Heat exchanger structure

A heat exchanger and heat transfer medium technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reduced service life of plate heat exchangers, large system resistance, and less effective heat energy, and achieve improved Effect of heat conversion efficiency, improvement of heat conversion coefficient, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

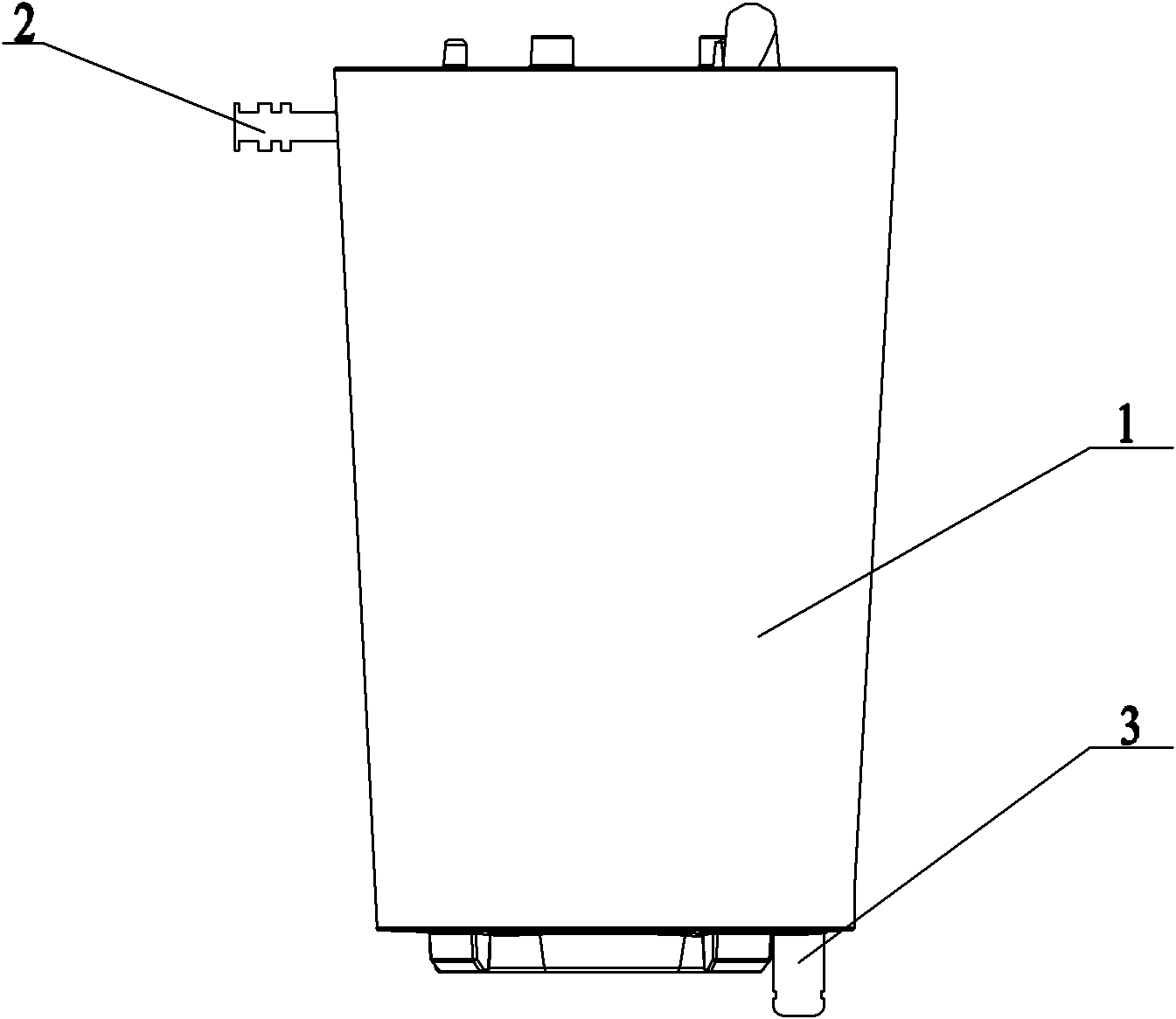

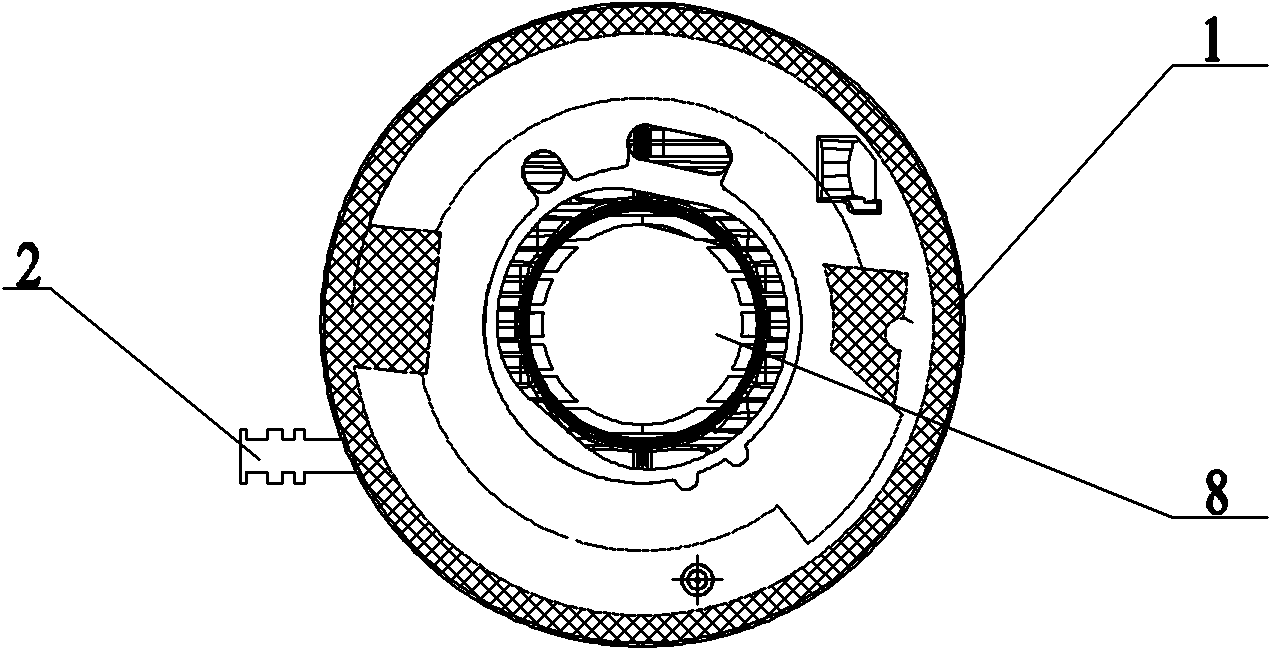

