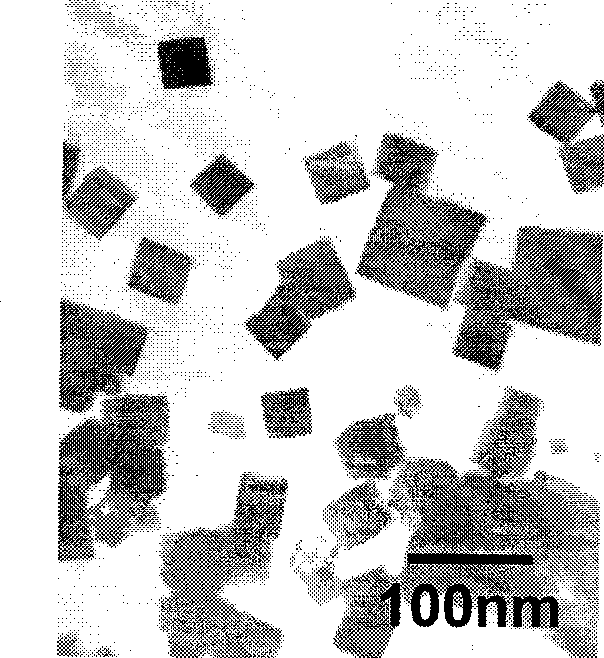

Novel Prussian blue mesocrystals and preparation method thereof

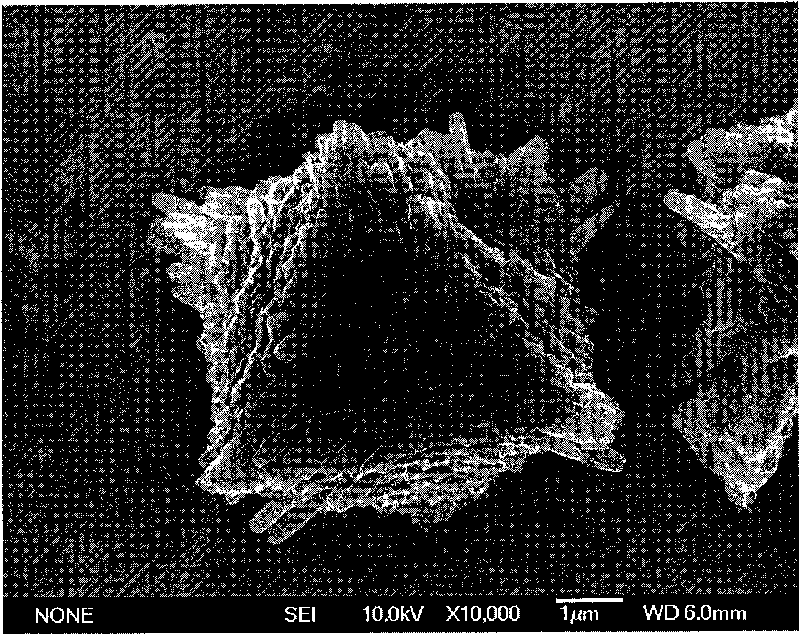

InactiveCN101704536ANovel and special microscopic appearanceSave raw materialsCyanic/isocyanic acidFerrocyanide saltOctahedron

The invention discloses novel Prussian blue mesocrystals and a preparation method thereof, and belongs to the technical field of the preparation of inorganic materials. The Prussian blue mesocrystals with novel hierarchical self-assembly structures are prepared by mixing ferrocyanide salt serving as a raw material with inorganic acid at a specific concentration through hydro-thermal treatment. The prepared integral mesomorphous particles are in shapes of scobinate octahedrons, similar octahedrons, similar spheroids and great lake rocks and consist of numerous small-scale crystals, and all the small-scale crystals are nanorods and nanocubes of between 150 and 250 nm. The Prussian blue mesocrystals can be applied in the field of catalysis due to larger specific surface areas and a mass of pore spaces; and the invention has the advantages of novel morphology of product particles, low cost, simple equipment, easy operation and the like.

Owner:EAST CHINA NORMAL UNIV

A kind of preparation method of metal electrode of crystalline silicon solar cell

ActiveCN102299200AReduce manufacturing costImprove yieldFinal product manufactureSemiconductor devicesSilicon solar cellMetal electrodes

The invention discloses a method for preparing metal electrodes of a crystal silicon solar cell, which comprises the steps that: after the PN junction is prepared on a p-type crystal silicon substrate through diffusion, a silicon nitride antireflection layer is prepared on the surface of a n type emitting electrode, then, a thin Al layer with the thickness being 100nm to 1000nm is prepared on thesurface of a p-type conducting back through the vacuum sputtering technology, the vapor deposition technology or the screen printing technology, in addition, a thin Ag grid line layer with the thickness being 1mum to 5mum is prepared on the surface of the silicon nitride antireflection layer through the screen printing, next, an Al back field seed layer and an Ag grid line seed layer are formed through the traditional high-temperature sintering technology, finally, tin, copper or nickel is electroplated on the Ag grid line seed layer and the Al back field seed layer through the electroplatingprocess, and the metal electrodes are formed after the thickening. Compared with the prior art, the method combines the advantages of the screen printing process, the magnetron sputtering process, the vapor deposition process and the electroplating process, front metal grid line electrodes with high electrical conductivity and low light shielding rate can be obtained, and simultaneously, the consumption of expensive metal Ag can be effectively reduced, so important industrialized application prospects are realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

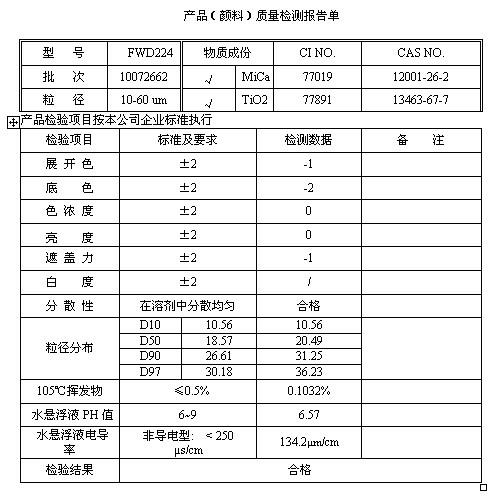

Preparation process of mica-based pearlescent pigment with high weather resistance

ActiveCN103421357AGuaranteed high dispersionThe operation process is simplePigment treatment with organosilicon compoundsIron oxideWeather resistance

The invention relates to a preparation process of a mica-based pearlescent pigment with high weather resistance. The preparation process comprises the following steps: using metal oxide such as titanium dioxide and ferric oxide to clad the surface of mica with a certain grain size distribution to obtain a base material in a certain series of the pearlescent pigment, using photostable substances such as SiO2, Al2O3 and CeO2 to cover the surface of the base material, performing organic modification on the surface of the pigment by using a silane coupling agent KH570, and then obtaining the mica-based pearlescent pigment with the high weather resistance after suction filtration, washing and drying. The preparation process of the mica-based pearlescent pigment is reasonable in design, simple in operation, low in equipment cost, low in energy consumption, and suitable for large-scale production; the prepared pearlescent pigment is good in color and gloss, and suitable for occasions such as automotive, marine and outdoor decoration which have high weather resistance requirements.

Owner:杭州弗沃德精细化工有限公司

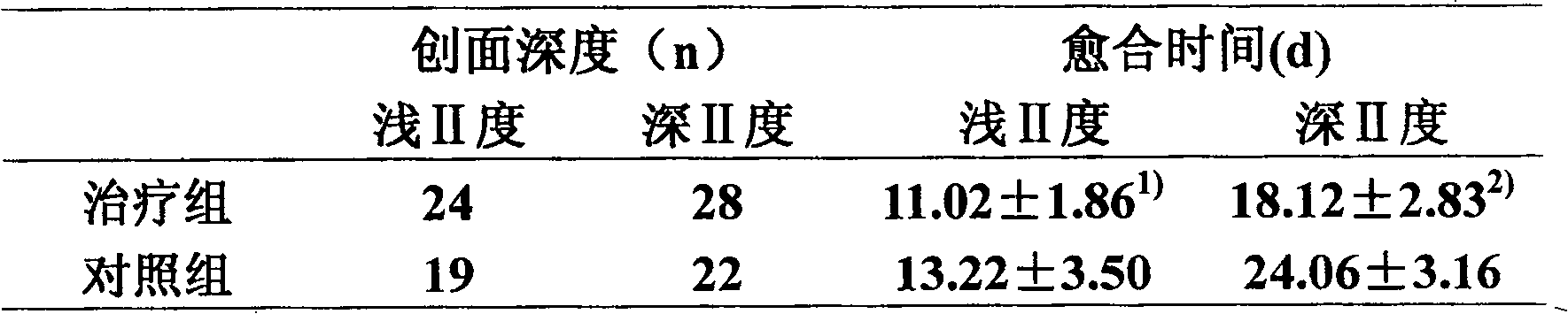

Wound-protection liquid, and its preparing method

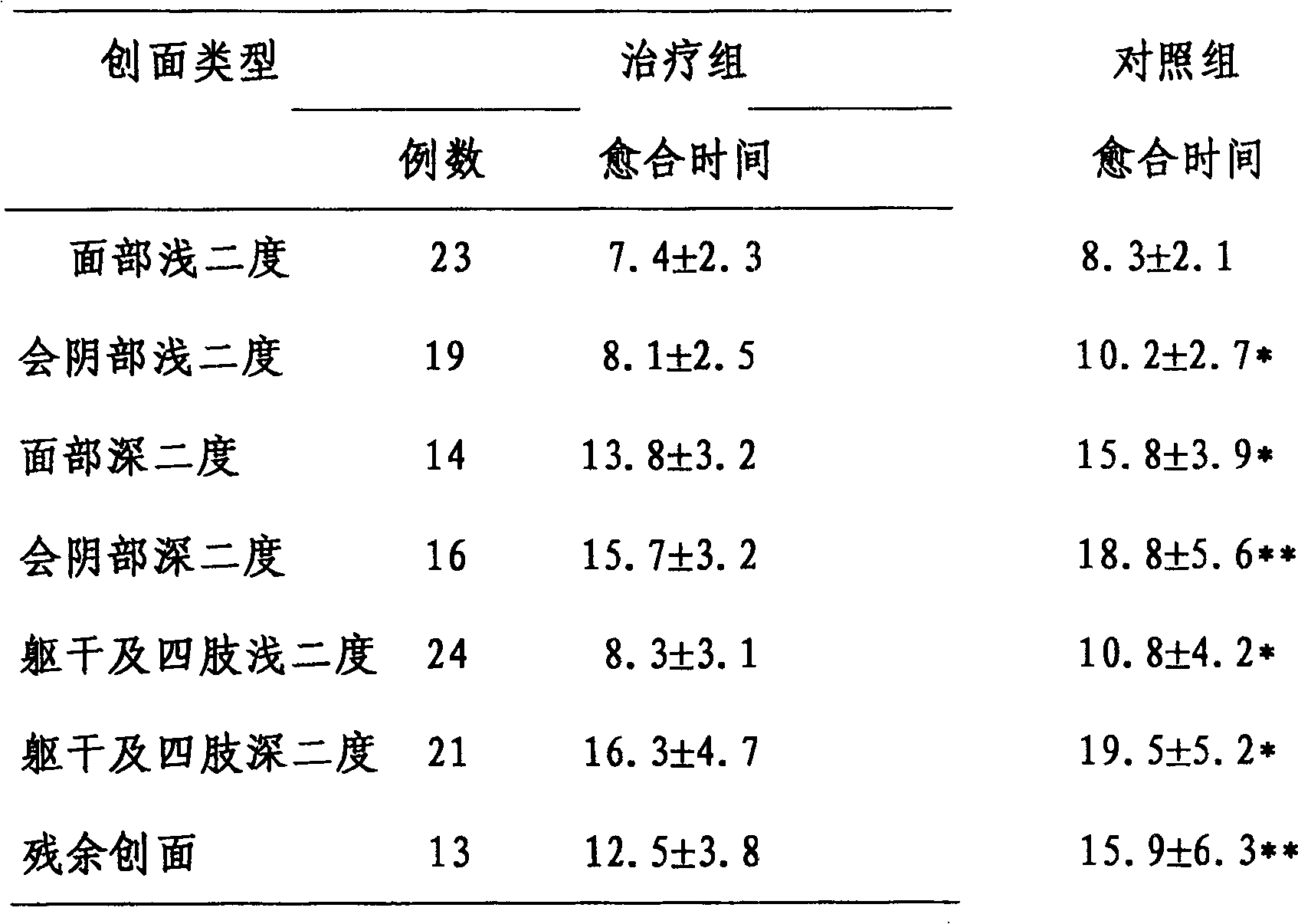

ActiveCN100560057CNo side effectsShorten wound healing timeInorganic active ingredientsPharmaceutical delivery mechanismSide effectNecrotic tissue

