Patents

Literature

1475results about How to "Reduce maintenance times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

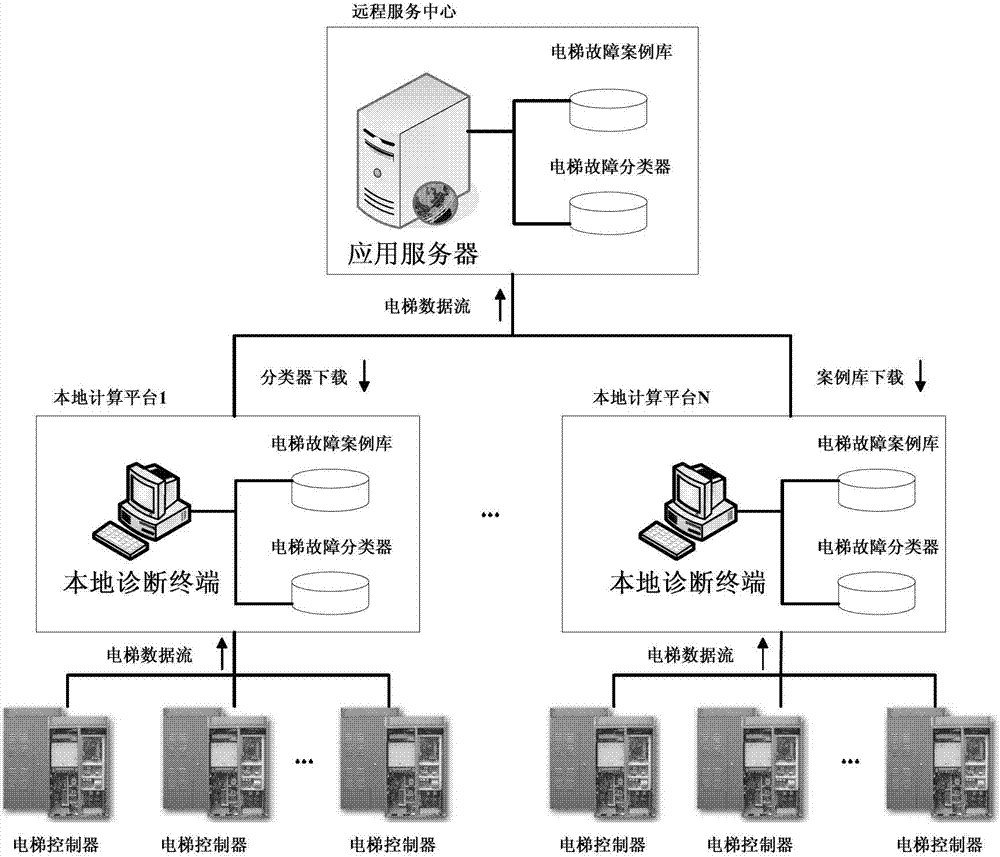

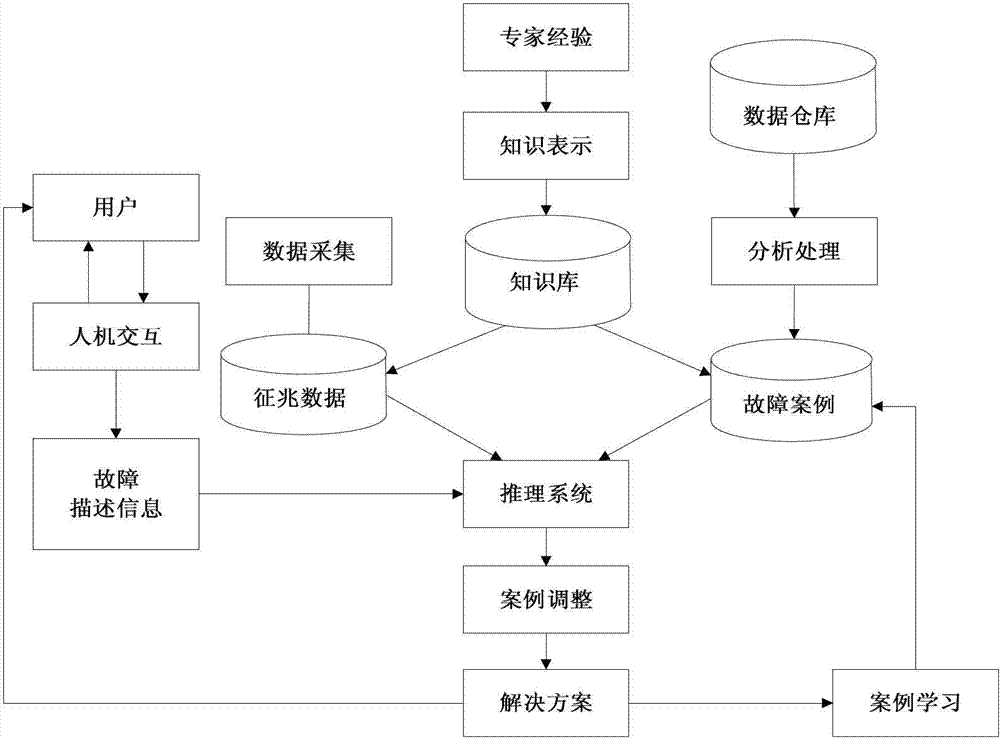

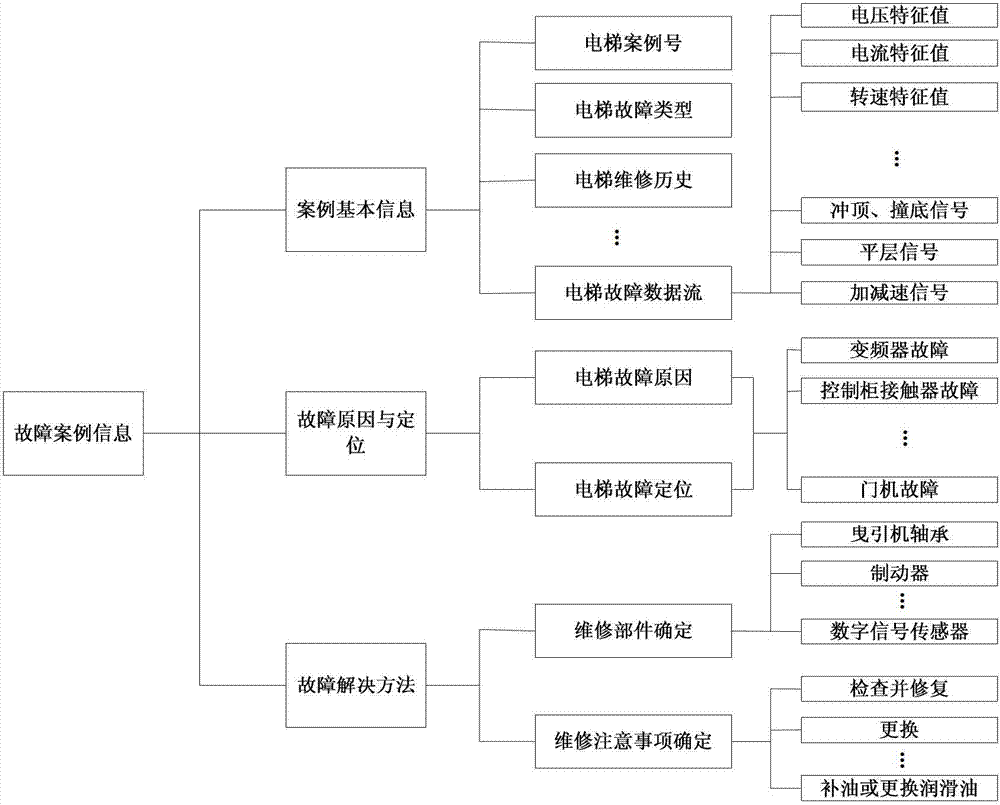

Elevator fault diagnosis and early-warning method based on data drive

InactiveCN102765643AAutomatic acquisitionImprove diagnostic efficiencyElevatorsData streamReliability engineering

The invention relates to the field of elevators. In order to early discover and diagnose A elevator fault, the invention adopts the technical scheme that an elevator fault diagnosis and early-warning method based on data drive is achieved by means of a remote service center, a fault diagnosis and prediction terminal and an elevator controller, and the method comprises the steps as follows: firstly, elevator fault data are mined to obtain characteristic information in an elevator fault data stream, and the mined result is stored in an elevator fault case base of the fault diagnosis and prediction terminal; secondly, an elevator fault knowledge base on the fault diagnosis and prediction terminal is updated by the elevator fault case base; thirdly, the case retrieval is carried out on the characteristic of a new elevator fault problem, and the fault diagnosis is carried out on the elevator system by adopting the fault diagnosis method based on the case-base reasoning; and finally information with the characteristic that is most similar with that of the new elevator fault problem is acquired through retrieval of the knowledge or the case in the elevator fault knowledge base to solve the diagnosis problem. The method is mainly suitable for manufacturing and designing image sensors.

Owner:TIANJIN UNIV

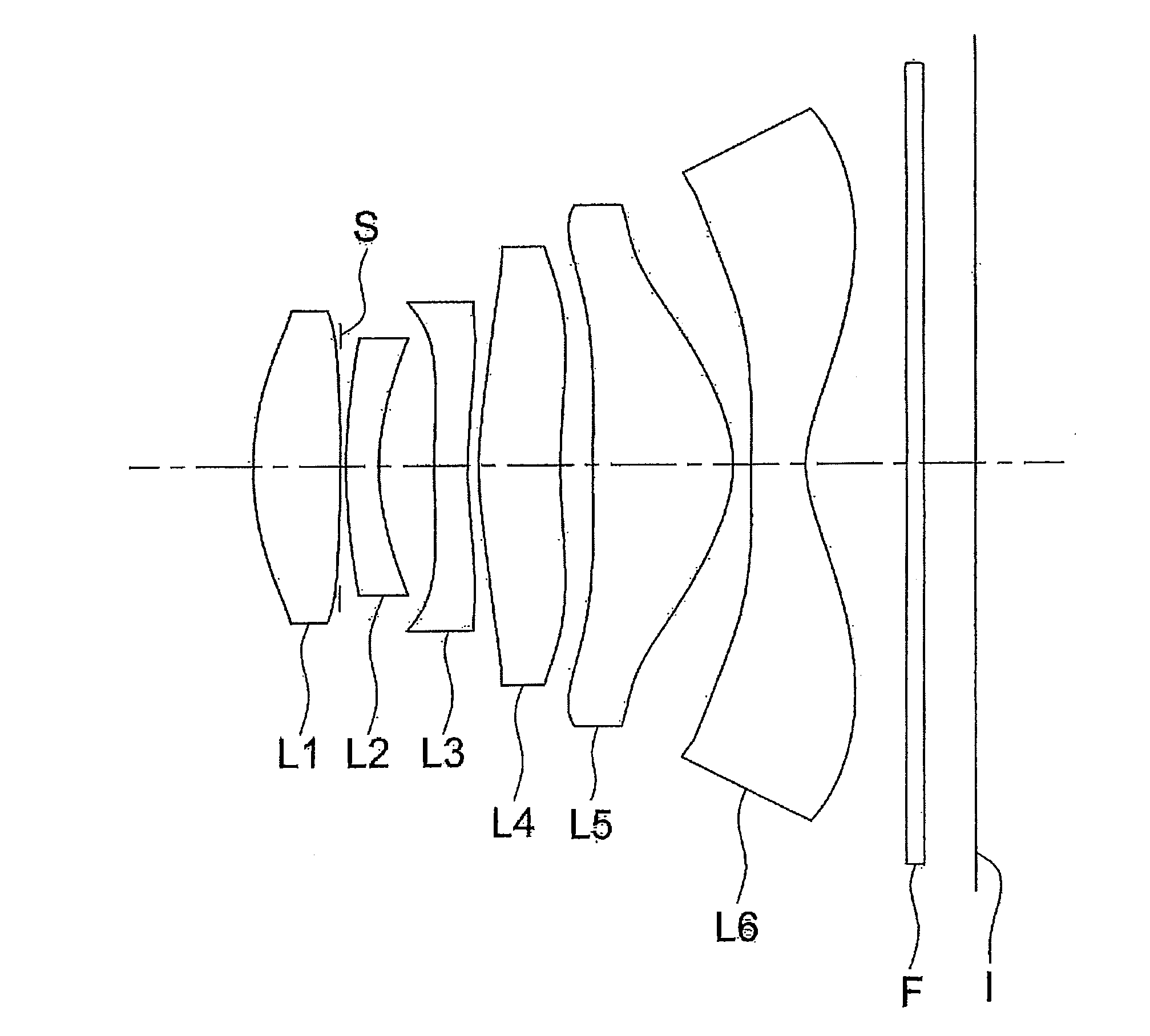

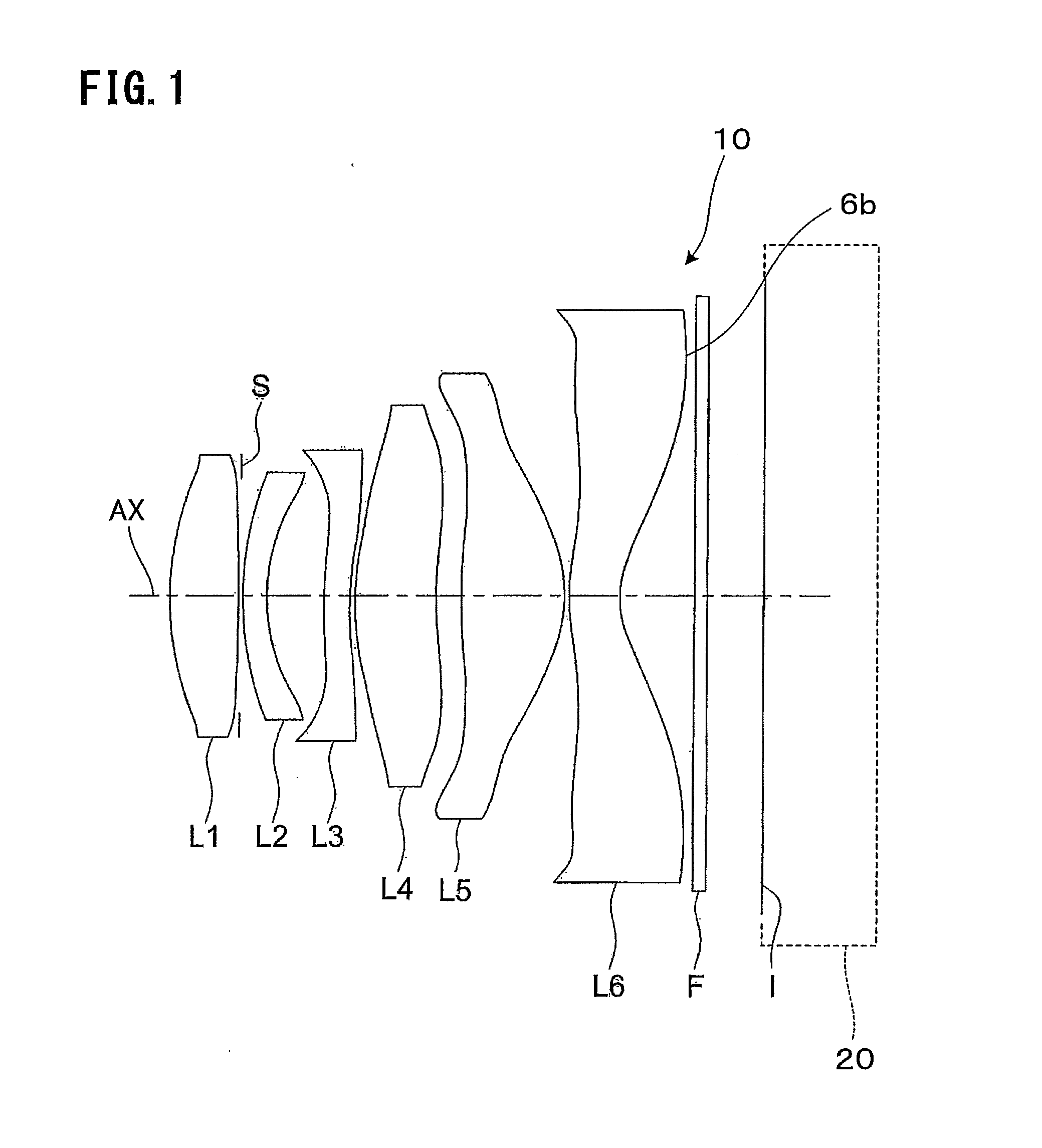

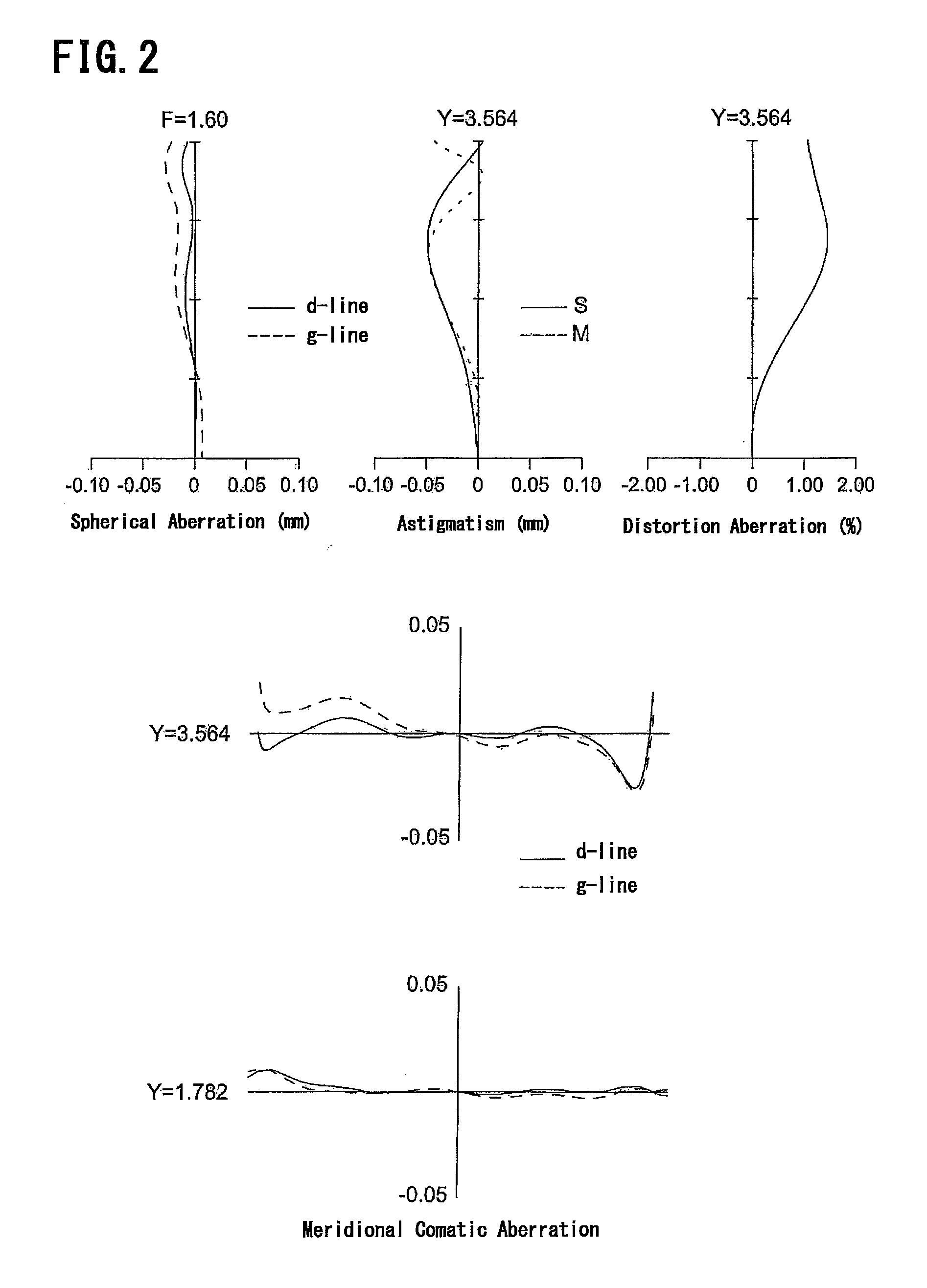

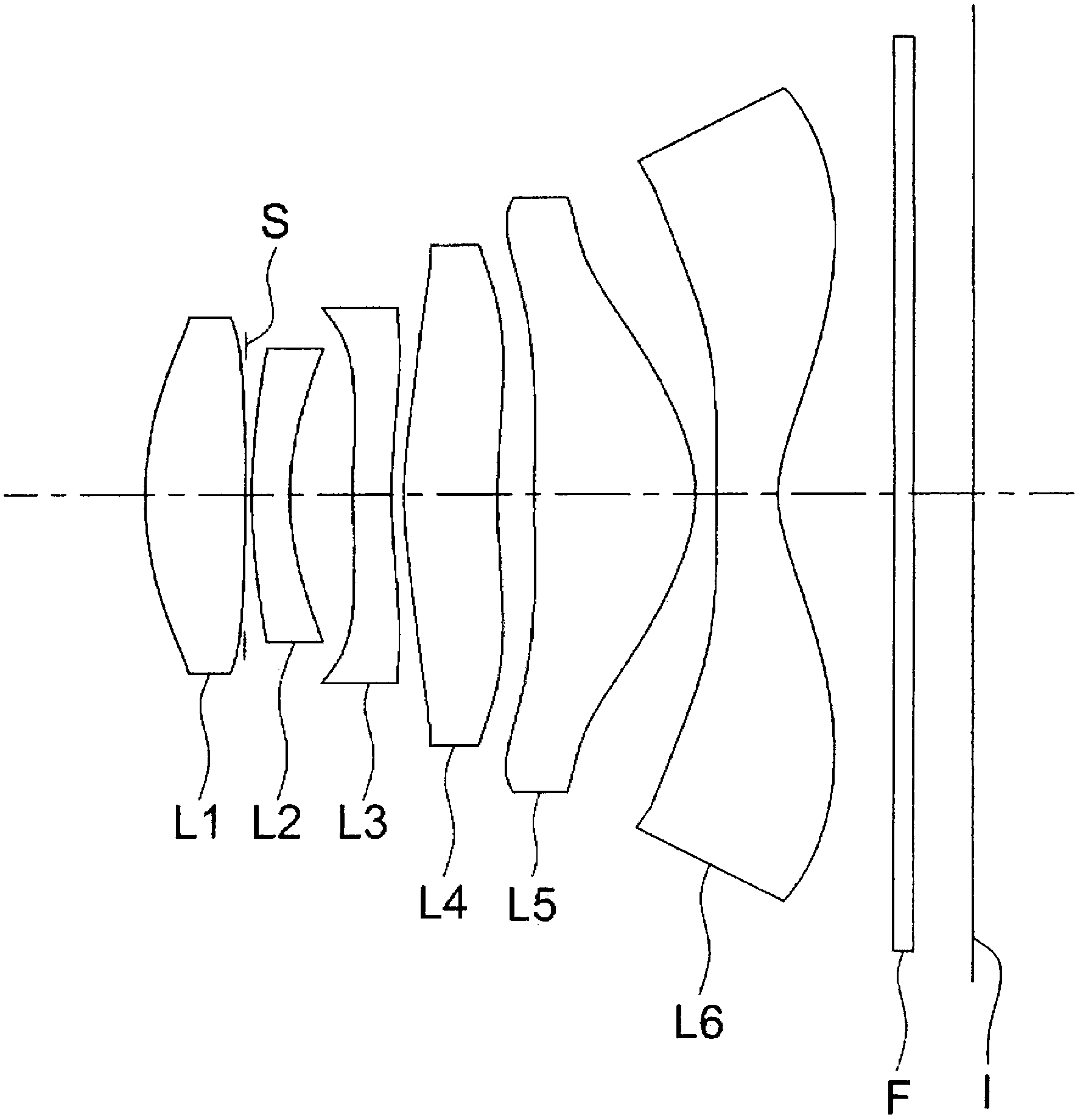

Image Capture Lens

There is provided an image pickup lens having a 6-element structure which has a small size and a sufficiently lens speed of F / 2 or less and in which various aberrations are corrected favorably. This image pickup lens includes a first lens having a positive refractive power and comprising a convex surface directed to the object side; a second lens having a negative refractive power and comprising a concave surface directed to the image side; a third lens having a positive or negative refractive power; a fourth lens having a positive refractive power; a fifth lens having a positive refractive power and comprising a convex surface directed to the image side; and a sixth lens having a negative refractive power and comprising a concave surface directed to the image side, in this order from the object side, wherein the image side surface of the sixth lens has an aspherical shape and an inflection point at a position other than an intersection point with the optical axis, and the image pickup lens satisfies the following conditional expressions.ν1>50ν2≦30where,ν1 is an Abbe number of the first lens, andν2 is an Abbe number of the second lens.

