Patents

Literature

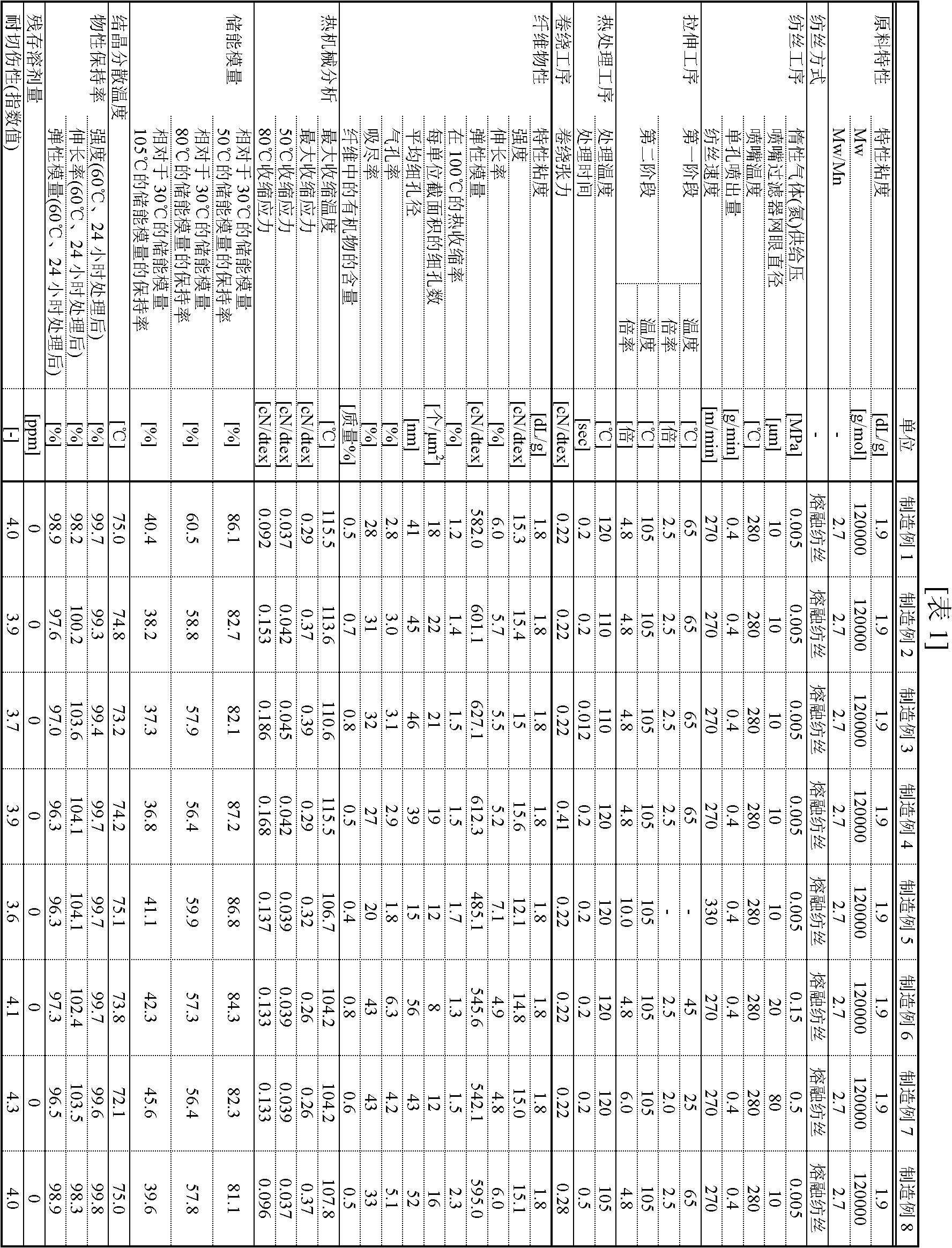

96results about How to "High exhaustion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

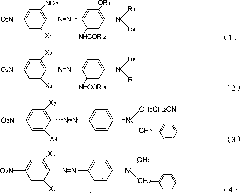

Black and blue disperse dye composition

ActiveCN101798472AWide range of applicationsGood compatibilityOrganic dyesDyeing processSunlightPhotochemistry

The invention discloses a black and blue disperse dye composition which comprises the components by weight percent: at least one 30-70% of dye monomer A shown in formula (1), at least one 15-40% of dye monomer B shown in formula (2), at least one 5-50% of dye monomer C shown in formula (3) and at least one 5-50% of dye monomer D shown in formula (4). The disperse dye composition has wide application scope of pH value, good compatibility, strong dye depth property, high color yield, good uniformity, and good sublimation fastness, washing fastness and fastness to sunlight; more importantly, the black and blue disperse dye composition has low price and convenient use, and makes up the defects of compatibility, dye depth property and tiger color of black and blue disperse dye spliced by disperse orange 288 model.