Owner:苏州汇涵医用科技发展有限公司

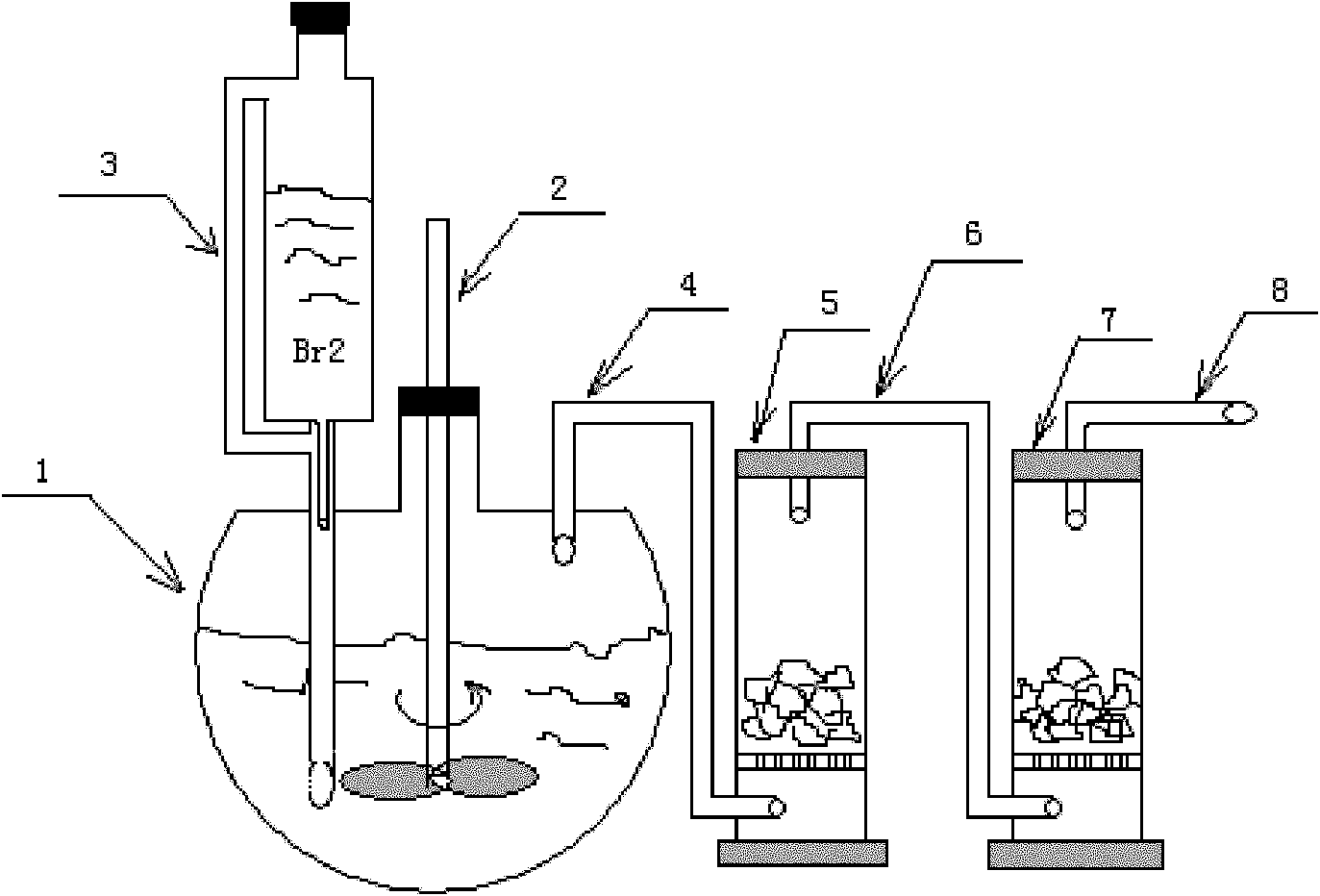

Preparation method of bromine hydride gas and generating device thereof

InactiveCN102001627AIncrease profitRaw materials are cheap and easy to getBromine/hydrogen-bromidePhosphorous acidBromine

The invention relates to a preparation method of bromine hydride gas and a generating device thereof in the field of medicaments, fine chemicals, chemical agents and the like. The preparation method of the bromine hydride gas is characterized by comprising the following steps of: selecting red phosphorus, concentrated hydrobromic acid and bromine according to the weight ratio of the red phosphorus to the concentrated hydrobromic acid to the bromine of 1:3.5-4.5:6-7; putting the red phosphorus and concentrated hydrobromic acid into a reaction vessel, stirring at the room temperature; dropping the bromine into a reactor from a constant pressure dropping liquid device; treating the generated bromine hydride gas in a bromine removing tower and a drying tower, namely leading out dried bromine hydride gas; and filtering kettle bottom solution in the reactor to remove unreacted red phosphorus, and depressurizing to remove the bromine hydride so as to obtain a byproduct of phosphorous acid. The preparation method has the advantages of low-price and readily-available raw materials, mild condition and simple device.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Oxygen-free copper rod production method

InactiveCN108517419ACompact structureBright surfaceProcess efficiency improvementElectrolysisGraphite

The invention discloses an oxygen-free copper rod production method, which comprises the following steps of adding baked electrolytic copper and dried deoxidants into a melting furnace in batches formelting; after the melting, performing stirring through a graphite stirrer arranged in the melting furnace; then, introducing copper liquid deoxidized by a deoxidant into a heat insulation furnace; introducing nitrogen gas containing 1-percent natural gas into the heat insulation furnace; using an upper guiding method traction pulling casting machine to perform pulling casting on copper liquid toobtain the oxygen-free copper rod. The oxygen-free copper rod production method has the advantages that the process is simple; the production cost is low; the multiplex deoxygenation is performed on the raw materials; the deoxygenation effect is improved; meanwhile, the safety coefficient is high; the conditions are not harsh; wide market prospects are realized; the oxygen-free copper rod preparedby the method has a compact structure and bright surface; the oxygen content can be lower than 3ppm.

Owner:中海宏祥铜业江苏有限公司

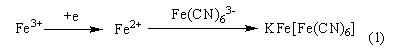

Process for preparing iron blue with fantastic color effect

The invention relates to a process for preparing iron blue with fantastic color effect, and belongs to preparation of strong interference pigments of multi-coated laminar base materials. Ferrous cyanide, trivalent ferric salt and transparent laminar base material are used as raw materials in the iron blue pigment with fantastic color effect; and the process comprises the following steps of: continuously stirring the raw materials at the temperature of between 10 and 70 DEG C, and precipitating reactants of certain concentration on the transparent laminar base material to obtain an iron blue coated fantastic color effect pigment. Different iron blue color phases are obtained by changing reaction parameters, and then a finished product is obtained by filtering, washing and drying. The process has the advantages of reasonability in design, simplicity in production process, low pollution and low equipment cost and energy consumption.

Owner:杭州弗沃德精细化工有限公司

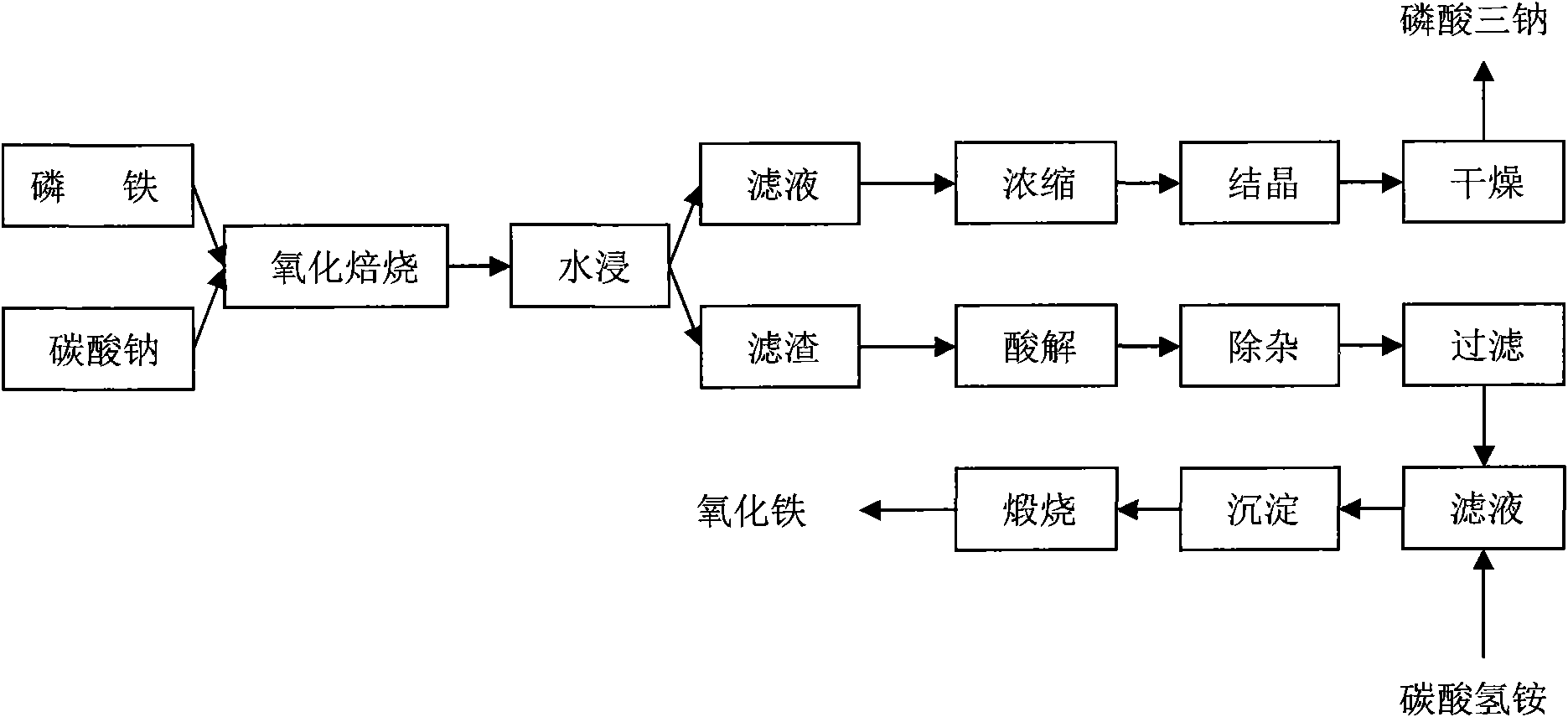

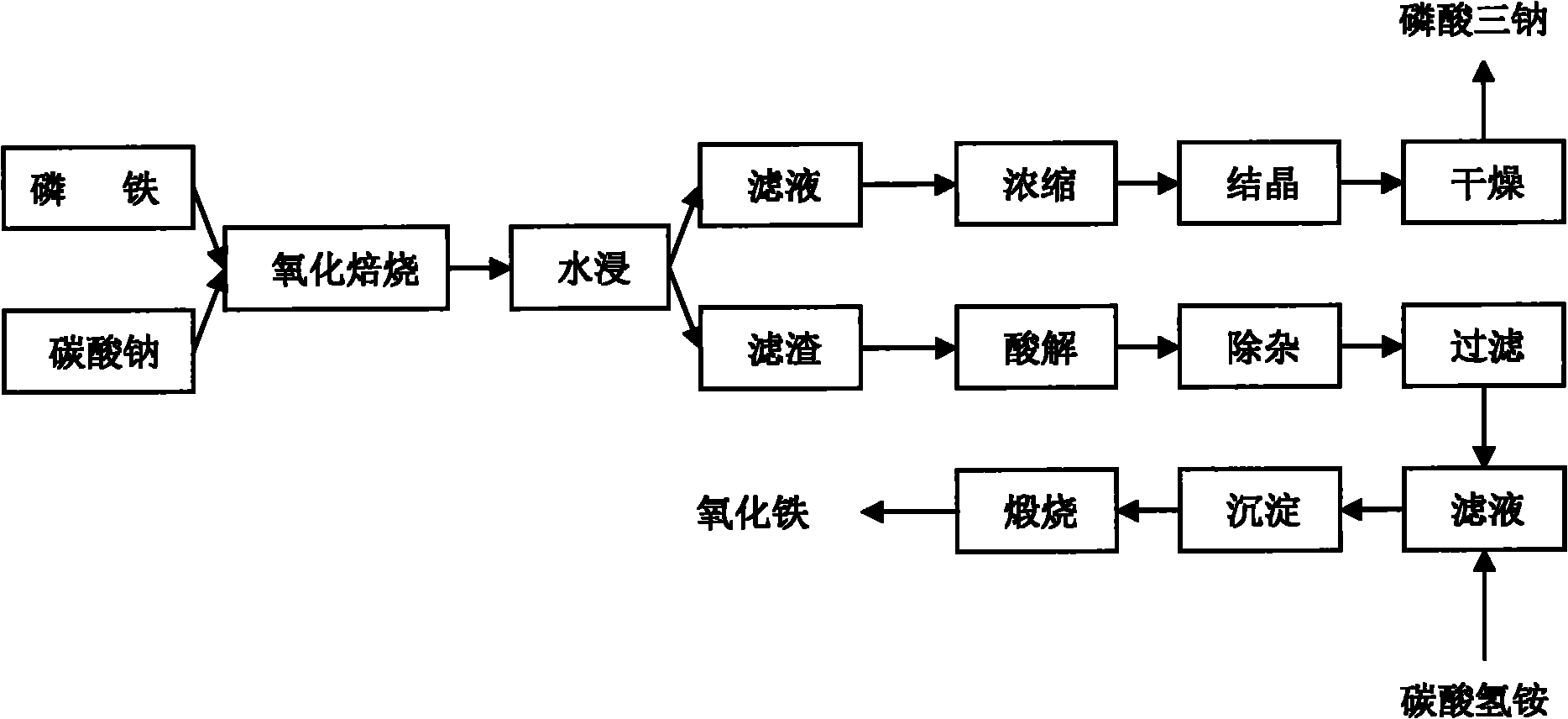

Method for preparing high-purity iron oxide and trisodium phosphate by ferro-phosphorus alkalization process

InactiveCN101774648AIncrease profitImprove product added valueFerric oxidesPhosphorus compoundsSlagWater immersion