Owner:KONICA MINOLTA OPTO

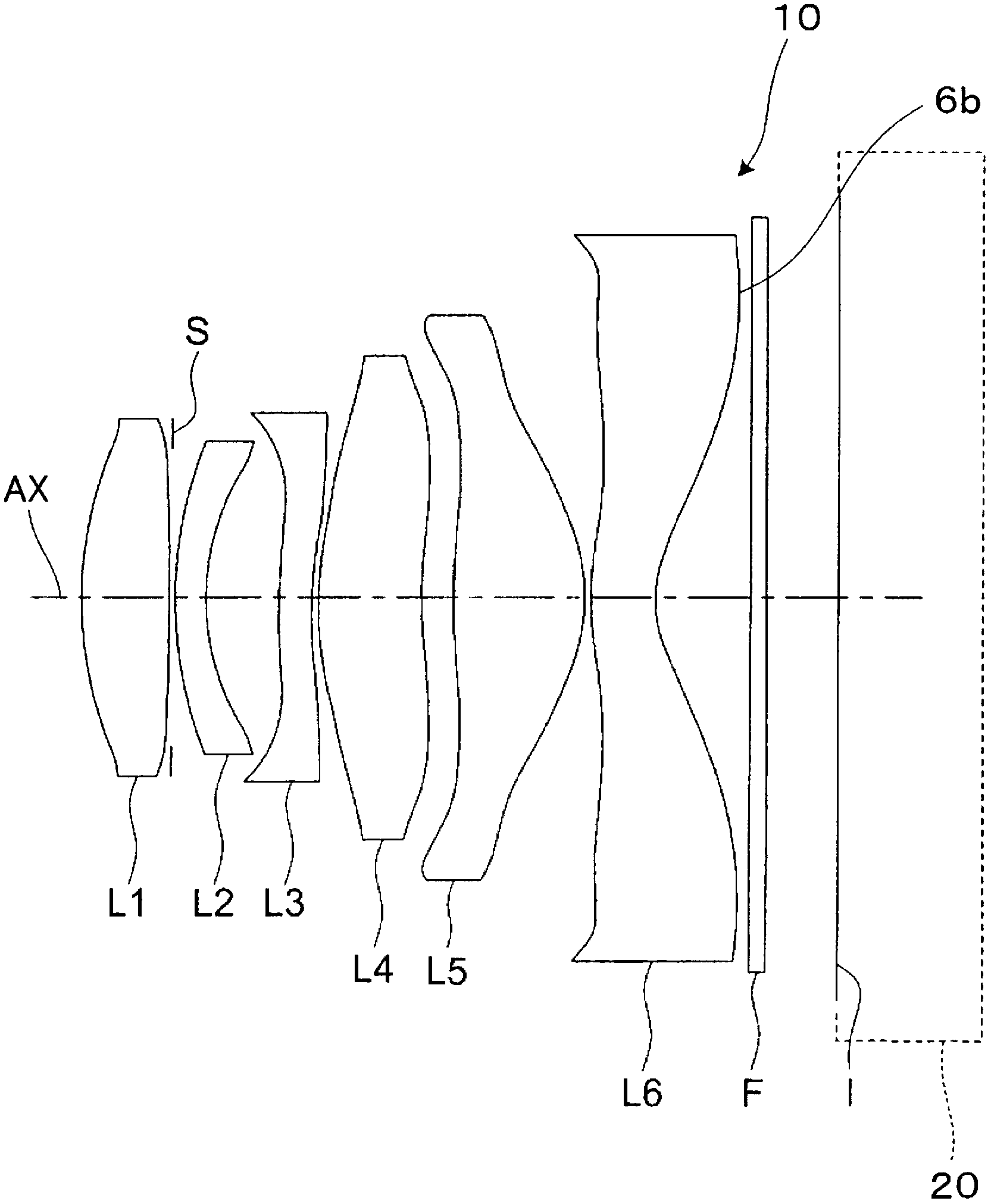

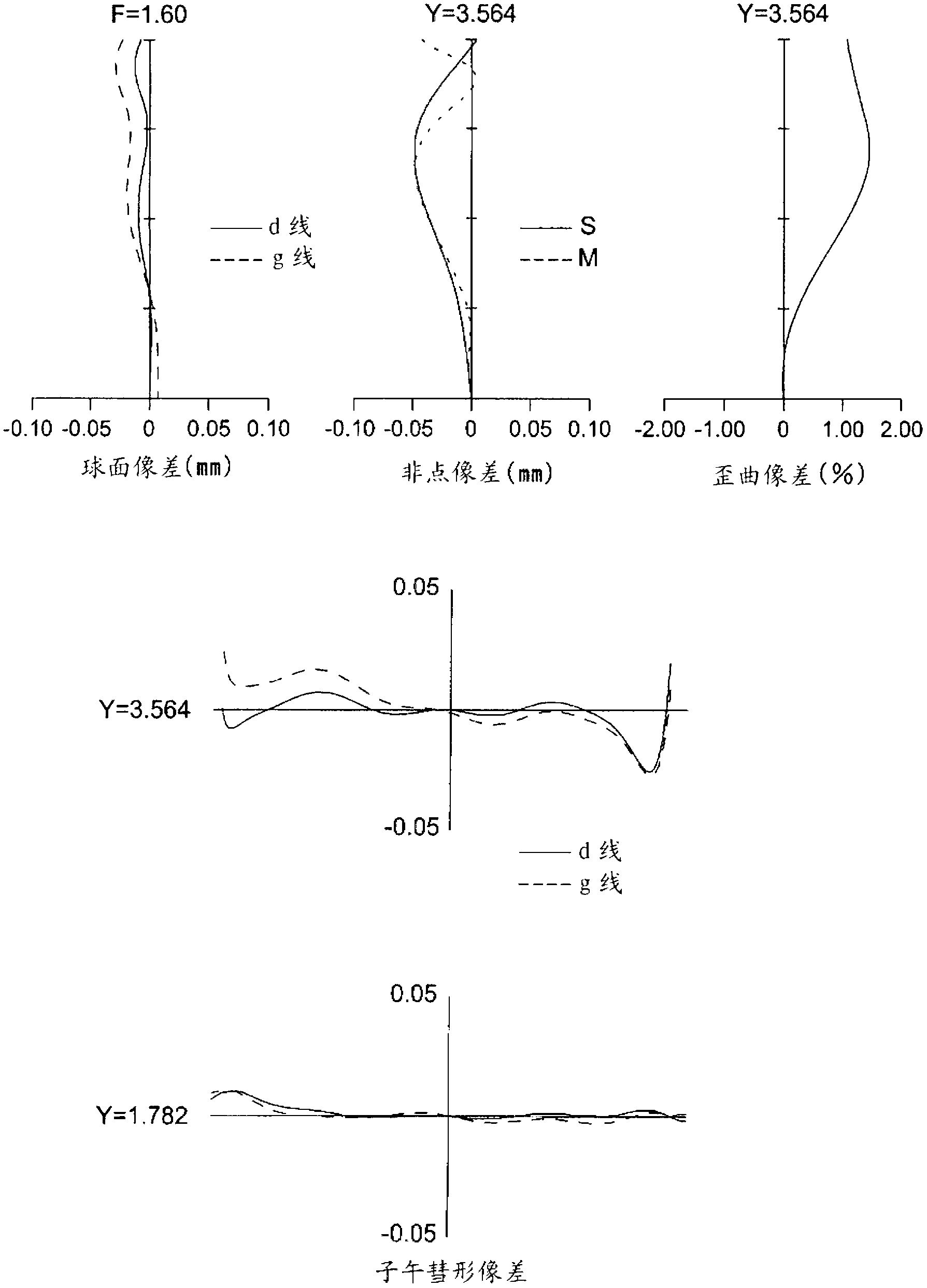

Image capture lens

ActiveCN102985865ASmall outer diameterInhibition lossTelevision system detailsLensNegative refractionCamera lens

Provided is a six-layer configuration image capture lens that is compact and has adequate light at F2 or less, and wherein all aberrations are effectually corrected. In order from the object side, the image capture lens is configured of a first lens having a positive refraction and with a convex face oriented toward the object side; a second lens having a negative refraction and with a concave face oriented toward the imaging side; a third lens having either a positive or a negative refraction; a fourth lens having a positive refraction; a fifth lens having a positive refraction and with a convex face oriented toward the imaging side; and a sixth lens having a negative refraction and with a concave face oriented toward the imaging side. The imaging side face of the sixth lens further comprises an aspherical face shape, has an inflection point in a location other than a point of intersection with the optical axis, and satisfies the following formulae: ? d1 > 50, and ? d2 = 30, wherein ? d1 is the Abbe's number of the first lens, and ? d2 is the Abbe's number of the second lens.

Owner:KONICA MINOLTA INC

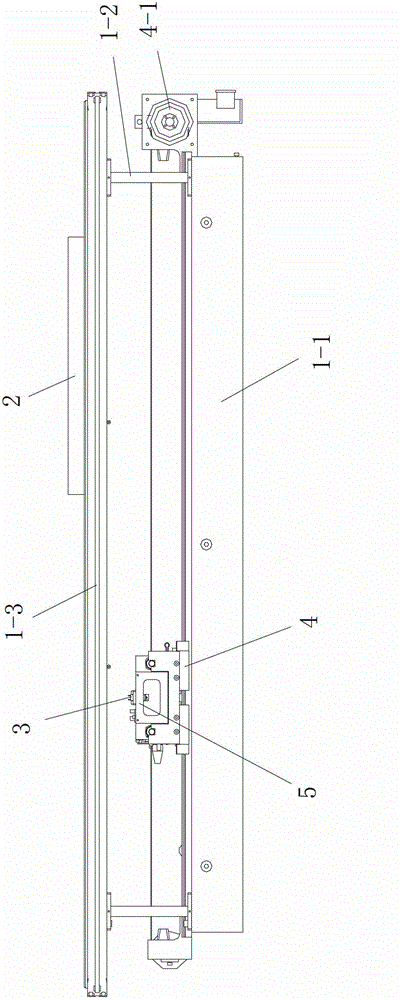

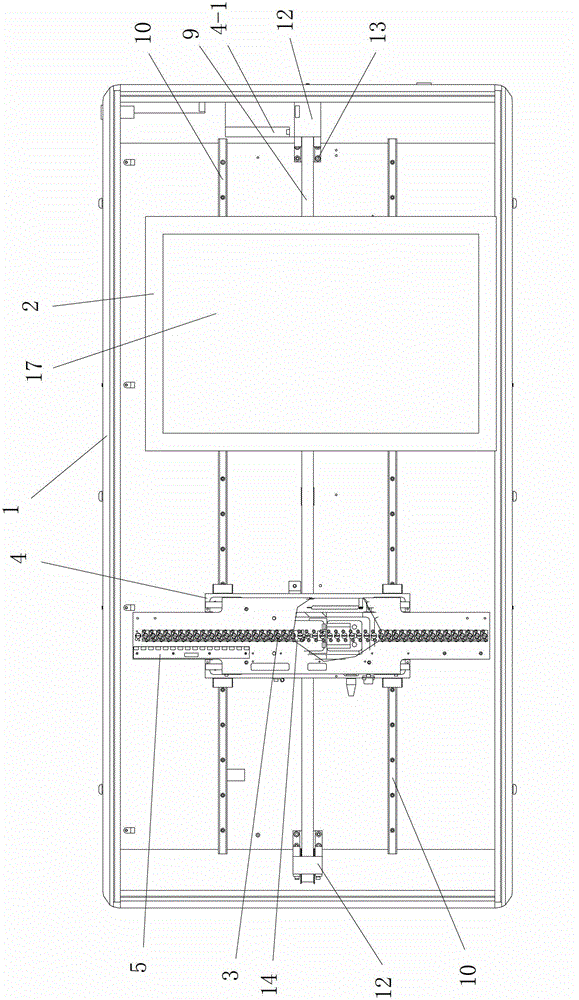

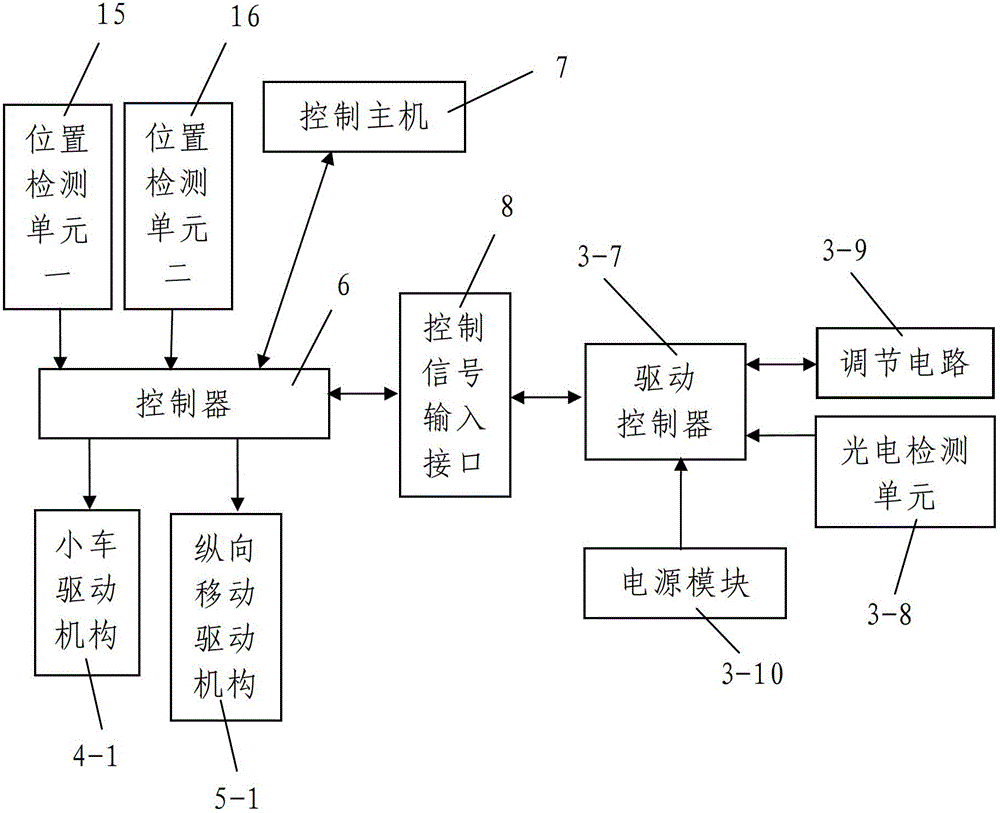

Laser direct plate marking device for plane screen print plate and device

ActiveCN103149801ASimple structureReasonable designPhotomechanical exposure apparatusMicrolithography exposure apparatusScreen printingEngineering

The invention discloses a laser direct plate marking device for a plane screen print plate and device. The device comprises a screen frame for screen printing, a screen mesh stretched on the screen frame for screen printing, wherein the bottom of the screen mesh is coated with a photosensitive material coating, an optical component arranged below the screen frame for screen printing and used for performing exposure treatment on the photosensitive material coating, a scanning trolley for driving the optical component to reciprocate on the horizontal surface, and a longitudinal moving member for driving the optical component to shuttle on the horizontal surface; and the optical component comprises a plurality of lasers arranged on the same horizontal surfaces, the plurality of lasers are arranged on the same straight line parallel to a longitudinal central line of a rectangular screen frame from front to the back. The method comprises the following steps of confirming a control parameter of a mechanical structure, confirming a control parameter of a laser, and exposure imaging. The device disclosed by the invention is reasonable in design, low in investment cost, simple for use and operation, good in use effect, and wide in application range, and can be used for finishing the print plate manufacturing process of a screen frame in different sizes.

Owner:深圳市先地图像科技有限公司 +2

Online monitoring and condition maintenance management system

InactiveCN102436226AImprove power supply reliabilityImprove economyTotal factory controlProgramme total factory controlData centerElectric power system

The invention relates to an online monitoring and condition maintenance management system, which is a layered and distributed data management and computer system, faces to a plurality of substation high-voltage equipment and adopts a multi-server level-to-level management system. The online monitoring and condition maintenance management system comprises an online monitoring equipment layer, a substation data network layer and a remote data center. By constructing and applying the management system, the online monitoring system is promoted to be transitioned to an all-round, networked, intelligent and comprehensive condition monitoring, diagnosis and service management system from the traditional isolated and static experimental system. The system provides a powerful technical supporting platform for overcoming periodic maintenance blindness, reducing maintenance times, reducing maintenance expenses, delaying maintenance cycle to the utmost extent, truly realizing condition maintenance for power system operation and management departments and further improving the operation rate of the equipment and the safety of power grids.

Owner:文存润 +1

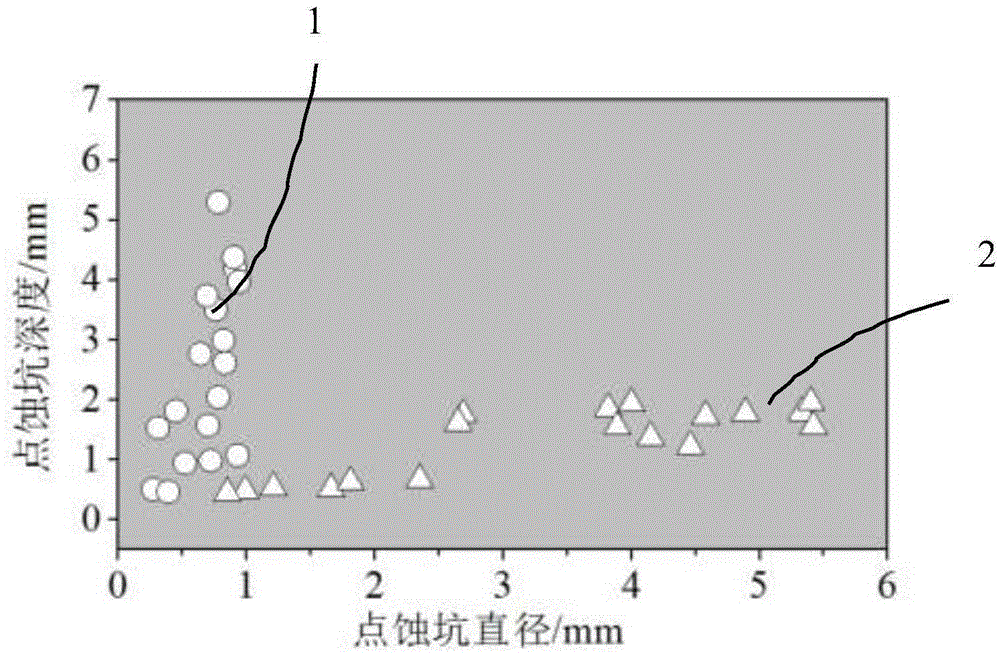

Grounding grid corrosion rate level prediction method

InactiveCN103136539AEasy to handleNovel and reasonable designCharacter and pattern recognitionGrounding gridData set

The invention discloses a grounding grid corrosion rate level prediction method which comprises the following steps: (1) inputting training sample data; (2) randomly sampling training samples according to a bootstrap sampling principle in a Bagging algorithm, forming training sample bootstrap subsets with the number of M, and constituting training sample bootstrap subset data sets; (3) structuring a weak classifier model according to a k-nearest neighbor (KNN) algorithm, sequentially training the training sample bootstrap subsets with the number of M, and obtaining weak classifiers with the number of M; (4) structuring a strong classifier model according to an Adaboost algorithm; (5) inputting to-be-tested sample data, predicting a grounding grid corrosion rate level, obtaining a predicting result, and displaying the predicting result through a displayer. The grounding grid corrosion rate level prediction method has the advantages of being novel and reasonable in design, convenient and fast to use and operate, high in predicting precision, capable of achieving an accurate prediction to the grounding grid corrosion rate level by means of a small amount of data samples which are measured in the prior art, low in implementation cost, strong in practicability and high in value of popularization and application.

Owner:XIAN UNIV OF SCI & TECH

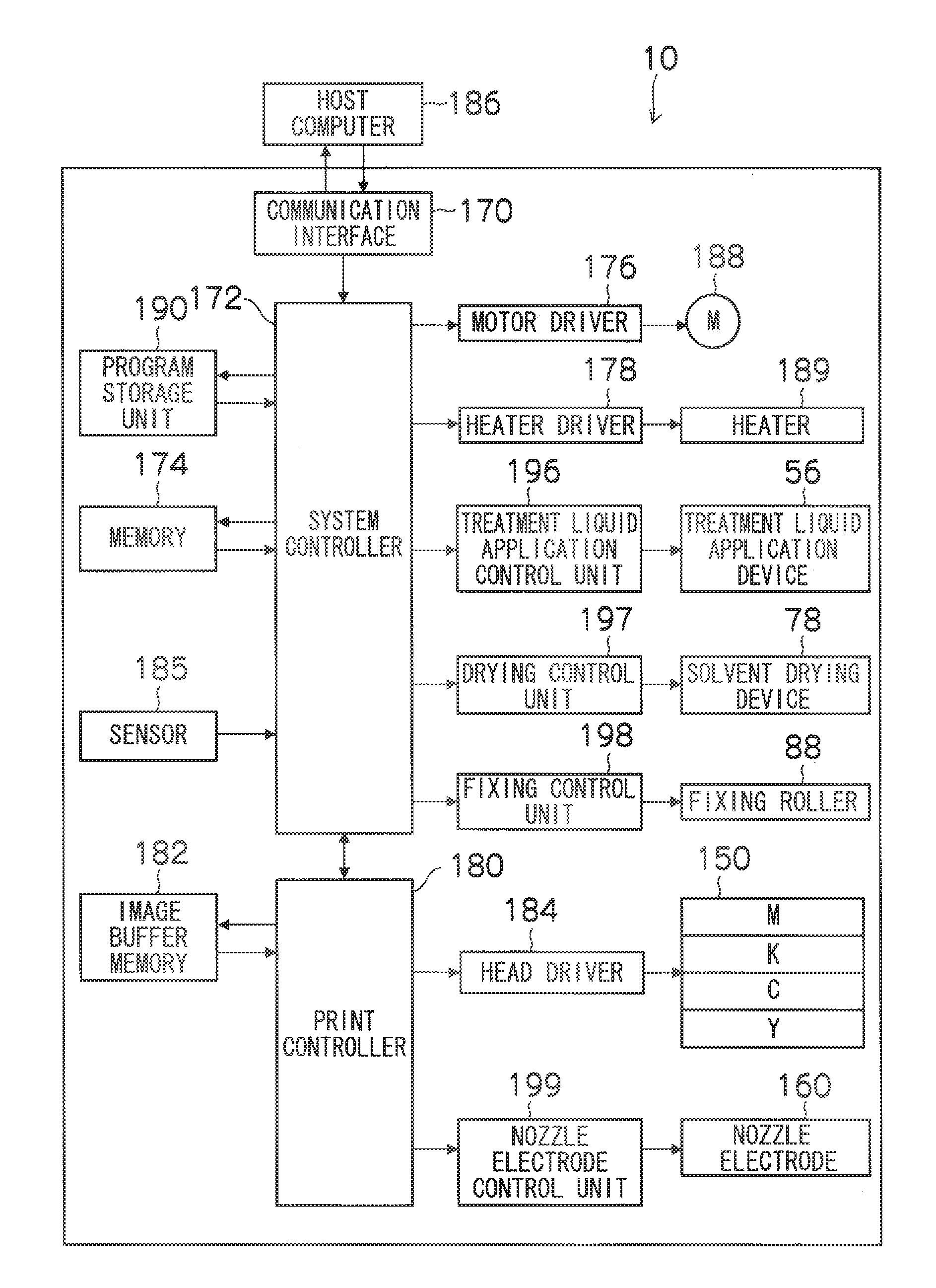

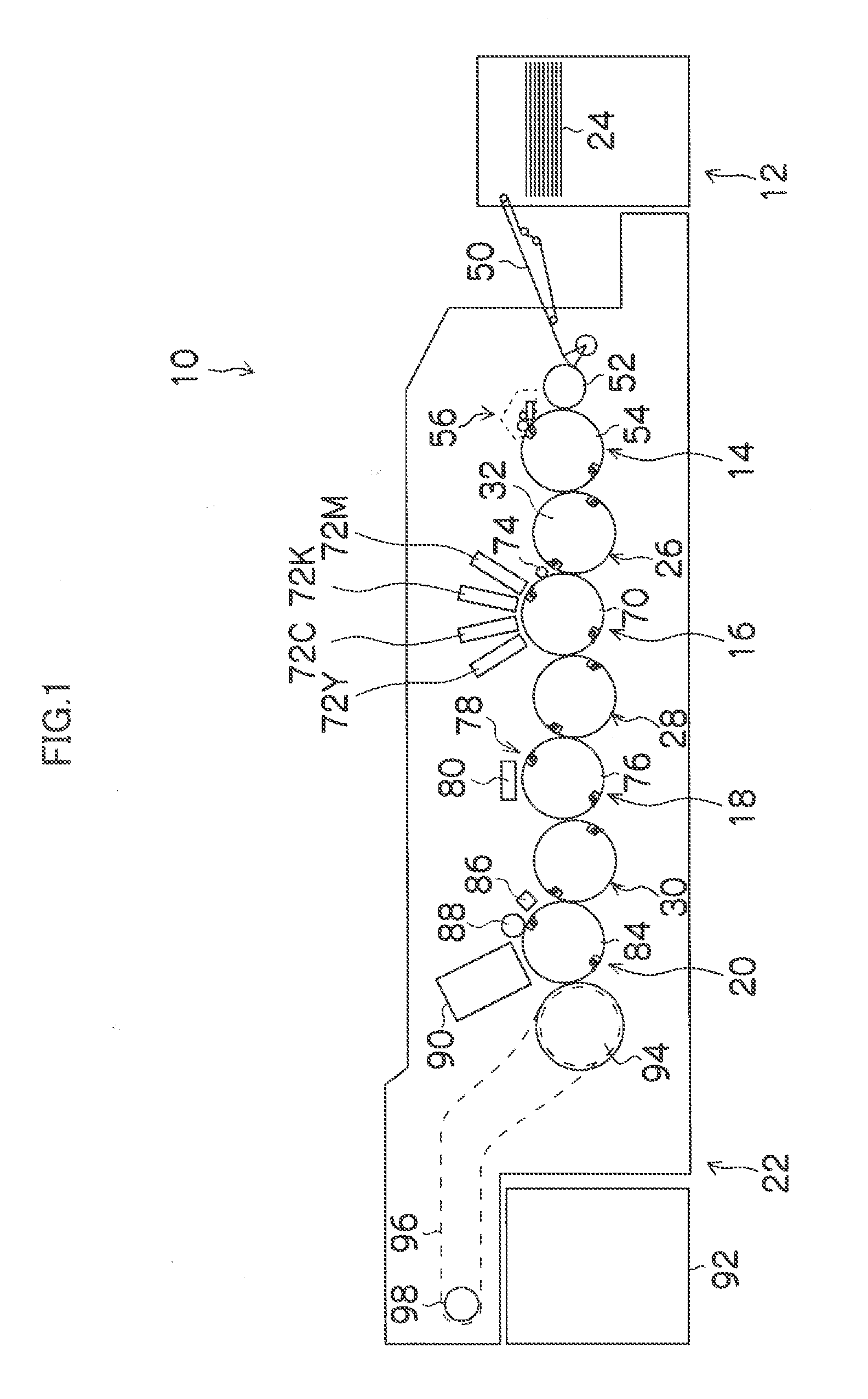

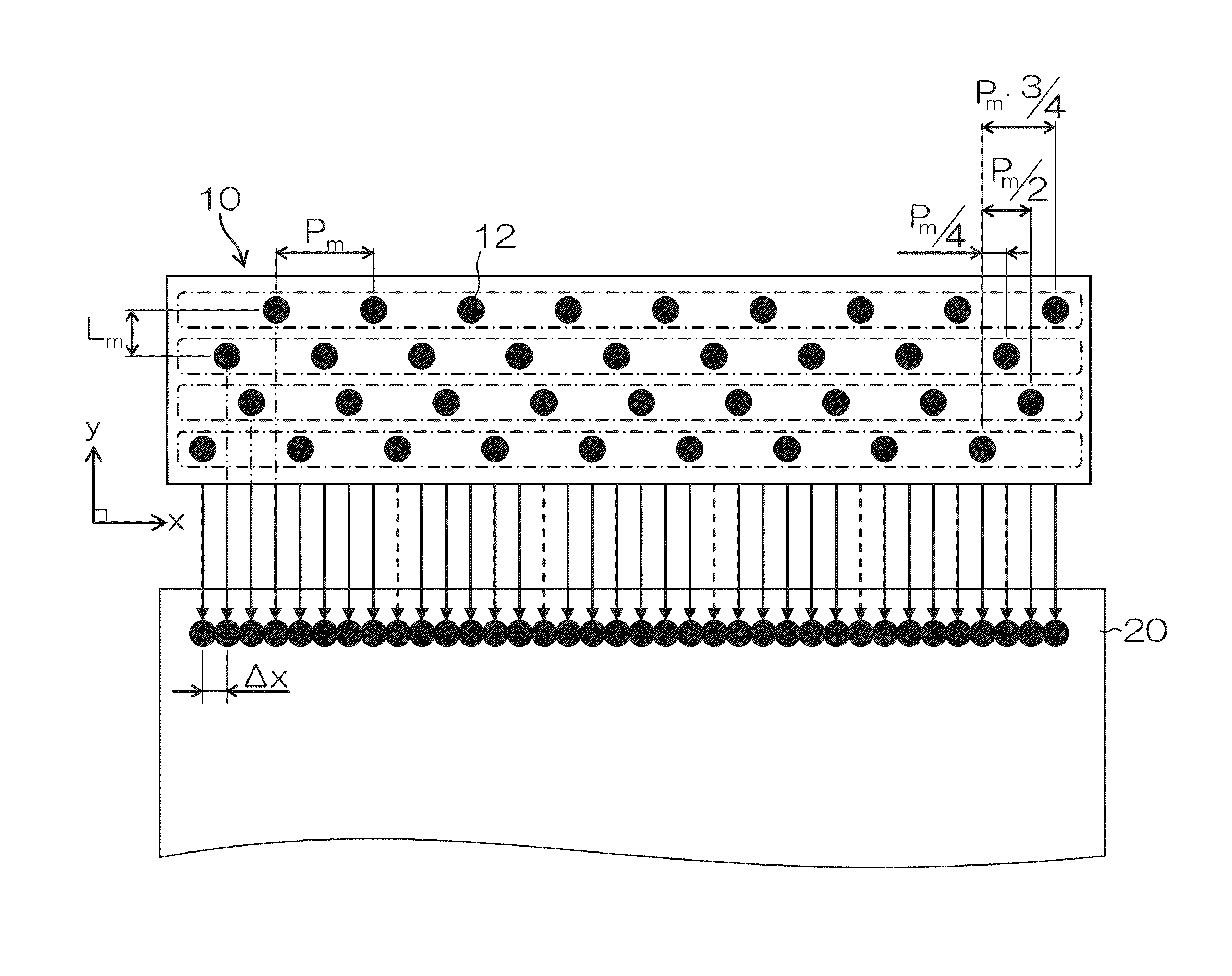

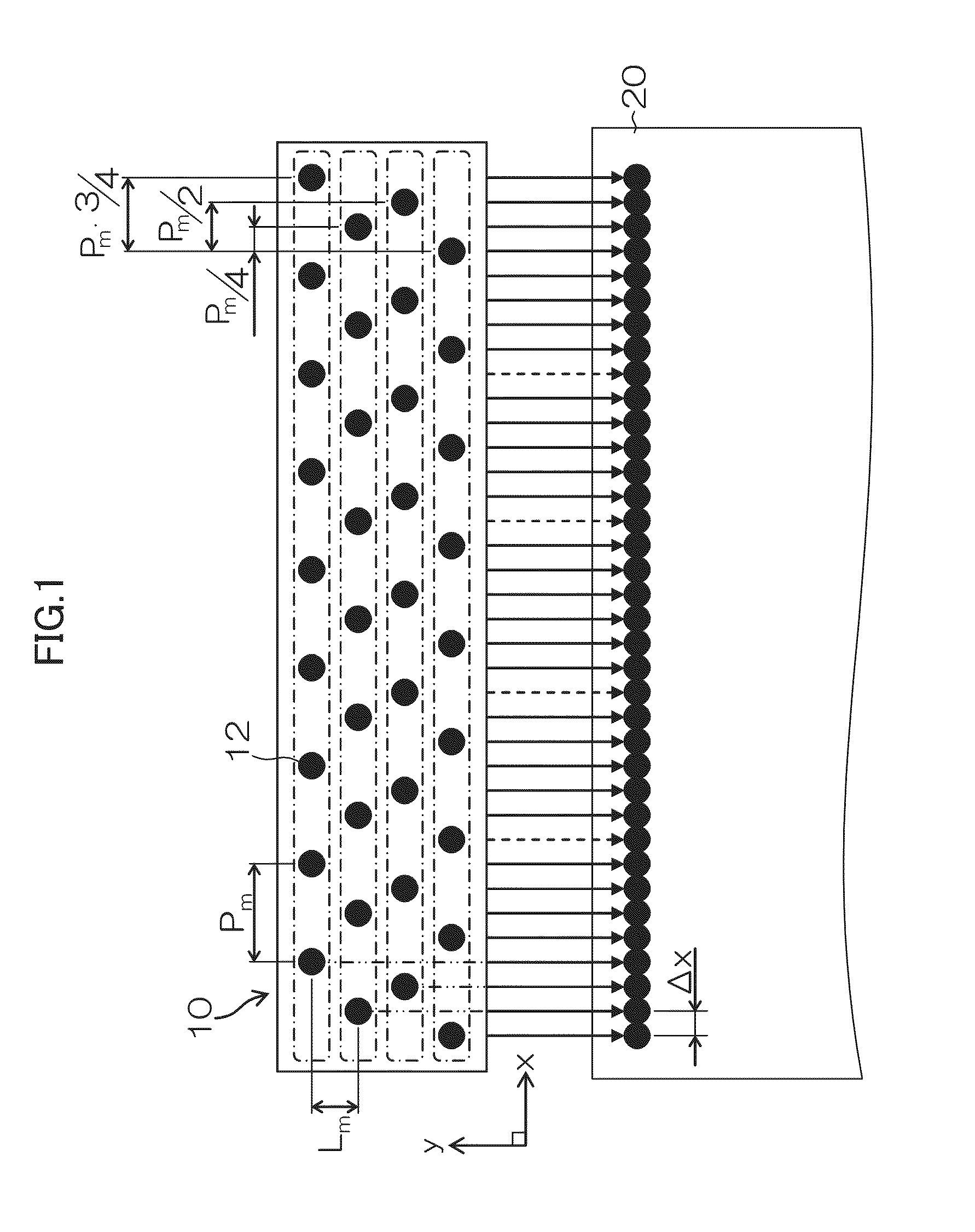

Image Forming Apparatus And Mist Recovery Method

InactiveUS20100231623A1Reduce maintenance timesAvoid stickingInking apparatusOther printing apparatusRecovery methodImage formation

The image forming apparatus includes: an inkjet head of an on-demand ejection type having a nozzle plate in which a nozzle electrode is arranged in a vicinity of a nozzle through which liquid is ejected; and a voltage application device which makes a polarity of the nozzle electrode one of positive and negative in accordance with a start of an ejection operation of the liquid, and then switches the polarity of the nozzle electrode to an opposite polarity to the one of positive and negative in accordance with a timing of ejecting the liquid through the nozzle.