Owner:ZHEJIANG RUNTU

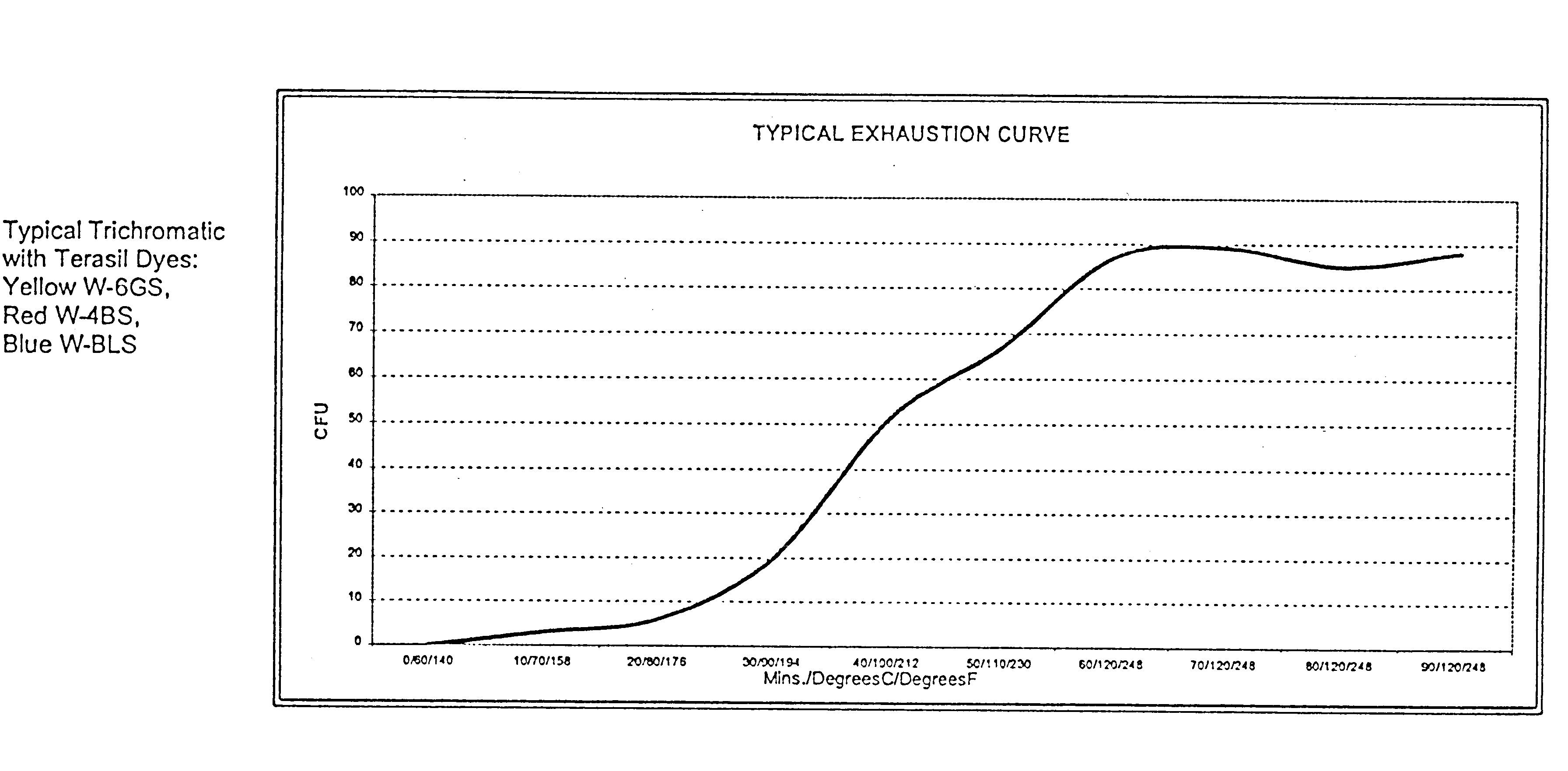

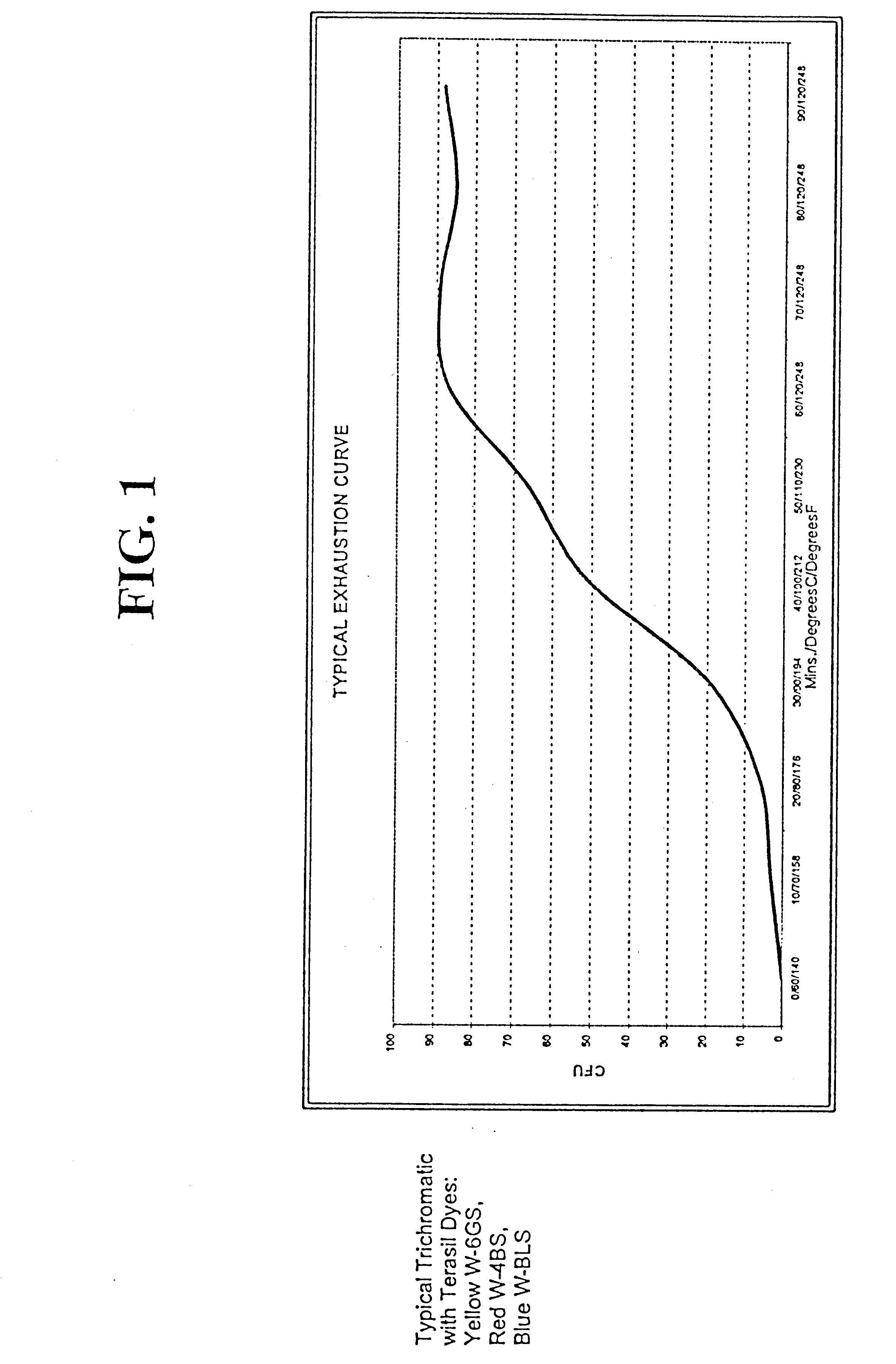

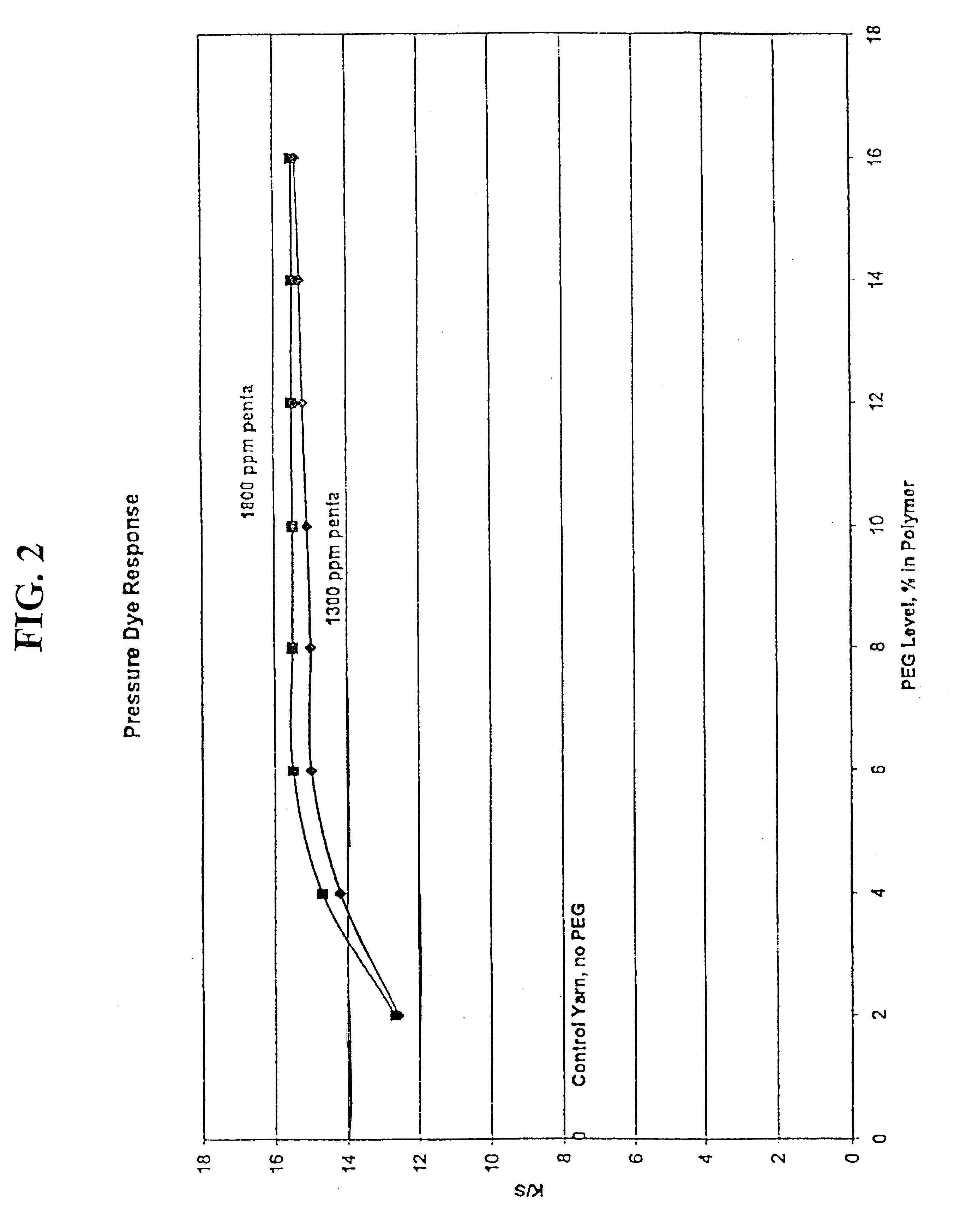

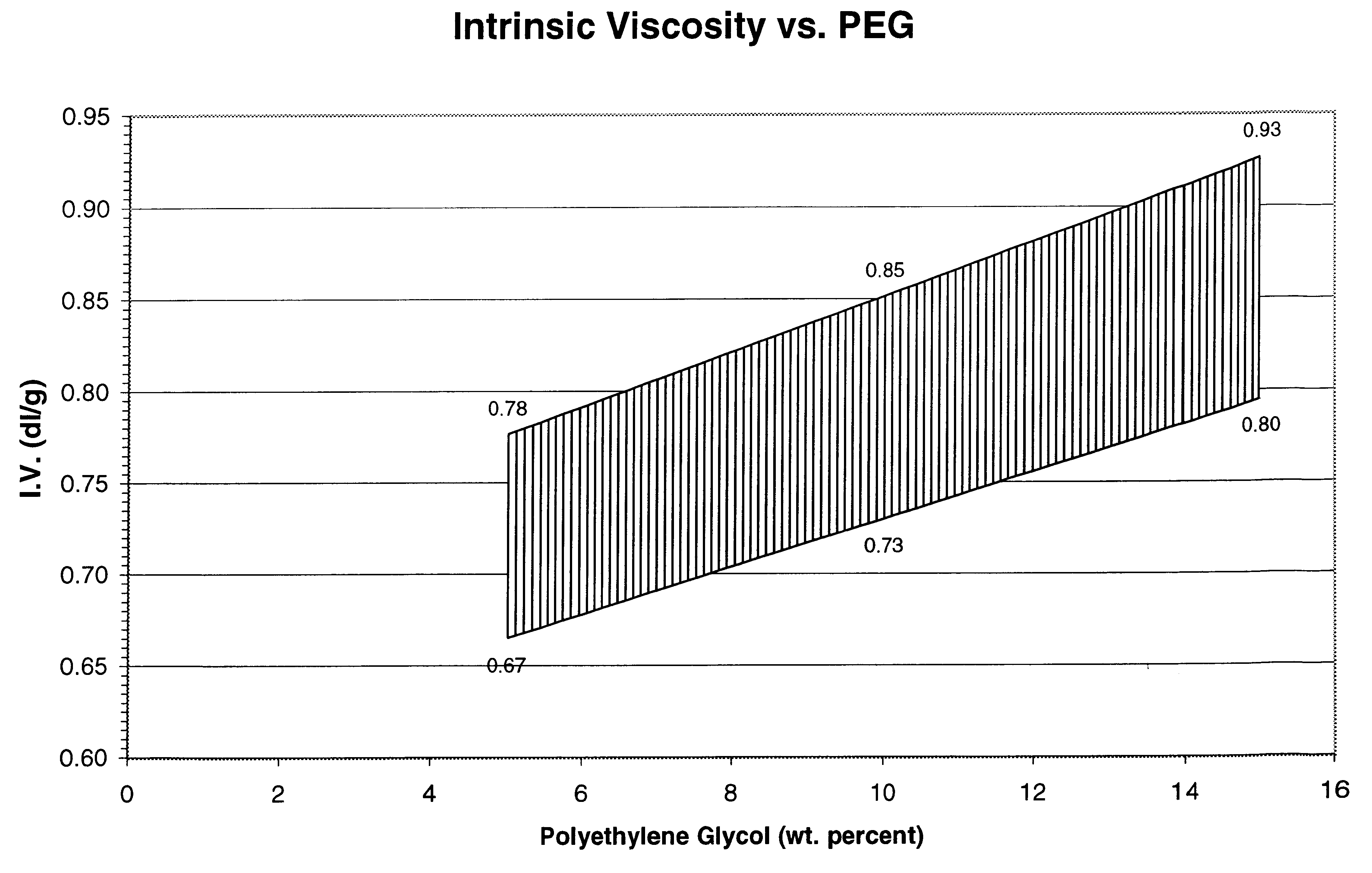

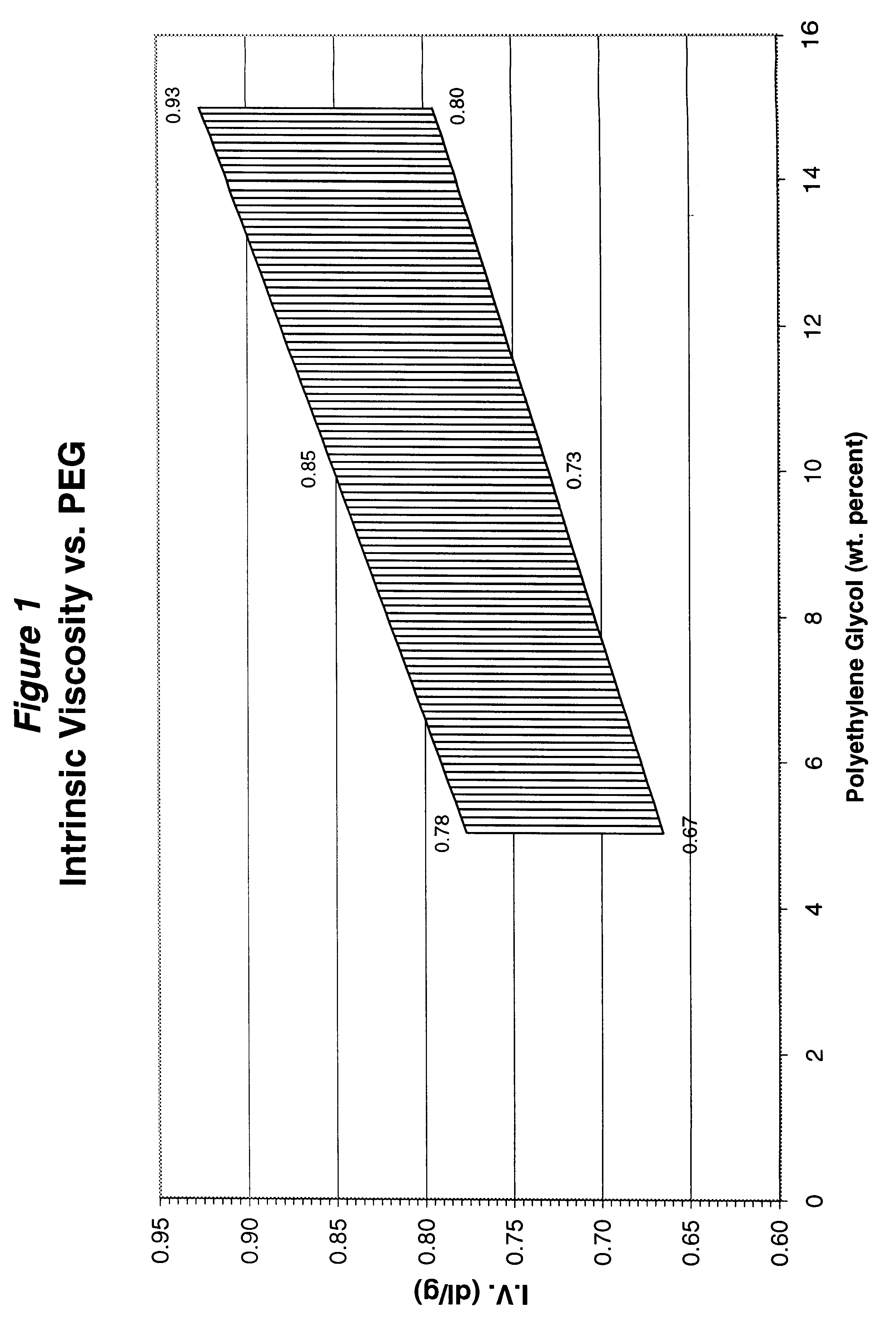

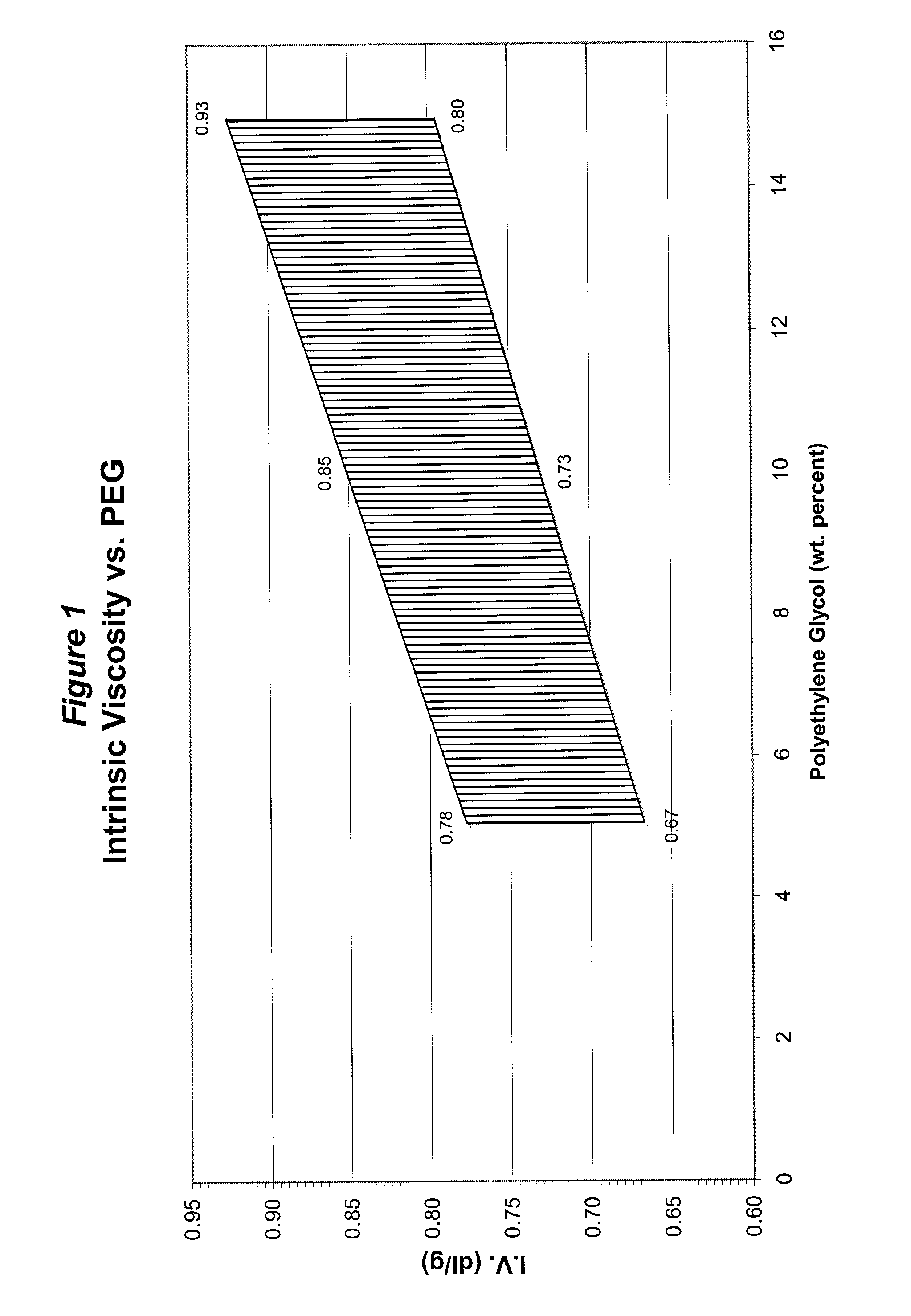

Polyethylene glycol modified polyester fibers and method for making the same

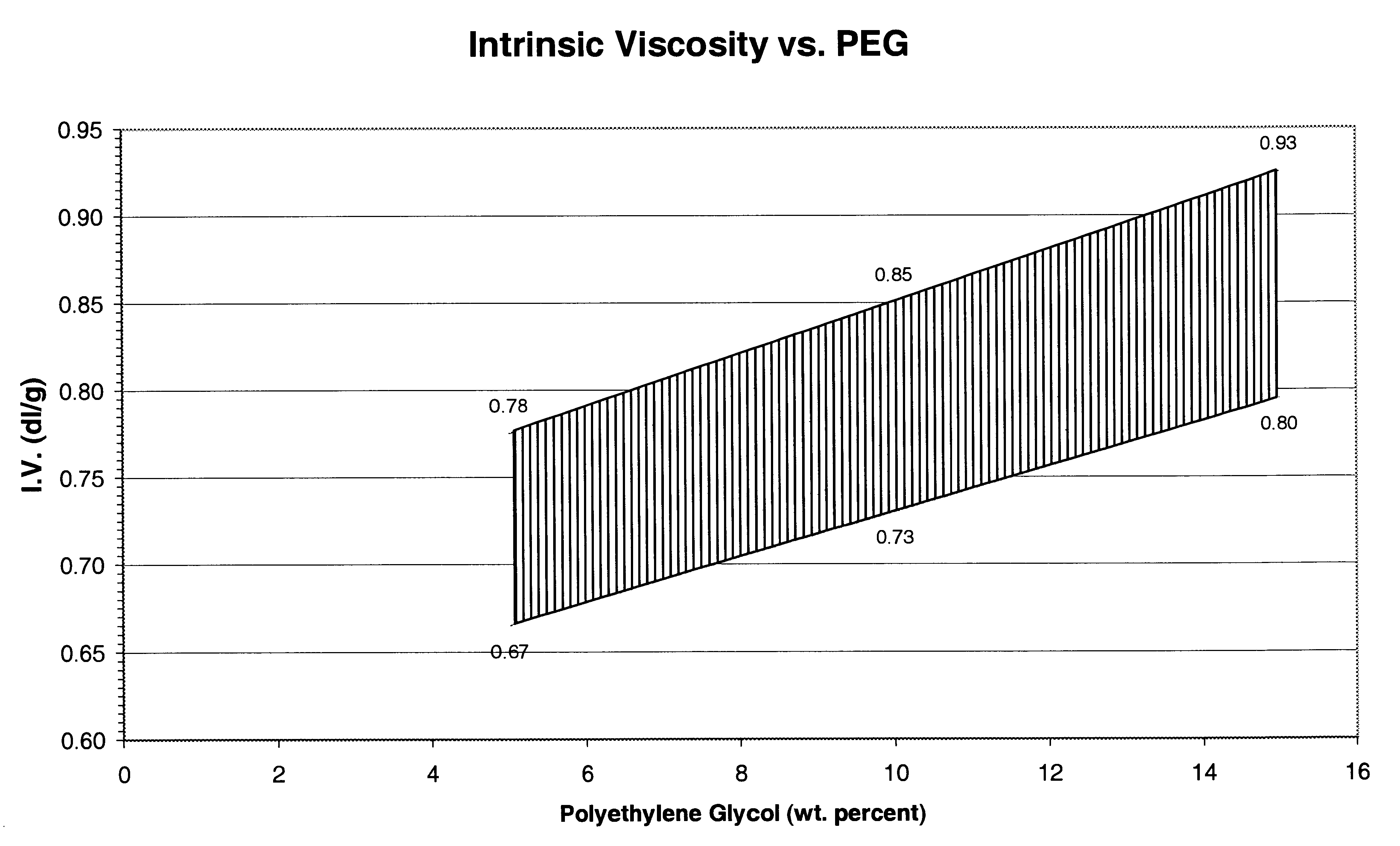

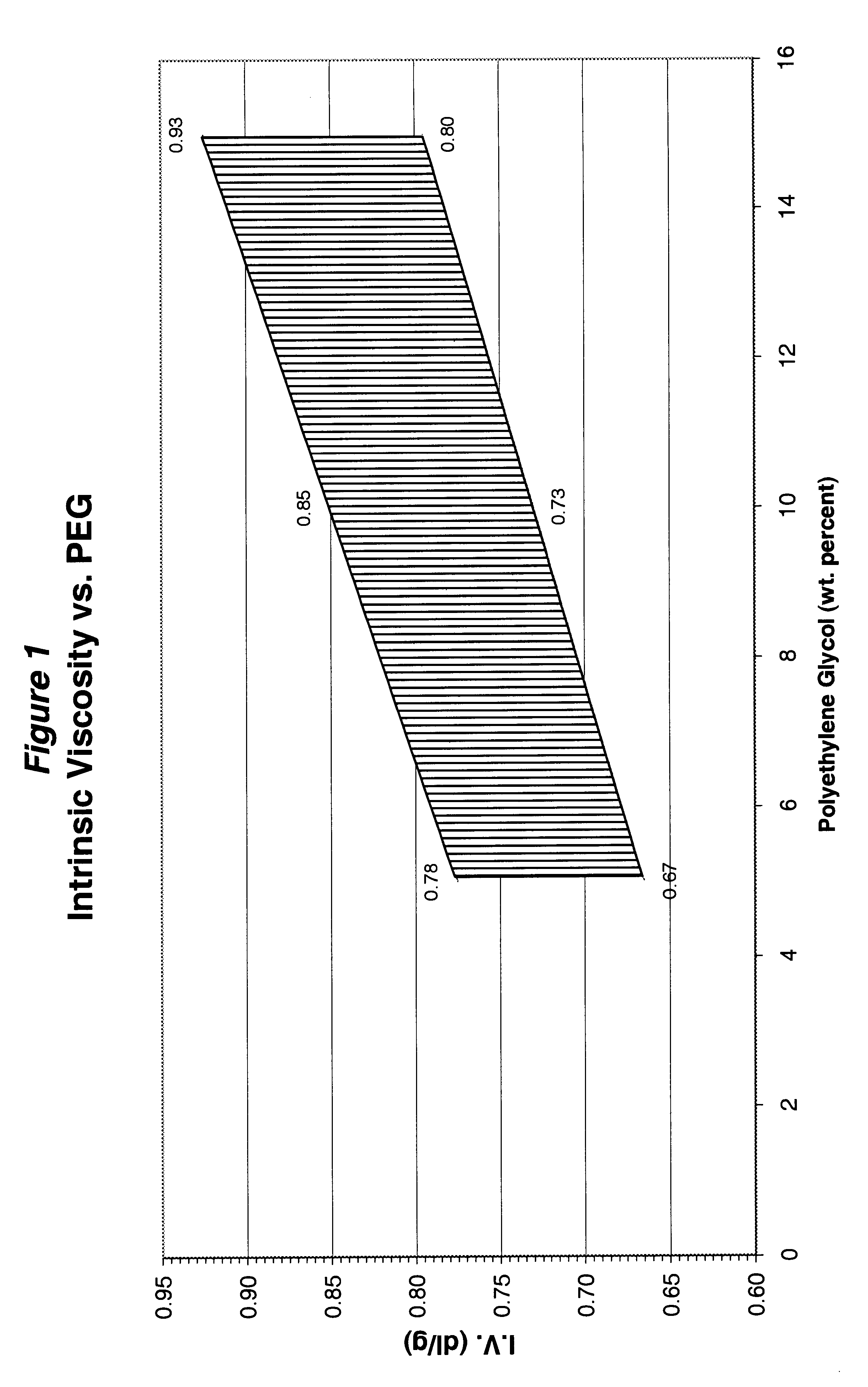

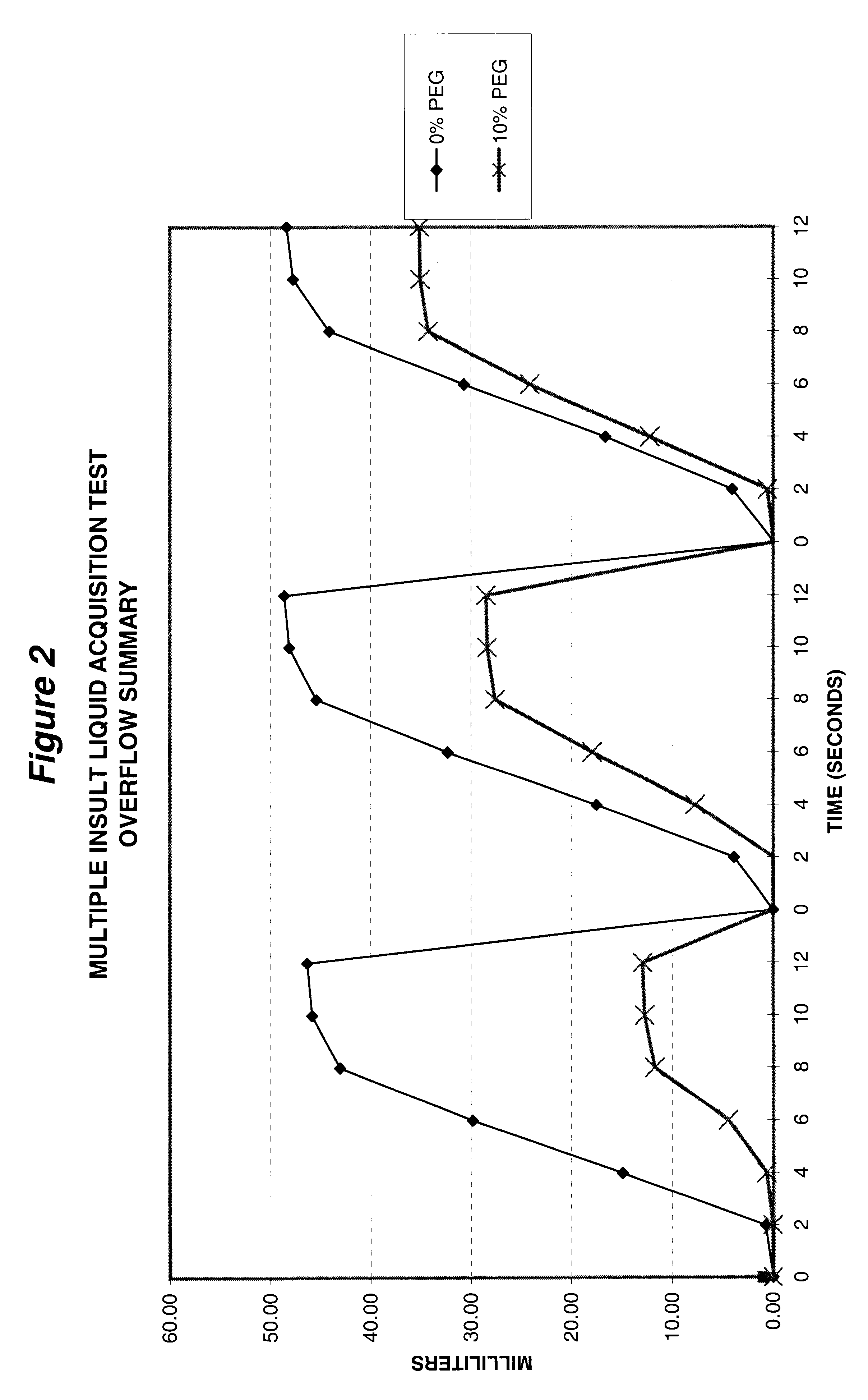

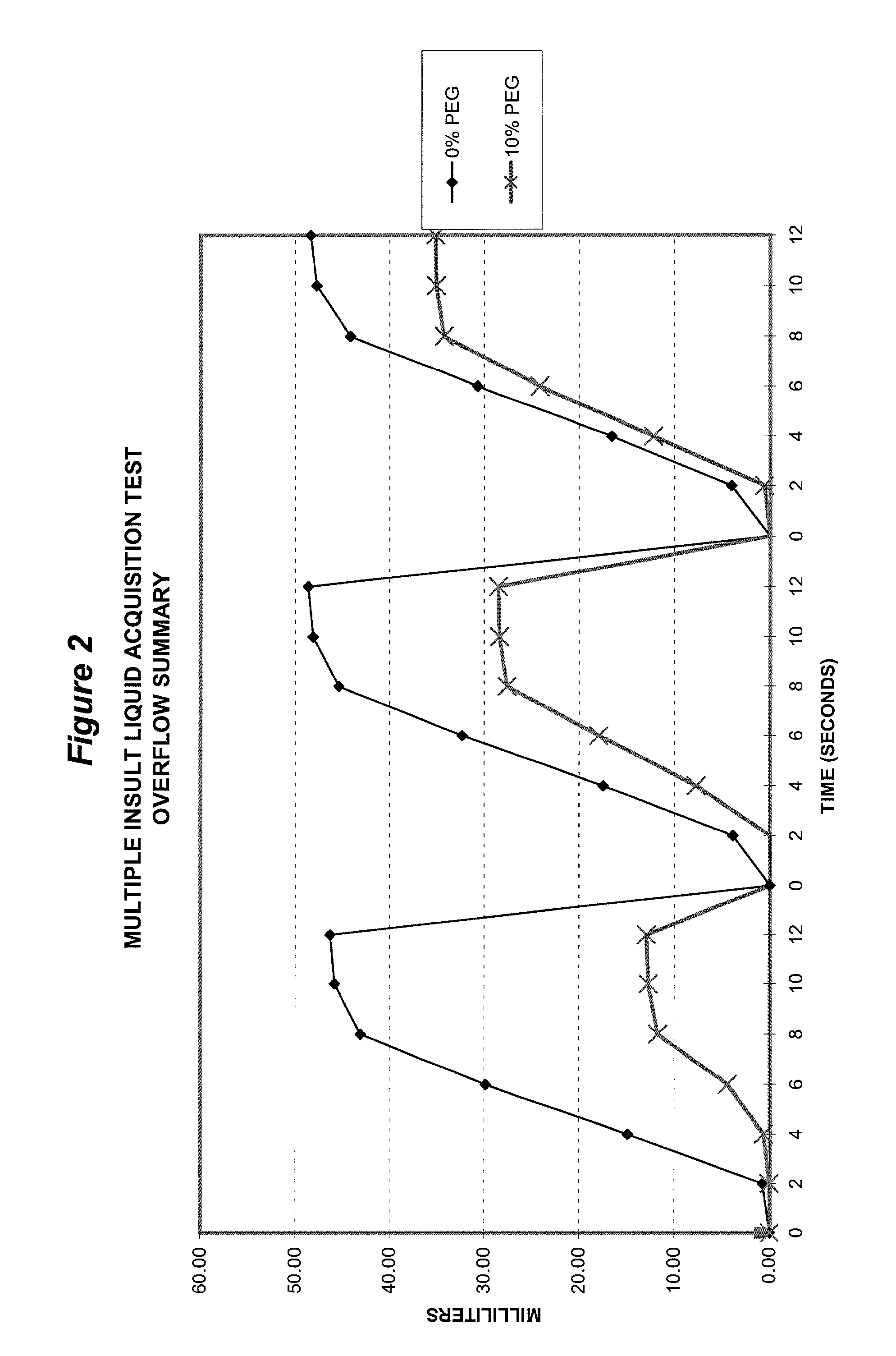