The invention relates to a method for preparing high-purity iron oxide and trisodium phosphate by a ferro-phosphorus alkalization process, which comprises the following steps of: mixing ferro-phosphorus slag with calcined soda and then roasting the mixture; performing water immersion on a roasted product, and using filter residues obtained after the water immersion to prepare the high-purity iron oxide; and using the filtrate obtained after the water immersion of the roasted product to prepare the trisodium phosphate. The process provided by the invention can fully utilize the iron and phosphorus elements in ferro-phosphorus at the same time, and has a certain value in energy-saving and emission-reduction; the comprehensive utilization ratio of the ferro-phosphorus is high, the conversion rate of the iron element can reach 91.3 to 93.2, the conversion rate of the phosphorus element can reach 89.8 to 91.1 percent, the product added value is high, the prepared high-purity iron oxide accords with a national standard HG / T 2574-94, the iron trioxide content can reach 98.8 to 99.4 percent; and compared with the existing common method for producing high-purity industrial iron oxide, the method for preparing the high-purity iron oxide and the trisodium phosphate by the ferro-phosphorus alkalization process greatly reduces the production cost, has a simple production process and non-demanding conditions, and is easy to implement.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for auxiliary preparation of different-shape nano-cerium oxide with microwave

InactiveCN101508456AAchieve human controllabilityHigh utility valueMicrowave heatingRare earth metal compoundsControllabilityOleic Acid Triglyceride

The invention belongs to the technical field of nanometer material preparation, in particular to a method for preparing nanometer cerium oxide with different appearances by microwave assistance. The method comprises the following steps: 1) preparing 0.01 to 0.1 mol / L aqueous solution of Ce(NO3)3 at room temperature; adding the Ce(NO3)3 aqueous solution, glycol, oleic acid and tert-butylamine into a high-temperature reaction kettle according to volume ratio of 100: (80-120) : (5-10) : (0.6-1.2) without any stirring; 2) sealing and placing the high-temperature reaction kettle in a microwave environment to be heated for 5 to 10 minutes with microwave power of between 100 and 1,000 watt; and 3) after reaction of step (2) is finished, cooling the obtained mixture till room temperature, adding acetone accounting for 3 to 5 times of the mixture by volume into the mixture to wash the glycol and the oleic acid, centrifugalizing the mixture after ultrasonic treatment, washing the centrifugalized solid by absolute ethyl alcohol, carrying out ultrasonic treatment and centrifugalization on the solid for 5 to 6 times, and drying the obtained solid powder to obtain the cerium oxide nanometer material. The method has the advantages of low cost, simple process and good controllability.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

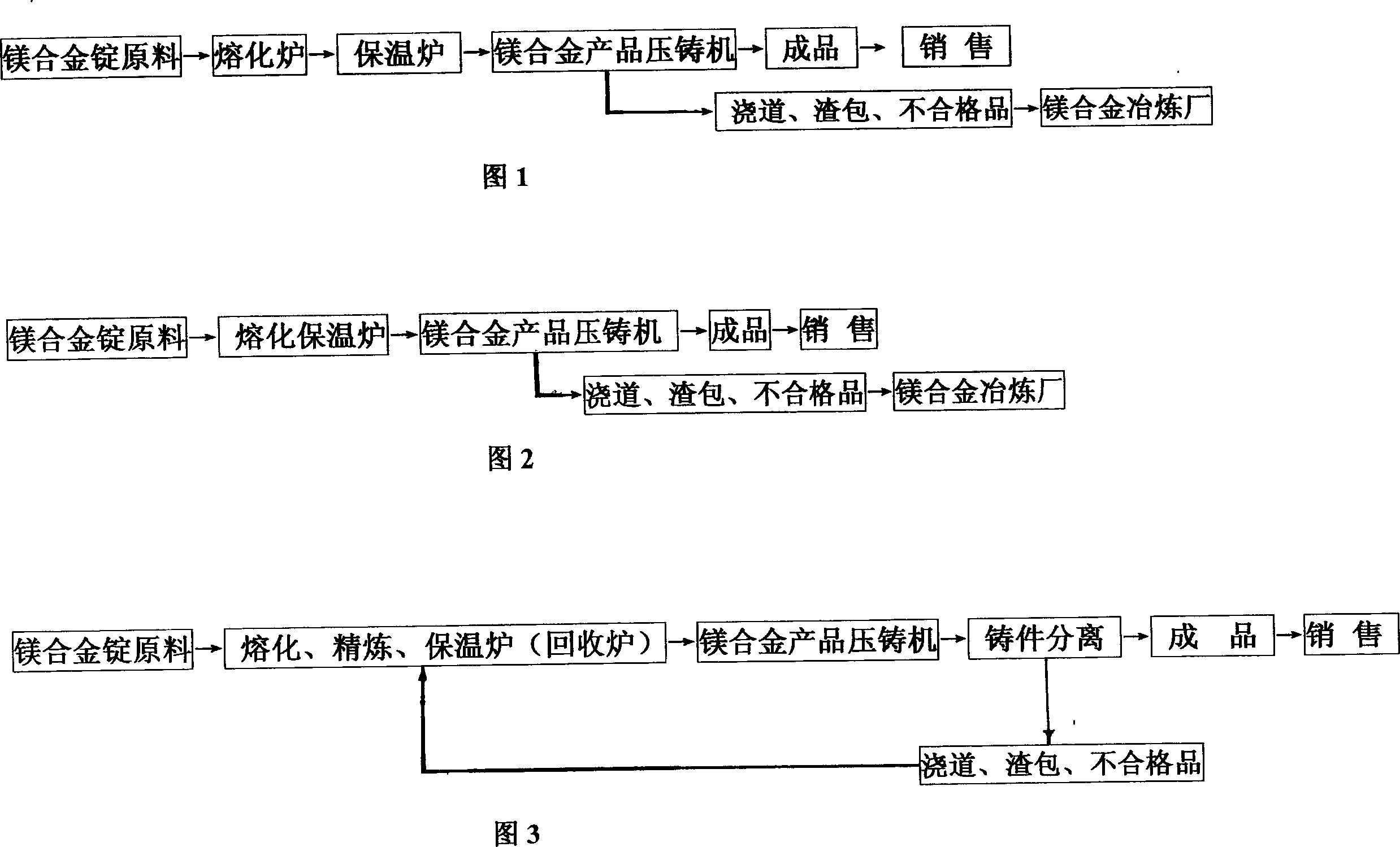

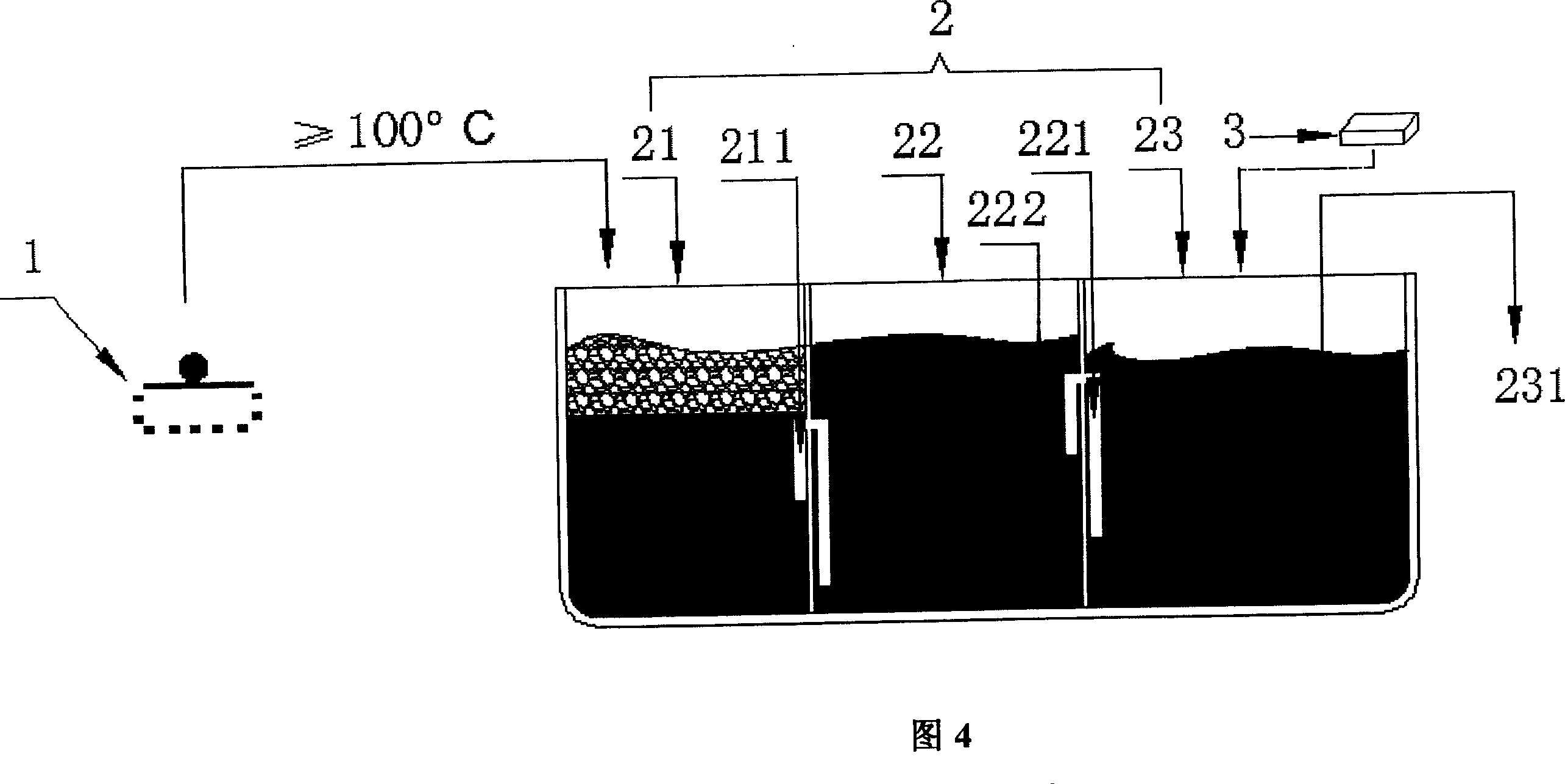

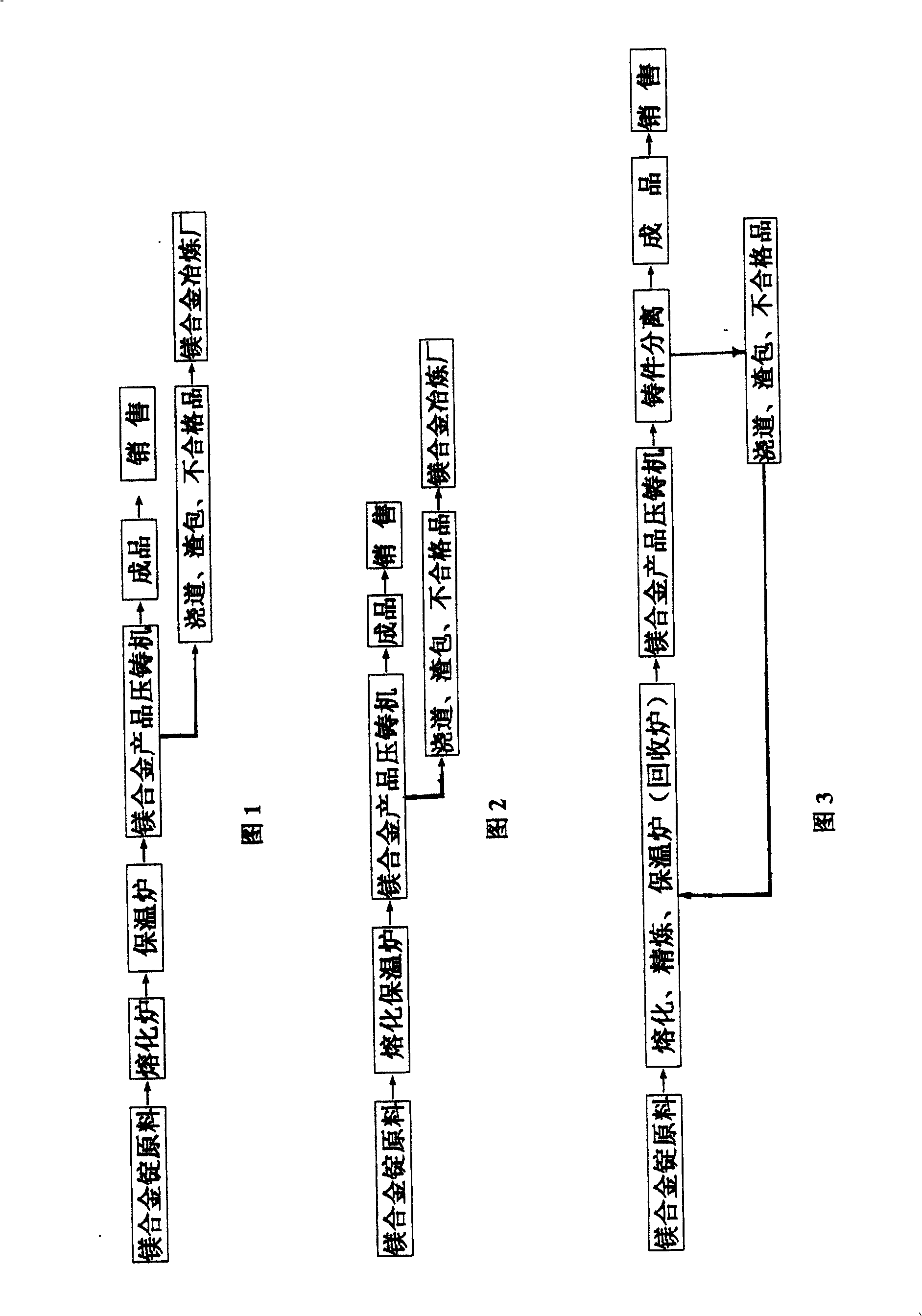

Recycle utilization process of magnesium alloy compression casting waste material