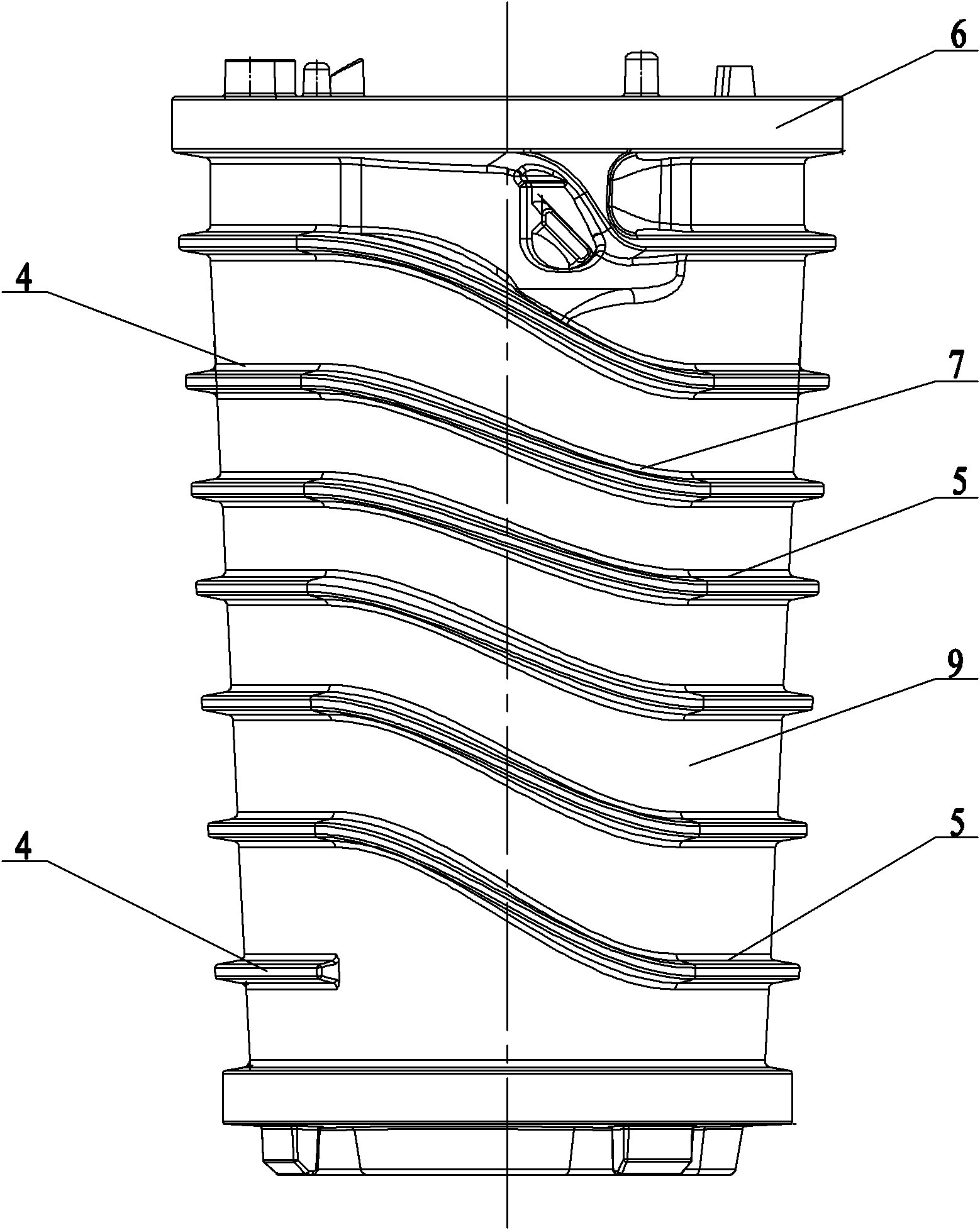

[0012] Such as Figure 1~Figure 3 Shown: the present invention comprises heat exchanger housing 1, water inlet pipe 2, water outlet pipe 3, first positioning block 4, second positioning block 5, combustion chamber 6, third positioning block 7, combustion chamber cavity 8 and transmission Heat medium channel 9.

[0013] Such as figure 1 , figure 2 and image 3 As shown: the heat exchanger housing 1 is provided with a combustion chamber 6 , and the combustion chamber 6 includes a combustion chamber cavity 8 . The outer wall of the combustion chamber 6 is provided with uniformly distributed first positioning blocks 4 and second positioning blocks 5 , and the first positioning blocks 4 and the second positioning blocks 5 are alternately distributed. The corresponding adjacent ends of the first positioning block 4 and the second positioning block 5 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com