Owner:FUJIFILM CORP

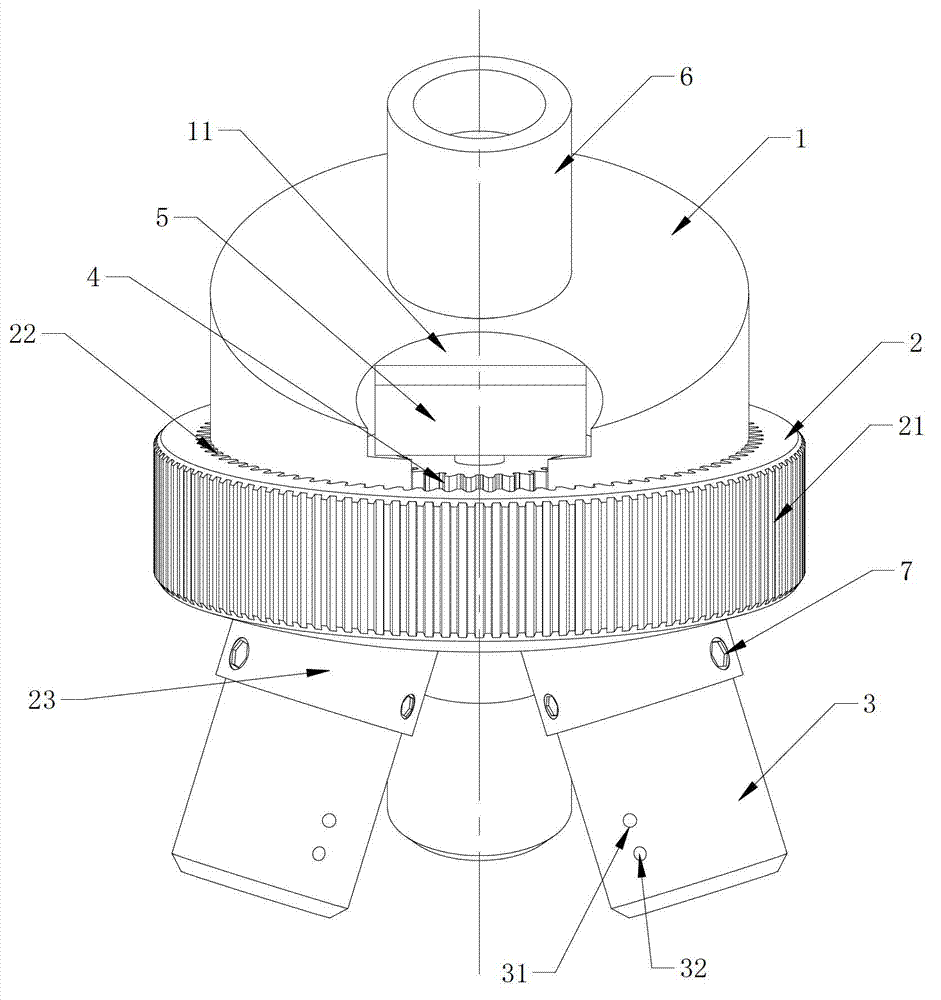

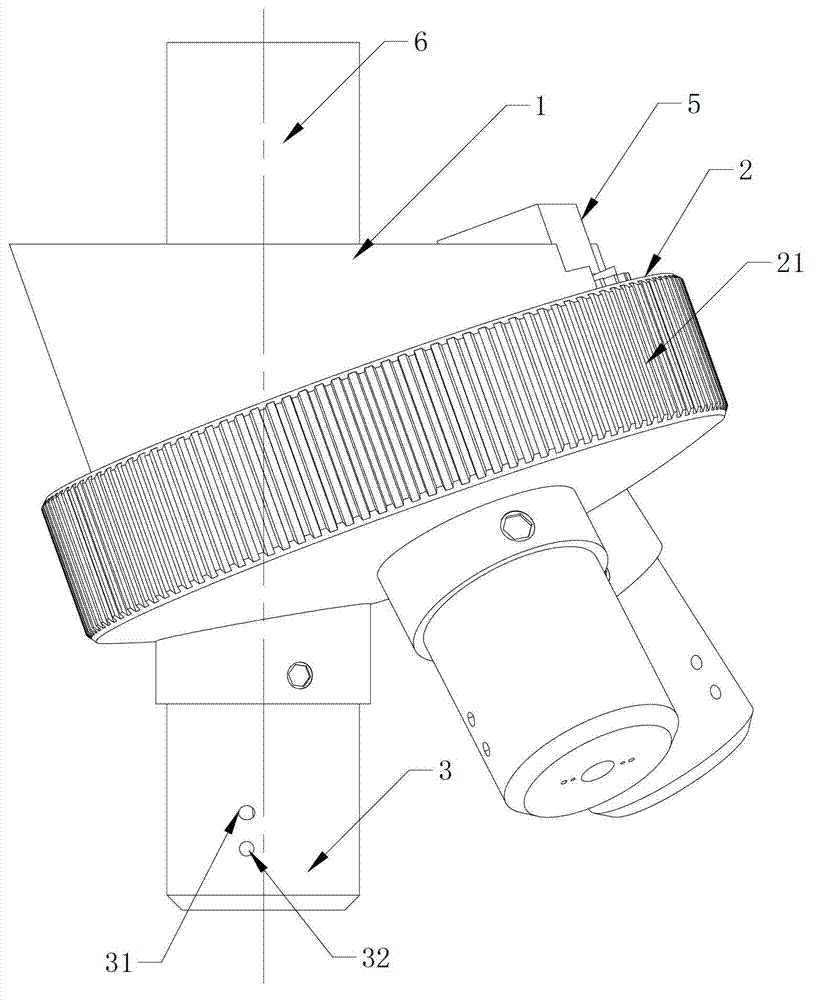

Laser 3D (three-dimensional) printing device with multiple inkjet heads

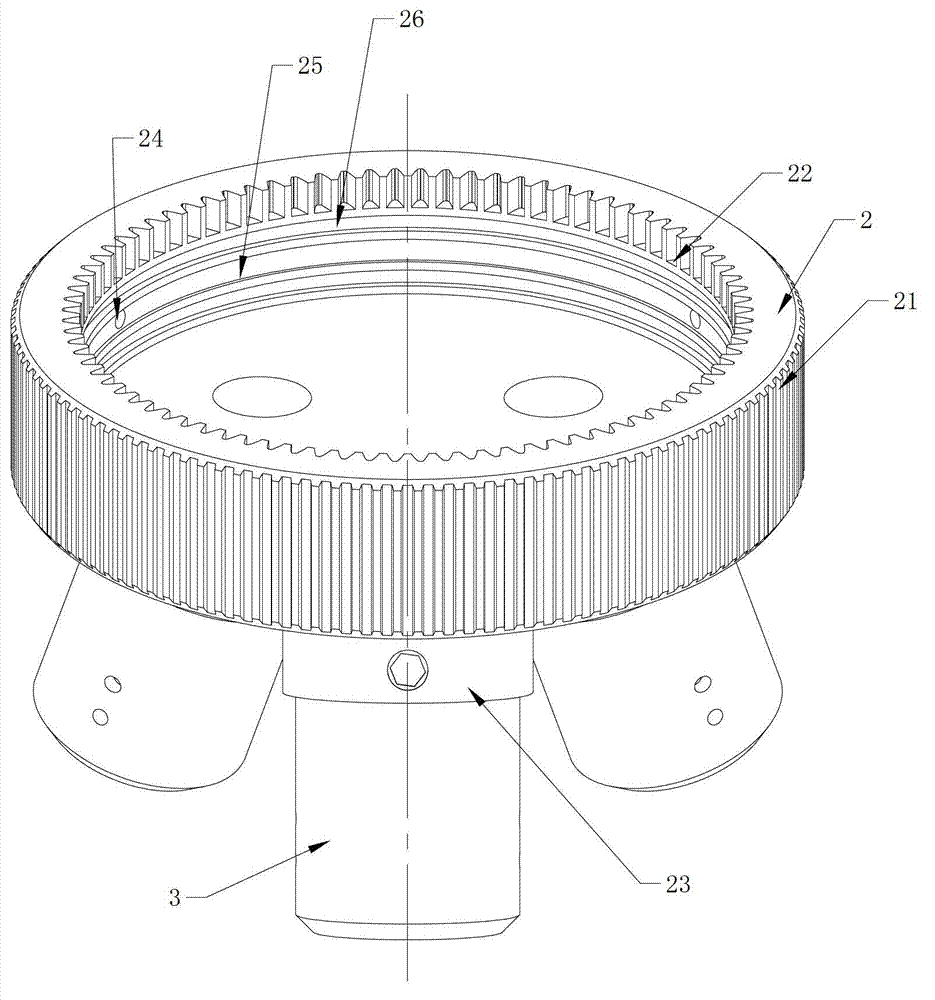

The invention discloses a laser 3D printing device with multiple inkjet heads. The laser 3D printing device with multiple inkjet heads includes a laser generator, a laser inkjet head, a mechanical arm and a working table, wherein the laser inkjet head includes a laser head and a power inkjet head assembly, the power inkjet head assembly comprises a connecting base, a rotating disc and at least two power inkjet heads, the rotating disc is sleeved outside the periphery of the connecting base, the connecting base is provided with a laser through hole which is coaxially communicated with a laser jet hole of the laser head, the at least two power inkjet heads are detachably arranged on the rotating disc and are distributed relative to the periphery of the rotating center of the rotating disc, any power inkjet head is coaxially communicated with the laser jet hole when rotating to a working station, and a fixing unit is arranged between the rotating plate and the connecting base. The laser inkjet head of the laser 3D printing device with the multiple inkjet heads is provided with a plurality of powder inkjet heads and the plurality of powder inkjet heads can be used alternately so that the laser 3D printing device can use a plurality of metal powers to print under the condition that the laser inkjet head is not changed, and the laser 3D printing device meets the 3D printing requirements of FGM (Functionary Gradient Materials) metal pieces.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Large-scale computer fixing base with shock-absorption function

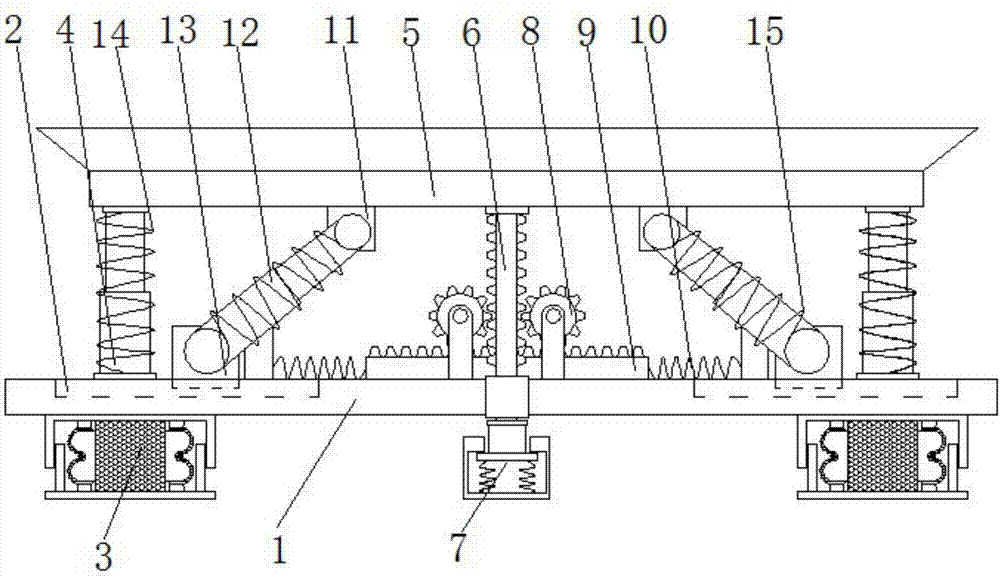

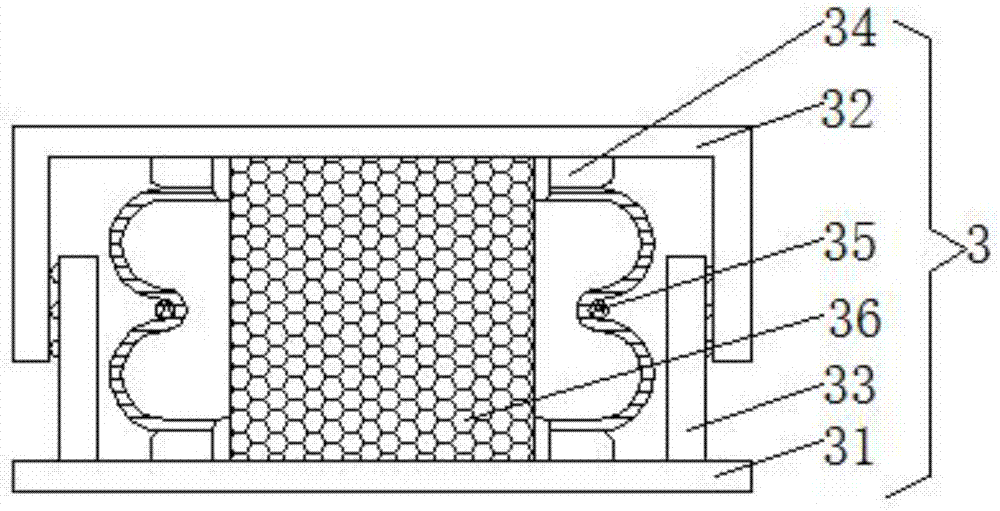

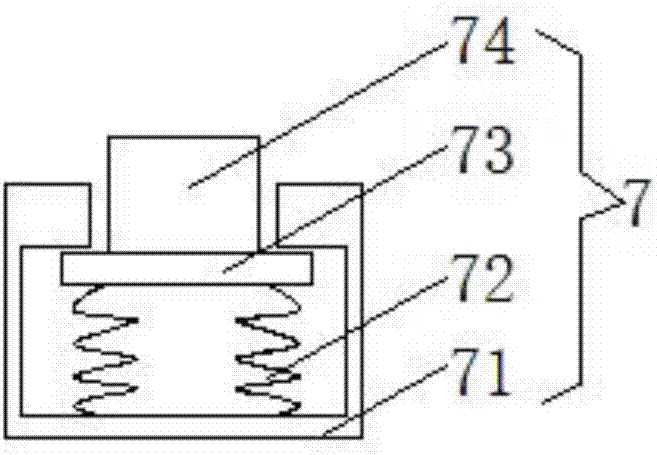

InactiveCN107299958AFix damageNot easy to damageNon-rotating vibration suppressionDigital data processing detailsMainframe computerAbsorption effect

The invention discloses a large-scale computer fixing seat with a shock absorbing function, which comprises a load bearing plate. Both sides of the top of the load bearing plate are provided with slide grooves, and both sides of the bottom of the load bearing plate are fixedly connected with shock absorbing devices. Both sides are fixedly connected with a first telescopic rod, the top of the first telescopic rod is fixedly connected with a fixed plate, and the middle of the bottom of the fixed plate is fixedly connected with a double rack, and the bottom of the double rack runs through the load-bearing plate and extends to the bottom of the load-bearing plate , The present invention relates to the field of computer technology. The large-scale computer fixing seat with shock-absorbing function solves the problem that the current large-scale computer has a poor shock-absorbing effect and is easy to cause damage to the computer during the moving process, prolongs the service life of the computer, and ensures the normal operation of the computer. operation, to avoid causing huge economic losses to people, the computer is not easy to be damaged, and the maintenance times are reduced.