InactiveCN101012517AMeet immediate recycling requirementsIncrease profitProcess efficiency improvementSlagMolding machine

The invention discloses a circulating utilizing technique of magnesium alloy cast slag, which comprises the following steps: separating cast piece of magnesium alloy through squeeze molding machine on the spot; obtaining waste material of magnesium alloy; transmitting magnesium alloy waste into fusing chamber of recycling device and refining chamber; obtaining magnesium alloy liquid; insulating; casting; stewing refined magnesium liquid under high temperature; transmitting the liquid into insulating chamber of recycling device; regenerating raw material.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH

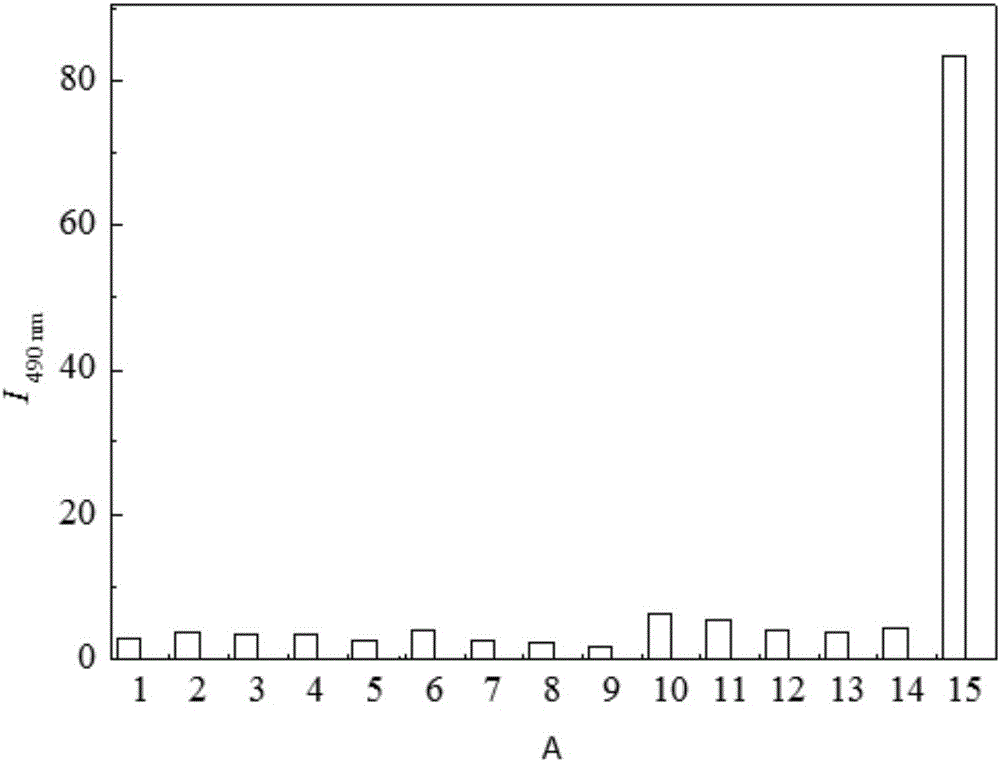

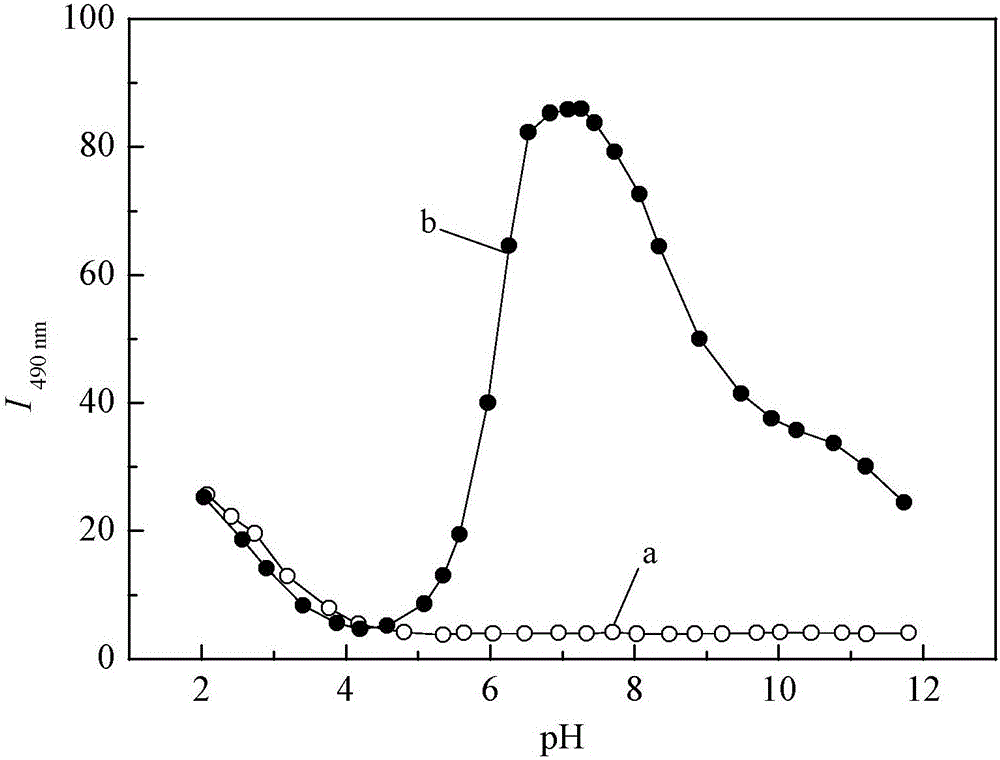

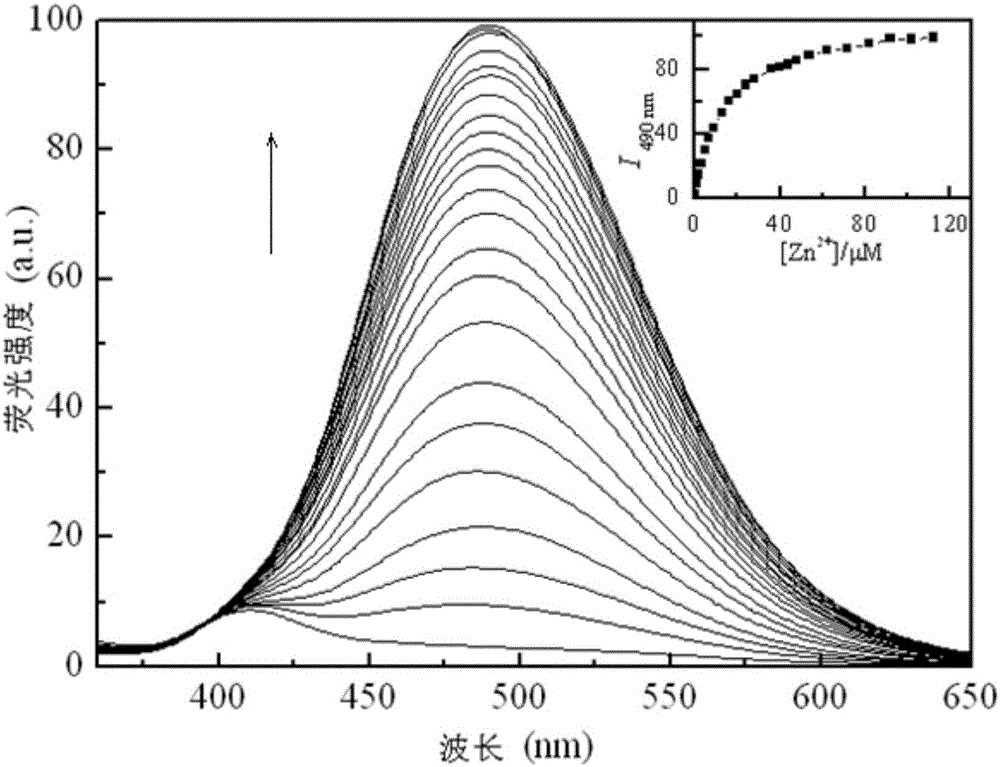

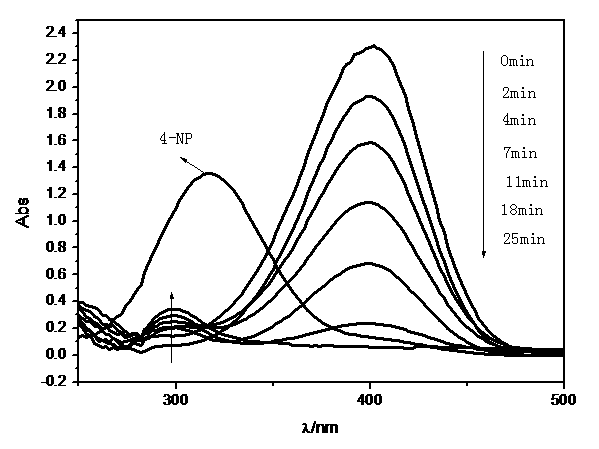

Oxalyl aminoquinoline derivative fluorescent molecular probe and preparation method and application thereof

InactiveCN105733559AHigh selectivityHigh sensitivityOrganic chemistryFluorescence/phosphorescenceFluorescenceSynthesis methods

The invention relates to a biological fluorescent molecular probe and its synthetic method and application, in particular to an oxalyl aminoquinoline derivative fluorescent molecular probe and a preparation method and application thereof and aims to solve the technical problem that an existing molecular probe is made from various synthetic materials under harsh synthetic conditions. A structural general formula of the oxalyl aminoquinoline derivative fluorescent molecular probe is shown as follows; wherein R is an alkoxy group, an amino group, an alkyl amino group, an aromatic amino group or a hydroxyl alkyl group. A first preparation method comprises: reacting 8-aminoquinoline with diethyl oxalate to prepare an intermediate, and reacting the intermediate with amine to obtain a mono-substituted oxalyl aminoquinoline derivative fluorescent molecular probe; a second preparation method comprises: adding 8-aminoquinoline and diethyl oxalate into diethyl oxalate for reacting, and purifying to obtain a bis-substituted oxalyl aminoquinoline derivative fluorescent molecular probe. The molecular probe is useful in detecting zinc ions that are zinc ions in a solution or zinc ions in an organism.

Owner:QIQIHAR UNIVERSITY

Method for treating sewage by utilizing compound bacteria

ActiveCN105600945AImprove survival rateSolve the problem of recessionBiological water/sewage treatmentVitamin CPhosphate

The invention discloses a method for treating sewage by utilizing compound bacteria. Different compound bacteria are creatively adopted and are added in steps. The method for treating sewage by utilizing the compound bacteria comprises the following concrete steps: adding clear water into a biochemical pool until the biochemical pool is filled with the clear water, and aerating until dissolved oxygen in pool water reaches 3-4 mg / L; then adding a first part of compound bacteria, wherein viable count per gram is 109-1011; then adding glucose until COD of water body in the pool reaches 800mg / L; then adding urea, potassium dihydrogen phosphate and vitamin C into the pool; aerating the biochemical pool for oxygenation, so as to keep dissolved oxygen of the pool water to be 1-3 mg / L, and promoting bacteria to grow into a biological film on filler; and continuously introducing sewage at a flow of 5-20 m<3> / h, after 24 hours, adding a second part of compound bacteria into the pool until C:N:P in the pool is 100:(1-1.1):5, and aerating the pool water for keeping the dissolved oxygen to be not less than 4 mg / L.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

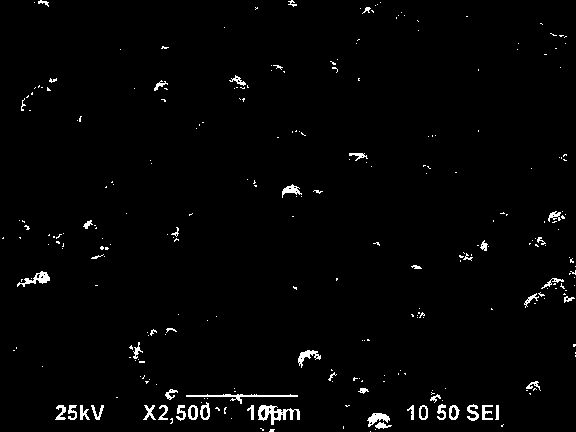

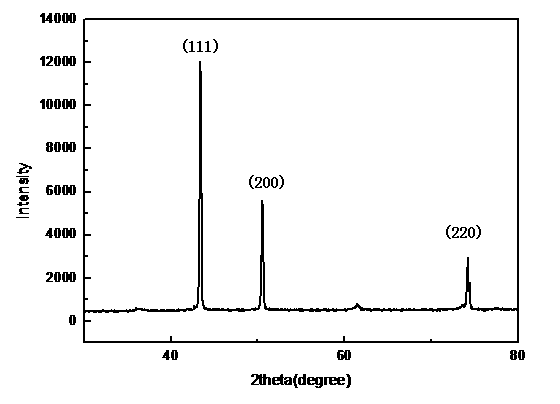

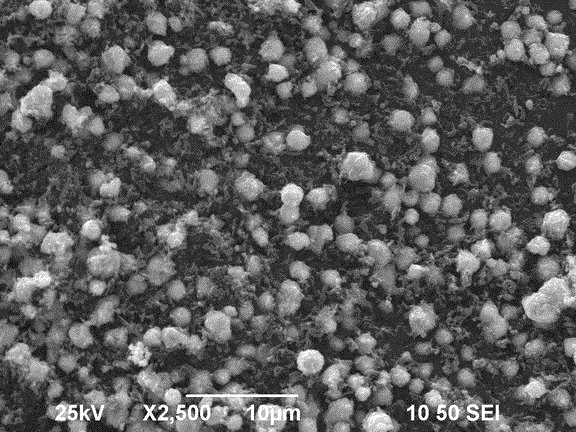

Micron-scale elemental copper catalyst and preparation method and application thereof

