Highly functional polyethylene fiber, and dyed highly functional polyethylene fiber

一种聚乙烯纤维、高功能的技术,应用在聚乙烯纤维领域,能够解决无法维持产品性能、尺寸变化等问题,达到优异性能和外观性、物性变化小、广泛应用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

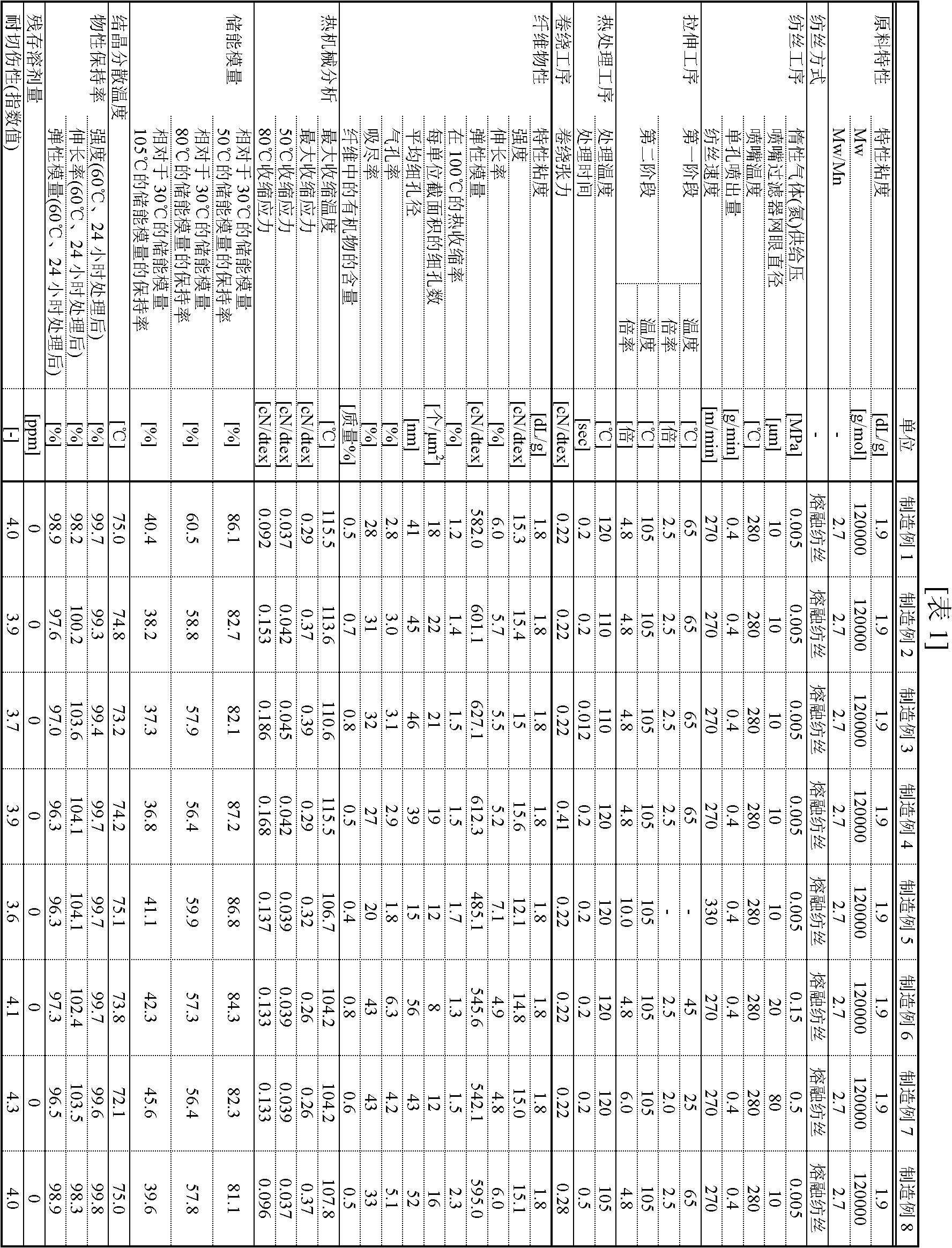

manufacture example 1~16

[0149] A solid viscoelasticity measuring device (manufactured by T.A. Instruments, "DMA Q800") was used for the measurement. The measurement conditions are that the measurement sample length is 10 mm, and the sample fineness is 100 dtex. During the measurement, use adhesive and double-sided tape to clamp both ends of the fiber sample with thick paper to avoid slipping between the fiber sample and the chuck of the device and rupture of the monofilament. By interposing the thick paper between the fiber sample and the device chuck during the measurement in this way, slippage on the device chuck and breakage of monofilaments can be suppressed. The measurement start temperature was set at -10°C, the measurement end temperature was set at 140°C, and the heating rate was set at 1.0°C / min. The amount of deformation was set to 0.04%, and the initial load at the start of the measurement was set to 0.05 cN / dtex. And, the measurement frequency was set to 11 Hz. The analysis of the data...

manufacture example 17~31

[0152] A solid viscoelasticity measuring device (manufactured by T.A. Instruments, "DMA Q800") was used for the measurement. As for the measurement conditions, the length of the measurement sample was adjusted to be 10 mm, and the fineness of the sample was adjusted to be about 100 dtex. During the measurement, both ends of the measurement sample are clamped with thick paper using adhesive and double-sided tape to avoid slippage between the fiber sample and the chuck of the device and rupture of the monofilament. By interposing the thick paper between the measurement sample and the device chuck during the measurement in this way, slippage on the device chuck and breakage of monofilaments can be suppressed in the case of fibers. In addition, the measurement start temperature was set at -140°C, the measurement end temperature was set at 140°C, and the temperature increase rate was set at 1.0°C / min. The amount of deformation was set to 0.04%, and the initial load at the start of...

manufacture example 1

[0208] High-density polyethylene pellets having an intrinsic viscosity of 1.9 dL / g, a weight average molecular weight of 120,000, and a ratio of weight average molecular weight to number average molecular weight of 2.7 were filled in a container supplied with nitrogen gas at a pressure of 0.005 MPa. The pellets are supplied to the extruder and melted at 280°C. The mesh diameter of the nozzle filter is set to 10 μm. Under the conditions, it is sprayed with a single hole spray rate of 0.4g / min. Let the extruded filaments pass through a 10cm heat preservation zone, and then cool them with a quenching wind with a wind speed of 0.5m / sec at 40°C, and then wind them into a bobbin shape at a spinning speed of 270m / min to obtain undrawn filaments .

[0209] Then, before winding into a bobbin shape, 2% by mass of octane / ethylene glycol (=80 / 20; mass ratio) liquid mixture was added to the undrawn yarn, and it was left still in a bobbin shape for a day. As part of the above-mentioned oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com