Owner:合肥雷呈信息技术有限公司

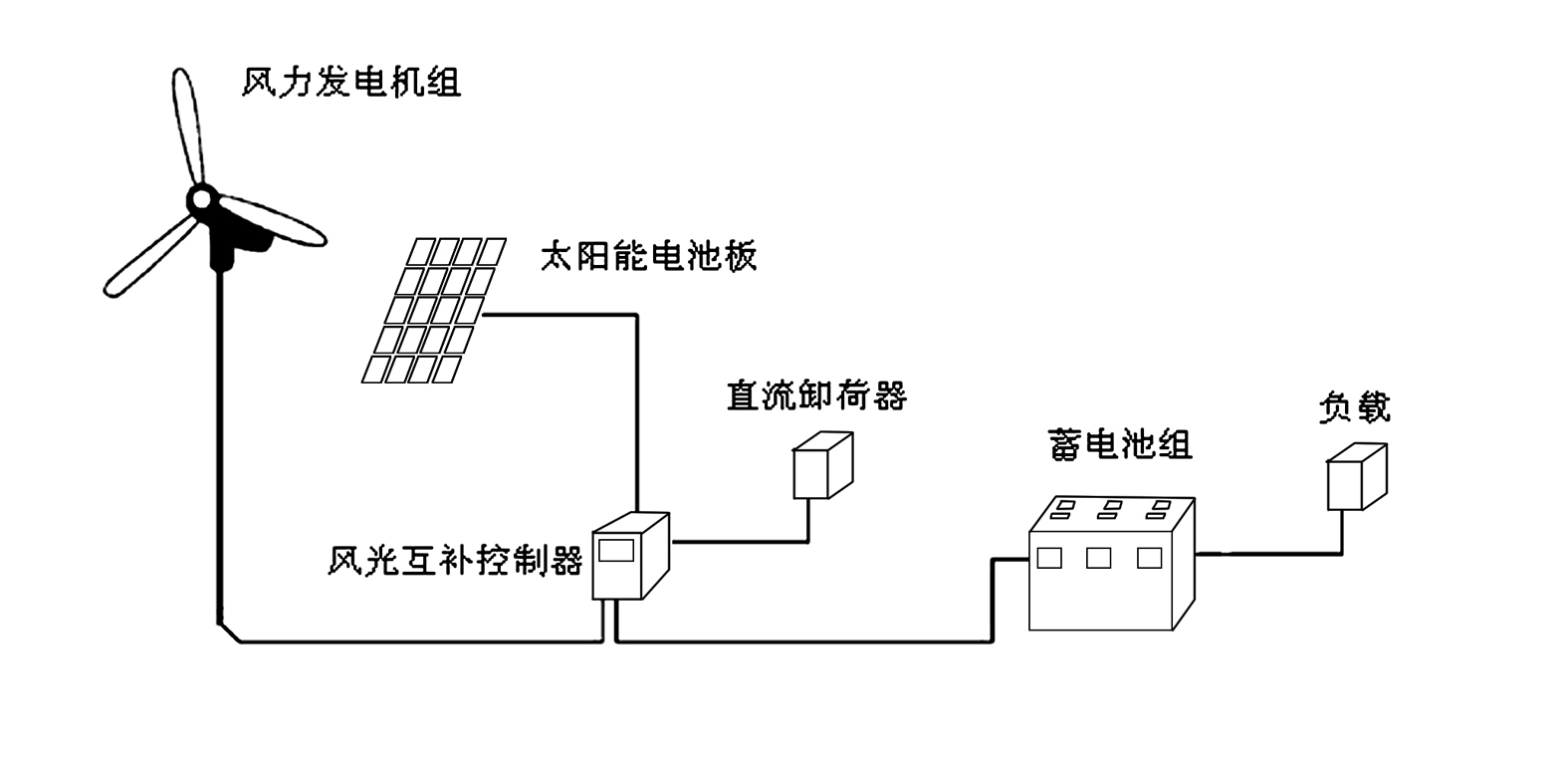

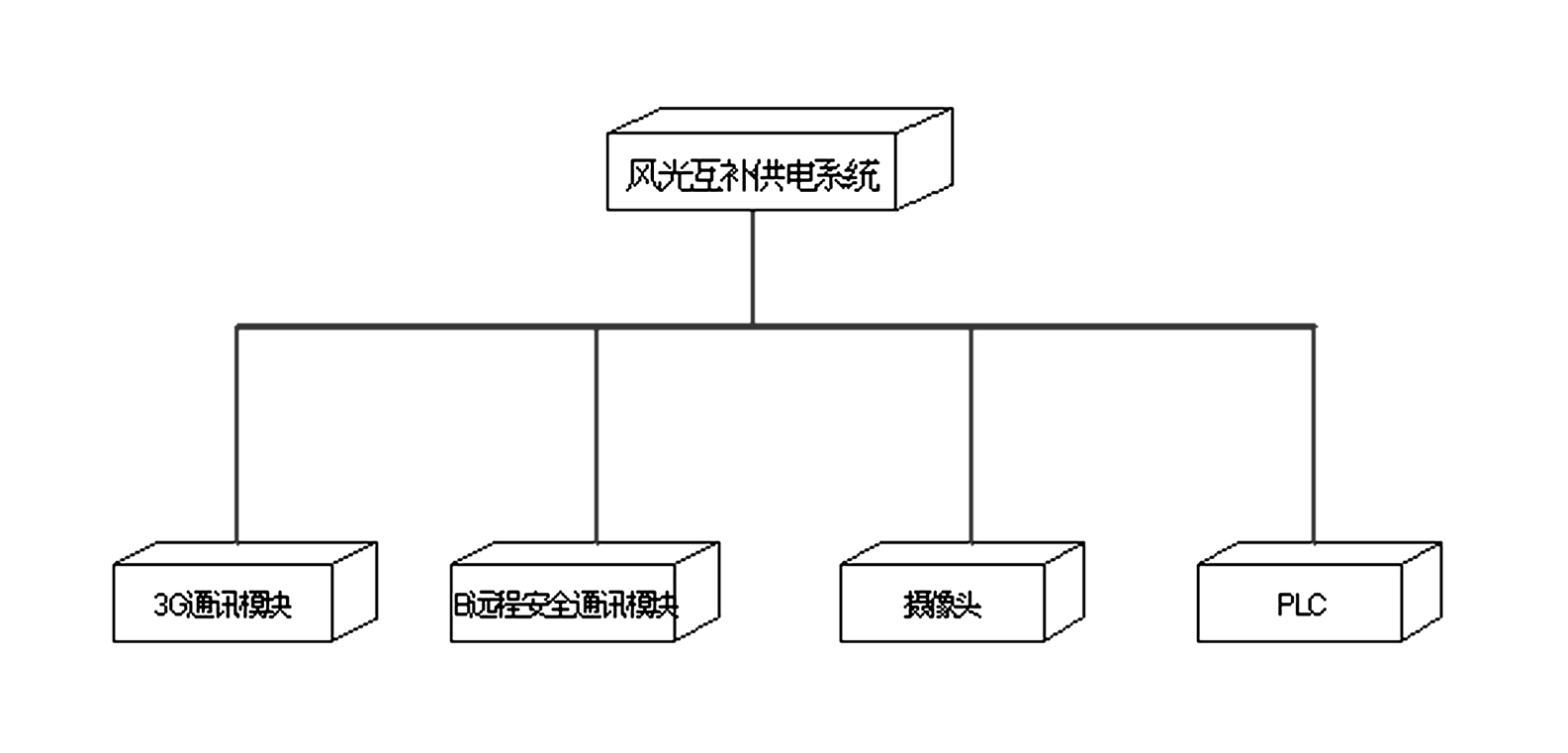

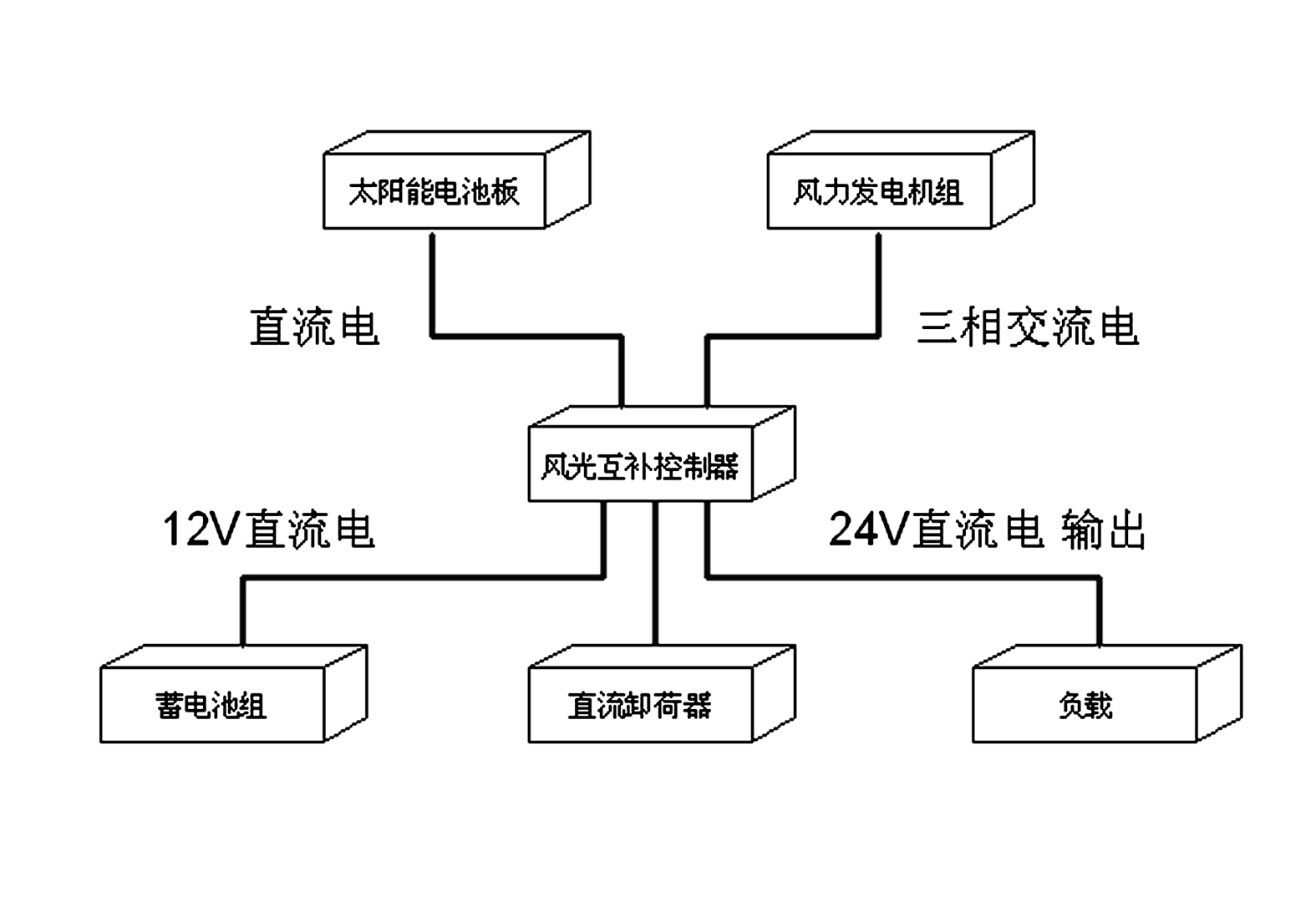

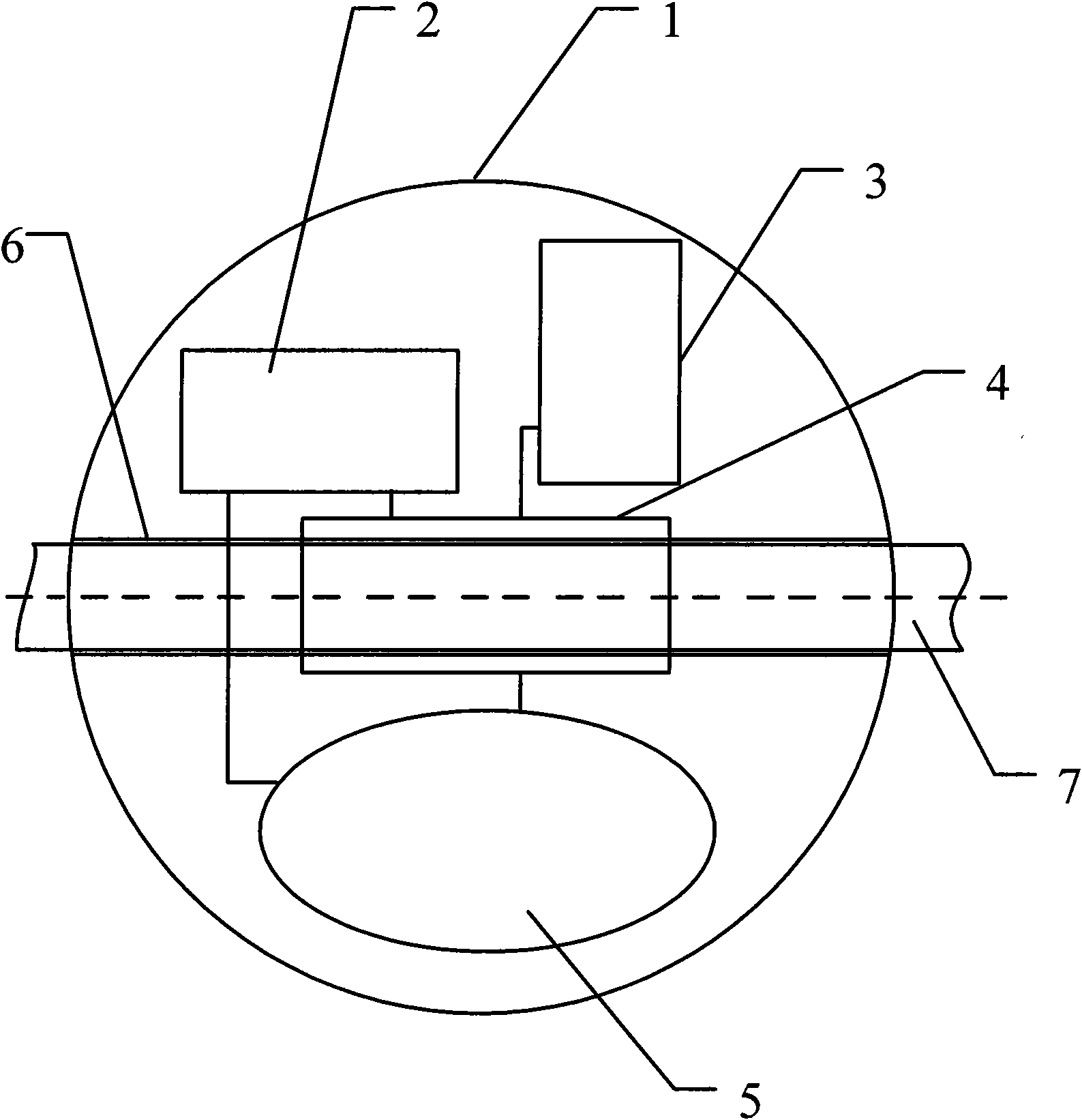

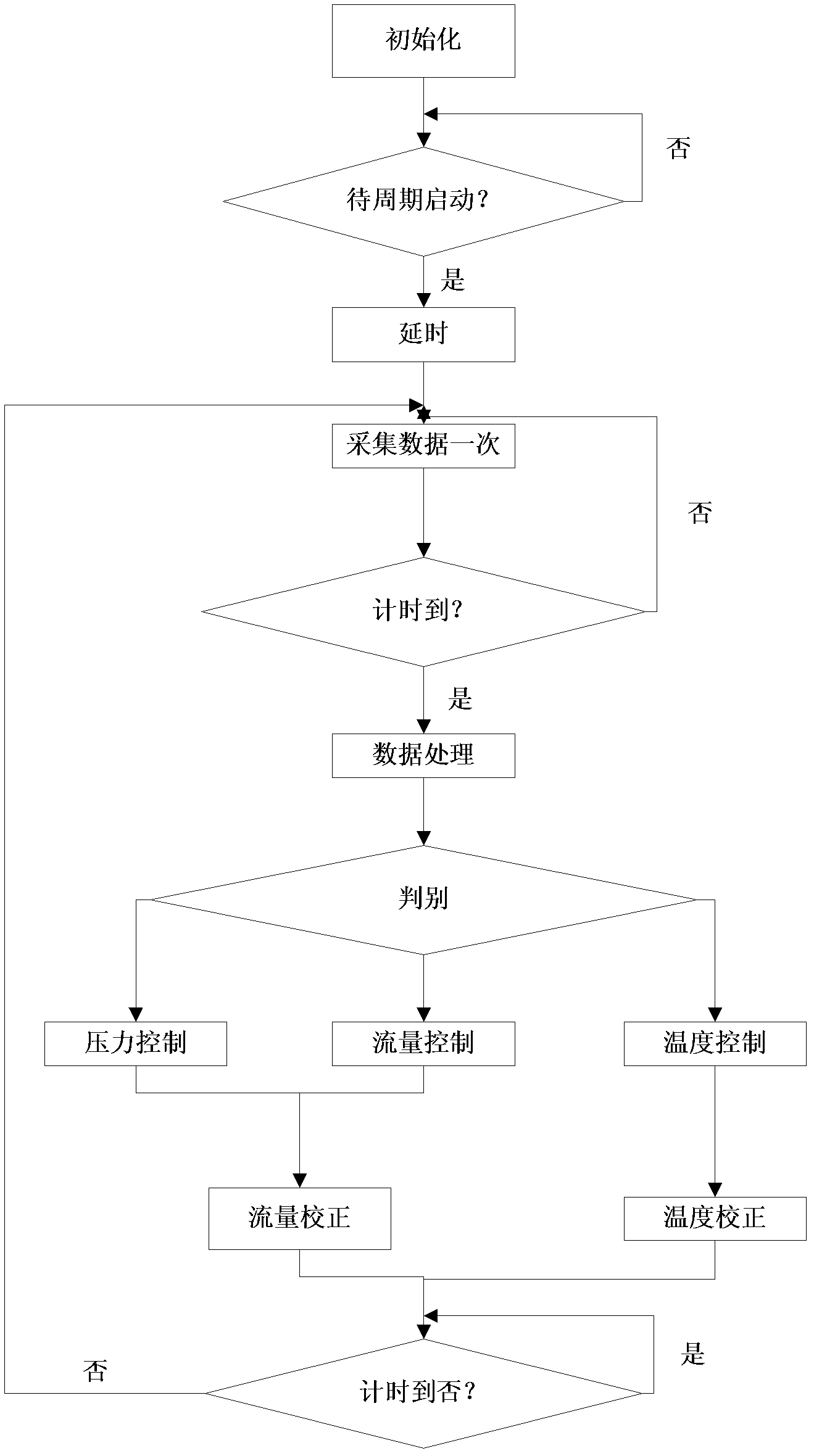

Remote monitoring maintenance method and system based on 3G and wind-solar complementary power supply technology

ActiveCN102081399ANo pollution in the processGuaranteed collection of dataTotal factory controlProgramme total factory controlDistributed structureNew energy

The invention discloses a remote monitoring maintenance method and a remote monitoring maintenance system based on 3G and wind-solar complementary power supply technology. The method comprises programmable logic controller (PLC) data acquisition and control, wind-solar complementary power supply, 3G wireless communication and remote monitoring maintenance, wherein wind-solar complementary new energy power supply technology, 3G network communication technology and automation control technology are organically combined to acquire data of temperature, pressure, flow, water level, water quality and other data of a pump station and monitor the pump station on site. The remote monitoring maintenance system and the PLC data acquisition and control system adopt a distributed structure; the remotemonitoring maintenance system monitors the data of each PLC data acquisition and control system on line in real time; a 3G wireless communication system provides smooth and rapid communication for the remote monitoring maintenance system and the PLC data acquisition and control system; and a wind-solar complementary power supply system provides power supply for the PLC data acquisition and control system. The method and the system realize wireless energy of the remote pump station and data transmission operation.

Owner:SHENZHEN FUTURELOOKS AUTOMATION SYST

Power transmission line warning ball

InactiveCN101923763AEven by forceWill not affect normal useOverhead installationAlarmsIlluminanceButt joint

The invention belongs to the technical field of early warning equipment, and in particular relates to a power transmission line warning ball. The warning ball is made into a spherical shape so as to improve wind proofing capacity thereof, is fixed on a power transmission line and acquires working power supply from the power transmission line to automatically start an LED lamp when the ambient illumination is less than a threshold; an super-bright LED which has high brightness and long service life is adopted; an ultrasonic distance measurement triggering module and a buzzer are arranged in the warning ball; when an object approaches the power transmission line, the warning ball can measure the distance between the object and the wire, send out a sound warning signal within a warning distance and automatically stop when the object gets away from the dangerous region; and the warning ball can realize butt joint with a robot and be installed by using the robot. The warning ball has the advantages of good rain proofing function, good early warning effect, simple structure, convenient installation and long service life.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-temperature acid chloride ion corrosion resistant steel plate and manufacturing method thereof

The invention relates to a high-temperature acid chloride ion corrosion resistant steel plate and a manufacturing method thereof. The high-temperature acid chloride ion corrosion resistant steel plate is prepared from, by mass, 0.01%-0.3% of C, 0.02%-2.0% of Si, 0.1%-2.0% of Mn, 0-0.01% of S, 0-0.05% of P, 0.01%-0.1% of Al, 0.05%-2.0% of Ni, 0.05%-2.0% of Cu, 0.005%-1.0% of Cr, 0.05%-0.3% of Sn, 0.0005%-0.3% of Se, 0.005%-0.2% of Ti, 0.01%-0.1% of V, 0.003%-0.3% of Nb, and the balance Fe and inevitable impurities. The steel plate is excellent in high-temperature acid chloride ion corrosion resistance, and meanwhile the corrosion resistance is little changed along with the temperature of a corrosion medium, so that the service life is prolonged, the safety is improved, and the oil leakage accident is reduced.

Owner:CENT IRON & STEEL RES INST +1

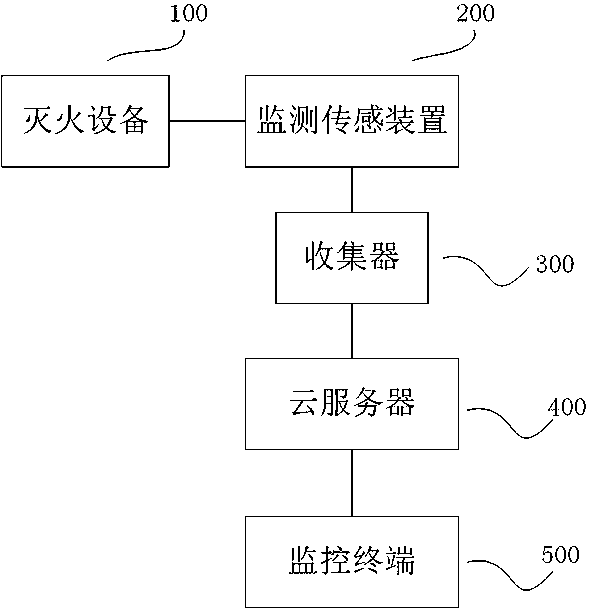

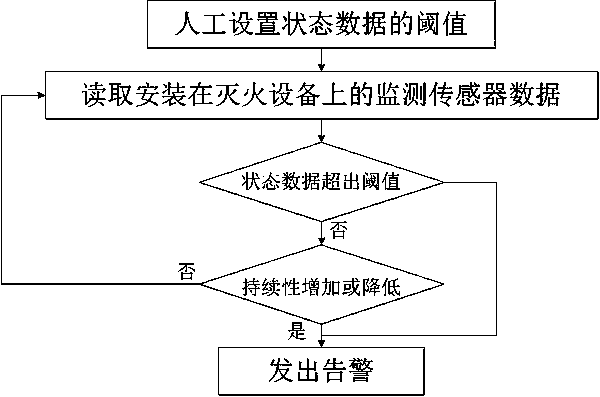

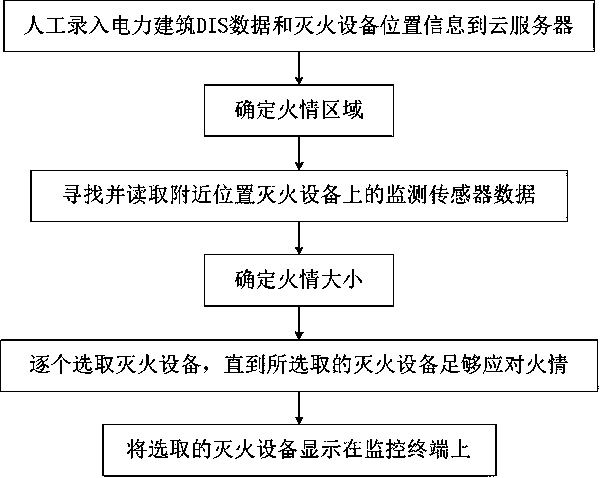

Intelligent fire fighting system based on extensive electric power internet of things

ActiveCN110314305AImprove securityImprove accuracyFire rescueFire alarm smoke/gas actuationFire controlElectric power system

The invention relates to the technical field of fire control, in particular to an intelligent fire fighting system based on the extensive electric power internet of things. The intelligent fire fighting system is applicable to an extensive internet of things electric power system comprising a data server. A plurality of fire extinguishing devices used for fire extinguishing and arranged nearby anelectric power building or electric power equipment, a plurality of monitoring sensing devices, a collector, a cloud server and a monitoring terminal are included. The monitoring sensing devices monitor the electric power building fire behavior or the state of the fire extinguishing devices and arranged on the electric power building or the fire extinguishing devices. The collector collects the sensor data and is in communication connection with the monitoring sensing devices. The cloud server analyzes the sensor data, monitors the fire control state of the electric power system and is in communication connection with the collector and the data server. The monitoring terminal displays the fire control state of the electric power system, interacts with a user and is connected with the cloudserver. The intelligent fire fighting system has the substantive effects that the cloud server is used for conducting fire behavior early warning and fire extinguishing strategy and accident reason study and judgment, the advantages of the internet of things are brought into full play, and the fire control level is improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

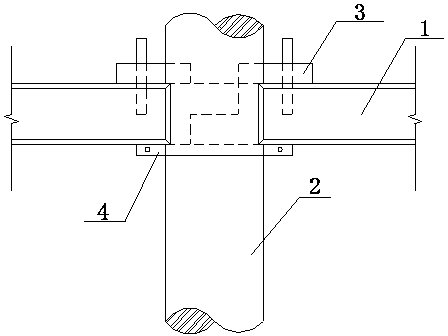

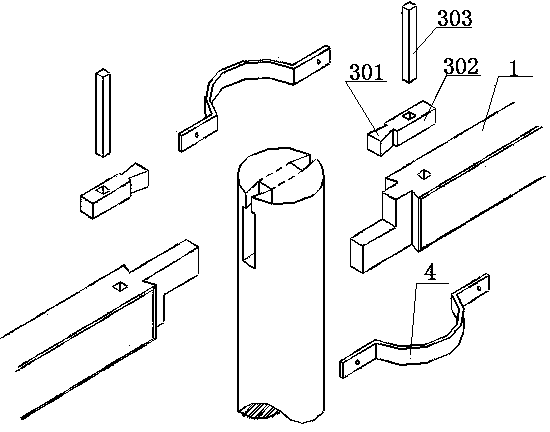

Steel-wood composited reinforcement device for ancient wood frames

InactiveCN103835525AImprove integrityImprove seismic performanceBuilding repairsMortise and tenonShock resistance

Disclosed is a steel-wood composited reinforcement device for ancient wood frames. The steel-wood composited reinforcement device needs not to be fixed with iron cramps or angle steel, horizontal displacement of mortises and tenons can be prevented through wood components, and bending resistance of beams and columns can be improved through steel fasteners. The steel-wood composited reinforcement devcie is high in flexibility, shock resistance and twisting resistance; with the reinforcement technology, maintenance and replacement can be achieved, and protection and renovation of the wood structure is benefited.

Owner:LUOYANG INST OF SCI & TECH

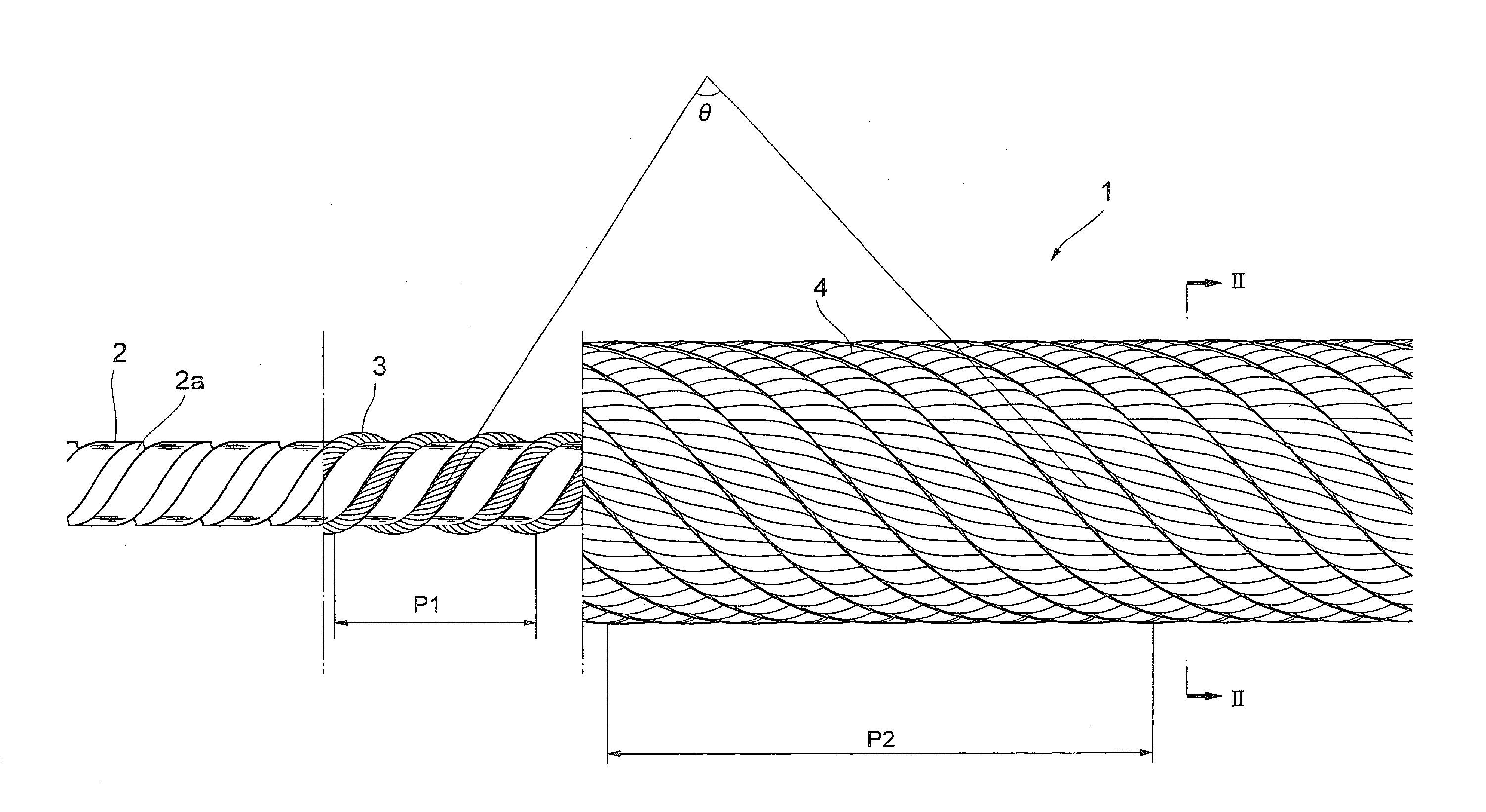

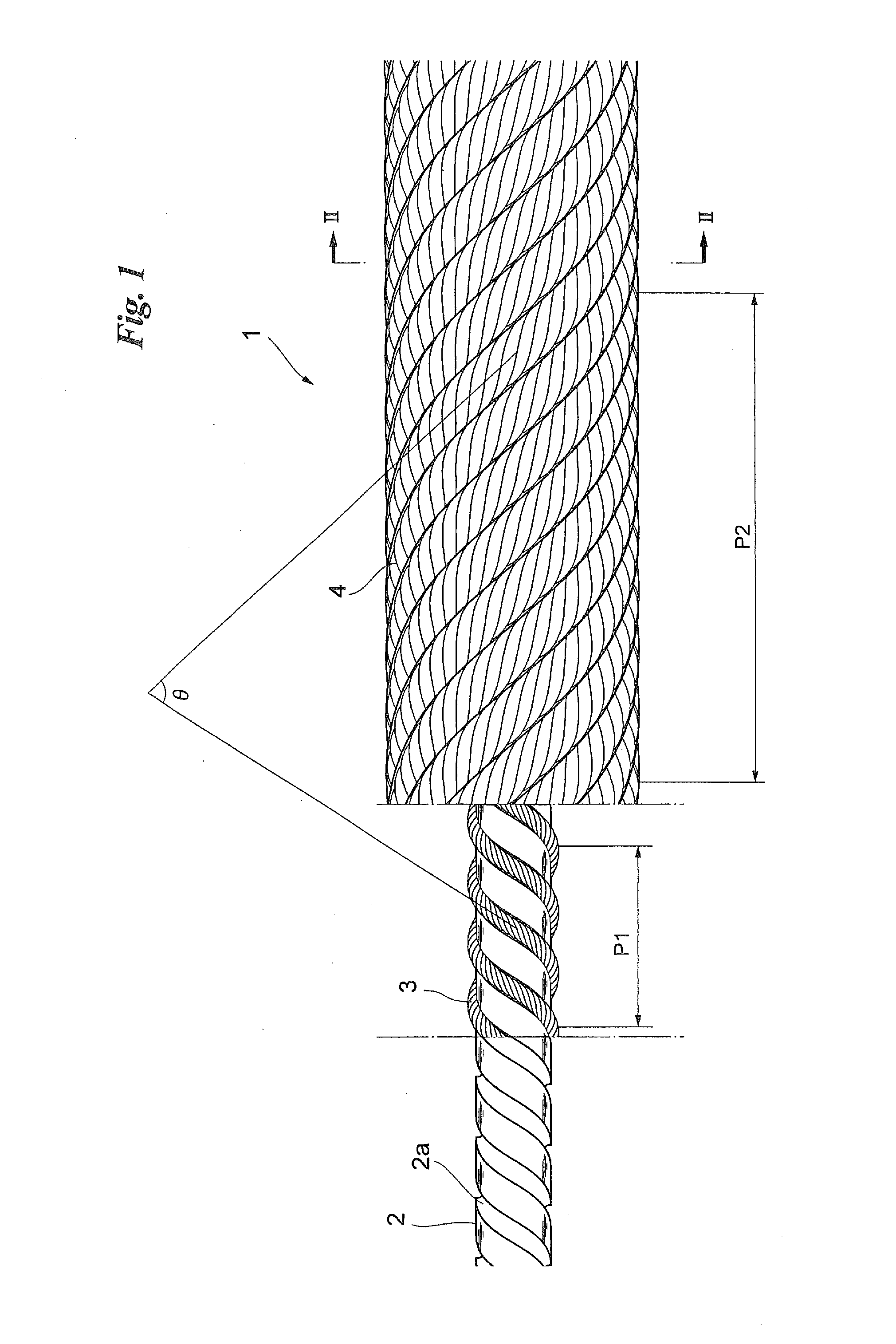

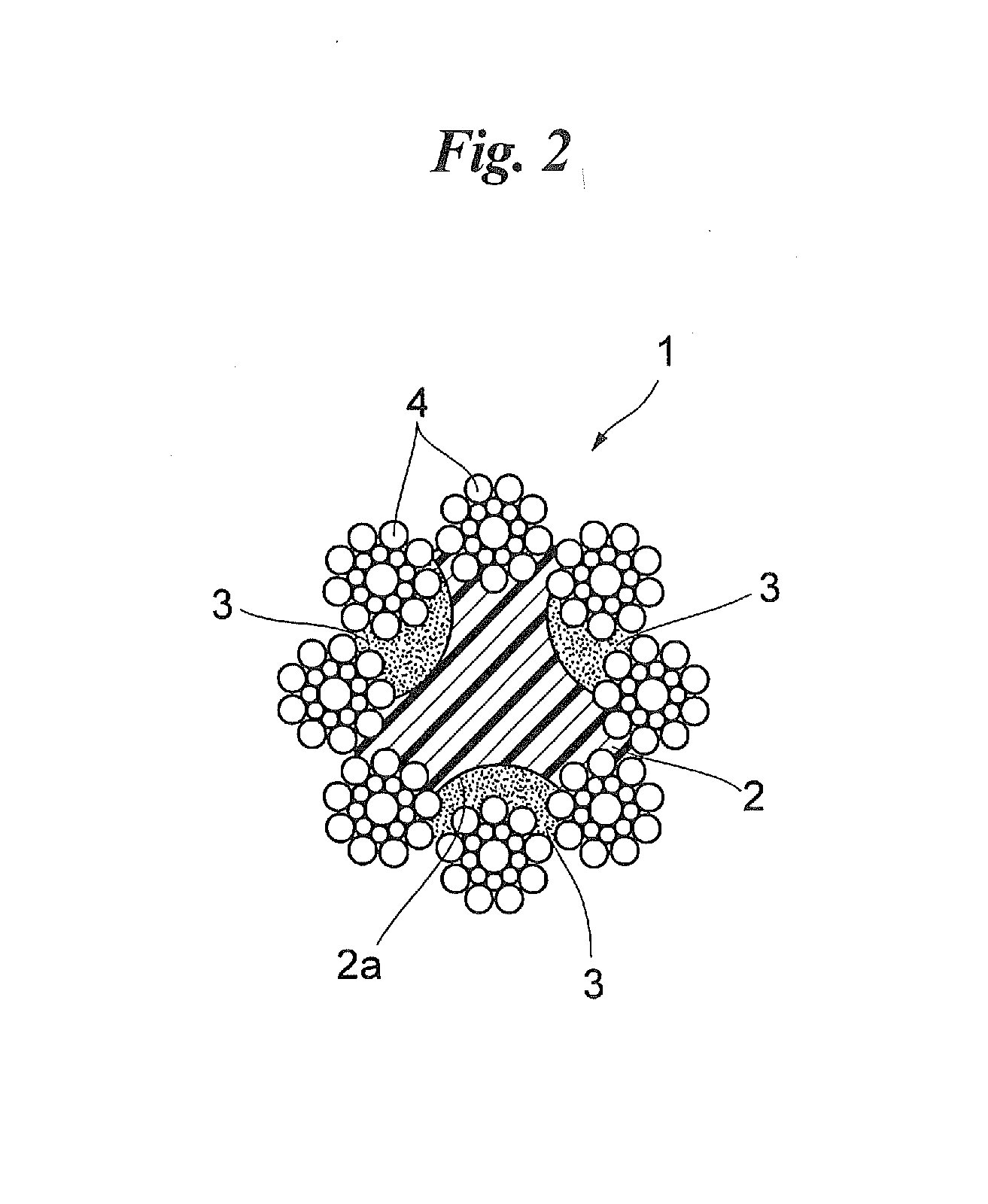

Hybrid core rope

ActiveUS20130318937A1Accelerate the rate of decreaseReduce maintenance tasksRope making machinesYarnFiber bundleEngineering

The present invention is to provide a hybrid core rope which does not require maintenance or a hybrid core rope capable of reducing a maintenance task. The hybrid core rope includes a resin solid core in which a plurality of spiral grooves is formed in the longitudinal direction on an outer peripheral surface thereof, a plurality of fiber bundles respectively spirally wound around the outer peripheral surface of the resin solid core along the plurality of spiral grooves, the fiber bundles having thickness to fill the spiral grooves, and a plurality of steel strands spirally wound around the outer peripheral surface of the resin solid core around which the fiber bundles are wound. The fiber bundles and the strands are respectively wound so as to have angles which are not parallel to each other.