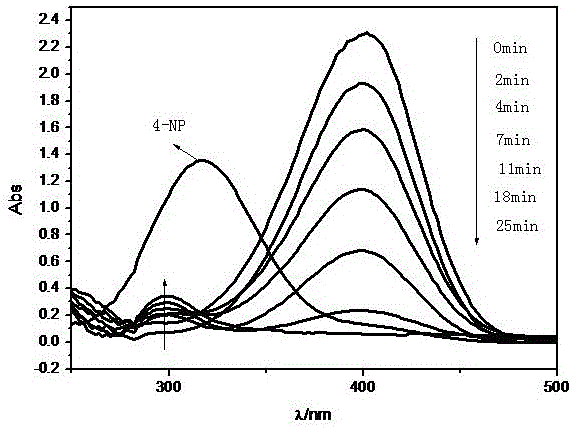

InactiveCN104028268ARecyclable performanceEffective catalytic degradationWater/sewage treatment by irradiationWater contaminantsMicron scaleNitrogen gas

The invention discloses a micron-scale elemental copper catalyst and a preparation method and application thereof. According to the key points of the technical scheme, the micron-scale elemental copper catalyst is prepared by the steps of reacting copper salt with an organic ligand to form a precursor and then performing calcination under the protection of nitrogen at the temperature of 400 to 800 DEG C, wherein the molar mass ratio of the copper salt (n) to the organic ligand (n) is (1-4) to 1, the copper salt is Cu(NO3)2.3H2O, and the organic ligand is 1,3,5-trimesic acid, terephthalic acid, isophthalic acid, phthalic acid, formic acid or 4,4',4''-s-triazine-1,3,5-three-para aminobenzoic acid. The invention further discloses the preparation method of the catalyst and the application of the catalyst to processing of nitrophenol waste water. The micron-scale elemental copper catalyst has the advantages of environmental friendliness, simple preparation process, high innovativeness and practicability and the like, nitrophenol pollutants in organic waste water can be effectively catalyzed and degraded, and the catalyst has circulating renewable use performance.

Owner:HENAN NORMAL UNIV

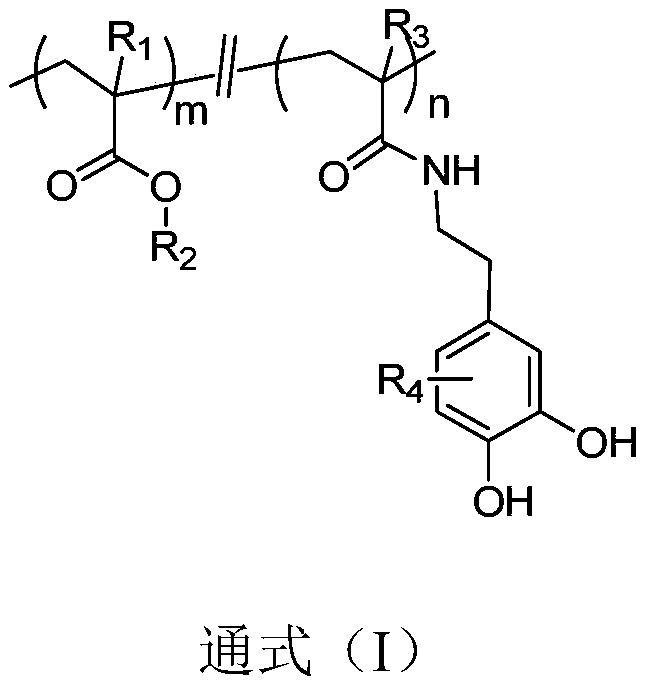

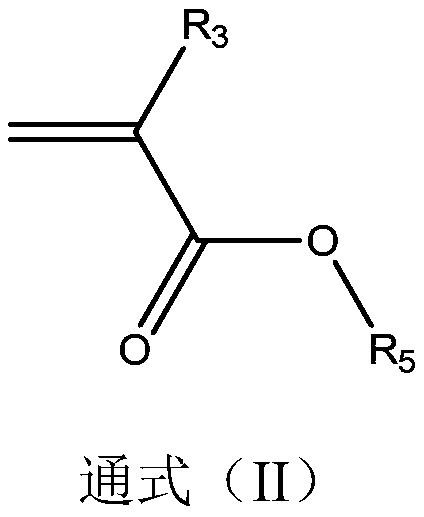

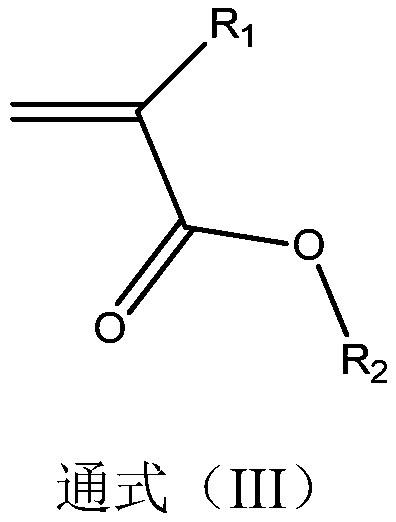

Surface coating polymer, and preparation method and application thereof

InactiveCN110054732AExcellent Adhesive PropertiesImprove adhesion stabilityAntifouling/underwater paintsSurgeryPolymer scienceStructural unit

The invention relates to a surface coating polymer, and a preparation method and application thereof. The surface coating polymer comprises a random copolymer of a structural unit containing catecholgroups and a structural unit containing zwitterionic groups; and in the random copolymer, the molar ratio of the structural unit containing the zwitterionic group to the structural unit containing thecatechol group is 50-280: 70-430. The surface coating polymer simultaneously contains the repetition structural unit containing the zwitterionic group and the repetition structural unit containing the catechol group, the excellent antibacterial property of the zwitterionic group and the good adhesion property of the catechol group are combined by the polymer, and the polymer has strong adhesion to the surface of a substrate, has good adhesion stability, is not easy to fall off, and has excellent antibacterial property and a bacteria adhesion resisting function.

Owner:SUN YAT SEN UNIV

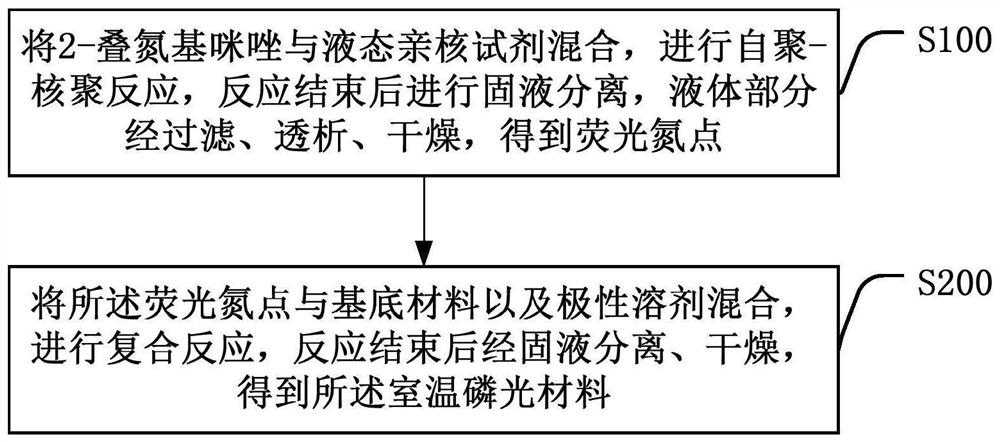

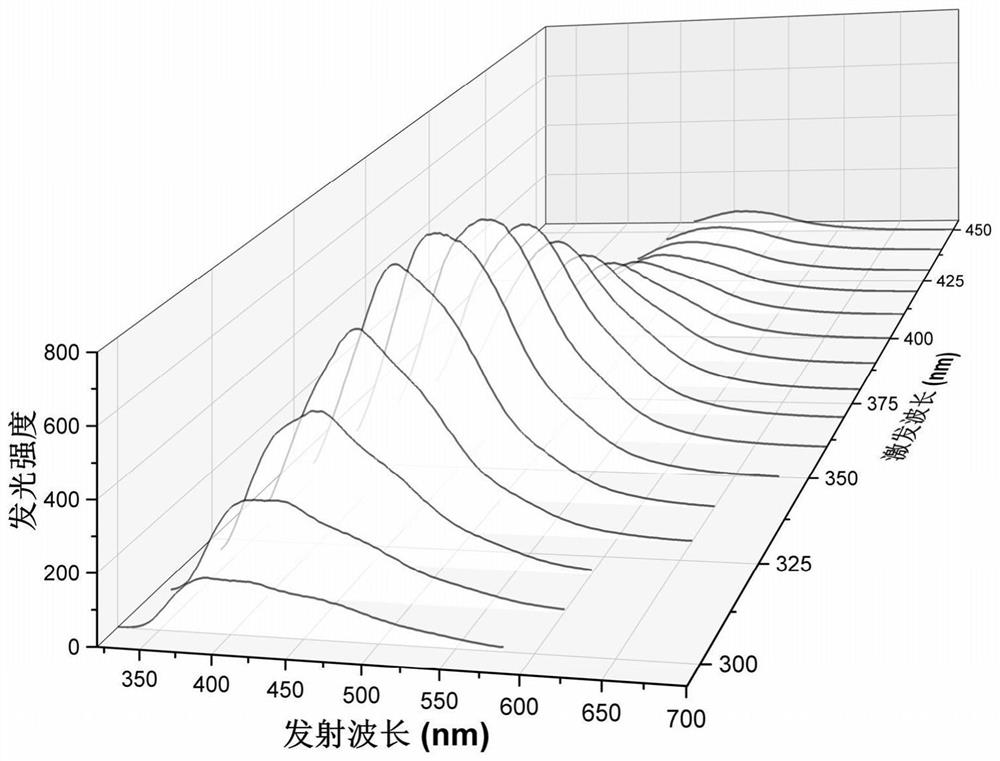

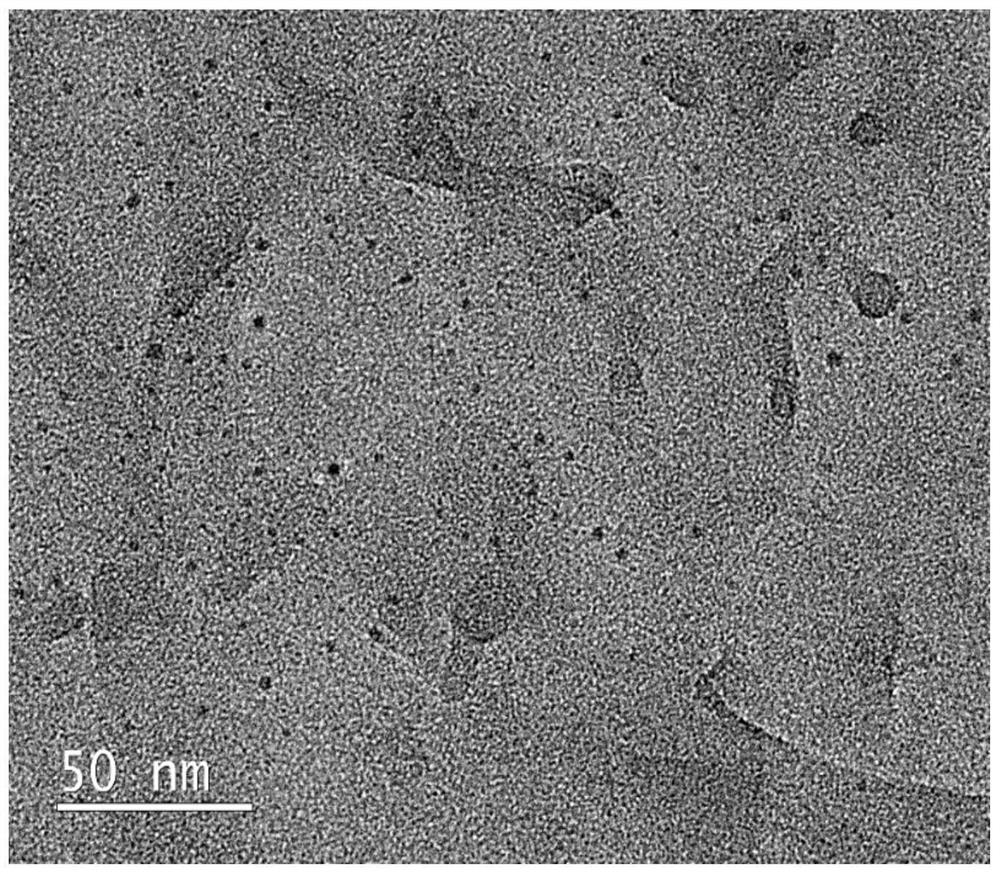

Nitrogen point-based room-temperature phosphorescent material and preparation method and application thereof

The invention discloses a nitrogen point-based room-temperature phosphorescent material and a preparation method and application thereof. The preparation method comprises the following steps: taking 2-azido imidazole with high reaction activity (azido at the 2 position) as a precursor, carrying out self-polymerization and nucleophilic polymerization in the presence of a liquid nucleophilic reagentto obtain a fluorescent nitrogen point; and enabling the fluorescent nitrogen point to be compounded with a substrate material so as to prepare the room-temperature phosphorescent material. The method for preparing the room-temperature phosphorescent material is simple, controllable, low in energy consumption, convenient to operate, not harsh in condition, good in reproducibility and beneficial to expanded production. The room-temperature phosphorescent material prepared by the method has the characteristics of strong luminescence and good stability, and still has excellent room-temperature phosphorescent characteristics, ultra-long phosphorescent service life and long afterglow time in an amorphous or glassy state; the material can be applied to the fields of environmental detection andbiochemical analysis, and can also be used for preparing fluorescent ink for ink-jet printing, anti-counterfeiting marks and the like.