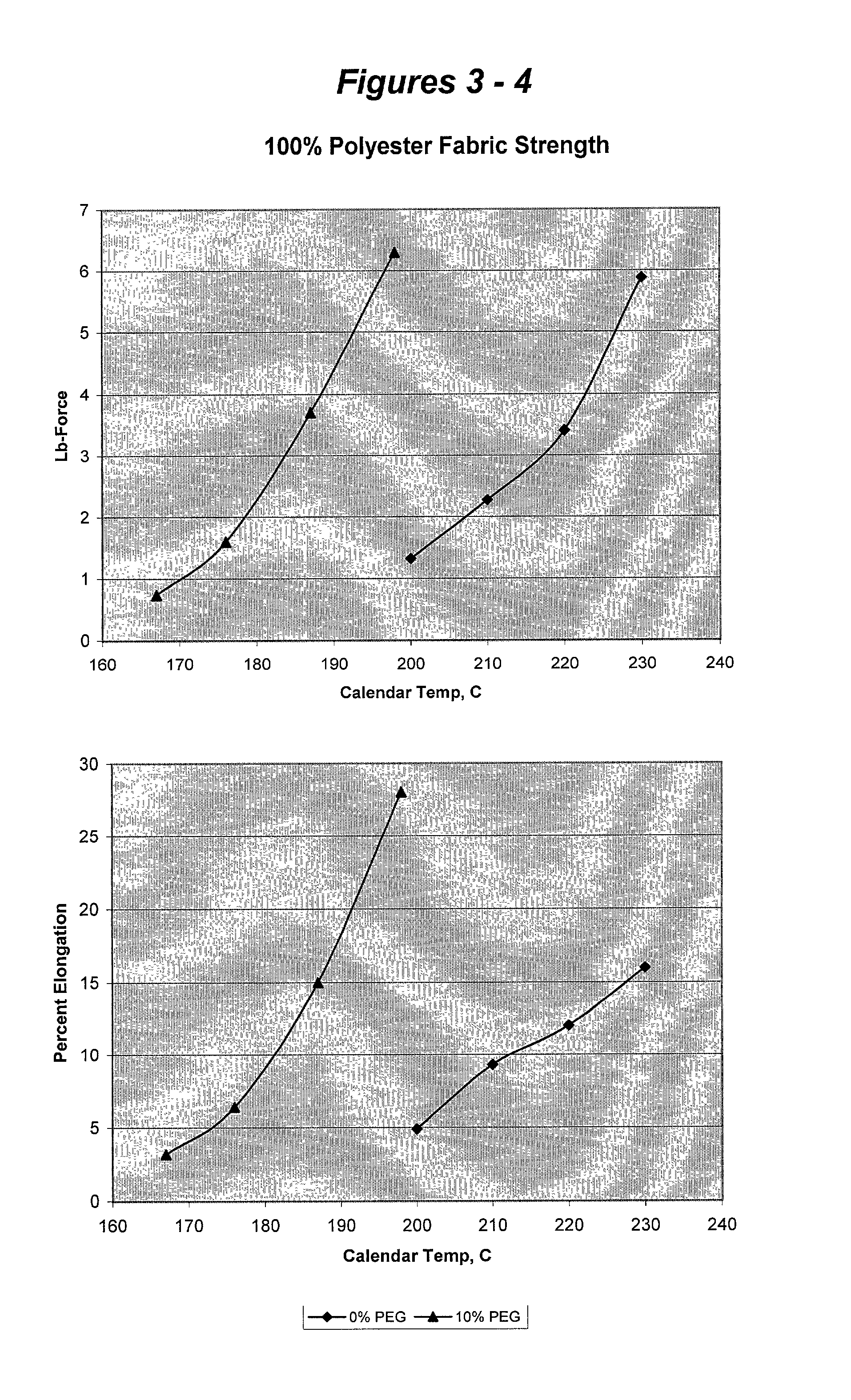

InactiveUS6623853B2Easy to dyeEnhance dye uptakeMonocomponent polyetheresters artificial filamentAnimal housingYarnFiber

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6291066B1Easy to dyeImprove dyeing effectProtective fabricsMonocomponent polyetheresters artificial filamentFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, drying, stretching, abrasion-resistance, flame-retardancy, static-dissipation, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

