Flat plate solar heat collector

A solar heat collector, a flat-plate technology, applied in the field of solar heat collectors, can solve the problems of poor joints of heat collectors, expensive plate cores, poor heat collection effects, etc., and achieve good heat collection effects, simple structure, The effect of strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

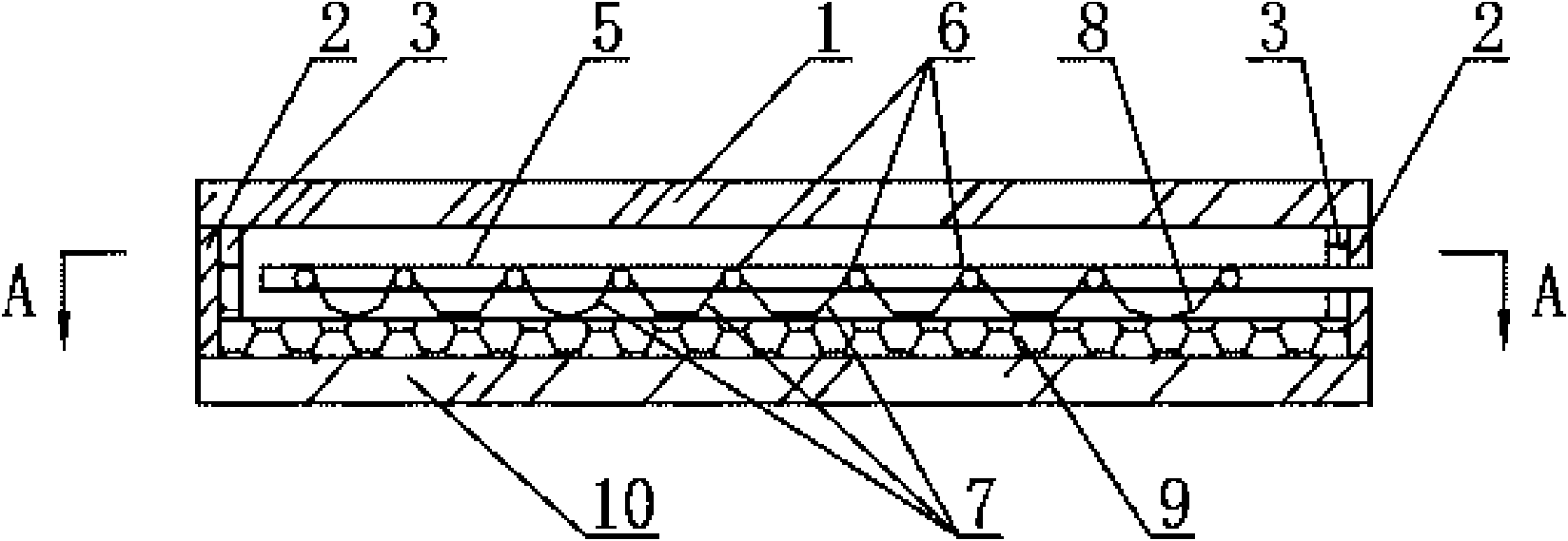

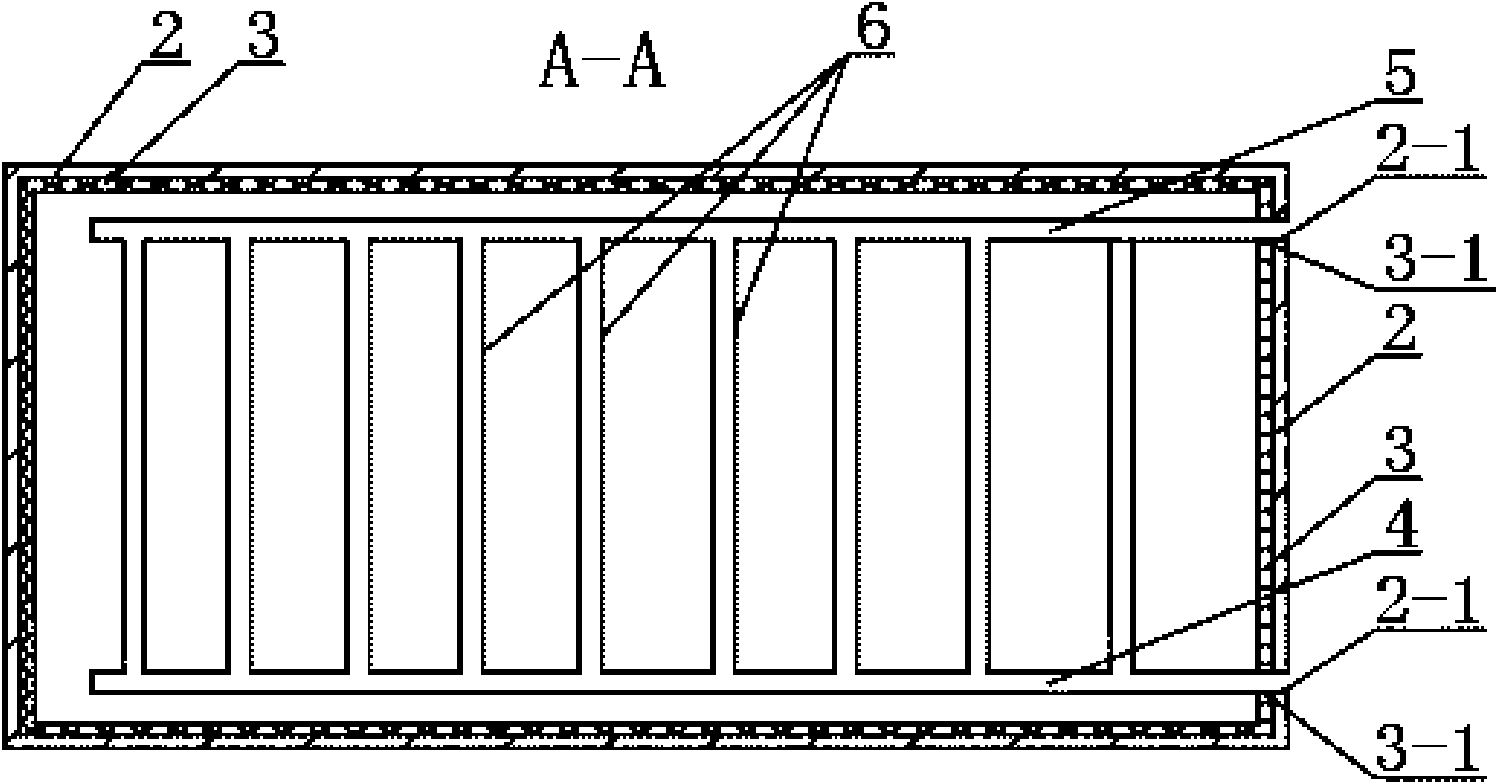

[0007] Specific implementation mode one: as figure 1 with 2 As shown, the flat-plate solar collector described in this embodiment includes a cover plate 1, a rectangular frame 2, a frame insulation layer 3, a water inlet pipe 4, an outlet pipe 5, a plurality of stainless steel pipes 6, a heat-absorbing coating 8, and a thermal insulation layer. Layer 9 and bottom plate 10, the heat collector also includes a plurality of heat collecting plates 7, the rectangular frame 2 is fixed horizontally on the upper end surface of the bottom plate 10, and the inner wall around the rectangular frame 2 is provided with a frame insulation layer 3, The insulation layer 9 is arranged on the upper end surface of the bottom plate 10 and is located in the rectangular frame 2, the water inlet pipe 4 and the water outlet pipe 5 are arranged in the rectangular frame 2 along the length direction of the rectangular frame 2, and a plurality of stainless steel pipes 6 are arranged in parallel on the wate...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 with 2 As shown, the heat-absorbing coating 8 in this embodiment is a black chrome coating. Such setting can make the heat collecting plate absorb more heat energy. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 with 2 As shown, the water inlet pipe 4 and the water outlet pipe 5 in this embodiment are all stainless steel pipes. Stainless steel tubes are used for good heat transfer performance. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com