Owner:TOKYO ROPE MFG

Method for preparing tropism silicon steel

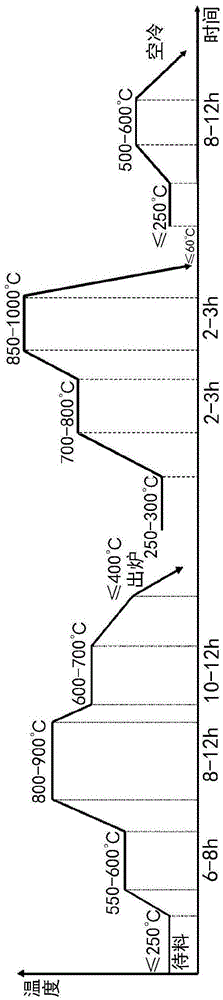

InactiveCN101210297ALow heating temperatureShorten heating timeTemperature control deviceHeat treatment process controlMultiple frameThermal treatment

The invention discloses a manufacture method of an oriented silicon steel, which adopts smelting, continuous casting, heating, rough rolling, finish rolling, normalizing, cold rolling and heat treatment processes. The method is characterized in that continuous bending, continuous straightening, low-head vertical-bending medium-thin slab caster is adopted, the tundish superheat is 15 to 45 DEG C, the drawing speed is 2 to 4 m / min, the temperature gradient of a cast strand is 80 to 200 DEG C / mm, the surface temperature is 850 to 1,150 DEG C, the slab thickness is 100 to 170 mm, the surface charging temperature of a section cast strand and a continuous cast strand is not less than 800 DEG C, and the heating speed is larger than 5 DEG C / min; and a hot coil box is adopted after rough rolling, the cold rolling is achieved by single-frame rolling or multi-frame once or twice cold rolling, the temperature of a steel strip entering a finishing mill is 1,100 to 1,250 DEG C, the output temperature of the finishing mill is larger than 800 DEG C, and laminar cooling is adopted after rolling to reach a final cooling temperature of 400 to 800 DEG C. By controlling the state of a depressant in continuous casting and by adopting high-temperature, short-time and rapid hot rolling process, etc, the invention can achieve uniform product performance, high quality, reduced energy consumption as well as high efficiency.

Owner:ANGANG STEEL CO LTD

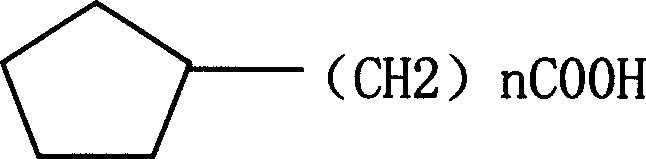

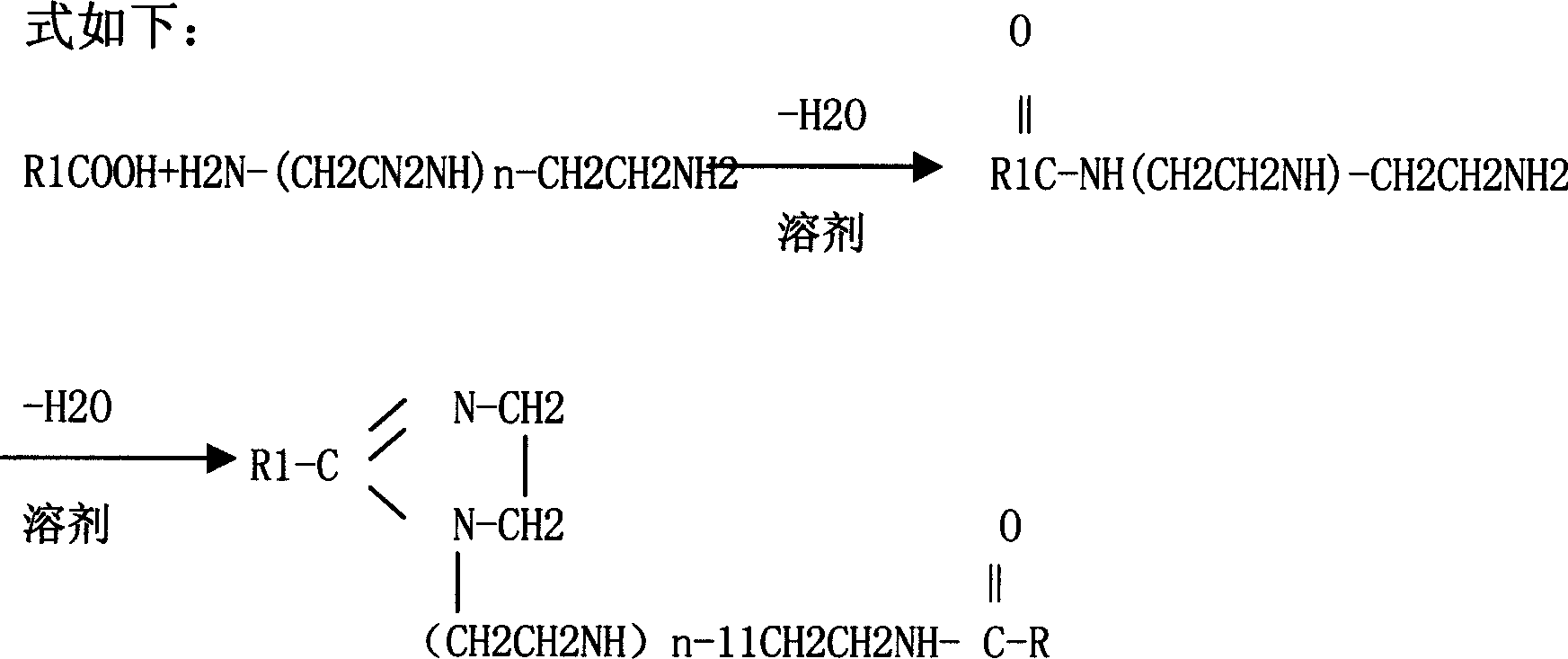

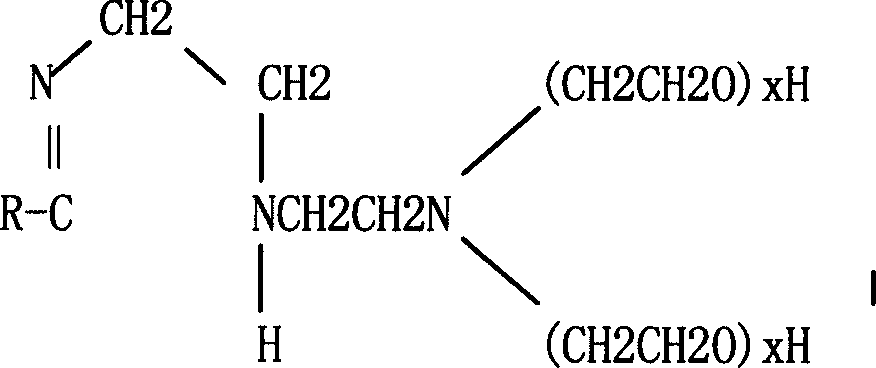

Water-soluble corrosion-retarding neutralizer and its preparation process

The invention relates to a water-soluble neutralizing agent mainly for oil-extraction plant low-temperature light oil position metallic conservation, which is prepared form naphthenic acid, polyenamine and organic acid anhydrides or ethylene oxide as raw material through mixing with neutralization agent and dissolvent.

Owner:PETROCHINA CO LTD

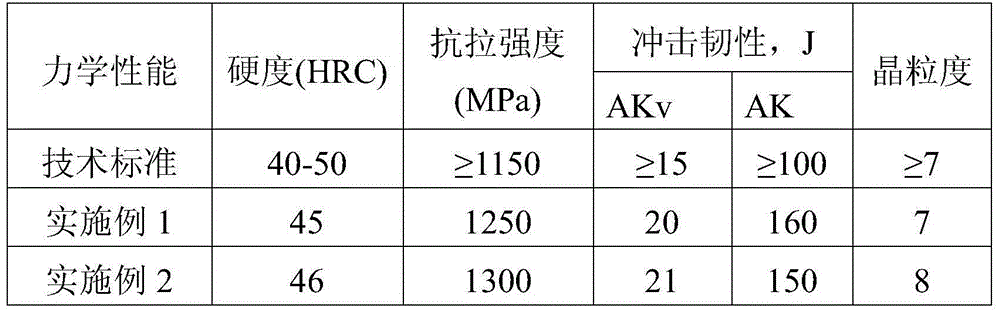

Alloy composition, semi-autogenous mill lining plate and manufacturing method of lining plate

InactiveCN104087862AImprove mechanical propertiesImprove wear resistanceFurnace typesGrain treatmentsEconomic benefitsWear resistance

The invention provides an alloy composition, comprising the following components in percentage by weight: 0.3-0.5% of C, 0.5-0.8% of Si, 0.7-1.3% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.5-3% of Cr, 0.2-0.4% of Mo, 0.15-0.35% of Ni, 0.005-0.020% of Ti, 0.1-0.35% of Cu, 0.001-0.006% of B, 0.02-0.07% of La, less than or equal to 0.03% of Al and the balance of Fe. The invention further provides a semi-autogenous mill lining plate made of the alloy composition and a manufacturing method of the lining plate. The semi-autogenous mill lining plate disclosed by the invention has excellent mechanical property and good abrasion resistance, so that the overhauling frequency is reduced, repeated work is avoided, the labor intensity is reduced, the service life of equipment is prolonged, and the economic benefit is improved.

Owner:TAIYUAN HEAVY IND

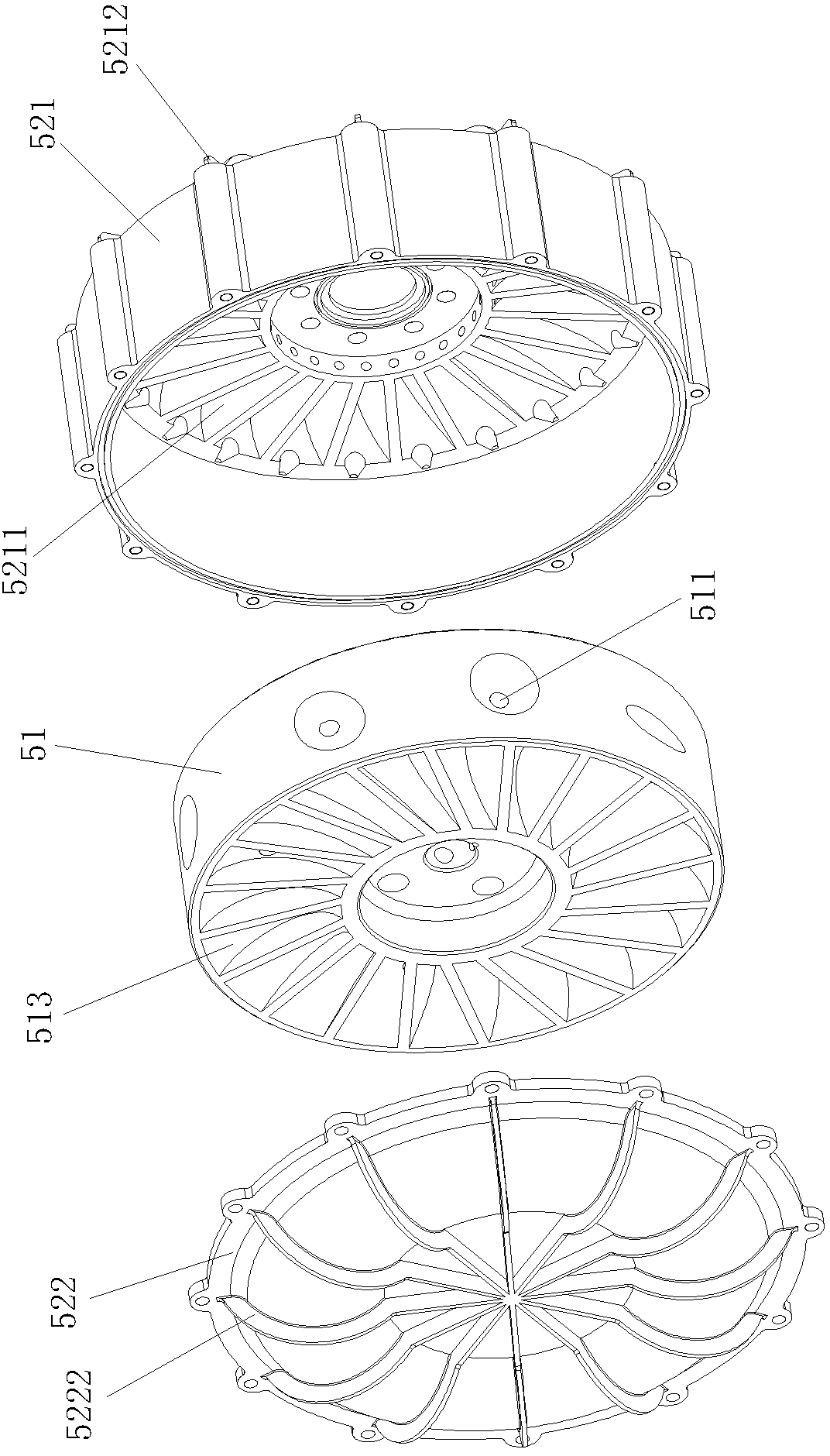

Auxiliary brake device applied to non-drive axle

InactiveCN103101522AIncrease braking powerSmooth decelerationBraking element arrangementsHydrodynamic brakesImpellerControl engineering

The invention discloses an auxiliary brake device applied to a non-drive axle. The auxiliary brake device applied to the non-drive axle comprises an axle shell of the non-drive axle, wherein shaft heads are respectively fixed at two ends of the axle shell, the outer surface of each shaft head is connected with a wheel hub through a bearing, a hydraulic retarder is arranged between the wheel hub and an end portion of each shaft head, each hydraulic retarder comprises a stator impeller fixed on the outer surface of the end portion of each shaft head and a rotor impeller which is covered outside each stator impeller and fixed with the wheel hub, and a hydraulic oil work cavity is formed between the inner surface of each rotor impeller and the outer surface of each stator impeller. An oil inlet pipe and an oil return pipe are arranged on the axle shell, each shaft head is provided with an axial through hole, each axial trough hole forms a part of an oil pipeline passage of each hydraulic retarder, and the oil inlet pipe and the oil return pipe are communicated with the hydraulic oil work cavities through the axial through holes in the shaft heads. The auxiliary brake device applied to the non-drive axle is capable of effectively improving the brake capacity of vehicles, especially a trailer, a semitrailer, a heavy truck and a large bus, and guarantees driving safety.

Owner:XIAMEN YULONG MACHINERY +1

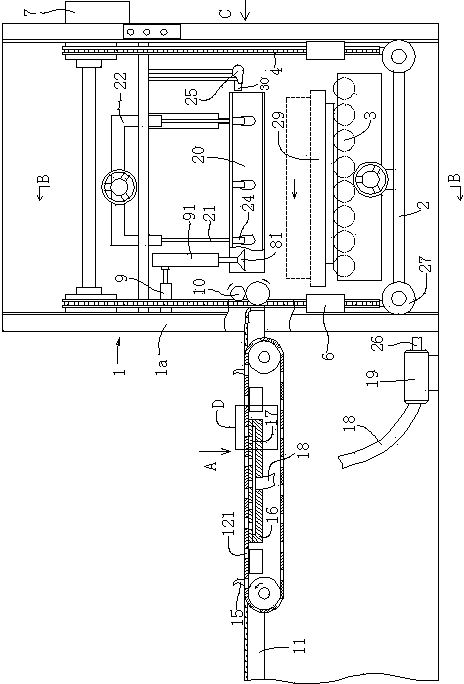

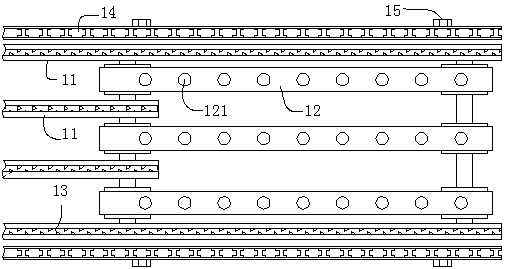

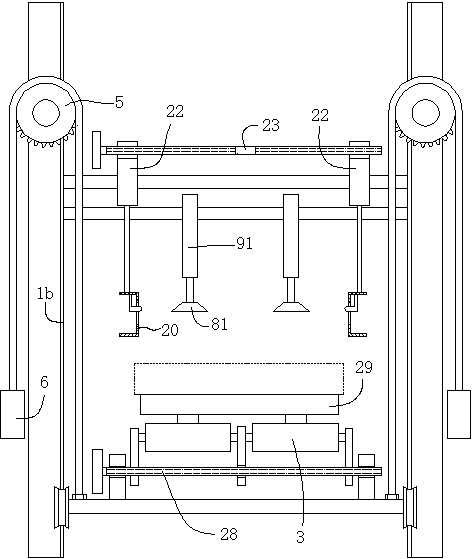

Sheet material feeding and conveying device

ActiveCN103894506AEasy to importAvoid scratchesMetal-working feeding devicesPositioning devicesProduction lineReciprocating motion

The invention relates to a sheet material feeding and conveying device. The sheet material feeding and conveying device comprises a rack which is located on the two sides of a conveying production line and provided with stand columns, a lifting machine base is arranged on the lower portion of the rack, a row of transmission rollers used for supporting stacked sheets is arranged on the machine base, sling chains are connected beside the front side and the rear side of the machine base respectively and used for driving the machine base to ascend and descend, the sling chains stride transmission chain wheels on the rack respectively, and a sling sinker used for balancing weight is arranged at the outer side end of each sling chain; the front transmission chain wheel and the rear transmission chain wheel on the same side are driven by a same stepping motor transmission mechanism; the front side and the rear side of the upper portion of the machine base are respectively provided with a lifting sucker used for adsorbing the sheets, the lifting sucker on the front side is connected with a transverse air cylinder connected to the rack so that the lifting sucker on the front side can be driven to move front and back in a reciprocating mode, the front side of the lifting sucker on the front side is provided with a pair of horizontal rollers used for drawing the sheets to move forward, and the output end of each horizontal roller is provided with a sheet conveying device. Not only is the sheet material feeding and conveying device beneficial for guiding a sheet bearing base from the production line, but also lifting control and transmission are convenient and accurate, and feeding is smooth.

Owner:FUJIAN FUZHEN METAL PACKING CO LTD

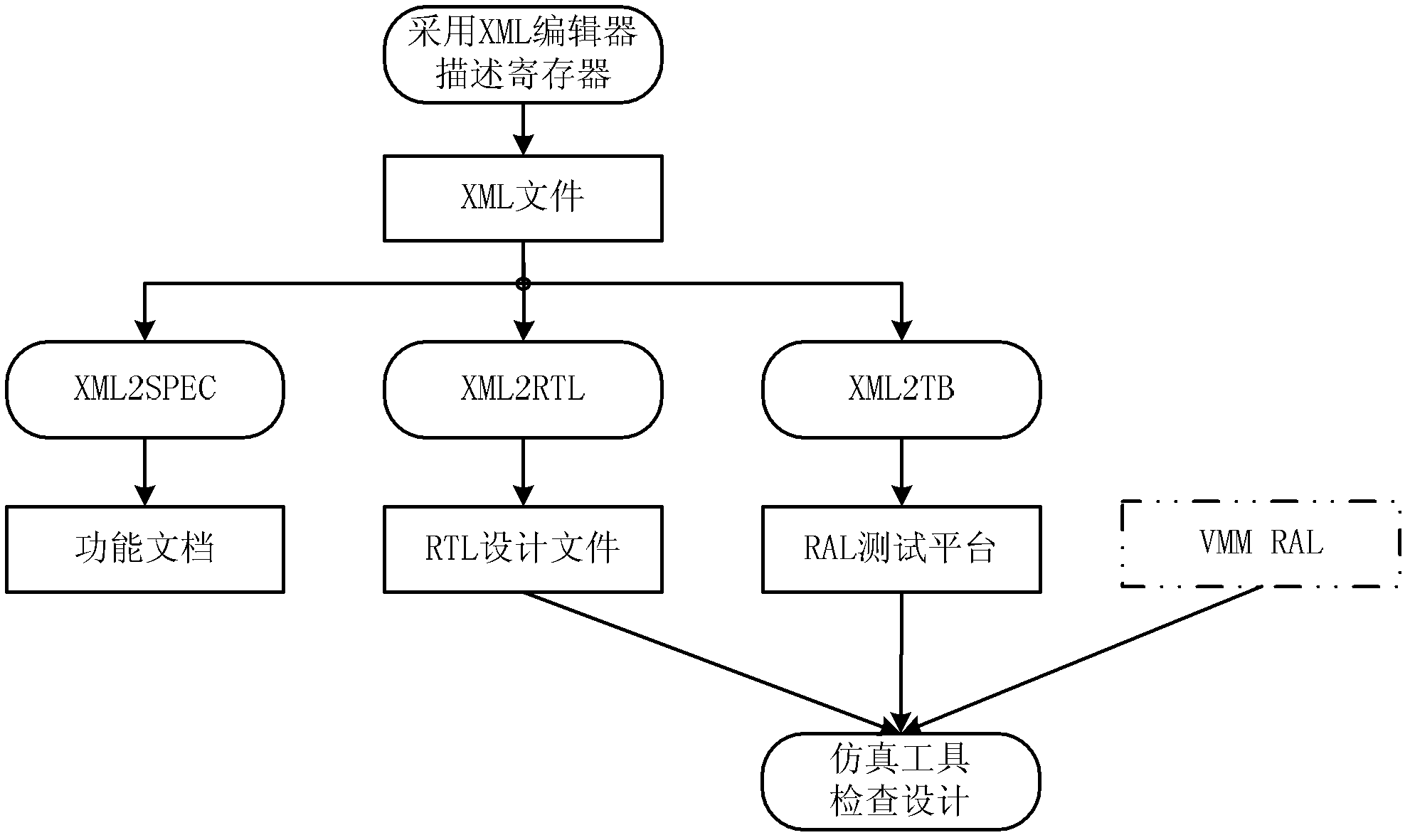

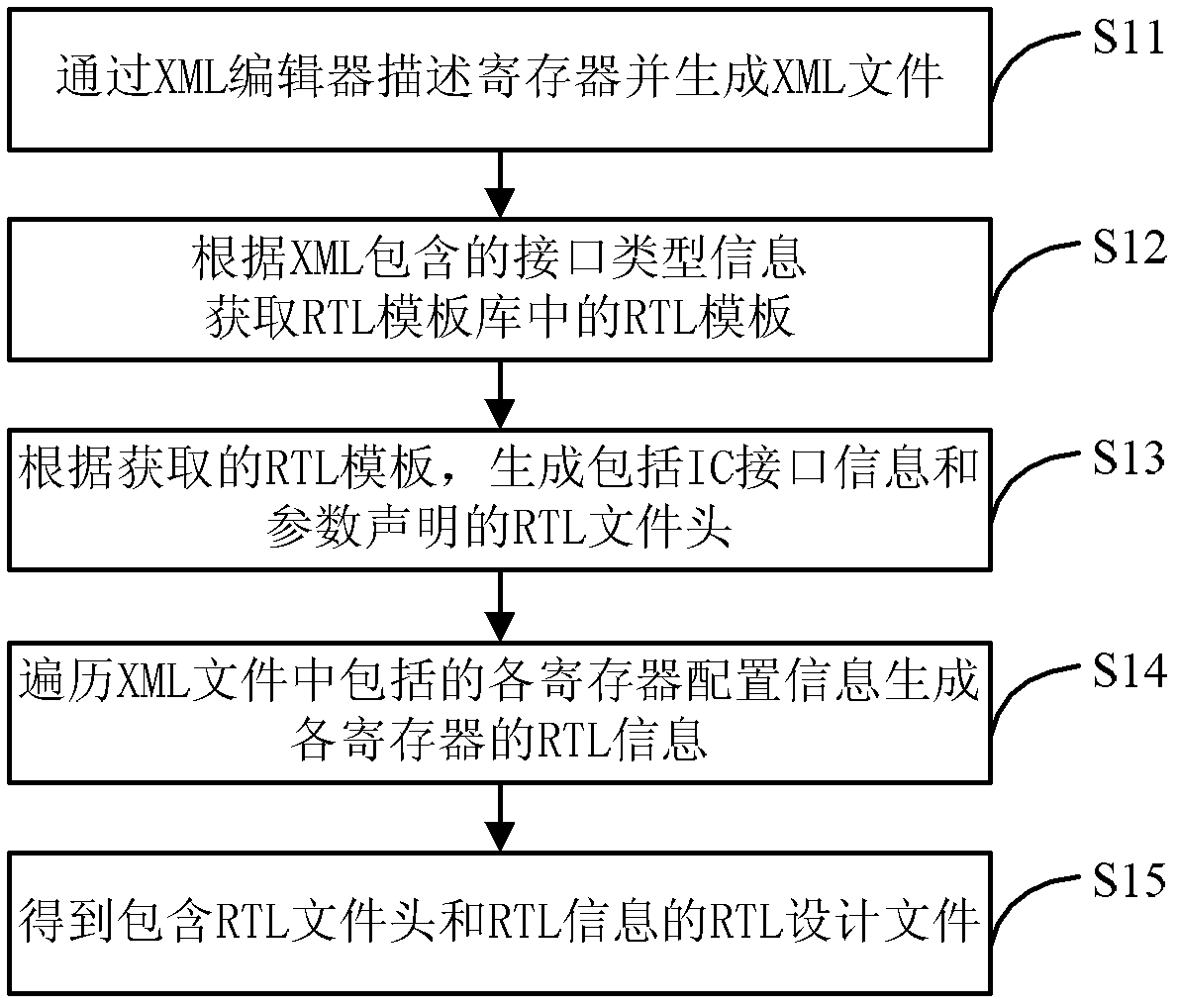

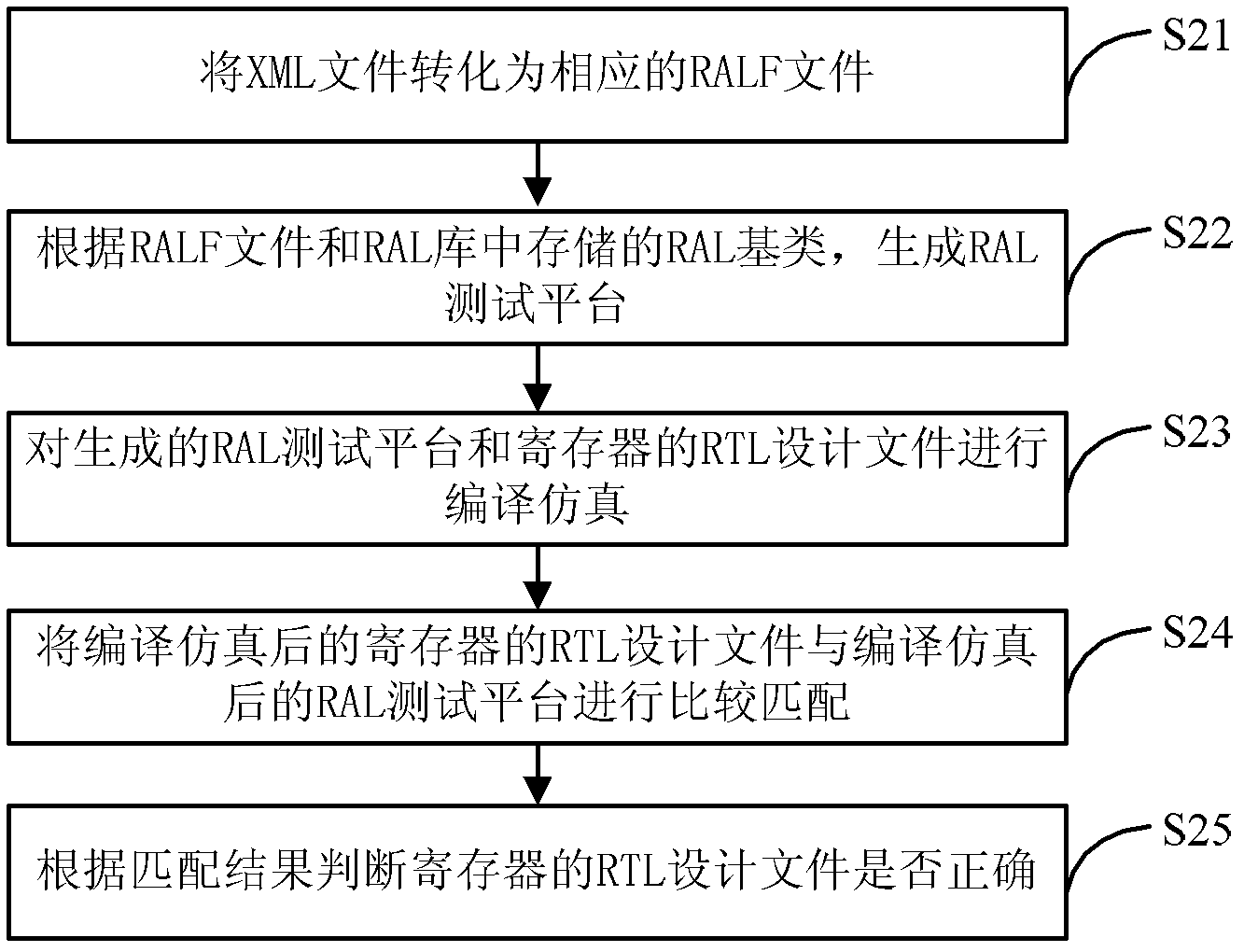

Register designing method and register designing device in integrated circuit designing process