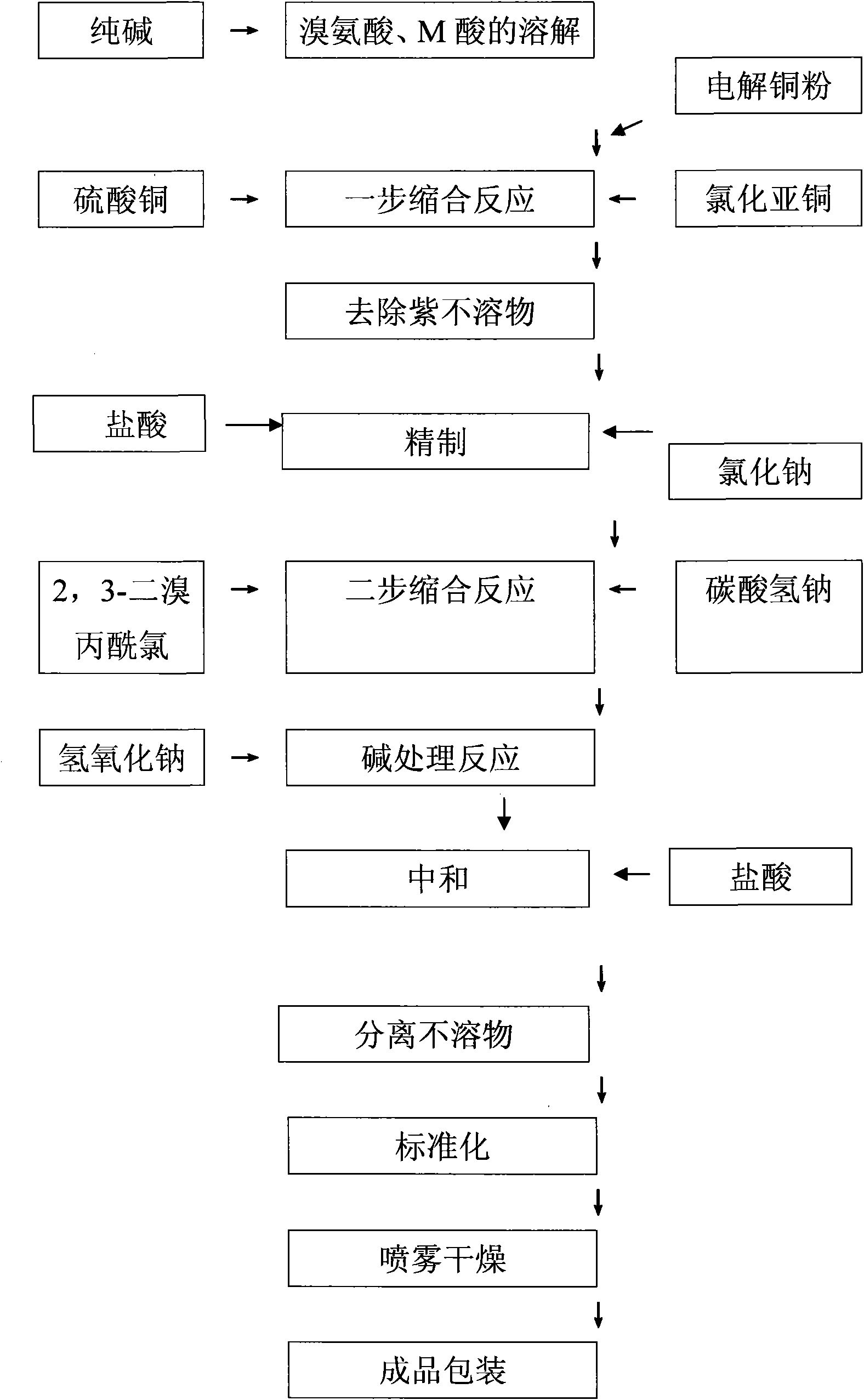

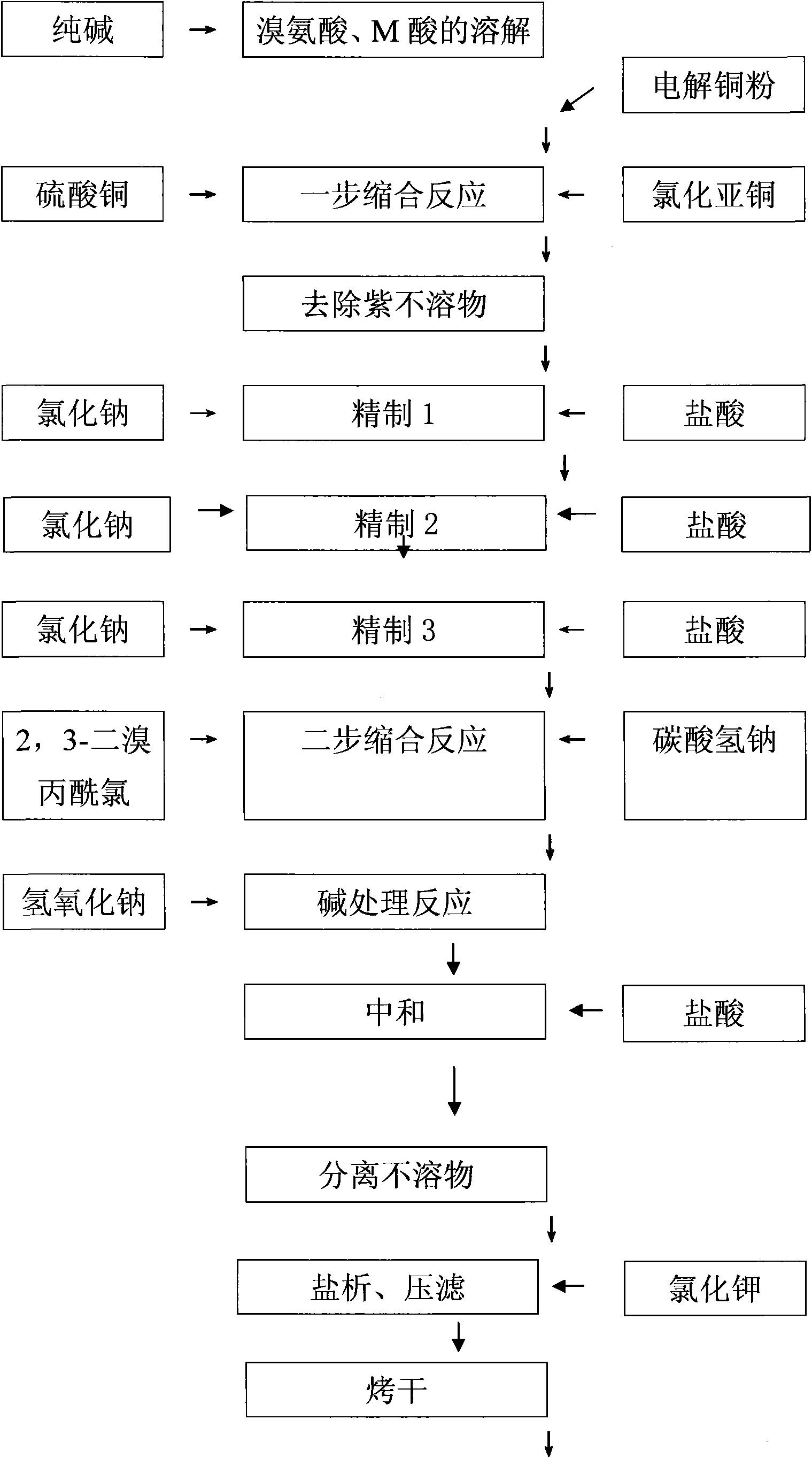

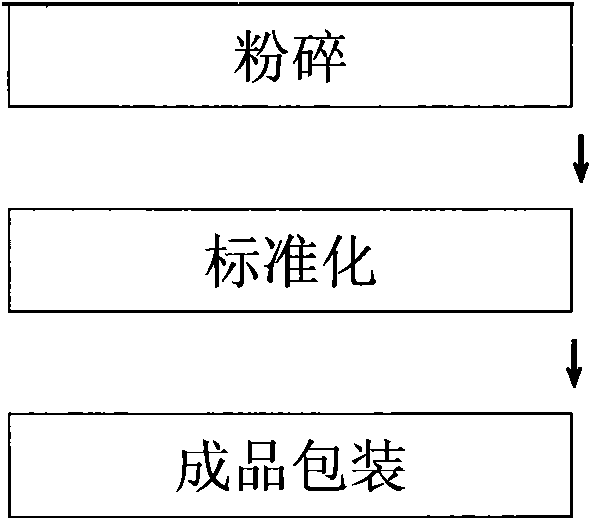

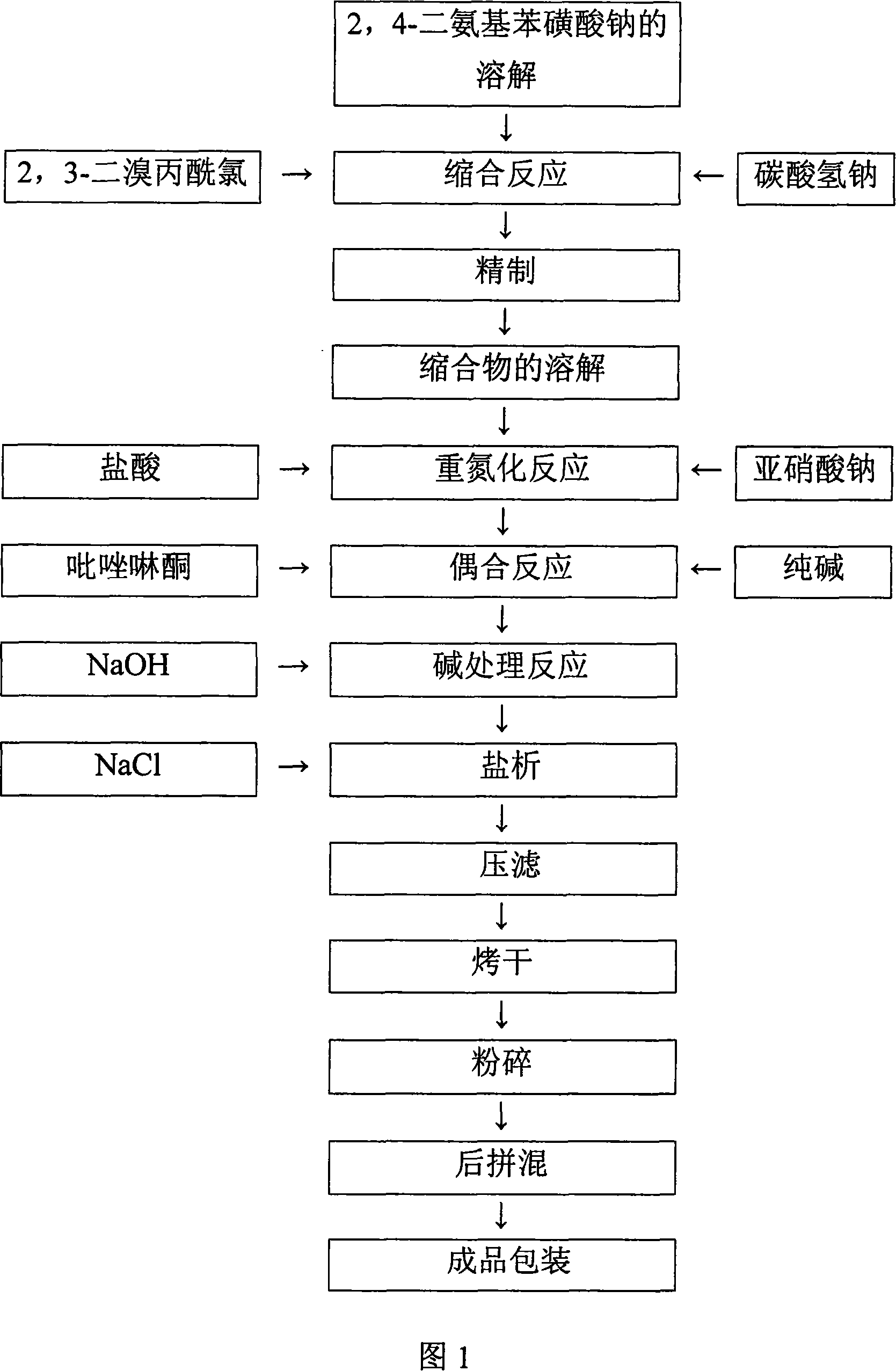

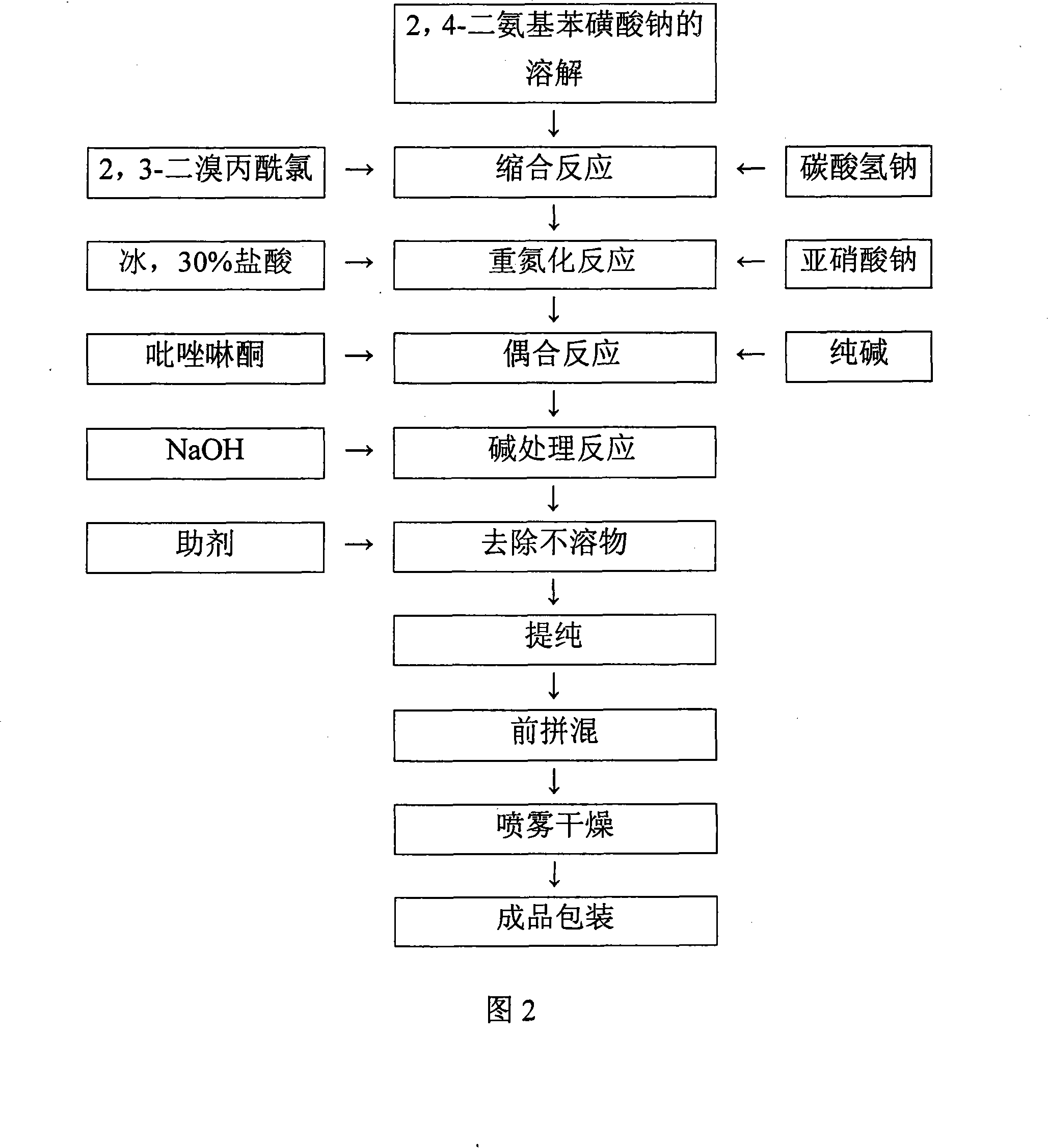

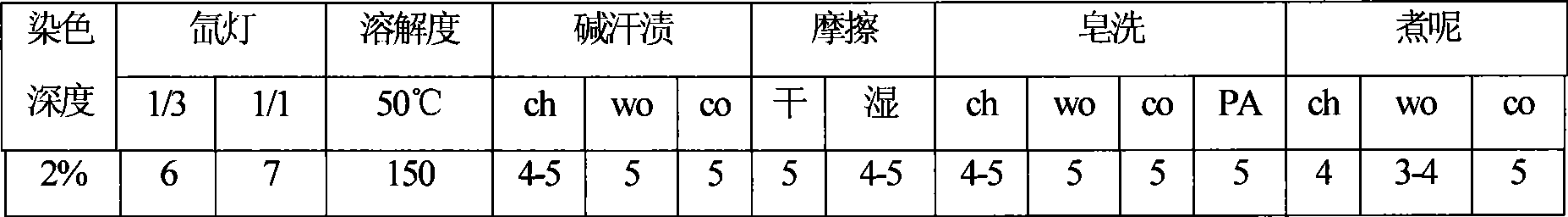

Method for preparing wool reactive-dye brilliant blue

ActiveCN101585974AReduce adverse effectsReduce consumption of raw materialsReactive dyesChemistryWool

The invention provides a method for preparing wool reactive-dye brilliant blue 4R. The method comprises the steps of condensing bromamine acid with M acid under the action of a catalyst, removing purple insoluble substances, condensing with 2,3-dibromo propionyl chloride, performing alkali treatment, neutralizing and blending. The method is characterized by removing the purple insoluble substancesat a temperature between 30 and 45 DEG C, thereby reducing a refining link in the prior art, for example, changing three times of refining in the prior art into one time of refining. More preferably,the method changes the steps of salting-out, filter-pressing, baking, grinding and blending in the prior technical method into the steps of directly blending neutralized color paste solution and thenperforming spray-drying.

Owner:TIANJIN DEK CHEM

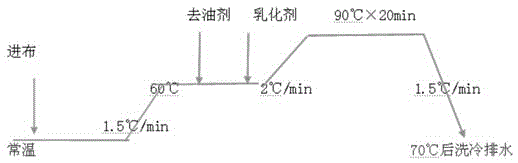

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

Preparation technology of ving/polymer/modified montmorillonoid nano composite tanoing agent

InactiveCN1556225AImprove performanceMeet the requirements of shrinkage temperatureTanning treatmentMontmorilloniteMoisture permeability

A process for preparing the nano-class composite tanning agent includes using ammonium hexadecane bromide to modify Na-base montmorillonite, using vinyl monomer (acrylic acid, acrylonitrile, or ethyl acrylate) to prepare vinyl polymer, and combounding them together by solution stripping-adsorption method. Its advantages are high effect on raising the shrinking temp of sheep leather to 76 deg.C and increasing leather thickness, and high air and moisture permeability of leather.

Owner:SHAANXI UNIV OF SCI & TECH

Method of treating wool using composite protease directed against wool structure and dyestuff characteristics

InactiveCN1556275AHigh exhaustion rateIncrease speedBiochemical fibre treatmentProteinase activityIsomerase

A process for treating wool by use of different composite enzymes according to wool structure and dye characteristics includes ecological pretreating with H2O2 or disulfide-bond isomerase and modifying wool by the composite enzyme consisting of two or more different proteinases. It can realize low-temp dyeing and increase the dye exhausting rare, dyeing rate, and color fastness.

Owner:DONGHUA UNIV +1

Composite dye composition, composite disperse dye and preparation method thereof

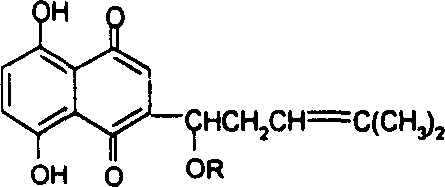

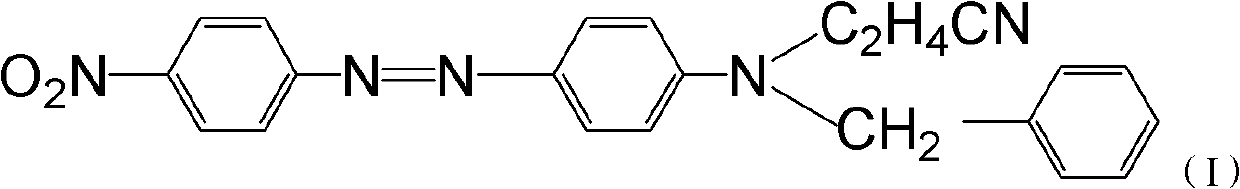

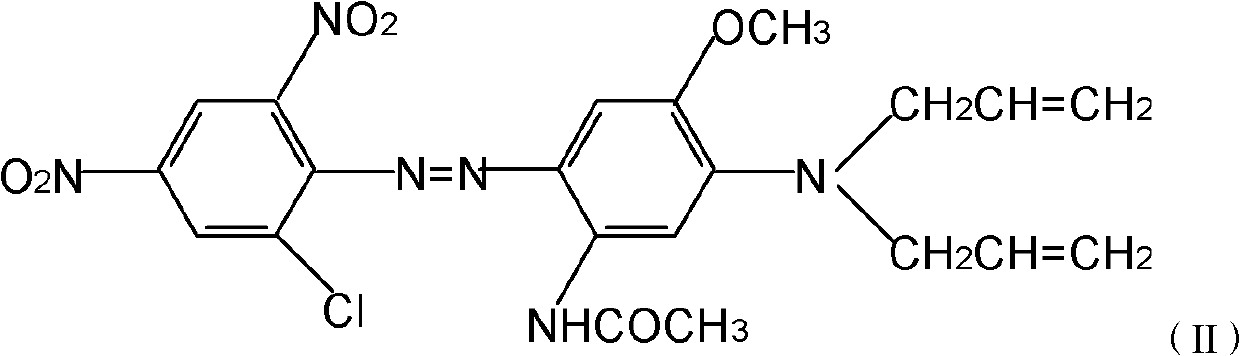

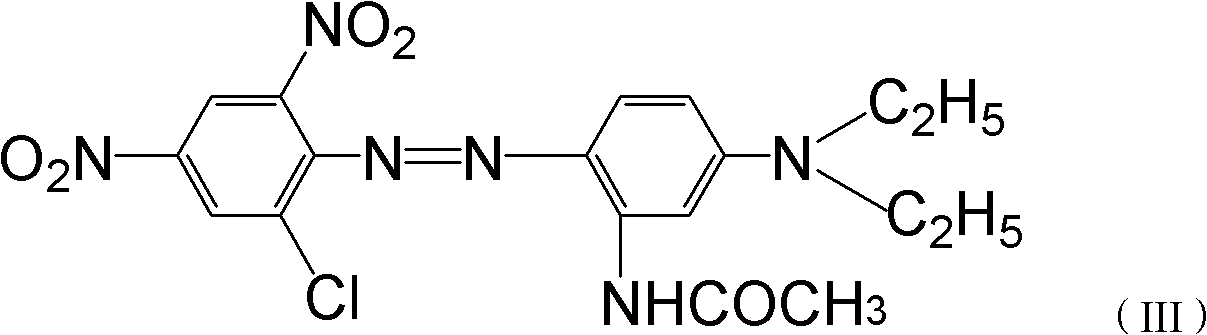

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of a formula (I), a formula (II), a formula (III) and an optional formula (IV). The composite disperse dye prepared from the composite dye composition has high intensity and lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

Polyethylene glycol modified polyester fibers

InactiveUS6509091B2Easy to dyeImprove dyeing effectMonocomponent polyetheresters artificial filamentDyeing processFiberPolymer science

Disclosed is a polyethylene glycol modified copolyester fiber that has exceptional moisture management characteristics and that can be formed into exceptionally comfortable fabrics. The copolyester fiber includes polyethylene terephthalate in an amount sufficient for the copolyester fiber to possess dimensional stability properties substantially similar to those of conventional, unmodified polyethylene terephthalate fibers, polyethylene glycol in an amount sufficient for the copolyester fiber to possess wicking properties that are superior to those of conventional, unmodified polyethylene terephthalate fibers, and chain branching agent in an amount less than about 0.0014 mole-equivalent branches per mole of standardized polymer.

Owner:FIBER IND INC

Processing method of multifunctional double-side bicolor knitted fabric

InactiveCN104452069ADurableImprove product added valueWeft knittingHeating/cooling textile fabricsDisperse dyeSewage

The invention discloses a processing method of multifunctional double-side bicolor knitted fabric. The processing method includes steps of preparing gray fabric, pre-treating, dyeing, dewatering, sectioning, shaping, inspecting and packaging. By adopting two different kinds of functional fabric and a double-side knitting method, the fabric has four functions of being hygroscopic and sweat releasing, antibiosis, static prevention and pilling resistance integrated and is durable. By adopting low-temperature disperse dye and cationic dye-one-bathing-one-stage method, dyeing temperature is lowered, sewage discharge is reduced, and influence on nano-silver fiber antibiosis performance by high temperature is prevented. Cationic modification polyester is adopted on the front side, and the fabric is bright in color, soft in hand feeling, good in hygroscopic performance and conductivity and pilling resistance and overcomes the defect of poor wearability of common polyester. Nano-silver hygroscopic and sweat-releasing profile polyester fibers are adopted on the back side, so the close-fitting side of the fabric is hygroscopic and sweat-releasing, anti-microbial and odor resistant, and clothes manufactured by the fabric are healthy, environment friendly and comfortable and have the double-side bicolor effect.

Owner:IANGSU COLLEGE OF ENG & TECH

Method for dyeing mercerizing wool or mercerizing wool fabric by yellow chrysanthemum flower dye

InactiveCN101117775AReduce the chance of occurrenceImprove uniformityDyeing processSodium bicarbonatePhosphate

The present invention relates to a method of dyeing mercerized wool or mercerized wool fabrics with yellow chrysanthemum paint, which is taken as the paint, and the dyeing method is divided into two steps including ecological pretreatment and subsequent innocuous mordant dyeing: the first step, treatment conditions: baking soda of 1-3 percent of cloth weight, 1-5 percent coconut oil diethanol amide as detergent of 1-5 percent of cloth weight, 0.2-1.0g / L neutral phosphate, temperature 20-60 DEG C, duration 10-60min, bathing ratio 1 to 20-50; the second step, mordant dyeing: the mercerized wool or mercerized wool fabrics with ecological pretreatment is treated with mordant front dyeing, single bathing or post dyeing. The yellow chrysanthemum resources are rich, easy for expanding plantation, with sound dyeing and less damage to mercerized wool during dyeing.

