Light-absorbing and heat-emitting composition and preparation method of fabric containing same

A light-absorbing, heat-generating, composition-based technology, applied in the field of materials, can solve the problems of fabric spinning quality and quality reduction, unsatisfactory fabric warmth retention, excessive fabric residual dyeing liquor, etc., to reduce heat diffusion and loss, good warmth retention, The effect of good heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

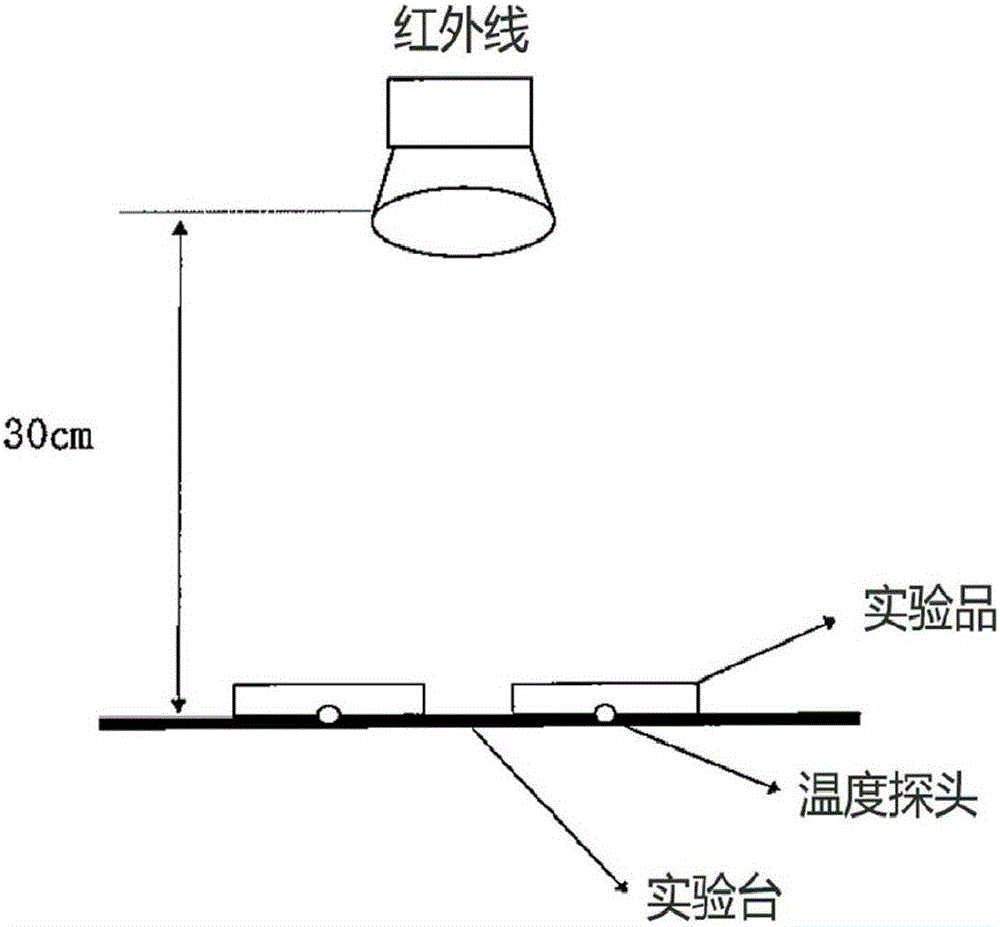

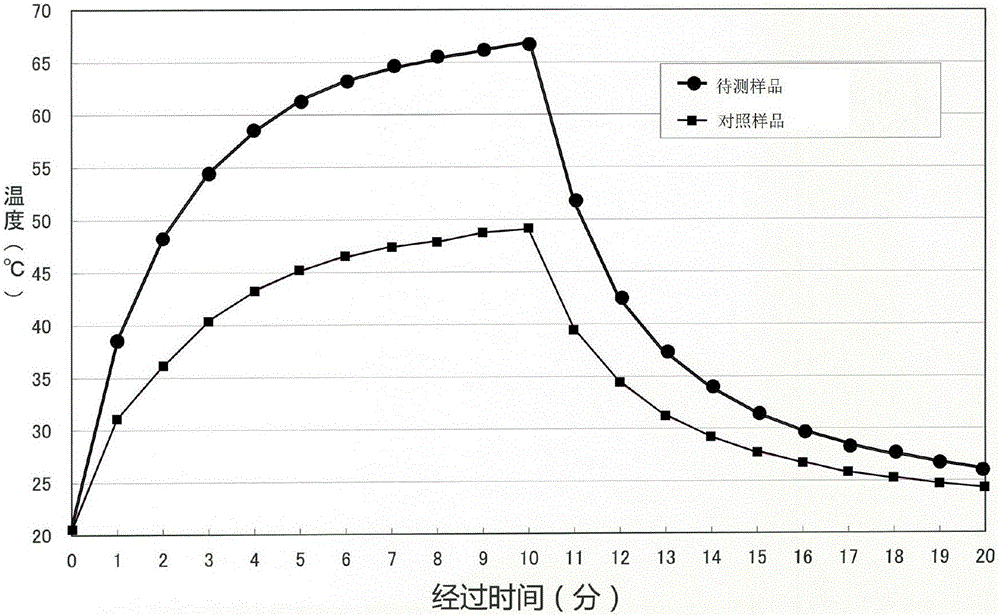

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a light-absorbing and heat-generating composition, and the raw material components include:

[0033] The first dispersant is non-ionic surfactant polyoxyethylene sorbitan trioleate (cloud point is 40 DEG C), 5 parts by weight;

[0034] Zinc-tin oxide (ATO, tin: the mol ratio of antimony is 9:1), 20 parts by weight;

[0035] Zirconium carbide, 0.1 parts by weight;

[0036] Defoamer, 0.1 parts by weight.

[0037] Further, a method for fabric containing the light-absorbing and heat-generating composition is provided, the steps include:

[0038] (1) Weigh each raw material component according to the above weight parts and fully mix to prepare the light-absorbing and exothermic composition, add water to the light-absorbing and exothermic composition for the first time and fully disperse to form a solid content of 10wt% homogeneous dispersion;

[0039] (2) wet-grinding the dispersion described in step (1), so that the particle diameter of the soli...

Embodiment 2

[0042] This embodiment provides a light-absorbing and heat-generating composition, and the raw material components include:

[0043] The first dispersant is nonionic surfactant polyoxyethylene lauryl ether (cloud point is 80 DEG C), 20 parts by weight;

