Flat-plate-type air solar heat collector and production method for heat absorption plate thereof

A solar heat collector and solar energy absorption technology, applied in the field of heat collectors, can solve the problems of high production cost and limited area, and achieve the effects of low production cost, reduced emissivity, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

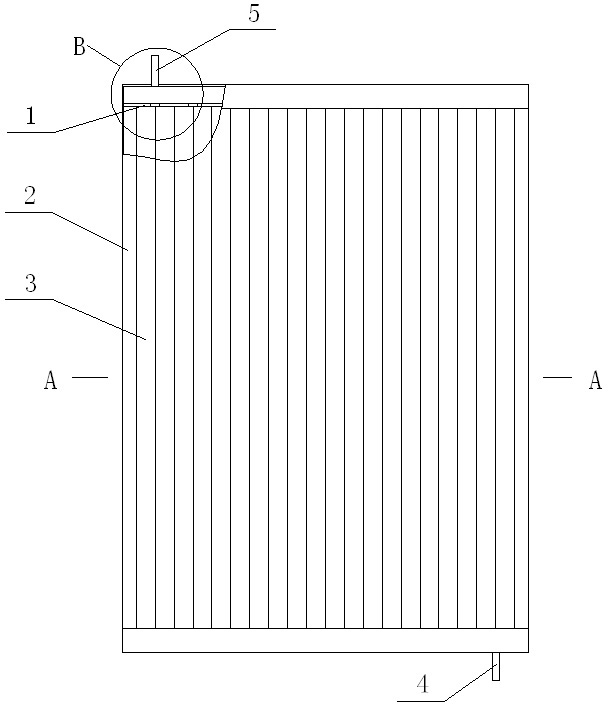

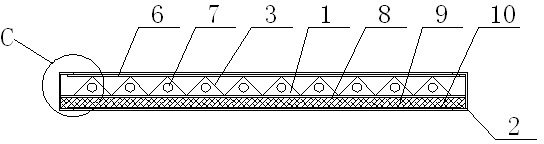

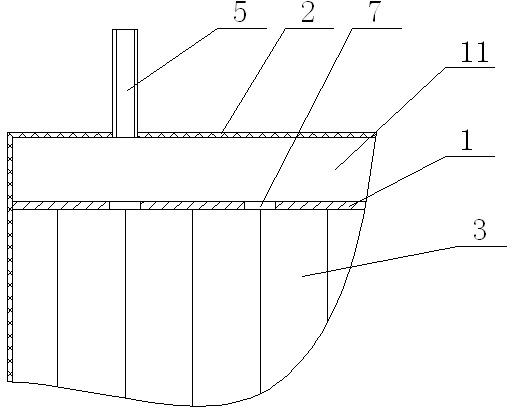

[0016] Such as figure 1 , 2 , 3, 4 shows the flat-panel air solar heat collector, is made up of frame 2 and the translucent protective plate 6, heat absorbing plate 3, thermal insulation layer 9 and rear panel 10 that are installed in the frame sequentially, the heat absorbing plate The cross-section is wavy, and a separator 8, an insulation layer 9 and a rear panel 10 are sequentially installed on the back of the heat-absorbing plate. A parallel triangular air heating chamber is formed between the separator and the wavy heat-absorbing plate. The two ends of the heat absorbing plate are equipped with sealing baffles 1, and holes 7 for air in and out are opened on the baffle corresponding to the triangular air heating chamber, so that the heat absorbing plate, the partition and the sealing baffle are surrounded by a Multiple triangular air heating chambers are provided. There is a certain distance between the two baffles and the corresponding frame, between the two baffles an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com