Owner:HAILAN GRP +1

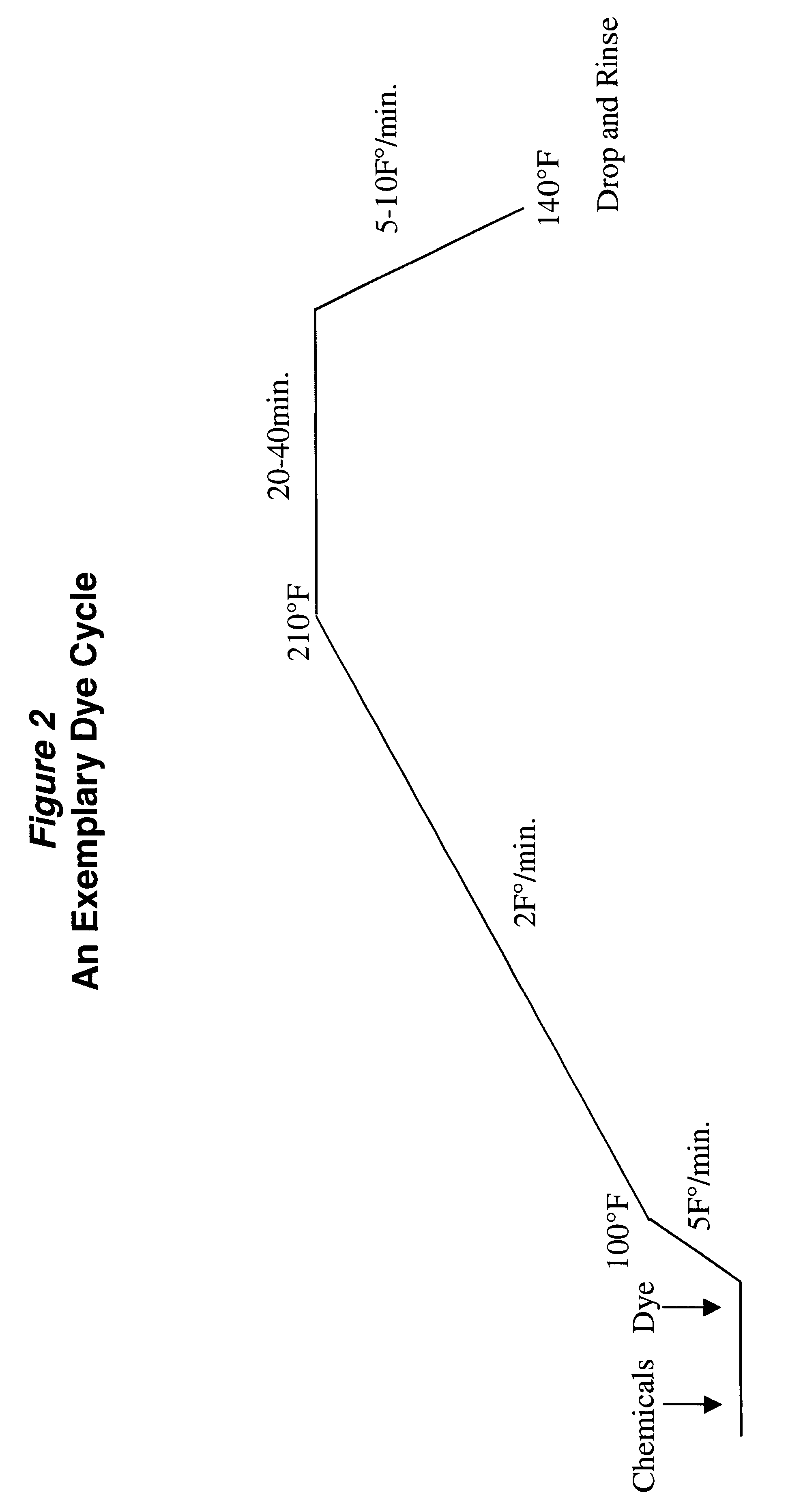

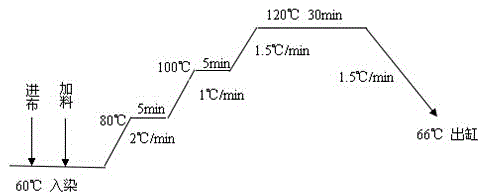

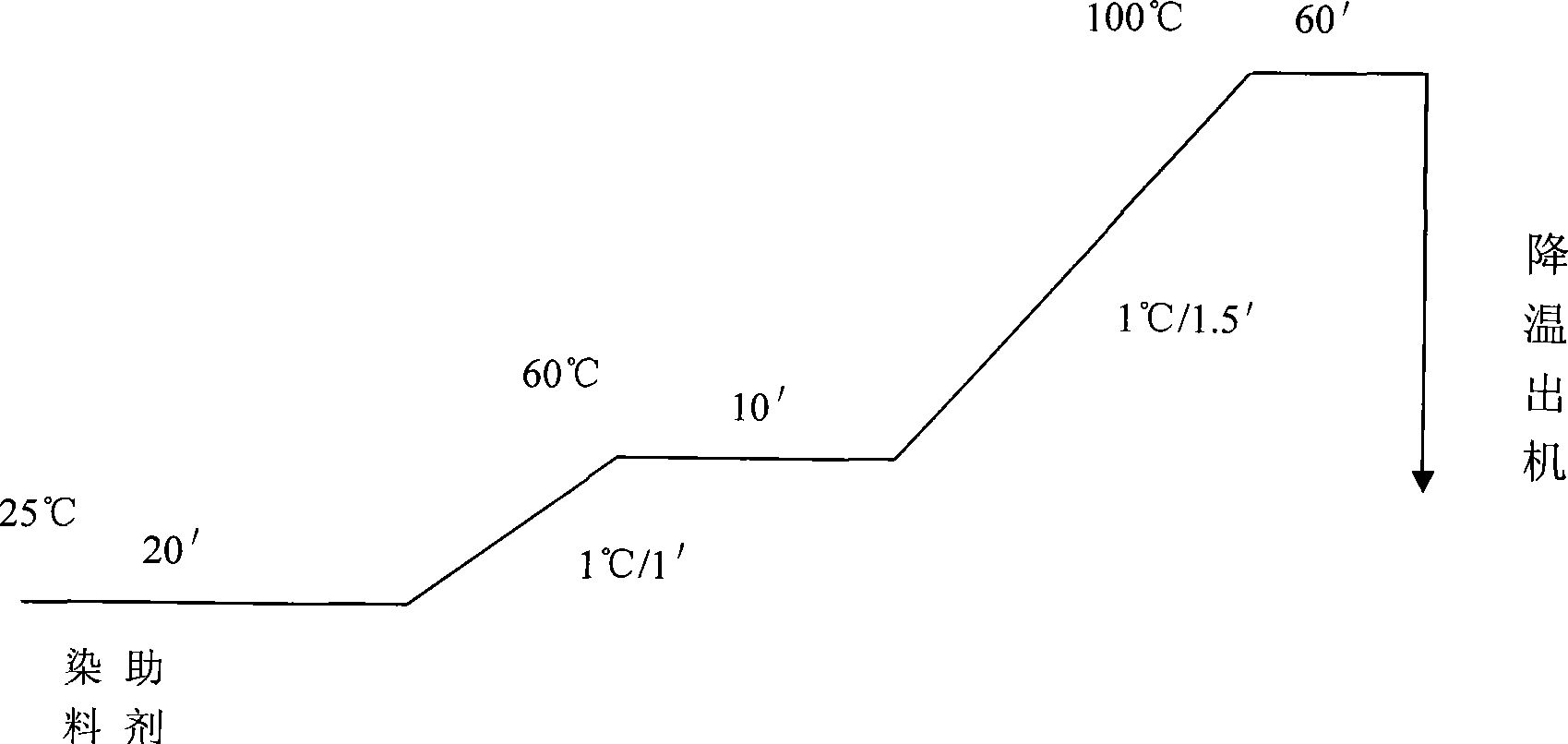

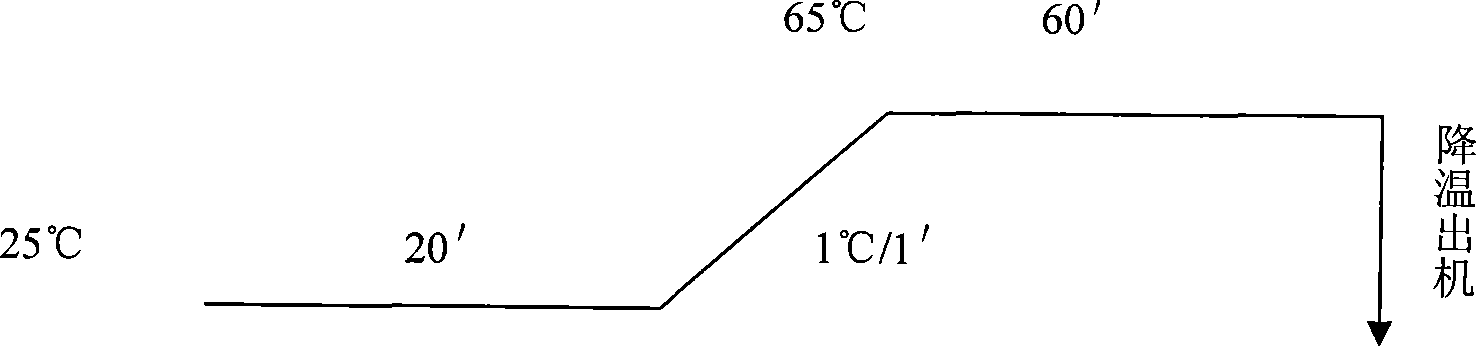

Low temperature dyeing technique for wool

InactiveCN101469518ASimple processSimple and fast operationDyeing processSocial benefitsWater resources

The invention relates to a wool low temperature dyeing process, which adopts dyeing process and dyeing equipment in prior art. The dyeing process mainly includes: adding sulphuric acid, glauber salt, low temperature accelerating agent SY-7, operating for 20 minutes; adding adequately dissolved acid color, heating to 65 DEG C. according to 1 DEG C. per 1 minute, keeping the temperature for 30 minutes; adding 1% sulphuric acid, keeping temperature for 30 minutes, reducing the temperature. The invention has beneficial effects: (1) simple in process, easy to operate, with great dyeing and fixation effect; (2) energy and water resource saving, pollution reducing, having great economic and social benefit; (3) color and adjuvant saving, product cost reducing.

Owner:TIANJIN TEXTILE ENG RES INST

Method for preparing nano composite high-absorptivity chrome tanning auxiliary agent by combining polycarboxylic acid copolymer with montmorillonite

The invention relates to a method for preparing a nano composite high-absorptivity chrome tanning auxiliary agent by combining polycarboxylic acid copolymer with montmorillonite. In the traditional chrome tanning method, the absorptivity is not high, and serious pollution is caused by direct discharge of a great deal of chromium-containing waste liquid. The method comprises the steps of: dispersing 2-10 g of nano montmorillonite with 150-400 g of distilled water, adding 0.5-1.5 g of cetyl trimethyl ammonium chloride, reacting at the temperature of 60-95 DEG C for 4-6 hours and ultrasonically treating for 0.5-2 hours to obtain modified montmorillonite; and dispersing 2-10 g of modified montmorillonite with 150-300 g of water for 2-5 hours, adding 15-30 g of methacrylic acid, reacting for 0.5-2 hours, heating in water bath, keeping dropwise adding methacrylic acid and an initiator at 50-80 DEG C for 30 minutes, carrying out an isothermal reaction for 1-3 hours, cooling and discharging to obtain a final product. The method has the advantages that: a pickling working procedure in the traditional chrome tanning process is omitted, the absorptivity to the chrome tanning waste liquid is improved, and the final product is a environment-friendly nano composite material.

Owner:SHAANXI UNIV OF SCI & TECH

Nonwoven fabrics formed from polyethylene glycol modified polyester fibers and method for making the same

InactiveUS20010039160A1Easy to dyeImprove dyeing effectEngine sealsProtective fabricsPolyesterPolyethylene terephthalate

Disclosed is a nonwoven fabric that is formed of polyethylene glycol modified copolyester staple fibers. The copolyester staple fibers include polyethylene terephthalate in amount sufficient for the copolyester staple fibers to possess dimensional stability properties substantially similar to those of conventional, unmodified polyethylene terephthalate fibers, polyethylene glycol in an amount sufficient for the copolyester staple fibers to possess wicking characteristics that are superior to those of conventional, unmodified polyethylene terephthalate fibers, and chain branching agent in an amount less than about 0.0014 mole-equivalent branches per mole of standardized polymer. Also disclosed are methods for making such nonwoven fabrics.

Owner:FIBER IND INC

Dyeing method of cationic modified cellulose fiber fabric

InactiveCN105672003ASolve the problem of energy consumptionSolve pollutionHeating/cooling textile fabricsDyeing processCellulose fiberAmmonium

The invention relates to a dyeing method of a cationic modified cellulose fiber fabric. The method comprises the following steps of fiber modification, gray fabric pre-setting, reduction clearing, dyeing auxiliary formula design, preparation, dyeing process and fixation aftertreatment, wherein two cationic modifiers of a micromolecule quaternary ammonium salt modifier and a macromolecule quaternary ammonium salt modifier are used for conducting modification treatment on a cellulose fiber fabric, then dyeing is conducted, and dyeing auxiliaries with special components are added for promoting dyeing. The dyeing method of the cationic modified cellulose fiber fabric has the advantages that cationic modified cellulose fibers are adopted for dyeing, and meanwhile the dyeing auxiliaries with the special components are added to increase the exhaustion rate and fixation rate of dye and improve color fastness to washing of dyeing materials.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

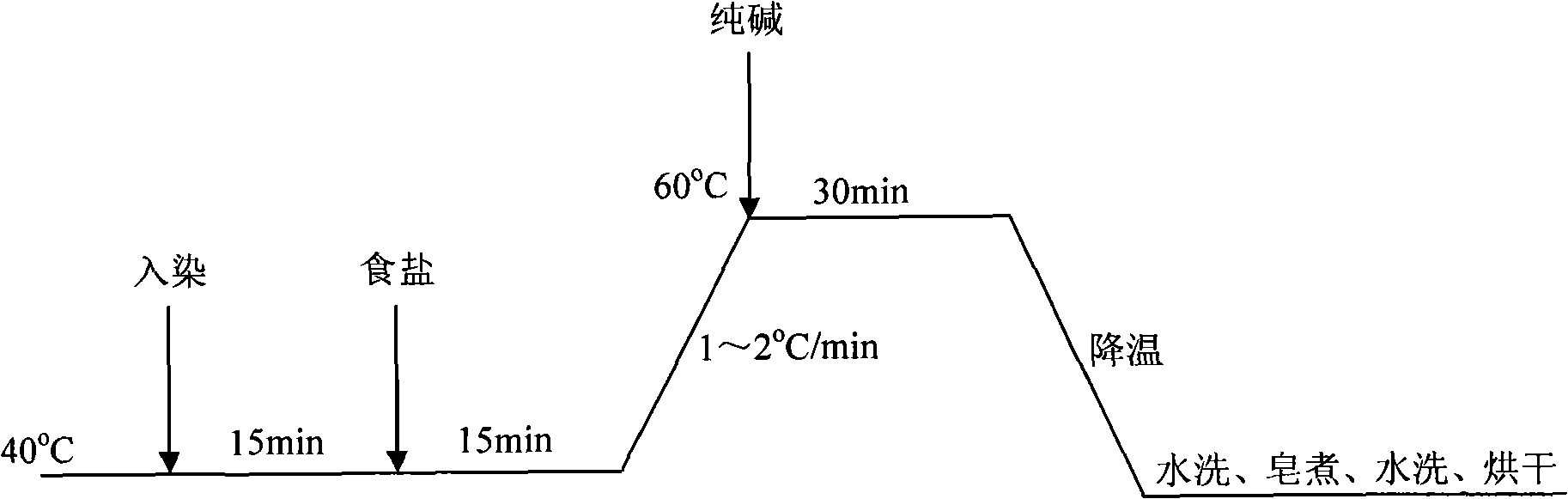

Method for dyeing mercerization baffeta with deep color on reactive dyes

InactiveCN101280526AIncrease dye uptakeIncrease profitDyeing processVegetal fibresColour fastnessCyclodextrin

The invention relates to a method that a mercerized cotton fabric is colored in deep tone with reactive dye, which comprises that: 1) the cotton fabric can be pretreated by being added with bicyclic oxides and weak base in room temperature, and then the cotton fabric can be added with cyclodextrin of 0.5 percent to 9 percent(o.w.f) for further processing while being implemented with mercerization; 2) after being dyed for 10 to 20 min, the processed mercerized cotton fabric is added with salt in a bath ratio of 20-40 :1 under the temperature of 30 DEG C to 40 DEG C, and then is added with calcined soda after 10 to 20 min; after 20 to 40 min, the processed mercerized cotton fabric is washed and boiled with soap, and then is washed again and dried; meanwhile, which is compared with the dyeing of general mercerized cotton fabric; 3) the degree of exhaustion, fixation rate, K / S value and color fastness of the dye and dyed fabrics are tested. The method can effectively improve the deep-dyeing property of which the mercerized cotton fabric is dyed with mesothermal reactive dye in the condition of low-temperature fixation, moreover, the method has the advantages of low fixation temperature, low energy consumption, economy and environmental protection.

