Process for preparing iron blue with fantastic color effect

A preparation process, iron blue technology, applied in the direction of fibrous fillers, etc., can solve the problems of product quality impact, pigment final performance, etc., and achieve the effects of reducing production costs, convenient and easy operation of the process, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

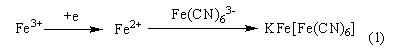

Method used

Image

Examples

Embodiment 1

[0036] Weigh 30g of Ferward Symphony Interference Blue Pearlescent Pigment, put it into a reaction container, add 450mL of deionized water, stir and heat up to 30°C, and calculate the iron with a coating rate of 18-20% by weight on a transparent sheet-like substrate The amount of ferrocyanide salt solution and ferric salt solution required by the blue is pumped into the calculated amount of 0.24mol / L potassium ferrocyanide and 0.33mol / L ferric chloride in parallel with a constant flow pump Solution, the reactant turns blue immediately, the reaction material is added within 4~5h, and then the reaction is continued for 30min. Filter the suspension of the blue pigment, wash it with deionized water until there is no acid and salt, and dry it in an oven at 100°C for 4-6 hours. The result is a vivid turquoise Iron Blue with intense chroma, high opacity and dramatic shimmer.

Embodiment 2

[0038] Weigh 30g of Ferward Symphony Interference Blue Pearlescent Pigment, put it into a reaction container, add 450mL of deionized water, stir and heat up to 30°C, and calculate the iron with a coating rate of 18-20% by weight on a transparent sheet-like substrate The amount of ferrocyanide salt solution and ferric salt solution required by the blue is pumped into the calculated amount of 0.24mol / L sodium ferrocyanide and 0.33mol / L ferric ammonium sulfate solution in parallel with a constant flow pump , the reactant immediately turned blue, and the reaction material was added within 4~5h, and then continued to react for 30min. Filter the suspension of the blue pigment, wash it with deionized water until there is no acid and salt, and dry it in an oven at 100°C for 4-6 hours. The result is a deep violet-blue Iridescent Iron Blue with intense chroma, high opacity and pronounced shimmer.

Embodiment 3

[0040] Weigh 30g of Ferward Symphony Interference Blue Pearlescent Pigment, put it into a reaction container, add 450mL of deionized water, stir and heat up to 30°C, and calculate the iron with a coating rate of 18-20% by weight on a transparent sheet-like substrate The amount of ferrocyanide salt solution and ferric nitrate solution required by the corresponding needs of the blue is pumped into the calculated amount of 0.20mol / L ammonium ferrocyanide and 0.24mol / L ferric nitrate solution in parallel with a constant flow pump, The reactant turns blue immediately, and the reaction material is added within 4~5h, and then the reaction is continued for 30min. Filter the suspension of the blue pigment, wash it with deionized water until there is no acid and salt, and dry it in an oven at 100°C for 4-6 hours. The result is a light purple-blue Iridescent Iron Blue with intense chroma, high opacity and pronounced shimmer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com