Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

A technology for aluminum alloys and pipe fittings, which is applied in the field of solid solution-bending-aging forming devices for aluminum alloy pipe fittings for car bodies, can solve problems affecting the forming quality of pipes, improper arrangement of water spray holes, inconsistent spray angles, etc., shorten the forming process, improve The effect of improving the forming quality and forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

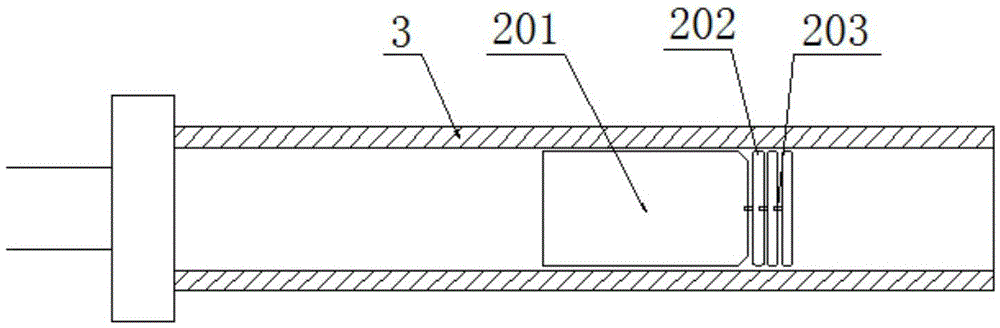

[0058] In embodiment 1, the supporting mandrel is a rigid mandrel.

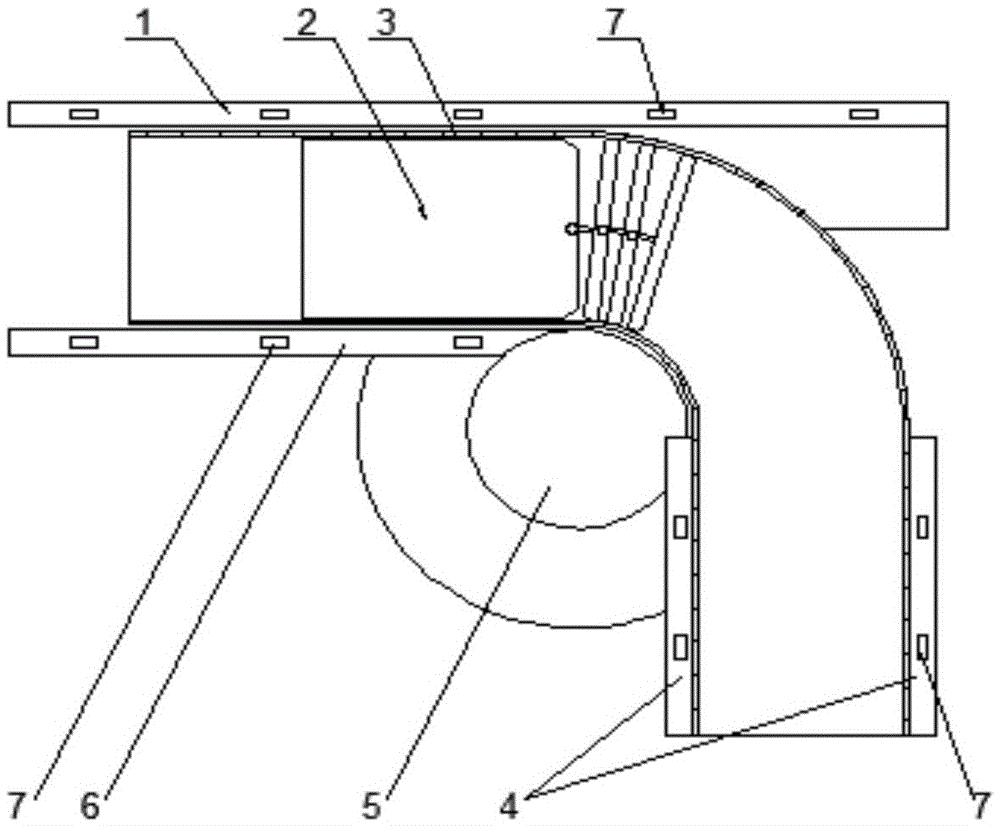

[0059] Such as Figure 1-Figure 3 As shown, a method for solid solution-bending-aging forming of an aluminum alloy pipe fitting for a vehicle body comprises the following steps:

[0060] S1. The material of the aluminum alloy pipe fittings is 2A12, the diameter of the pipe fittings is 80mm, the thickness is 1mm (that is, the ratio of diameter to thickness is 80), the length is 500mm, the bending radius of the bending part is 120mm, and the outer diameter of the mandrel and core ball is 78mm. The core ball is arranged in series on the mandrel through a hinge, the mandrel is put into the pipe, and the induction coil is placed on the outer circumference of the pipe to be bent;

[0061] S2. Adjust the high-frequency power of the high-frequency power supply according to the specifications of the pipe fittings, wall thickness, etc., use the high-frequency power supply to heat the bending part of the pipe fittings ...

Embodiment 2

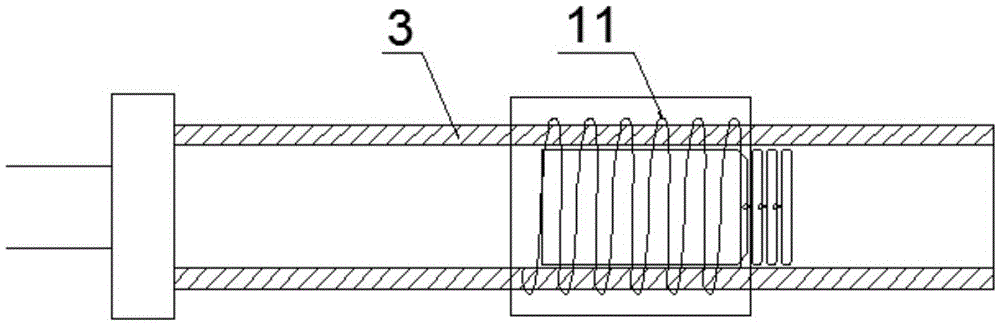

[0065] In embodiment 2, the supporting mandrel is a rigid steel ball.

[0066] Such as Figure 6-Figure 8 As shown, a method for solid solution-bending-aging forming of an aluminum alloy pipe fitting for a vehicle body comprises the following steps:

[0067] S1. The material of the aluminum alloy pipe fittings is 2A12, the diameter of the pipe fittings is 80mm, the thickness is 1mm (that is, the ratio of diameter to thickness is 80), the length is 500mm, and the bending radius of the bending part is 120mm. Different quantities and sizes of small steel balls are filled into the Inside the pipe fitting (steel ball diameter ≤ 4mm), the two ends of the pipe fitting are sealed by the steel wire rope 10, and the induction coil is placed on the outer circumference of the pipe fitting to be bent;

[0068] S2. Adjust the high-frequency power according to the requirements of the pipe fitting specification, wall thickness, etc., use the high-frequency power supply to conduct circumferen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com