Owner:DONGHUA UNIV

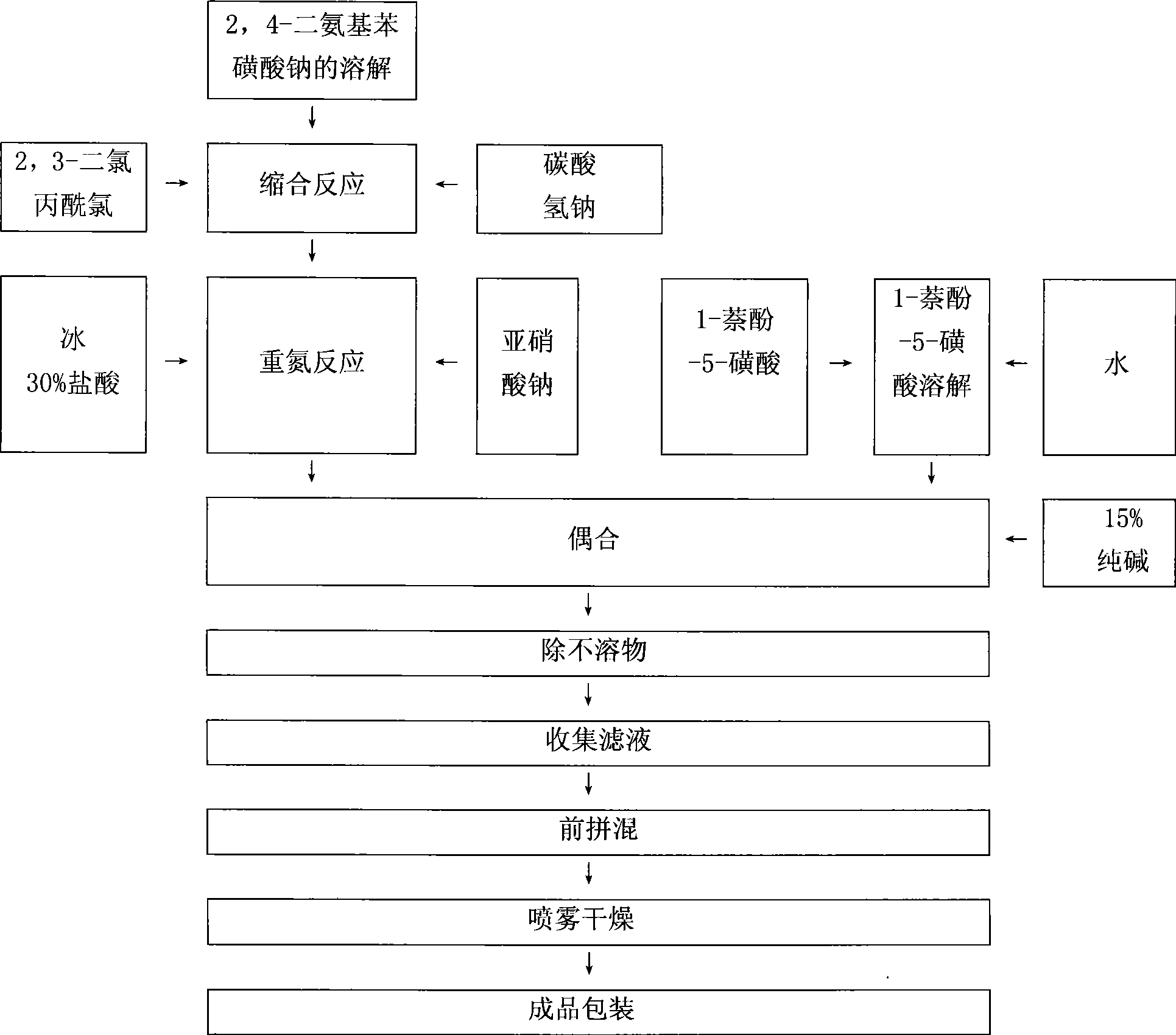

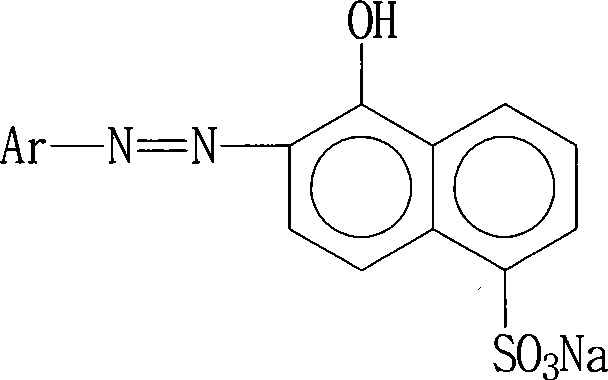

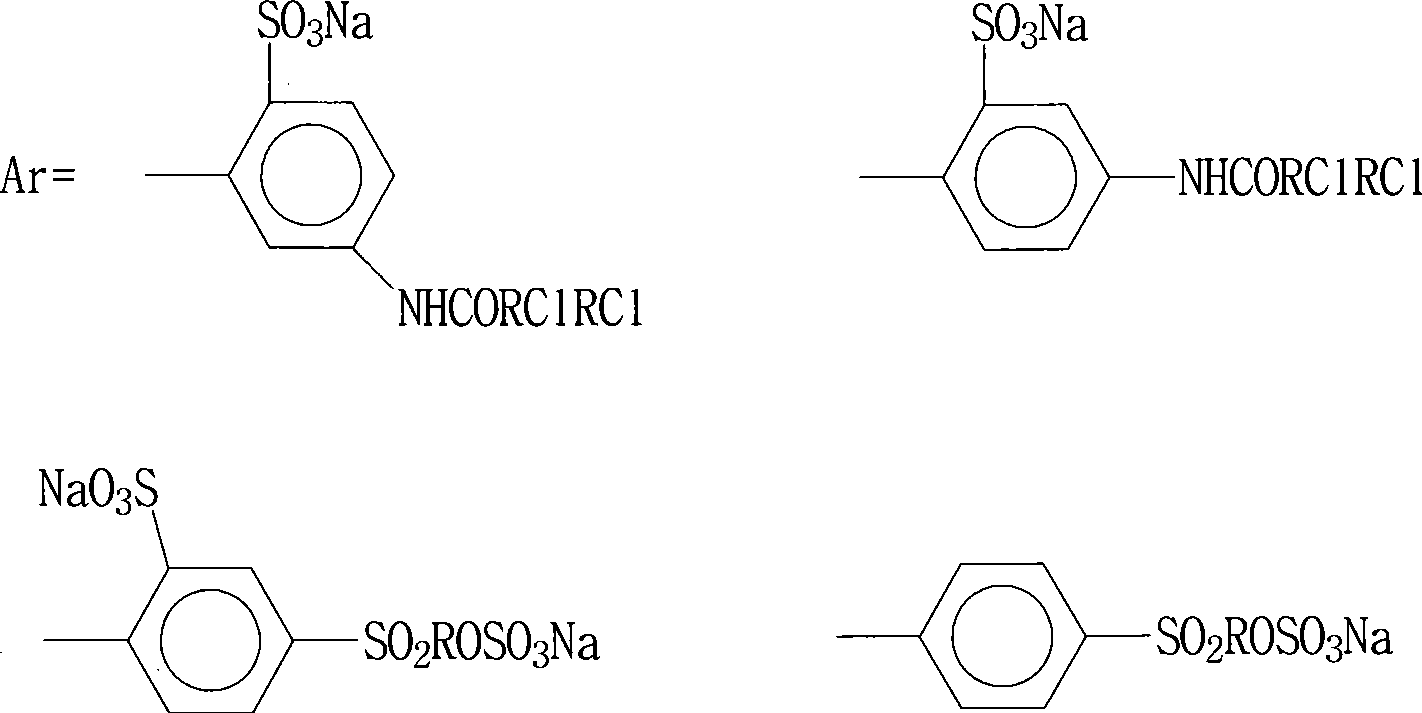

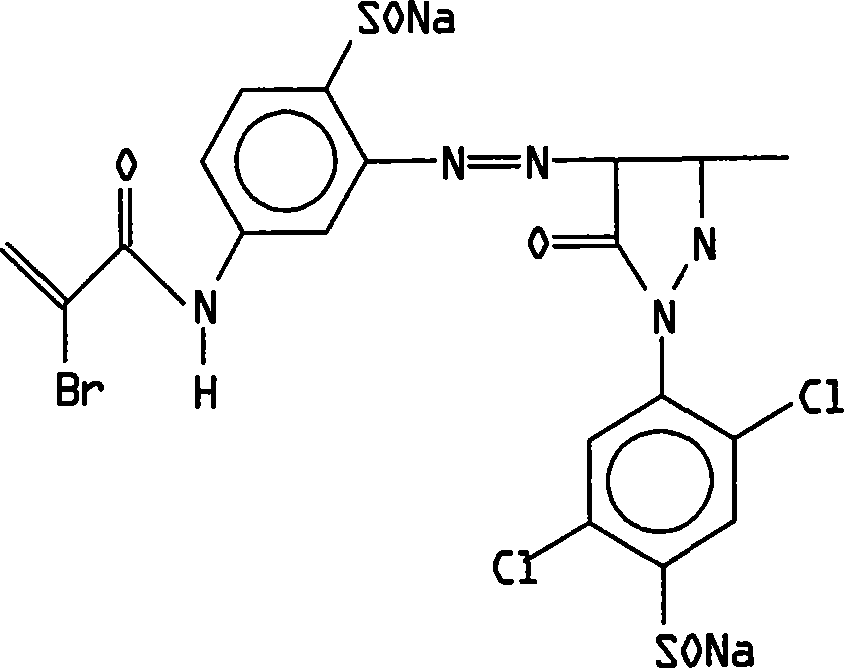

Red reactive dye for fur and preparation thereof

InactiveCN101481523AImprove responseImprove solubilityReactive dyesDyeing processSolubilitySulfonate

The invention discloses a red reactive dye used for fur and a preparation method thereof. The red reactive dye used for fur takes 2, 4-diaminobenzene sodium sulfonate, 1-naphthol-5-sulfoacid, 2, 3-dichloro propionyl chloride as main raw materials. The red reactive dye of the invention is prepared by condensation, diazotization, coincidence, chromatic light adjustment, intensity adjustment, drying and packaging. The red reactive dye used for fur in the invention has relatively high responsiveness, good solubility and bright-colored and beautiful chromatic light; in addition, the light fastness property is relatively good, the exhaustion rate and the color fixing rate are very high. The pre-blending technology and the virgin stock spraying technology are adopted after film processing. Therefore, waste water and waste residue are not generated, greatly contributing to the environmental protection.

Owner:TIANJIN DEK CHEM

Highly functional polyethylene fiber, and dyed highly functional polyethylene fiber

ActiveCN102812170AHigh exhaustion rateLittle change in physical propertiesWeft knittingFibre typesFiberPolymer science

Provided is a highly functional polyethylene fiber which is small in changes of physical properties and has excellent dimensional stability over a wide range of product processing temperature and a wide range of product's service temperature. Also provided is a highly functional polyethylene fiber which is capable of achieving a high dye exhaustion ratio by a simple dyeing operation and has excellent color fastness. The highly functional polyethylene fibers of the present invention are characterized by having a limiting viscosity [n] of 0.8 dL / g to 4.9 dL / g (inclusive), a repeating unit that is substantially composed of ethylene, a maximum contraction stress as determined by TMA (thermomechanical analysis) of 0.4 cN / dtex or less and a thermal shrinkage at 100 DEG C of 2.5% or less.

Owner:TOYOBO MC CORP

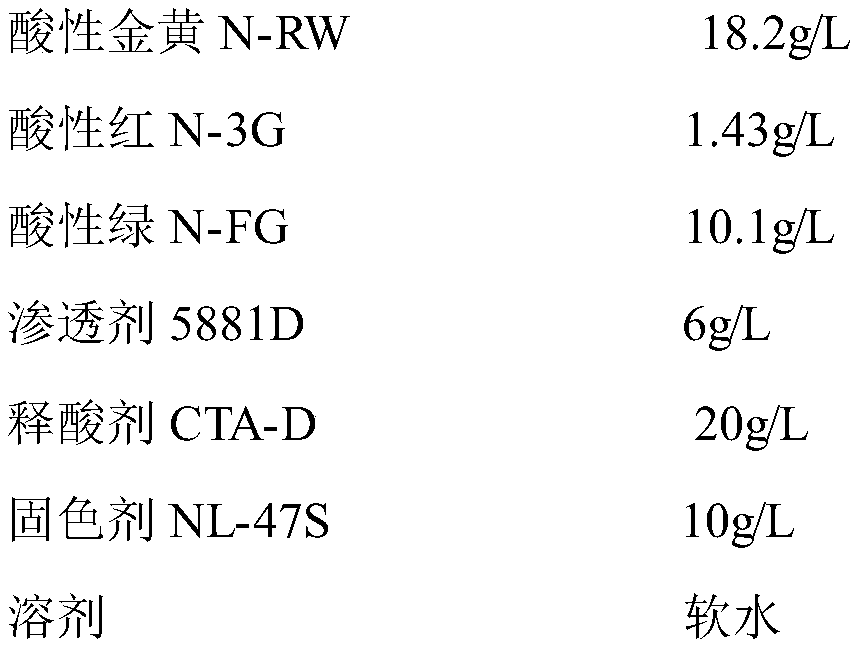

Acid dye mixture with good colourability

InactiveCN102408750AImprove wet fastnessHigh exhaustion rateOrganic dyesDyeing processFiberWastewater

The invention discloses an acid dye mixture with good colourability. The acid dye mixture has the following beneficial effects: as a natural auxiliary is added, the wet fastness of the acid dye after mixing is improved, the fiber handfeel can not be changed and the exhaustion of the dye is substantially improved; the wastewater generated after dyeing can be entirely degraded biologically; and the acid dye mixture is more suitable to dye nylons, silk, leathers, wool, paper, synthetic resins and other substances, simultaneously is quite suitable for various novel fibers and has uniform dyeing effect.

Owner:DAFENG QIANCAI FINE CHEM

Sea island ultra-fine fiber dark-brown polyester dispersion dye with high color deepening capability and color fastness

InactiveCN101575461AHigh exhaustion rateReduce usageOrganic dyesDyeing processDisperse dyeUltra fine

The invention relates to a sea island ultra-fine fiber dark-brown polyester dispersion dye with high color deepening capability and color fastness. The dispersion dye comprises the following components according to the weight percentage: 20-27 of Color Index C.I. dispersion orange 30, 8-14 of C.I. dispersion orange 61, 4.5-4.8 of C.I. dispersion yellow 163, 0-0.22 of C. I. dispersion red 82, 50-58 of dispersant, 1-2 of dust laying oil and 0.2-0.3 of dispersed complexing agent. The dispersion dye can obviously improve the exhaustion rate of dyes, obviously reduce the amount of the dyes in use, improve the color fastness and also reduce the sewage discharge and treatment.

Owner:SHANGHAI ANOKY GRP

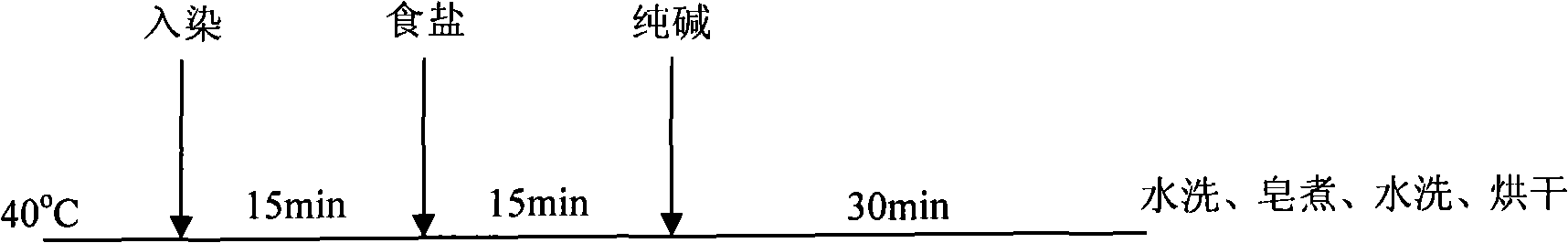

Dyeing and finishing technique of cellulose fiber textile

The invention discloses a dyeing and finishing technique of cellulose fiber textile, which sequentially comprises the following steps of: pretreating, dyeing, water washing, neutralizing, soaping and water washing the fiber textile; and the dyeing technique comprises the steps of: under the conditions of 30 DEG C and bath ratio of 1:7-1:15, adding vinyl sulfone type low-temperature dye with the weigh of 2-10% of the textile, and carrying out heat preservation for 10-15min; then, adding anhydrous sodium sulphate and sodium hydroxide which is 1 / 4-1 / 3 of the total weight, and carrying out heat preservation for 10-15min; adding another sodium hydroxide which is 3 / 4-2 / 3 of the total weight, and carrying out heat preservation for 10-15min; and heating to 40 DEG C at the speed of 1 DEG C / min, carrying out heat preservation for 40-60min, and completing the dyeing technique. The dyeing and finishing technique of the cellulose fiber textile has the characteristics of low using quantity of dye, high soaping fastness, low using quantity of alkali color fixing agent, less pollution discharge and reduced cost.