ActiveCN102592023AAvoid the problem of difficult and cumbersome design and maintenanceReduce Design DefectsSpecial data processing applicationsRegister allocationComputer architecture

The invention discloses a register designing method in an integrated circuit designing process. The register designing method comprises the steps of generating an XML (Xtensible Markup Language) file including register configuration information by an XML editor; according to the type of a register interface included in the register configuration information, obtaining an RTL (Register Transfer Level) template in an RTL template base; according to the obtained RTL template and the register configuration information, generating an RTL file header including the register interface information and the parameter declaration; traversing all the register configuration information included in the XML file to generate RTL information of all the registers; and obtaining an RTL designing file including the RTL file header and the RTL information. According to the register designing method of the invention, the IC (Integrated Circuit) designing defects are reduced, and the designing success rate is increased.

Owner:GUANGDONG NUFRONT COMP SYST CHIP

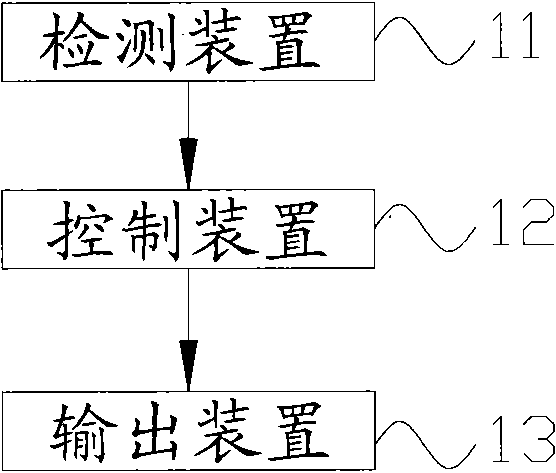

Wind generator set and fatigue load monitoring system thereof

InactiveCN101839806AImprove monitoring accuracyRepair in timeWind motor controlEngine testingFatigue loadingMonitoring system

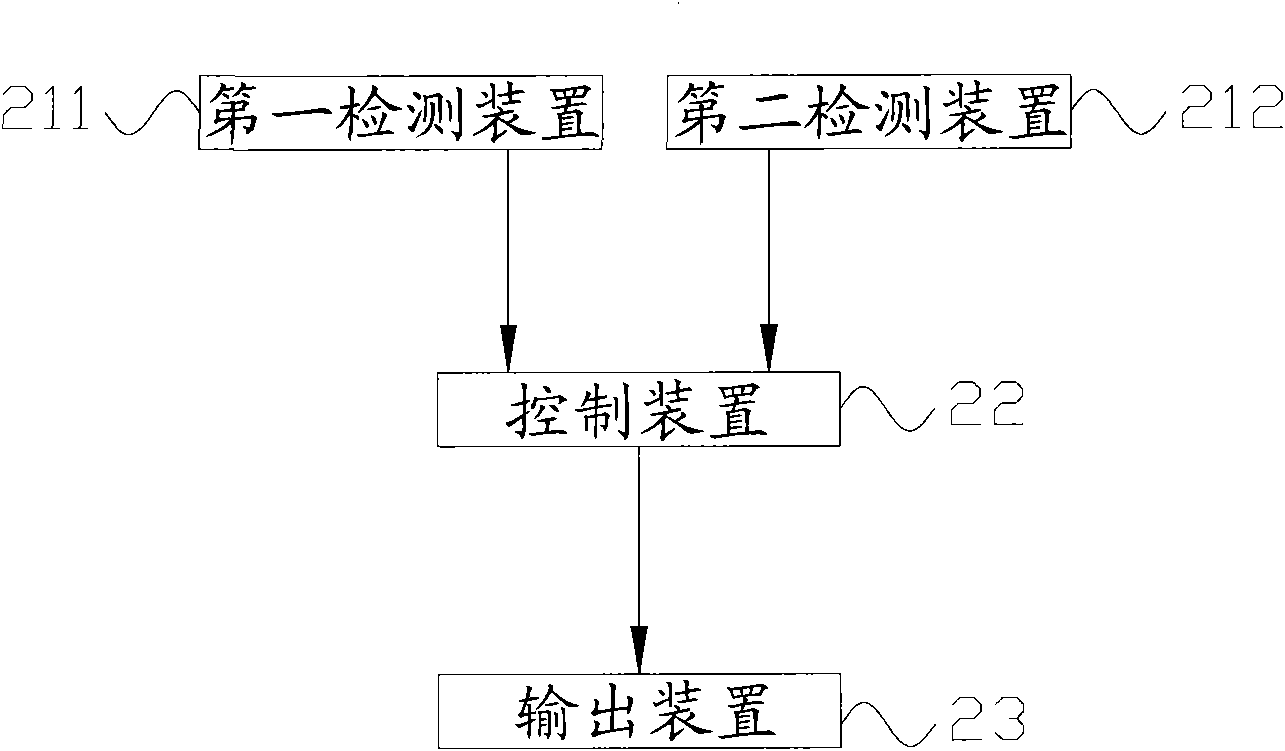

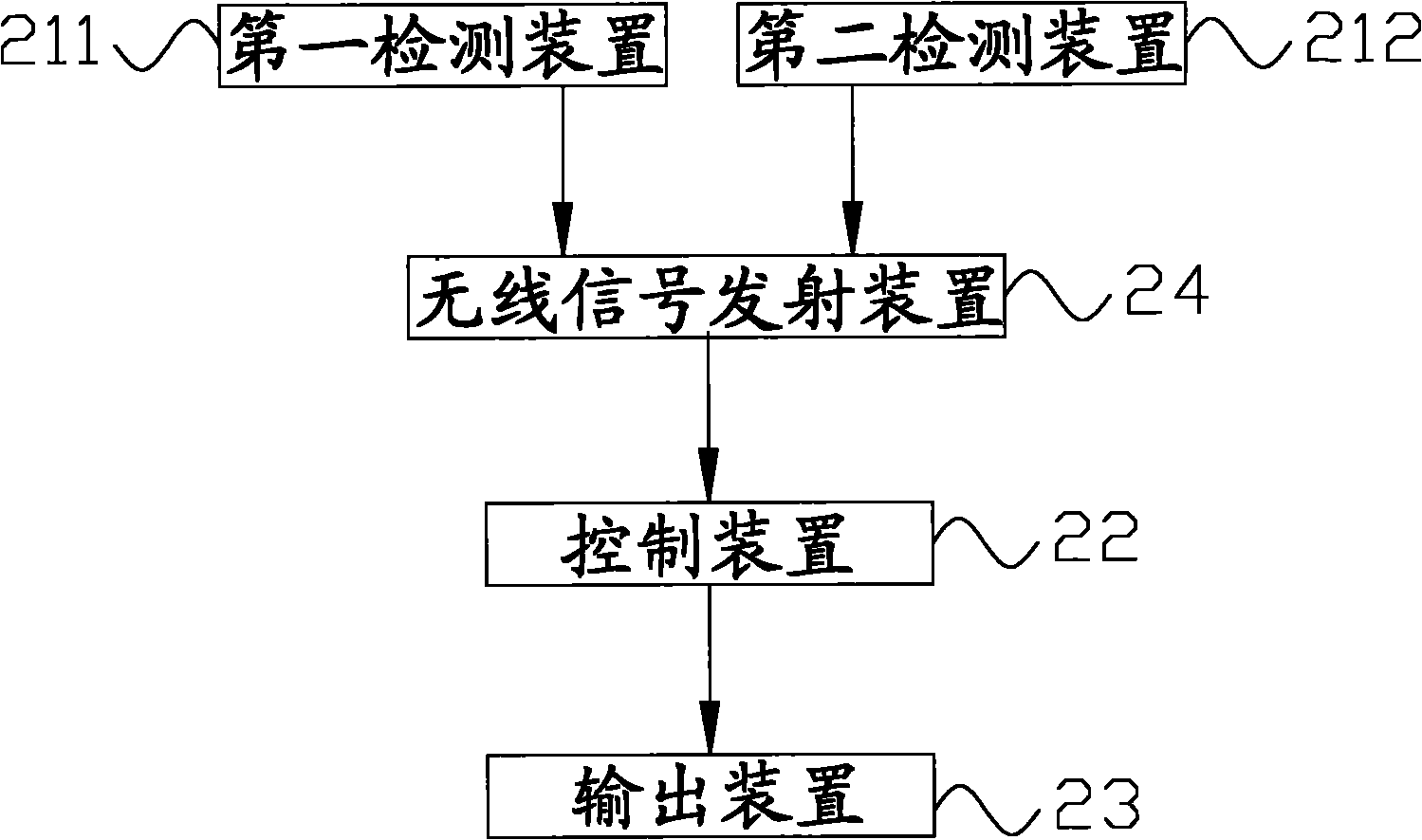

The invention discloses a fatigue load monitoring system for a wind generator set, comprising a first detecting device (211), a second detecting device (212), a control device (22) and an output device (23). The first detecting device (211) is used for detecting the fatigue state of the root of a tower barrel to obtain a first detection signal; the second detecting device (212) is used for detecting the fatigue state of at least one position outside the root of the tower barrel to obtain a second detection signal; the control device (22) is used for receiving the first detection signal and the second detection signal, processing the first detection signal and the second detection signal according to a preset strategy to obtain an actual damage value, and then comparing the actual damage value and the preset damage value to judge the damage state of the monitored position of the wind generator set; and the output device (23) is used for outputting the actual damage value of the monitored positioned. The fatigue load monitoring system has higher monitoring precision so as to maintain each member of the wind generator set in time and prolong the service life of each member. The invention also discloses the wind generator set comprising the fatigue load monitoring system.

Owner:SANY ELECTRIC CO LTD

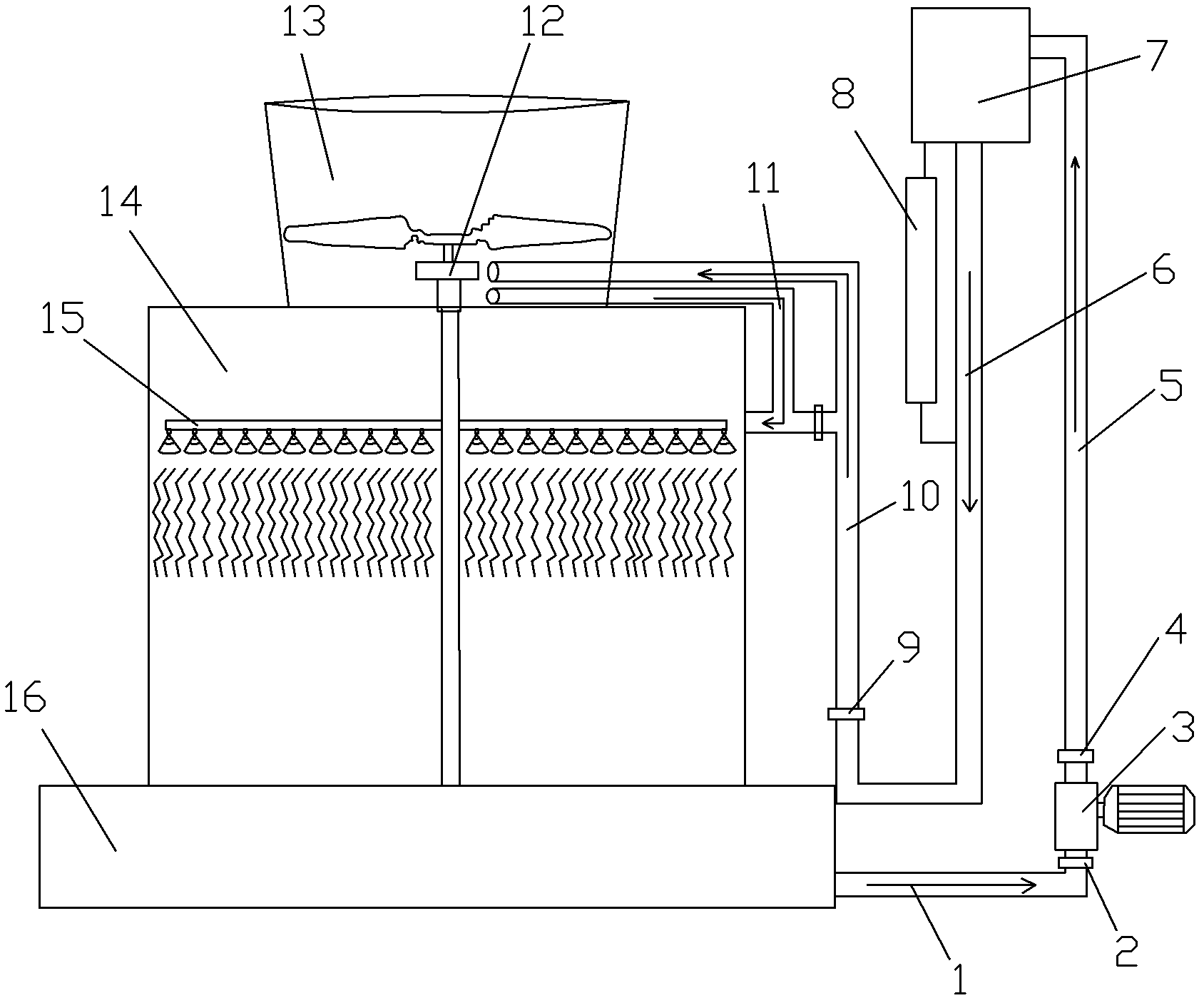

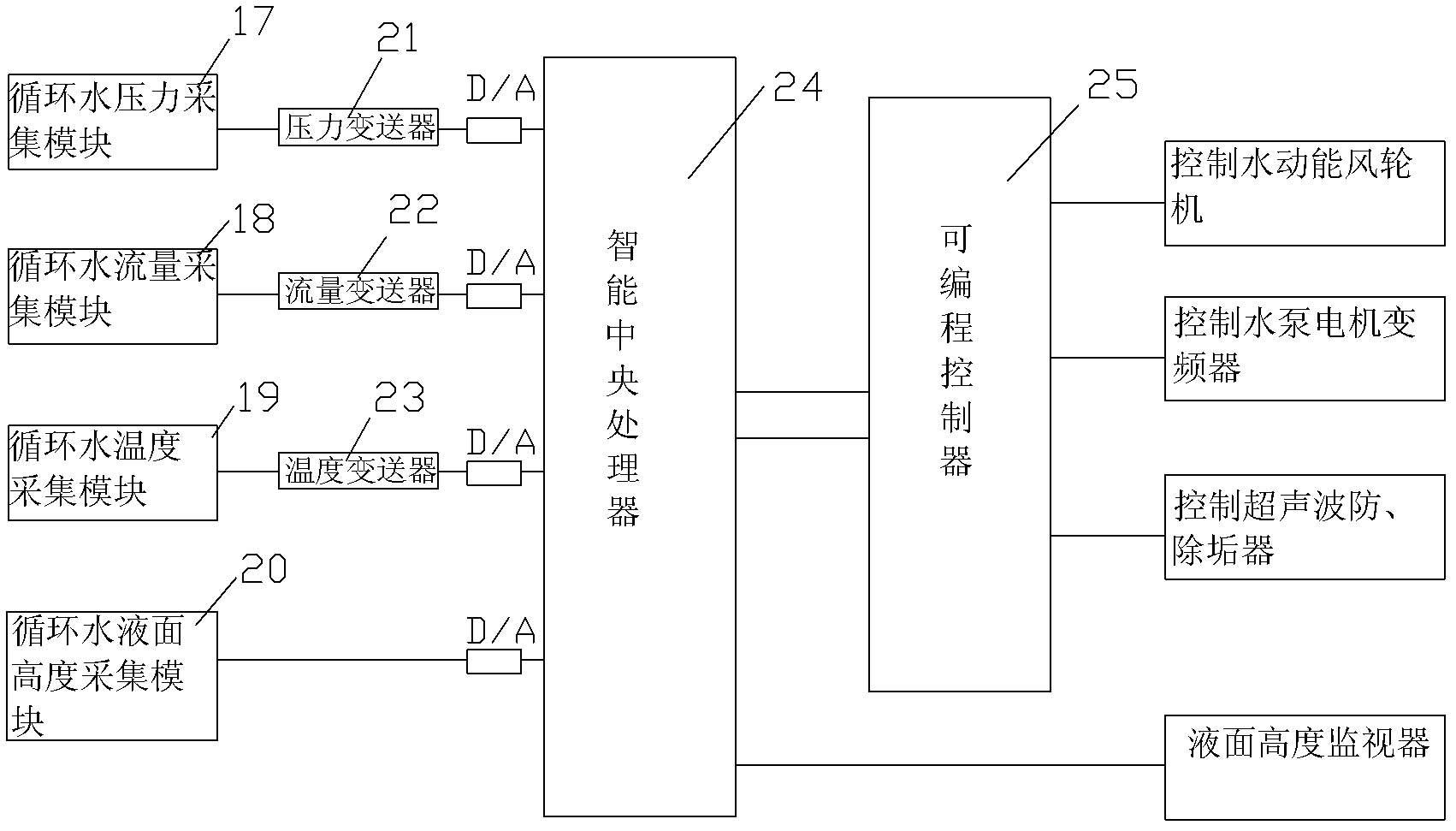

Circulating water cooling system for cooling towers

InactiveCN102853712AImprove heat exchange efficiencyPrevent scalingTrickle coolersCooling towerClosed loop

The invention relates to a circulating water cooling system, in particular to a circulating water cooling system for cooling towers, which is used for intelligent energy-saving and comprehensively uses devices such as a cooling tower, a heat exchanger, a circulating water pipeline, a cooling tower water pump and the like. The cooling system comprises a cooling tower, a heat exchanger, a circulating water pipeline and a cooling tower water pump, wherein a water kinetic energy wheel fan is arranged in an air tube; a circulating water input port is dead against the water kinetic energy wheel fan, and the kinetic energy of circulating water directly drives the water kinetic energy wheel fan to rotate; and an ultrasonic scale preventing and removing device is arranged in a second water feeding pipe behind the heat exchanger. The circulating water cooling system for cooling towers, disclosed by the invention, adopts a closed-loop intelligent control mode; and the flow and pressure of cooling water in the cooling tower circulating pipeline are main physical parameters of heat exchange efficiency, and the rotating speed of a water turbine blade, the frequency control of the water pump and the starting of the ultrasonic scale preventing and removing device are controlled through sampling the change values of the flow and pressure, thereby achieving an effect of improving the heat exchange efficiency according to the heat exchange requirements.