[0044] Indium tin oxide (ITO), 10 parts by weight;

[0045] Silicon carbide, 5 parts by weight;

[0046] The second dispersant is an anionic-nonionic composite system, 0.1 parts by weight;

[0047] Defoamer, 0.1 parts by weight.

[0048] Further, a method for fabric containing the light-absorbing and heat-generating composition is provided, the steps include:

[0049] (1) Weigh each raw material component according to the above parts by weight and fully mix it to obtain the light-absorbing heat-generating composition. Add water to the light-absorbing heat-generating composition for the first time and fully disperse it to form a solid content of 20wt%. homogeneous dispersion;

[0050] (2) wet-grinding the dispersion in ste...

Embodiment 3

[0053] This embodiment provides a light-absorbing and heat-generating composition, and the raw material components include:

[0054]The first dispersant is nonionic surfactant polyoxyethylene alcohol castor ether (cloud point is 60 DEG C), 15 parts by weight;

[0055] A mixture of antimony tin oxide and indium tin oxide in a mass ratio of 1:1, 10 parts by weight;

[0056] A mixture of zirconium carbide, silicon carbide, and boron carbide in a mass ratio of 1:1:1, 5 parts by weight;

[0057] The second dispersant is an anionic-nonionic composite system, 5 parts by weight;

[0058] Additive, 5 parts by weight;

[0059] The additive is a mixture composed of a thickener, an anti-settling agent, a defoamer, an antistatic agent, a water-repellent agent, an antibacterial agent and an ultraviolet stabilizer in equal parts by mass.

[0060] Further, a method for fabric containing the light-absorbing and heat-generating composition is provided, the steps include:

[0061] (1) Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com