Owner:冯惠英

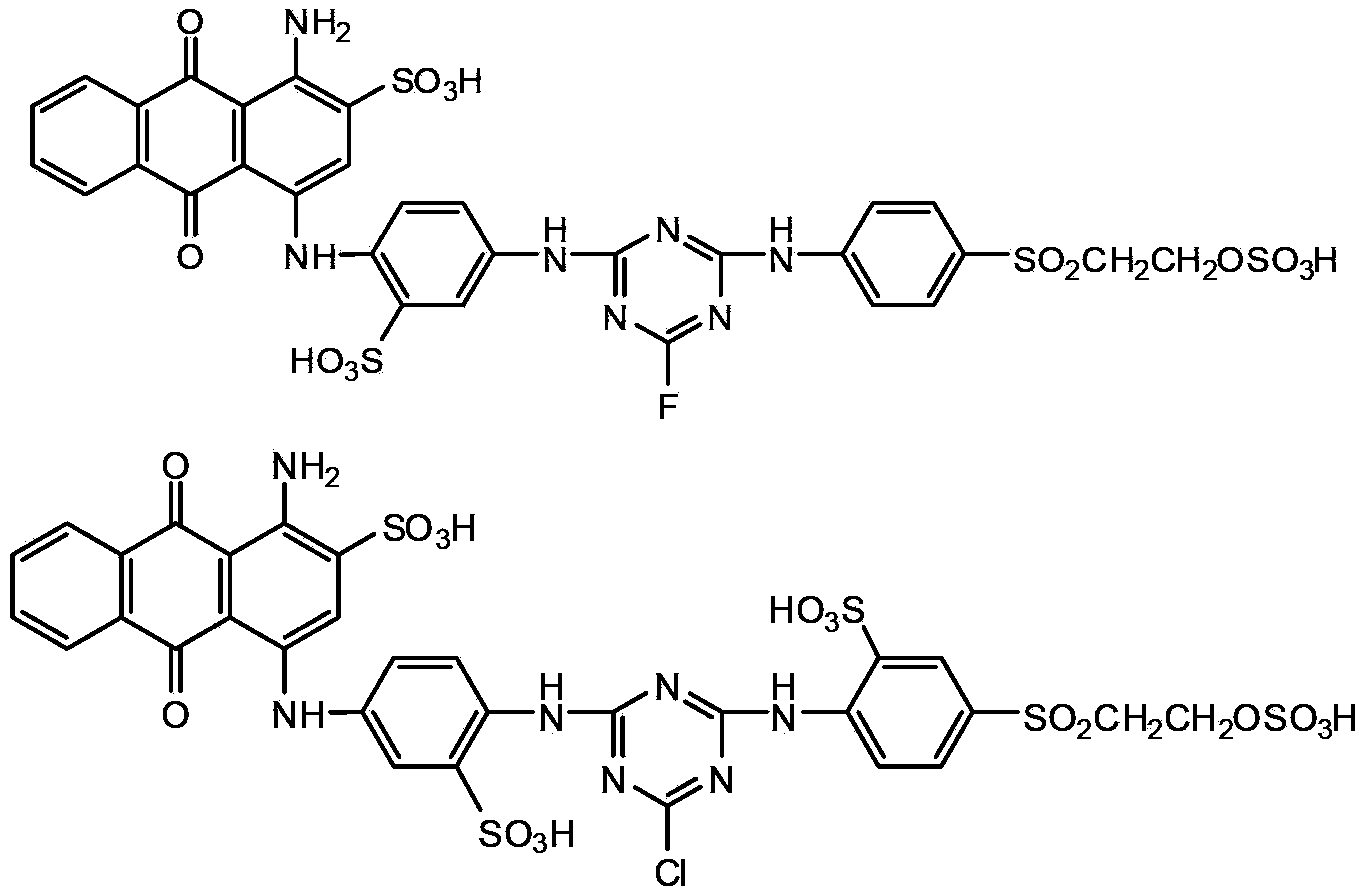

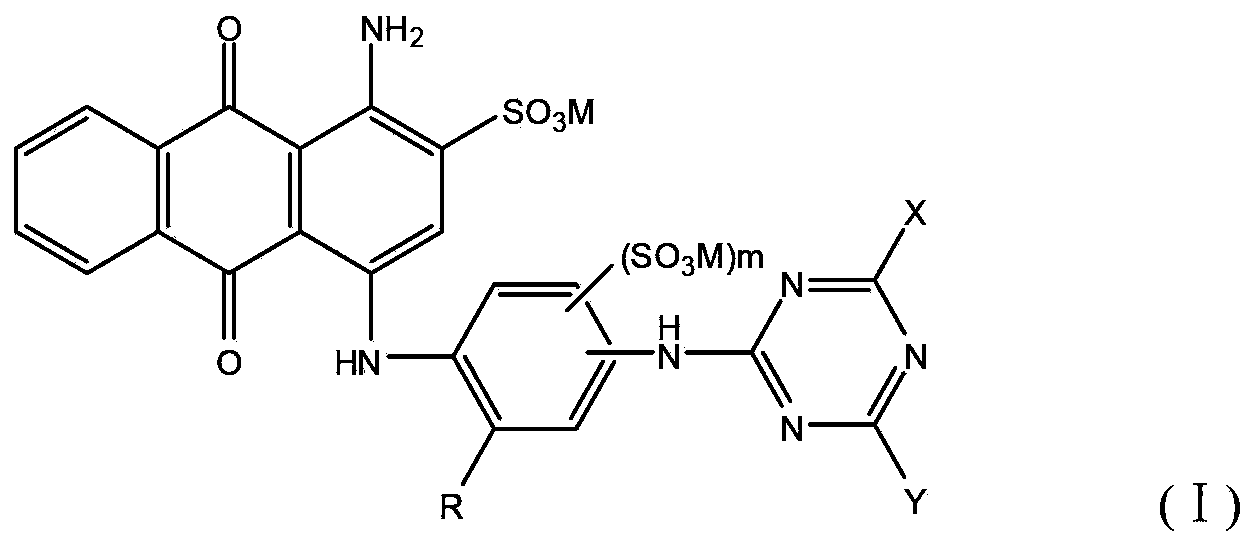

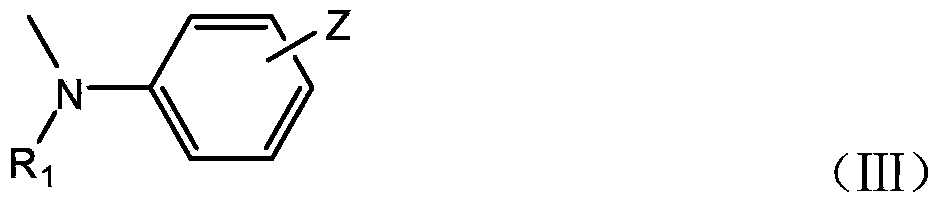

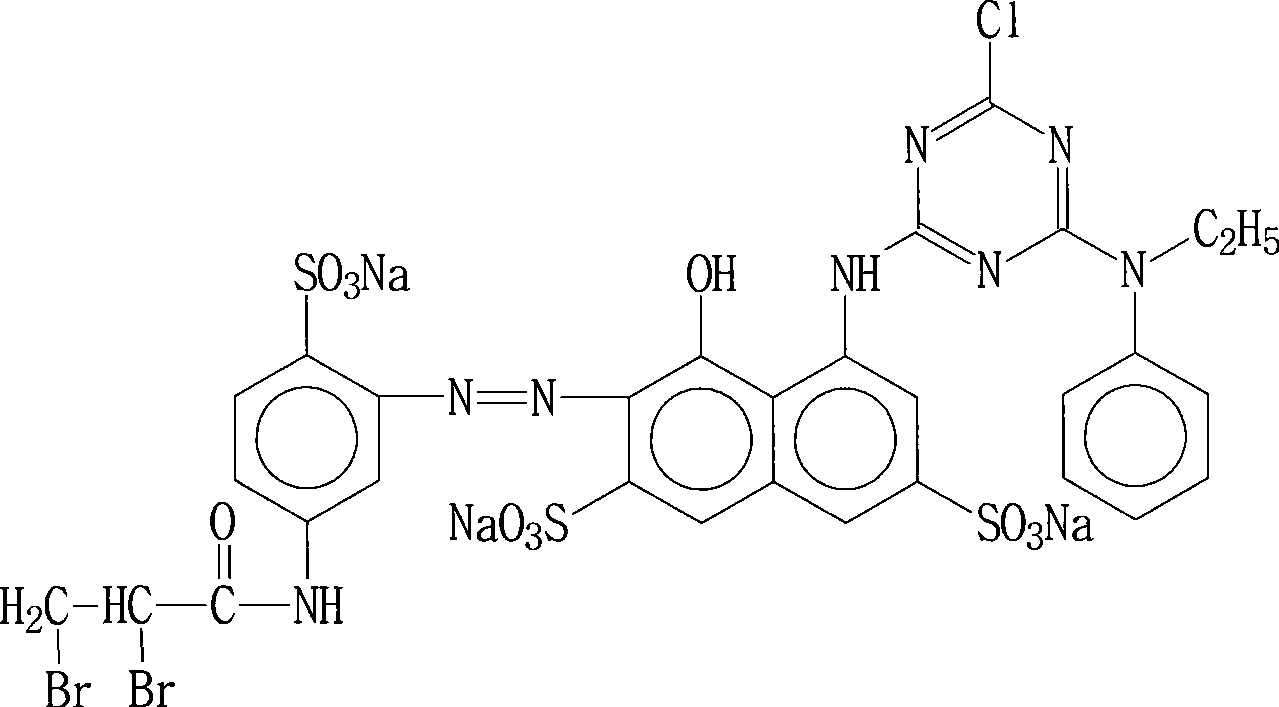

Reactive brilliant blue dye and preparation method thereof

InactiveCN104341794AHigh color fixing rateHigh fastnessReactive dyesDyeing processCellulose fiberProtein fiber

The invention belongs to the field of fine chemical engineering, and particularly relates to a reactive brilliant blue dye and a preparation method thereof. The structure of the reactive brilliant blue dye is a compound as shown in a general formula (I) in the specification, wherein each group in the formula is defined in the specification. The preparation method comprises the following steps: firstly, enabling cyanuric chloride (or cyanuric fluoride) to react with a compound with a vinyl sulfone sulfate or chloroethyl sulfone group to obtain a first condensation compound; enabling the first condensation compound to react with a compound shown in a general formula (II) in the specification to obtain a second condensation compound, namely a part of reactive brilliant blue dye containing a vinyl sulfone sulfate or chloroethyl sulfone group as shown in the general formula (I); and hydrolyzing the second condensation compound under an alkaline condition to obtain another part of reactive brilliant blue dye containing a vinyl sulfone group in the general formula (I). The preparation method disclosed by the invention is low in cost, low in energy consumption, low in pollution and suitable for industrial large-scale production; the reactive brilliant blue dye is used for dyeing and printing of protein fibers, synthetic fibers, cellulosic fibers and blended fabrics thereof; and the fabric is bright and gorgeous in color after being dyed.

Owner:中国中化股份有限公司 +1

Method of preparing yellow active dyestuff

The invention discloses a process for preparing a yellow reactive dye, which comprises utilizing 2, 4-diamino benzensulfonate, 2, 3-dibromo propionyl chlorine, hydrochloric acid, sodium nitrite, 1-(2,5- dichloro-4- sulfonic acid) phenyl group-3 -methyl-5-pyrazolone and caustic soda to be main raw material, and condensing, diazotizing, coupling, handling alkali, adding auxiliary agent, improving dye strength, adjusting color cast, adjusting intensity, dying and packing. The invention adopts front color matching, color yield percentage is high, and the cost of raw material which is needed is lowered, compared with the original technique, the invention reduces the discharging of waste water, and the dissolvability of dye is improved to a new level.

Owner:TIANJIN DEK CHEM

Reactive dye compounds

InactiveCN1351636AHigh exhaustion rateLarge stainingCosmetic preparationsHair cosmeticsCompound aFiber

A reactive dye compound comprising: (a) at least one chromophore moiety; (b) at least one SO2C2H4 group which is attached to the chromophore moiety either directly via the sulphur atom of the SO2C2H4 group or a linking group L; characterised in that at least one SO2C2H4 group is substituted on its terminal carbon atom with at least one Y group wherein Y is -A(CO)R* wherein A is selected from O or S and wherein R' contains at least one terminal nucleophilic group, such as OH, NH2, SH, COOH, N, NHR<1> and NR<1>R<2> wherein R<1> and R<2> may be the same or different and may be selected from C1-C4 alkyl; and salts thereof. Also claimed is a process of manufacture of the compounds herein and products obtainable by the process. The compounds herein have high Exhaustion Values (E), high Fixation Values (F) and high Efficiency Values (T) and show significant improvements in terms of reducing spent dyestuff in effluent, increasing dye affinity to the substrate, increasing the dye-substrate covalent bonding, increasing the ability to dye substrates at room temperature, decreasing the amount of dye that is removed during the post dyeing 'soaping off process' and therefore simplifying the post dyeing 'soaping off process' traditionally associated with dyeing cotton with fibre reactive dyes and reduction of staining of adjacent white fabrics. In addition, the compounds prepared above provide more intense dyeings and require less levels of salt for dyeing cotton substrates.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

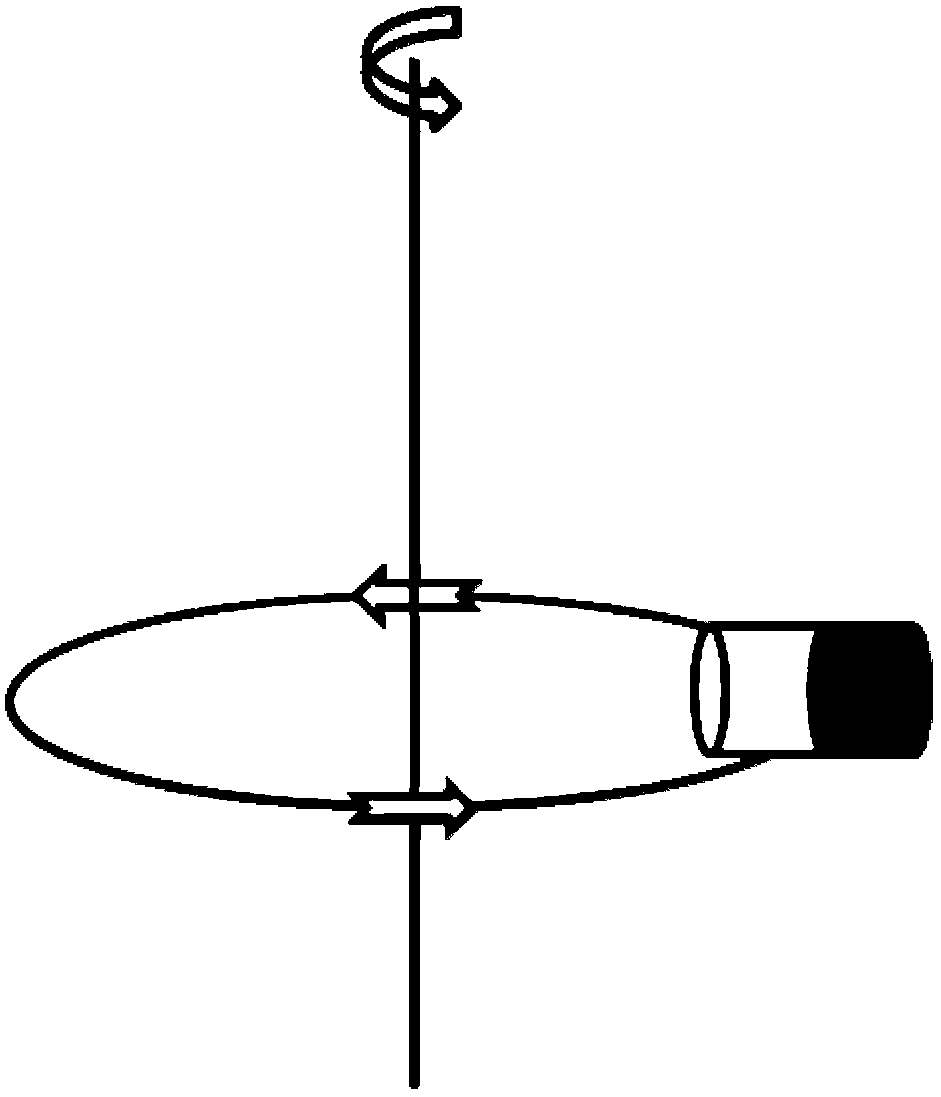

Quick discharging method for tiny bubbles from optical fiber coating

ActiveCN103212220AReduce the number of bubblesReduce Coating DefectsFoam dispersion/preventionEngineeringOptical fiber cable

The invention discloses a quick discharging method for tiny bubbles from an optical fiber coating, and relates to the field of optical fiber communication. The quick discharging method comprises the following steps of: introducing the coating into a closed coating tank, heating the coating to the temperature of 30-65 DEG C, preserving the heat, vacuumizing the closed coating tank to 1*10<-4>-5,000 Pa, and retaining the vacuum degree; inclining the middle axis of the sealed coating tank by a certain angle relative to a rotating shaft, so that the sealed coating tank does centrifugal motion around the rotating shaft, and coatings are always positioned at the bottom of the sealed coating tank; and increasing the centrifugal rotating speed from 0 rpm until the centrifugal rotating speed is up to 500-22,000 rpm, performing the centrifugal motion for 5-25 minutes at the centrifugal rotating speed, and then reducing the centrifugal rotating speed until the centrifugal rotating speed is 0 rpm, wherein at most one tiny bubble of which the diameter is 0.01-0.15 mm exists in every cubic centimeters, and bubbles of which the diameters are more than 0.15 do not exist. By the quick discharging method, the time for discharging the tiny bubbles during the heat preservation of the optical fiber coating can be reduced, the discharging speed and the exhaust rate of the tiny bubbles can be improved, and the number of bubbles in the optical fiber coating and the defects of the coating layers are reduced.

Owner:FENGHUO COMM SCI & TECH CO LTD

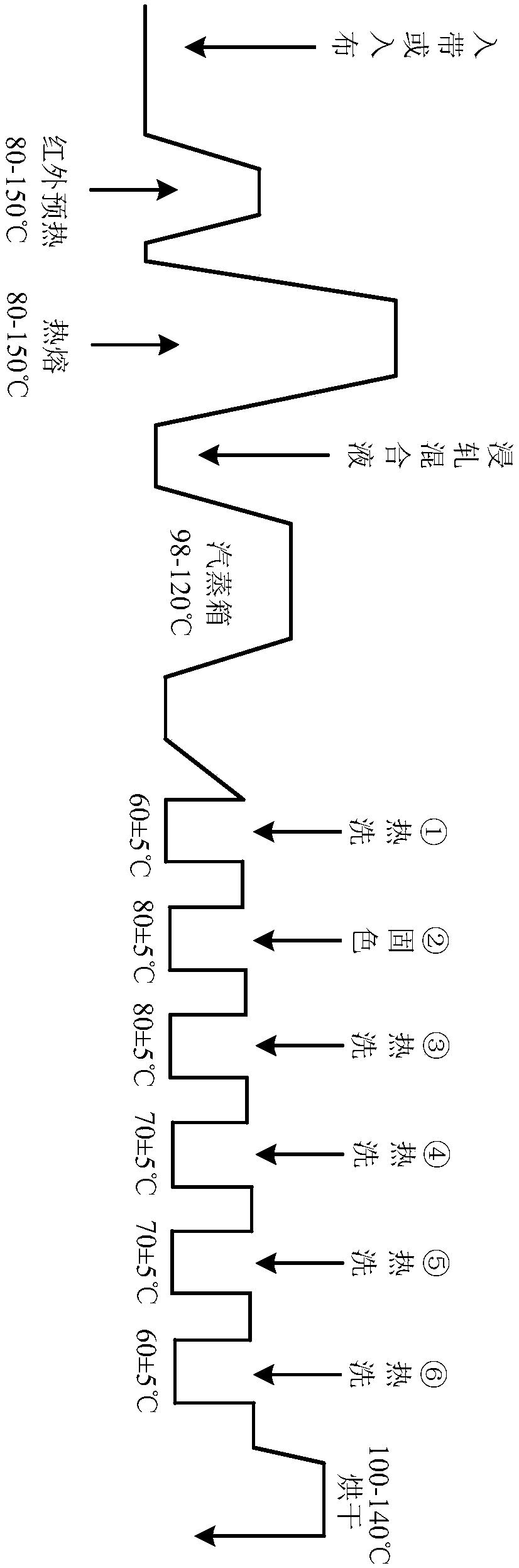

Acid dye continuous pad dyeing method for polyamide woven tapes

The invention discloses an acid dye continuous pad dyeing method for polyamide woven tapes. The acid dye continuous pad dyeing method sequentially includes steps of 1, pretreating the polyamide woventapes; 2, drying the polyamide woven tapes by infrared rays or hot air; 3, simultaneously carrying out pad dyeing by acid dye liquor and color fixing agents; 4, carrying out steaming dyeing and primary color fixing treatment; 5, carrying out hot washing; 6, carrying out secondary color fixing treatment; 7, carrying out hot washing; 8 carrying out drying; 9, dropping tapes. The acid dye continuouspad dyeing method has the advantages that the polyamide woven tapes have bright colors by the aid of acid dye steaming processes and color fixing one-bath dyeing schemes, the dye depths of the polyamide woven tapes can be effectively increased, the acid dye continuous pad dyeing method is good in deep dyeing property in polyamide woven tape dyeing procedures, and the polyamide woven tapes can be dyed with rich dark colors by the aid of the acid dye continuous pad dyeing method; pad dyeing is carried out on the polyamide woven tapes by acid dye, combined effects can be realized by an early color fixing scheme and a late color fixing scheme, the dye and the woven tapes are firmly combined with one another by chemical bonds, and the problem of poor color fastness of existing polyamide woven tapes after burning-preventive finishing is carried out on the existing polyamide woven tapes can be effectively solved by the aid of the acid dye continuous pad dyeing method.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