Owner:SHANGHAI LONGXIE ELECTRONICS TECH

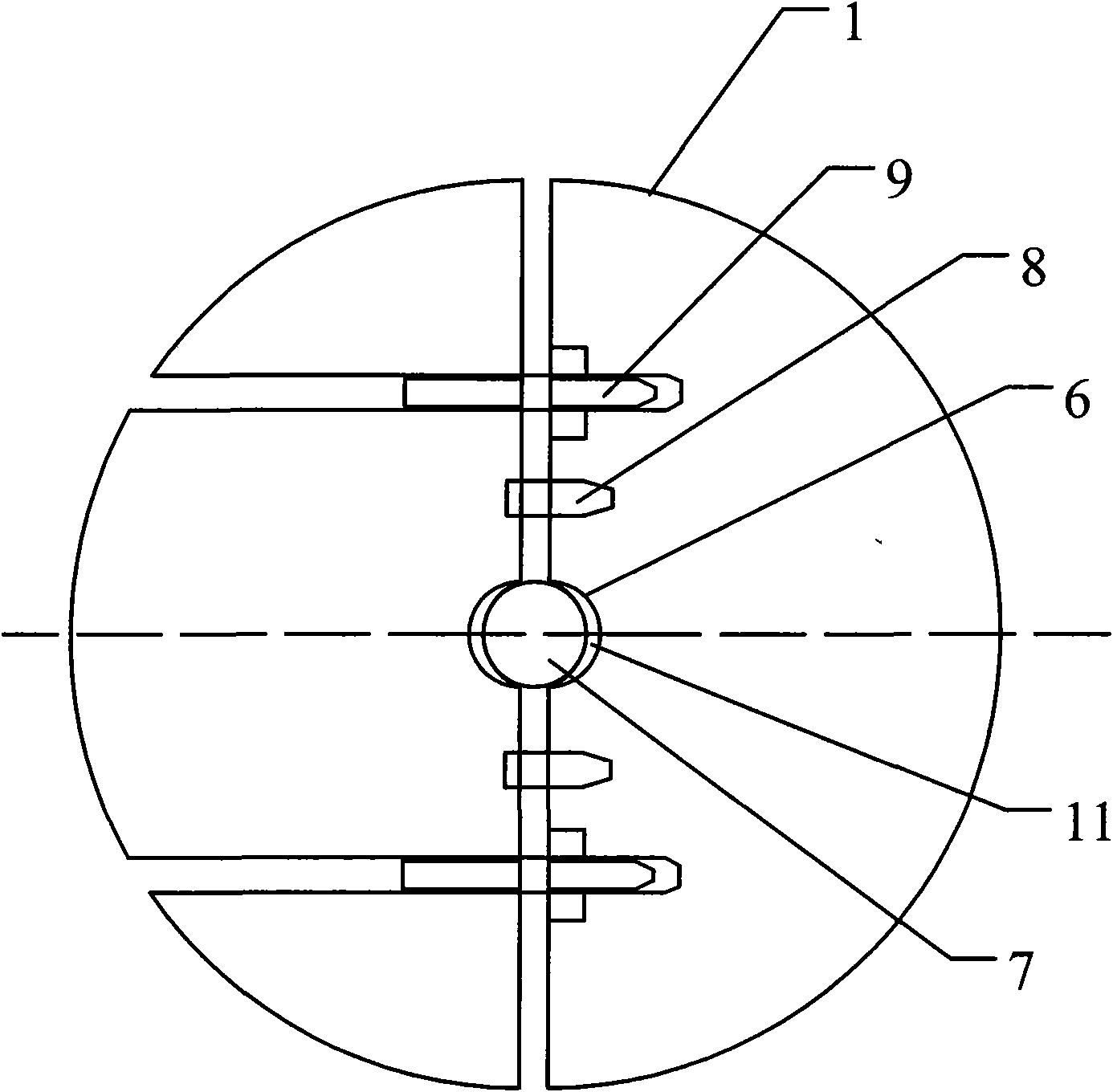

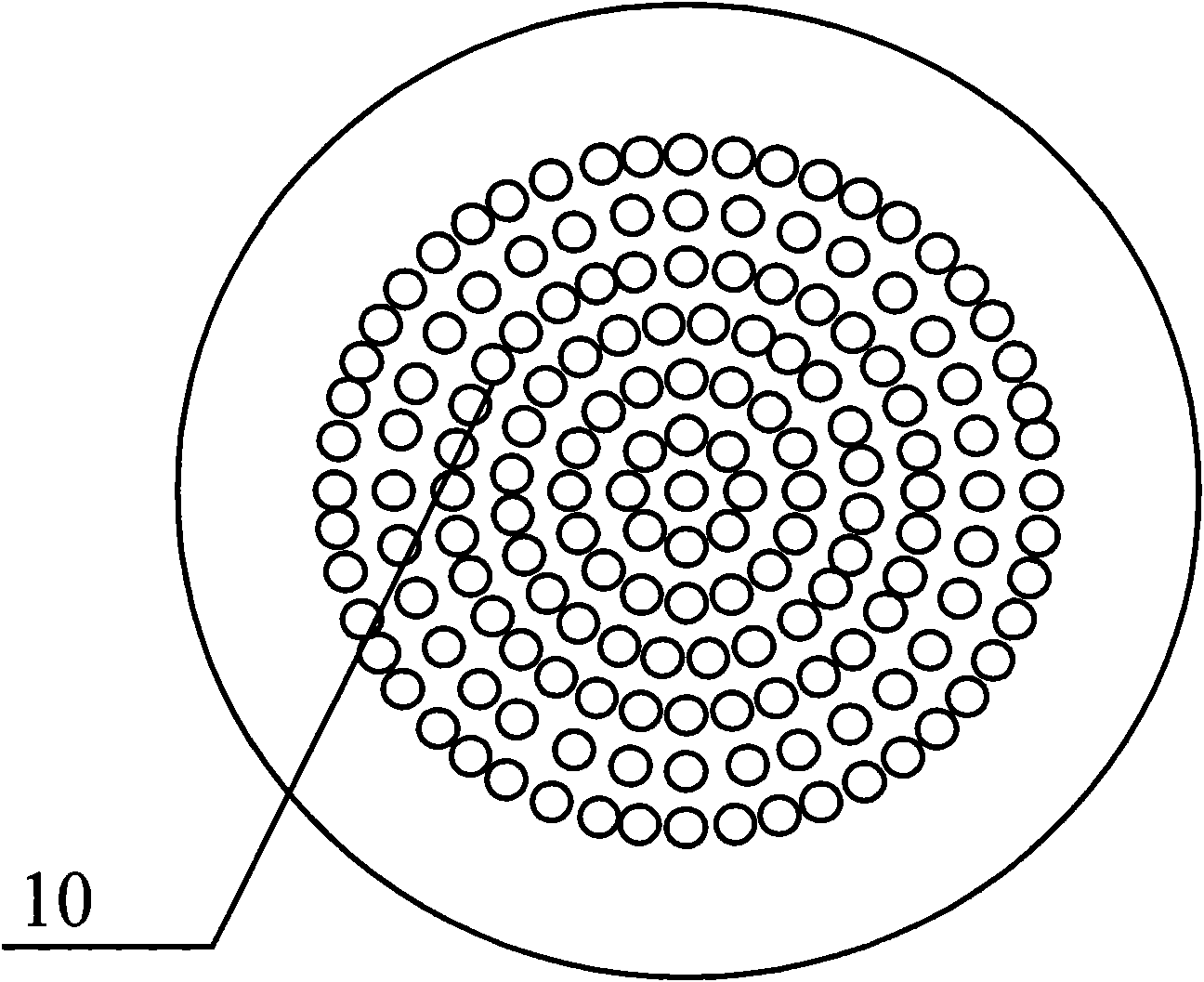

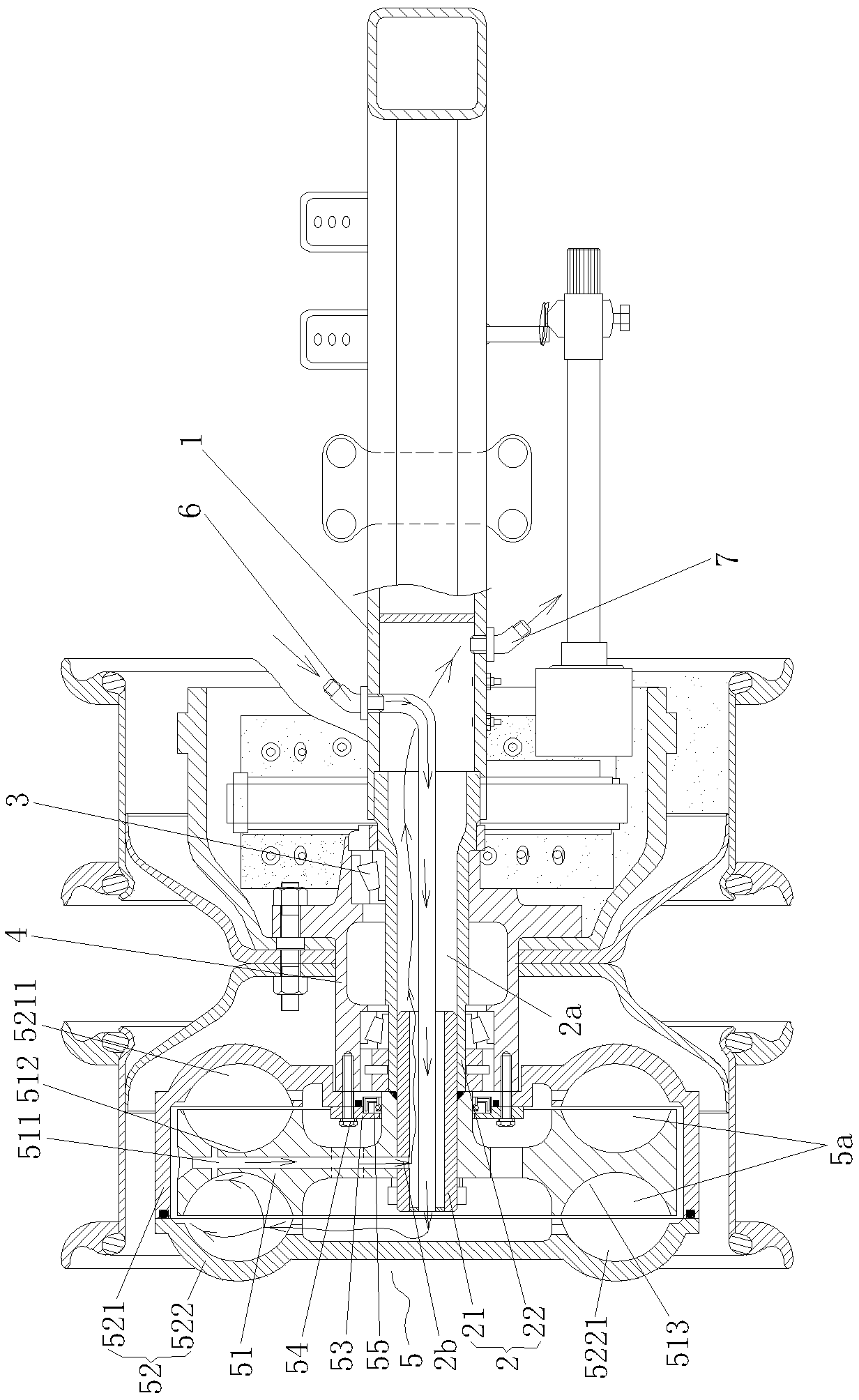

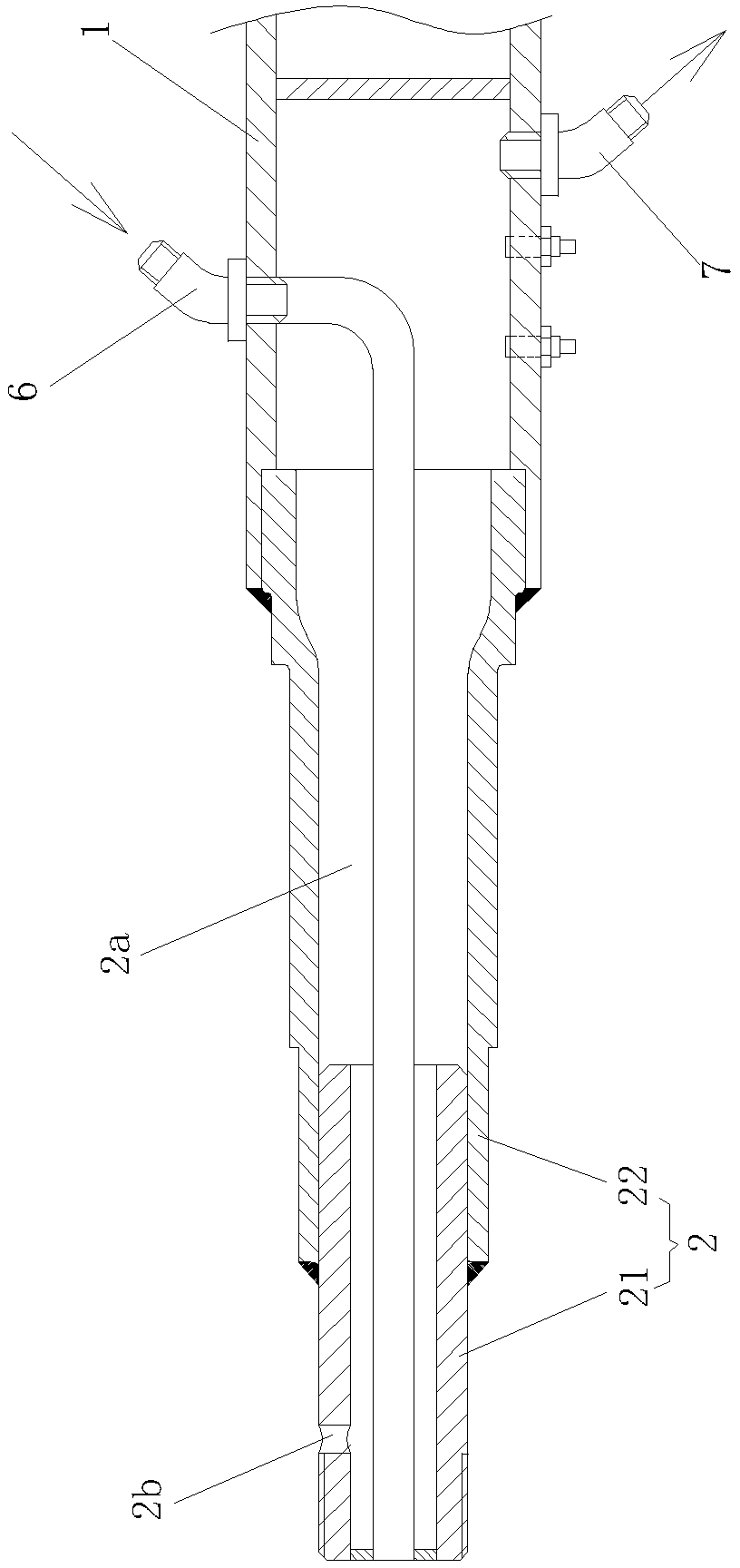

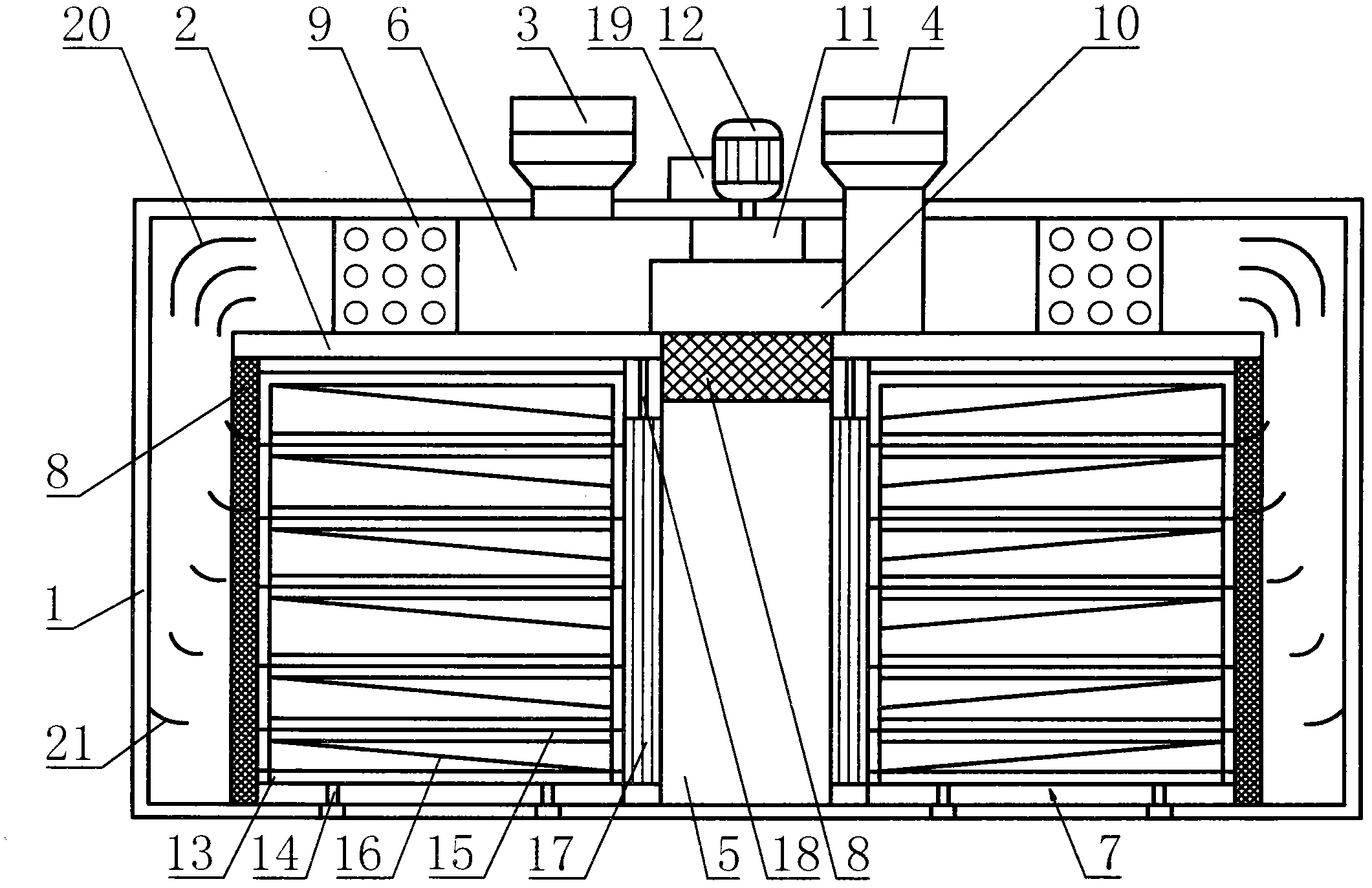

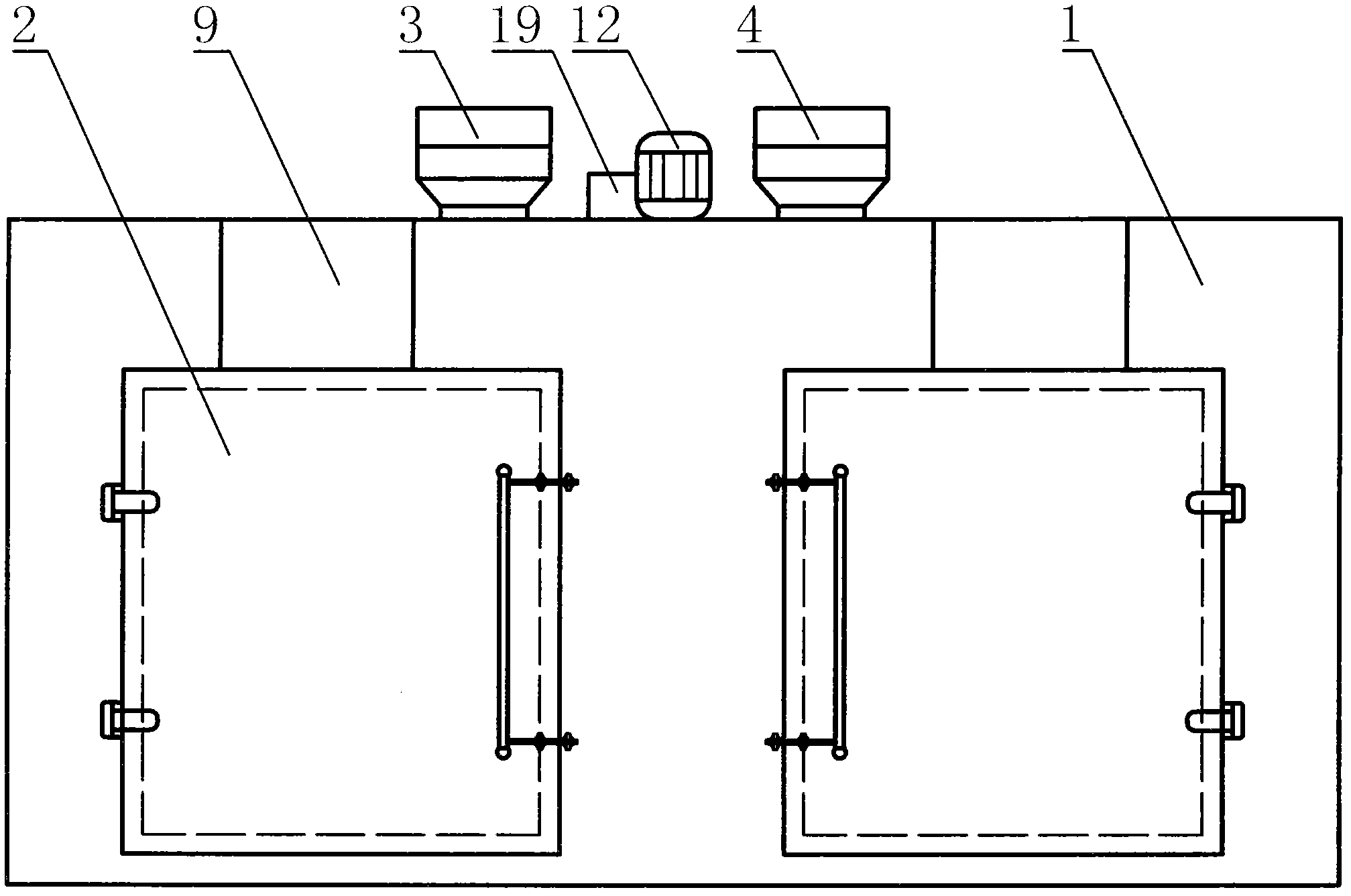

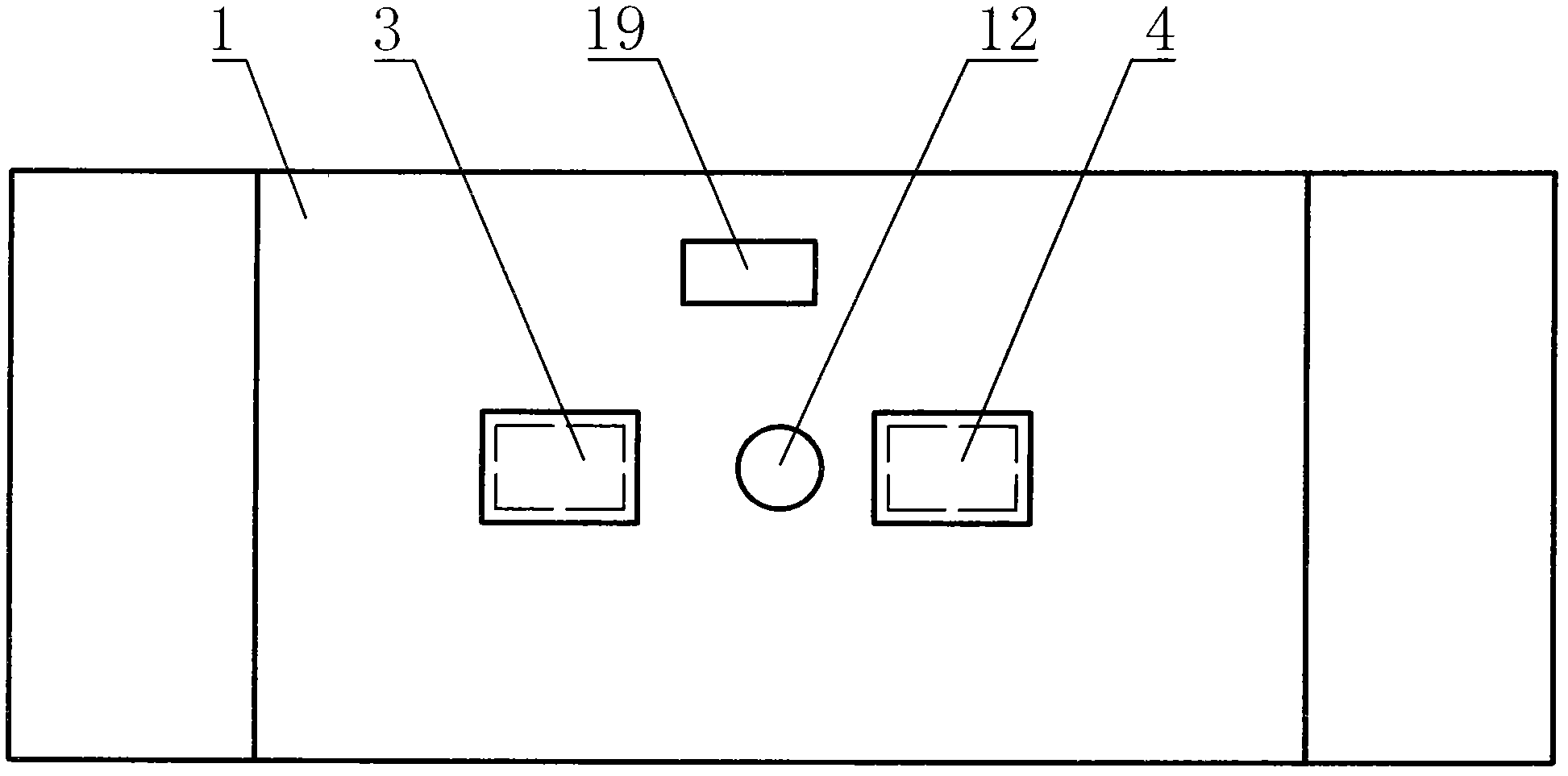

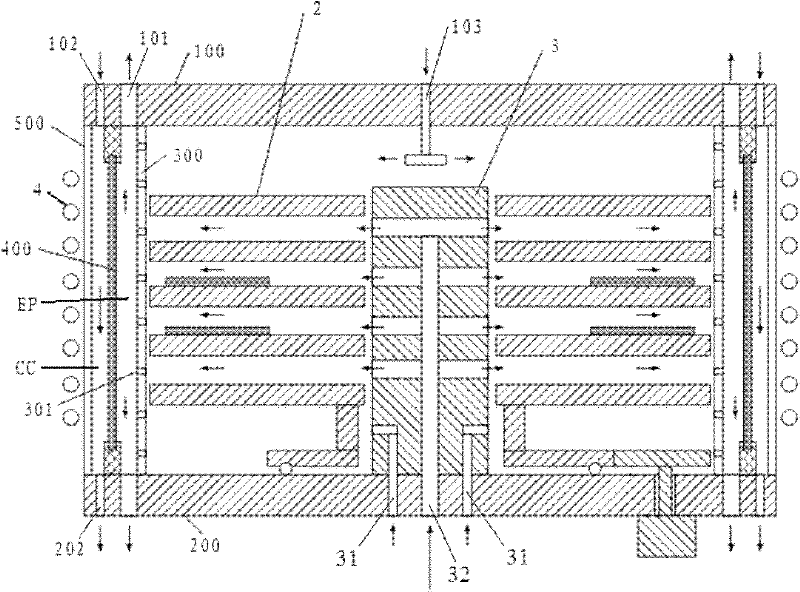

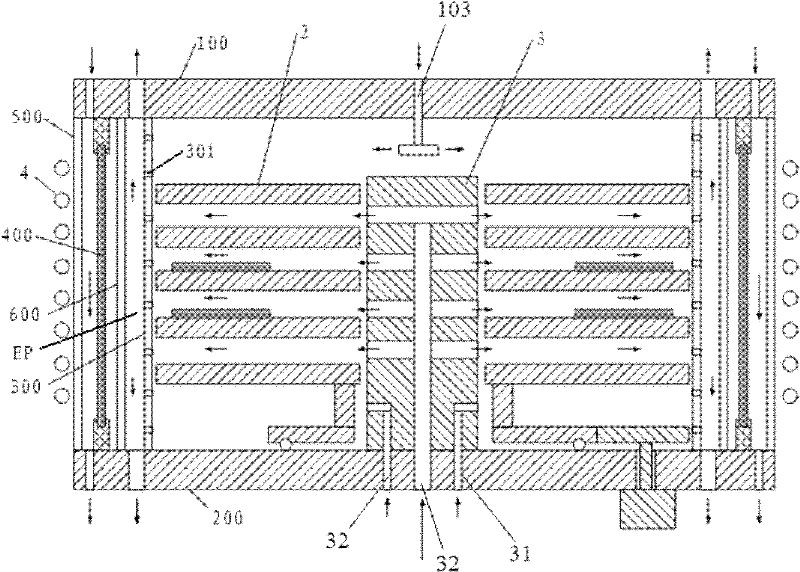

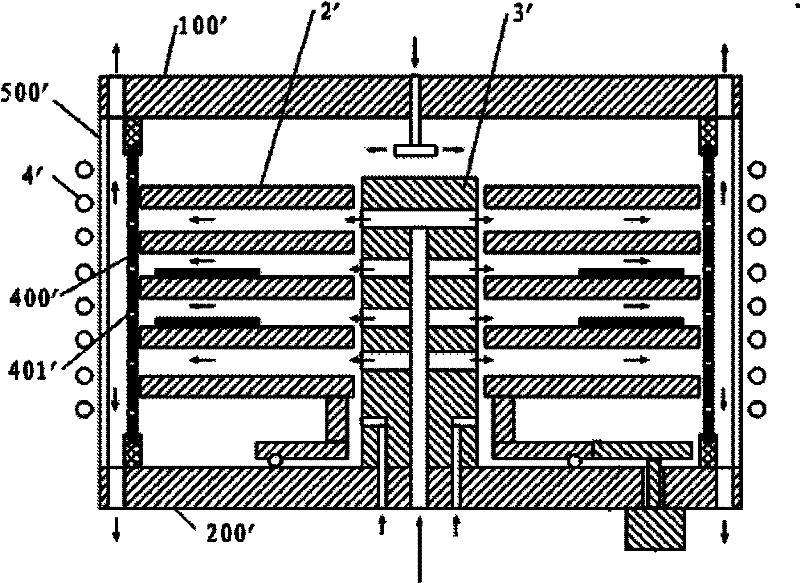

Inflatable-seal-type cross-flow drying oven with dual drying cars

InactiveCN102620533AIncrease throughputReduce drying costsDrying gas arrangementsDrying solid materialsFresh airMoisture

The invention relates to the field of drying equipment, in particular to an inflatable-seal-type cross-flow drying oven with dual drying cars, which has the advantages of even drying, large processing capacity, good sealing property and high heat utilization rate. The drying oven comprises a oven body (1); two drying chambers (2) are arranged in the oven body (1) symmetrically; a fresh air inlet (3), a moisture outlet (4) and an air draft device are arranged at the top of the oven box (1) respectively; an air-out chamber (5) is arranged between the drying chambers (2); an air-in chamber (6) is formed among the top of the drying chamber (2), the side of the drying chambers (2) close to the oven body (1) and the oven body (1); drying cars (7) are arranged in the drying chambers (2); a filter (8) is arranged at the side, close to the air-in chamber (6), of the drying chambers (2) and the other side is communicated with the air-out chamber (5) by an inflatable-seal device; the filter (8) is arranged at the part corresponding to the air draft device, above the air-out chamber (5); the fresh air inlet (3) is communicated with the drying chambers (2) by a heater (9) arranged in the air-in chamber (6); and the moisture outlet (4) is connected with the air draft device.

