Anti-freeze high-efficiency flat solar water heater without water tank

A solar water heater, no water tank technology, applied in solar thermal power generation, solar thermal devices, heating devices and other directions, can solve the problems of complicated water tank installation, troublesome system maintenance, low temperature of hot water, etc., and achieves simple and reasonable structure and good heat preservation. Effect, effect of high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

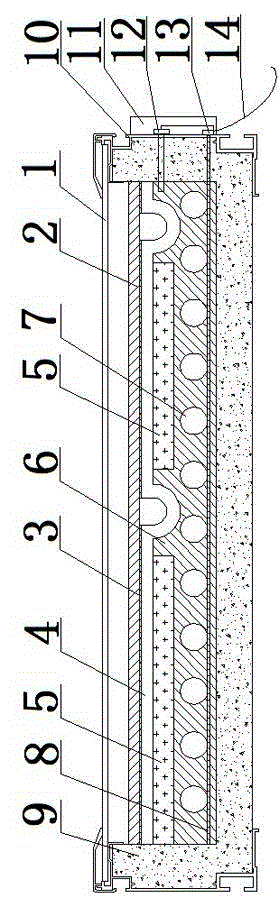

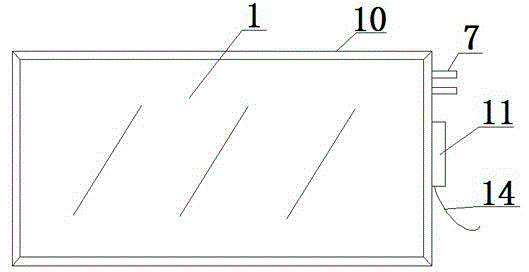

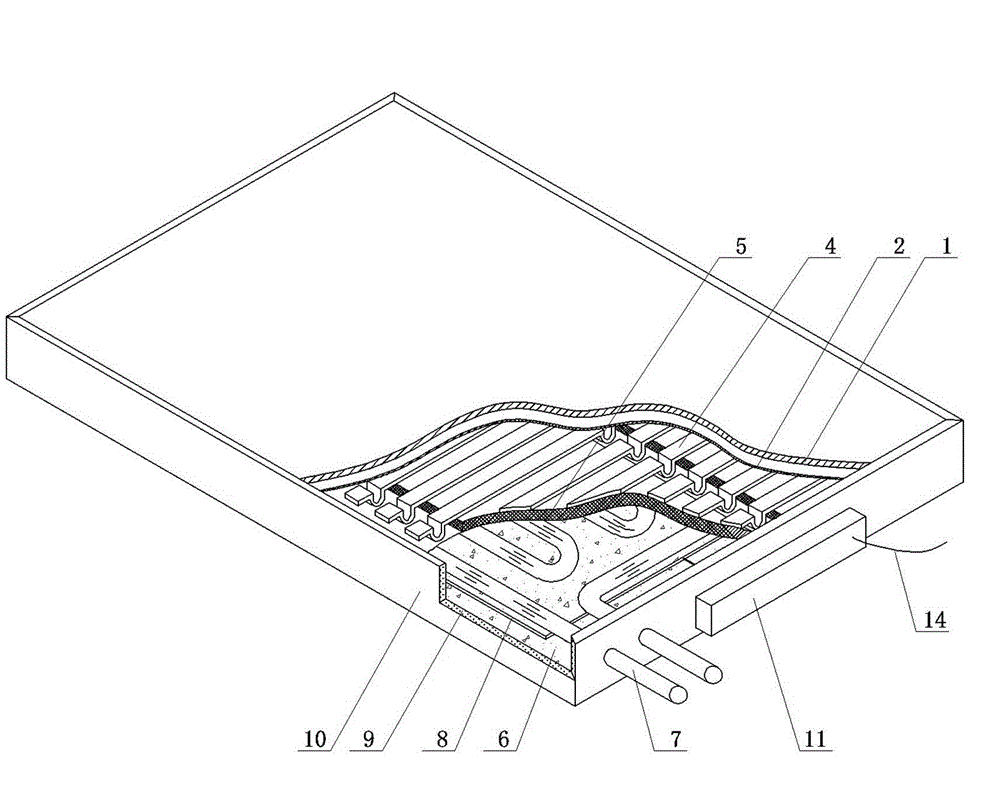

[0017] see Figure 1 ~ Figure 3 , the antifreeze type tankless high-efficiency flat plate solar water heater of the present embodiment comprises an aluminum frame shell 10 with an opening, the inner walls of the frame shell 10 are provided with insulation layers 9, and the opening of the frame shell 10 is provided with a glass cover plate 1, Heat-absorbing plate core 2, heat-conducting silica gel 3, inorganic flat superconducting heat pipe 4, phase-change heat storage material layer 6 are arranged in the insulation layer 9 sequentially from top to bottom, and a hot water coil is arranged in the phase-change heat storage material layer 6 7. The hot water coil 7 is usually made of copper, and the two ends of the hot water coil 7 are respectively connected with a cold water inlet pipe and a hot water outlet pipe. A heat insulating material layer 5 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com