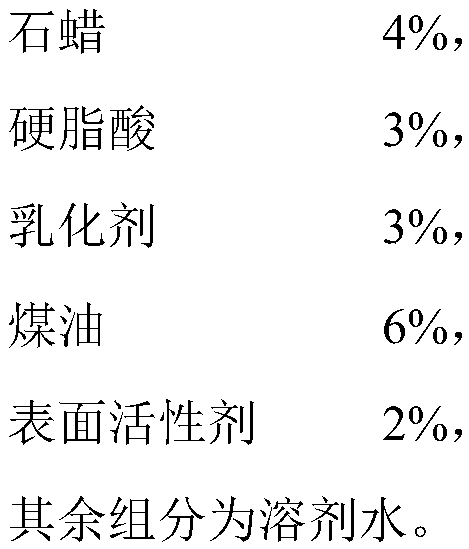

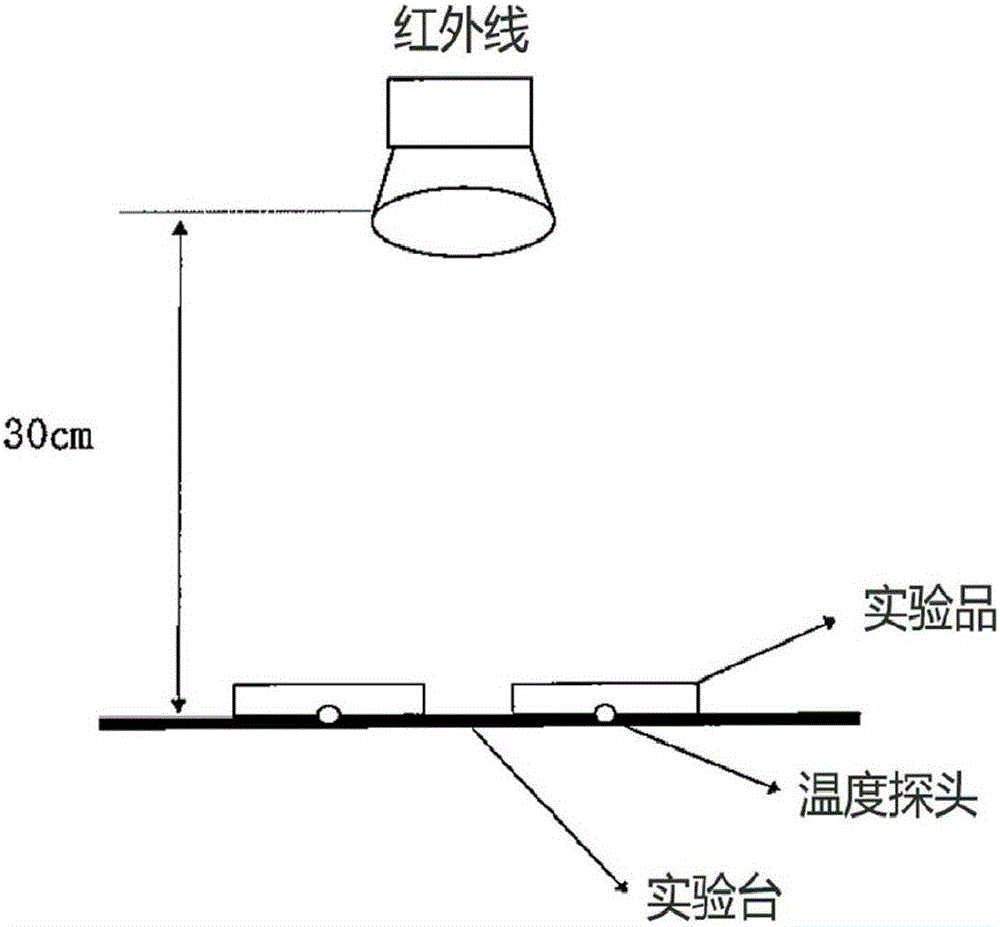

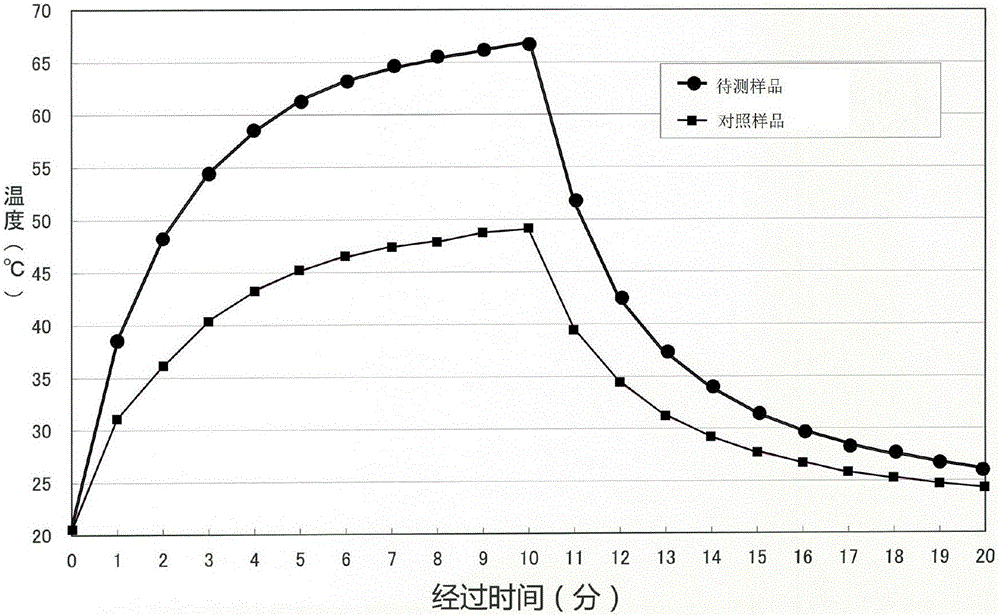

Light-absorbing and heat-emitting composition and preparation method of fabric containing same

The invention relates to a light-absorbing and heat-emitting composition. First dispersant, metal and / or metal oxide and carbide are adopted as raw material components and compounded appropriately, the prepared light-absorbing and heat-emitting composition absorbs sunlight and emits heat and meanwhile can effectively reflect heat of the human body so as to reduce heat diffusion and loss, heat storage performance is high, furthermore, when the light-absorbing and heat-emitting composition is applied to the process of dipping fabric in the composition, the completely absorbing rate is high, compatibility is good, the fabric containing the light-absorbing and heat-emitting composition is finally prepared, sunlight is absorbed, heat is emitted, meanwhile, heat of the human body can be reflected so as to reduce heat diffusion and loss, heat storage performance is high, and the heat retention property is good.

Owner:崔铉泽

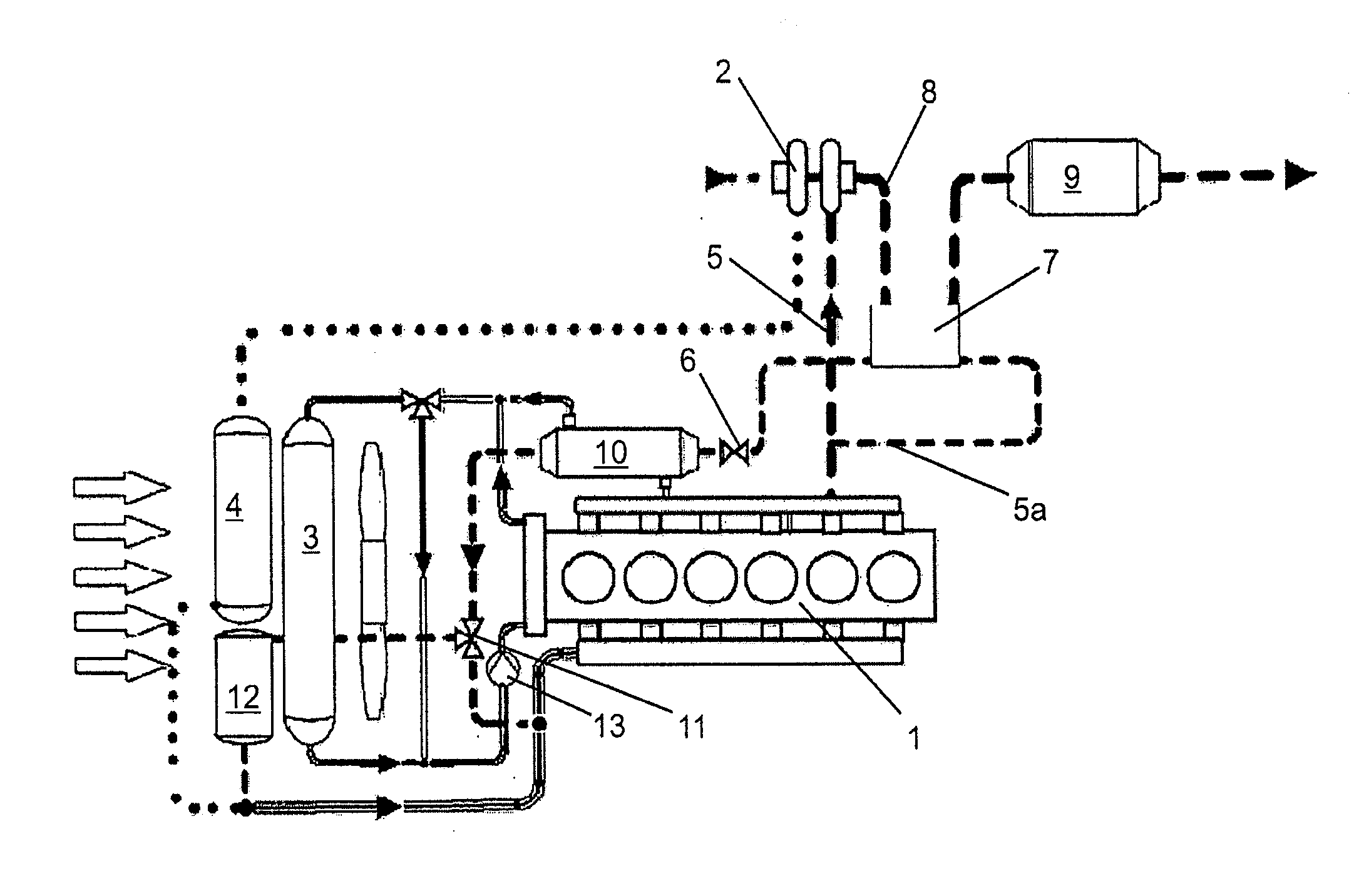

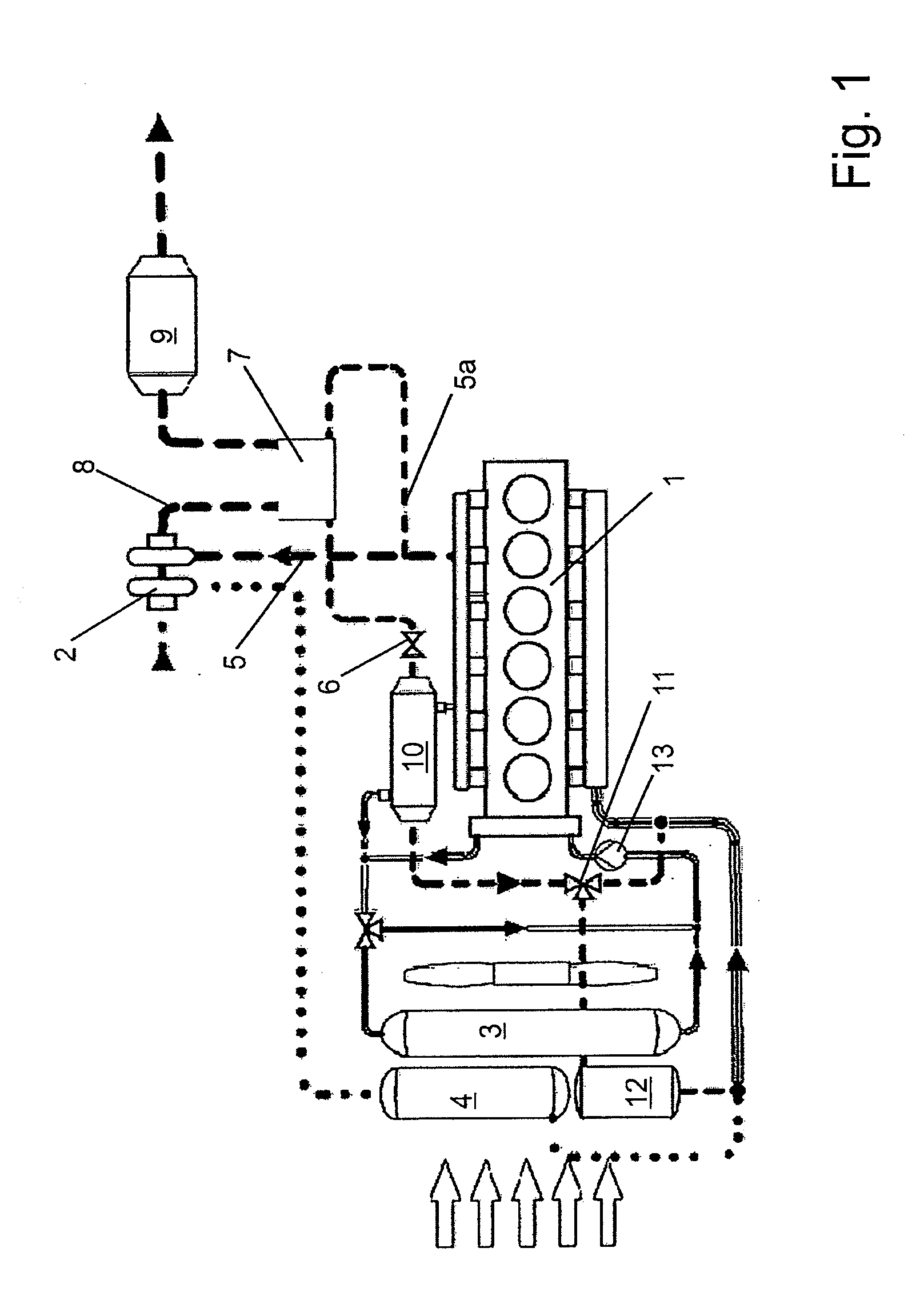

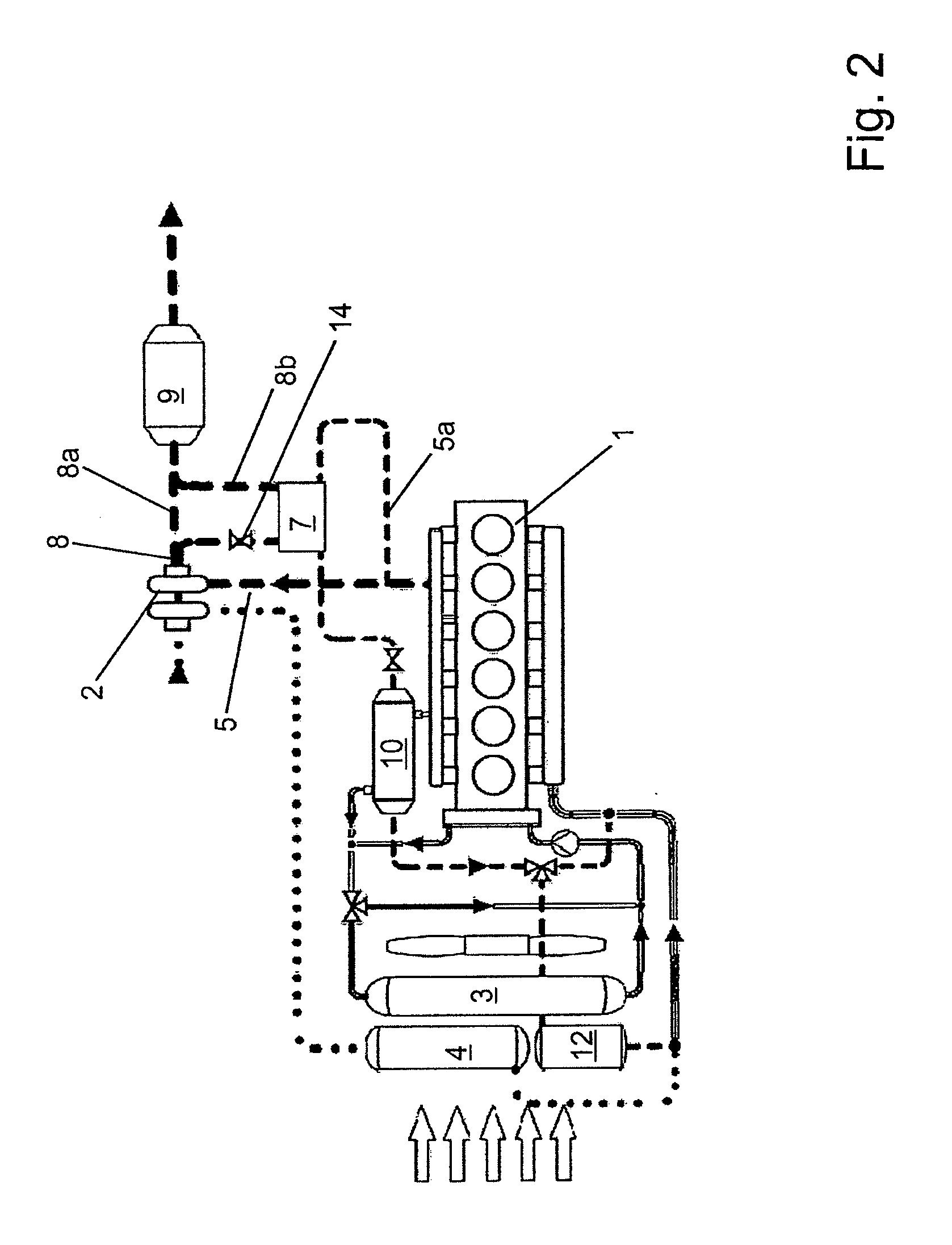

Device and method for recirculating exhaust gas in an internal combustion engine

InactiveUS20100199664A1High exhaustion rateHigh rate of exhaust gas recirculationNon-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineExhaust fumes

An apparatus for returning exhaust gas of an internal combustion engine is provided. The apparatus includes a compressor that is driven by exhaust gas, wherein an exhaust-gas flow enters into the compressor on a high-pressure side and exits the compressor on a low-pressure side. A branch is provided on the high-pressure side with regard to the compressor for returned exhaust gas, and at least one exhaust-gas cooler is provided for transferring heat out of the branched-off exhaust-gas flow into a cooling medium. A heat exchanger is provided, via which heat can be transferred between the exhaust-gas flow, which branches off on the high-pressure side, and an exhaust-gas flow on the low-pressure side with regard to the compressor.

Owner:BEHR GMBH & CO KG

Sea island ultra-fine fiber special-black polyester dispersion dye with high color deepening capability and color fastness

InactiveCN101575462AHigh exhaustion rateReduce usageOrganic dyesDyeing processDisperse dyeHigh color

The invention relates to a sea island ultra-fine fiber special-black polyester dispersion dye with high color deepening capability and color fastness. The dispersion dye comprises the following components according to the weight percentage: 13-15 of Color Index C.I. dispersion blue 291, 13-15 of C.I. dispersion blue 291:1, C.I. 3-4 of dispersion blue 60, 5-6 of C.I. dispersion violet 93, 4-6 of C.I. dispersion orange 288, 4-6 of C.I. dispersion orange 61, 50-52 of dispersant, 1-2 of dust laying oil and 0.3 of dispersed complexing agent. The dispersion dye can obviously improve the exhaustion rate of dyes, obviously reduce the amount of the dyes in use, improve the color fastness and also reduce the sewage discharge and treatment.

Owner:SHANGHAI ANOKY GRP

Preparation of red reactive dye for fur

The invention provides a method for preparing vital red GN, comprising the following steps: firstly, H acid solution is added to cyanuric chloride solution for reaction, after the reaction is over, N-hexyl aniline is added for reaction, thus obtaining condensation solution; then 2, 3-dibromo propionyl chloride is added to 2, 4-diaminobenzene sulfonic acid sodium for reaction, after the reaction is over, diazo reaction is carried out by adding sodium nitrite solution under acidic condition, thus obtaining diazonium solution; finally, coincidence reaction is carried out by adding the diazonium solution into the condensation solution, thus obtaining the vital red GN of the invention. The vital red GN for fur prepared by the invention has relatively high responsiveness, good solubility and bright-colored and beautiful chromatic light; in addition, the light fastness property is very good, the wet fastness property is excellent and the exhaustion rate and the color fixing rate are very high. The vital red GN of the invention can be applicable for dyeing wool, pashm and non-shrinkable wool.

Owner:TIANJIN DEK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com