Owner:马文

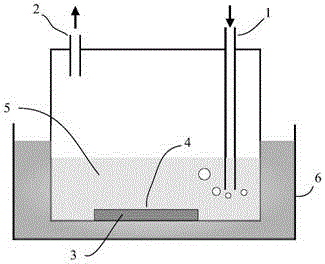

Corrosion resistant multi-aluminum bronze material for pipe

The invention provides a pipe corrosion-resistant multielement aluminium bronze alloy material and the ingredients are as follows: 4.0 to 10.0wt percent of Al, 1.0 to 4.5wt percent of Fe, 1.0 to 4.5wt percent of Mn, 0.8 to 4.0wt percent of Ni, 0.05 to 0.5wt percent of Cr and the balance of Cu and unavoidable impurities; in casting state, the tensile strength is more than 385MPa, the yield strength is more than 180MPa, the yield ratio is more than 0.48, and the specific elongation is more than 27 percent; in annealing state, the tensile strength is more than 525MPa, the yield strength is more than 285MPa, the yield ratio is more than 0.55, the specific elongation is more than 42 percent and the complete immersion uniform corrosion rate is 0.01 to 0.035mm / a; the copper alloy has excellent performance, is particularly suitable for the environment with high flow rate of seawater and is an ideal material for manufacturing sea water desalinating condenser equipment, shipping sea water condenser equipment and seashore power plant condensers.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

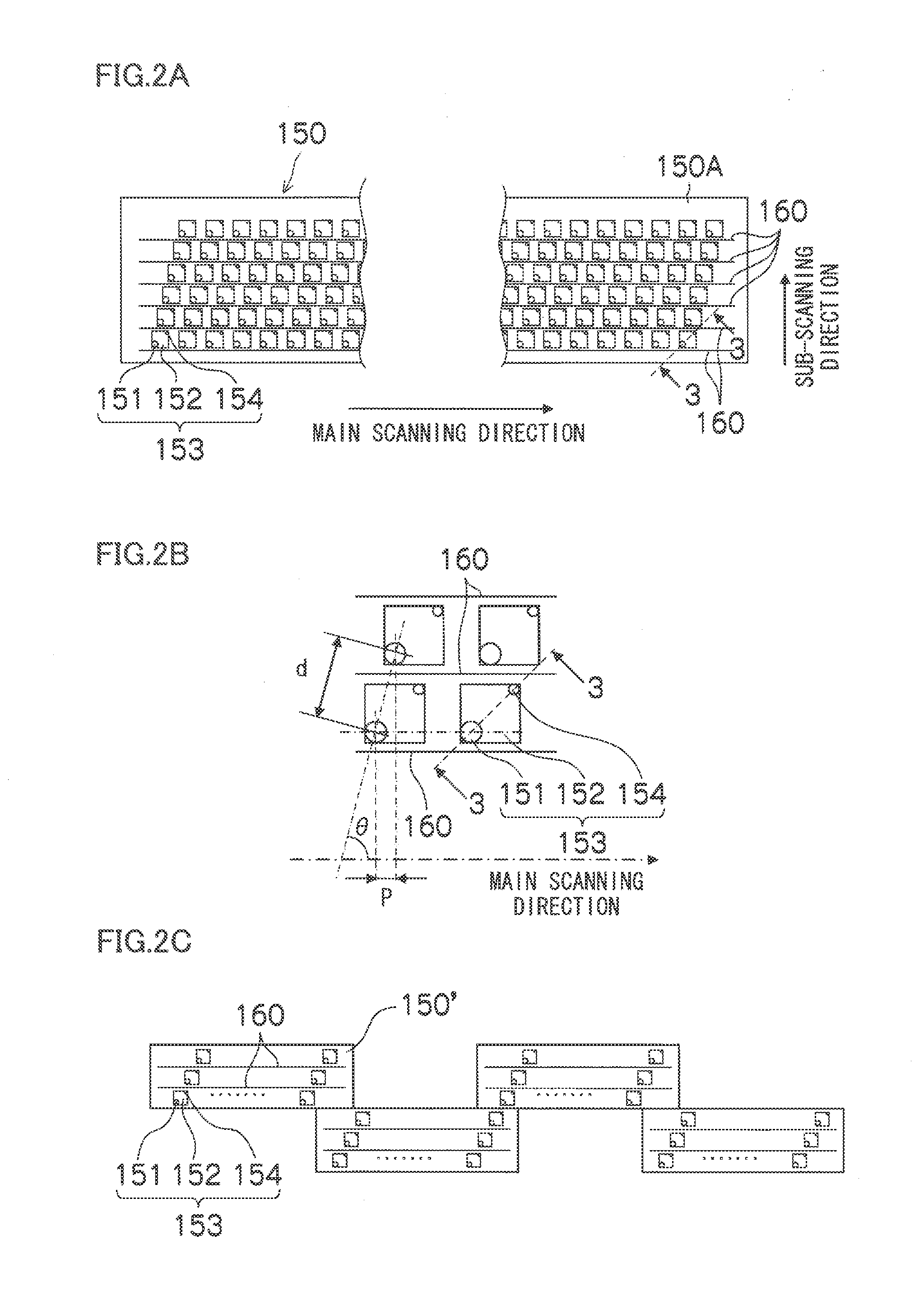

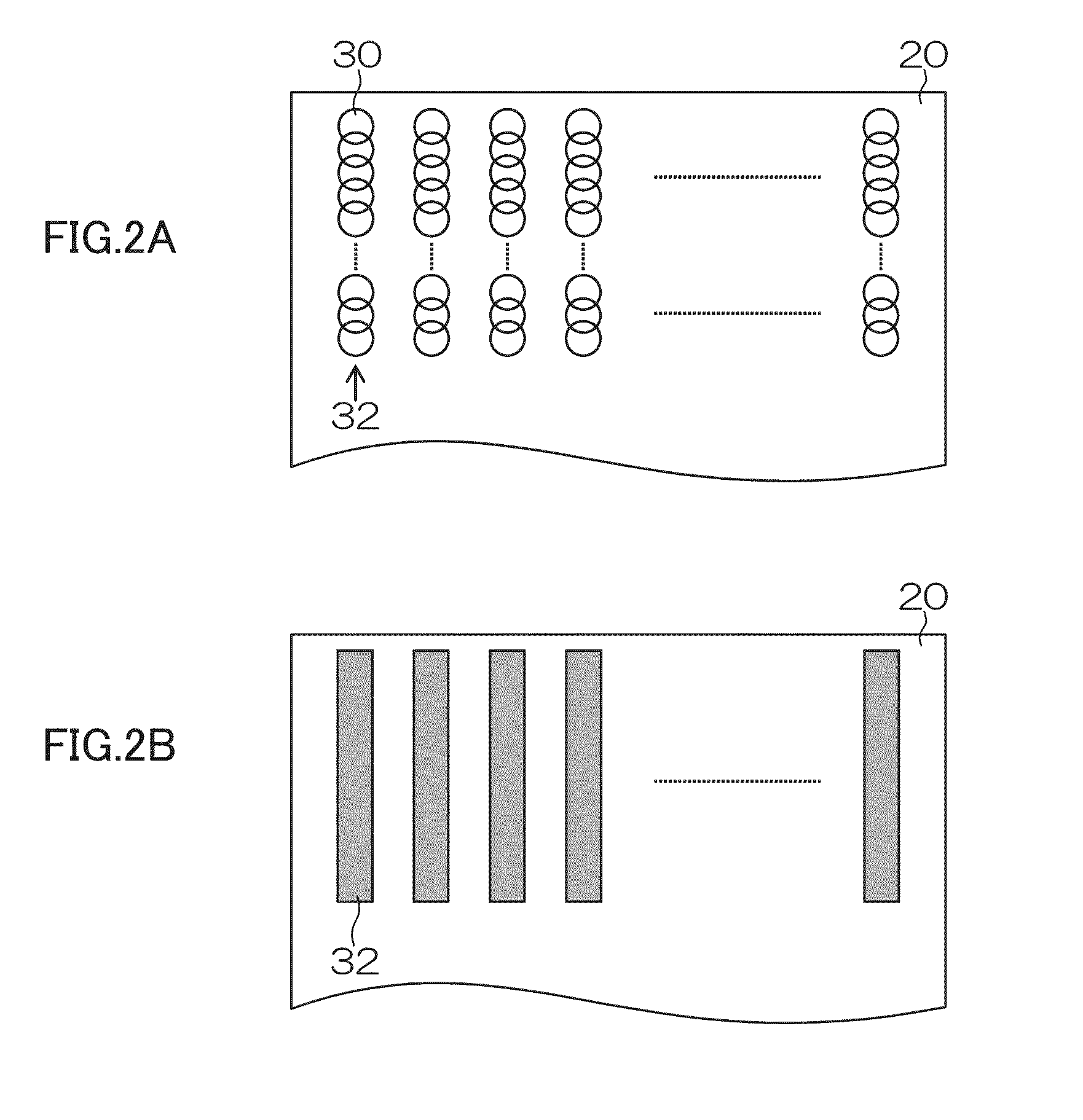

Method of printing test pattern and inkjet recording apparatus

InactiveUS20110234676A1The effect is accurateMaintain recording stabilityOther printing apparatusWaveform shapingEngineering

A test pattern is printed for ascertaining ejection characteristics of nozzles arranged in a recording head in an inkjet recording apparatus which forms and records a desired image on a recording medium by performing ejection of droplets of liquid from the nozzles and deposition of the droplets onto the recording medium. Ejection of droplets of the liquid from the recording head is performed by applying, to the recording head, a drive signal having a test waveform in which at least one of a voltage, a frequency and a waveform shape is altered with respect to a drive signal having a recording waveform which is applied to the recording head when the desired image is formed, to thereby perform the ejection with an increased ejection force compared with a case where the drive signal having the recording waveform is applied; and the test pattern is formed by the ejected droplets.

Owner:FUJIFILM CORP

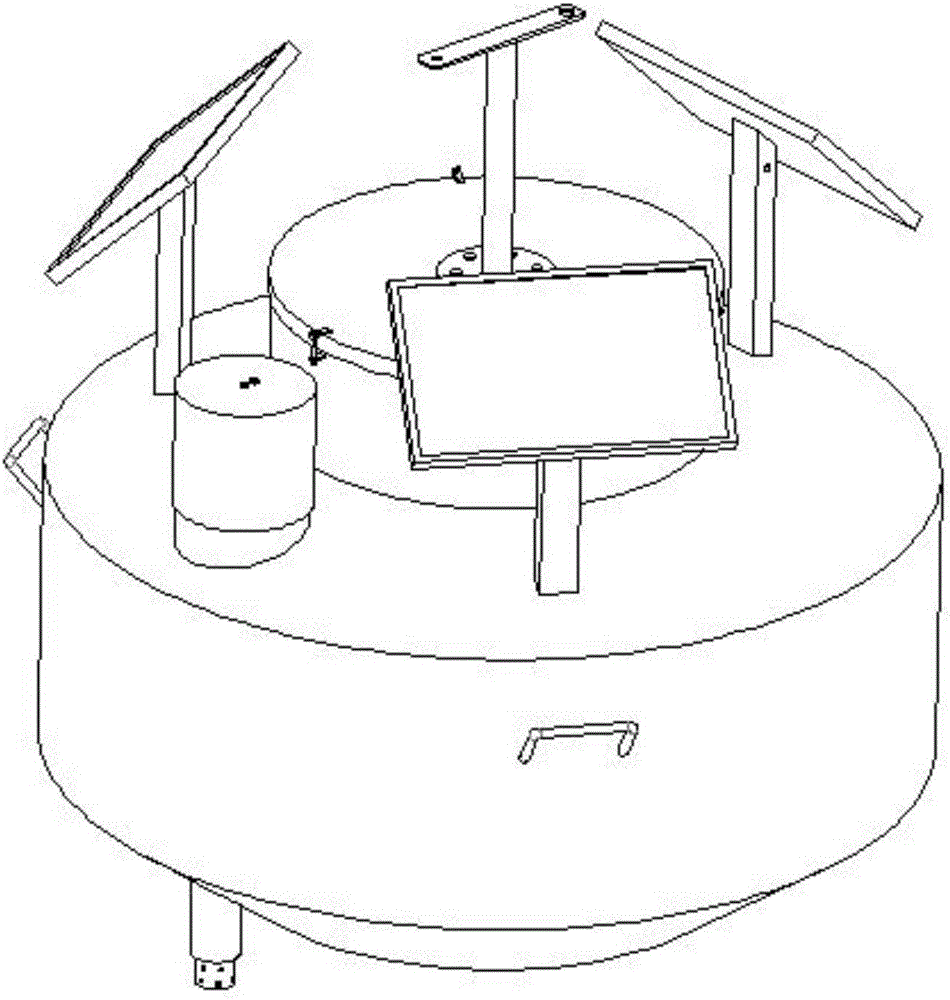

Liftable type water-quality monitoring buoy

ActiveCN106442912AReduce lossExtended service lifeWaterborne vesselsGeneral water supply conservationWater qualityEngineering

The invention discloses a liftable type water-quality monitoring buoy. The liftable type water-quality monitoring buoy comprises a floating body suspending on an aquaculture water area, wherein the floating body is internally provided with a cavity body; a guiding drum is arranged in the cavity body; the top of the guiding drum is communicated with the cavity body, and the bottom of the guiding drum is communicated with the outside; a water-quality sensor is arranged in the guiding drum; a lifting motor is arranged in the cavity body and is coupled with a connecting mechanism by a lifting shaft; one end of the connecting mechanism is fixedly connected with the lifting shaft, and the other end of the connecting mechanism is connected with the water-quality sensor; the water-quality sensor can move up and down along the inner wall of the guiding drum under the driving of the lifting motor and the connecting mechanism. The liftable type water-quality monitoring buoy disclosed by the invention has the advantages that when not in use, the water-quality sensor is in a dry and cleaner environment, so that the growth of microorganisms adhered on the sensor can not be fast excessively, the loss of pollutants in water to the sensor is reduced, the service life of the sensor is greatly prolonged and the times for periodical cleaning and maintenance are reduced.

Owner:汇朋智能科技(江苏)有限公司

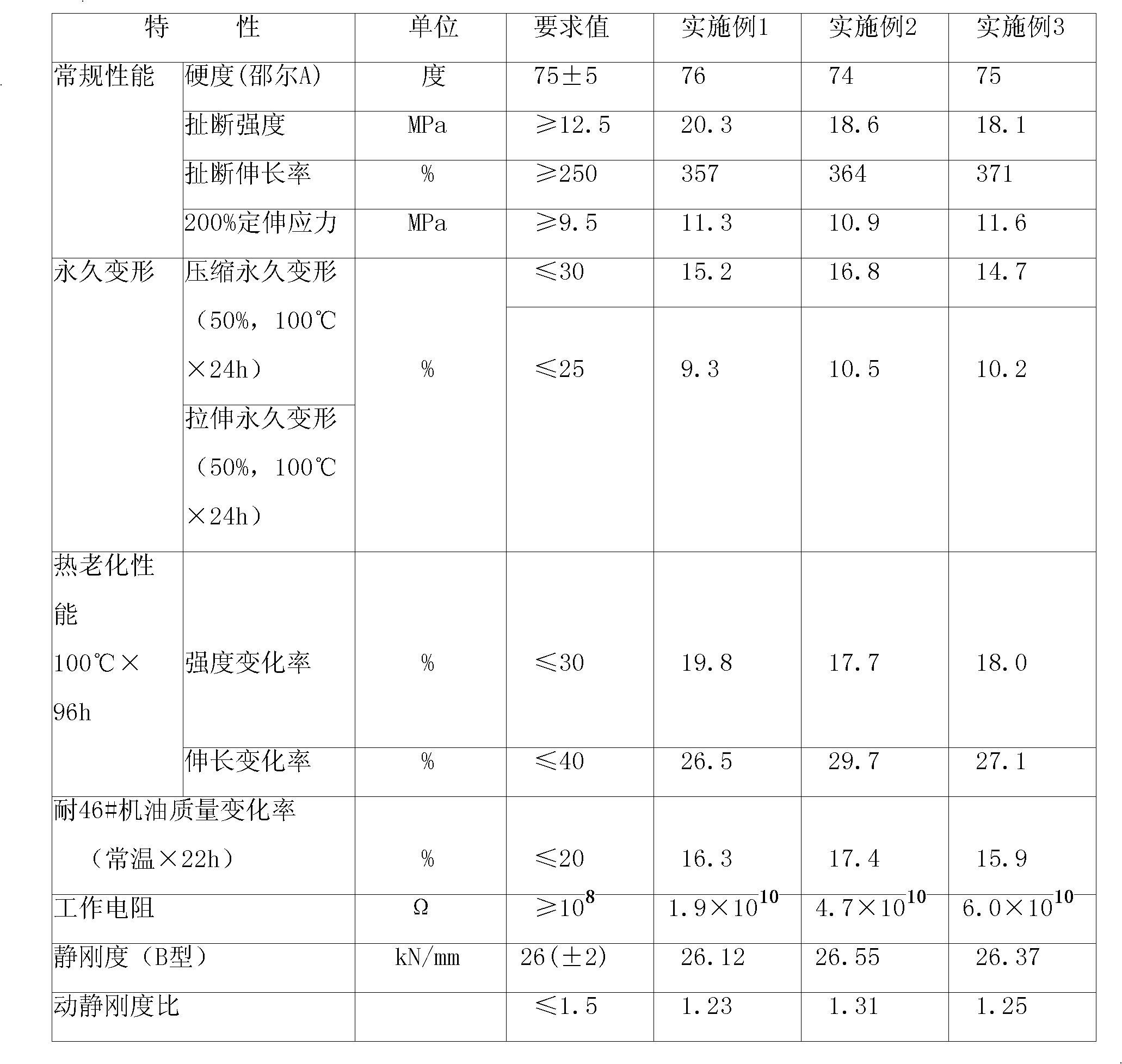

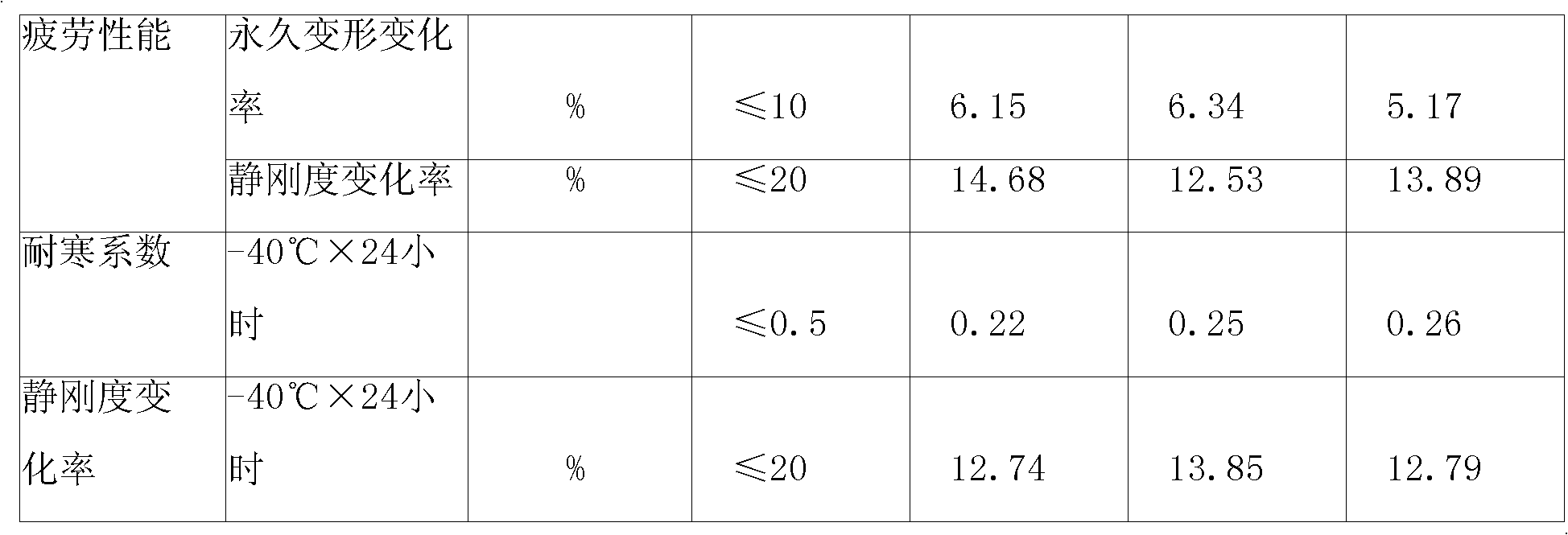

Creep-resisting and aging-resisting rubber tie plate under rail and preparation method thereof

The invention provides a creep-resisting and aging-resisting rubber tie plate under rail and a preparation method thereof. The rubber tie plate is characterized in that content proportions of rubber components by weight are as follows: 85-95 parts of natural rubber; 5-15 parts of cis-butadiene rubber; 30-50 parts of carbon black; 25-40 parts of white carbon black; 5-15 parts of organic modified montmorillonite; 1.5-2.5 parts of sulfur; 0.5-1.0 part of a promoter; 0.8-1.5 parts of promoter DM; 5-8 parts of zinc oxide; 1-2 parts of stearic acid; 1-2 parts of anti-aging agent RD; 1-2 parts of anti-aging agent AW; 1-2 parts of anti-aging agent D; 0.5-1 part of scorch retarder CTP; and 2-4 parts of a surface modifier. The rubber tie plate can resist creep and aging, prolongs service life, and has simple process and reasonable raw material proportioning.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

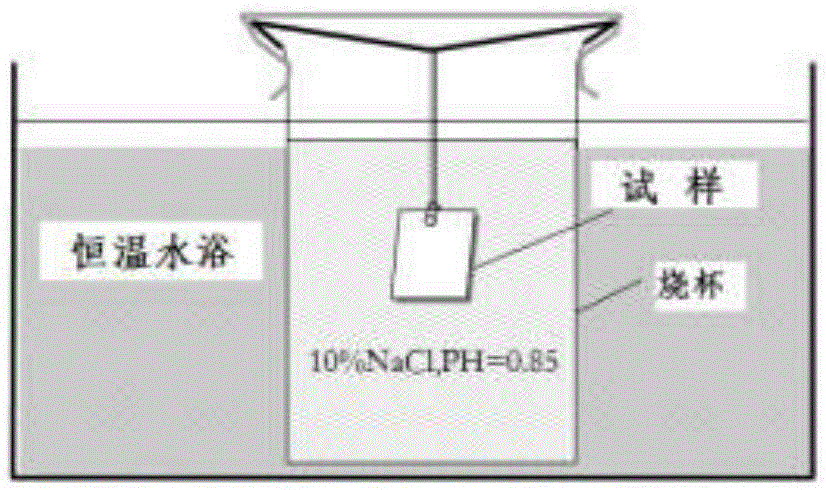

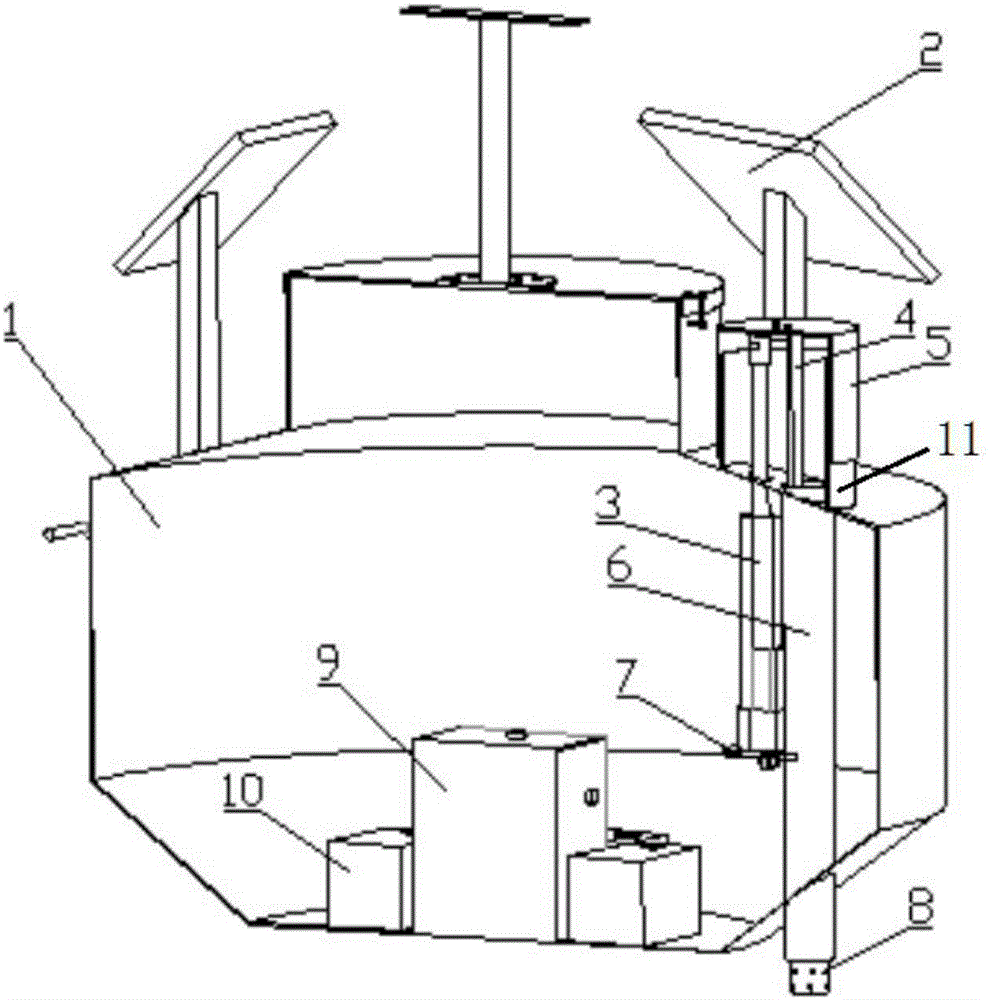

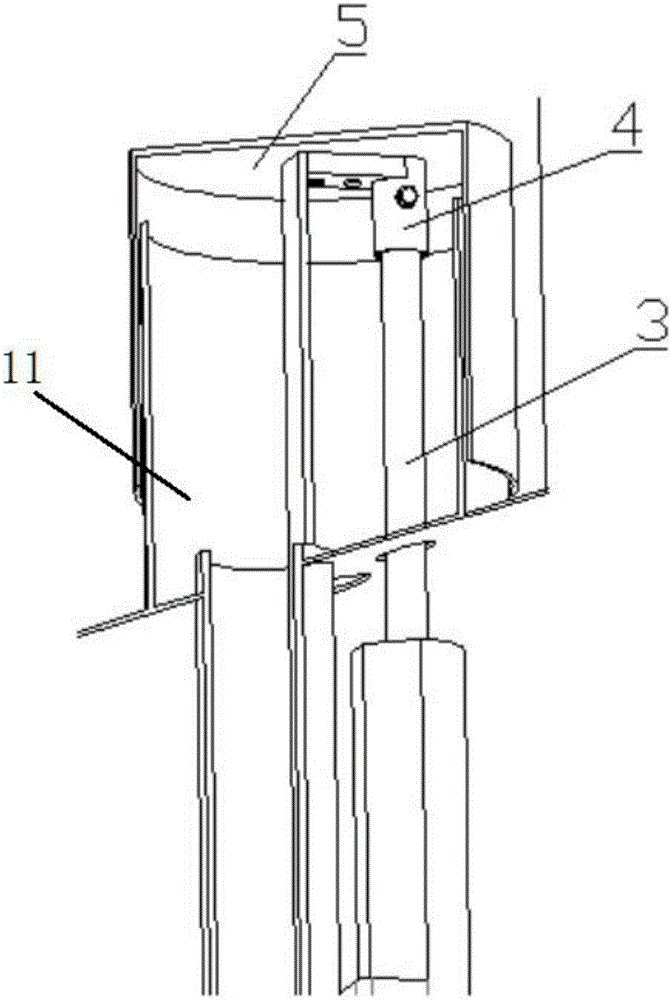

Process chamber device and epitaxial equipment with it

ActiveCN102691100AImprove temperature field distributionReduce maintenance timesSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGraphitePulp and paper industry

The invention discloses a process chamber device and epitaxial equipment with the process chamber device. The process chamber device comprises: a top cap and a bottom cap; an inner quartz tube, which is located between the top cap and the bottom cap and provided with exhaust holes, and defines a process chamber together with the top cap and the bottom cap; a graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the inner quartz tube, with an exhaust path defined between the graphite sleeve and the inner quartz tube, communicated with the outside, and communicated with the process chamber through the exhaust holes; and an outer graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the graphite sleeve, with a cooling channel defined between the outer graphite sleeve and the graphite sleeve and communicated with the outside. According to the process chamber in embodiment of the invention, temperature field distribution in the process chamber can be improved, and ultimately, uniformity of the radial temperature in the process chamber and further in a substrate can be realized. Also, the maintenance frequency and the maintenance cost of the graphite sleeve can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Method for manufacturing anticorrosion steel plate for upper deck on crude oil tanker oil cargo tank and steel plate

ActiveCN103286127AReduce corrosion rateReduce generationWork treatment devicesMetal rolling arrangementsChemical compositionSheet steel

The invention discloses a method for manufacturing an anticorrosion steel plate for an upper deck on a crude oil tanker oil cargo tank and the steel plate and belongs to the technical field of steel for a hot-rolling slab ship structure. The steel plate is manufactured through the processes of plate blank heating, plate blanking scale removing, rolling, ACC water cooling and air cooling. The steel plate comprises the following chemical composition, by weight, 0.02%-0.25% of C, 0.05%-0.5% of Si, 0.1%-2.0% of Mn, <=0.025% of P, <=0.01% of S, 0.05%-2% of Cu, 0.05%-2% of Ni, 0.01%-5% of Cr, 0.001%-1% of W, 0.001%-0.1% of Zr, 0.0002%-0.01% of Ca, 0.005%-0.1% of Ti, 0.001%-0.008% of N, 0.020%-0.1% of Als, and the balance Fe and unavoidable impurities. The steel plate has the advantages of being capable of being used directly at an exposed state and obviously reducing the uniform corrosion rate on the upper deck, free of the requirements for coating protection and capable of prolonging service life.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com