Owner:SHENZHEN UNIV

Process for preparing iron blue with fantastic color effect

The invention relates to a process for preparing iron blue with fantastic color effect, and belongs to preparation of strong interference pigments of multi-coated laminar base materials. Ferrous cyanide, trivalent ferric salt and transparent laminar base material are used as raw materials in the iron blue pigment with fantastic color effect; and the process comprises the following steps of: continuously stirring the raw materials at the temperature of between 10 and 70 DEG C, and precipitating reactants of certain concentration on the transparent laminar base material to obtain an iron blue coated fantastic color effect pigment. Different iron blue color phases are obtained by changing reaction parameters, and then a finished product is obtained by filtering, washing and drying. The process has the advantages of reasonability in design, simplicity in production process, low pollution and low equipment cost and energy consumption.

Owner:杭州弗沃德精细化工有限公司

Method for preparing metal electrodes of crystal silicon solar cell

ActiveCN102299200BReduce manufacturing costImprove yieldFinal product manufactureSemiconductor devicesSilicon solar cellMetal electrodes

The invention discloses a method for preparing metal electrodes of a crystal silicon solar cell, which comprises the steps that: after the PN junction is prepared on a p-type crystal silicon substrate through diffusion, a silicon nitride antireflection layer is prepared on the surface of a n type emitting electrode, then, a thin Al layer with the thickness being 100nm to 1000nm is prepared on thesurface of a p-type conducting back through the vacuum sputtering technology, the vapor deposition technology or the screen printing technology, in addition, a thin Ag grid line layer with the thickness being 1mum to 5mum is prepared on the surface of the silicon nitride antireflection layer through the screen printing, next, an Al back field seed layer and an Ag grid line seed layer are formed through the traditional high-temperature sintering technology, finally, tin, copper or nickel is electroplated on the Ag grid line seed layer and the Al back field seed layer through the electroplatingprocess, and the metal electrodes are formed after the thickening. Compared with the prior art, the method combines the advantages of the screen printing process, the magnetron sputtering process, the vapor deposition process and the electroplating process, front metal grid line electrodes with high electrical conductivity and low light shielding rate can be obtained, and simultaneously, the consumption of expensive metal Ag can be effectively reduced, so important industrialized application prospects are realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Xylitol-containing high-fiber coix seed milk tablet and production method thereof

The invention discloses a xylitol-containing high-fiber coix seed milk tablet and a production method thereof, and belongs to the technical field of nutritional foods and processing thereof. The milk tablet is formed by, by weight, 10-15 parts of coix seed powder, 8-15 parts of whole milk powder, 10-20 parts of non-dairy creamer, 10-20 parts of crystallized xylitol, 5-10 parts of maltodextrin, 0.1-0.5 parts of fresh milk essence, and 0.1-0.3 parts of malt essence. Coix seed fiber powder is selected as one of raw materials, so the coix seed milk tablet is rich in dietary fibers, and is helpful for improving the dietary fiber intake of people; and the method has the advantages of simple process steps, non-strict conditions, and meeting of industrial production requirements.

Owner:贵州百科薏仁生物科技有限公司

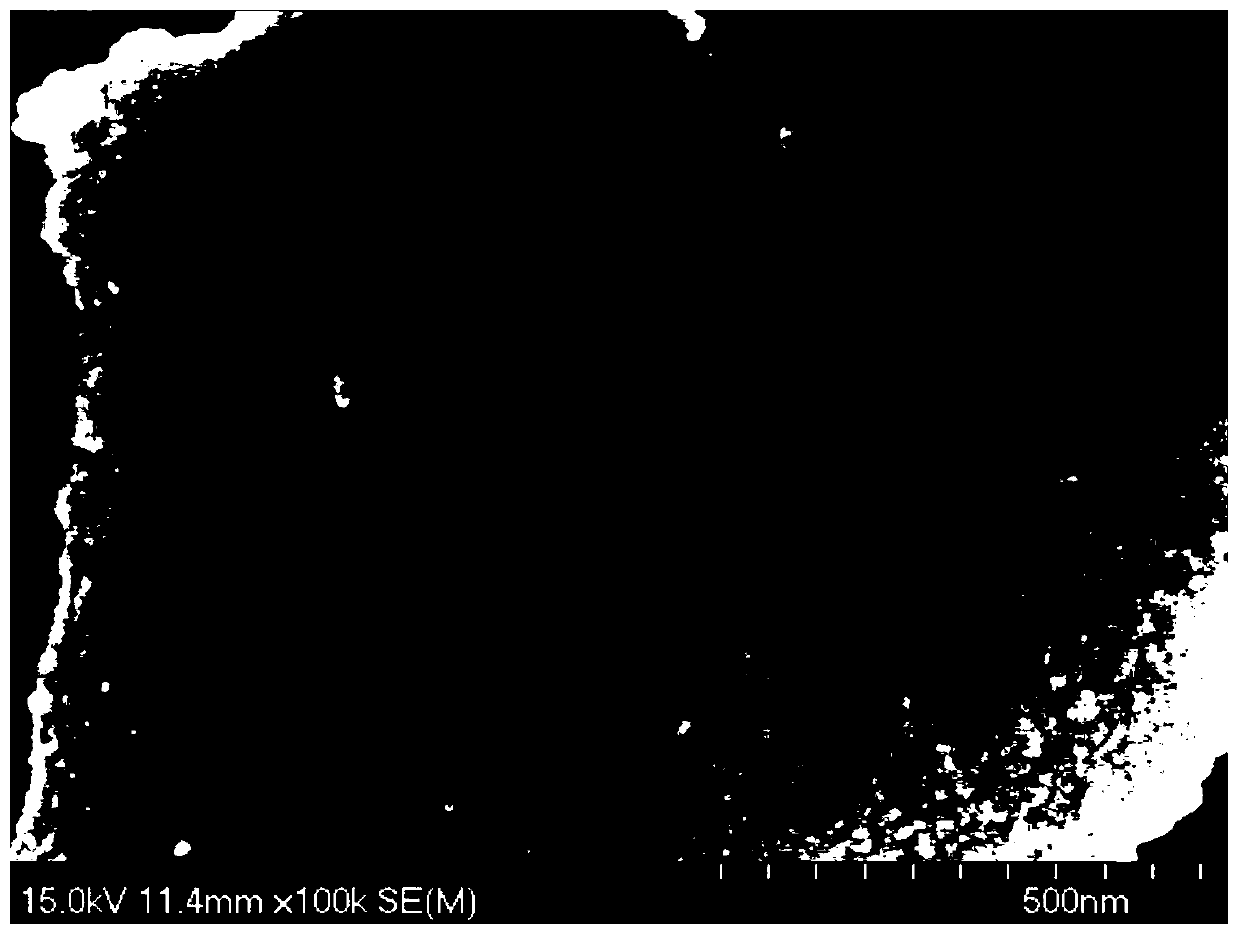

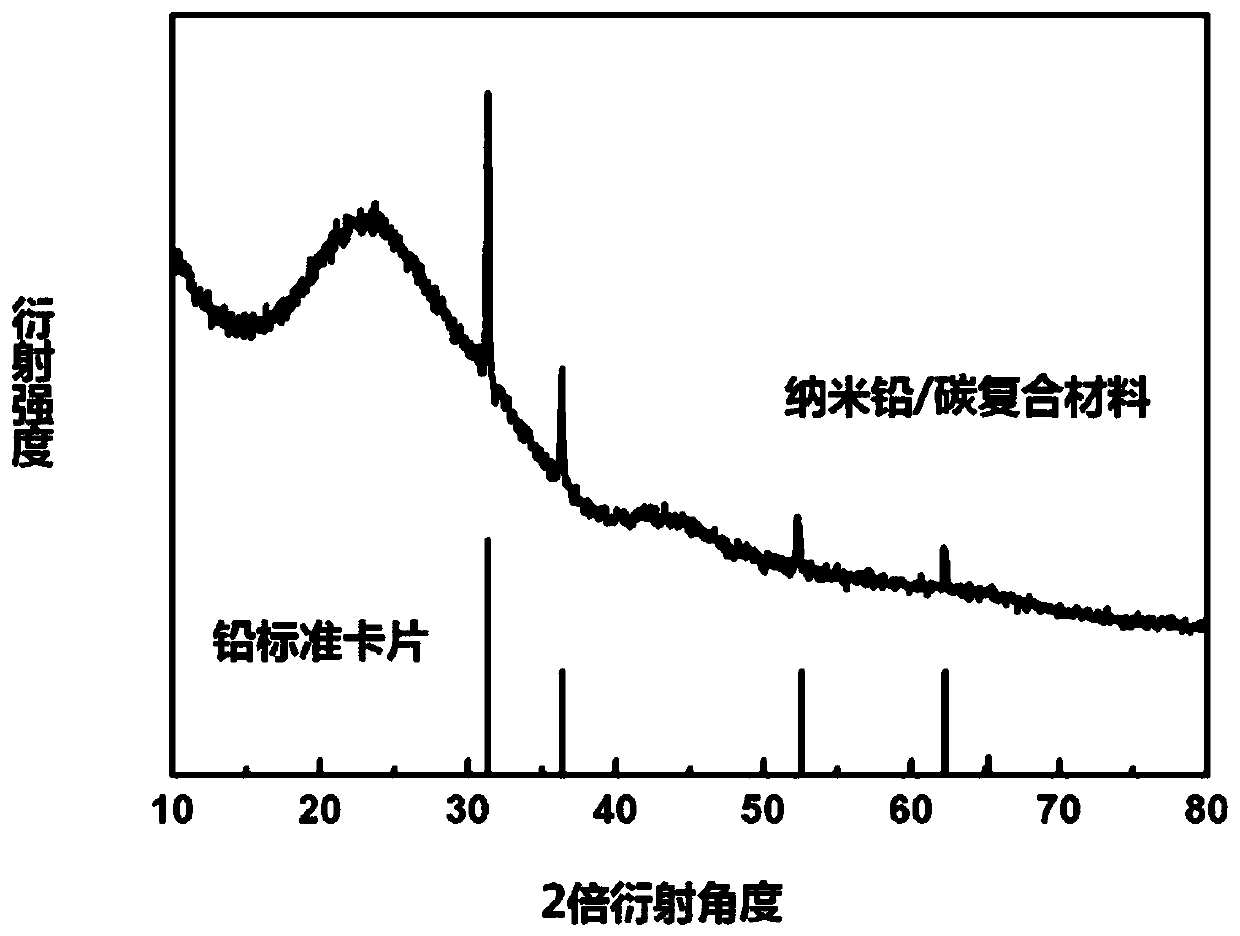

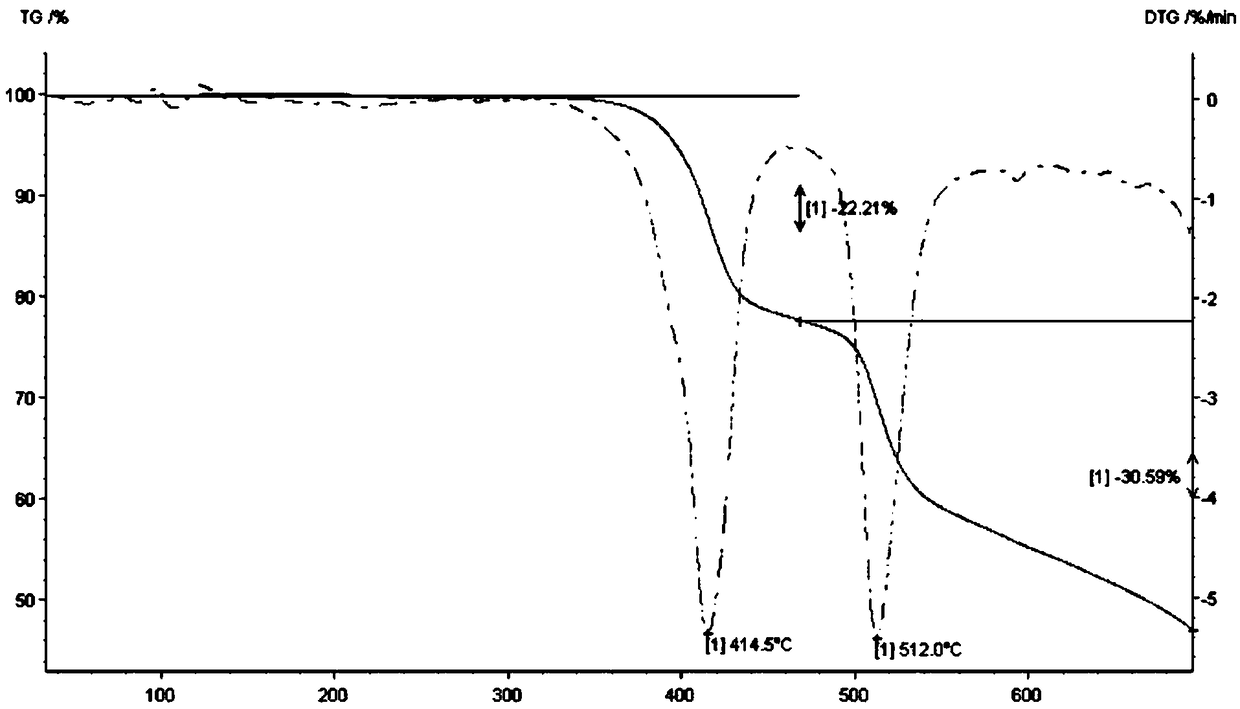

Preparation method of nano lead/carbon composite material and application of nano lead/carbon composite material

InactiveCN109860531ASmall sizeEvenly dispersedLead-acid accumulatorsCell electrodesCarbon compositesHydrogen

The present invention discloses a preparation method of a nano lead / carbon composite material and application of a nano lead / carbon composite material. The preparation method comprises the following steps of: (1) adding a carbon material into an oxidant aqueous solution for oxidation treatment to obtain a mixed liquor A; (2) mixing a lead source aqueous solution with the mixture A for stirring above 0.5 hours to allow lead ions to be absorbed at the surface of the carbon material to obtain a mixed liquor B; (3) adding a surfactant into the mixed liquor B for stirring above 0.5 hours, and performing filtering and vacuum drying to obtain a precursor; and (4) in a protective atmosphere, performing calcinations of the obtained precursor at a temperature of 300-700 DEG C, and performing thermaltreatment to obtain a nano lead / carbon composite material. The present invention provides application of the nano lead / carbon composite material taken as a super Pb-C battery anode material. The preparation method of the nano lead / carbon composite material is simple in operation, the obtained lead particles are very small and are uniformly dispersed on the surface of the carbon material, and thecomposite material can better inhibit the hydrogen evolution reaction.

