Alloy composition, semi-autogenous mill lining plate and manufacturing method of lining plate

A semi-autogenous mill and manufacturing method technology, applied in the direction of manufacturing tools, grain processing, furnace types, etc., can solve the problems affecting the civilized production of modern enterprises, waste of manpower, material resources, financial resources, maintenance and replacement, etc. The effect of avoiding duplication of labor, reducing labor intensity, and reducing the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

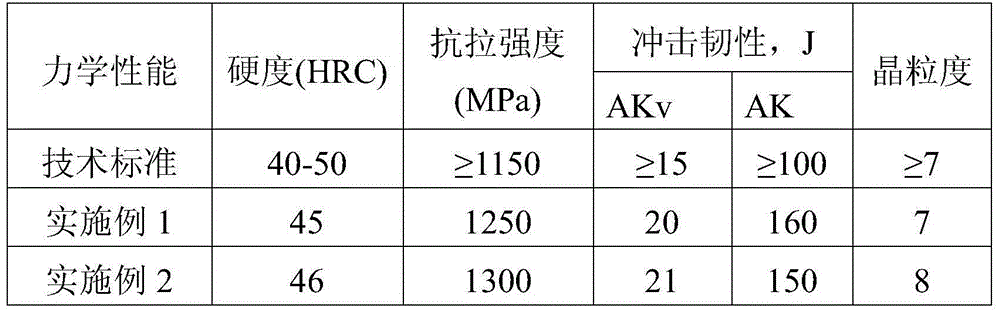

Embodiment 1

[0055] Select each component according to the required content of the semi-autogenous mill liner, by weight percentage, C: 0.4%, Si: 0.5%, Mn: 0.75%, P: ≤0.025%, S: ≤0.025%, Cr: 1.8 %, Mo: 0.25%, Ni: 0.2%, Ti: 0.015%, Cu: 0.2%, B: 0.002%, La: 0.03%, Al: ≤0.03%, the balance is Fe, and then cast the liner;

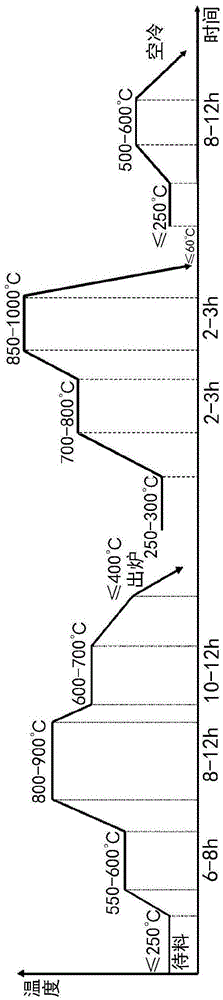

[0056] Annealing treatment: heat the cast liner to 550°C and hold it for 7 hours, then heat it to 850°C and hold it for 10 hours, then cool it to 600°C in about 3 hours and hold it for 12 hours, and finally cool it to 400°C with the furnace then air-cooled to room temperature;

[0057] Quenching treatment: heat the annealed liner to 700°C and hold it for 3 hours, then heat it to 900°C and hold it for 3 hours, then cool it in oil to below 60°C;

[0058] Tempering treatment: heat the quenched liner to 550°C and keep it warm for 12 hours, then cool it in the air to obtain the heat-treated semi-autogenous mill liner;

[0059] Finally, finishing and grinding, flaw detection and...

Embodiment 2

[0061] Select each component according to the required content of the semi-autogenous mill liner, by weight percentage, C: 0.35%, Si: 0.55%, Mn: 0.8%, P: ≤0.025%, S: ≤0.025%, Cr: 1.6 %, Mo: 0.27%, Ni: 0.25%, Ti: 0.02%, Cu: 0.2%, B: 0.002%, La: 0.04%, Al: ≤0.03%, the balance is Fe, and then cast the liner;

[0062] Annealing treatment: heat the cast liner to 600°C and hold it for 6 hours, then heat it to 950°C and hold it for 9 hours, then cool it to 700°C in about 3 hours and hold it for 10 hours, and finally cool it to 400°C with the furnace then air-cooled to room temperature;

[0063] Quenching treatment: heat the annealed liner to 800°C and hold it for 2.5 hours, then heat it to 950°C and hold it for 2.5 hours, then cool it in oil to below 60°C;

[0064] Tempering treatment: heat the quenched liner to 520°C and keep it warm for 10 hours, then cool it in the air to obtain the heat-treated semi-autogenous mill liner;

[0065] Finally, finishing and grinding, flaw detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com