Owner:ZHEJIANG UNIV OF TECH

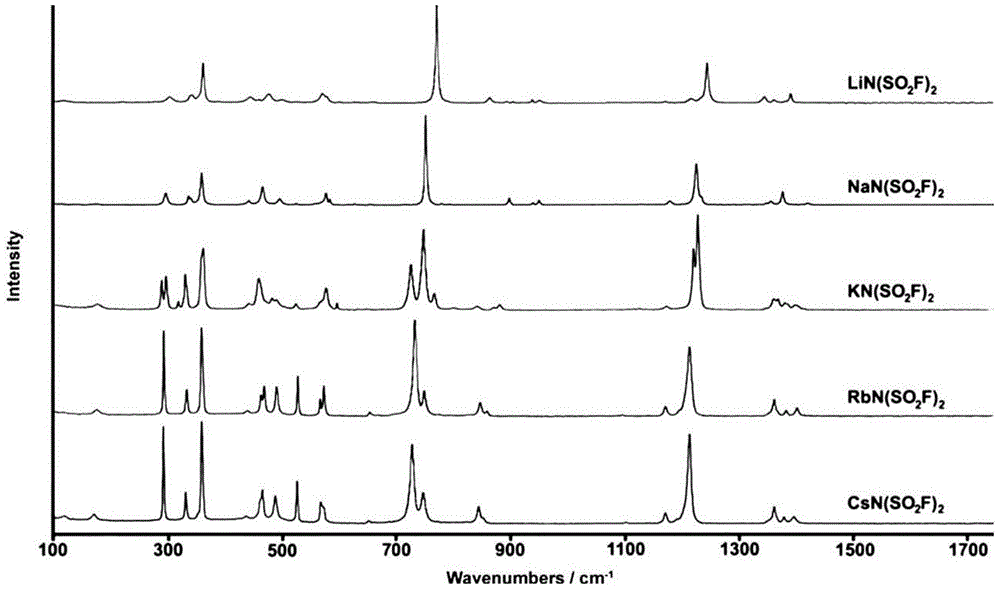

A kind of preparation method of bisfluorosulfonimide salt

The invention relates to a preparation method of a difluoro-sulfonyl imine salt, and belongs to the field of fine chemical engineering. The difluoro-sulfonyl imine salt is MN(SO2F)2, wherein M is Li, Na, K, Rb or Cs. The preparation method comprises the following steps: mixing FSO2X, a nitrogen source, an acid-binding agent and an aprotic solvent to obtain a mixture, wherein X is F, Cl, Br or I, the nitrogen source is anammonium salt or anhydrous NH3, the acid-binding agent is a lithium, sodium, potassium, rubidium or cesium salt, the mole ratio of NH3 or ammonium ion to FSO2X is 1:(2-10), and the mole ratio of NH3 or the ammonium ion to the acid-binding agent is 1:(3-10); heating to perform reflux reaction on the mixture for 5-8 hours; cooling to obtain a filtrate; and removing the solvent to obtain a crude product, and performing vacuum drying to obtain the difluoro-sulfonyl imine salt. The preparation method has easily available raw material, is safe and pollution-free, is high in yield, is easy to realize separation and purification, is simple in step, is not severe in requirement of operation equipment, and is suitable for industrial production.

Owner:PERIC SPECIAL GASES CO LTD

Method for producing high-purity triazine-based charring agent

InactiveCN108997240AHigh purityEasy to controlOrganic chemistryReaction temperatureAmmonium hydroxide

The invention provides a method for producing a high-purity triazine-based charring agent. The method comprises the following steps: using cyanuric chloride, 25% aqueous ammonia solution and an aminesubstance as raw materials; using water as a solvent; and adding an alkali substance for production. The method provided by the invention uses the cyanuric chloride, the 25% aqueous ammonia solution and the amine substance as the raw materials, uses the water as the solvent, and adds the alkali substance to synthesize high-purity and high-yield triazine-based charring agent by controlling a reaction temperature and time in a reactor equipped with a stirring device, a condensing device and a refluxing device and in a vacuum drier.

Owner:中山苏特宝新材料有限公司

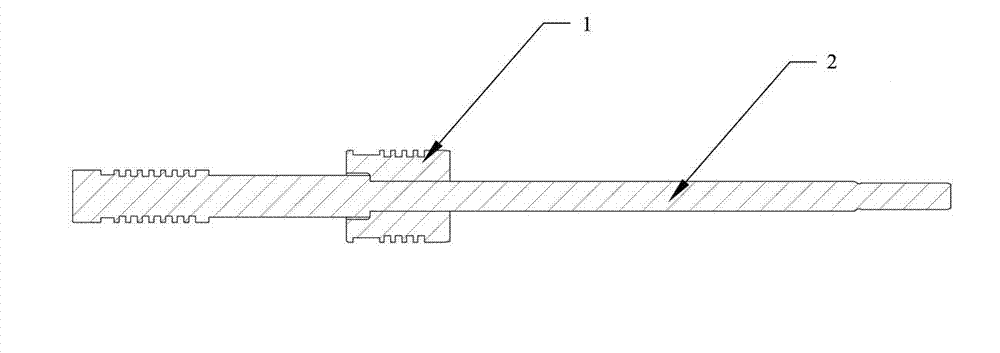

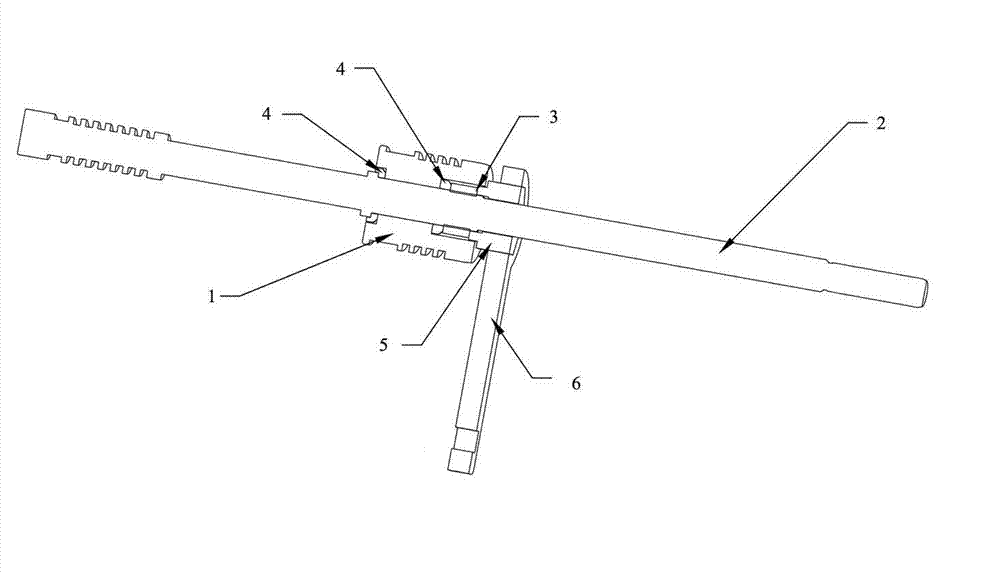

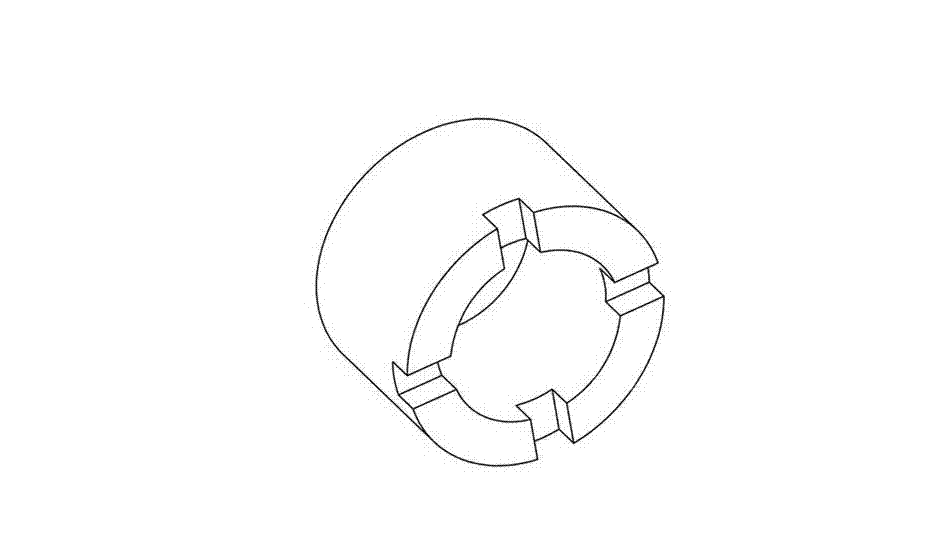

Threaded connecting structure of differential piston

ActiveCN102889196ASimple structureConditions are not harshPositive displacement pump componentsMulti-stage pumpsEngineeringScrew thread

The invention discloses a threaded connecting structure of a differential piston used for a differential piston in a piston type compressor. The threaded connecting structure comprises a piston, a piston rod, a locknut, steel pads, an outer hexagonal wrench and an inner hexagonal wrench, and is characterized in that a part on the piston rod, which is connected with the piston, is provided with a screw thread, an internal thread is arranged in the locknut, the screw thread on the piston rod is matched with the design of an internal thread of the locknut, and the diameters are equal, and the steel pads are respectively arranged between the piston and a shaft shoulder, and between the piston and the locknut. Through the technical scheme provided by the invention, the connecting mechanism of the differential piston has the advantages of simple structure, un-harsh installation and working operation conditions, simple maintenance and adjustment, and durability.

Owner:天津凯德实业有限公司

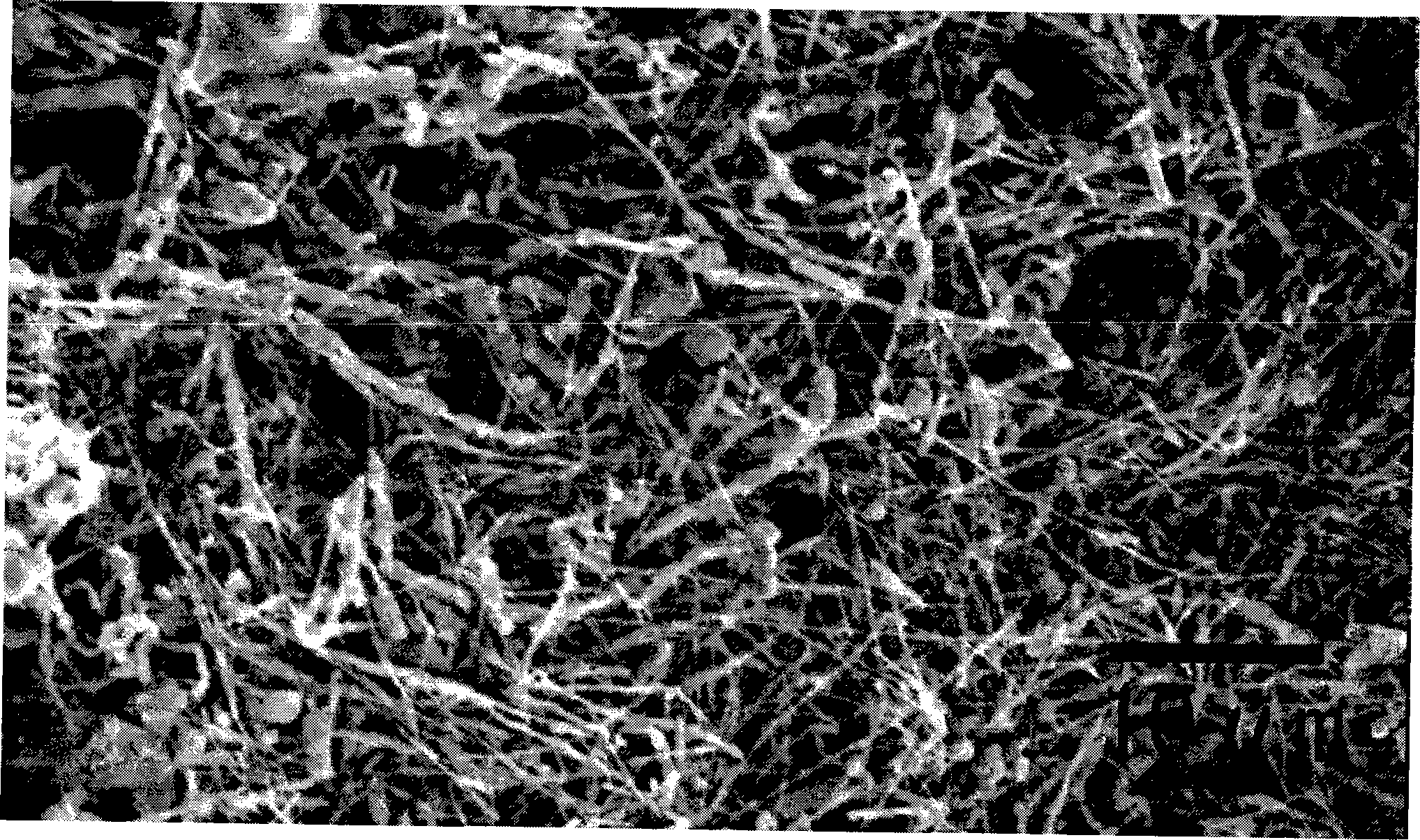

Method for preparing silver nano-wire in large batch

ActiveCN101310899BEasy to prepareLow costPolycrystalline material growthSingle crystal growth detailsReducerSolvent

The invention discloses a method for preparing nanometer silver lines in large batch. anhydrous silver nitrate AgNO3 with the concentration of 99.9percent, anhydrous glycol (C2H6O2) of 99.8percent and polyvinylpyrrolidone (PVP, with the molecular weight of 55,000) of 98percent are selected as the raw materials; in a microwave-assisting environment, the method of adopting the glycol to reduce the silver nitrate is adopted to prepare nanometer silver lines in large batch. By replacing the original solvent heating method with the high-heat environment created by microwave, the method not only greatly saves the reaction time but also reduces the preparing costs for the nanometer silver lines. The glycol, a moderate reducer, can slow the reaction, thus providing the time for the growth of nanometer silver lines. The method of the invention is the optimal method for preparing the nanometer silver line according to testing results by comparing the influence of micro strength, precursor concentration and microwave processing time on the appearance and size of the prepared nanometer lines. The method of the invention has low cost, is simple method and easily controlled and has high practical value in the application to the industrial production developing nanometer silver lines.

Owner:溧阳常大技术转移中心有限公司

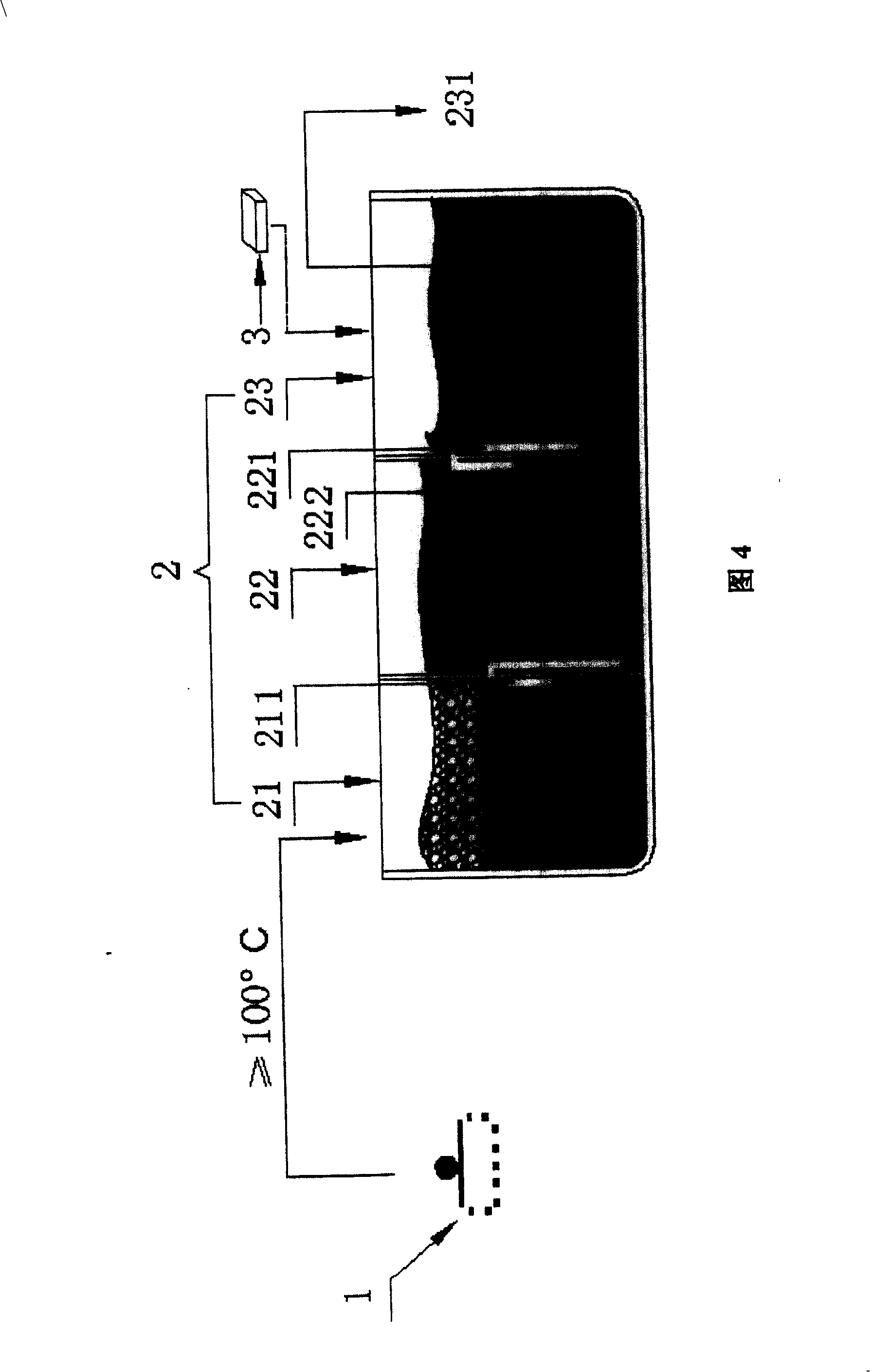

One-step temperature-rising starting method for high-temperature anaerobic digestion reaction of sludge

InactiveCN108341571AShorten the one-step heating and start-up culture cycleImprove start-up efficiencyBiological sludge treatmentBuffering agentHot Temperature

The invention provides a one-step temperature-rising starting method for a high-temperature anaerobic digestion reaction of sludge. The method comprises the following steps: rapidly heating raw sludgeto 35 DEG C under anaerobic conditions, performing inoculation by using mesophilic anaerobic digestion seed sludge, and performing uniform mixing; and adding a combined agent of a biological accelerant and a buffering agent, rising temperature to 55 DEG C in one step, and performing continuous stirring to complete start of the high-temperature anaerobic digestion reaction of the sludge. Comparedwith the prior art, the method provided by the invention has the following beneficial effects: 1, the method can greatly shorten a culture cycle of one-step high-temperature anaerobic digestion of thesludge, significantly improve start efficiency and make the reaction operate efficiently, and the start cycle can be shortened by 30 days or more compared with that of a conventional method; and 2, the method has the advantages of a simple process, low investment costs and unharsh conditions, and has certain practical significance for promotion and application of a high-temperature anaerobic digestion technology of the sludge.

Owner:SHANGHAI JIAO TONG UNIV

A kind of preparation method of palladium carbon catalyst

ActiveCN106732563BEnhanced interactionImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsWater vaporFiltration

The invention relates to a preparation method of a palladium-carbon catalyst, and belongs to the field of noble metal catalysts. The preparation method comprises the following steps: performing high-temperature pretreatment on a carbon support with a high specific surface area, and dispersing in a water phase; dropwisely adding a prepared palladium precursor solution into the carbon support dispersion solution, and stirring and impregnating for some time; performing vacuum filtration on the loaded dispersion solution, washing, and drying; and roasting the dried carbon support in a nitrogen protective atmosphere, and reducing with mixed gas of nitrogen / argon, carbon monoxide and vapor to obtain the palladium-carbon catalyst. In the prepared palladium-carbon catalyst, the active carbon with a high specific surface area is used as the support, and the noble metal Pd is loaded; and the content of the metal Pd in the palladium-carbon catalyst based on mass percent is 0.5-10%.

Owner:厦门嘉氢科技有限公司

A kind of micron-scale elemental copper catalyst and its preparation method and application

InactiveCN104028268BRecyclable performanceEffective catalytic degradationWater/sewage treatment by irradiationWater contaminantsBenzoic acidPtru catalyst

The invention discloses a micron-scale elemental copper catalyst and a preparation method and application thereof. According to the key points of the technical scheme, the micron-scale elemental copper catalyst is prepared by the steps of reacting copper salt with an organic ligand to form a precursor and then performing calcination under the protection of nitrogen at the temperature of 400 to 800 DEG C, wherein the molar mass ratio of the copper salt (n) to the organic ligand (n) is (1-4) to 1, the copper salt is Cu(NO3)2.3H2O, and the organic ligand is 1,3,5-trimesic acid, terephthalic acid, isophthalic acid, phthalic acid, formic acid or 4,4',4''-s-triazine-1,3,5-three-para aminobenzoic acid. The invention further discloses the preparation method of the catalyst and the application of the catalyst to processing of nitrophenol waste water. The micron-scale elemental copper catalyst has the advantages of environmental friendliness, simple preparation process, high innovativeness and practicability and the like, nitrophenol pollutants in organic waste water can be effectively catalyzed and degraded, and the catalyst has circulating renewable use performance.

Owner:HENAN NORMAL UNIV

Supersonic liquid phase reduction process for preparing monodisperse nano germanium crystal

InactiveCN1315605CEasy to prepareLow costPolycrystalline material growthSingle crystal growth detailsWater bathsHigh energy

The present invention is the process of utilizing metal hydride to reduce germanium chloride to prepare near monodisperse nanometer germanium crystal under supersonic reaction condition. The present invention has high energy supersonic water bath to replace high temperature reaction environment to promote the formation of nanometer crystal and the dispersion in the solution, and adopts strongly reductive metal hydride as reductant for preparing near monodisperse nanometer germanium crystal under room temperature condition. Through experiments, the nanometer germanium crystal preparing conditions are optimized. Preparing monodisperse nanometer germanium crystal is significant in research of the relationship between the performance and the size of nanometer material and is valuable in the design and manufacture of semiconductor devices.

Owner:ZHEJIANG UNIV

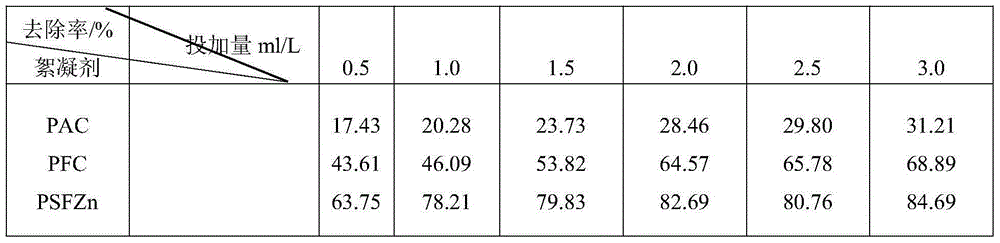

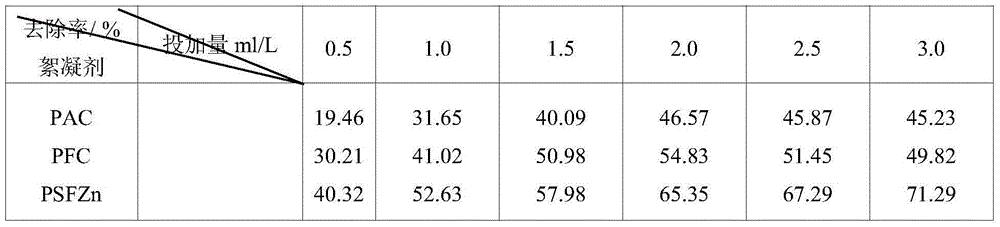

A flocculant for purifying landscape water and its preparation method

InactiveCN103936118BImprove stabilityEasy to storeWater/sewage treatment by flocculation/precipitationSodium bicarbonateSulfate

The invention provides a flocculant for purifying landscape water and a preparation method of the flocculant. The flocculant is used for improving the quality of landscape water in cities, parks, residential districts and the like, and the flocculant disclosed by the invention is a flocculant PSFZn which is low in preparation raw material, simple in process, safe and efficient. The flocculant is prepared from the following raw materials in percentage by weight: 15-30% of sodium silicate, 1-8% of ferric chloride, 2-4% of zinc sulfate, 10-20% of a dilute hydrochloric acid, 1-10% of sodium bicarbonate and the balance of deionized water, wherein the mass concentration of the dilute hydrochloric acid is 10%, and the silica content of sodium silicate is 21-25%.

Owner:江苏立能环保水处理工程有限公司

Recycle utilization process of magnesium alloy compression casting waste material

InactiveCN100427621CMeet immediate recycling requirementsIncrease profitProcess efficiency improvementSlagMolding machine

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com